Zero Voltage Switching Condition in Class-E Inverter for Capacitive Wireless Power Transfer Applications

Abstract

1. Introduction

- Lower cost: CWPT does not need expensive magnetic cores and Litz wires to reduce the parasitic resistance due to skin and proximity effects [15,16]. The power is transferred through low-cost metallic plates. Because of this characteristic, a CWPT also results in smaller volumes and weights than IWPT.

- Higher stability in metallic surrounding environment: metallic materials block an inductor magnetic flux transmitted between two coils. Additionally, eddy currents induced by a changing magnetic field generate heat and increase the power losses and safety concerns.

- Capability to transfer power through metal barriers thanks to the coupling capacitive effect.

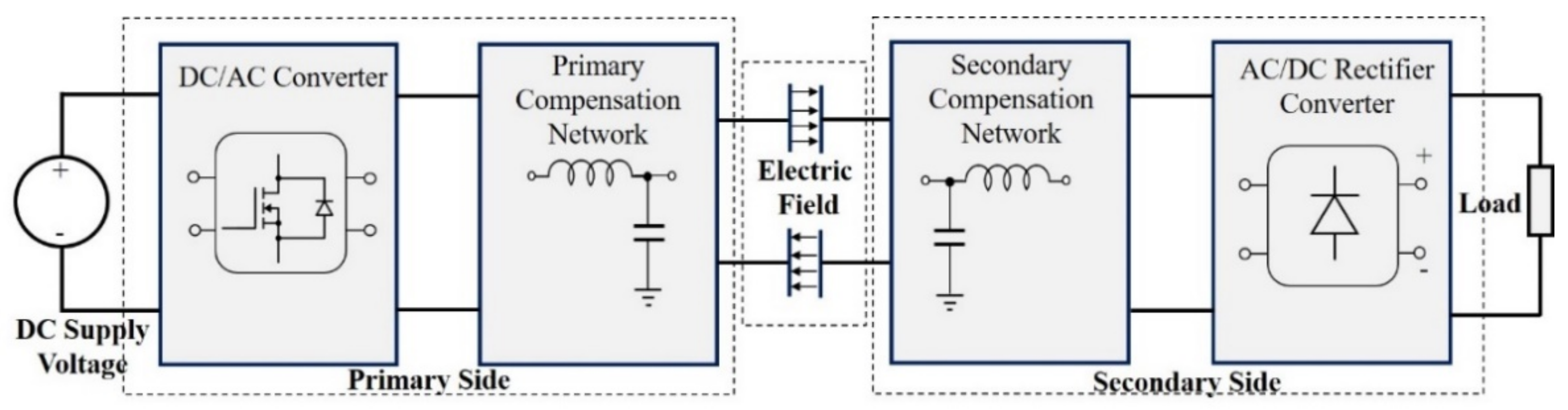

2. LC Compensated Capacitive Wireless Power Transfer System

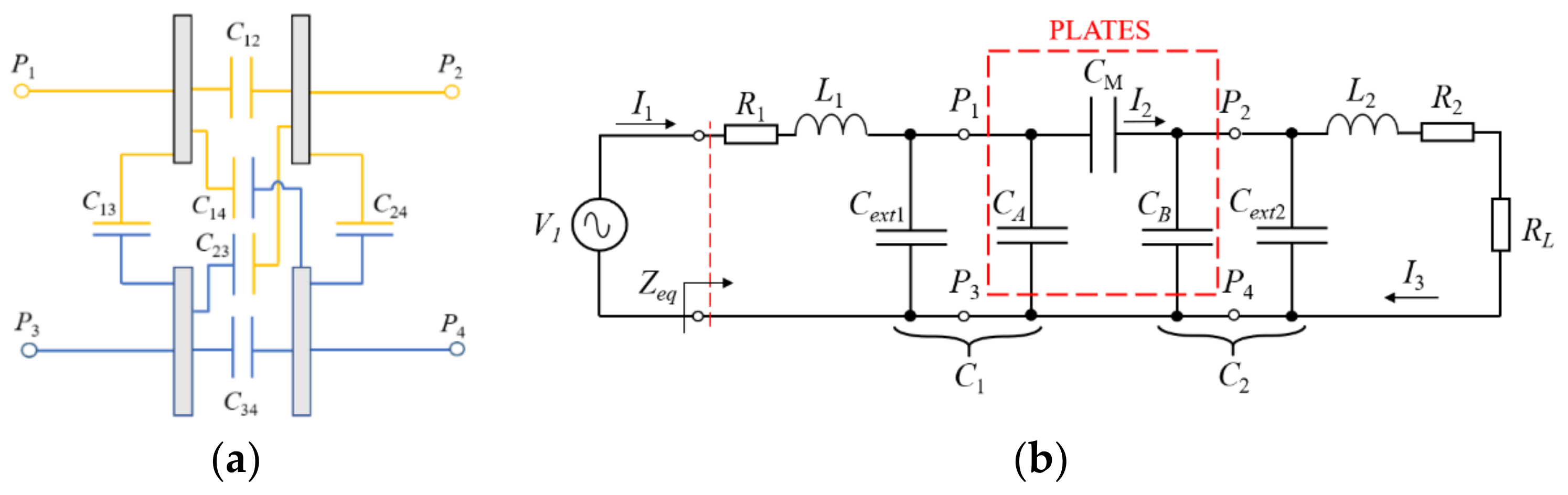

2.1. Equivalent Impedance

2.2. Efficiency and Output Power

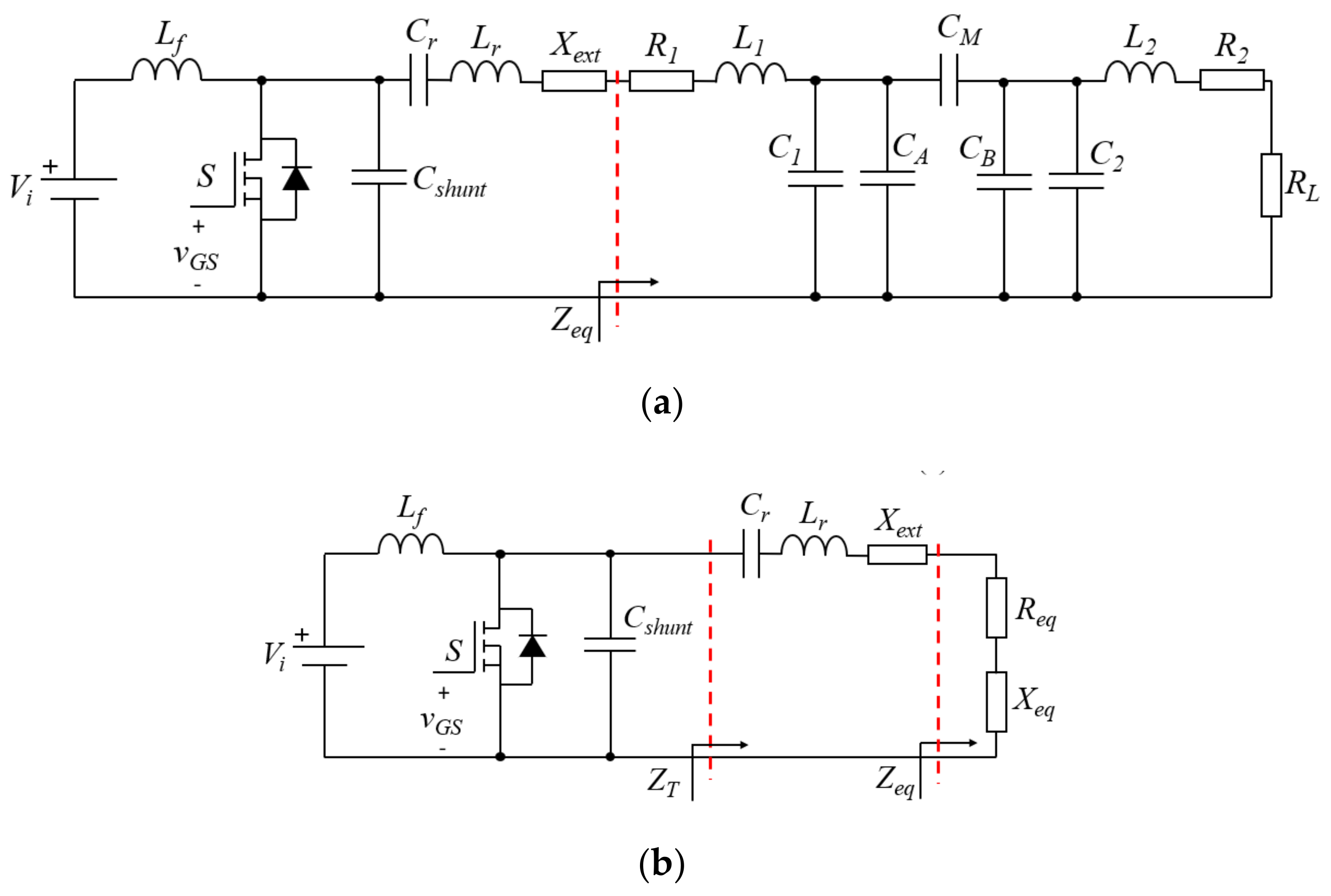

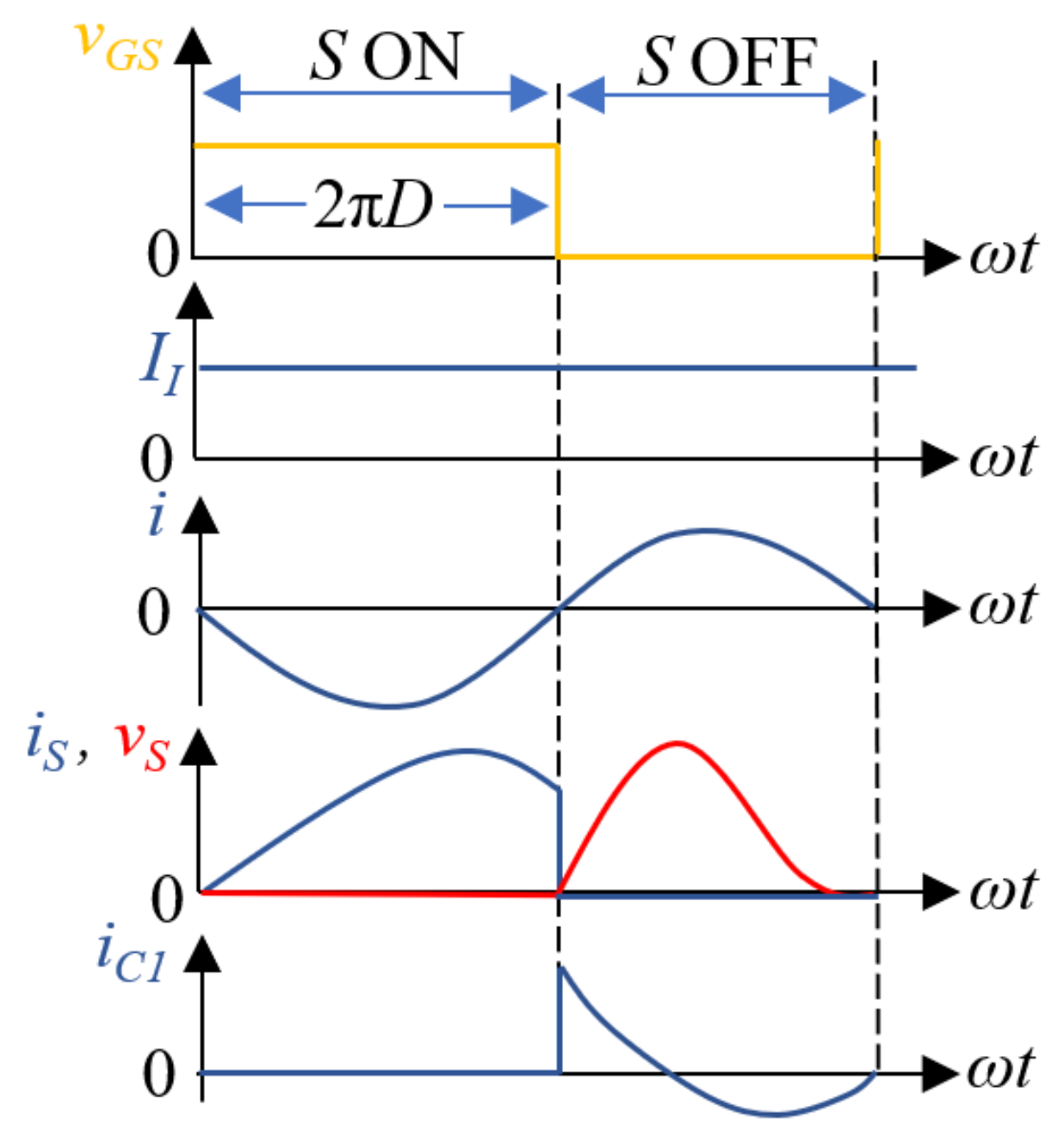

3. CWPT Class-E Inverter Circuit Analysis

3.1. Assumptions

- The duty cycle D of the MOSFET is 0.5;

- The MOSFET turns ON and OFF instantly;

- The MOSFET ON-resistance is zero;

- The MOSFET output capacitance is linear and frequency invariant;

- The loaded quality factor QL of the resonant network is high enough such that the currents through the transformer windings are sinusoidal (e.g., QL > 7);

- The choke inductance is large enough to neglect the input current ac component. The dc resistance of the choke inductor is ignored. The self-capacitance of the choke inductor is absorbed into the shunt capacitance of the MOSFET.

3.2. Circuit Descriptions

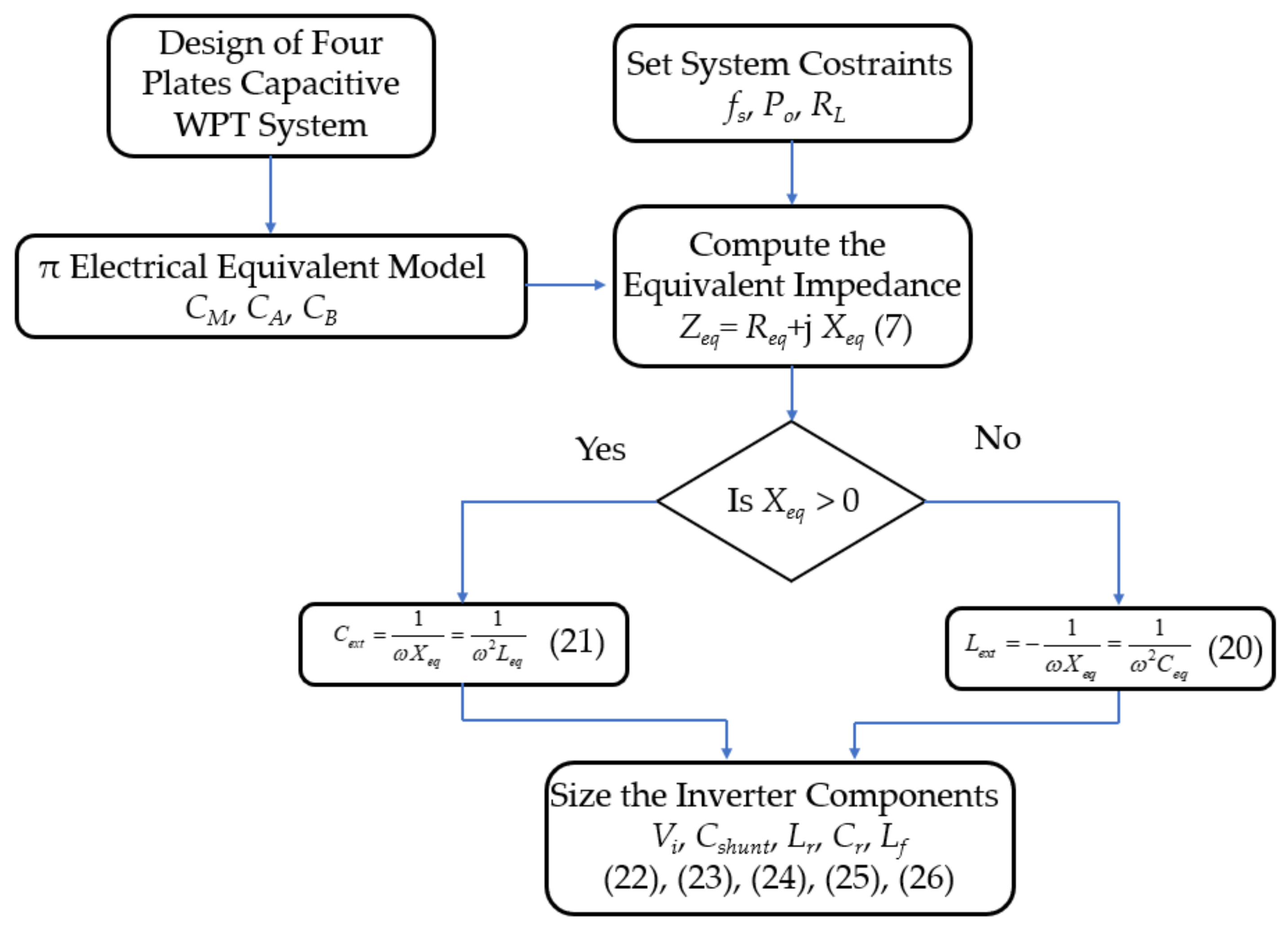

3.3. Optimum Design Procedure

3.4. Design Example

4. Class-E Inverter Behavior at Any Coupling Coefficient

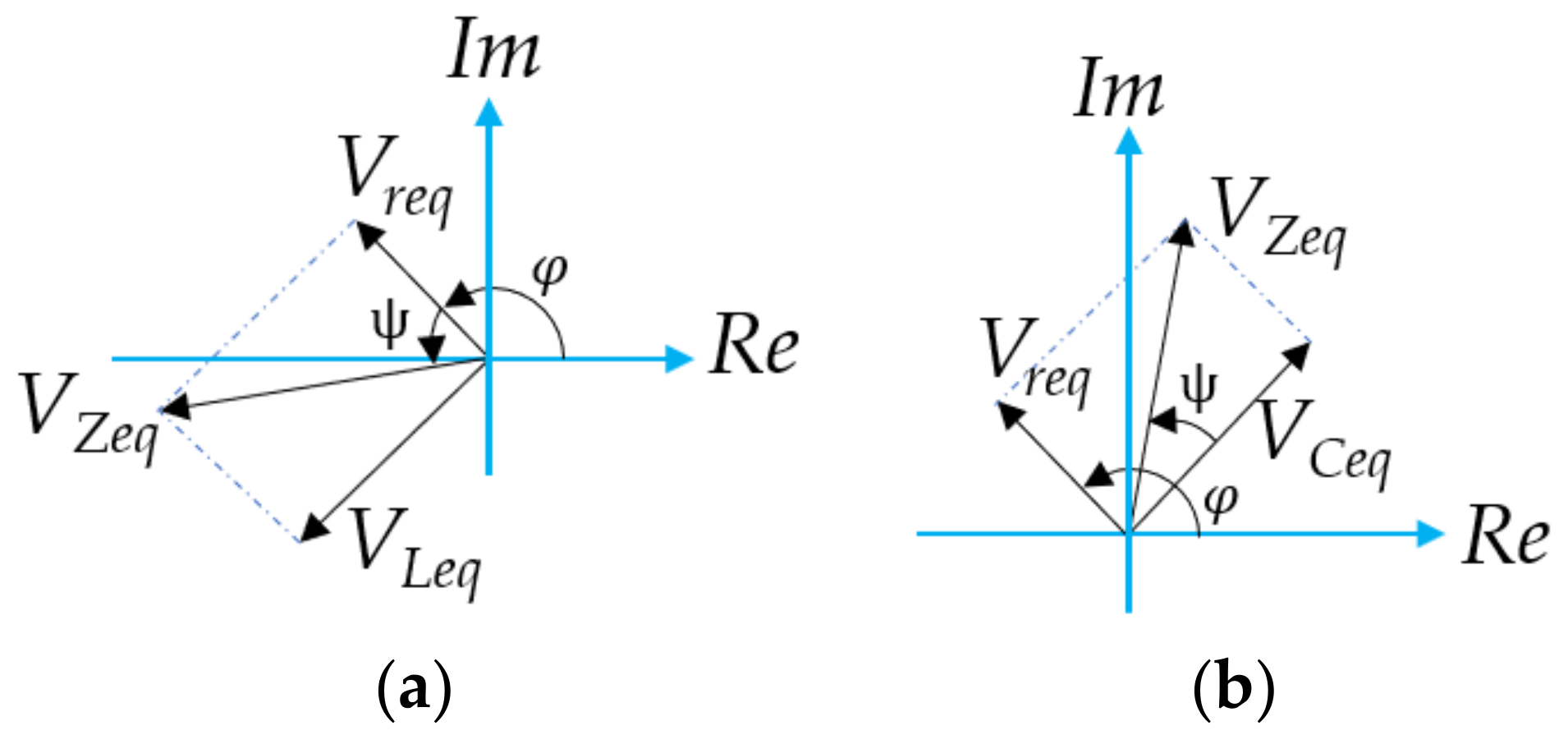

4.1. Analytical Model

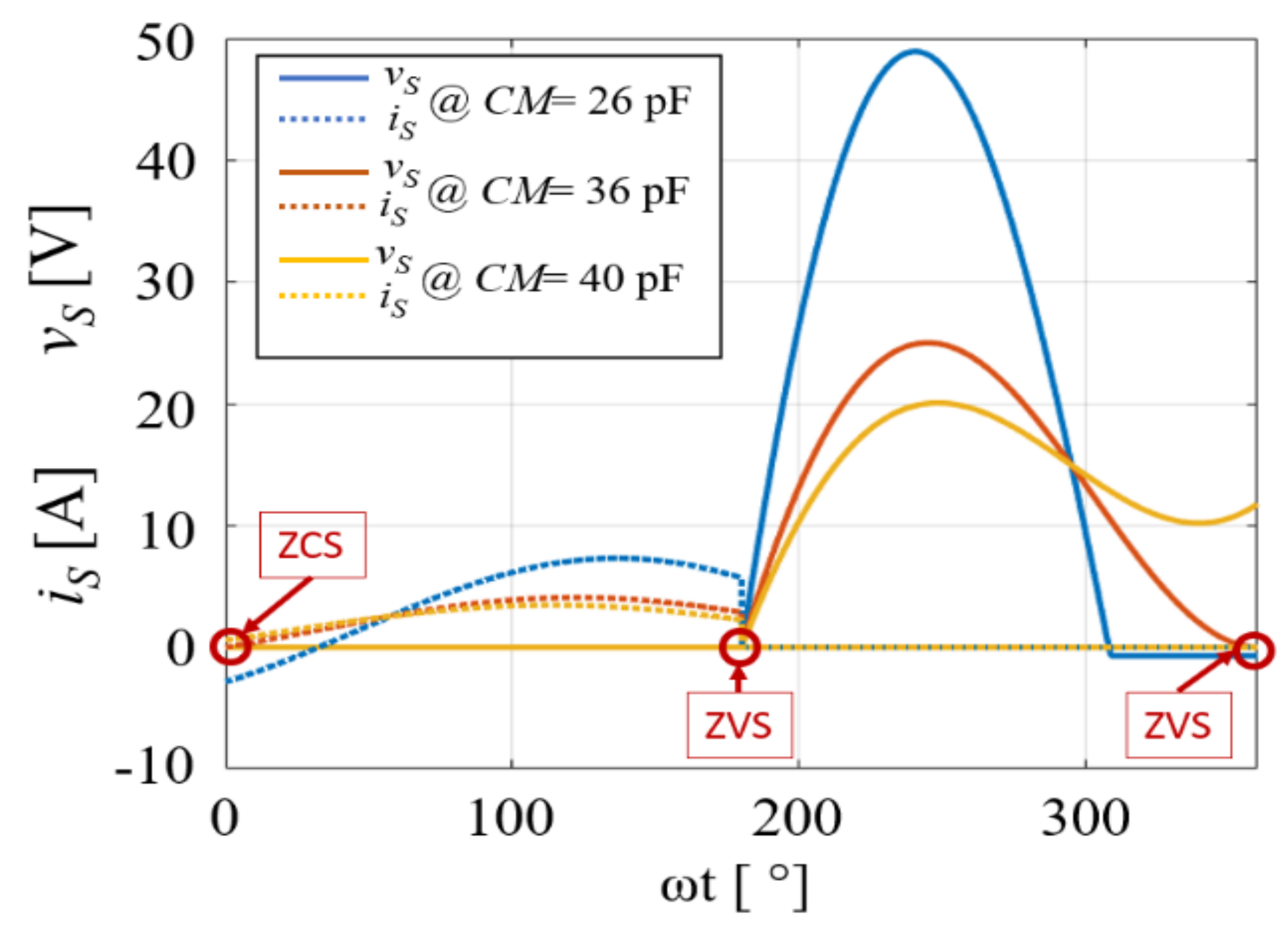

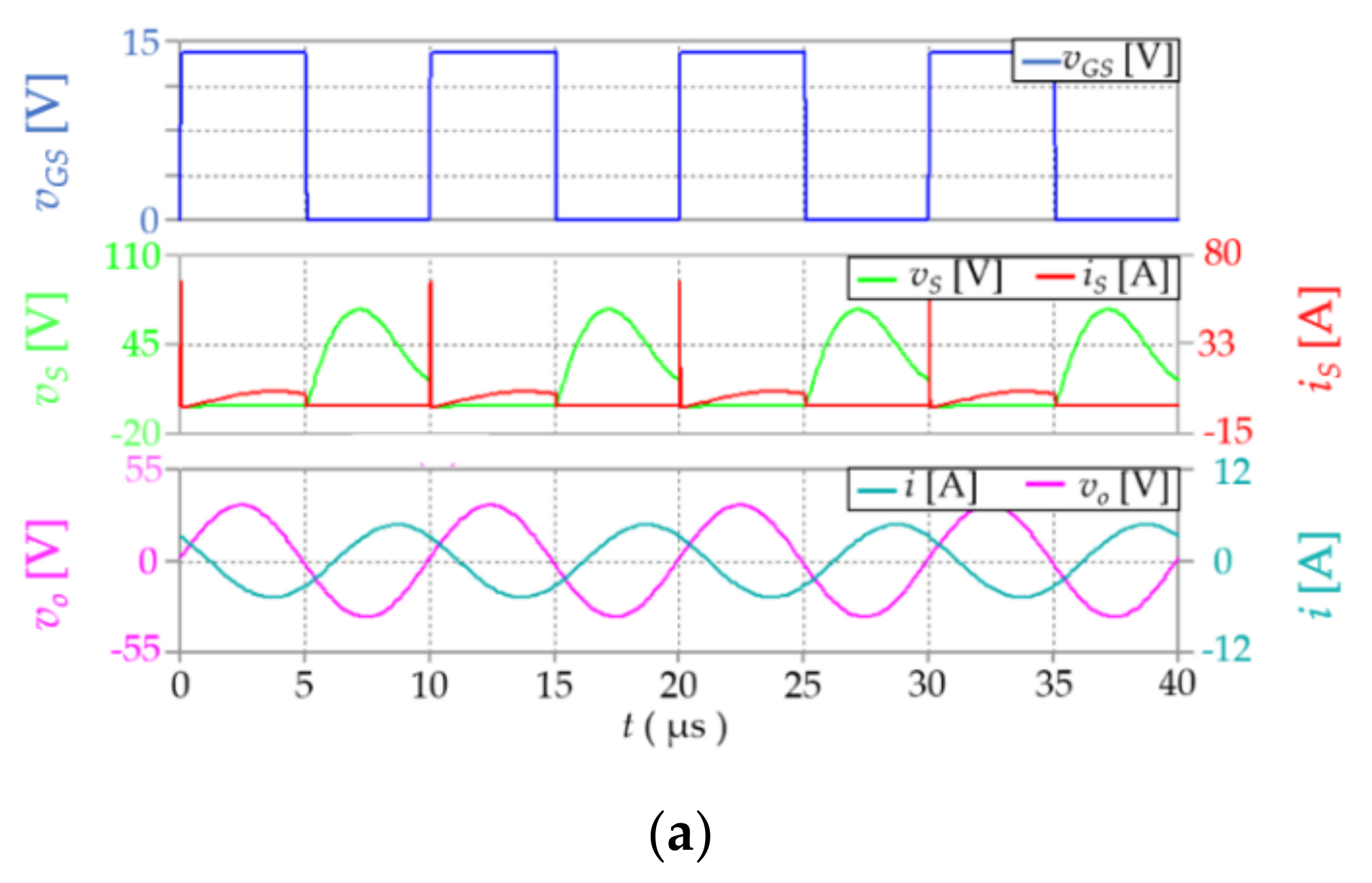

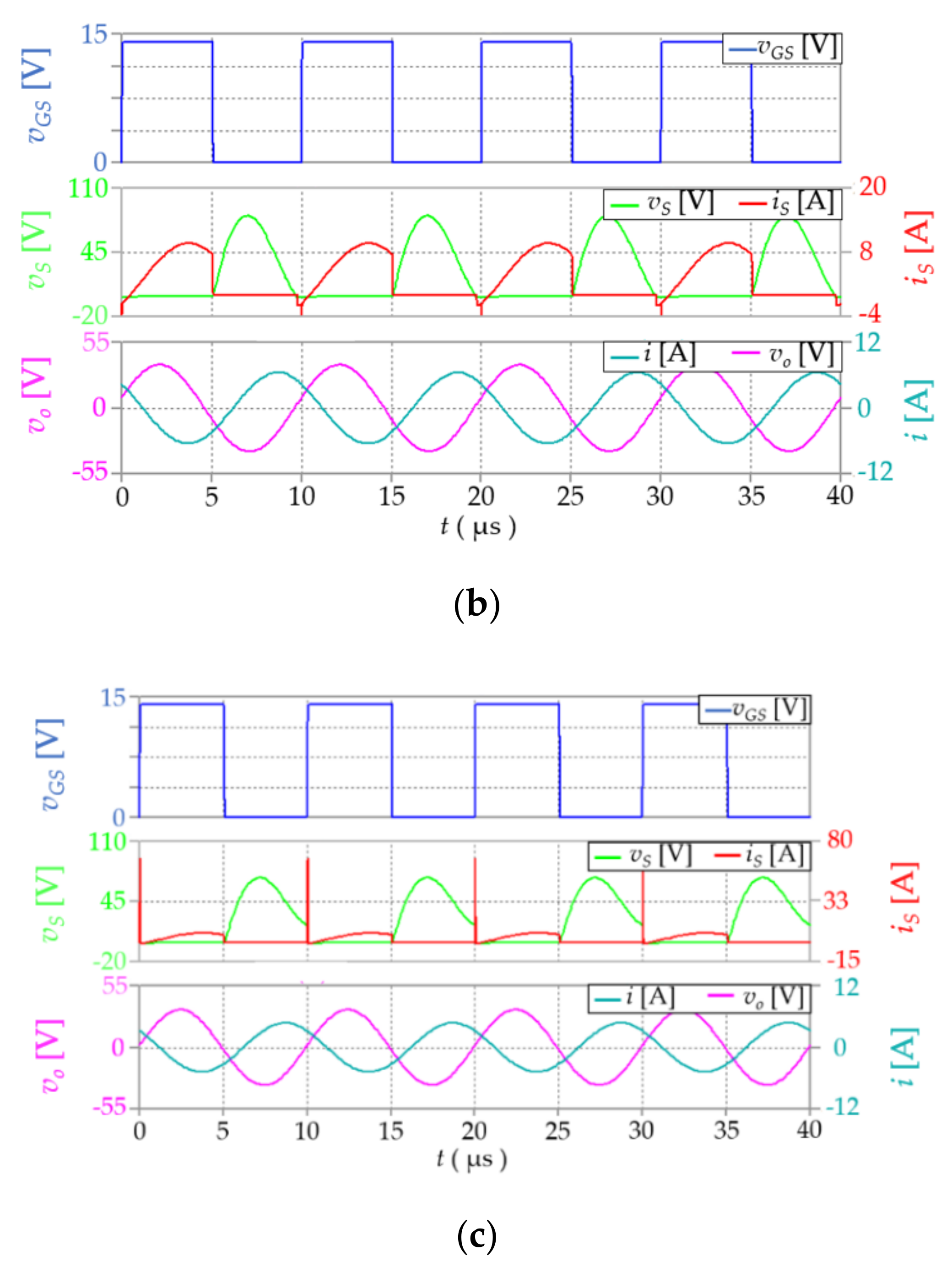

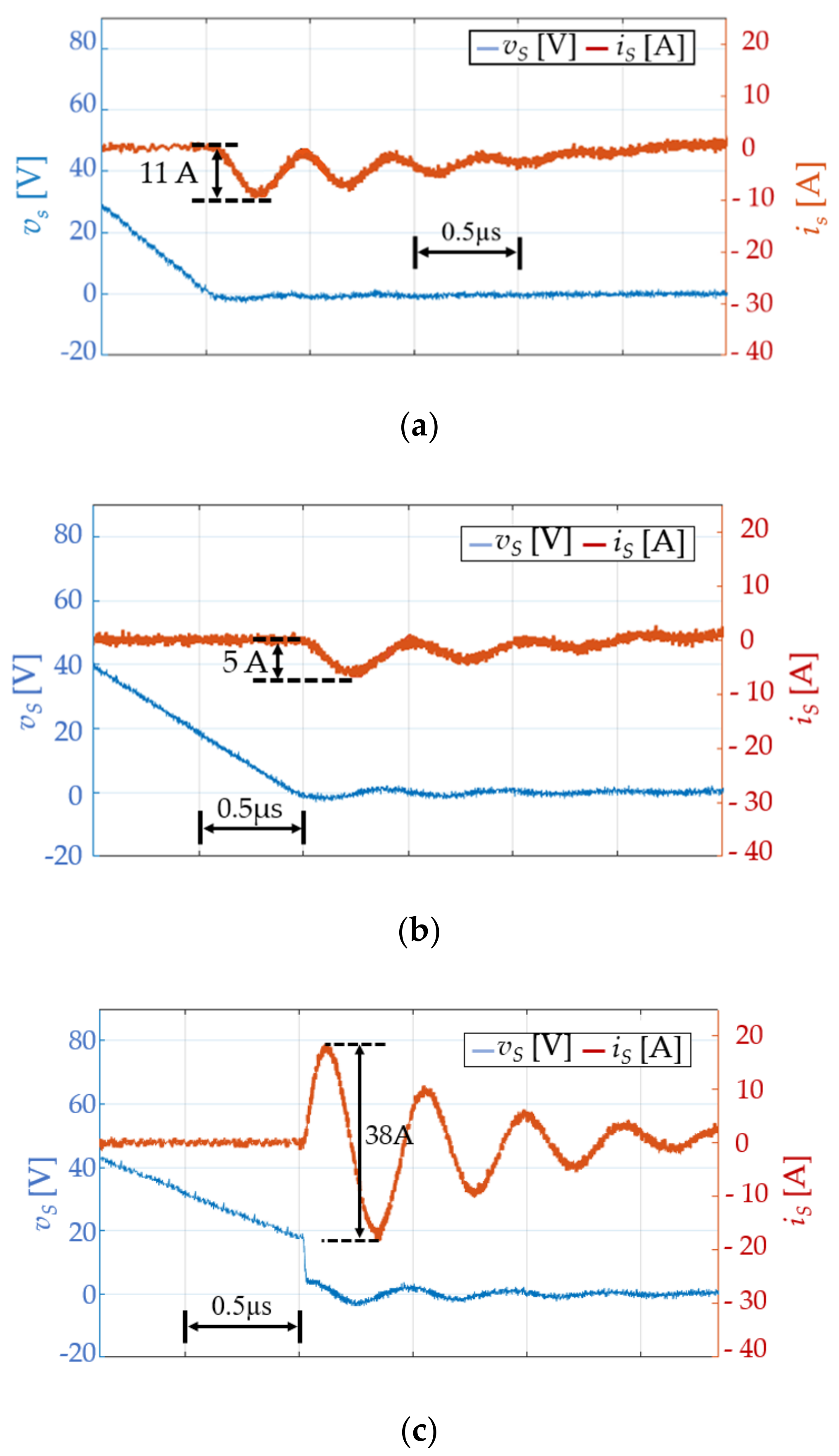

4.2. Voltage and Current Waveforms

5. Simulation and Experimental Results

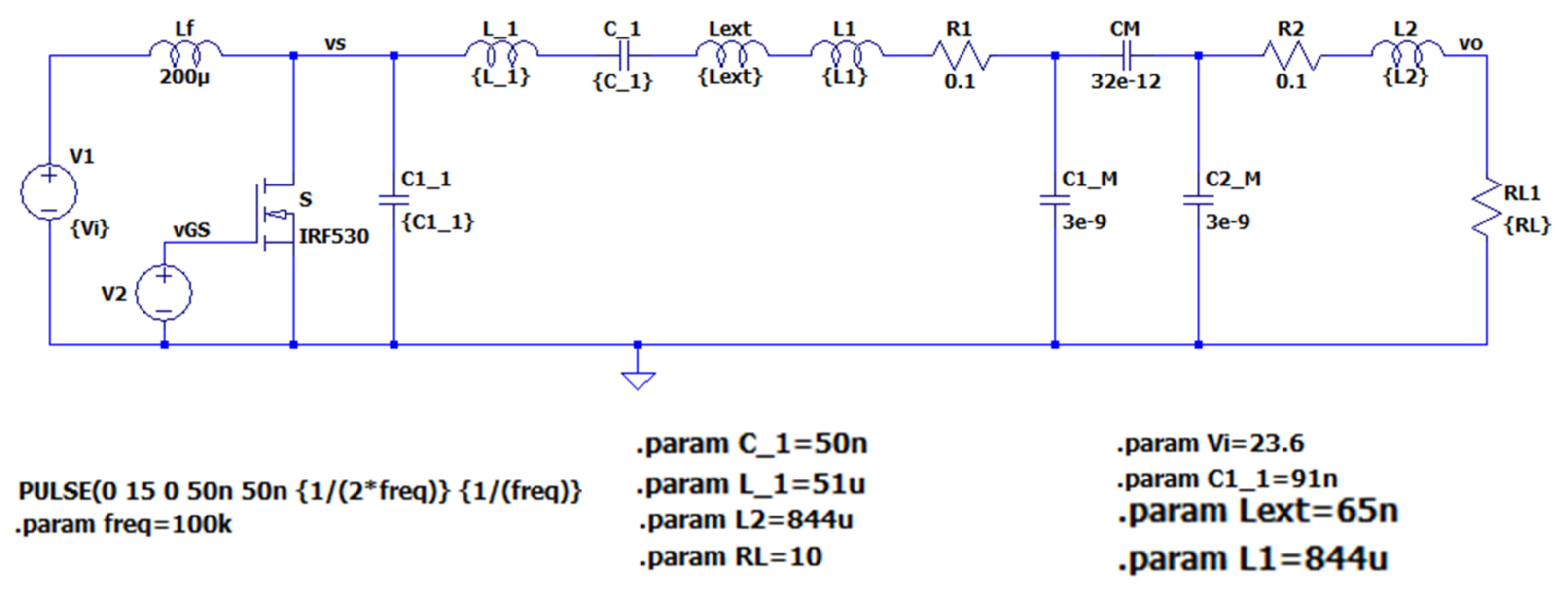

5.1. Simulations

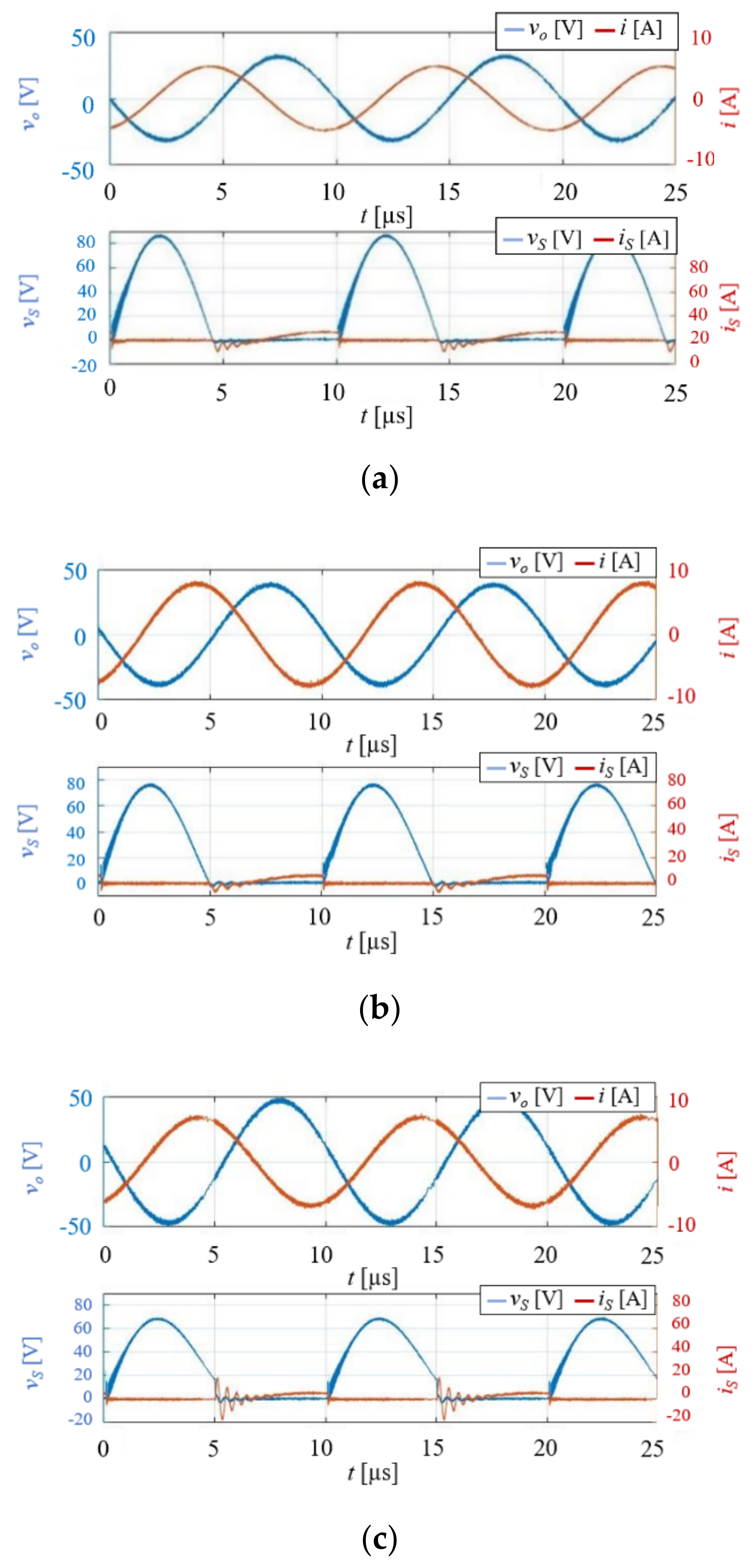

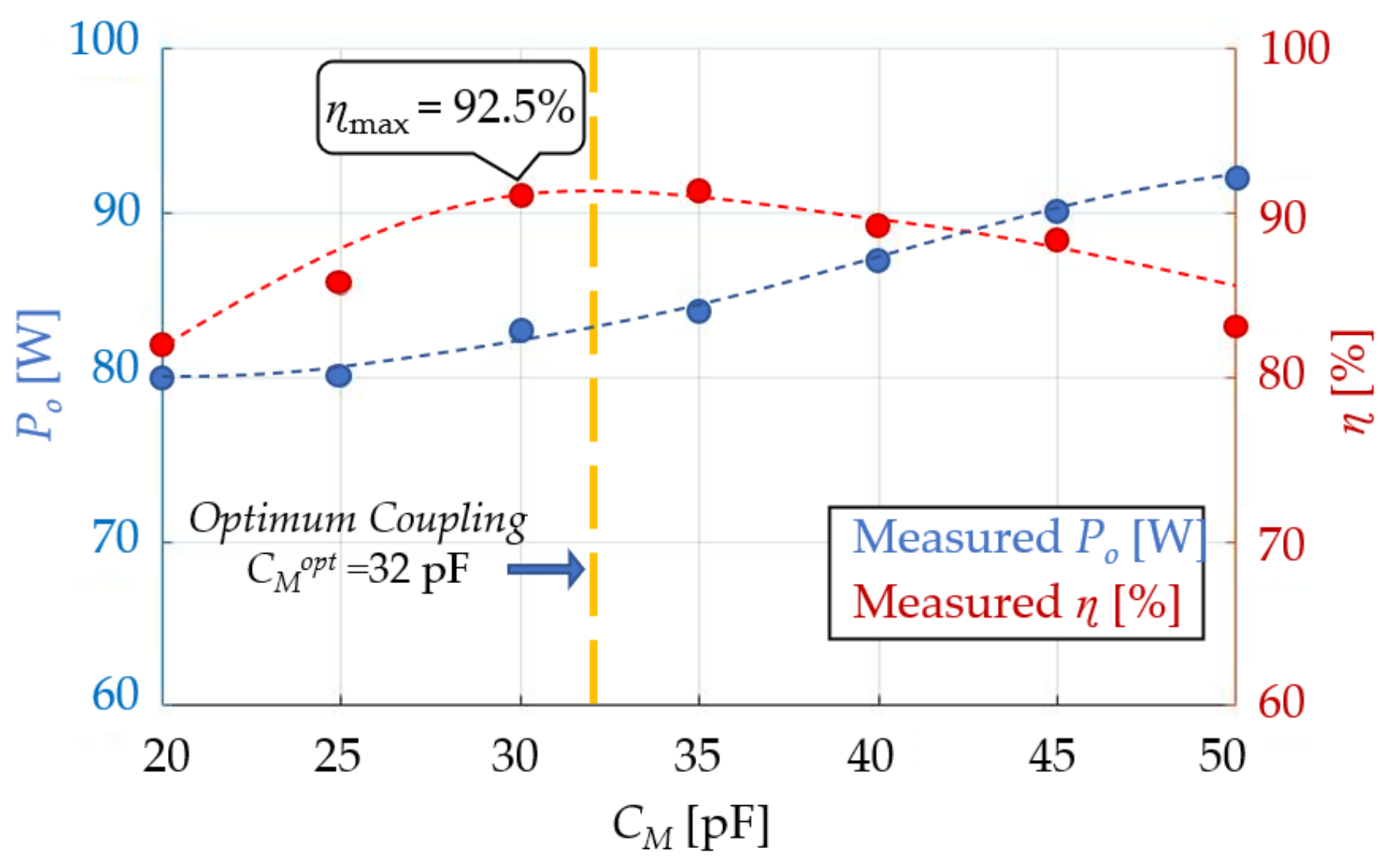

5.2. Experimental Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schormans, M.; Valente, V.; Demosthenous, A. Correction to Practical Inductive Link Design for Biomedical Wireless Power Transfer: A Tutorial. IEEE Trans. Biomed. Circuits Syst. 2019, 13, 592. [Google Scholar] [CrossRef] [PubMed]

- Covic, G.A.; Boys, J.T. Modern Trends in Inductive Power Transfer for Transportation Applications. IEEE J. Emerg. Sel. Top. Power Electron. 2013, 1, 28–41. [Google Scholar] [CrossRef]

- Corti, F.; Reatti, A.; Pierini, M.; Barbieri, R.; Berzi, L.; Nepote, A.; De La Pierre, P. A Low-Cost Secondary-Side Controlled Electric Vehicle Wireless Charging System using a Full-Active Rectifier. In Proceedings of the 2018 International Conference of Electrical and Electronic Technologies for Automotive, Milan, Italy, 9–11 July 2018; pp. 1–6. [Google Scholar]

- Carobolante, F.; Menegoli, P.; Marino, F.A.; Jeong, N.S. A Novel Charger Architecture for Resonant Wireless Power Transfer. IEEE J. Emerg. Sel. Top. Power Electron. 2018, 6, 571–580. [Google Scholar] [CrossRef]

- Zaman, H.U.; Islam, T.; Hasan, K.S.; Antora, R.K. Mobile phone to mobile phone wireless power transfer. In Proceedings of the 2015 International Conference on Advances in Electrical Engineering (ICAEE), Dhaka, Bangladesh, 17–19 December 2015; pp. 206–209. [Google Scholar]

- Liu, Y.; Li, B.; Huang, M.; Chen, Z.; Zhang, X. An Overview of Regulation Topologies in Resonant Wireless Power Transfer Systems for Consumer Electronics or Bio-Implants. Energies 2018, 11, 1737. [Google Scholar] [CrossRef]

- Tampubolon, M.; Pamungkas, L.; Chiu, H.-J.; Liu, Y.-C.; Hsieh, Y. Dynamic Wireless Power Transfer for Logistic Robots. Energies 2018, 11, 527. [Google Scholar] [CrossRef]

- Xie, L.; Shi, Y.; Hou, Y.T.; Lou, A. Wireless power transfer and applications to sensor networks. IEEE Wirel. Commun. 2013, 20, 140–145. [Google Scholar] [CrossRef]

- Bartolini, A.; Corti, F.; Reatti, A.; Ciani, L.; Grasso, F.; Kazimierczuk, M.K. Analysis and Design of Stand-Alone Photovoltaic System for precision agriculture network of sensors. In Proceedings of the 2020 IEEE International Conference on Environment and Electrical Engineering and 2020 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Madrid, Spain, 9–12 June 2020; pp. 1–5. [Google Scholar]

- Hui, S.Y.R.; Zhong, W.; Lee, C.K. A Critical Review of Recent Progress in Mid-Range Wireless Power Transfer. IEEE Trans. Power Electron. 2014, 29, 4500–4511. [Google Scholar] [CrossRef]

- Dai, J.; Ludois, D.C. A Survey of Wireless Power Transfer and a Critical Comparison of Inductive and Capacitive Coupling for Small Gap Applications. IEEE Trans. Power Electron. 2015, 30, 6017–6029. [Google Scholar] [CrossRef]

- Minnaert, B.; Stevens, N. Maximizing the Power Transfer for a Mixed Inductive and Capacitive Wireless Power Transfer System. In Proceedings of the 2018 IEEE Wireless Power Transfer Conference (WPTC), Montreal, QC, Canada, 3–7 June 2018; pp. 1–4. [Google Scholar]

- Yi, K. Capacitive Coupling Wireless Power Transfer with Quasi-LLC Resonant Converter Using Electric Vehicles’ Windows. Electronics 2020, 9, 676. [Google Scholar] [CrossRef]

- Funato, H.; Kobayashi, H.; Kitabayashi, T. Analysis of transfer power of capacitive power transfer system. In Proceedings of the 2013 IEEE 10th International Conference on Power Electronics and Drive Systems (PEDS), Kitakyushu, Japan, 22–25 April 2013; pp. 1015–1020. [Google Scholar]

- Mazli, M.S.; Fauzi, W.N.N.W.; Khan, S.; Aznan, K.A.; Nataraj, C.; Adam, I.; Kadir, K.; Ahmed, M.M.; Yaacob, M. Inductive & Capacitive Wireless Power Transfer System. In Proceedings of the 2018 7th International Conference on Computer and Communication Engineering (ICCCE), Kuala Lumpur, Malaysia, 19–20 September 2018; pp. 307–312. [Google Scholar]

- Pagano, R.; Abedinpour, S.; Raciti, A.; Musumeci, S. Efficiency optimization of an integrated wireless power transfer system by a genetic algorithm. In Proceedings of the 2016 IEEE Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 20–24 March 2016; pp. 3669–3676. [Google Scholar]

- Pagano, R.; Abedinpour, S.; Raciti, A.; Musumeci, S. Modeling of planar coils for wireless power transfer systems including substrate effects. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 1129–1136. [Google Scholar]

- Shenai, K. Future Prospects of Widebandgap (WBG) Semiconductor Power Switching Devices. IEEE Trans. Electron Devices 2014, 62, 248–257. [Google Scholar] [CrossRef]

- Liu, K.-H.; Lee, F. Zero-voltage switching technique in DC/DC converters. IEEE Trans. Power Electron. 1990, 5, 293–304. [Google Scholar] [CrossRef]

- Ogi, Y.; Ebihara, F.; Wei, X.; Sekiya, H. A Novel Circuit Topology and Its Design for Class-E2 DC-DC Converter. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; pp. 1256–1260. [Google Scholar]

- Aldhaher, S.; Luk, P.C.; Bati, A.F.; Whidborne, J.F. Wireless Power Transfer Using Class E Inverter With Saturable DC-Feed Inductor. IEEE Trans. Ind. Appl. 2014, 50, 2710–2718. [Google Scholar] [CrossRef]

- Li, Y.-F.; Sue, S.-M. Exactly analysis of ZVS behavior for class E inverter with resonant components varying. In Proceedings of the 2011 6th IEEE Conference on Industrial Electronics and Applications, Beijing, China, 21–23 June 2011; pp. 1245–1250. [Google Scholar]

- Dong, G.; Liangzong, H.; Bing, C.; Han, G. An Active Clamping Strategy for Class-E Inverter in Wireless Power Transfer System. In Proceedings of the 2019 IEEE International Symposium on Predictive Control of Electrical Drives and Power Electronics (PRECEDE), Quanzhou, China, 1 May–2 June 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Ahmad, S.; Muharam, A.; Hattori, R. Rotary Capacitive Power Transfer with Class-E Inverter And Balun Circuit. In Proceedings of the 2020 IEEE PELS Workshop on Emerging Technologies: Wireless Power Transfer (WoW), Seoul, Korea, 15–19 November 2020; pp. 330–333. [Google Scholar]

- Ueda, H.; Koizumi, H. Class-E2 DC-DC Converter With Basic Class-E Inverter and Class-E ZCS Rectifier for Capacitive Power Transfer. IEEE Trans. Circuits Syst. II Express Briefs 2020, 67, 941–945. [Google Scholar] [CrossRef]

- Chokkalingam, B.; Padmanaban, S.; Leonowicz, Z.M. Class E Power Amplifier Design and Optimization for the Capacitive Coupled Wireless Power Transfer System in Biomedical Implants. Energies 2017, 10, 1409. [Google Scholar]

- Domingos, F.C.; Freitas, S.V.D.C.D.; Mousavi, P. Capacitive Power Transfer based on Compensation Circuit for Class E Resonant Full-Wave Rectifier. In Proceedings of the 2018 IEEE Wireless Power Transfer Conference (WPTC), Montreal, QC, Canada, 3–7 June 2018; pp. 1–4. [Google Scholar]

- Huang, L.; Hu, A.P. Power Flow Control of Capacitive Power Transfer by Soft Switching of Extra Capacitors in Class E Converter. In Proceedings of the 2018 IEEE 4th Southern Power Electronics Conference (SPEC), Singapore, 10–13 December 2018; pp. 1–5. [Google Scholar]

- Yusop, Y.; Saat, S.; Husin, H.; Nguang, S.K.; Hindustan, I. Analysis of Class-E LC Capacitive Power Transfer System. Energy Proc. 2016, 100, 287–290. [Google Scholar] [CrossRef]

- Yusop, Y.; Saat, S.; Husin, H.; Hindustan, I.; Rahman, F.A.; Kamarudin, K.; Nguang, S.K. A Study of Capacitive Power Transfer Using Class-E Resonant Inverter. Asian J. Sci. Res. 2016, 9, 258–265. [Google Scholar] [CrossRef][Green Version]

- Kazimierczuk, M.; Bui, X. Class-E DC/DC converters with a capacitive impedance inverter. IEEE Trans. Ind. Electron. 1989, 36, 425–433. [Google Scholar] [CrossRef]

- Ayachit, A.; Corti, F.; Reatti, A.; Kazimierczuk, M.K. Zero-voltage switching operation of transformer Class-E inverter at any coupling coeffi-cient. IEEE Trans. Ind. Electron. 2019, 66, 1809–1819. [Google Scholar] [CrossRef]

- Corti, F.; Grasso, F.; Reatti, A.; Ayachit, A.; Saini, D.K.; Kazimierczuk, M.K. Design of class-E ZVS inverter with loosely-coupled transformer at fixed coupling coefficient. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 5627–5632. [Google Scholar]

- Zhang, H.; Lu, F.; Hofmann, H.; Mi, C. A loosely coupled capacitive power transfer system with LC compensation circuit topology. In Proceedings of the 2016 IEEE Energy Conversion Congress and Exposition (ECCE), Milwaukee, WI, USA, 18–22 September 2016; pp. 1–5. [Google Scholar]

- Kazimierczuk, M.K.; Czarkowski, D. Resonant Power Converters, 2nd ed.; Wiley Interscience: Hoboken, NJ, USA, 2012. [Google Scholar]

- Ayachit, A.; Saini, D.K.; Kazimierczuk, M.K.; Reatti, A. Design of choke inductor in Class-E ZVS power amplifier. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 5621–5626. [Google Scholar]

- Raciti, A.; Rizzo, S.A.; Salerno, N.; Susinni, G.; Scollo, R.; Scuto, A.; Musumeci, S.; Armando, E. Modeling of the Power Losses due to Coss in SJ MOSFETs Submitted to ZVS: Identification of the Passive Parameters by a Genetic Algorithm. In Proceedings of the IECON 2018—44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA, 21–23 October 2018; pp. 1321–1326. [Google Scholar]

- Bojoi, R.; Fusillo, F.; Raciti, A.; Musumeci, S.; Scrimizzi, F.; Rizzo, S. Full-Bridge DC-DC Power Converter for Telecom applications with Advanced Trench Gate MOSFETs. In Proceedings of the 2018 IEEE International Telecommunications Energy Conference (INTELEC), Turin, Italy, 7–11 October 2018; pp. 1–7. [Google Scholar] [CrossRef]

- Kessler, D.J.; Kazimierczuk, M.K. Power losses and efficiency of class-E power amplifier at any duty ratio. IEEE Trans. Circuits Syst. I Regul. Pap. 2004, 51, 1675–1689. [Google Scholar] [CrossRef]

| Parameter | Calculated |

|---|---|

| CMopt | 32 pF |

| Vi | 23.6 V |

| Lf | 200 µH |

| Cshunt | 91 nF |

| Lr | 51 nH |

| Cr | 56 nF |

| L1 | 844 µH |

| C1 | 3 nF |

| L2 | 844 µH |

| C2 | 3 nF |

| RL | 10 Ω |

| Parameter | Measured |

|---|---|

| CMopt | 32 pF |

| Vi | 23.6 V |

| fs | 100 kHz |

| Lf | 214.3 µH/ESRLf = 26 mΩ |

| Cshunt | 90.2 nF/ESRCshunt = 35 mΩ |

| Lr | 50.3 nH/ESRL = 35 mΩ |

| Cr | 57.3 nF/ESRC = 7 mΩ |

| L1 | 839.6 µH/ESRL1 = 13 mΩ |

| C1 | 3.2 nF/ESRC1 = 4 mΩ |

| L2 | 842.3 µH/ESRL2 = 13 mΩ |

| RL | 9.96 Ω |

| Parameter | Value | Conditions |

|---|---|---|

| VBR,DSS | 600 V | VGS = 0 V, ID = 1 mA |

| RDS,ON | 0.234 Ω | VGS = 15 V, ID = 10 A, TJ = 25 °C |

| ID | 20 A | Ta = 25 °C |

| Ciss | 1500 pF | VGS = 0 V, VDS = 100 V, f = 1 MHz |

| Coss | 90 pF | --- |

| Crss | 1.9 pF | --- |

| Capacitive Coupling | DC | THD |

|---|---|---|

| 25 pF | 493 µV | 0.35% |

| 32 pF | 238 µV | 0.64% |

| 45 pF | 238 µV | 0.42% |

| Parameter | Output Power | Frequency | Efficiency | Capacitive Coupling |

|---|---|---|---|---|

| [24] | 20 W | 6.78 MHz | 80% | 5.8 pF |

| [25] | 1.7 W | 1 MHz | 75% | 112 pF |

| [26] | 5 W | 13.56 MHz | 95% | 176 pF |

| [27] | 3 W | 6.78 MHz | 85% | 940 pF |

| [28] | 360 mW | 2 MHz | - | 250 pF |

| [29] | 10 W | 1 MHz | 93.4% | 350 pF |

| [30] | 9.45 W | 1 MHz | 98.4% | 2.20 nF |

| Proposed | 83.5 W | 100 kHz | 92.3% | 32 pF |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Corti, F.; Reatti, A.; Wu, Y.-H.; Czarkowski, D.; Musumeci, S. Zero Voltage Switching Condition in Class-E Inverter for Capacitive Wireless Power Transfer Applications. Energies 2021, 14, 911. https://doi.org/10.3390/en14040911

Corti F, Reatti A, Wu Y-H, Czarkowski D, Musumeci S. Zero Voltage Switching Condition in Class-E Inverter for Capacitive Wireless Power Transfer Applications. Energies. 2021; 14(4):911. https://doi.org/10.3390/en14040911

Chicago/Turabian StyleCorti, Fabio, Alberto Reatti, Ya-Hui Wu, Dariusz Czarkowski, and Salvatore Musumeci. 2021. "Zero Voltage Switching Condition in Class-E Inverter for Capacitive Wireless Power Transfer Applications" Energies 14, no. 4: 911. https://doi.org/10.3390/en14040911

APA StyleCorti, F., Reatti, A., Wu, Y.-H., Czarkowski, D., & Musumeci, S. (2021). Zero Voltage Switching Condition in Class-E Inverter for Capacitive Wireless Power Transfer Applications. Energies, 14(4), 911. https://doi.org/10.3390/en14040911