Efficiency Enhancement on Hybrid Power System Composed of Irreversible Solid Oxide Fuel Cell and Stirling Engine by Finite Time Thermodynamics

Abstract

1. Introduction

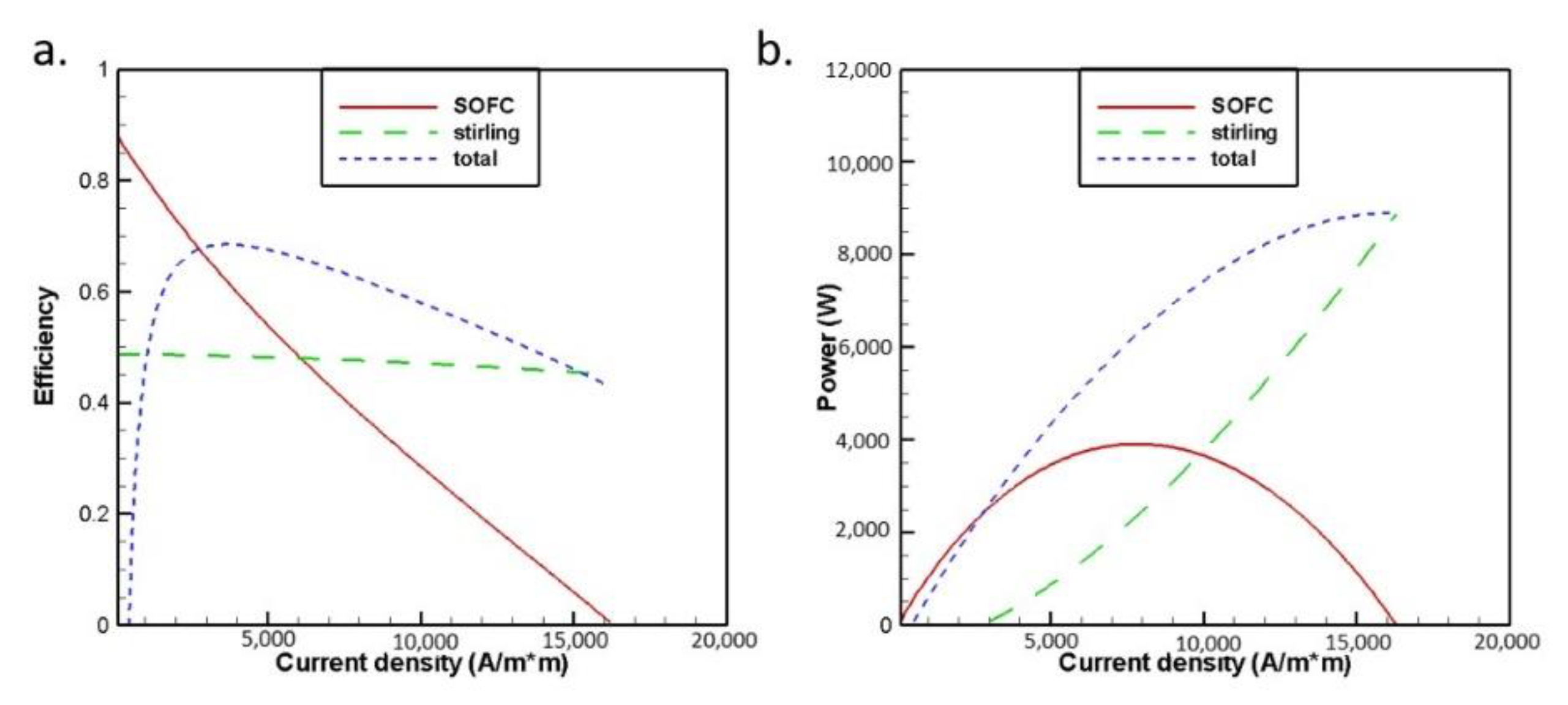

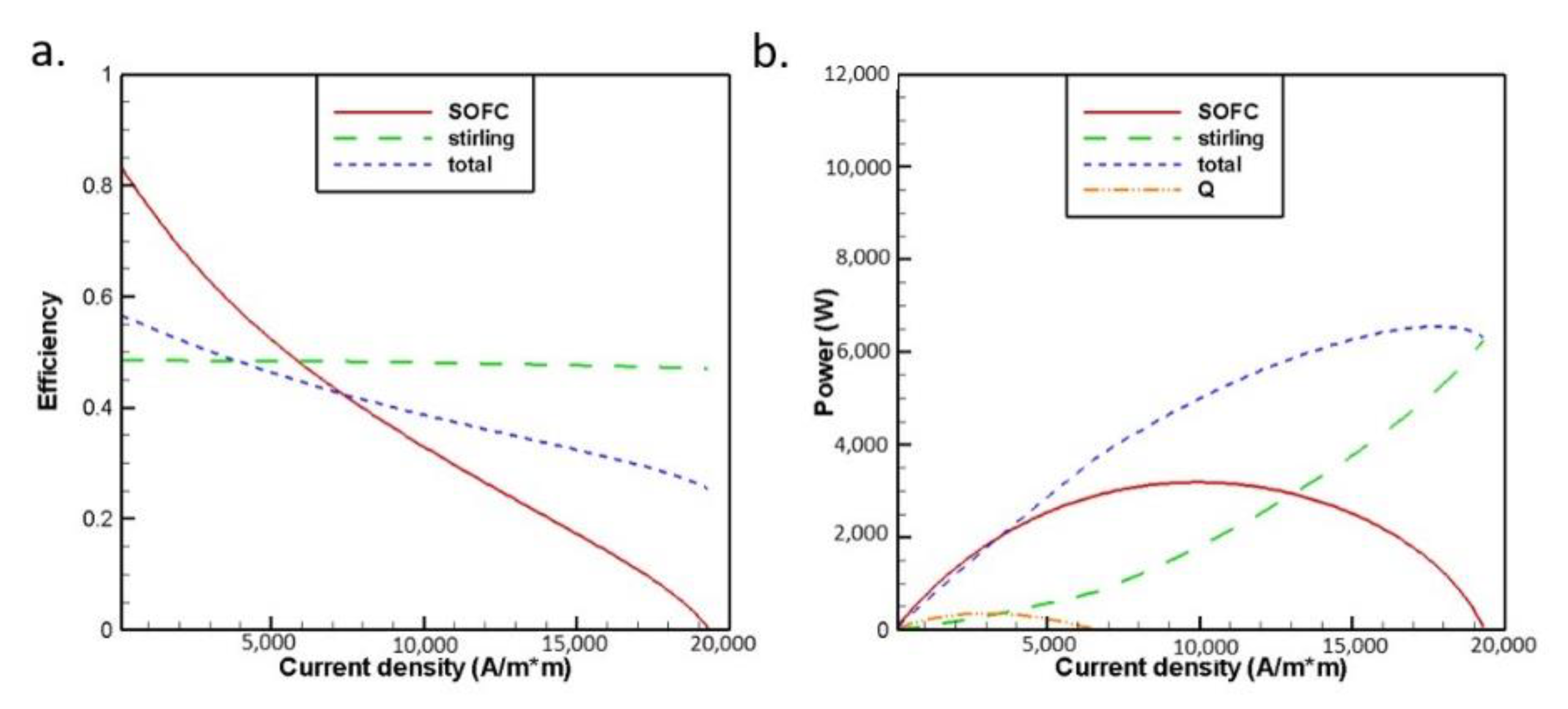

2. Modeling and Methods

2.1. Irreversibility of SOFC in Power Generation

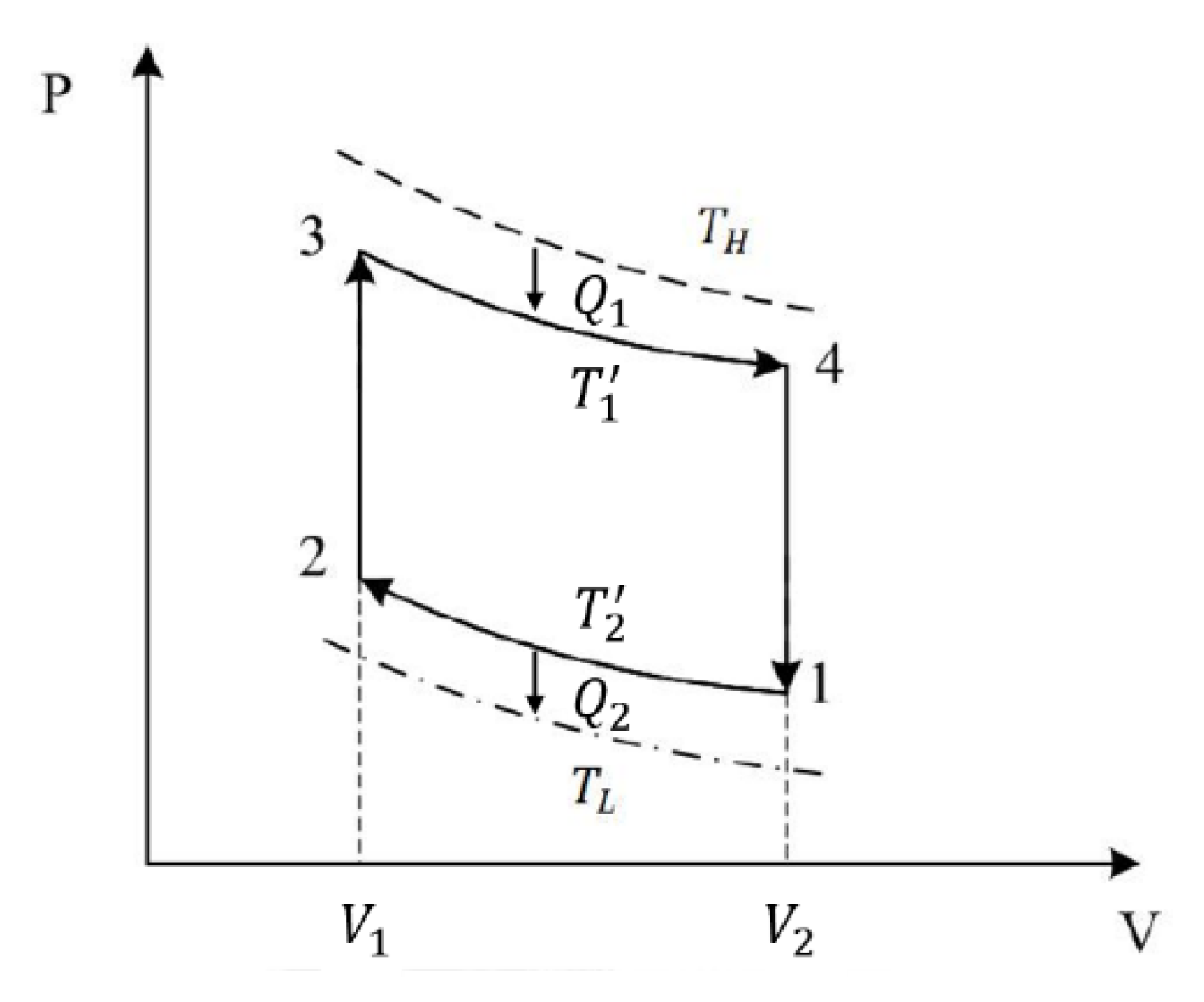

2.2. Power Generation and Efficiency of the Stirling Engine Using Finite-Time Thermodynamics

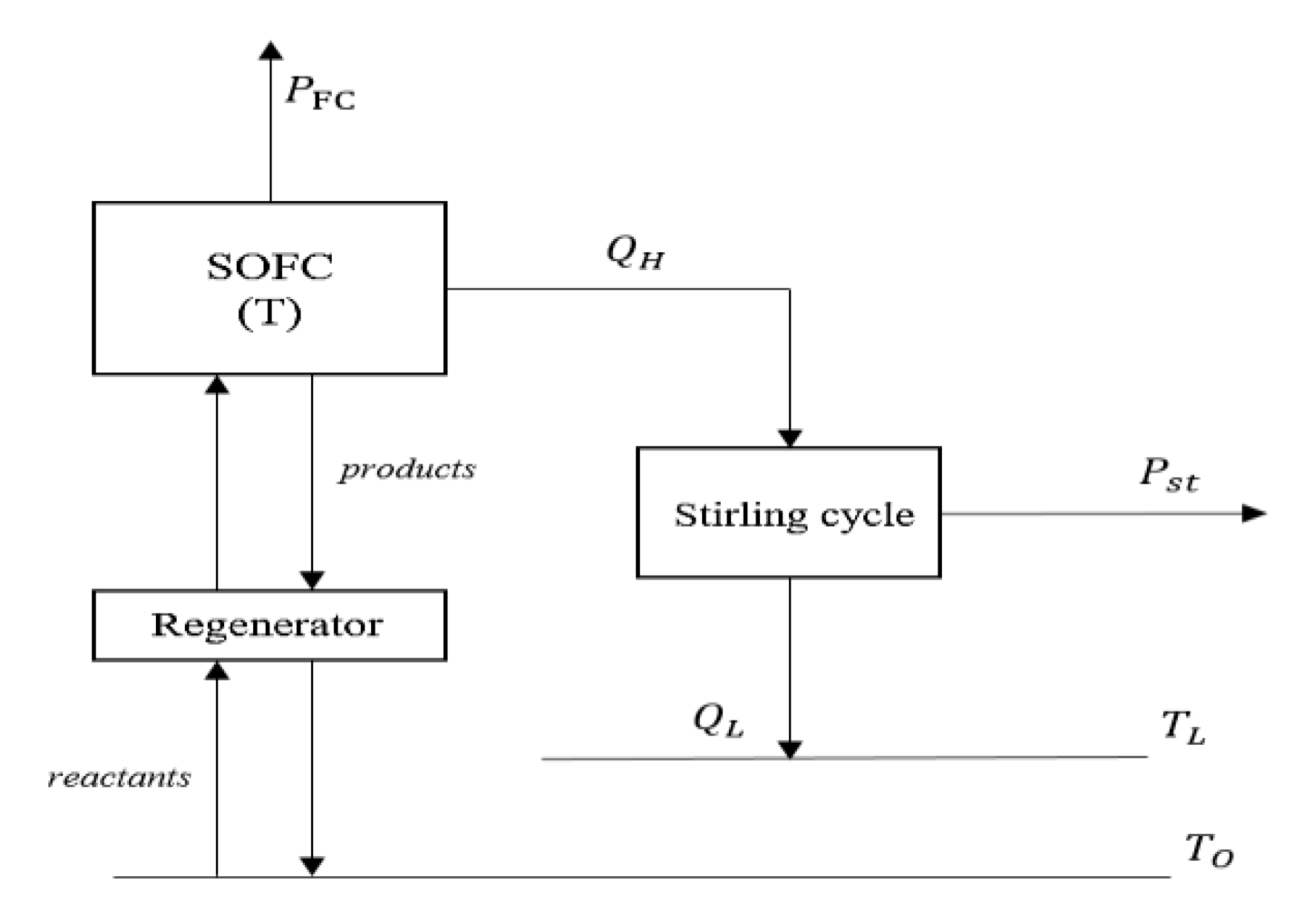

2.3. Power Generation and Efficiency of Hybrid SOFC-SE System

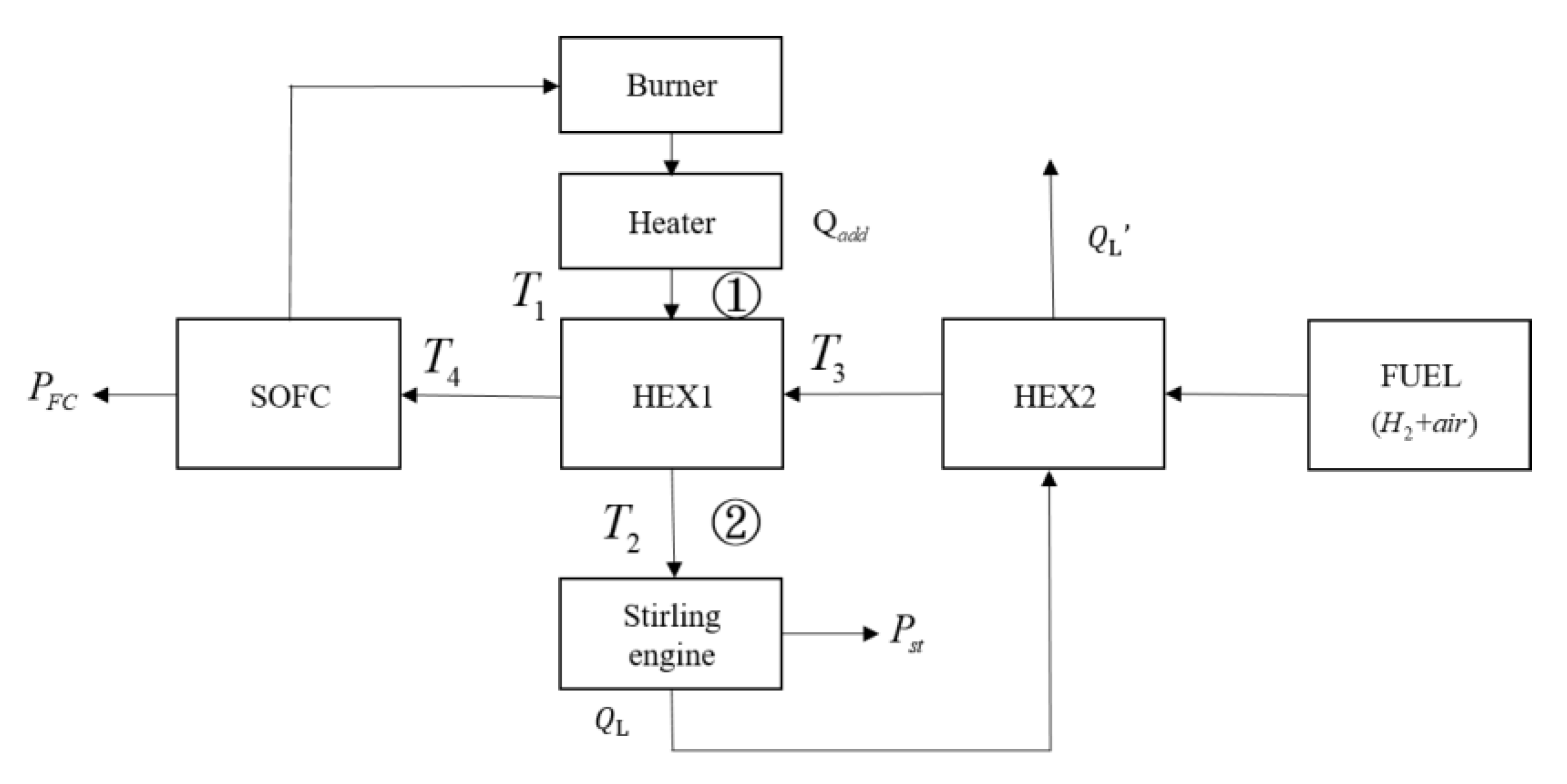

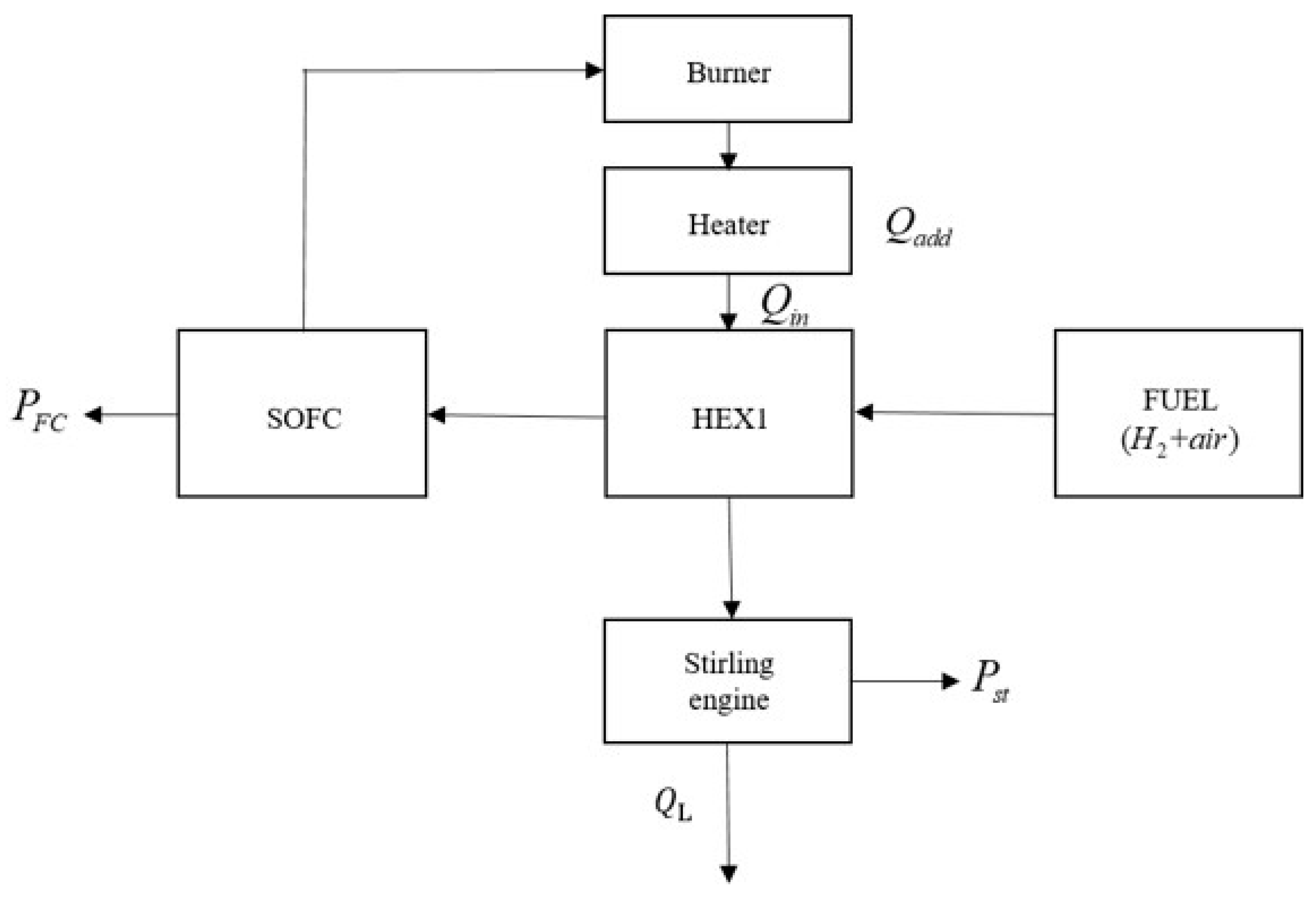

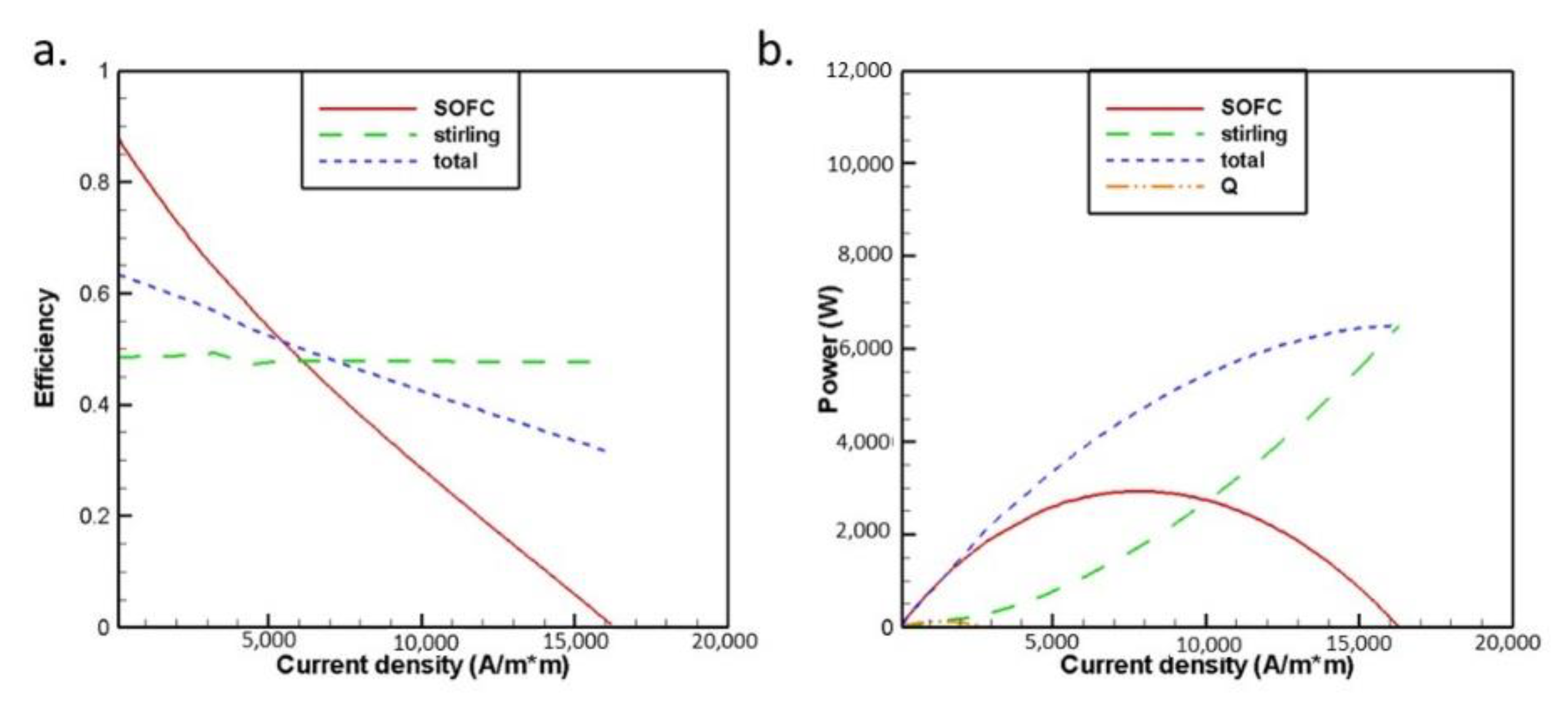

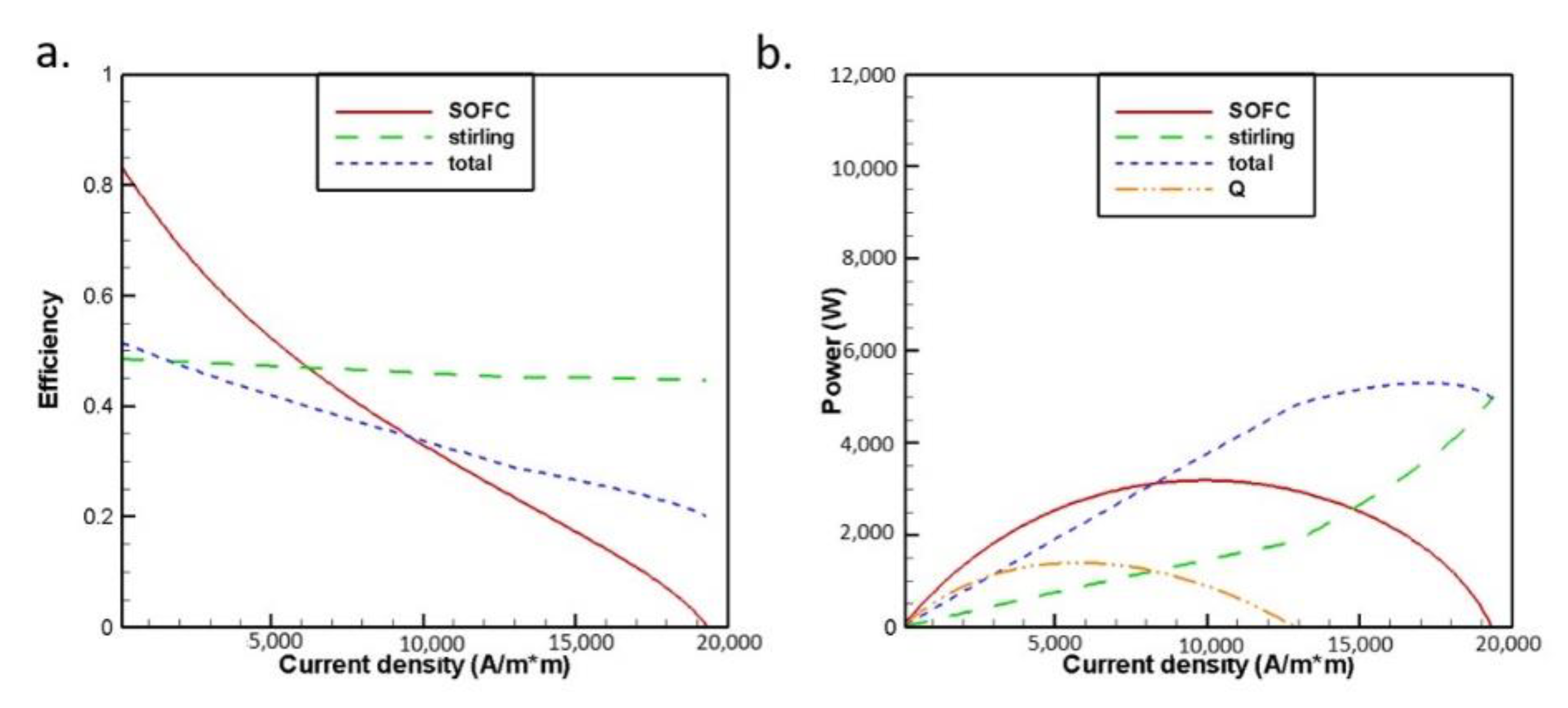

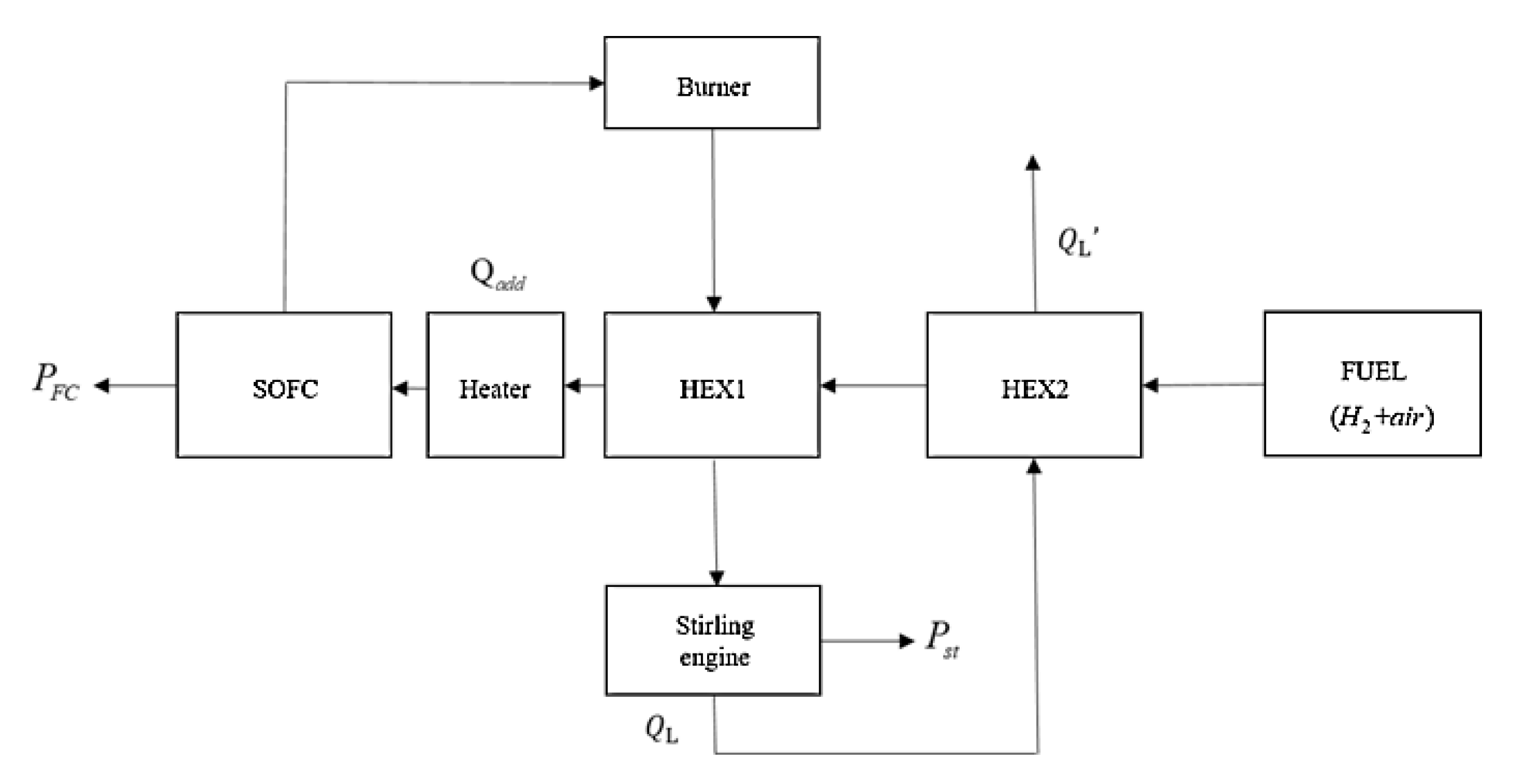

2.4. Operation Parameters and Loops of the Hybrid SOFC-SE

- All system components are operated in a steady state.

- All gas used in the system is assumed ideal.

- To estimate temperature differences among various components in the whole system, the input or output temperature of the SOFC stack is assumed constant.

- The type of cell used is electrolyte-supported, and the materials for the anode, electrolyte, and cathode are Ni-YSZ (Yttria-stabilized zirconia,), YSZ, and LSM (Strontium substituted Lanthanum Manganite).

- Radiant heat transfer is not considered in this study.

- All fuel is assumed fully consumed in the burner.

3. Results and Discussion

4. Conclusions

- The results presented in this study are based on finite-time thermodynamics, capable of characterizing not only system irreversibility but also the realistic performance of various hybrid systems.

- The results of this study reveal that the optimal design of a system configuration is very essential in building a highly efficient SOFC hybrid system. Based on the simulation results, the system efficiency is raised from 63.41% to 67.67% at 873 K using a double heat-exchanger to recycle the exhaust gas.

- The results of this research also reveal the fact that system working temperature is essential to the efficiency of the hybrid SOFC power system. As presented in Table 2 and Table 3, with the increase of system operating temperature from 873 K to 1173 K, the efficiency of the hybrid SOFC-SE system is decreased from 67.67% to 56.56%. That is because that greater input heat source can raise the operating temperature, but not necessarily the overall system efficiency. Therefore, the decrease of operating temperature to maintain a higher system efficiency becomes an essential consideration in the design of hybrid system looping configurations, especially for a hybrid SOFC power system.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Singhal, S. Advances in tubular solid oxide fuel cell technology. Adv. Tubul. Solid Oxide Fuel Cell Technol. 1996, 135, 305–313. [Google Scholar] [CrossRef][Green Version]

- Patel, H.C.; Woudstra, T.; Aravind, P.V. Thermodynamic Analysis of Solid Oxide Fuel Cell Gas Turbine Systems Operating with Various Biofuels. Fuel Cell 2012, 12, 1115–1128. [Google Scholar] [CrossRef]

- Chan, S.; Ho, H.; Tian, Y. Modelling of simple hybrid solid oxide fuel cell and gas turbine power plant. J. Power Sources 2002, 109, 111–120. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Ando, Y.; Kabata, T.; Nishiura, M.; Tomida, K.; Matake, N. Extremely High-efficiency Thermal Power Sys-tem-Solid Oxide Fuel Cell (SOFC) Triple Combined-cycle System. Mitsubishi Heavy Ind. Tech. Rev. 2011, 48, 9–15. [Google Scholar]

- Zhang, X.; Chen, J. Performance analysis and parametric optimum criteria of a class of irreversible fuel cell/heat engine hybrid systems. Int. J. Hydrog. Energy 2010, 35, 284–293. [Google Scholar] [CrossRef]

- Al-Sulaiman, F.A.; Dincer, I.; Hamdullahpour, F. Energy analysis of an integrated solid oxide fuel cell and organic Rankine cycle for cooling, heating and power production. J. Power Sources 2010, 195, 2346–2354. [Google Scholar] [CrossRef]

- Qin, J.; Zhou, W.; Bao, W.; Yu, D. Thermodynamic analysis and parametric study of a closed Brayton cycle thermal manage-ment system for scramjet. Int. J. Hydrog. Energy 2010, 35, 356–364. [Google Scholar] [CrossRef]

- Sánchez, D.; Chacartegui, R.; Torres, M. Stirling based fuel cell hybrid systems: An alternative for molten carbonate fuel cells. J. Power Sources 2009, 192, 84–93. [Google Scholar] [CrossRef]

- Wu, F.; Chen, L.; Wu, C.; Sun, F. Optimum performance of irreversible stirling engine with imperfect regeneration. Energy Convers. Manag. 1998, 39, 727–732. [Google Scholar] [CrossRef]

- Costea, M.; Feidt, M. The effect of the overall heat transfer coefficient variation on the optimal distribution of the heat trans-fer surface conductance or area in a Stirling engine. Energy Convers. Manag. 1998, 39, 1753–1761. [Google Scholar] [CrossRef]

- Chen, J.; Yan, Z.; Chen, L.; Andresen, B. Efficiency bound of a solar-driven stirling heat engine system. Int. J. Energy Res. 1998, 22, 805–812. [Google Scholar] [CrossRef]

- Durmayaz, A.; Sogut, O.S.; Sahin, B.; Yavuz, H. Optimization of thermal systems based on finite-time thermodynamics and ther-mos economics. Prog. Energy Combust. Sci. 2004, 135, 305–313. [Google Scholar]

- Kongtragool, B.; Wongwises, S. Optimum absorber temperature of a once-reflecting full conical concentrator of a low-temperature differential Stirling engines. Renew. Energy 2005, 30, 1671–1687. [Google Scholar] [CrossRef]

- Yilmaz, T.; Ust, Y.; Erdil, A. Optimum operating conditions of irreversible solar driven heat engines. Renew. Energy 2006, 31, 1333–1342. [Google Scholar] [CrossRef]

- Li, Y.Q.; He, Y.L.; Wang, W.W. Optimization of solar-powered Stirling heat engine with finite-time thermodynamics. Renew. Energy 2011, 36, 421–427. [Google Scholar]

- Carnot, S. Reflections on the Motive Power of Fire; Bachelier: Paris, France, 1824. [Google Scholar]

- Novikov, I. The efficiency of atomic power stations (a review). J. Nucl. Energy 1954 1958, 7, 125–128. [Google Scholar] [CrossRef]

- Chambadal, P. Les Centrales Nucleaires; Armand Colin: Paris, France, 1957; pp. 41–58. [Google Scholar]

- Curzon, F.L.; Ahlborn, B. Efficiency of a Carnot engine at maximum power output. Am. J. Phys. 1975, 43, 22–24. [Google Scholar] [CrossRef]

- Açıkkalp, E. Thermo-environmental performance analysis of irreversible solid oxide fuel cell–Stirling heat engine. Int. J. Ambient Energy 2017, 39, 751–758. [Google Scholar] [CrossRef]

- Hosseinpour, J.V.; Sadeghi, M.S.; Chitsaz, A.T.; Ranjbar, F.R.M.; Rosen, M.C.A. Exergy assessment and optimization of a co-generation system based on a solid oxide fuel cell integrated with a Stirling engine. Energy Convers. Manag. 2017, 143, 448–458. [Google Scholar] [CrossRef]

- Yuan, D. Reply to Comment on: The Analytical Method of Finite Time Thermodynamics about the Physical and the Chemical Performances of the Full Cell. Chin. J. Chem. Phys. 2001, 14, 381. [Google Scholar]

- Frank, K.; Manglik, R.M.; Bohn, M.S. Principles of Heat Transfer; Cengage Learning: Stamford, CT, USA, 2012. [Google Scholar]

- Chen, X.; Pan, Y.; Chen, J. Performance and Evaluation of a Fuel Cell-Thermoelectric Generator Hybrid System. Fuel Cells 2010, 10, 1164–1170. [Google Scholar] [CrossRef]

| Parameters | Volume |

|---|---|

| SOFC reaction area, () | 1 |

| SOFC output gas temperature, () | 873; 1173 |

| Temperature drop between input and output gas in the SOFC stack, () | 110 |

| Ambient temperature, () | 300 |

| Number of electrons transferred, | 2 |

| Partial pressure of hydrogen and water, (atm); (atm) | 0.97; 0.03 |

| Partial pressure of oxygen and nitrogen, (atm); (atm) | 0.21; 0.79 |

| Anode and cathode exchange current density for SOFC in 873 K and 1173 K, () | ; ; ; |

| Electrolyte thickness, () | 20 |

| Activation energy of , () | |

| The factor of activation energy for , () | |

| Anode and cathode limiting current density for SOFC at 873 K and 1173 K, () | ; ; |

| Faraday constant, () | |

| Ideal gas constant, () | 8.314 |

| Enthalpy at 873 K and 1173 K, () | −247,172, 248,921 |

| Gibbs energy at 873 K and 1173 K, () | −199,762, 183,100 |

| Efficiency of the heater, | 0.95 |

| Heat capacity for air, () | 1.006@ 1073 [23] |

| Heat capacity for hydrogen, () | 15.09@ 1073 K [23] |

| Gas volume ratio between air and hydrogen, : | 5:1 |

| Molar mass of air, () | 28.97 |

| Molar mass of hydrogen, () | 2.016 |

| SOFC-SE Hybrid Systems with Different Design Configurations | Efficiency Drop (%) as Compared to That of the System Given in Emin [20] | ||

|---|---|---|---|

| SOFC+SE+R [20] | 68.52 | 8891 | - |

| SOFC+B+H+HEX1+SE | 63.41 | 6505 | 7.46 |

| SOFC+B+HEX1+H+SE+HEX2 | 67.67 | 7248 | 0.80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, H.-Y.; Li, Y.-T.; Chan, Y.-H. Efficiency Enhancement on Hybrid Power System Composed of Irreversible Solid Oxide Fuel Cell and Stirling Engine by Finite Time Thermodynamics. Energies 2021, 14, 1037. https://doi.org/10.3390/en14041037

Lai H-Y, Li Y-T, Chan Y-H. Efficiency Enhancement on Hybrid Power System Composed of Irreversible Solid Oxide Fuel Cell and Stirling Engine by Finite Time Thermodynamics. Energies. 2021; 14(4):1037. https://doi.org/10.3390/en14041037

Chicago/Turabian StyleLai, Hsin-Yi, Yi-Ting Li, and Yen-Hsin Chan. 2021. "Efficiency Enhancement on Hybrid Power System Composed of Irreversible Solid Oxide Fuel Cell and Stirling Engine by Finite Time Thermodynamics" Energies 14, no. 4: 1037. https://doi.org/10.3390/en14041037

APA StyleLai, H.-Y., Li, Y.-T., & Chan, Y.-H. (2021). Efficiency Enhancement on Hybrid Power System Composed of Irreversible Solid Oxide Fuel Cell and Stirling Engine by Finite Time Thermodynamics. Energies, 14(4), 1037. https://doi.org/10.3390/en14041037