A Numerical Study on the Combustion Process and Emission Characteristics of a Natural Gas-Diesel Dual-Fuel Marine Engine at Full Load

Abstract

1. Introduction

2. Simulated Engine and CFD Models

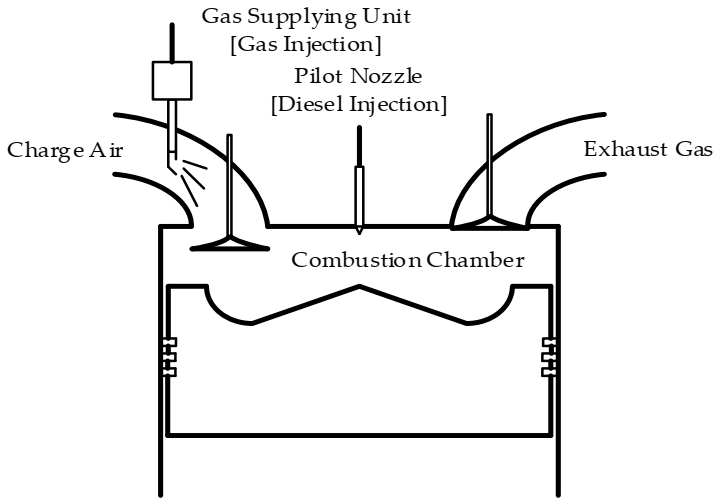

2.1. Simulated Engine Specifications

2.2. Three-Dimensional CFD Simulation Models

2.3. Computational Domain and Initial Conditions

2.4. Simulation Conditions

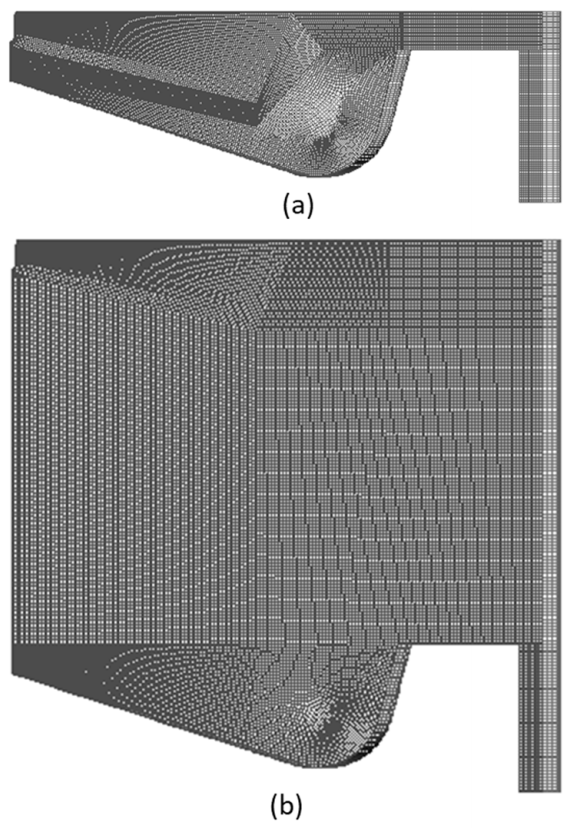

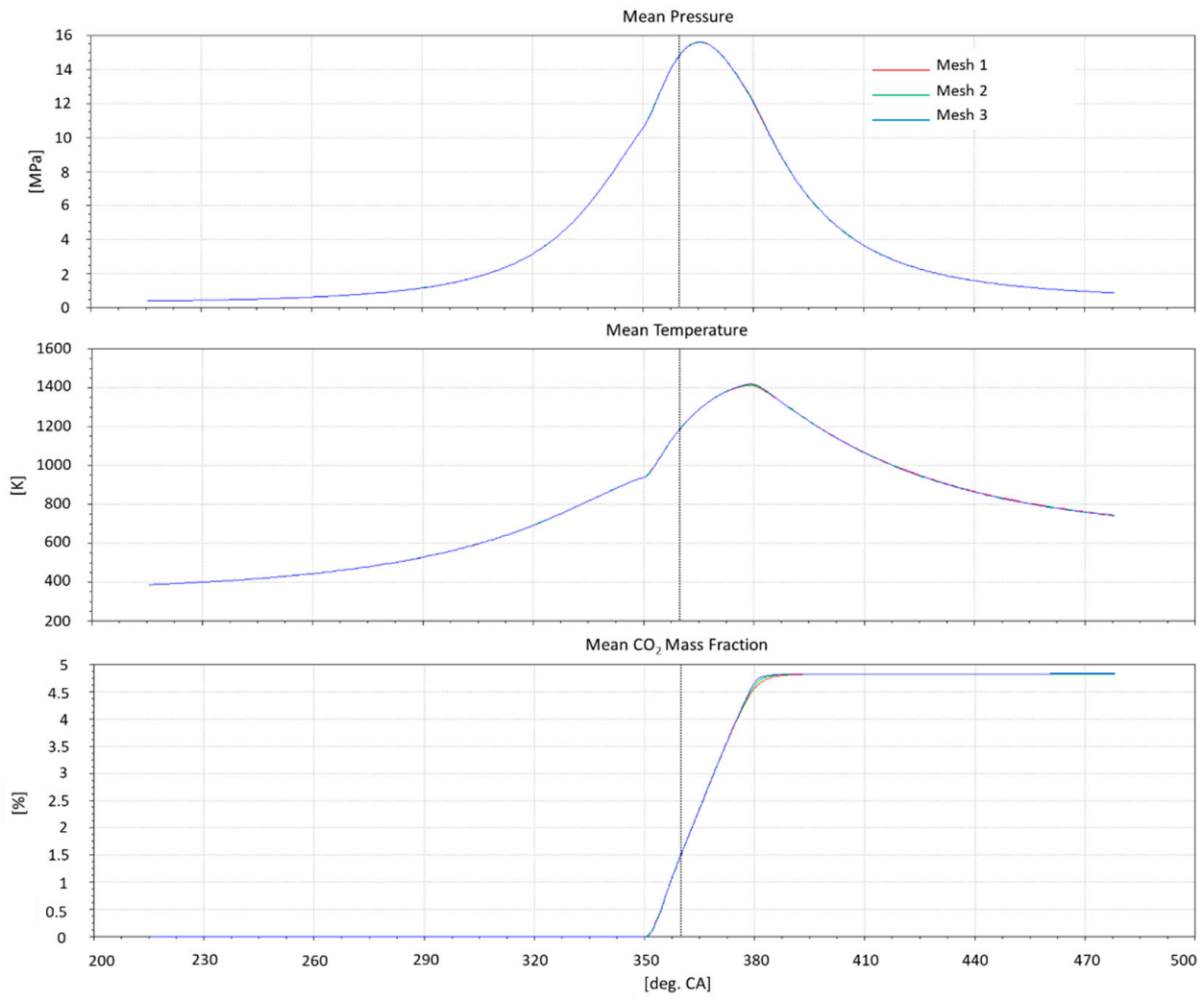

2.5. Mesh Independence Analysis

2.6. CFD Simulation Model Validations

3. Simulation Results

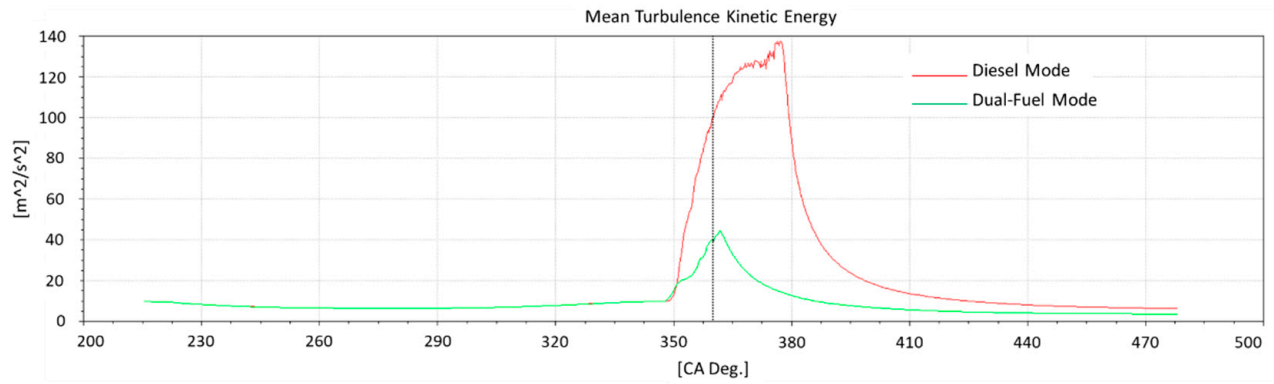

3.1. In-Cylinder Fluid Flow Turbulence

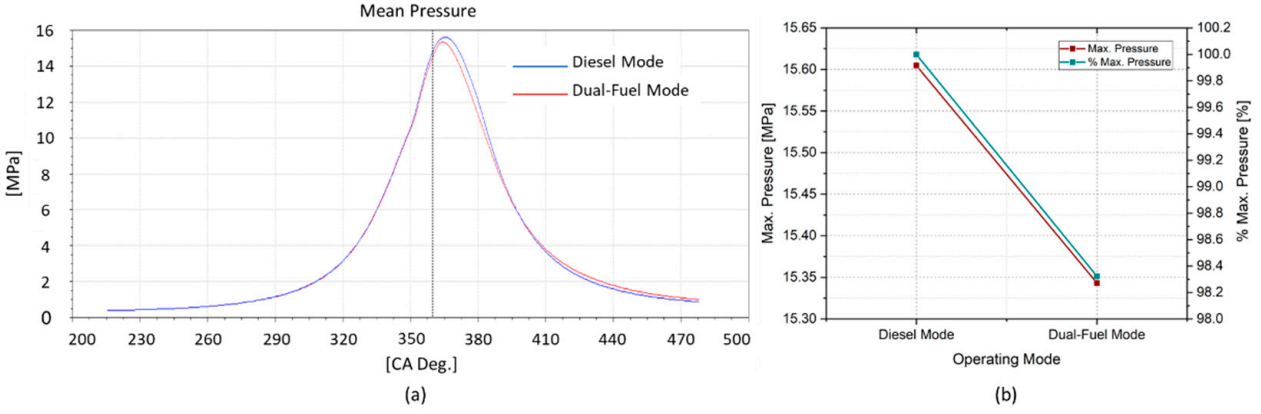

3.2. In-Cylinder Pressure

3.3. In-Cylinder Temperature and NO Emission

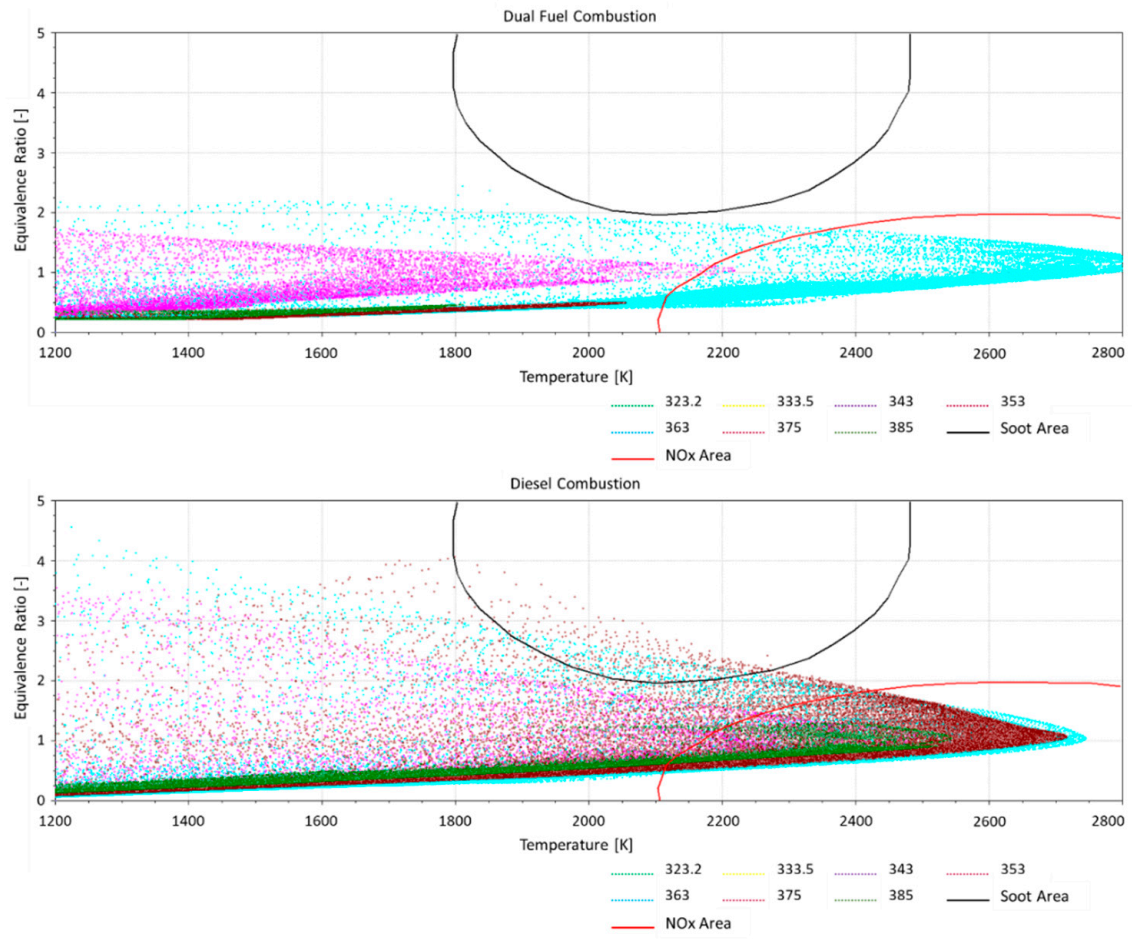

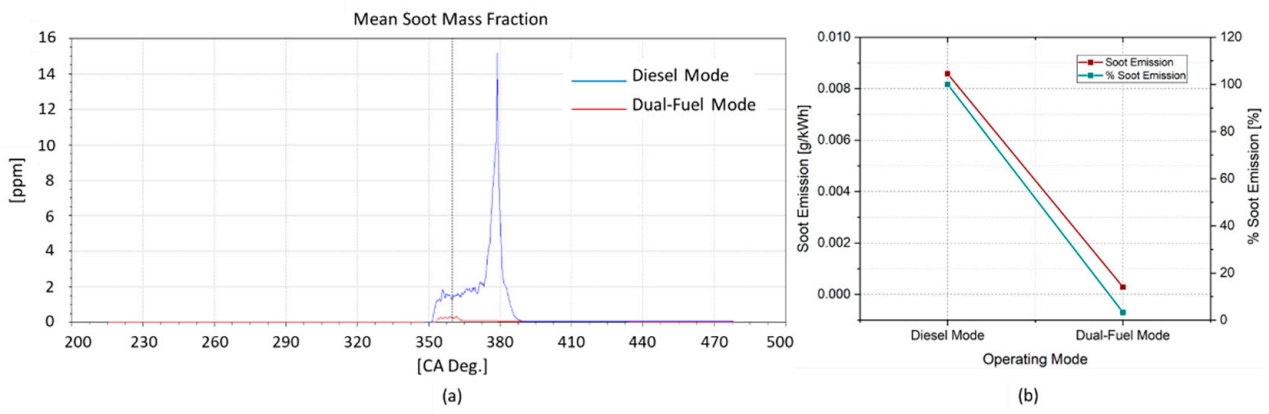

3.4. Soot Formation

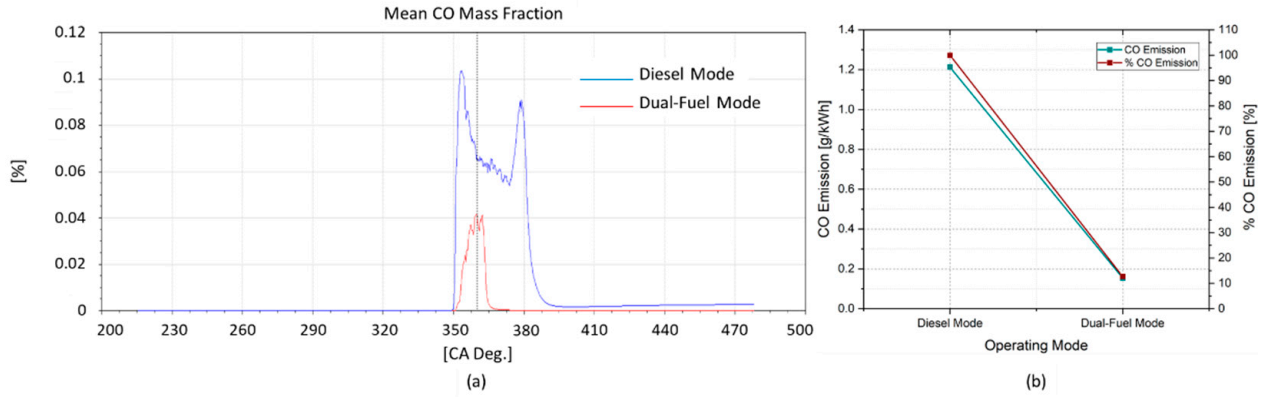

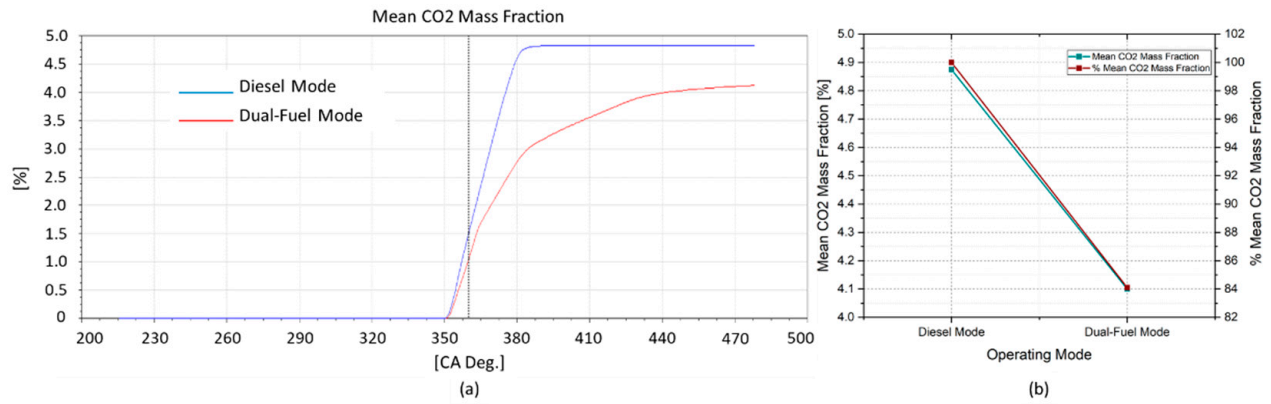

3.5. Carbon Monoxide (CO) and Carbon Dioxide (CO2) Emissions

3.6. In-Cylinder Temperature Contours

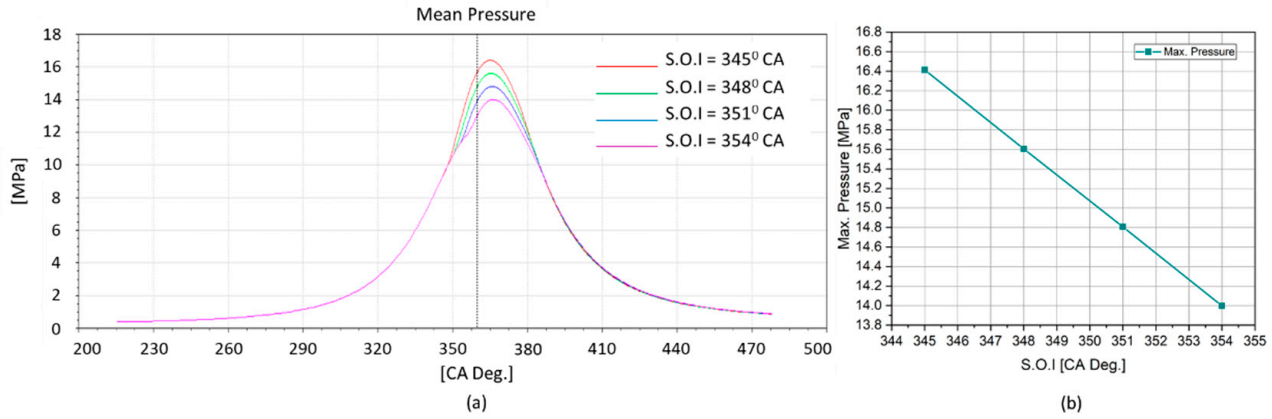

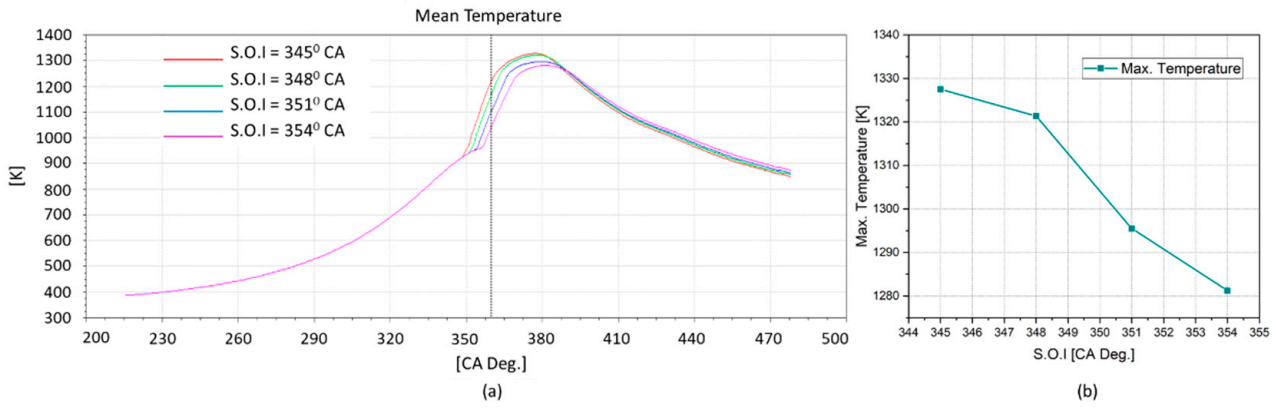

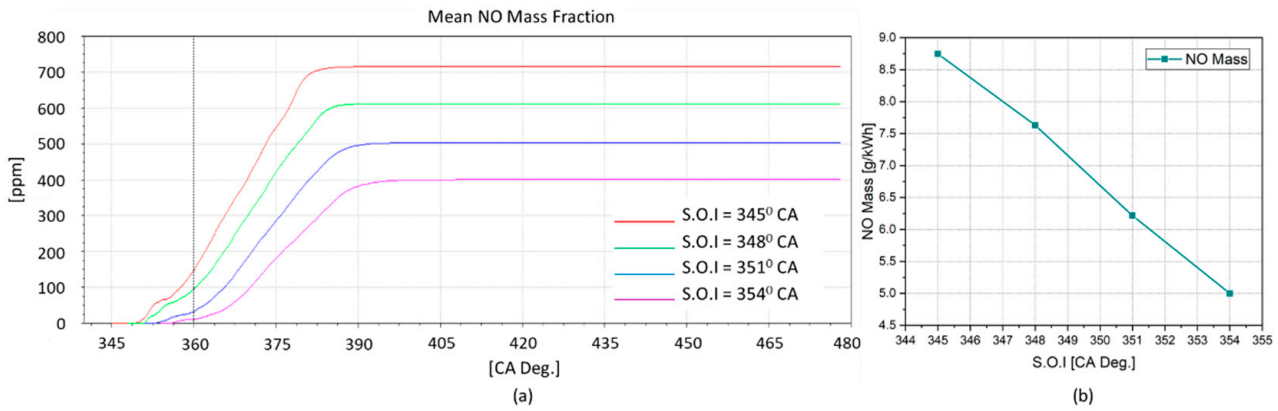

3.7. Effects of the Injection Timing on Combustion and Emission Formations

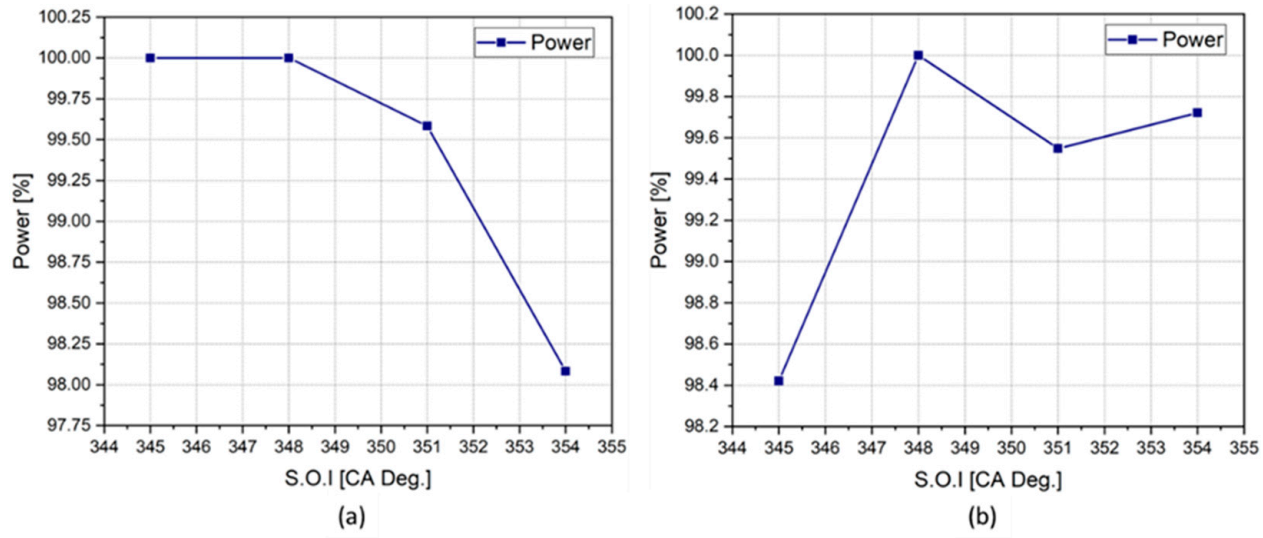

3.7.1. In-Cylinder Pressure and Temperature

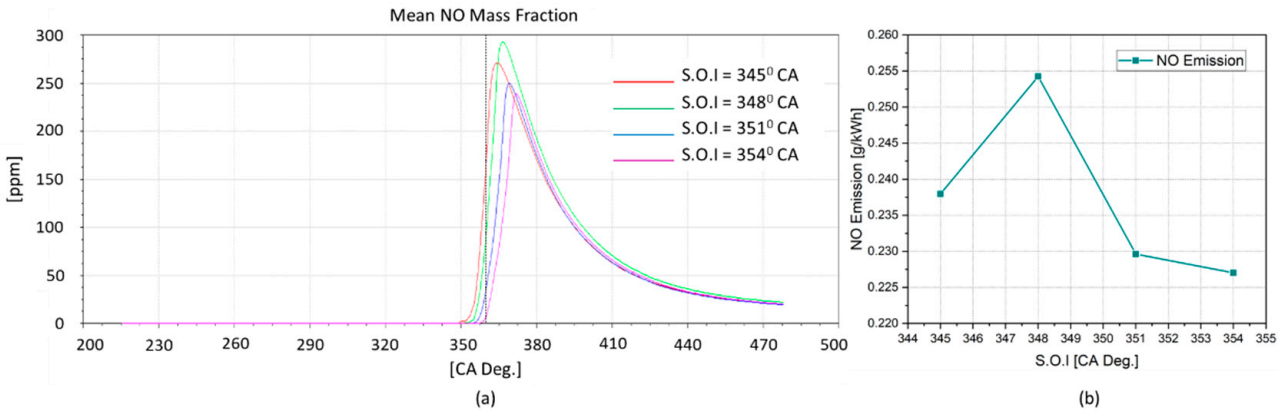

3.7.2. NO Emission

3.7.3. CO Emission

4. Conclusions

- The maximum mean TKE, as well as the mean TKE at the end of the combustion processes in the diesel mode, are larger than those in the dual-fuel mode, indicating larger turbulence velocities of the fluid flow in the engine cylinder when running the engine in the diesel mode.

- The maximum in-cylinder pressure in the dual-fuel mode is 1.7% lower than that in comparison to the diesel mode.

- The in-cylinder temperature peak in the dual-fuel mode was reduced by 6.75% compared to that in the diesel mode.

- The NO emission generated in the case of dual-fuel combustion is significantly reduced compared to that in the diesel combustion. The NO emission generated in the diesel mode and dual-fuel mode is 7.63 g/kWh and 0.254 g/kWh, respectively. Meaning that NO emission is reduced up to more than 96% in the dual-fuel mode.

- The amount of soot generated is significantly reduced when operating the engine in the dual-fuel mode. The soot emission generated in the diesel mode and dual-fuel mode is 0.0086 g/kWh and 0.000283 g/kWh, respectively. Meaning that soot emission is reduced up to more than 96% in the dual-fuel mode.

- The CO emission amount in the case of diesel and dual-fuel mode are 1.21274 g/kWh and 0.153643 g/kWh, respectively. Meaning that the CO emission in the dual-fuel mode is reduced up to more than 87.33%.

- The CO2 emission amount in the case of diesel and dual-fuel mode are 597.182 g/kWh and 463.189 g/kWh, respectively. Meaning that the CO2 emission in the dual-fuel mode is reduced by 22.44% compared to that in the diesel mode.

- The results also show better and more uniform combustion at the late stage of the combustion inside the engine cylinder when operating in the dual-fuel mode.

- The in-cylinder pressure and temperature peaks are reduced when we reduce the S.O.I angle in both cases of combustions, resulting in reductions in NO emission, however, there also are reductions in the engine power. In another aspect, the simulation results point that the engine reaches the optimal power at the designed S.O.I angle of 348 CAD in both cases of combustions. CO emissions are increased when we reduce the S.O.I angle less than 12 CAD BTDC (348 CAD) in both cases of combustions. Therefore, operating the engine in the dual-fuel mode with the S.O.I angle of 12 CAD BTDC is the best solution to reduce emissions while keeping the optimal engine power.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Appendix A

- The Standard Species Transport Model Variables and Equations [25]

Appendix B

- The Extended Coherent Flame Model (ECFM) Chemical Kinetic Reactions

Appendix C

- The NO Formation Mechanism

- The Thermal NO Reaction Rate

Appendix D

- The Kinetic Soot Model

References

- Thomson, H.; Corbett, J.J.; Winebrake, J.J. Natural gas as a marine fuel. Energy Policy 2015, 87, 153–167. [Google Scholar] [CrossRef]

- Maurya, R.K.; Mishra, P. Parametric investigation on combustion and emissions characteristics of a dual fuel (natural gas port injection and diesel pilot injection) engine using 0-D SRM and 3D CFD approach. Fuel 2017, 210, 900–913. [Google Scholar] [CrossRef]

- Xiang, L.; Song, E.; Ding, Y. A Two-Zone Combustion Model for Knocking Prediction of Marine Natural Gas SI Engines. Energies 2018, 11, 561. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill Education: New York, NY, USA, 1998. [Google Scholar]

- Turns, S.R. An Introduction to Combustion: Concepts and Applications; McGraw-Hill Education: New York, NY, USA, 2013. [Google Scholar]

- Mansurov, Z.A. Soot Formation in Combustion Processes (Review). Combust. Explos. Shock. Waves 2005, 41, 727–744. [Google Scholar] [CrossRef]

- Akihama, K.; Takatori, Y.; Inagaki, K.; Sasaki, S.; Dean, A.M. Mechanism of the Smokeless Rich Diesel Combustion by Reducing Temperature. SAE Tech. Pap. Ser. 2001, 110, 648–662. [Google Scholar] [CrossRef]

- Neely, G.D.; Sasaki, S.; Huang, Y.; Leet, J.A.; Stewart, D.W. New Diesel Emission Control Strategy to Meet US Tier 2 Emissions Regulations. SAE Tech. Pap. Ser. 2005, 114, 512–524. [Google Scholar] [CrossRef]

- Caton, J.A. The thermodynamic characteristics of high efficiency, internal-combustion engines. Energy Convers. Manag. 2012, 58, 84–93. [Google Scholar] [CrossRef]

- Ma, J.; Lü, X.; Ji, L.; Huang, Z. An experimental study of HCCI-DI combustion and emissions in a diesel engine with dual fuel. Int. J. Therm. Sci. 2008, 47, 1235–1242. [Google Scholar] [CrossRef]

- Leermakers, C.; Luijten, C.; Somers, L.; Kalghatgi, G.; Albrecht, B. Experimental Study of Fuel Composition Impact on PCCI Combustion in a Heavy-Duty Diesel Engine. SAE Tech. Pap. Ser. 2011, 1, 1351. [Google Scholar] [CrossRef]

- Kokjohn, S.L.; Hanson, R.M.; A Splitter, D.; Reitz, R.D. Fuel reactivity controlled compression ignition (RCCI): A pathway to controlled high-efficiency clean combustion. Int. J. Engine Res. 2011, 12, 209–226. [Google Scholar] [CrossRef]

- Splitter, D.; Wissink, M.; Delvescovo, D.; Reitz, R.D. RCCI Engine Operation Towards 60% Thermal Efficiency. SAE Tech. Pap. Ser. 2013, 1, 0279. [Google Scholar] [CrossRef]

- Eder, L.; Ban, M.; Pirker, G.; Vujanovic, M.; Priesching, P.; Wimmer, A. Development and Validation of 3D-CFD Injection and Combustion Models for Dual Fuel Combustion in Diesel Ignited Large Gas Engines. Energies 2018, 11, 643. [Google Scholar] [CrossRef]

- Faramawy, S.; Zaki, T.; Sakr, A.-E. Natural gas origin, composition, and processing: A review. J. Nat. Gas Sci. Eng. 2016, 34, 34–54. [Google Scholar] [CrossRef]

- Yang, B.; Wei, X.; Xi, C.; Liu, Y.; Zeng, K.; Lai, M.-C. Experimental study of the effects of natural gas injection timing on the combustion performance and emissions of a turbocharged common rail dual-fuel engine. Energy Convers. Manag. 2014, 87, 297–304. [Google Scholar] [CrossRef]

- Yousefi, A.; Birouk, M.; Guo, H. An experimental and numerical study of the effect of diesel ignition timing on natural gas/diesel dual-fuel combustion at low load. Fuel 2017, 203, 642–657. [Google Scholar] [CrossRef]

- Yousefi, A.; Guo, H.; Birouk, M. An experimental and numerical study on diesel ignition split of a natural gas/diesel dual-fuel engine at a low engine load. Fuel 2018, 212, 332–346. [Google Scholar] [CrossRef]

- Shu, J.; Fu, J.; Liu, J.; Zhang, L.; Zhao, Z. Experimental and computational study on the effects of injection timing on thermodynamics, combustion and emission characteristics of a natural gas (NG)-diesel dual fuel engine at low speed and low load. Energy Convers. Manag. 2018, 160, 426–438. [Google Scholar] [CrossRef]

- Shu, J.; Fu, J.; Liu, J.; Ma, Y.; Wang, S.; Deng, B.; Zeng, D. Effects of injector spray angle on combustion and emissions characteristics of a natural gas (NG)-diesel dual fuel engine based on CFD coupled with reduced chemical kinetic model. Appl. Energy 2019, 182–195. [Google Scholar] [CrossRef]

- Ghomashi, H.; Olley, P.; Mason, B.A.; Ebrahimi, M. Simulating the influence of injection timing, premixed ratio, and inlet temperature on natural gas/diesel dual-fuel HCCI combustion in a diesel engine. Int. J. Powertrains 2015, 4, 36. [Google Scholar] [CrossRef]

- Ding, C.; Liu, W. Numerical Simulation of Emission Characteristics for Single-Cylinder Diesel Engine. Energy Power Eng. 2016, 8, 92–98. [Google Scholar] [CrossRef][Green Version]

- Durbin, P.A. Near-wall turbulence closure modeling without “damping functions”. Theor. Comput. Fluid Dyn. 1991, 3, 1–13. [Google Scholar]

- Candel, S.; Veynante, D.; Lacas, F.; Maistret, E.; Darabiha, N.; Poinsot, T. Coherent flamelet model: Applications and current extensions. Recent Adv. Combust. Model. 1990, 19–64. [Google Scholar] [CrossRef]

- AVL FIRE® R2018a. Combustion Module User Manual; AVL List GmbH: Graz, Austria, 2018. [Google Scholar]

- AVL FIRE® R2018a. Spray Module User Manual; AVL List GmbH: Graz, Austria, 2018. [Google Scholar]

- Beale, J.C.; Reitz, R.D. Modeling spray atomization with the kelvin-helmotz/Rayleigh-taylor hybrid model. At. Sprays. 1999, 9, 623–650. [Google Scholar] [CrossRef]

- AVL FIRE® R2018a. Emission Module User Manual; AVL List GmbH: Graz, Austria, 2018. [Google Scholar]

- Raine, R.; Stone, C.; Gould, J. Modeling of nitric oxide formation in spark ignition engines with a multizone burned gas. Combust. Flame 1995, 102, 241–255. [Google Scholar] [CrossRef]

- Naber, J.; Reitz, R.D. Modeling Engine Spray/Wall Impingement. SAE Tech. Pap. Ser. 1988, 97, 118–140. [Google Scholar] [CrossRef]

- National Center for Biotechnology Information. PubChem Compound Summary for CID 8900, Heptane. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/Heptane (accessed on 7 September 2020).

- Friend, D.G.; Ely, J.F.; Ingham, H. Thermophysical Properties of Methane. J. Phys. Chem. Ref. Data 1989, 18, 583–638. [Google Scholar] [CrossRef]

- Savli, M. Turbulence Kinetic Energy–TKE; Faculty of Mathematics and Physics, University of Ljubljana: Ljubljana, Slovenia, 2012; Volume 9. [Google Scholar]

- Polk, A.C.; Carpenter, C.D.; Srinivasan, K.K.; Krishnan, S.R. An investigation of diesel–ignited propane dual fuel combustion in a heavy-duty diesel engine. Fuel 2014, 132, 135–148. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, M.; Shao, S. Combustion process and emissions of a heavy-duty engine fueled with directly injected natural gas and pilot diesel. Appl. Energy 2015, 157, 217–228. [Google Scholar] [CrossRef]

- Sahoo, B.; Sahoo, N.; Saha, U. Effect of engine parameters and type of gaseous fuel on the performance of dual-fuel gas diesel engines—A critical review. Renew. Sustain. Energy Rev. 2009, 13, 1151–1184. [Google Scholar] [CrossRef]

- Wei, L.; Geng, P. A review on natural gas/diesel dual fuel combustion, emissions and performance. Fuel Process. Technol. 2016, 142, 264–278. [Google Scholar] [CrossRef]

- Kuo, K.K. Principles of Combustion, 2nd ed.; John Wiley and Sons: New York, NY, USA, 2005. [Google Scholar]

- Maricq, M.M.; Chase, R.E.; Xu, N.; Laing, P.M. The effects of the catalytic converter and fuel sulfur level on motor vehicle particulate matter emissions: Light duty diesel vehicles. Environ. Sci. Technol. 2002, 36, 283–289. [Google Scholar] [CrossRef]

- Burnett, R.T.; Cakmak, S.; Brook, J.R.; Krewski, D. The role of particulate size and chemistry in the association between summertime ambient air pollution and hospitalization for cardiorespiratory diseases. Environ. Health Perspect. 1997, 105, 614–620. [Google Scholar] [CrossRef] [PubMed]

- Kittelson, D.; Watts, W.; Johnson, J. On-road and laboratory evaluation of combustion aerosols—Part1: Summary of diesel engine results. J. Aerosol Sci. 2006, 37, 913–930. [Google Scholar] [CrossRef]

- Rounce, P.; Tsolakis, A.; York, A.P.E. Speciation of particulate matter and hydrocarbon emissions from biodiesel combustion and its reduction by after-treatment. Fuel 2012, 96, 90–99. [Google Scholar] [CrossRef]

- Blauvens, J.; Smets, B.; Peters, J. In Proceedings of the 16th Symposium (International) on Combustion; The Combustion Institute: New York, NY, USA, 1977. [Google Scholar]

- Flower, W.L.; Hanson, R.K.; Kruger, C.H. In Proceedings of the 15th Symposium (International) on Combustion; The Combustion Institute: New York, NY, USA, 1975; p. 823. [Google Scholar]

- Monat, J.P.; Hanson, R.K.; Kruger, C.H. In Proceedings of the 17th Symposium (International) on Combustion; The Combustion Institute: New York, NY, USA, 1979; p. 543. [Google Scholar]

- Baulch, D.L.; Drysdall, D.D.; Horne, D.G.; Lloyd, A.C. Evaluated Kinetic Data for High Temperature Reactions. Vol. 2: Homogeneous Gas Phase Reactions of the H2—N2—O2 System. Berichte der Bunsengesellschaft für Physikalische Chemie 1974, 78, 212–213. [Google Scholar]

- Hanson, R.K.; Salimian, S. Survey of Rate Constants in the N/H/O System. Combust. Chem. 1984, 361–421. [Google Scholar] [CrossRef]

| Parameter | Value | Unit |

|---|---|---|

| Type of Engine | 4-Stroke Dual-Fuel Engine | |

| Name of Engine | 6H35DF | |

| Fuel Gas Supplying | Gas Fuel Port Injection | |

| No. of Cylinder | 6 | |

| Cylinder Bore | 350 | mm |

| Stroke | 400 | mm |

| Compression Ratio | 13.5:1 | |

| Connecting Rod Length | 870 | mm |

| Engine Speed | 720 | rpm |

| Power | 2880 @ 720 rpm | kW |

| Indicated Mean Effective Pressure (IMEP) | 20 | bar |

| No. of Pilot Injector | 1 | |

| Injector Spray Angle | 155 | deg. |

| Gas Fuel | NG | |

| Lower Calorific Value (LCV) of Natural Gas (NG) | 50000 * | kJ/kg |

| Pilot Fuel | Diesel | |

| Lower Calorific Value (LCV) of Diesel | 42343 * | kJ/kg |

| Model | Description | |

|---|---|---|

| Combustion | Standard Species Transport Model (Appendix A) | |

| Extended Coherent Flame Model—ECFM (Appendix B) | ||

| Emission | NO | Extended Zeldovich (Appendix C) |

| Soot | Kinetic Soot formation (Appendix D) | |

| Ignition | Auto-Ignition Model (Diesel Mode) Diesel Ignition Gas Engine (Dual-Fuel Mode) | |

| Spray | Evaporation | Dukowicz Model (Diesel Mode) Multi-component (Dual-Fuel Mode) |

| Breakup | WAVE | |

| Wall interaction | Walljet1 | |

| Turbulence | k-zeta-f | |

| Boundary Conditions | Boundary Type/Specific Condition |

| Cylinder head | Wall/Temp./570.15 K |

| Piston | Mesh movement/Temp./570.15 K |

| Liner | Wall/Temp./470.15 K |

| Segment cut | Periodic/Inlet/Outlet |

| Initial conditions | Value |

| Pressure at IVC | 3.5 bar |

| Temperature at IVC | 320.5 K |

| IVC | 35 CAD ABDC |

| EVO | 62 CAD BBDC |

| S.O.I | 12 CAD BTDC |

| Diesel injection duration | 15 CAD in the dual-fuel mode |

| 32 CAD in the diesel mode |

| Fuel | Diesel | NG | Unit |

|---|---|---|---|

| Density | 680 | 0.657 | kg/m3 @ 25 °C, 1 at |

| Chemical name/formula | n-Heptane/C7H16 | Methane/CH4 | |

| Lower calorific value | 42,343 | 50,000 | kJ/kg |

| Molecular weight | 100.205 | 16.043 | g/mol |

| Boiling point | 98.38 | −162 | °C |

| Auto-Ignition temperature | 223 | 537 | °C |

| Specific heat capacity (Cp) | 224.64 | 35.69 | J/mol·K @ 25 °C |

| Stoichiometric air-fuel ratio | 15.2 | 17.19 | kg/kg |

| Mesh Resolutions | Mesh 1—Coarse | Mesh 2—Medium | Mesh 3—Fine |

|---|---|---|---|

| Number of faces on haft of 2D mesh at the TDC | 12,949 faces | 17,715 faces | 39,307 faces |

| Total number of cells of entire 3D mesh | 586,796 cells | 882,620 cells | 1,593,732 cells |

| Calculation time | 24 h | 36 h | 92 h |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pham, V.C.; Choi, J.-H.; Rho, B.-S.; Kim, J.-S.; Park, K.; Park, S.-K.; Le, V.V.; Lee, W.-J. A Numerical Study on the Combustion Process and Emission Characteristics of a Natural Gas-Diesel Dual-Fuel Marine Engine at Full Load. Energies 2021, 14, 1342. https://doi.org/10.3390/en14051342

Pham VC, Choi J-H, Rho B-S, Kim J-S, Park K, Park S-K, Le VV, Lee W-J. A Numerical Study on the Combustion Process and Emission Characteristics of a Natural Gas-Diesel Dual-Fuel Marine Engine at Full Load. Energies. 2021; 14(5):1342. https://doi.org/10.3390/en14051342

Chicago/Turabian StylePham, Van Chien, Jae-Hyuk Choi, Beom-Seok Rho, Jun-Soo Kim, Kyunam Park, Sang-Kyun Park, Van Vang Le, and Won-Ju Lee. 2021. "A Numerical Study on the Combustion Process and Emission Characteristics of a Natural Gas-Diesel Dual-Fuel Marine Engine at Full Load" Energies 14, no. 5: 1342. https://doi.org/10.3390/en14051342

APA StylePham, V. C., Choi, J.-H., Rho, B.-S., Kim, J.-S., Park, K., Park, S.-K., Le, V. V., & Lee, W.-J. (2021). A Numerical Study on the Combustion Process and Emission Characteristics of a Natural Gas-Diesel Dual-Fuel Marine Engine at Full Load. Energies, 14(5), 1342. https://doi.org/10.3390/en14051342