Cross-Flow Tidal Turbines with Highly Flexible Blades—Experimental Flow Field Investigations at Strong Fluid–Structure Interactions

Abstract

1. Introduction

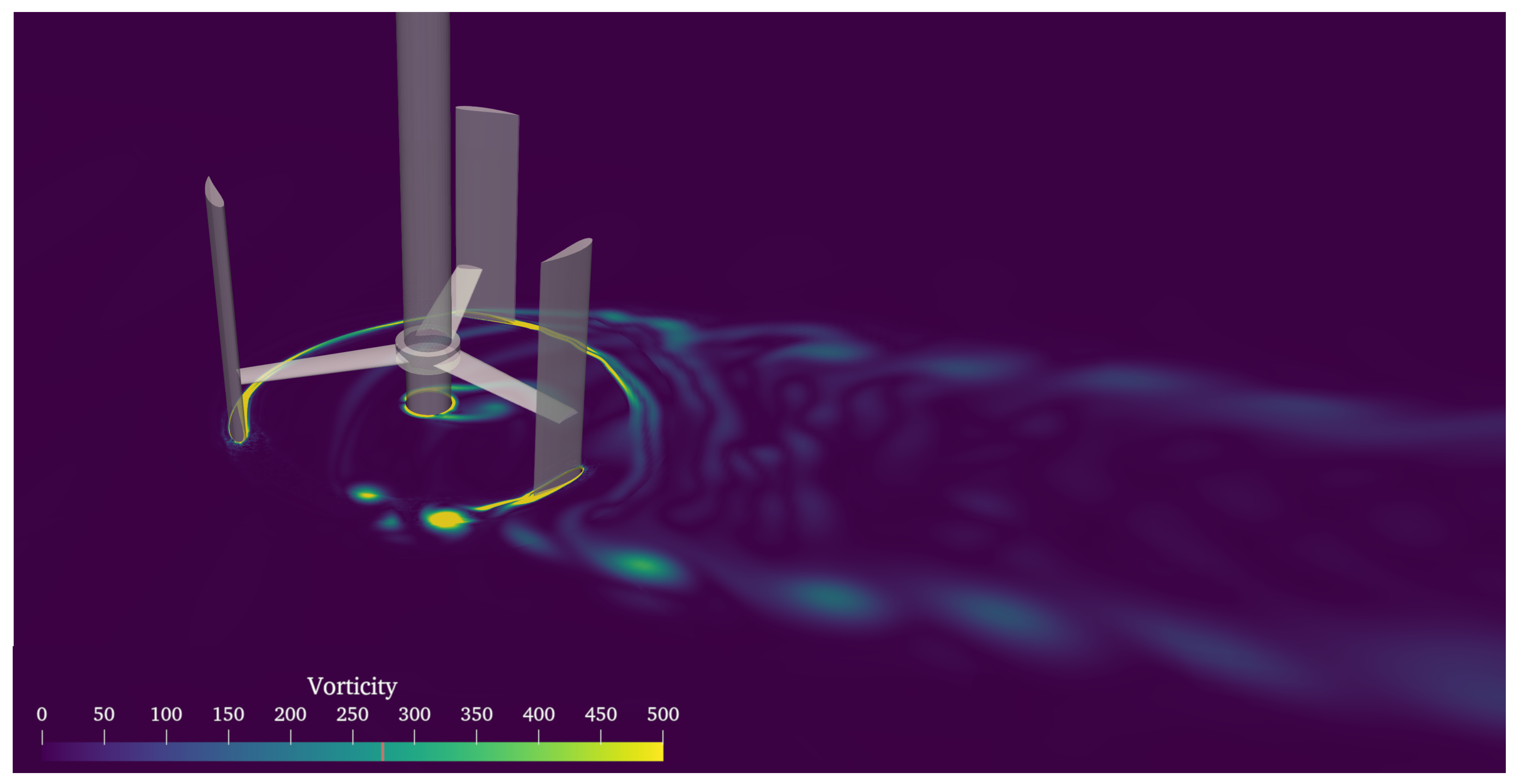

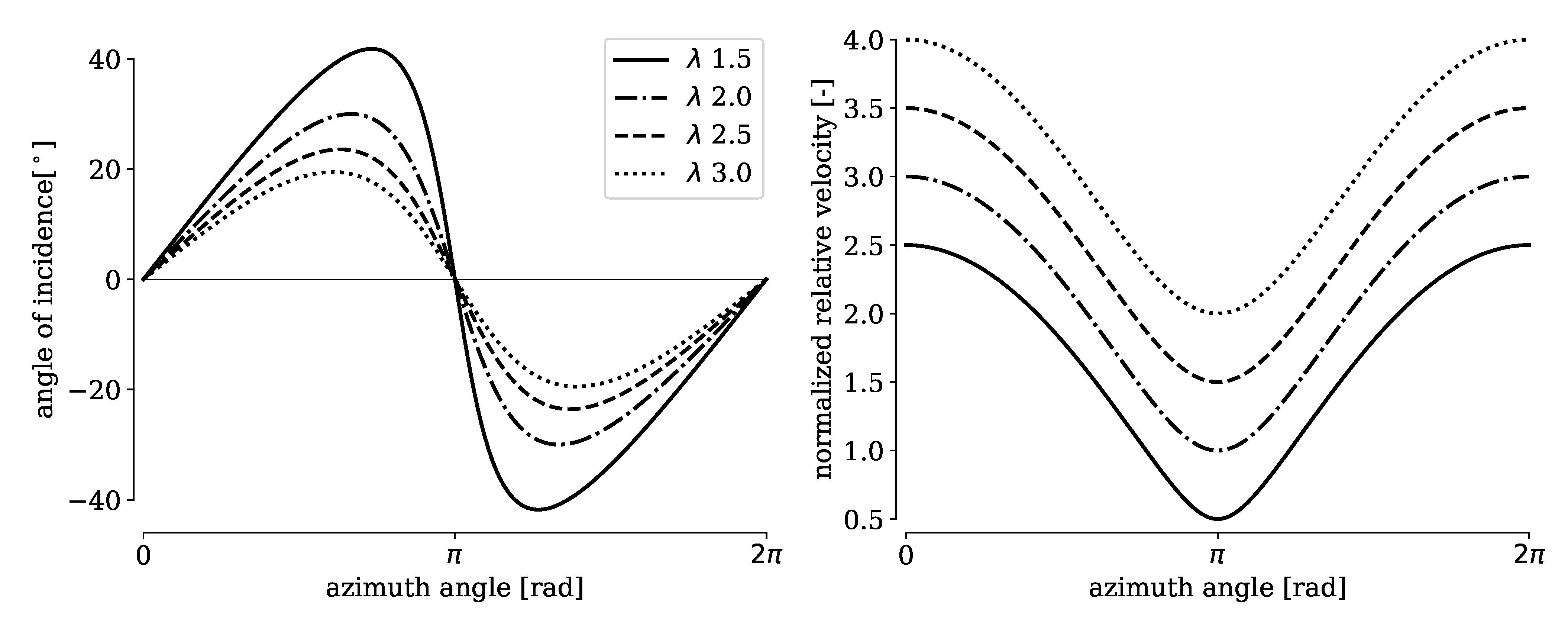

1.1. State of Science and Technology

1.2. Blade Dynamics and Modeling

- a high solidity along with high tip-speed ratio will lead to strong blade-blade interaction. Blades then operate under unfavorable conditions, since the flow is not able to convect away the wake of the preceding blades;

- a low solidity along with low tip-speed ratio will lead to profile stall and poor efficiency, due to high angles of incidence and a low "harvesting" area of the rotor.

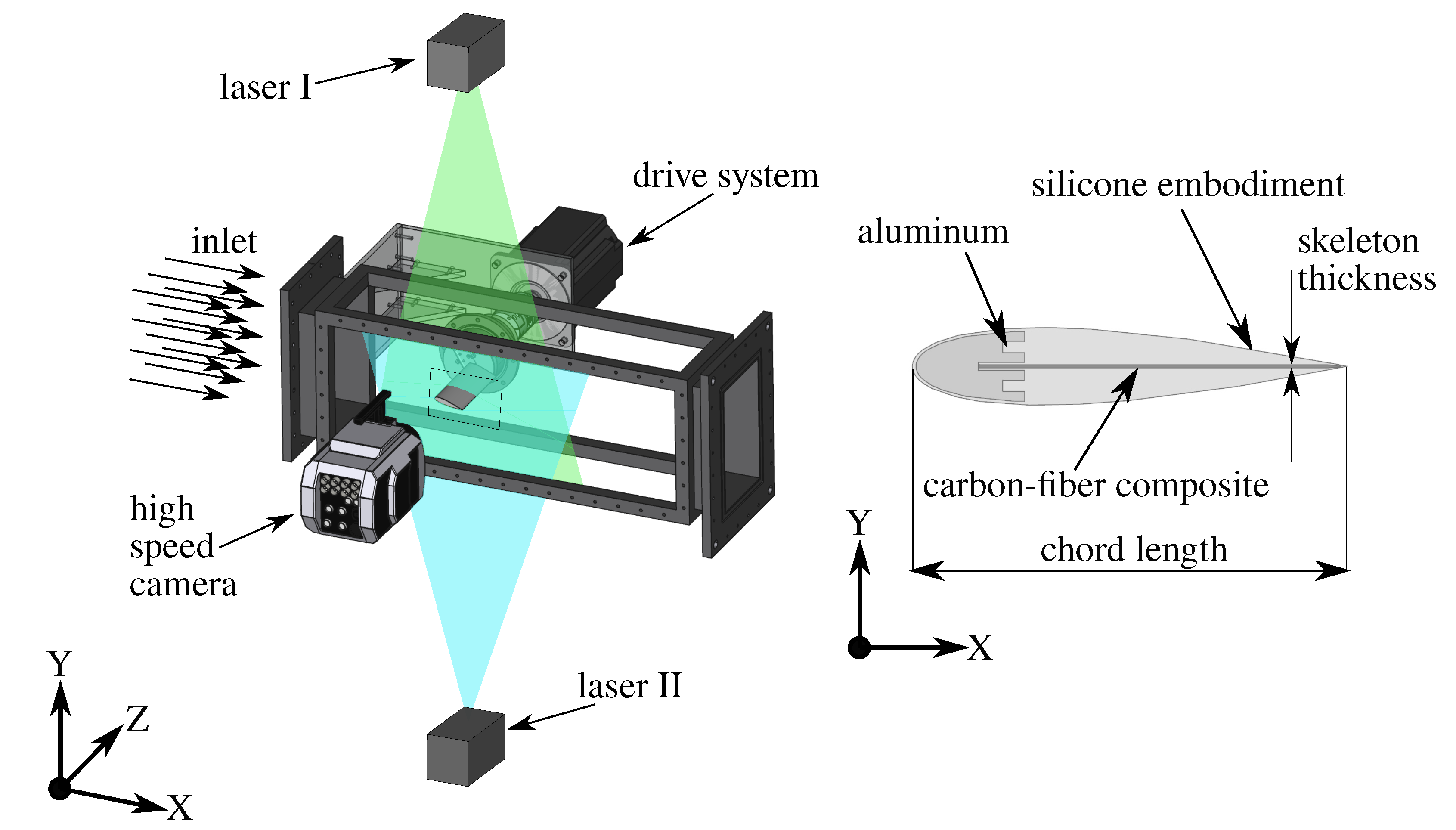

2. Experimental Model and Setup

2.1. Experimental Facility

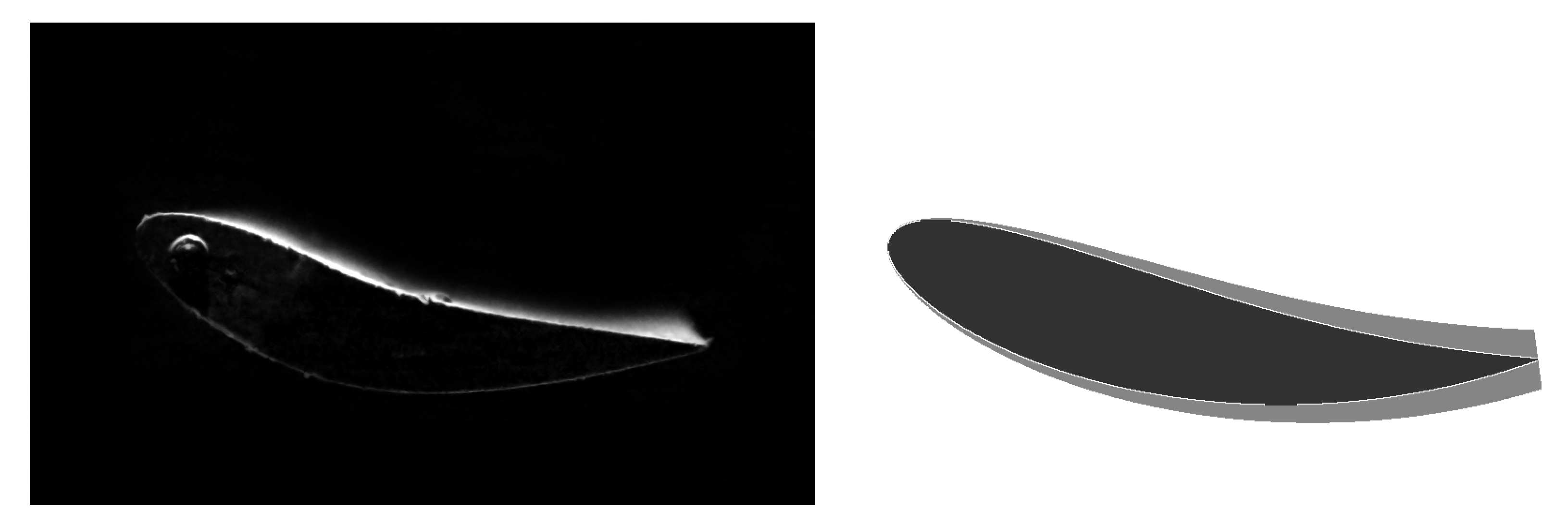

2.2. Highly Flexible Hydrofoils

2.3. Pitch Motion Setup

2.4. PIV Hardware Setup

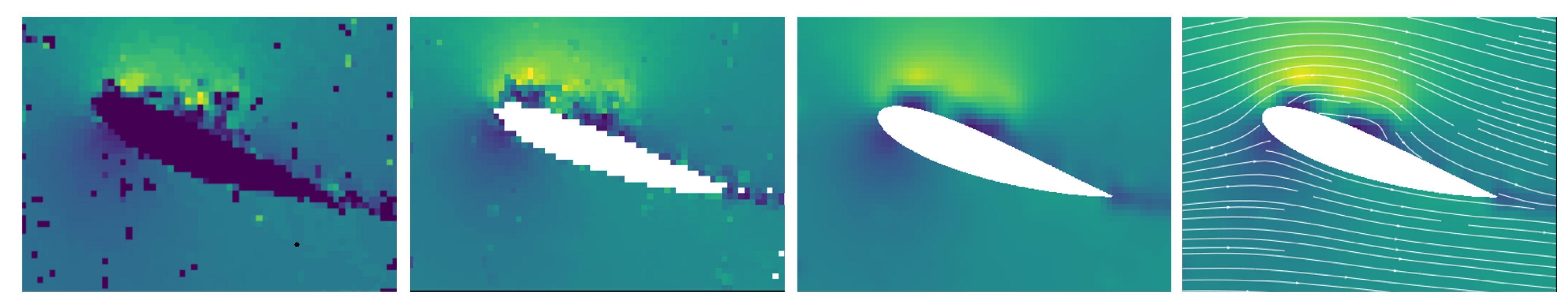

2.5. Preprocessing and Masking

2.6. Processing

2.7. Post-Processing

2.8. Uncertainty Estimation

3. Results and Discussion

3.1. The Influence of the Flexibility on Profile Stall

3.2. The Influence of the Profile Flexibility on the Periodicity of the Flow Field

4. Conclusions

5. Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| 2D2CV | Two dimensions two components |

| BEP | Best-efficiency point |

| CAD | Computer-aided design |

| CFTT | Cross-flow tidal turbines |

| PIV | Particle image velocimetry |

| LDA | Laser-Doppler anemometry |

| LEGI | Laboratoire des Écoulements Géophysiques et Industriels |

| NACA | National Advisory Committee for Aeronautics |

| NaN | Not-a-Number |

| SSIM | Structural Similarity Index |

| TPS | Thin plate spline |

| Angle of attack [°] | |

| Tip-speed ratio [-] | |

| Density [kg/m³] | |

| Rotor solidity [-] | |

| Rotor azimuth angle [rad] | |

| Angular velocity [rad/s] | |

| f | Frequency [Hz] |

| k | Reduced frequency [-] |

| n | Number of blades [-] |

| v | Absolute flow velocity [m/s] |

| w | Relative flow velocity [m/s] |

| C | Blade chord length [m] |

| H | Height [m] |

| L | Length [m] |

| R | Turbine radius [m] |

| W | Width [m] |

| Re | Reynolds number [-] |

| free-stream condition | |

| water channel | |

| maximum | |

| oscillation | |

| temporal derivation | |

| average |

References

- Brownstein, I.; Kinzel, M.; Dabiri, J. Performance enhancement of downstream vertical-axis wind turbines. J. Renew. Sustain. Energy 2016, 8, 053306. [Google Scholar] [CrossRef]

- Dabiri, J. Potential order-of-magnitude enhancement of wind farm power density via counter-rotating vertical-axis wind turbine arrays. J. Renew. Sustain. Energy 2011, 3. [Google Scholar] [CrossRef]

- Whittlesey, R.; Liska, S.; Dabiri, J. Fish schooling as a basis for vertical axis wind turbine farm design. Bioinspir. Biomimetics 2010, 5, 035005. [Google Scholar] [CrossRef] [PubMed]

- Jiang, C.; Shu, X.; Chen, J.; Bao, L.; Li, H. Research on Performance Evaluation of Tidal Energy Turbine under Variable Velocity. Energies 2020, 23, 6313. [Google Scholar] [CrossRef]

- Shiono, M.; Suzuki, K.; Kiho, S. An experimental study of the characteristics of a Darrieus turbine for tidal power generation. Electr. Eng. Jpn. 2000, 132, 38–47. [Google Scholar] [CrossRef]

- Paraschivoiu, I. Wind Turbine Design: With Emphasis on Darrieus Concept, 2nd ed.; Presses Internationales Polytechnique: Montréal, QC, Canada, 2002; ISBN 987-2-553-00931-0. [Google Scholar]

- Laneville, A.; Vittecoq, P. Dynamic Stall: The Case of the Vertical Axis Wind Turbine. J. Sol. Energy Eng. Trans. ASME 1986, 108, 140–145. [Google Scholar] [CrossRef]

- Ferreira, C.S.; van Kuik, G.; van Bussel, G.; Scarano, F. Visualization by PIV of dynamic stall on a vertical axis wind turbine. Exp. Fluids 2009, 46, 97–108. [Google Scholar] [CrossRef]

- Gorle, J.; Chatellier, L.; Pons, F.; Ba, M. Flow and performance analysis of H-Darrieus hydroturbine in a confined flow: A computational and experimental study. J. Fluids Struct. 2016, 66, 382–402. [Google Scholar] [CrossRef]

- Buchner, A.J.; Honnery, D.; Soria, J. Stability and three-dimensional evolution of a transitional dynamic stall vortex. J. Fluid Mech. 2017, 823, 166–197. [Google Scholar] [CrossRef]

- Buchner, A.J.; Soria, J.; Honnery, D.; Smits, A. Dynamic stall in vertical axis wind turbines: Scaling and topological considerations. J. Fluid Mech. 2018, 841, 746–766. [Google Scholar] [CrossRef]

- Miller, M.; Duvvuri, S.; Brownstein, I.; Lee, M.; Dabiri, J.; Hultmark, M. Vertical-axis wind turbine experiments at full dynamic similarity. J. Fluid Mech. 2018, 844, 707–720. [Google Scholar] [CrossRef]

- Benton, S.; Visbal, M. The onset of dynamic stall at a high, transitional Reynolds number. J. Fluid Mech. 2019, 861, 860–885. [Google Scholar] [CrossRef]

- Müller-Vahl, H.; Strangfeld, C.; Nayeri, C.; Paschereit, C.; Greenblatt, D. Control of thick airfoil, deep dynamic stall using steady blowing. AIAA J. 2014, 53, 277–295. [Google Scholar] [CrossRef]

- Müller-Vahl, H.; Nayeri, C.; Paschereit, C.; Greenblatt, D. Dynamic stall control via adaptive blowing. Renew. Energy 2016, 97, 47–64. [Google Scholar] [CrossRef]

- Lazauskas, L.; Kirke, B. Modelling passive variable pitch cross flow hydrokinetic turbines to maximize performance and smooth operation. Renew. Energy 2012, 45, 41–50. [Google Scholar] [CrossRef]

- Khalid, S.; Liang, Z.; Sheng, Q.H.; Zhang, X.W. Difference between Fixed and Variable Pitch Vertical Axis Tidal Turbine—Using CFD Analysis in CFX. Res. J. Appl. Sci. Eng. Technol. 2013, 5, 319–325. [Google Scholar]

- Mauri, M.; Bayati, I.; Belloli, M. Design and realisation of a high-performance active pitch-controlled H-Darrieus VAWT for urban installations. In Proceedings of the 3rd Renewable Power Generation Conference, Naples, Italy, 24–25 September 2014. [Google Scholar] [CrossRef]

- Abbaszadeh, S.; Hoerner, S.; Maître, T.; Leidhold, R. Experimental investigation of an optimised pitch control for a vertical-axis turbine. IET Renew. Power Gener. 2019, 13, 3106–3112. [Google Scholar] [CrossRef]

- Strom, B.; Brunton, S.; Polagye, B. Intracycle angular velocity control of cross-flow turbines. Nat. Energy 2016, 2, 1–9. [Google Scholar] [CrossRef]

- Fish, F. Power output and propulsive efficiency of swiming bottlenose dolphins (tursiops truncatus). J. Exp. Biol. 1993, 183, 179–193. [Google Scholar]

- Zeiner-Gundersen, D. A novel flexible foil vertical axis turbine for river, ocean and tidal applications. Appl. Energy 2015, 151, 60–66. [Google Scholar] [CrossRef]

- MacPhee, D.; Beyene, A. Fluid–structure interaction analysis of a morphing vertical axis wind turbine. J. Fluids Struct. 2016, 60, 143–159. [Google Scholar] [CrossRef]

- Hoerner, S.; Abbaszadeh, S.; Maître, T.; Cleynen, O.; Thévenin, D. Characteristics of the fluid—Structure interaction within Darrieus water turbines with highly flexible blades. J. Fluids Struct. 2019, 88C, 13–30. [Google Scholar] [CrossRef]

- Hoerner, S.; Bonamy, C.; Cleynen, O.; Maître, T.; Thévenin, D. Darrieus vertical-axis water turbines: Deformation and force measurements on bioinspired highly flexible blade profiles. Exp. Fluids 2020, 61. [Google Scholar] [CrossRef]

- Ly, K.; Chasteau, V. Experiments on an Oscillating Aerofoil and Applications to Wind-Energy Converters. J. Energy 1981, 5, 116–121. [Google Scholar] [CrossRef]

- Hoerner, S. Characterization of the Fluid–Structure Interaction on a Vertical Axis Turbine with Deformable Blades. Ph.D. Thesis, University Otto-von-Guericke, Magdeburg, Germany, 2020. [Google Scholar] [CrossRef]

- Augier, P.; Mohanan, V.; Bonamy, C. FluidDyn: A Python open-source framework for research and teaching in fluid dynamics by simulations, experiments and data processing. J. Open Res. Softw. 2019, 7. [Google Scholar] [CrossRef][Green Version]

- McCroskey, W.; Carr, L.; McAllister, K. Dynamic Stall Experiments on Oscillating Airfoils. AIAA J. 1976, 57–63. [Google Scholar] [CrossRef]

- Ducoin, A.; Astolfi, J.A.; Sigrist, J.F. An experimental analysis of fluid structure interaction on a flexible hydrofoil in various flow regimes including cavitating flow. Eur. J. Mech. B/Fluids 2012, 36, 63–74. [Google Scholar] [CrossRef]

- Ducoin, A.; Deniset, F.; Astolfi, J.A.; Sigrist, J.F. Computational and experimental investigation of flow over a transient pitching hydrofoil. Eur. J. Mech. 2009, 28, 728–743. [Google Scholar] [CrossRef]

- Hoerner, S.; Bonamy, C. Structured-light-based surface measuring for application in fluid—Structure interaction. Exp. Fluids 2019, 60, 168. [Google Scholar] [CrossRef]

- Wang, Z.; Bovik, A.C.; Sheikh, H.R.; Simoncelli, E.P. Image quality assessment: From error visibility to structural similarity. IEEE Trans. Image Process. 2004, 13, 600–612. [Google Scholar] [CrossRef]

| Spectra Physics Millenia | ||

|---|---|---|

| Wave length | [nm] | 532 |

| Type | continous NdYV04 | |

| Power | [W] | 2 (pro 2 SJ)/5 (pro 5 SJ) |

| Phantom | V2511 | ||||

|---|---|---|---|---|---|

| Resolution | [px] | 1280 × 800 | Pixel size | [m] | 28 |

| CMOS area | [mm] | 35.8 × 22.4 | Color depth | [bit] | 12 |

| Focus | [mm] | 105 | Acquisition rate | [fps] | 25,000 |

| Davis | Fluidimage | |||

|---|---|---|---|---|

| Denoise | counts | 1000 | threshold | counts > 85% |

| substraction | ||||

| Vector calculation | time-series | multi-pass | time-series | multi-step |

| Window size/Steps | 64 × 64 | 2 | 128 × 128 | 1 |

| Overlap | 0 | 50% | ||

| Smoothing | Gaussian weight | 1:1 | TPS | |

| Correction | standard | correl < 0.3 | ||

| Window size/Steps | 64 × 64 | 1 | ||

| Overlap | 50% | |||

| Smoothing | TPS | |||

| Correction | correl < 0.3 | |||

| Window size/Steps | 32 × 32 | 2 | 32 × 32 | 1 |

| Overlap | 50% | 50% | ||

| Smoothing | Gaussian weight | 1:1 | TPS | |

| Correction | standard | correl < 0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hoerner, S.; Kösters, I.; Vignal, L.; Cleynen, O.; Abbaszadeh, S.; Maître, T.; Thévenin, D. Cross-Flow Tidal Turbines with Highly Flexible Blades—Experimental Flow Field Investigations at Strong Fluid–Structure Interactions. Energies 2021, 14, 797. https://doi.org/10.3390/en14040797

Hoerner S, Kösters I, Vignal L, Cleynen O, Abbaszadeh S, Maître T, Thévenin D. Cross-Flow Tidal Turbines with Highly Flexible Blades—Experimental Flow Field Investigations at Strong Fluid–Structure Interactions. Energies. 2021; 14(4):797. https://doi.org/10.3390/en14040797

Chicago/Turabian StyleHoerner, Stefan, Iring Kösters, Laure Vignal, Olivier Cleynen, Shokoofeh Abbaszadeh, Thierry Maître, and Dominique Thévenin. 2021. "Cross-Flow Tidal Turbines with Highly Flexible Blades—Experimental Flow Field Investigations at Strong Fluid–Structure Interactions" Energies 14, no. 4: 797. https://doi.org/10.3390/en14040797

APA StyleHoerner, S., Kösters, I., Vignal, L., Cleynen, O., Abbaszadeh, S., Maître, T., & Thévenin, D. (2021). Cross-Flow Tidal Turbines with Highly Flexible Blades—Experimental Flow Field Investigations at Strong Fluid–Structure Interactions. Energies, 14(4), 797. https://doi.org/10.3390/en14040797