Experimental Studies of Droplet Formation Process and Length for Liquid–Liquid Two-Phase Flows in a Microchannel

Abstract

1. Introduction

2. Experimental Method

2.1. Experimental Setup

2.2. Materials

2.3. Experimental Procedure

3. Results and Discussion

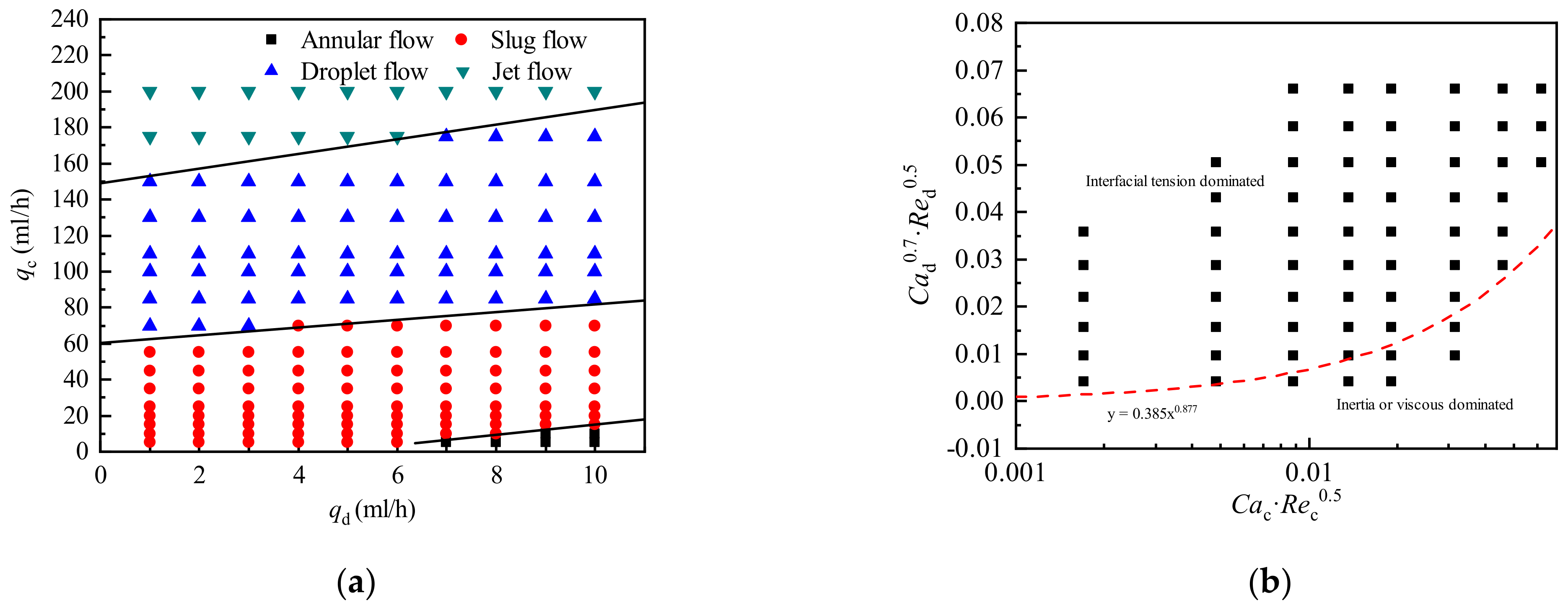

3.1. Flow Pattern Maps

3.2. Basic Flow Pattern Formation Processes

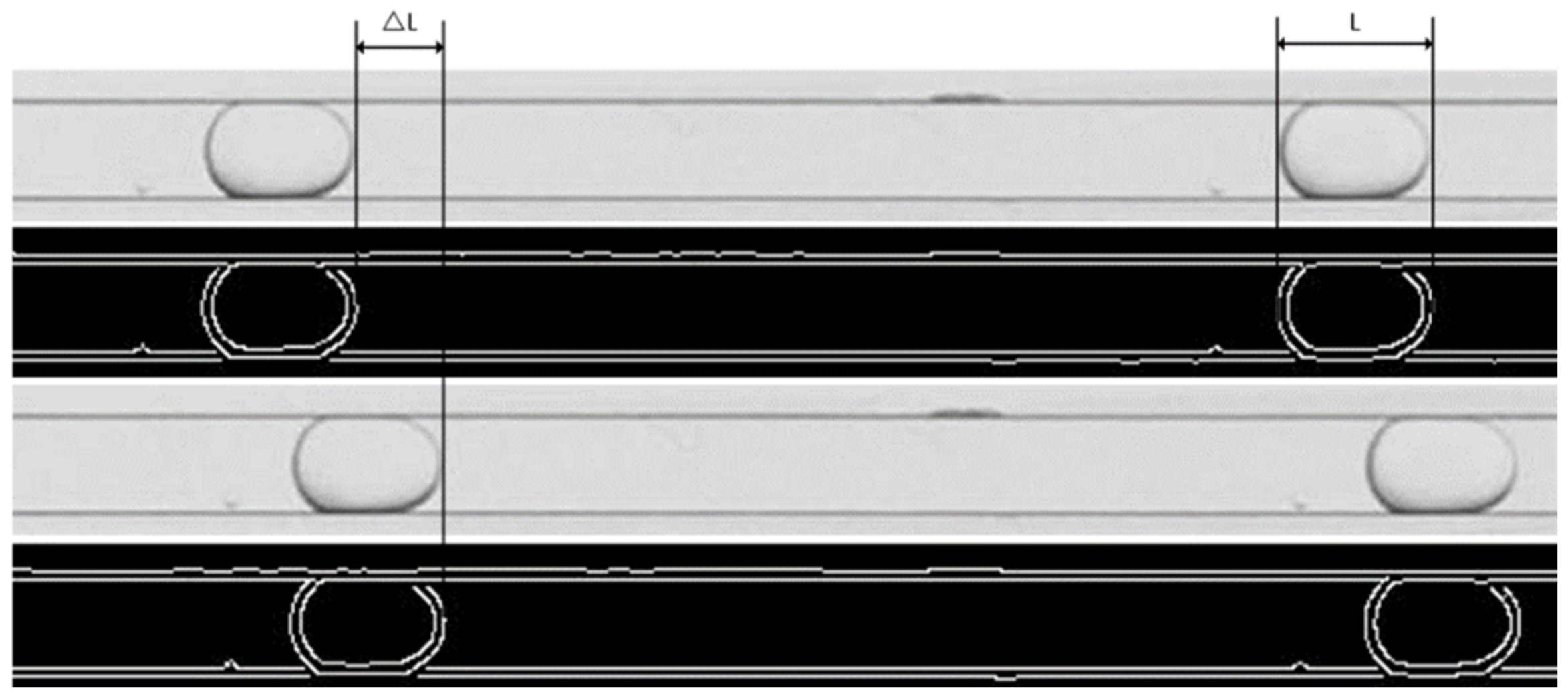

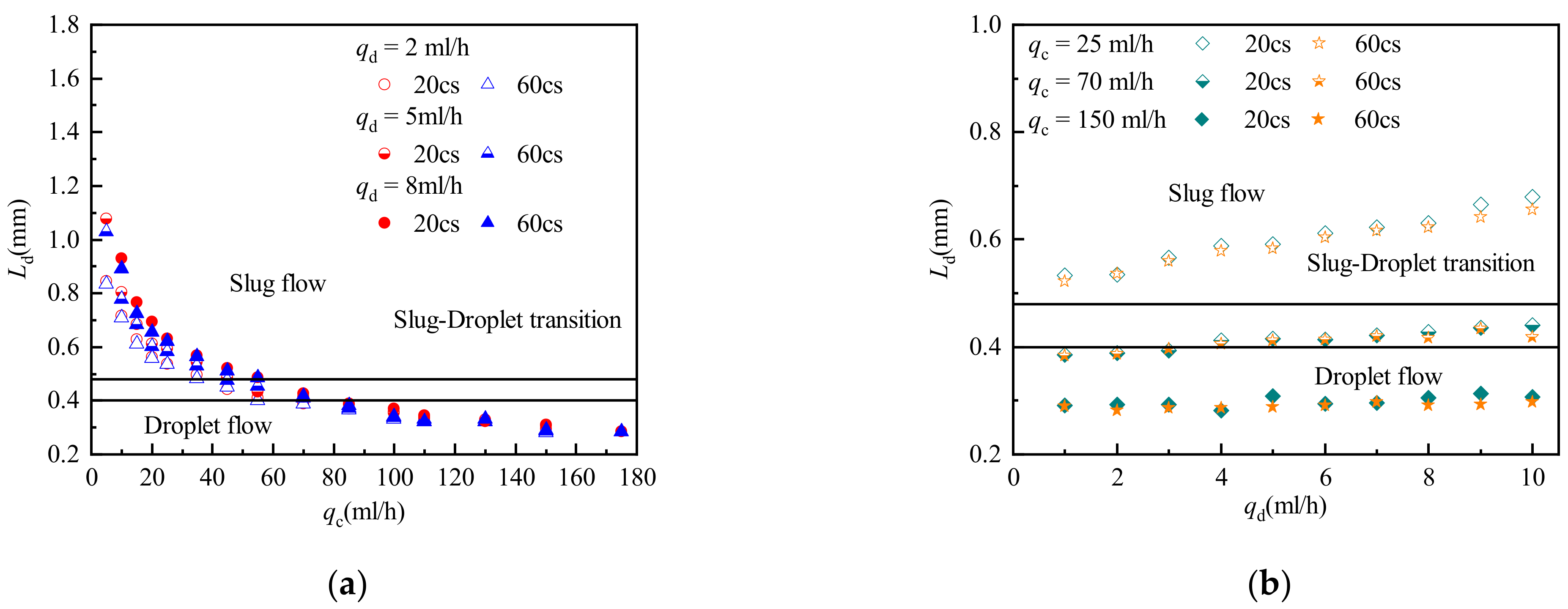

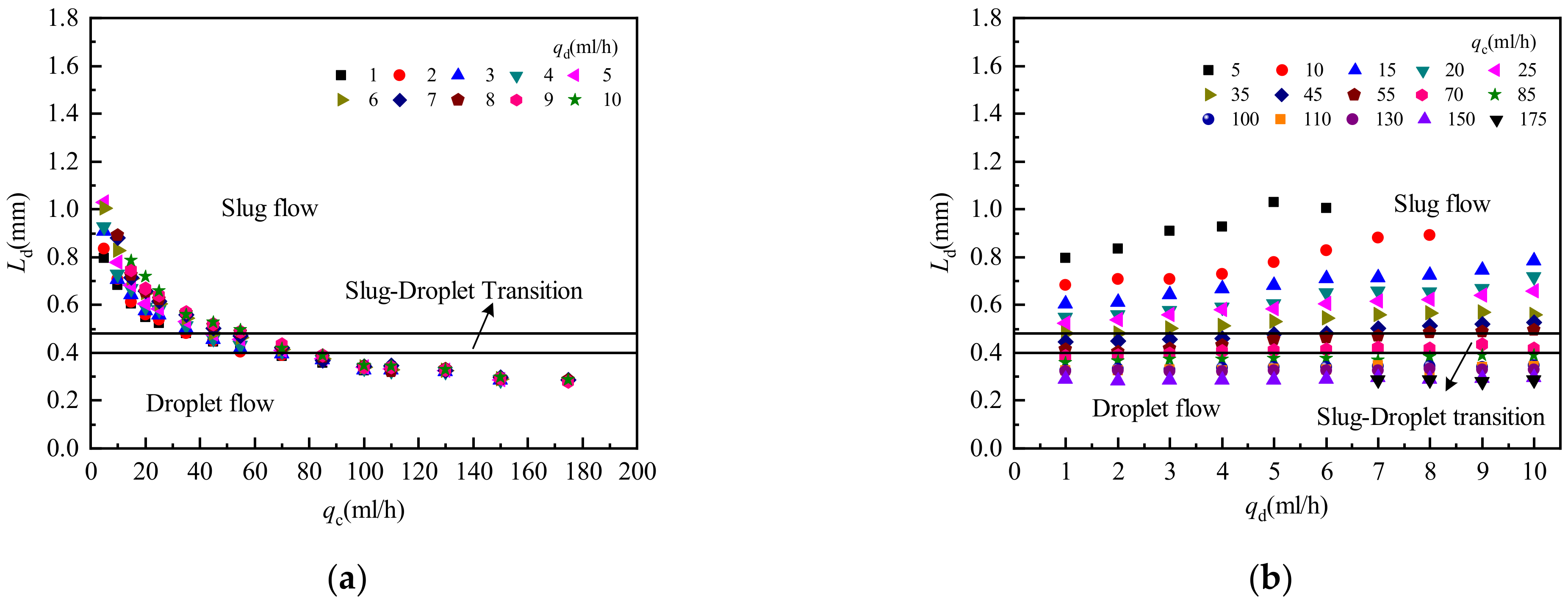

3.3. Analysis of Influencing Factors on Slug and Droplet Length

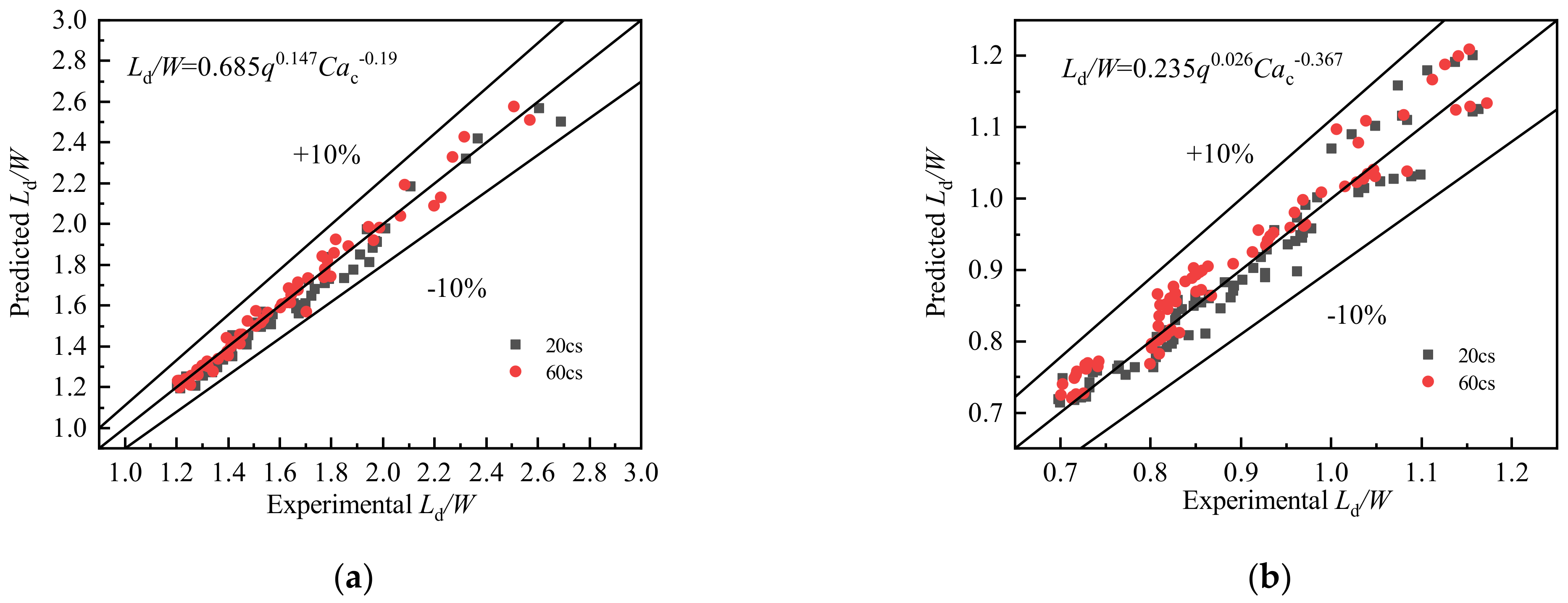

3.4. Scaling Law on Slug and Droplet Length

4. Conclusions

- By combining the flow pattern formation process and force analysis, the formation mechanisms of various flow patterns (annular flow, slug flow, droplet flow, and jet flow) were studied in this experiment. According to the mechanism forming the flow pattern, the pattern was divided into four categories. Annular flow is dominated by inertial force, slug flow is dominated by interfacial tension, droplet flow is dominated by shear force, and jet flow is controlled by shear force and drag force.

- The effects of various factors on flow pattern transition and droplet length were analyzed by changing the viscosity of the silicone oil and the two-phase flow parameters. The results show that changing the dispersed phase viscosity affects the flow pattern transition processes of annular flow to slug flow and slug flow to droplet flow, but has little effect on slug properties and droplet length. The length is mainly controlled by the flow rate ratio of the two phases and the continuous phase capillary number. The increase in the viscosity of the dispersed phase will increase the droplet generation time slightly. However, the droplet formation processes under different dispersed phase viscosities in the present work are nearly identical.

- Using dimensionless analysis, the droplet fluid dynamics were studied, and different prediction scaling laws were proposed for the slug and droplet lengths formed by different flow patterns. The prediction scaling laws were compared with other literature data to further verify their accuracy. The performance was excellent for the prediction results.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| A | Area, m2 |

| a | Height of the gas phase in the front view, m |

| b | Width of the gas phase in the bottom view, m |

| C0 | Distribution parameter |

| D | Inner diameter, m |

| Ld | Length of the flow domain, mm |

| LO* | Non-dimensional Laplace constant |

| Probability density function | |

| q | Volume flow rate, m3/s |

| S | Slip ratio |

| U | Superficial velocity, m/s |

| V | Volume, m3 |

| x | Gas mass fraction |

| Greek letters | |

| α | Void fraction |

| β | Volumetric gas flow ratio |

| μ | Dynamic viscosity, Pa·s |

| ρ | Density, kg/m3 |

| σ | Surface tension, N/m |

| τ | Time, s |

| Subscripts | |

| cs | Cross-sectional |

| vol | Volumetric |

| g | Gas phase |

| l | Liquid phase |

| m | Mixture of gas and liquid two phases |

| p | Pipe |

| d | Droplet |

References

- Manz, A.; Graber, N.; Widmer, H. Miniaturized total chemical analysis systems: A novel concept for chemical sensing. Sens. Actuators B Chem. 1990, 1, 244–248. [Google Scholar] [CrossRef]

- Bardiya, N.; Choi, J.-W.; Chang, S.-I. Analysis of single nucleotide polymorphism in human angiogenin using droplet-based microfluidics. BioChip J. 2014, 8, 15–21. [Google Scholar] [CrossRef]

- Dittrich, P.S.; Manz, A. Lab-on-a-chip: Microfluidics in drug discovery. Nat. Rev. Drug Discov. 2006, 5, 210–218. [Google Scholar] [CrossRef]

- Du, G.-S.; Pan, J.-Z.; Zhao, S.-P.; Zhu, Y.; Toonder, J.M.D.; Fang, Q. Cell-Based Drug Combination Screening with a Microfluidic Droplet Array System. Anal. Chem. 2013, 85, 6740–6747. [Google Scholar] [CrossRef] [PubMed]

- Günther, A.; Jensen, K.F. Multiphase microfluidics: From flow characteristics to chemical and materials synthesis. Lab Chip 2006, 6, 1487–1503. [Google Scholar] [CrossRef] [PubMed]

- Jensen, K.F. Microreaction engineering—Is small better? Chem. Eng. Sci. 2001, 56, 293–303. [Google Scholar] [CrossRef]

- Zhao, C.-X. Multiphase flow microfluidics for the production of single or multiple emulsions for drug delivery. Adv. Drug Deliv. Rev. 2013, 65, 1420–1446. [Google Scholar] [CrossRef]

- Kinoshita, H.; Kaneda, S.; Fujii, T.; Oshima, M. Three-dimensional measurement and visualization of internal flow of a moving droplet using confocal micro-PIV. Lab Chip 2007, 7, 338–346. [Google Scholar] [CrossRef] [PubMed]

- Song, H.; Bringer, M.R.; Tice, J.D.; Gerdts, C.J.; Ismagilov, R.F. Experimental test of scaling of mixing by chaotic advection in droplets moving through microfluidic channels. Appl. Phys. Lett. 2003, 83, 4664–4666. [Google Scholar] [CrossRef]

- Adamo, A.; Beingessner, R.L.; Behnam, M.; Chen, J.; Jamison, T.F.; Jensen, K.F.; Monbaliu, J.-C.M.; Myerson, A.S.; Revalor, E.M.; Snead, D.R.; et al. On-demand continuous-flow production of pharmaceuticals in a compact, reconfigurable system. Science 2016, 352, 61–67. [Google Scholar] [CrossRef] [PubMed]

- Yao, C.; Zhao, Y.; Chen, G. Multiphase processes with ionic liquids in microreactors: Hydrodynamics, mass transfer and applications. Chem. Eng. Sci. 2018, 189, 340–359. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, H.; Zhao, S.; Yao, C.; Chen, G. Hydrodynamics and mass transfer characteristics of liquid–liquid slug flow in microchannels: The effects of temperature, fluid properties and channel size. Chem. Eng. J. 2019, 358, 794–805. [Google Scholar] [CrossRef]

- Zhou, F.; Zhang, B.; Yao, C.; Zhu, K.; Yang, M.; Chen, G. Cyclization of Pseudoionone Catalyzed by Sulfuric Acid in a Microreactor. Chem. Eng. Technol. 2016, 39, 849–856. [Google Scholar] [CrossRef]

- Winkelman, J.G.; Schuur, B.; Heeres, H.J.; Yue, J. Lactic Acid Extraction and Mass Transfer Characteristics in Slug Flow Capillary Microreactors. Ind. Eng. Chem. Res. 2016, 55, 4691–4702. [Google Scholar]

- Yang, L.; Zhao, Y.; Su, Y.; Chen, G. An Experimental Study of Copper Extraction Characteristics in a T-Junction Microchannel. Chem. Eng. Technol. 2013, 36, 985–992. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhao, K.; Jia, D.; Jiang, P.; Shen, R. Numerical Investigation on the Flow and Heat Transfer Characteristics of Supercritical Liquefied Natural Gas in an Airfoil Fin Printed Circuit Heat Exchanger. Energies 2017, 10, 1828. [Google Scholar] [CrossRef]

- Foroughi, H.; Abbasi, A.; Das, K.S.; Kawaji, M. Immiscible displacement of oil by water in a microchannel: Asymmetric flow behavior and nonlinear stability analysis of core-annular flow. Phys. Rev. E 2012, 85. [Google Scholar] [CrossRef]

- Ling, B.; Khan, H.J.; Druhan, J.L.; Battiato, I. Multi-Scale Microfluidics for Transport in Shale Fabric. Energies 2020, 14, 21. [Google Scholar] [CrossRef]

- Litster, S.; Sinton, D.; Djilali, N. Ex situ visualization of liquid water transport in PEM fuel cell gas diffusion layers. J. Power Sources 2006, 154, 95–105. [Google Scholar] [CrossRef]

- Zhang, J.; Li, W. Investigation of hydrodynamic and heat transfer characteristics of gas–liquid Taylor flow in vertical capillaries. Int. Commun. Heat Mass Transf. 2016, 74, 1–10. [Google Scholar] [CrossRef]

- Zhang, J.; Li, W. Thermal and Flow Characteristics of Water–Nitrogen Taylor Flow inside Vertical Circular Tubes. J. Heat Transf. 2018, 140, 082004. [Google Scholar] [CrossRef]

- Zunlong, J.; Shuiyun, L.; Mingshan, L. Numerical simulation of gas-liquid two-phase flow in a convection T-junction microchannels. Cryo. Supercond. 2013, 41, 42–46, 51. [Google Scholar]

- Markovic, T.; Ocket, I.; Baric, A.; Nauwelaers, B. Design and Comparison of Resonant and Non-Resonant Single-Layer Microwave Heaters for Continuous Flow Microfluidics in Silicon-Glass Technology. Energies 2020, 13, 2635. [Google Scholar] [CrossRef]

- Cai, W.; Zhang, J.; Zhang, X.; Wang, Y.; Qi, X. Enhancement of CO2 Absorption under Taylor Flow in the Presence of Fine Particles. Chin. J. Chem. Eng. 2013, 21, 135–143. [Google Scholar] [CrossRef]

- Jiang, S.; Zhu, C.; Zhang, F.; Ma, Y. Mass transfer performance of CO2/N2 mixture absorption into monoethanolamine aqueous solution in microchannel. CIESC J. 2017, 68, 643–652. [Google Scholar]

- Damiati, S.; Kompella, U.B.; Damiati, S.A.; Kodzius, R. Microfluidic Devices for Drug Delivery Systems and Drug Screening. Genes 2018, 9, 103. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, W.; Shao, T.; Zhang, M.; Jin, Y.; Cheng, Y. Mixing performance and drug nano-particle preparation inside slugs in a gas–liquid microchannel reactor. Chem. Eng. Sci. 2013, 100, 456–463. [Google Scholar] [CrossRef]

- Garstecki, P.; Fuerstman, M.J.; Stone, H.A.; Whitesides, G.M. Formation of droplets and bubbles in a microfluidic T-junction—scaling and mechanism of break-up. Lab Chip 2006, 6, 437–446. [Google Scholar] [CrossRef]

- Lefortier, S.G.R.; Hamersma, P.J.; Bardow, A.; Kreutzer, M.T. Rapid microfluidic screening of CO2 solubility and diffusion in pure and mixed solvents. Lab Chip 2012, 12, 3387–3391. [Google Scholar] [CrossRef] [PubMed]

- Van Steijn, V.; Kleijn, C.R.; Kreutzer, M.T. Predictive model for the size of bubbles and droplets created in microfluidic T-junctions. Lab Chip 2010, 10, 2513–2518. [Google Scholar] [CrossRef]

- Zhou, C.; Zhu, P.; Tian, Y.; Tang, X.; Shi, R.; Wang, L. Microfluidic generation of aqueous two-phase-system (ATPS) droplets by oil-droplet choppers. Lab Chip 2017, 17, 3310–3317. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, G.; Yuan, Q. Liquid-liquid two-phase flow patterns in a rectangular microchannel. AIChE J. 2006, 52, 4052–4060. [Google Scholar] [CrossRef]

- Salim, A.; Fourar, M.; Pironon, J.; Sausse, J. Oil-water two-phase flow in microchannels: Flow patterns and pressure drop measurements. Can. J. Chem. Eng. 2008, 86, 978–988. [Google Scholar] [CrossRef]

- Kashid, M.; Kiwi-Minsker, L. Quantitative prediction of flow patterns in liquid–liquid flow in micro-capillaries. Chem. Eng. Process. Process. Intensif. 2011, 50, 972–978. [Google Scholar] [CrossRef]

- Li, Y.K.; Liu, G.T.; Xu, J.H.; Wang, K.; Luo, G.S. A microdevice for producing monodispersed droplets under a jetting flow. RSC Adv. 2015, 5, 27356–27364. [Google Scholar] [CrossRef]

- Tsaoulidis, D.; Dore, V.; Angeli, P.; Plechkova, N.V.; Seddon, K.R. Flow patterns and pressure drop of ionic liquid–water two-phase flows in microchannels. Int. J. Multiph. Flow 2013, 54, 1–10. [Google Scholar] [CrossRef]

- Cherlo, S.K.R.; Kariveti, S.; Pushpavanam, S. Experimental and Numerical Investigations of Two-Phase (Liquid–Liquid) Flow Behavior in Rectangular Microchannels. Ind. Eng. Chem. Res. 2010, 49, 893–899. [Google Scholar] [CrossRef]

- Fu, T.; Wei, L.; Zhu, C.; Ma, Y. Flow patterns of liquid–liquid two-phase flow in non-Newtonian fluids in rectangular microchannels. Chem. Eng. Process. Process. Intensif. 2015, 91, 114–120. [Google Scholar] [CrossRef]

- Kashid, M.N.; Agar, D.W. Hydrodynamics of liquid–liquid slug flow capillary microreactor: Flow regimes, slug size and pressure drop. Chem. Eng. J. 2007, 131, 1–13. [Google Scholar] [CrossRef]

- Kashid, M.N.; Renken, A.; Kiwi-Minsker, L. Influence of Flow Regime on Mass Transfer in Different Types of Microchannels. Ind. Eng. Chem. Res. 2011, 50, 6906–6914. [Google Scholar] [CrossRef]

- Wu, Z.; Cao, Z.; Sundén, B. Liquid-liquid flow patterns and slug hydrodynamics in square microchannels of cross-shaped junctions. Chem. Eng. Sci. 2017, 174, 56–66. [Google Scholar] [CrossRef]

- Cubaud, T.; Mason, T.G. Capillary threads and viscous droplets in square microchannels. Phys. Fluids 2008, 20, 053302. [Google Scholar] [CrossRef]

- Cao, Z.; Wu, Z.; Sundén, B. Dimensionless analysis on liquid-liquid flow patterns and scaling law on slug hydrodynamics in cross-junction microchannels. Chem. Eng. J. 2018, 344, 604–615. [Google Scholar] [CrossRef]

- Bai, L.; Zhao, S.; Fu, Y.; Cheng, Y. Experimental study of mass transfer in water/ionic liquid microdroplet systems using micro-LIF technique. Chem. Eng. J. 2016, 298, 281–290. [Google Scholar] [CrossRef]

- Jose, B.M.; Cubaud, T. Formation and dynamics of partially wetting droplets in square microchannels. RSC Adv. 2014, 4, 14962–14970. [Google Scholar] [CrossRef]

- Bai, L.; Fu, Y.; Zhao, S.; Cheng, Y. Droplet formation in a microfluidic T-junction involving highly viscous fluid systems. Chem. Eng. Sci. 2016, 145, 141–148. [Google Scholar] [CrossRef]

- Foroughi, H.; Kawaji, M. Viscous oil–water flows in a microchannel initially saturated with oil: Flow patterns and pressure drop characteristics. Int. J. Multiph. Flow 2011, 37, 1147–1155. [Google Scholar] [CrossRef]

- Xu, J.H.; Li, S.W.; Tan, J.; Luo, G.S. Correlations of droplet formation in T-junction microfluidic devices: From squeezing to dripping. Microfluid. Nanofluidics 2008, 5, 711–717. [Google Scholar] [CrossRef]

- Dessimoz, A.-L.; Cavin, L.; Renken, A.; Kiwi-Minsker, L. Liquid–liquid two-phase flow patterns and mass transfer characteristics in rectangular glass microreactors. Chem. Eng. Sci. 2008, 63, 4035–4044. [Google Scholar] [CrossRef]

- Yagodnitsyna, A.A.; Kovalev, A.V.; Bilsky, A.V. Flow patterns of immiscible liquid-liquid flow in a rectangular microchannel with T-junction. Chem. Eng. J. 2016, 303, 547–554. [Google Scholar] [CrossRef]

- Yao, C.; Liu, Y.; Xu, C.; Zhao, S.; Chen, G. Formation of liquid-liquid slug flow in a microfluidic T-junction: Effects of fluid properties and leakage flow. AIChE J. 2017, 64, 346–357. [Google Scholar] [CrossRef]

- Wu, Z.; Cao, Z.; Sunden, B. Flow patterns and slug scaling of liquid-liquid flow in square microchannels. Int. J. Multiph. Flow 2019, 112, 27–39. [Google Scholar] [CrossRef]

- Zhang, Q.; Fu, T.; Zhu, C.; Ma, Y. Formation and size prediction of slug droplet in viscoelastic fluid in flow-focusing microchannel. CIESC J. 2016, 67, 504–511. [Google Scholar]

- Dang, M.; Ren, M.; Chen, G. Effect of microchannel inlet configuration on Taylor bubble formation in microreactors. CIESC J. 2014, 65, 805–812. [Google Scholar]

- Yao, C.; Zhao, Y.; Ye, C.; Dang, M.; Dong, Z.; Chen, G. Characteristics of slug flow with inertial effects in a rectangular microchannel. Chem. Eng. Sci. 2013, 95, 246–256. [Google Scholar]

- Guo, F.; Chen, B. Numerical Study on Taylor Bubble Formation in a Micro-channel T-Junction Using VOF Method. Microgravity Sci. Technol. 2009, 21, 51–58. [Google Scholar] [CrossRef]

- De Menech, M.; Garstecki, P.; Jousse, F.; Stone, H.A. Transition from squeezing to dripping in a microfluidic T-shaped junction. J. Fluid Mech. 2008, 595, 141–161. [Google Scholar] [CrossRef]

- Christopher, G.F.; Noharuddin, N.N.; Taylor, J.A.; Anna, S.L. Experimental observations of the squeezing-to-dripping transition in T-shaped microfluidic junctions. Phys. Rev. E 2008, 78, 036317. [Google Scholar] [CrossRef]

- Wei, L.; Zhu, C.; Fu, T.; Ma, Y. Experimental measurement and correlation of droplet size in T-junction microchannels. CIESC J. 2013, 64, 517–523. [Google Scholar]

- De Menech, M. Modeling of droplet breakup in a microfluidic T-shaped junction with a phase-field model. Phys. Rev. E 2016, 73, 031505. [Google Scholar] [CrossRef]

- Liu, W. Study on Two-Phase Flow Patterns and Droplet Formation in Microchannels. Master’s Thesis, Tianjin University, Tianjin, China, 2010. [Google Scholar]

| Fluid System | μ (Pa·s) | ρ (kg/m3) | σ (N/m) | |

|---|---|---|---|---|

| Continuous Phase | 0.5 wt % SDS | 0.00135 | 971.53 | -- |

| 20 wt % glycerol + 0.5 wt % SDS | 0.00182 | 1039.2 | 31.5 | |

| 40 wt % glycerol + 0.5 wt % SDS | 0.00365 | 1097.1 | 31.5 | |

| Dispersed phase | Silicone oil | |||

| 20cst | 0.0268 | 919.3 | 0.010649 | |

| 60cst | 0.0725 | 927.4 | 0.010856 | |

| Author | Microchannel Structure | Continuous Phase | Dispersed Phase | μc(Pa·s) | μd(Pa·s) |

|---|---|---|---|---|---|

| Bai et al. [46] | Standard T-type | Ethanol | Silicone oil | 0.000555~0.945 | 0.000895~0.0664 |

| w × h = 0.5 × 0.5 mm | |||||

| Xu et al. [48] | Standard T-type | Water + SDS | Normal octane | 0.00092 | 0.001 |

| w × h = 0.2 × 0.15 mm | |||||

| Yao et al. [51] | Convective T-type w × h = 0.6 × 0.6 mm | ||||

| Case I | Silicone oil + SDS | Octane | 0.00089~0.00332 | 0.00053 | |

| Case II | Octane + SPAN80 | Silicone oil | 0.00053 | 0.00089~0.00332 | |

| Wei et al. [59] | Standard T-type | Water + Silicone oil + SDS | Cyclohexane | 0.0011~0.0099 | --- |

| w × h = 0.4 × 0.4 mm | |||||

| De menech et al. [60] | Standard T-type | Oil phase | Water phase | 0.008 | 0.001 |

| numerical simulation | |||||

| Liu et al. [61] | Convective T-type | Water + SDS | Cyclohexane | 0.001~0.0099 | --- |

| w × h = 0.04 × 0.1 mm | |||||

| Present scaling law | Convective T-type | Water + SDS | Silicone oil | 0.00135~0.00365 | 0.0268~0.0725 |

| w × h = 0.4 × 0.4 mm |

| Author | Correlations | Slug Flow | Droplet Flow |

|---|---|---|---|

| MAD/% | MAD/% | ||

| Bai et al. [46] | Slug flow: Droplet flow: | 27.5 | 11.0 |

| Xu et al. [48] | 15.0 | 34.5 | |

| Yao et al. [51] | |||

| Case I | 27.6 | 72.4 | |

| Case II | 19.6 | 70.9 | |

| Wei et al. [59] | 23.4 | 11.3 | |

| De menech et al. [60] | 9.14 | 12.0 | |

| Liu et al. [61] | Slug flow: Droplet flow: | 17.6 | 57 |

| Present scaling law | Slug flow: Droplet flow: | 3.4 | 2.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, L.; Zhao, Y.; Chen, W.; Li, H.; Wang, X.; Zhang, J. Experimental Studies of Droplet Formation Process and Length for Liquid–Liquid Two-Phase Flows in a Microchannel. Energies 2021, 14, 1341. https://doi.org/10.3390/en14051341

Lei L, Zhao Y, Chen W, Li H, Wang X, Zhang J. Experimental Studies of Droplet Formation Process and Length for Liquid–Liquid Two-Phase Flows in a Microchannel. Energies. 2021; 14(5):1341. https://doi.org/10.3390/en14051341

Chicago/Turabian StyleLei, Li, Yuting Zhao, Wukai Chen, Huiling Li, Xinyu Wang, and Jingzhi Zhang. 2021. "Experimental Studies of Droplet Formation Process and Length for Liquid–Liquid Two-Phase Flows in a Microchannel" Energies 14, no. 5: 1341. https://doi.org/10.3390/en14051341

APA StyleLei, L., Zhao, Y., Chen, W., Li, H., Wang, X., & Zhang, J. (2021). Experimental Studies of Droplet Formation Process and Length for Liquid–Liquid Two-Phase Flows in a Microchannel. Energies, 14(5), 1341. https://doi.org/10.3390/en14051341