Hot Box Investigations of a Ventilated Bioclimatic Wall for NZEB Building Façade

Abstract

1. Introduction

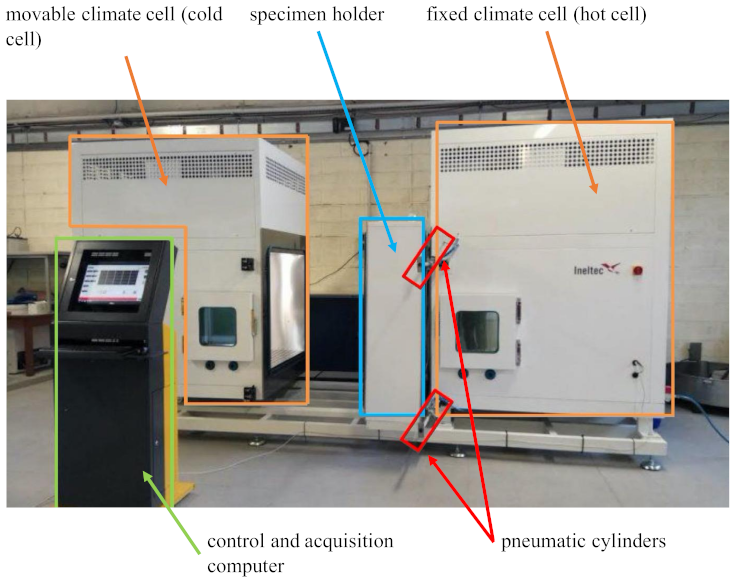

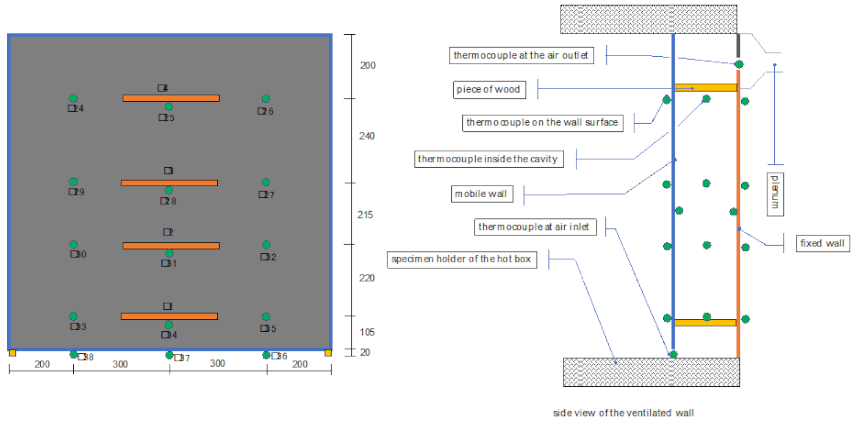

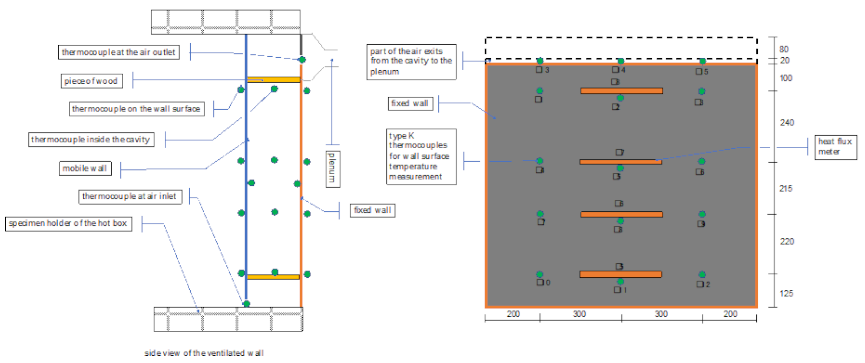

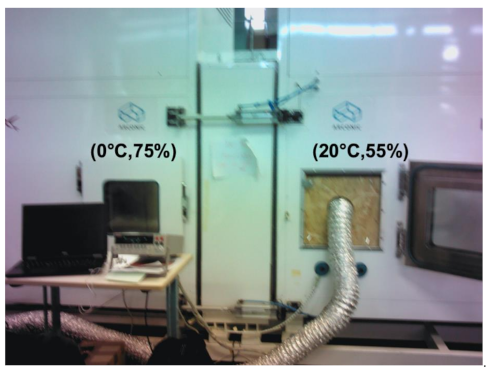

2. Experimental Setup

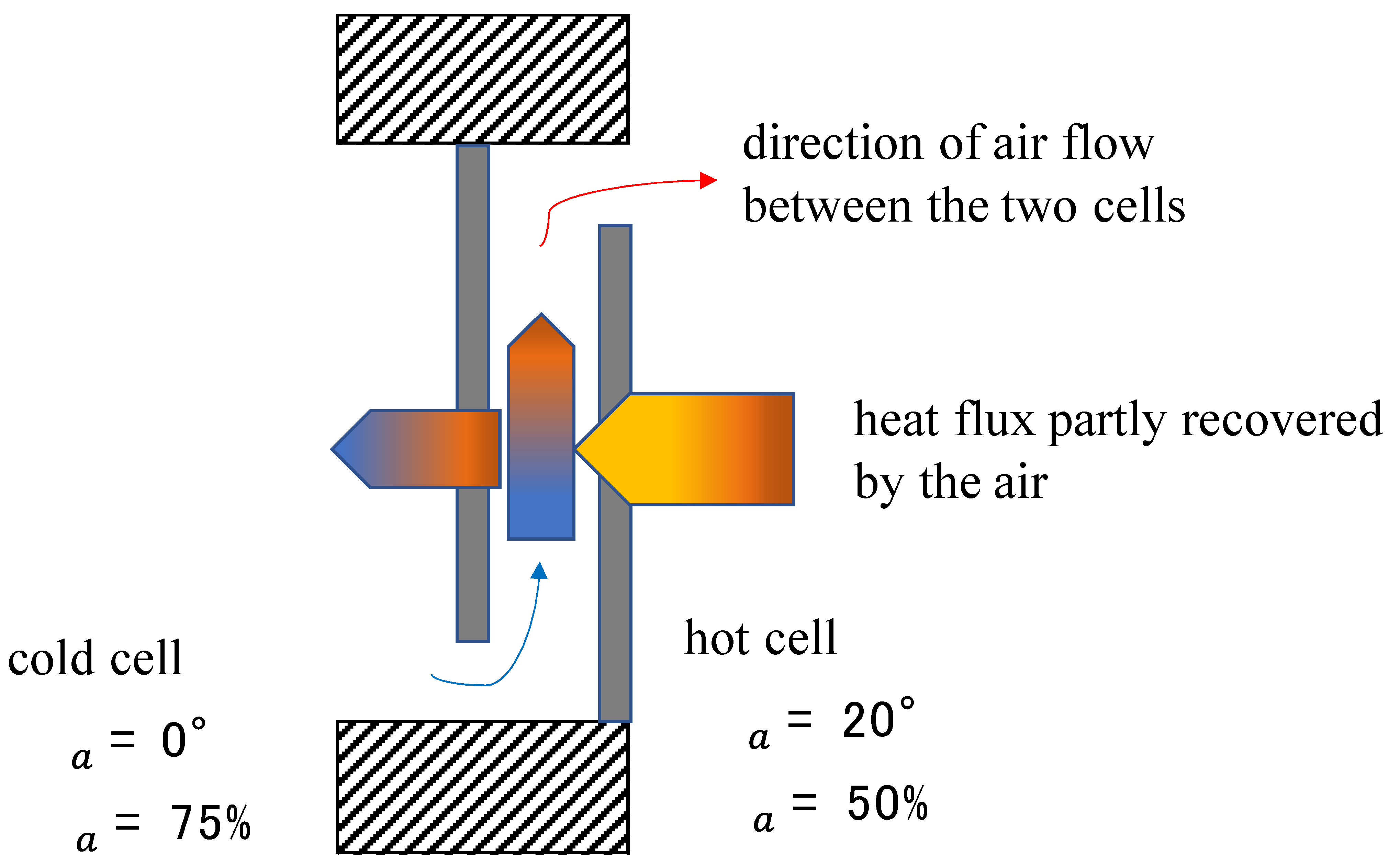

2.1. Bioclimatic Ventilated Wall and Hot Box

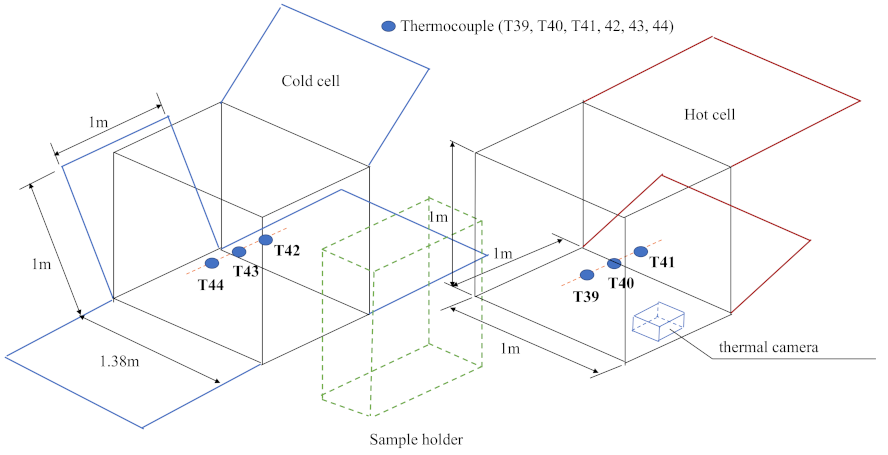

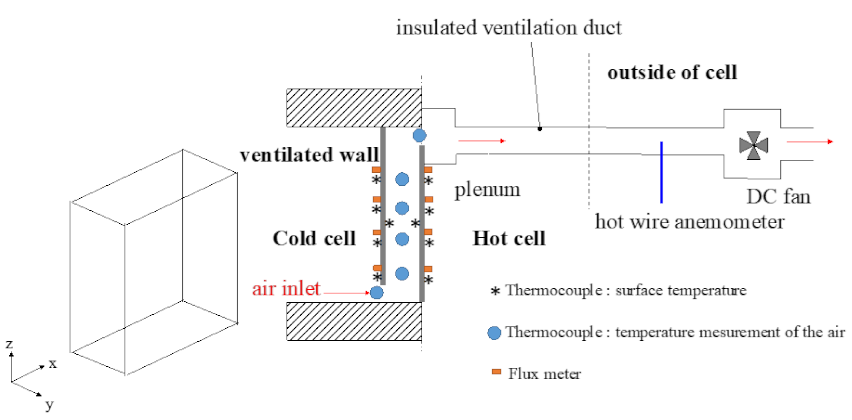

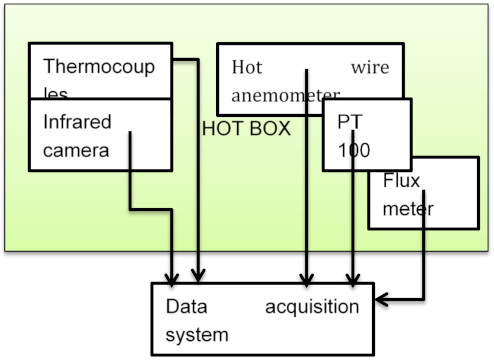

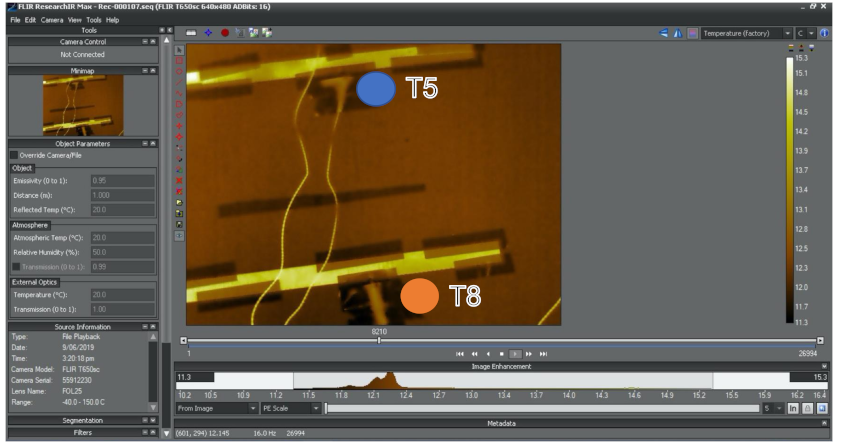

2.2. Thermal Metrology

3. Experimental Results

- -

- Hot cell: ambient temperature conditions of 20 °C and relative humidity (55%);

- -

- Cold cell: temperature conditions of 0 °C and relative humidity (75%);

- -

- Variable airflow rate: 10, 20, and 30 m3·h−1;

- -

- Variable air space thickness: from 5 to 85 mm.

3.1. Ambient Temperature

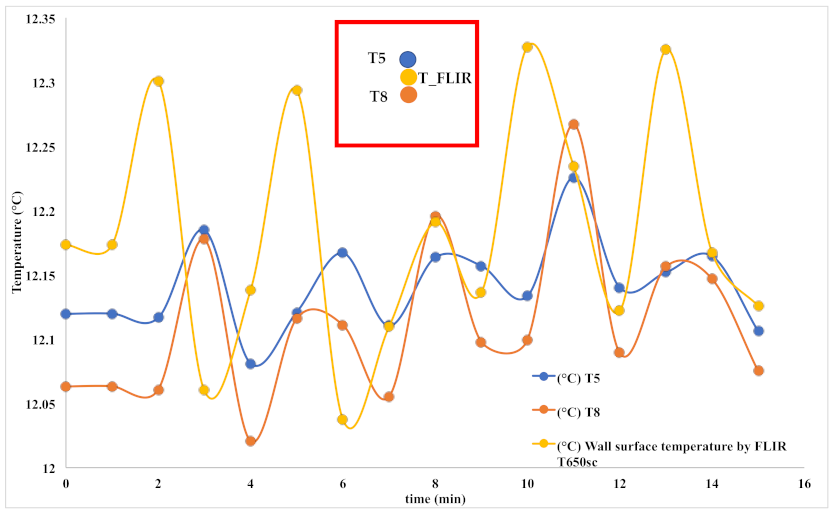

3.2. Surface Temperatures

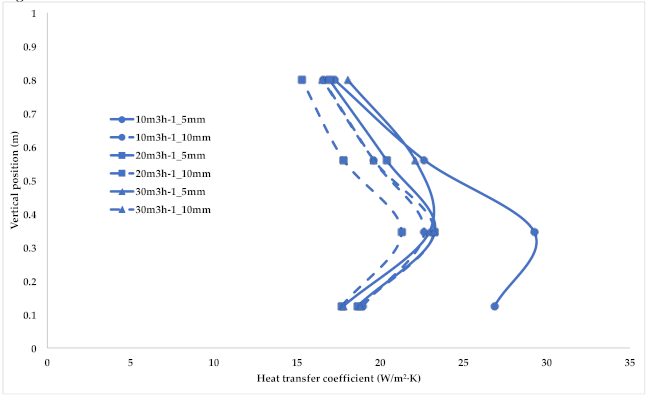

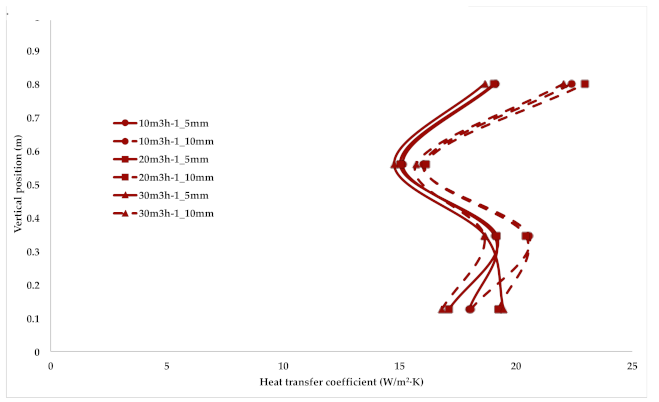

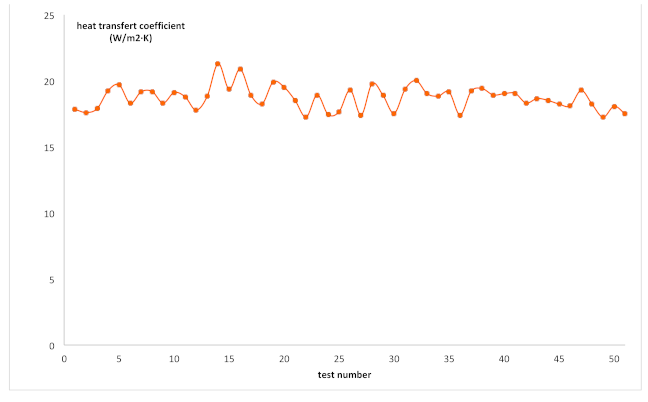

3.3. The Convection Heat Transfer Coefficient

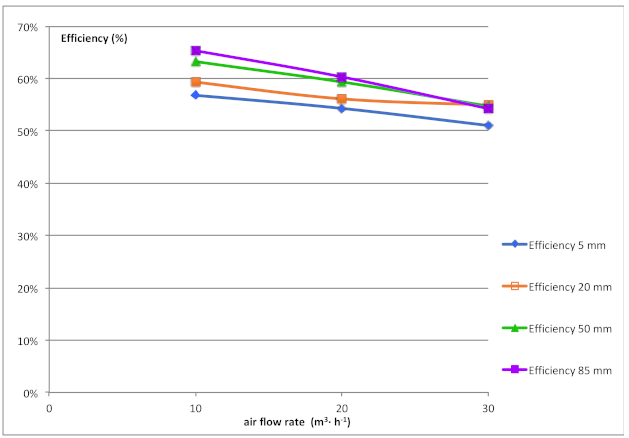

3.4. Thermal Performance of the Ventilated Wall

- -

- Tinlet: the supply air temperature measured in the top of the air cavity;

- -

- Tout: the outside air temperature (cold cell);

- -

- Tin: the inside air temperature (hot cell).

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| E | pre-heating efficiency of the ventilated wall |

| h | convection heat transfer coefficient, W.m−2·°C−1 |

| HR | relative humidity inside the cell, % |

| T | temperature, °C |

| q | flux density, W·m−2 |

Indices

| a | ambiance of the cell |

| in | relative to the inside air temperature (hot cell) |

| inlet | relative to the supply air temperature measured in the top of the air cavity |

| out | relative to the outside air temperature (cold cell) |

| s | wall surface |

References

- Bâtiments à Énergie Positive et Réduction Carbone. Available online: https://www.batiment-energiecarbone.fr (accessed on 2 September 2020).

- Evaluation of the Energy Performance of Building Directive 2010/31/EU. 2015. Available online: https://ec.europa.eu/smart-regulation/roadmaps/docs/2016_ener_023_evaluation_energy_performance_ofbuildings_directive_en.pdf (accessed on 1 June 2015).

- Pflug, T.; Nestle, N.; Kuhn, T.; Siroux, M.; Maurer, C. Modeling of facade elements with switchable U-value. Energy Build. 2018, 164, 1–13. [Google Scholar] [CrossRef]

- Pflug, T.; Bueno, B.; Siroux, M.; Kuhn, T. Potential analysis of a new removable insulation system. Energy Build. 2017, 154, 391–403. [Google Scholar] [CrossRef]

- Gregório-Atem, C.; Aparicio-Fernández, C.; Coch, H.; Vivancos, J.L. Opaque Ventilated Façade (OVF) Thermal Performance Simulation for Office Buildings in Brazil. Sustainability 2020, 12, 7635. [Google Scholar] [CrossRef]

- Loncour, X.; Deneyer, A.; Blasco, M.; Flamant, G.; Wouters, P. Classification & illustration of facade concepts. Contributed Report 03, Belgian Building Research Institute—BBRI. 2005. Available online: https://www.aivc.org/resource/cr-03-ventilated-double-skin-fa-ades-classification-illustration-facade-concepts (accessed on 1 June 2005).

- Chan, H.Y.; Riffat, S.B.; Zhu, J. Review of passive solar heating and cooling technologies. Renew. Sustain. Energy Rev. 2010, 14, 781–789. [Google Scholar] [CrossRef]

- Lai, C.M.; Hokoi, S. Solar façades: A review. Build. Environ. 2015, 91, 152–165. [Google Scholar] [CrossRef]

- Barbosa, S.; Ip, K. Perspectives of double skin façades for naturally ventilated buildings: A review. Renew. Sustain. Energy Rev. 2014, 40, 1019–1029. [Google Scholar] [CrossRef]

- Haase, M.; Marques da Silva, F.; Amato, F. Simulation of ventilated facades in hot and humide climate. Energy Build. 2009, 41, 361–373. [Google Scholar] [CrossRef]

- Ibanez-Puy, M.; Vidaurre Arbizu, M.; Sancristan-Fernandez, J.A.; Martin-Gomez, C. Opaque Ventilated Façades: Thermal and energy performance review. Renew. Sustain. Energy Rev. 2017, 79, 180–191. [Google Scholar] [CrossRef]

- Shameri, M.A.; Alghoul, M.A.; Sopian, K.; Zain, M.F.M.; Elayeb, O. Perspectives of double skin façade systems in buildings and energy saving. Renew. Sustain. Energy Rev. 2011, 15, 1468–1475. [Google Scholar] [CrossRef]

- Quesada, G.; Rousse, D.; Dutil, Y.; Badache, M.; Hallé, S. A comprehensive review of solar facades. Opaque solar facades. Renew. Sustain. Energy Rev. 2012, 16, 2820–2832. [Google Scholar] [CrossRef]

- Khanal, R.; Lei, C. Solar chimney—A passive strategy for natural ventilation. Energy Build. 2011, 43, 1811–1819. [Google Scholar] [CrossRef]

- Saadatian, O.; Sopian, K.; Lim, C.H.; Asim, N.; Sulaiman, M.Y. Trombe walls: A review of opportunities and challenges in research and development. Renew. Sustain. Energy Rev. 2012, 16, 6340–6351. [Google Scholar] [CrossRef]

- Alaidroos, A.; Krarti, M. Experimental validation of a numerical model for ventilated wall cavity with spray evaporative cooling systems for hot and dry climates. Energy Build. 2016, 131, 207–222. [Google Scholar] [CrossRef]

- Aleksandrowicz, O.; Yezioro, A. Mechanically ventilated double-skin facade in a hot and humid climate: Summer monitoring in an office tower in Tel Aviv. Archit. Sci. Rev. 2018, 61, 171–188. [Google Scholar] [CrossRef]

- Wang, J.; Du, Q.; Zhang, C.; Xu, X. Energy Performance of Triple Glazed Window with Built-in Venetian Blinds by Utilizing Forced Ventilated airflow. Procedia Eng. 2017, 205, 3993–4000. [Google Scholar] [CrossRef]

- Souza, L.C.; Souza, H.A.; Rodrigues, E.F. Experimental and numerical analysis of a naturally ventilated double-skin façade. Energy Build. 2018, 165, 328–339. [Google Scholar] [CrossRef]

- Parra, J.; Guardo, A.; Egusquiza, E.; Alavedra, P. Thermal performance of ventilated double skin façades with venetian blinds. Energies 2015, 8, 4882–4898. [Google Scholar] [CrossRef]

- Michaux, G.; Greffet, R.; Salagnac, P.; Ridoret, J.B. Modelling of an airflow window and numerical investigation of its thermal performances by comparison to conventional double and triple-glazed windows. Appl. Energy 2019, 242, 27–45. [Google Scholar] [CrossRef]

- Gloriant, F.; Joulin, A.; Tittelein, P.; Lassue, S. Using heat flux sensors for a contribution to experimental analysis of heat transfers on a triple-glazed supply-air window. Energy 2021, 215, 119154. [Google Scholar] [CrossRef]

- Asdrubaldi, F.; Baldinelli, G. Thermal transmittance measurements with the hot box method: Calibration, experimental procedures, and uncertainty analyses of three different approaches. Energy Build. 2011, 43, 1618–1626. [Google Scholar] [CrossRef]

- Lucchi, E.; Roberti, F.; Alexandra, T. Definition of an experimental procedure with the hot box method for the thermal performance evaluation of inhomogeneous walls. Energy Build. 2018, 179, 99–111. [Google Scholar] [CrossRef]

- Aviram, D.P.; Fried, A.N.; Roberts, J.J. Thermal properties of a variable cavity wall. Build. Environ. 2001, 36, 1057–1072. [Google Scholar] [CrossRef]

- Andreotti, M.; Calzolari, M.; Davoli, P.; Pereira, L.D.; Lucchi, E.; Malaguti, R. Design and Construction of a New Metering Hot Box for the In Situ Hygrothermal Measurement in Dynamic Conditions of Historic Masonries. Energies 2020, 13, 2950. [Google Scholar] [CrossRef]

- Sukamto, D.; Gloriant, F.; Siroux, M. Mise en place d ’un dispositif expérimental pour la caractérisation énergétique d’une paroi bioclimatique ventilée. In Proceedings of the Conférence SFT Belfort Therm. Mix Énergétique, Belfort, France, 1 June 2020. [Google Scholar]

- Padet, J. Convection Thermique et Massique Principes Généraux; Techniques de l’ingenieur: Saint-Denis, France, 2005; pp. 1–23. [Google Scholar]

- Fantuccia, S.; Serraa, V.; Perino, M. Dynamic insulation systems: Experimental analysis on a parietodynamic wall. Energy Procedia 2015, 78, 549–554. [Google Scholar] [CrossRef]

| Author | Years | Sample | Air Space Thickness |

|---|---|---|---|

| A. Alaidroos [16] | 2016 | Ventilated wall | 0.1 m |

| O. Aleksandrowicz [17] | 2018 | Double skin façade | 0.2 m |

| J. Wang [18] | 2017 | Triple glazed windows | 0.03 m, 0.01 m |

| L. C. O. Souza [19] | 2018 | Ventilated double-skin façade | 0.1 m |

| J. Parra [20] | 2015 | Ventilated double-skin façade | 0.2 m, 2 m |

| G. Michaux [21] | 2019 | Triple glazed windows | 0.01 m |

| F. Gloriant [22] | 2021 | Triple glazed windows | 0.013 m |

| Test Number | Air Space Thickness (mm) | Air Flow Velocity (m3·h−3) | Cold Cell Temperature Ta1 (°C) | Hot Cell Temperature Ta2 (°C) | Temperature Difference between Hot Cell and Cold Cell (°C) |

|---|---|---|---|---|---|

| 1 | 5 | 9.94 | −4.34 | 15.56 | 19.9 |

| 2 | 5 | 19.61 | −4.64 | 15.63 | 20.27 |

| 3 | 5 | 29.99 | −4.45 | 15.82 | 20.27 |

| 4 | 10 | 9.94 | −4.64 | 15.58 | 20.23 |

| 5 | 10 | 19.96 | −4.72 | 15.61 | 20.32 |

| 6 | 10 | 29.99 | −4.47 | 15.8 | 20.27 |

| 7 | 15 | 10 | −4.61 | 15.58 | 20.19 |

| 8 | 15 | 19.99 | −4.63 | 15.66 | 20.29 |

| 9 | 15 | 30.09 | −4.41 | 15.87 | 20.28 |

| 10 | 20 | 9.98 | −4.67 | 15.62 | 20.29 |

| 11 | 20 | 20.43 | −4.66 | 15.64 | 20.29 |

| 12 | 20 | 29.84 | −4.41 | 15.86 | 20.27 |

| 13 | 25 | 10.02 | −4.67 | 15.61 | 20.28 |

| 14 | 25 | 20.08 | −4.63 | 15.68 | 20.31 |

| 15 | 25 | 29.81 | −4.43 | 15.87 | 20.3 |

| 16 | 30 | 9.9 | −4.65 | 15.66 | 20.31 |

| 17 | 30 | 19.85 | −4.62 | 15.71 | 20.33 |

| 18 | 30 | 29.98 | −4.32 | 15.9 | 20.22 |

| 19 | 35 | 10.22 | −4.65 | 15.63 | 20.28 |

| 20 | 35 | 19.89 | −4.64 | 15.63 | 20.27 |

| 21 | 35 | 30.039 | −4.32 | 15.95 | 20.28 |

| 22 | 40 | 8.98 | −4.67 | 15.66 | 20.33 |

| 23 | 40 | 20.07 | −4.61 | 15.74 | 20.35 |

| 24 | 40 | 30.05 | −4.29 | 15.86 | 20.15 |

| 25 | 45 | 9.04 | −4.66 | 15.64 | 20.3 |

| 26 | 45 | 20.03 | −4.62 | 15.6 | 20.22 |

| 27 | 45 | 30.07 | −4.40 | 15.91 | 20.31 |

| 28 | 50 | 10.01 | −4.71 | 15.59 | 20.31 |

| 29 | 50 | 20.04 | −4.65 | 15.62 | 20.27 |

| 30 | 50 | 29.94 | −4.45 | 15.82 | 20.27 |

| 31 | 55 | 9.99 | −4.62 | 15.66 | 20.28 |

| 32 | 55 | 20.08 | −4.61 | 15.51 | 20.11 |

| 33 | 55 | 30.01 | −4.37 | 15.77 | 20.14 |

| 34 | 60 | 10.01 | −4.63 | 15.59 | 20.22 |

| 35 | 60 | 19.73 | −4.58 | 15.7 | 20.28 |

| 36 | 60 | 29.9 | −4.19 | 15.85 | 20.04 |

| 37 | 65 | 10.01 | −4.65 | 15.52 | 20.17 |

| 38 | 65 | 20.03 | −4.69 | 15.64 | 20.32 |

| 39 | 65 | 30.05 | −4.45 | 15.85 | 20.3 |

| 40 | 70 | 10.07 | −4.72 | 15.58 | 20.29 |

| 41 | 70 | 20.03 | −4.64 | 15.53 | 20.16 |

| 42 | 70 | 30.37 | −4.37 | 15.78 | 20.15 |

| 43 | 75 | 9.98 | −4.68 | 15.47 | 20.15 |

| 44 | 75 | 20.01 | −4.70 | 15.57 | 20.27 |

| 45 | 75 | 30.62 | −4.38 | 15.71 | 20.09 |

| 46 | 80 | 9.98 | −4.75 | 15.47 | 20.22 |

| 47 | 80 | 20.49 | −4.66 | 15.59 | 20.25 |

| 48 | 80 | 30.13 | −4.46 | 15.72 | 20.18 |

| 49 | 85 | 9.99 | −4.67 | 15.49 | 20.16 |

| 50 | 85 | 20.27 | −4.72 | 15.5 | 20.22 |

| Type | Metrologic Means | Range | Uncertainty |

|---|---|---|---|

| Air temperature | PT-100 | −70 °C to + 200 °C | 0.1 °C |

| K-type Thermocouples | −75 °C to + 250 °C | 0.02 °C | |

| Surface temperature | K-type Thermocouples | −75 °C to + 250 °C | 0.02 °C |

| Infrared camera FLIR T650 SC | −40 °C to + 150 °C | 1% | |

| Thermal Flux | Captec Flux meter | 5% | |

| Air flow velocity | Hot wire anemometer KIMO CTV 210 | 0–30 m/s | 0.3 m/s |

| Vertical Position (m) | Cold Cell | Hot Cell | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cavity of 5 mm for 10, 20, 30 Flow Rate (m3·h−1) | Cavity of 10 mm for 10, 20, 30 Flow Rate (m3·h−1) | Cavity of 5 mm for 10, 20, 30 Flow Rate (m3·h−1) | Cavity of 10 mm for 10, 20, 30 Flow Rate (m3·h−1) | |||||||||

| 10 | 20 | 30 | 10 | 20 | 30 | 10 | 20 | 30 | 10 | 20 | 30 | |

| 0.8 | 1.5 | 1.5 | 1.7 | 1.5 | 1.4 | 1.7 | 1.5 | 1.5 | 1.4 | 1.8 | 1.8 | 1.6 |

| 0.56 | 2.7 | 2.3 | 2.7 | 2.2 | 2.0 | 2.4 | 1.2 | 1.2 | 1.1 | 1.3 | 1.3 | 1.2 |

| 0.35 | 4.6 | 3.0 | 3.0 | 3.1 | 2.7 | 3.2 | 1.5 | 1.6 | 1.5 | 1.6 | 1.6 | 1.4 |

| 0.12 | 5.1 | 2.8 | 2.7 | 3.1 | 2.9 | 3.4 | 1.4 | 1.3 | 1.5 | 1.4 | 1.5 | 1.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sukamto, D.; Siroux, M.; Gloriant, F. Hot Box Investigations of a Ventilated Bioclimatic Wall for NZEB Building Façade. Energies 2021, 14, 1327. https://doi.org/10.3390/en14051327

Sukamto D, Siroux M, Gloriant F. Hot Box Investigations of a Ventilated Bioclimatic Wall for NZEB Building Façade. Energies. 2021; 14(5):1327. https://doi.org/10.3390/en14051327

Chicago/Turabian StyleSukamto, Dwinanto, Monica Siroux, and Francois Gloriant. 2021. "Hot Box Investigations of a Ventilated Bioclimatic Wall for NZEB Building Façade" Energies 14, no. 5: 1327. https://doi.org/10.3390/en14051327

APA StyleSukamto, D., Siroux, M., & Gloriant, F. (2021). Hot Box Investigations of a Ventilated Bioclimatic Wall for NZEB Building Façade. Energies, 14(5), 1327. https://doi.org/10.3390/en14051327