Efficiency Improvement of Photovoltaic Modules via Back Surface Cooling

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Site

2.2. The Cooling Systems

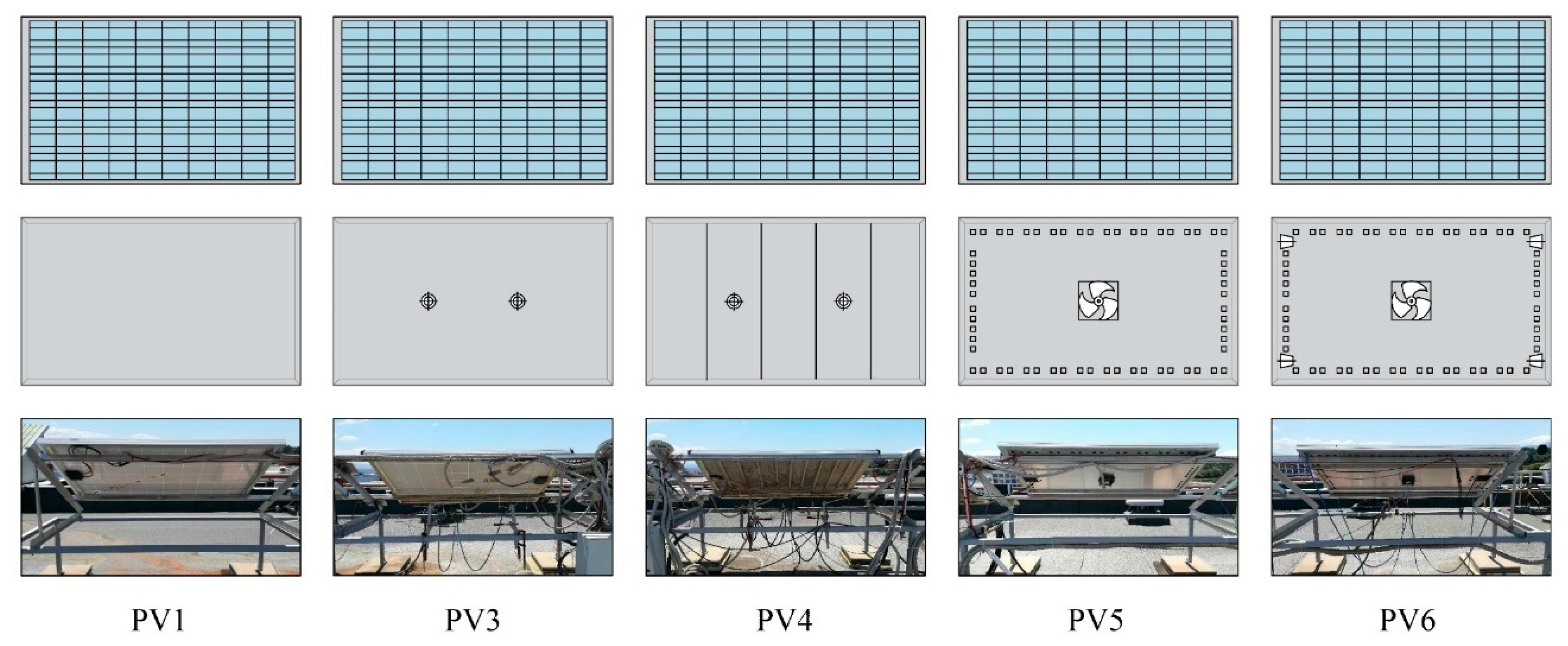

- Module PV1 had no cooling system and was left as a reference system for comparison in terms of temperature, power and efficiency;

- Module PV3 was equipped with two wide cone water spray nozzles positioned at roughly 50 cm from the back surface in order to have a perpendicular spray that covers the greatest rear area. A nominal water flow rate of 8.55 L/min is associated with a pressure of 3 bar.

- Module PV4 was equipped with the same nozzles as PV3, distant approximately 50 cm from the module but with the addition of a thin metallic panel fixed on the back surface (Figure 2) in the attempt to improve temperature uniformity of the rear surface.

- Module PV5 was equipped with a ventilation system that produced forced convection on the module back surface. A proper thin metallic cover installed on the rear part of the module creates a closed cavity in which a small mechanical fan operates expelling an air flow rate that has before extracted thermal energy from the rear surface. The air renewal is guaranteed by a series of small peripheral openings on the metallic structure that induce inside the cavity the same air flow extracted by the fan (Figure 3). The fan was selected to minimize energy consumption with a nominal power of 2 W.

- Module PV6 is equipped with the same ventilation system as PV5 with additional four spray nozzles installed at the four external corners of the metallic closed cavity.

3. Results

3.1. Preliminary Test for Base Case Comparison

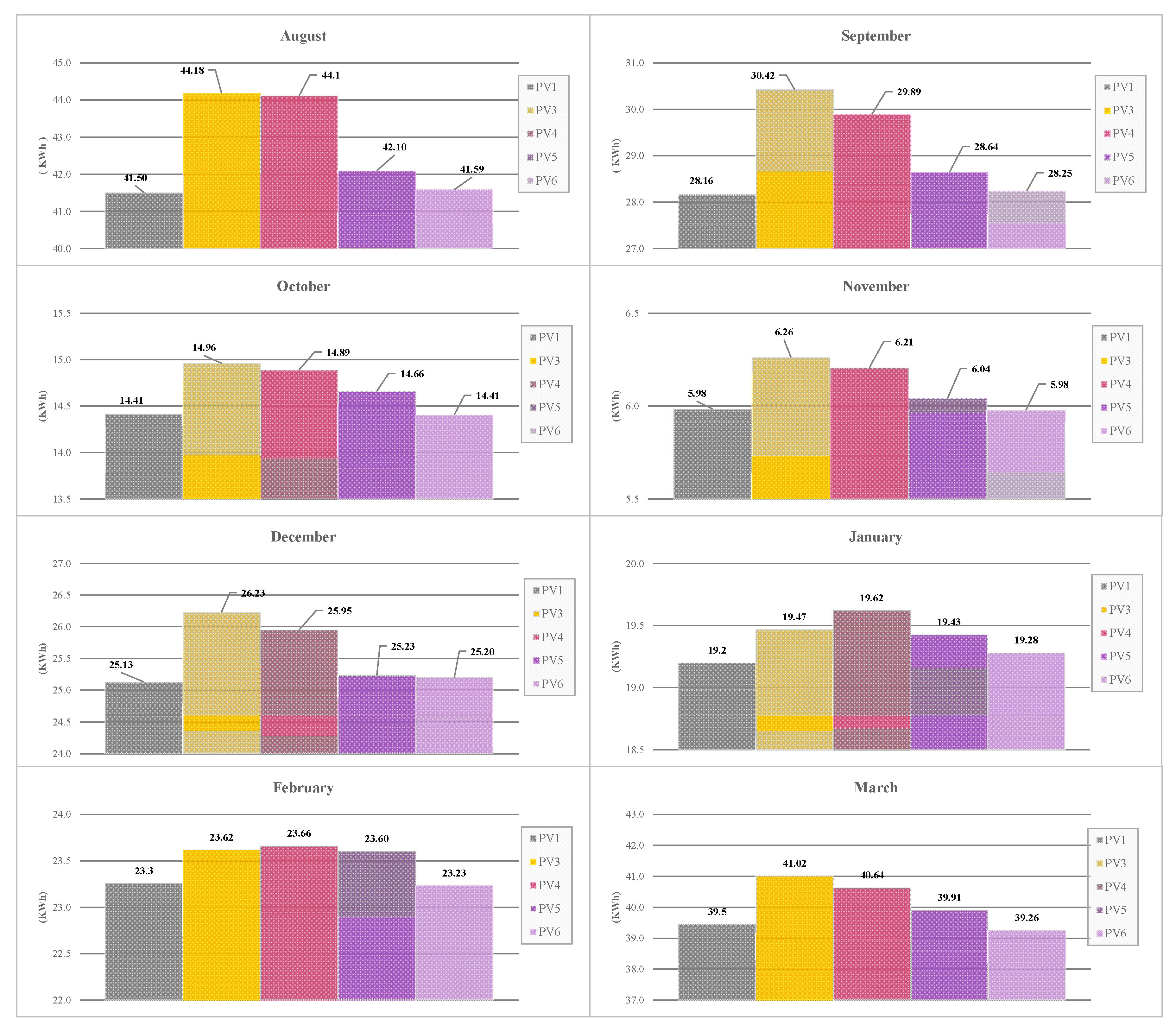

3.2. Electric Efficiency Analysis

3.3. Energy Production and Average Efficiency

3.4. Economic Implications of the Cooling Systems

- The cost of the electric energy is assumed 0.36 €/kWh;

- The cost of water for PV cooling is assumed 0.5 €/m3.

4. Conclusions

- The use of the metallic surface placed under the module is not recommended, since it improves the module efficiency on cloudy days where the electric production is already limited by the low available solar radiation;

- More complex systems based on forced ventilation or combined spray cooling and forced ventilation did not result as a promising and viable option, with very scarce energy performance and negative economic revenue;

- The most cost-effective solution appears to be the use of spray cooling, with simple installation and a rather low cost, that guaranteed a consistent increment of the electric performance of the PV module.

Author Contributions

Funding

Conflicts of Interest

References

- Telichenko, V.; Benuzh, A.; Eames, G.; Orenburova, E.; Shushunova, N. Development of Green Standards for Construction in Russia. Procedia Eng. 2016, 153, 726–730. [Google Scholar] [CrossRef]

- Korol, S.; Shushunova, N.; Shushunova, T. Indicators of the resource efficiency development in Russia. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2018; Volume 193, p. 05075. Available online: https://www.researchgate.net/publication/327116686_Indicators_of_the_resource_efficiency_development_in_Russia (accessed on 8 February 2021).

- Shushunova, T.; Shushunova, N.; Pervova, E.; Dernov, R.; Nazarova, K. Tendencies of the Green Construction in Russia. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Prague, Czech Republic, 1–5 September 2020; Volume 960. [Google Scholar]

- Pirouz, B.; Palermo, S.A.; Maiolo, M.; Arcuri, N.; Piro, P. Decreasing Water Footprint of Electricity and Heat by Extensive Green Roofs: Case of Southern Italy. Sustainability 2020, 12, 10178. [Google Scholar] [CrossRef]

- Pirouz, B.; Turco, M.; Palermo, S.A. A Novel Idea for Improving the Efficiency of Green Walls in Urban Environment (an Innovative Design and Technique). Water 2020, 12, 3524. [Google Scholar] [CrossRef]

- Maiolo, M.; Pirouz, B.; Bruno, R.; Palermo, S.A.; Arcuri, N.; Piro, P. The Role of the Extensive Green Roofs on Decreasing Building Energy Consumption in the Mediterranean Climate. Sustainability 2020, 12, 359. [Google Scholar] [CrossRef]

- Pirouz, B.; Arcuri, N.; Pirouz, B.; Palermo, S.A.; Turco, M.; Maiolo, M. Development of an Assessment Method for Evaluation of Sustainable Factories. Sustainability 2020, 12, 1841. [Google Scholar] [CrossRef]

- Pirouz, B.; Arcuri, N.; Maiolo, M.; Talarico, V.C.; Piro, P. A new multi-objective dynamic model to close the gaps in sustainable development of industrial sector. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Changsha, China, 18–20 September 2020; Volume 410, p. 012074. [Google Scholar]

- Gamayunova, O.; Radaev, A.; Petrichenko, M.; Shushunova, N. Energy audit and energy efficiency of modular military towns. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2019; Volume 110, Available online: https://www.researchgate.net/publication/335065597_Energy_audit_and_energy_efficiency_of_modular_military_towns (accessed on 8 February 2021).

- Bać, A.; Nemś, M.; Nemś, A.; Kasperski, J. Sustainable Integration of a Solar Heating System into a Single-Family House in the Climate of Central Europe—A Case Study. Sustainability 2019, 11, 4167. [Google Scholar] [CrossRef]

- Nemś, A.; Nemś, M. Analysis and selection criteria of photovoltaic panels for DHW. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2017. [Google Scholar]

- Ferraro, V.; Settino, J.; Cucumo, M.; Kaliakatsos, D. Parabolic Trough System Operating with Nanofluids: Comparison with the Conventional Working Fluids and Influence on the System Performance. Energy Procedia 2016, 101, 782–789. [Google Scholar] [CrossRef]

- Bruno, R.; Bevilacqua, P.; Longo, L.; Arcuri, N. Small Size Single-axis PV Trackers: Control Strategies and System Layout for Energy Optimization. Energy Procedia 2015, 82, 737–743. [Google Scholar] [CrossRef]

- Al-Amayreh, M.I.; Alahmer, A.; Manasrah, A. A novel parabolic solar dish design for a hybrid solar lighting-thermal ap-plications. Energy Rep. 2020, 6, 1136–1143. [Google Scholar] [CrossRef]

- Nemś, M.; Manikowska, A.; Nemś, A. Linear concentrating collector as an air heater in the heating system of building in Polish climatic conditions. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2016; Volume 10, p. 64. Available online: https://www.researchgate.net/publication/309221526_Linear_concentrating_collector_as_an_air_heater_in_the_heating_system_of_building_in_Polish_climatic_conditions (accessed on 8 February 2021).

- Nemś, M.; Kasperski, J. Experimental investigation of concentrated solar air-heater with internal multiple-fin array. Renew. Energy 2016, 97, 722–730. [Google Scholar] [CrossRef]

- Nemś, M.; Kolasinski, P.; Kasperski, J. Solar High-Temperature Heat Accumulation System with ORC Generator. In Proceedings of the ISES Solar World Congress, Kassel, Germany, 28 August–2 September 2011; pp. 1–10. [Google Scholar] [CrossRef]

- Dabwan, Y.N.; Pei, G.; Gao, G.; Li, J.; Feng, J. Performance analysis of integrated linear fresnel reflector with a conventional cooling, heat, and power tri-generation plant. Renew. Energy 2019, 138, 639–650. [Google Scholar] [CrossRef]

- Cucumo, M.; Ferraro, V.; Kaliakatsos, D.; Nicoletti, F. Study of Kinematic System for Solar Tracking of a Linear Fresnel Plant to Reduce End Losses. Eur. J. Electr. Eng. 2019, 21, 393–400. [Google Scholar] [CrossRef]

- Devabhaktuni, V.; Alam, M.; Depuru, S.S.S.R.; Green, R.C.; Nims, D.K.; Near, C. Solar energy: Trends and enabling technologies. Renew. Sustain. Energy Rev. 2013, 19, 555–564. [Google Scholar] [CrossRef]

- Cucumo, M.; Ferraro, V.; Kaliakatsos, D.; Mele, M.; Nicoletti, F. Calculation model using finite-difference method for energy analysis in a concentrating solar plant with linear fresnel reflectors. Int. J. Heat Technol. 2016, 34, 337–345. [Google Scholar] [CrossRef]

- Islam, T.; Huda, N.; Abdullah, A.; Saidur, R. A comprehensive review of state-of-the-art concentrating solar power (CSP) technologies: Current status and research trends. Renew. Sustain. Energy Rev. 2018, 91, 987–1018. [Google Scholar] [CrossRef]

- Cucumo, M.; Ferraro, V.; Kaliakatsos, D.; Mele, M.; Nicoletti, F. Law of motion of reflectors for a linear Fresnel plant. Int. J. Heat Technol. 2017, 35, S78–S86. [Google Scholar] [CrossRef]

- Cucumo, M.A.; Ferraro, V.; Kaliakatsos, D.; Mele, M.; Nicoletti, F. Linear Fresnel plant with primary reflectors movable around two axes. Adv. Model. Anal. A 2018, 99–107. [CrossRef]

- Nicoletti, F.; Cucumo, M.A.; Ferraro, V.; Kaliakatsos, D.; Settino, J. Performance Analysis of a Double-Sided PV Plant Oriented with Backtracking System. Math. Model. Eng. Probl. 2020, 7, 325–334. [Google Scholar] [CrossRef]

- Evola, G.; Margani, G. Renovation of apartment blocks with BIPV: Energy and economic evaluation in temperate climate. Energy Build. 2016, 130, 794–810. [Google Scholar] [CrossRef]

- Antonacci, A.; Scognamiglio, V. Photosynthesis-based hybrid nanostructures: Electrochemical sensors and photovoltaic cells as case studies. TrAC Trends Anal. Chem. 2019, 115, 100–109. [Google Scholar] [CrossRef]

- Kikuchi, M.; Makmuang, S.; Izawa, S.; Wongravee, K.; Hiramoto, M. Doped organic single-crystal photovoltaic cells. Org. Electron. 2019, 64, 92–96. [Google Scholar] [CrossRef]

- Cui, X.; Li, Y.; Sun, N.; Du, J.; Li, X.; Yang, H.; Hao, X. Double perovskite Bi2FeMoxNi1-xO6 thin films: Novel ferroelectric photovoltaic materials with narrow bandgap and enhanced photovoltaic performance. Sol. Energy Mater. Sol. Cells 2018, 187, 9–14. [Google Scholar] [CrossRef]

- Munshi, A.H.; Sasidharan, N.; Pinkayan, S.; Barth, K.L.; Sampath, W.; Ongsakul, W. Thin-film CdTe photovoltaics—The technology for utility scale sustainable energy generation. Sol. Energy 2018, 173, 511–516. [Google Scholar] [CrossRef]

- Reddy, V.R.M.; Pallavolu, M.R.; Guddeti, P.R.; Gedi, S.; Reddy, K.K.Y.B.; Pejjai, B.; Kim, W.K.; Kotte, T.R.R.; Park, C. Review on Cu2SnS3, Cu3SnS4, and Cu4SnS4 thin films and their photovoltaic performance. J. Ind. Eng. Chem. 2019, 76, 39–74. [Google Scholar] [CrossRef]

- Albero, J.; Clifford, J.N.; Palomares, E. Quantum dot based molecular solar cells. Co-ord. Chem. Rev. 2014, 263, 53–64. [Google Scholar] [CrossRef]

- Kaltenbrunner, M.; White, M.S.; Glowacki, E.D.; Sekitani, T.; Someya, T.; Sariciftci, N.S.; Bauer, S. Ultrathin and lightweight organic solar cells with high flexibility. Nat. Commun. 2012, 3, 770. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Duan, S.; Wang, Y.; Sun, C.; Wang, X.F.; Sasaki, S. ichi Chlorophyll-based organic solar cells with improved power conversion efficiency. J. Energy Chem. 2019, 38, 88–93. [Google Scholar] [CrossRef]

- Settino, J.; Sant, T.; Micallef, C.; Farrugia, M.; Staines, C.S.; Licari, J.; Micallef, A. Overview of solar technologies for electricity, heating and cooling production. Renew. Sustain. Energy Rev. 2018, 90, 892–909. [Google Scholar] [CrossRef]

- Manasrah, A.; Al Zyoud, A.; Abdelhafez, E. Effect of color and nano film filters on the performance of solar photovoltaic module. Energy Sources Part A Recover. Util. Environ. Eff. 2021, 43, 705–715. [Google Scholar] [CrossRef]

- Sargunanathan, S.; Elango, A.; Mohideen, S.T. Performance enhancement of solar photovoltaic cells using effective cooling methods: A review. Renew. Sustain. Energy Rev. 2016, 64, 382–393. [Google Scholar] [CrossRef]

- Hasanuzzaman, M.; Malek, A.; Islam, M.; Pandey, A.; Rahim, N. Global advancement of cooling technologies for PV systems: A review. Sol. Energy 2016, 137, 25–45. [Google Scholar] [CrossRef]

- Nižetić, S.; Papadopoulos, A.; Giama, E. Comprehensive analysis and general economic-environmental evaluation of cooling techniques for photovoltaic panels, Part I: Passive cooling techniques. Energy Convers. Manag. 2017, 149, 334–354. [Google Scholar] [CrossRef]

- Nižetić, S.; Giama, E.; Papadopoulos, A. Comprehensive analysis and general economic-environmental evaluation of cooling techniques for photovoltaic panels, Part II: Active cooling techniques. Energy Convers. Manag. 2018, 155, 301–323. [Google Scholar] [CrossRef]

- He, W.; Zhang, Y.; Ji, J. Comparative experiment study on photovoltaic and thermal solar system under natural circulation of water. Appl. Therm. Eng. 2011, 31, 3369–3376. [Google Scholar] [CrossRef]

- Amori, K.E.; Al-Najjar, H.M.T. Analysis of thermal and electrical performance of a hybrid (PV/T) air based solar collector for Iraq. Appl. Energy 2012, 98, 384–395. [Google Scholar] [CrossRef]

- Manasrah, A.; Alkhalil, S.; Masoud, M. Investigation of Multi-Way Forced Convective Cooling on the Backside of Solar Panels. Int. J. Energy Convers. (IRECON) 2020, 8, 181. [Google Scholar] [CrossRef]

- Ziapour, B.M.; Palideh, V.; Baygan, M. Performance comparison of four passive types of photovoltaic–thermal systems. Energy Convers. Manag. 2014, 88, 732–738. [Google Scholar] [CrossRef]

- Ji, J.; He, H.; Chow, T.; Pei, G.; He, W.; Liu, K. Distributed dynamic modeling and experimental study of PV evaporator in a PV/T solar-assisted heat pump. Int. J. Heat Mass Transf. 2009, 52, 1365–1373. [Google Scholar] [CrossRef]

- Ameri, M.; Mahmoudabadi, M.M.; Shahsavar, A. An Experimental Study on a Photovoltaic/Thermal (PV/T) Air Collector with Direct Coupling of Fans and Panels. Energy Sources Part A Recover. Util. Environ. Eff. 2012, 34, 929–947. [Google Scholar] [CrossRef]

- Tonui, J.; Tripanagnostopoulos, Y. Performance improvement of PV/T solar collectors with natural air flow operation. Sol. Energy 2008, 82, 1–12. [Google Scholar] [CrossRef]

- Teo, H.; Lee, P.; Hawlader, M. An active cooling system for photovoltaic modules. Appl. Energy 2012, 90, 309–315. [Google Scholar] [CrossRef]

- Kim, J.H.; Park, S.H.; Kim, J.T. Experimental performance of a photovoltaic-thermal air collector. Energy Procedia 2014, 48, 888–894. [Google Scholar] [CrossRef]

- Robles-Ocampo, B.; Ruíz-Vasquez, E.; Canseco-Sánchez, H.; Cornejo-Meza, R.; Trápaga-Martínez, G.; García-Rodriguez, F.; González-Hernández, J.; Vorobiev, Y. Photovoltaic/thermal solar hybrid system with bifacial PV module and transparent plane collector. Sol. Energy Mater. Sol. Cells 2007, 91, 1966–1971. [Google Scholar] [CrossRef]

- Evola, G.; Marletta, L. Exergy and thermoeconomic optimization of a water-cooled glazed hybrid photovoltaic/thermal (PVT) collector. Sol. Energy 2014, 107, 12–25. [Google Scholar] [CrossRef]

- Kumar, R.; Rosen, M.A. Performance evaluation of a double pass PV/T solar air heater with and without fins. Appl. Therm. Eng. 2011, 31, 1402–1410. [Google Scholar] [CrossRef]

- Browne, M.C.; Lawlor, K.; Kelly, A.; Norton, B.; Mc Cormack, S.J. Indoor Characterisation of a Photovoltaic/ Thermal Phase Change Material System. Energy Procedia 2015, 70, 163–171. [Google Scholar] [CrossRef]

- Huang, M.J.; Eames, P.C.; Norton, B. Phase change materials for limiting temperature rise in building integrated photovol-taics. Sol. Energy 2006, 80, 1121–1130. [Google Scholar]

- Atkin, P.; Farid, M.M. Improving the efficiency of photovoltaic cells using PCM infused graphite and aluminium fins. Sol. Energy 2015, 114, 217–228. [Google Scholar] [CrossRef]

- Indartono, Y.S.; Suwono, A.; Pratama, F.Y. Improving photovoltaics performance by using yellow petroleum jelly as phase change material. Int. J. Low-Carbon Technol. 2016, 11, 333–337. [Google Scholar] [CrossRef]

- Spertino, F.; D’Angola, A.; Enescu, D.; Di Leo, P.; Fracastoro, G.V.; Zaffina, R. Thermal–electrical model for energy estimation of a water cooled photovoltaic module. Sol. Energy 2016, 133, 119–140. [Google Scholar] [CrossRef]

- Bevilacqua, P.; Bruno, R.; Arcuri, N. Comparing the performances of different cooling strategies to increase photovoltaic modules electric in different meteorological conditions. Energy 2020, 195, 116950. [Google Scholar] [CrossRef]

- Bevilacqua, P.; Morabito, A.; Bruno, R.; Ferraro, V.; Arcuri, N. Seasonal performances of photovoltaic cooling systems in different weather conditions. J. Clean. Prod. 2020, 272, 122459. [Google Scholar] [CrossRef]

- Wang, Y.; Fang, Z.; Zhu, L.; Huang, Q.; Zhang, Y.; Zhang, Z. The performance of silicon solar cells operated in liquids. Appl. Energy 2009, 86, 1037–1042. [Google Scholar] [CrossRef]

- Han, X.; Wang, Y.; Zhu, L. Electrical and thermal performance of silicon concentrator solar cells immersed in dielectric liquids. Appl. Energy 2011, 88, 4481–4489. [Google Scholar] [CrossRef]

- Mehrotra, S.; Rawat, P.; Debbarma, M.; Sudhakar, K.; Centre, E.; Pradesh, M. Performance of a Solar Panel with Water Im-mersion. Int. J. Sci. Technol. 2014, 3, 1161–1172. [Google Scholar]

- Rosa-Clot, M.; Rosa-Clot, P.; Tina, G.M.; Scandura, P.F. Submerged photovoltaic solar panel: SP2. Renew. Energy 2010, 35, 1862–1865. [Google Scholar] [CrossRef]

- Abdulgafar, S.A.; Omar, O.S.; Yousif, K.M. Improving the Efficiency of Polycrystalline Solar Panel Via Water Immersion Method. Int. J. Innov. Res. Sci. Eng. Technol. 2014, 3, 8127–8132. [Google Scholar]

- Krauter, S. Increased electrical yield via water flow over the front of photovoltaic panels. Sol. Energy Mater. Sol. Cells 2004, 82, 131–137. [Google Scholar] [CrossRef]

- Moharram, K.; Abd-Elhady, M.; Kandil, H.; El-Sherif, H. Enhancing the performance of photovoltaic panels by water cooling. Ain Shams Eng. J. 2013, 4, 869–877. [Google Scholar] [CrossRef]

- Abdolzadeh, M.; Ameri, M. Improving the effectiveness of a photovoltaic water pumping system by spraying water over the front of photovoltaic cells. Renew. Energy 2009, 34, 91–96. [Google Scholar] [CrossRef]

- Odeh, S.; Behnia, M. Improving Photovoltaic Module Efficiency Using Water Cooling. Heat Transf. Eng. 2009, 30, 499–505. [Google Scholar] [CrossRef]

- Hachicha, A.A.; Ghenai, C.; Hamid, A.K. Enhancing the Performance of a Photovoltaic Module Using Different Cooling Methods. Int. J. Energy Power Eng. 2015, 9, 1106–1109. [Google Scholar]

- Irwan, Y.; Leow, W.; Irwanto, M.; Fareq, M.; Amelia, A.; Gomesh, N.; Safwati, I. Indoor Test Performance of PV Panel through Water Cooling Method. Energy Procedia 2015, 79, 604–611. [Google Scholar] [CrossRef]

- Nižetić, S.; Čoko, D.; Yadav, A.; Grubišić-Čabo, F. Water spray cooling technique applied on a photovoltaic panel: The per-formance response. Energy Convers. Manag. 2016, 108, 287–296. [Google Scholar] [CrossRef]

- Schiro, F.; Benato, A.; Stoppato, A.; Destro, N. Improving photovoltaics efficiency by water cooling: Modelling and experi-mental approach. Energy 2017, 137, 798–810. [Google Scholar] [CrossRef]

- Bahaidarah, H.M.S.; Subhan, A.; Gandhidasan, P.; Rehman, S. Performance evaluation of a PV (photovoltaic) module by back surface water cooling for hot climatic conditions. Energy 2013, 59, 445–453. [Google Scholar] [CrossRef]

- Zilli, B.M.; Lenz, A.M.; De Souza, S.N.M.; Secco, D.; Nogueira, C.E.C.; Junior, O.H.A.; Nadaleti, W.C.; Siqueira, J.A.C.; Gurgacz, F. Performance and effect of water-cooling on a microgeneration system of photovoltaic solar energy in Paraná, Brazil. J. Clean. Prod. 2018, 192, 477–485. [Google Scholar] [CrossRef]

- Nizetic, S.; Čabo, F.G.-; Marinić-Kragić, I.; Papadopoulos, A. Experimental and numerical investigation of a backside convective cooling mechanism on photovoltaic panels. Energy 2016, 111, 211–225. [Google Scholar] [CrossRef]

| PV Modules | Micro-Inverter | ||

|---|---|---|---|

| Nominal power (W) | 245 | Maximum DC power (W) | 265 |

| Output tolerance (%) | +5/−0 | Operative DC input voltage (V) | 18…58 |

| Rated voltage (V) | 29.9 | MPPT DC voltage range (V) | 20…50 |

| Rated current (A) | 8.20 | Maximum DC input voltage (A) | 65 |

| Open circuit voltage (V) | 37.41 | Maximum DC input current (A) | 10 |

| Short circuit current (A) | 8.80 | Start voltage DC input (V) | 25 |

| Temperature coefficient—Pmpp (%/°C) | −0.43 | Nominal outlet AC power (W) | 250 |

| Temperature coefficient—Isc (%/°C) | +0.06 | Nominal outlet AC voltage (V) | 230 |

| Temperature coefficient—Uoc (%/°C) | −0.31 | AC output voltage range (V) | 180…264 |

| Normal Operating Cell Temperature (°C) | 43 ± 2 | Maximum AC output current (A) | 1.2 |

| Temperature | Relative Humidity | Wind Speed | Wind Direction | ||||

|---|---|---|---|---|---|---|---|

| Sensor | Pt 100 1/3 | Sensor | Capacitive | Range (m/s) | 0…75 | Sensor | No contact hall |

| Range (°C) | −50…70 | Range (%) | 0…100 | Accuracy | 2.5 % | Range (°) | 0…360 |

| Accuracy (°C) | 0.1 (0 °C) | Accuracy | ±1.5 (RH5–95%) | Threshold (m/s) | 0.5 | Accuracy (°) | 5 |

| Data | ΔPV3–1 | ΔPV4–1 | ΔPV5–1 | ΔPV6–1 | η3-η1 | η4-η1 | η5-η1 | η6-η1 |

|---|---|---|---|---|---|---|---|---|

| 01/05/2015 | 0.57% | 1.29% | 0.88% | 0.00% | 0.08% | 0.19% | 0.13% | 0.00% |

| 02/05/2015 | 0.27% | 1.45% | 0.92% | 0.11% | 0.04% | 0.21% | 0.14% | 0.02% |

| 03/05/2015 | 0.73% | 1.26% | 0.63% | −0.28% | 0.10% | 0.18% | 0.09% | −0.04% |

| 04/05/2015 | 0.94% | 1.16% | 0.31% | −0.61% | 0.13% | 0.16% | 0.04% | −0.08% |

| 05/05/2015 | 0.82% | 1.25% | 0.38% | −0.61% | 0.11% | 0.17% | 0.05% | −0.08% |

| 06/05/2015 | 0.86% | 1.28% | 0.63% | −0.38% | 0.12% | 0.17% | 0.09% | −0.05% |

| 07/05/2015 | 0.52% | 1.43% | 0.89% | −0.03% | 0.08% | 0.20% | 0.13% | 0.00% |

| 08/05/2015 | 0.79% | 1.31% | 0.74% | −0.19% | 0.11% | 0.18% | 0.10% | −0.03% |

| 09/05/2015 | 0.65% | 1.35% | 0.88% | −0.08% | 0.09% | 0.20% | 0.13% | −0.01% |

| 10/05/2015 | - | - | - | - | - | - | - | - |

| 11/05/2015 | 0.68% | 1.26% | 0.37% | −0.70% | 0.10% | 0.18% | 0.05% | −0.10% |

| 12/05/2015 | 0.75% | 1.08% | 0.20% | −0.95% | 0.11% | 0.16% | 0.03% | −0.14% |

| 13/05/2015 | 0.56% | 1.39% | 0.86% | −0.03% | 0.08% | 0.20% | 0.12% | 0.00% |

| 14/05/2015 | 0.41% | 1.44% | 0.95% | 0.06% | 0.06% | 0.21% | 0.14% | 0.01% |

| 15/05/2015 | 0.64% | 1.34% | 0.78% | −0.18% | 0.09% | 0.19% | 0.11% | −0.02% |

| 16/05/2015 | 0.12% | 1.52% | 0.57% | −0.68% | 0.02% | 0.23% | 0.08% | −0.10% |

| 17/05/2015 | -0.42% | 1.95% | 0.76% | −0.44% | -0.07% | 0.31% | 0.12% | −0.07% |

| 18/05/2015 | 0.16% | 1.38% | 0.43% | −0.86% | 0.02% | 0.21% | 0.06% | −0.13% |

| 19/05/2015 | 0.26% | 1.48% | 0.50% | −0.45% | 0.04% | 0.22% | 0.07% | −0.06% |

| 20/05/2015 | 0.78% | 1.33% | 0.65% | −0.25% | 0.11% | 0.18% | 0.09% | −0.04% |

| 21/05/2015 | -0.18% | 1.85% | 0.65% | −0.41% | -0.03% | 0.28% | 0.10% | −0.06% |

| 22/05/2015 | 0.40% | 1.47% | 0.96% | 0.23% | 0.06% | 0.22% | 0.14% | 0.03% |

| 23/05/2015 | 0.07% | 1.61% | 0.86% | −0.07% | 0.01% | 0.24% | 0.13% | −0.01% |

| 24/05/2015 | 0.34% | 1.63% | 0.92% | 0.05% | 0.05% | 0.24% | 0.14% | 0.01% |

| 25/05/2015 | 0.46% | 1.49% | 0.97% | 0.18% | 0.07% | 0.22% | 0.14% | 0.03% |

| 26/05/2015 | 0.58% | 1.46% | 0.75% | −0.39% | 0.09% | 0.22% | 0.11% | −0.06% |

| 27/05/2015 | 0.18% | 1.58% | 0.70% | −0.37% | 0.03% | 0.24% | 0.11% | −0.06% |

| 28/05/2015 | 0.20% | 1.54% | 0.73% | −0.34% | 0.03% | 0.23% | 0.11% | −0.05% |

| 29/05/2015 | - | - | - | - | - | - | - | - |

| 30/05/2015 | 1.01% | 0.54% | 0.64% | −0.31% | 0.14% | 0.08% | 0.09% | −0.04% |

| 31/05/2015 | 0.50% | 1.01% | 0.57% | −0.50% | 0.07% | 0.15% | 0.08% | −0.07% |

| Average | 0.47% | 1.38% | 0.69% | −0.29% | 0.07% | 0.20% | 0.10% | −0.04% |

| Minimum Hourly Efficiency | Average Hourly Efficiency | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| PV1 | PV3 | PV4 | PV5 | PV6 | PV1 | PV3 | PV4 | PV5 | PV6 | |

| August | 12.8% | 14.4% | 14.0% | 13.0% | 12.8% | 13.7% | 14.8% | 14.7% | 14.0% | 13.8% |

| September | 13.4% | 15.0% | 14.4% | 13.6% | 13.3% | 14.9% | 16.0% | 15.9% | 15.2% | 15.0% |

| October | 13.5% | 13.9% | 13.6% | 13.7% | 13.3% | 14.7% | 15.0% | 15.0% | 15.0% | 14.7% |

| November | 14.9% | 16.0% | 15.6% | 15.0% | 14.9% | 16.3% | 16.5% | 16.9% | 16.4% | 16.3% |

| December | 15.5% | 16.4% | 15.9% | 15.3% | 15.3% | 16.2% | 16.3% | 16.7% | 16.2% | 16.2% |

| January | 14.9% | 15.2% | 15.0% | 15.0% | 14.7% | 15.4% | 15.7% | 15.8% | 15.8% | 15.6% |

| February | 13.9% | 14.2% | 14.0% | 14.1% | 13.8% | 15.2% | 15.8% | 15.7% | 15.7% | 15.5% |

| March | 13.9% | 15.2% | 14.6% | 13.8% | 13.7% | 14.4% | 15.3% | 15.1% | 14.6% | 14.4% |

| Daily Average Energy (Wh) | Daily Average Efficiency (-) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| PV1 | PV3 | PV4 | PV5 | PV6 | PV1 | PV3 | PV4 | PV5 | PV6 | |

| August | 1338.8 | 1425.1 | 1423.0 | 1358.0 | 1341.5 | 0.135 | 0.143 | 0.143 | 0.137 | 0.135 |

| September | 938.8 | 1014.1 | 996.3 | 954.6 | 941.6 | 0.121 | 0.130 | 0.128 | 0.123 | 0.122 |

| October * | 464.9 | 482.6 | 480.3 | 472.9 | 464.8 | 0.127 | 0.131 | 0.132 | 0.130 | 0.128 |

| November * | 664.9 | 695.8 | 689.6 | 671.6 | 664.3 | 0.151 | 0.157 | 0.157 | 0.153 | 0.152 |

| December | 866.4 | 904.5 | 894.8 | 870.1 | 868.9 | 0.160 | 0.167 | 0.166 | 0.162 | 0.161 |

| January | 619.3 | 628.0 | 633.0 | 626.7 | 622.0 | 0.164 | 0.167 | 0.169 | 0.167 | 0.166 |

| February | 830.6 | 843.5 | 845.0 | 843.0 | 829.7 | 0.157 | 0.160 | 0.161 | 0.161 | 0.158 |

| March | 1272.7 | 1323.1 | 1310.9 | 1287.3 | 1266.3 | 0.151 | 0.157 | 0.156 | 0.153 | 0.151 |

| Month | Number of Sprays per Day | l/day | €/day |

|---|---|---|---|

| August | 153 | 21.8 | 0.34 |

| September | 146 | 20.7 | 0.31 |

| * October | 146 | 20.8 | 0.18 |

| * November | 105 | 15.0 | 0.07 |

| * December | 109 | 15.4 | 0.22 |

| January | 115 | 16.3 | 0.25 |

| February | 133 | 18.90 | 0.27 |

| March | 151 | 21.52 | 0.33 |

| Month | Number of Hours per Day | Wh/day | Wh/month |

|---|---|---|---|

| August | 12.8 | 25.5 | 790.5 |

| * September | 12.1 | 24.3 | 728.0 |

| * October | 12.2 | 24.4 | 414.2 |

| * November | 8.8 | 17.5 | 157.5 |

| December | 9.0 | 18.0 | 523.0 |

| January | 9.6 | 19.1 | 592.1 |

| February | 11.1 | 22.1 | 618.8 |

| March | 12.6 | 25.2 | 780.2 |

| Month | ΔPV3–1 kWh/month | ΔPV4–1 kWh/month | ΔPV5–1 kWh/month | PV3 €/month | PV4 €/month | PV5 €/month |

|---|---|---|---|---|---|---|

| August | 2674.4 | 2608.9 | 593.6 | 0.62 | 0.60 | −0.07 |

| September | 2259.1 | 1726.6 | 475.8 | 0.50 | 0.31 | −0.09 |

| * October | 549.2 | 479.5 | 250.1 | 0.02 | 0.00 | −0.06 |

| * November | 277.8 | 222.3 | 60.0 | 0.03 | 0.01 | −0.04 |

| * December | 1102.4 | 822.9 | 106.5 | 0.17 | 0.07 | −0.15 |

| January | 268.7 | 423.6 | 228.0 | −0.16 | −0.10 | −0.13 |

| February | 362.8 | 405.0 | 347.8 | −0.13 | −0.12 | −0.10 |

| March | 1563.9 | 1183.7 | 452.7 | 0.23 | 0.09 | −0.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bevilacqua, P.; Perrella, S.; Cirone, D.; Bruno, R.; Arcuri, N. Efficiency Improvement of Photovoltaic Modules via Back Surface Cooling. Energies 2021, 14, 895. https://doi.org/10.3390/en14040895

Bevilacqua P, Perrella S, Cirone D, Bruno R, Arcuri N. Efficiency Improvement of Photovoltaic Modules via Back Surface Cooling. Energies. 2021; 14(4):895. https://doi.org/10.3390/en14040895

Chicago/Turabian StyleBevilacqua, Piero, Stefania Perrella, Daniela Cirone, Roberto Bruno, and Natale Arcuri. 2021. "Efficiency Improvement of Photovoltaic Modules via Back Surface Cooling" Energies 14, no. 4: 895. https://doi.org/10.3390/en14040895

APA StyleBevilacqua, P., Perrella, S., Cirone, D., Bruno, R., & Arcuri, N. (2021). Efficiency Improvement of Photovoltaic Modules via Back Surface Cooling. Energies, 14(4), 895. https://doi.org/10.3390/en14040895