Machine-Learning-Based Condition Assessment of Gas Turbines—A Review

Abstract

:1. Introduction

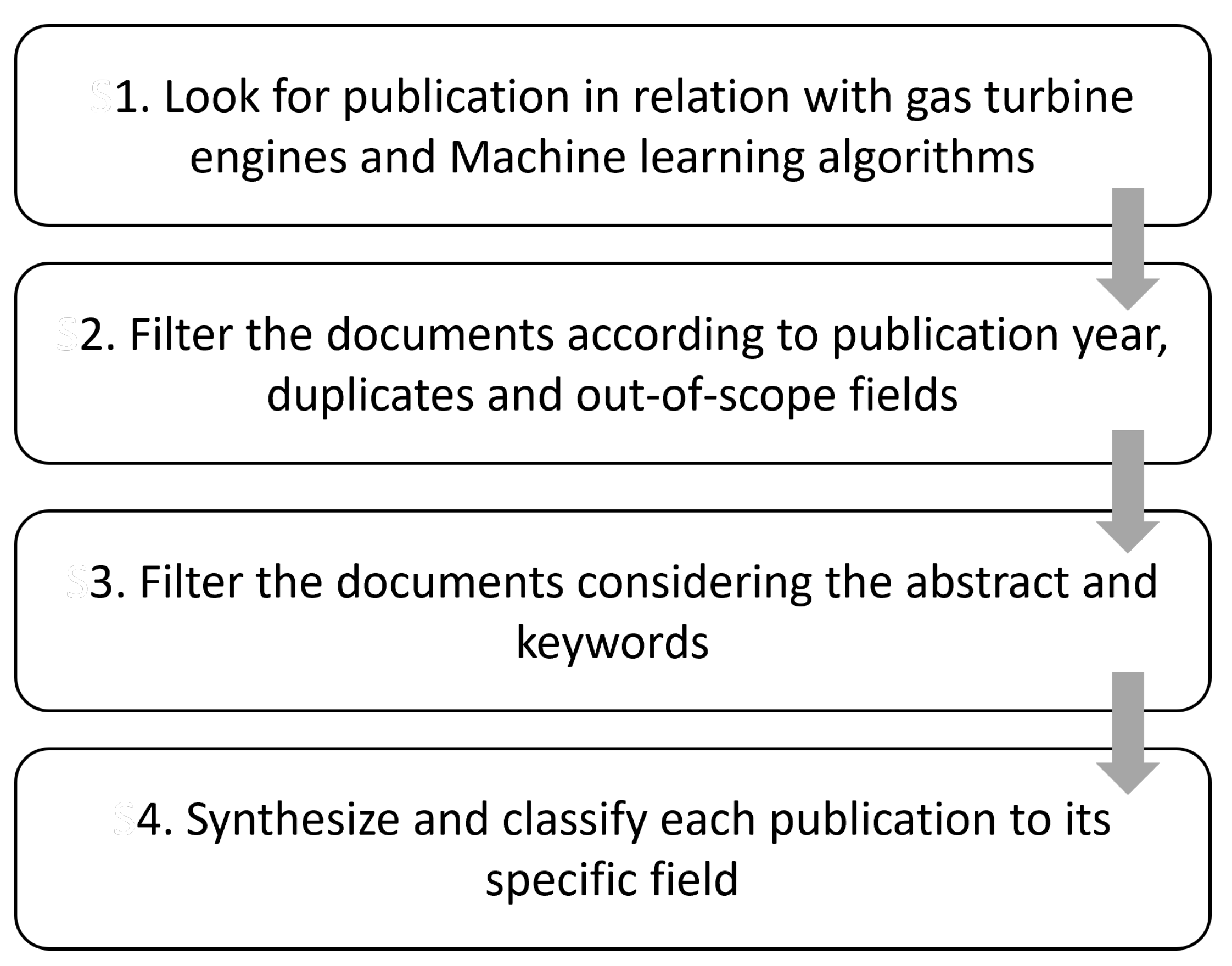

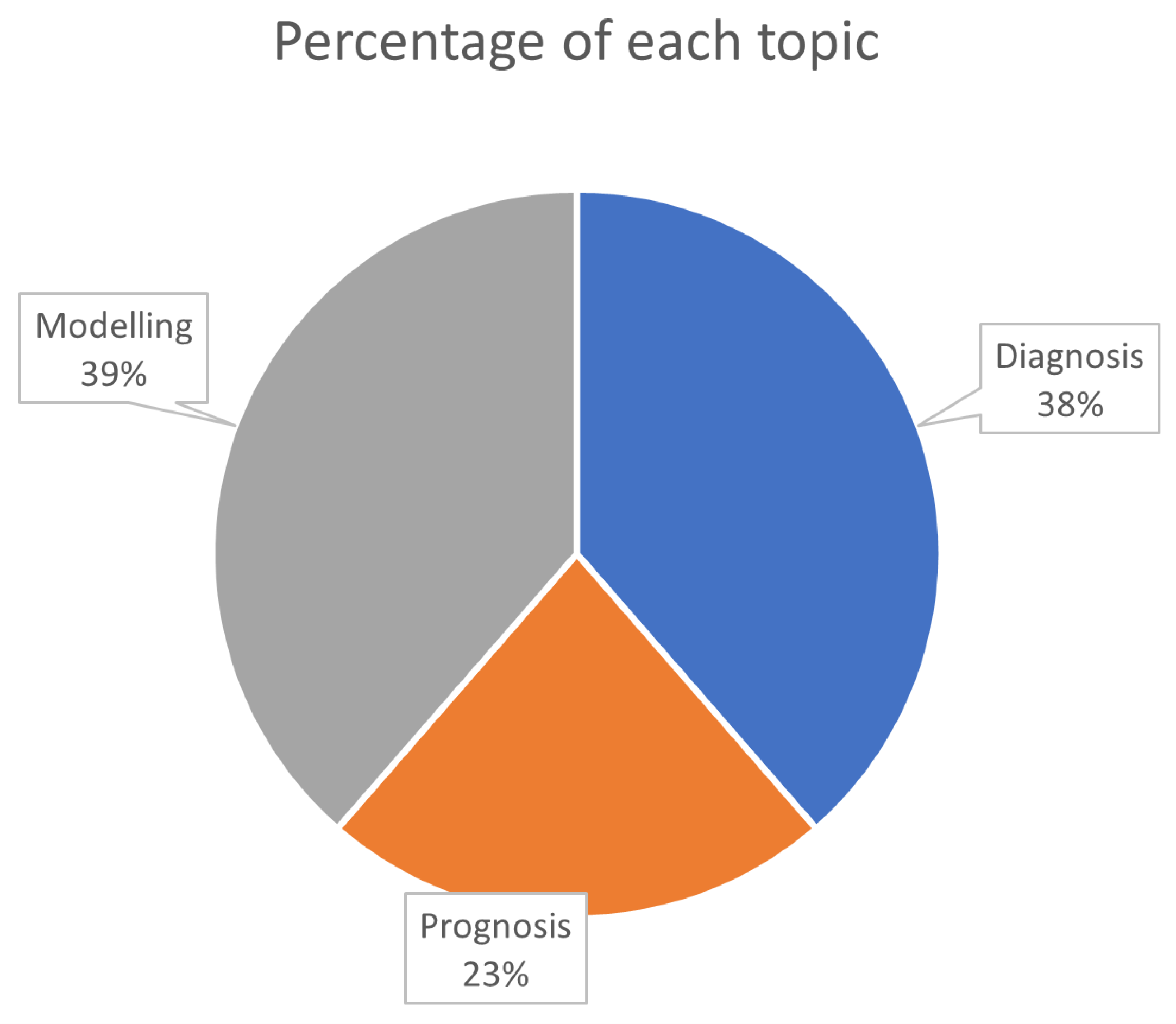

2. Methodology of Review

- Only machine-learning-based algorithms were accepted. The definition of machine-learning techniques is described in Section 1. Hybrid methodologies that included model-based algorithms were also excluded;

- Documents that were related to the simulation of gas turbines, as well as their design were also excluded;

- Publications devoted to enhancing the standard control systems of gas turbines using machine-learning techniques were also not accepted.

3. Background

3.1. Gas Turbines

3.2. Maintenance

3.3. Machine Learning

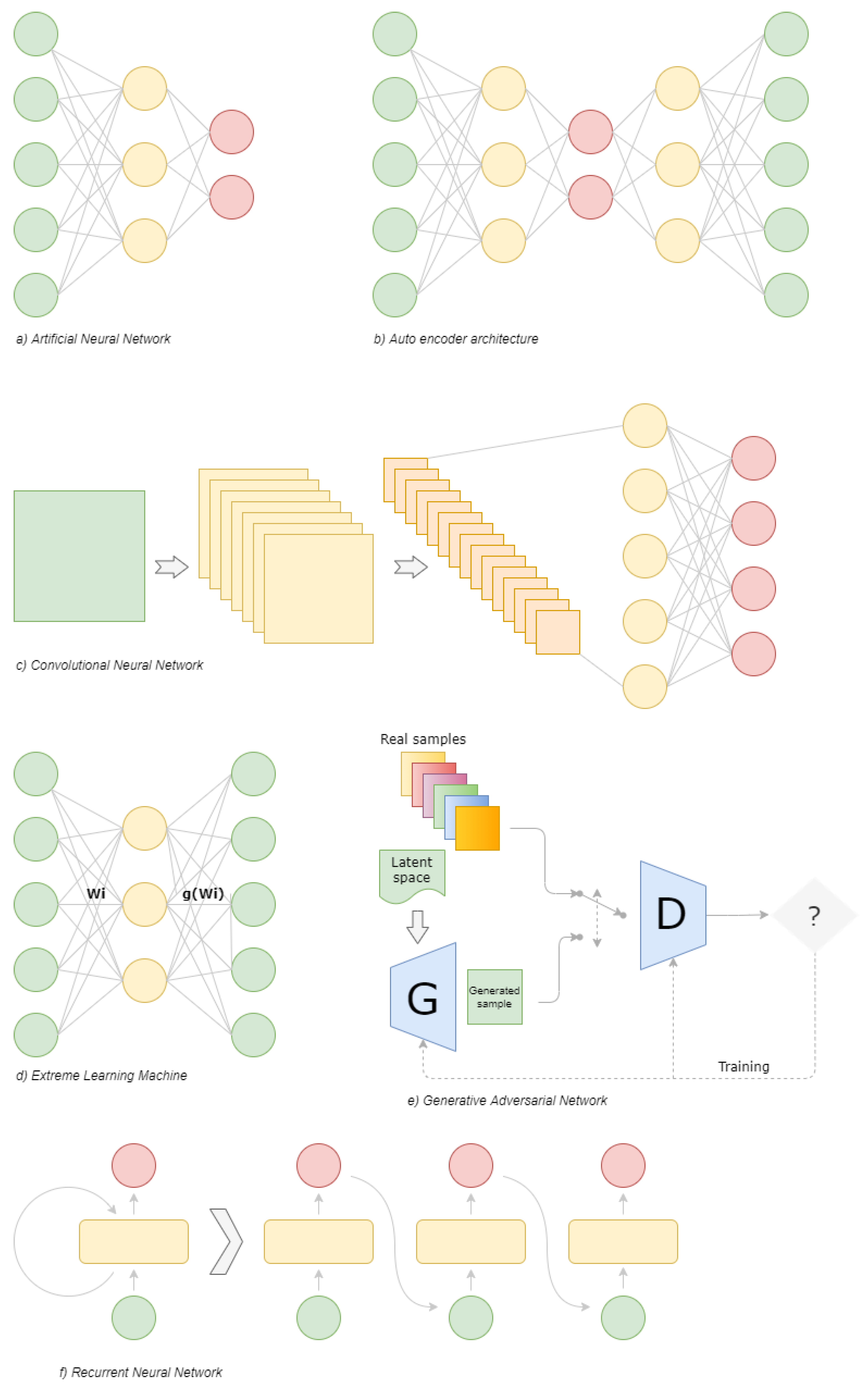

3.3.1. Artificial Neural Networks

Auto-Encoder

Convolutional Neural Network

Extreme Learning Machine

Generative Adversarial Network

Recurrent Neural Networks

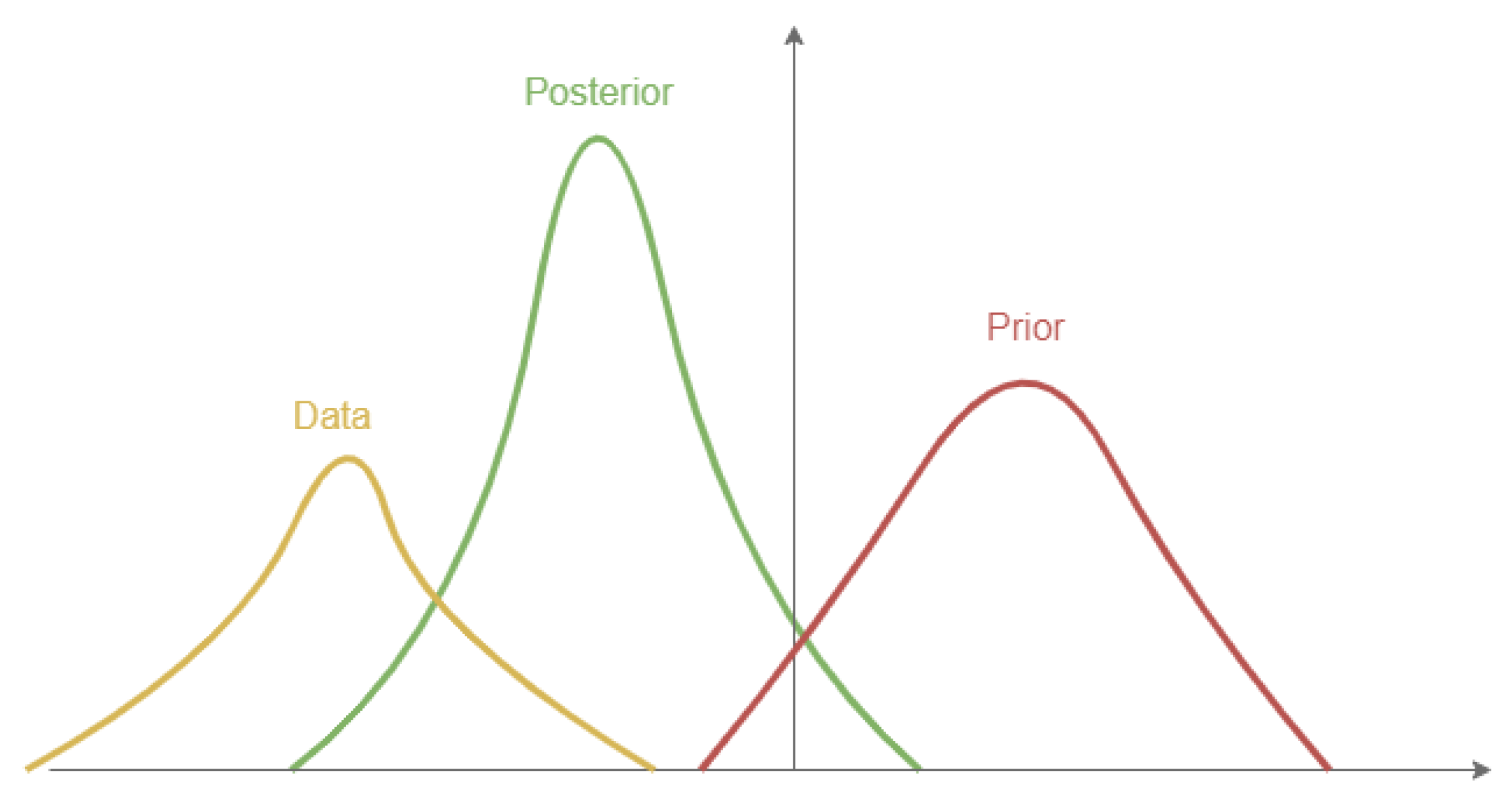

3.3.2. Bayesian Model

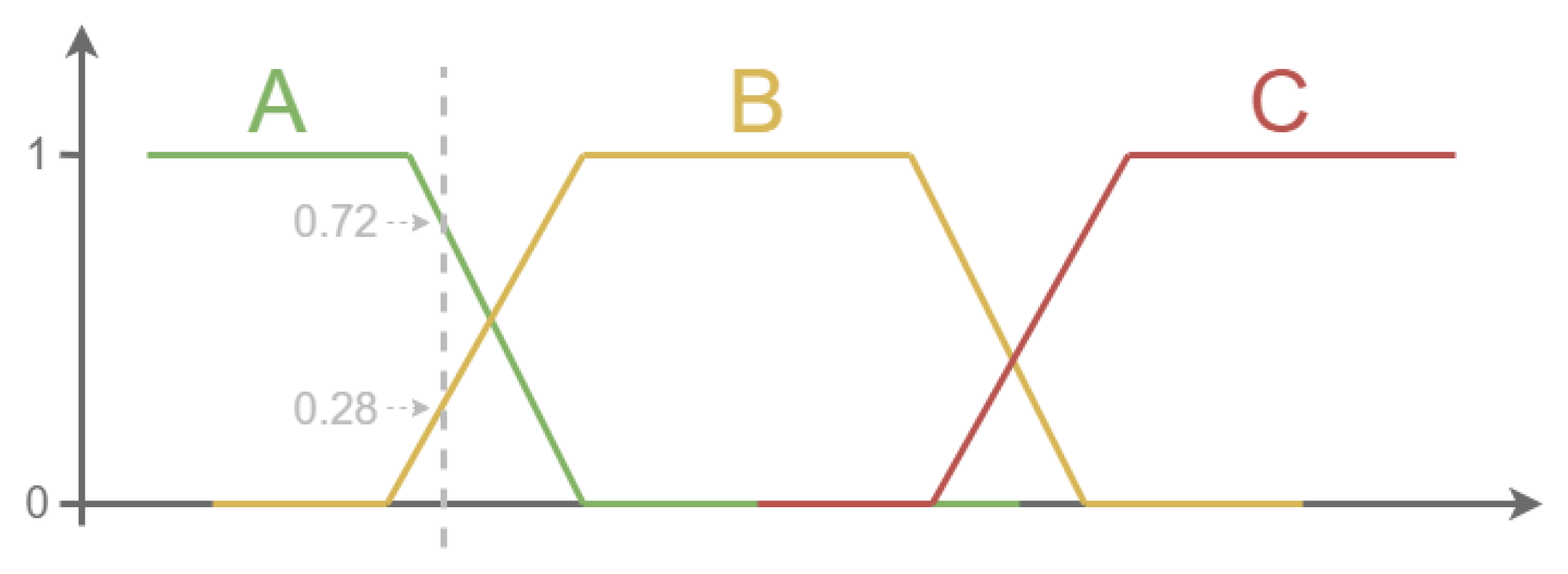

3.3.3. Fuzzy Logic

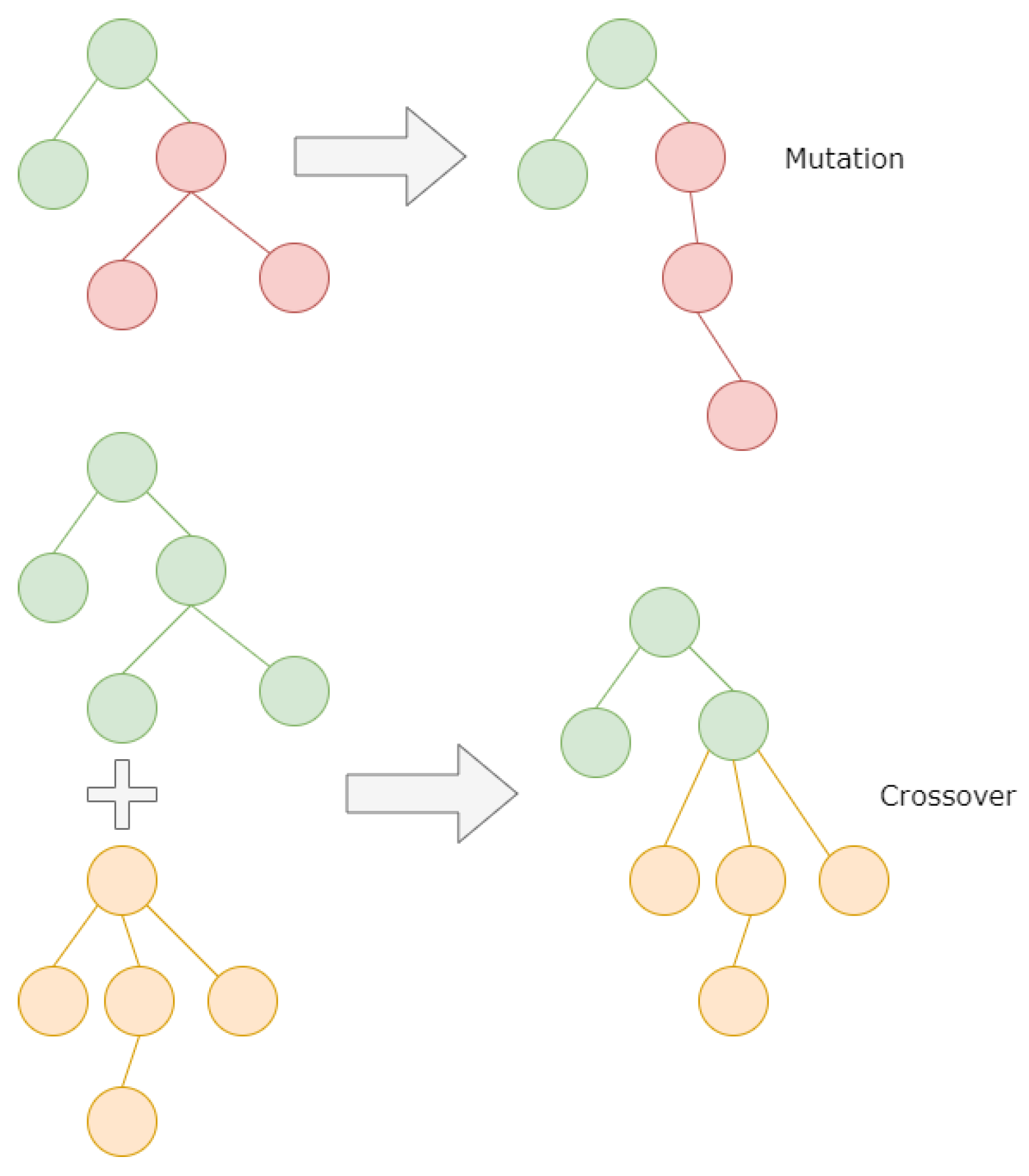

3.3.4. Genetic Programming

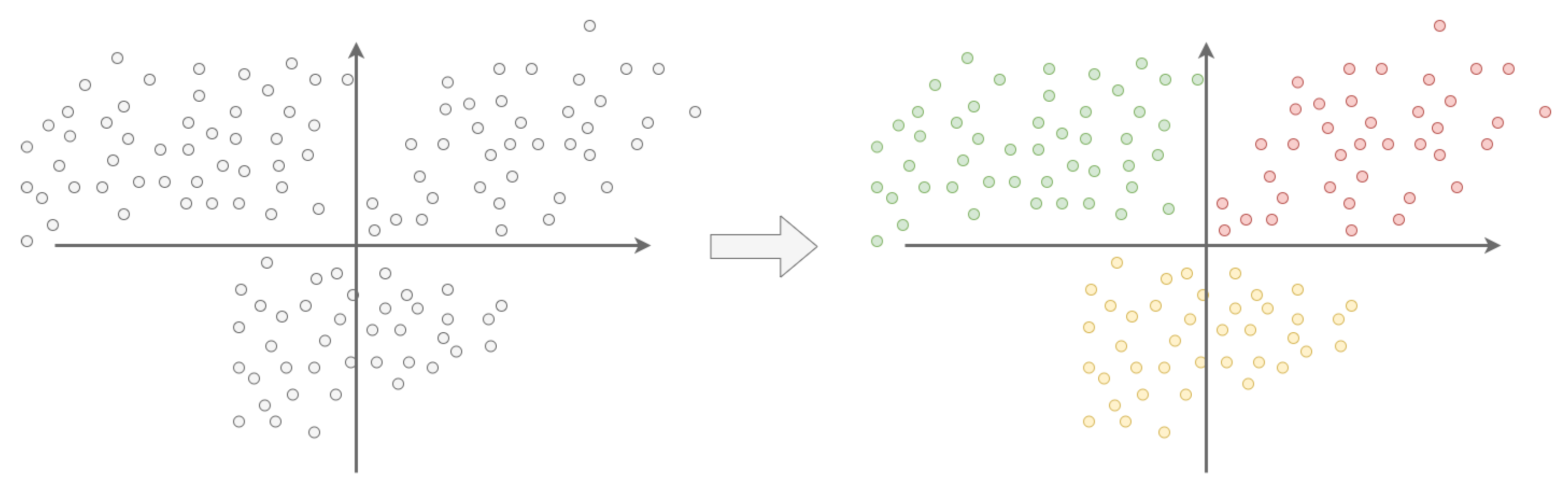

3.3.5. Clustering

3.3.6. Linear and Nonlinear Regression Models

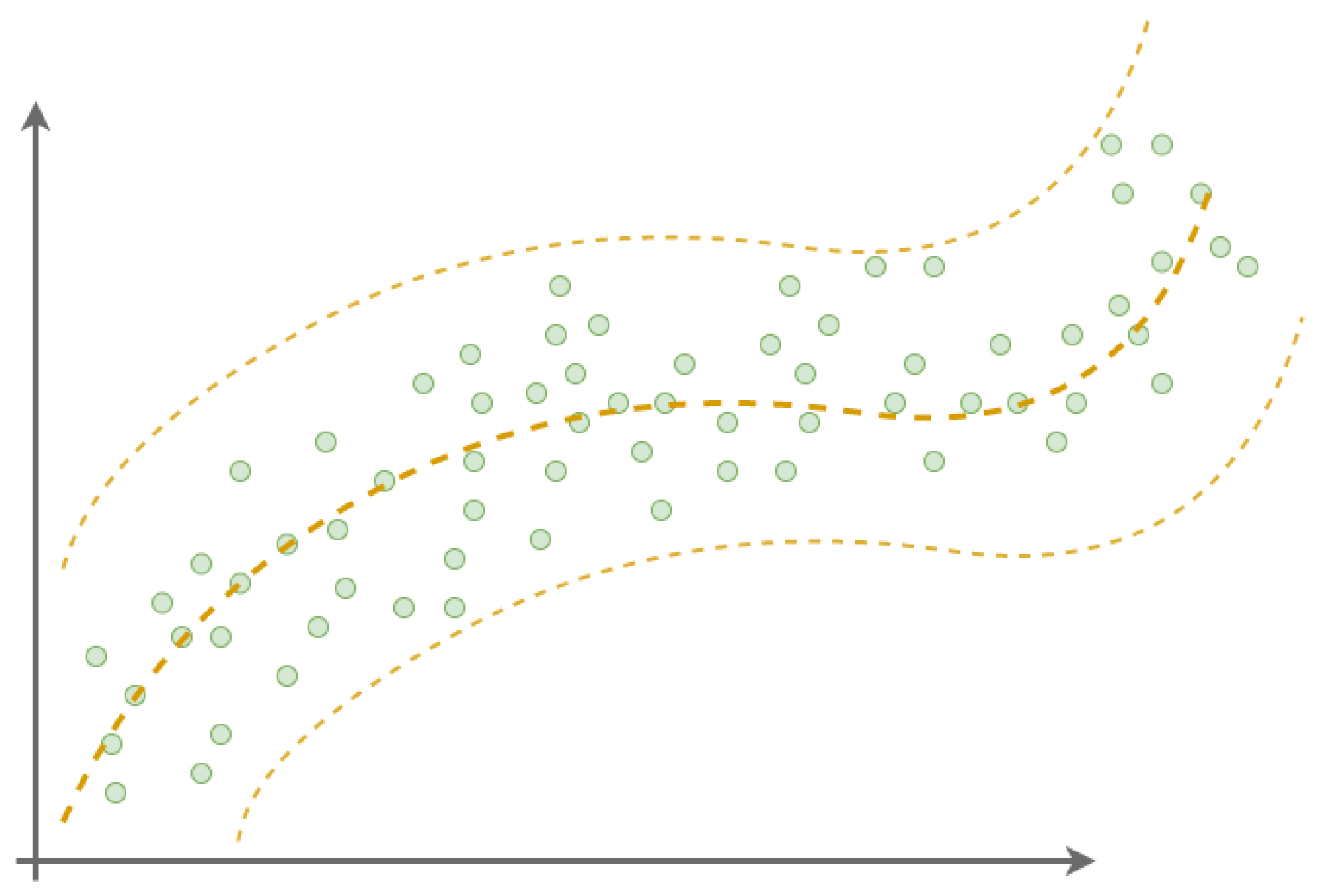

Linear Regression

Nonlinear Regression

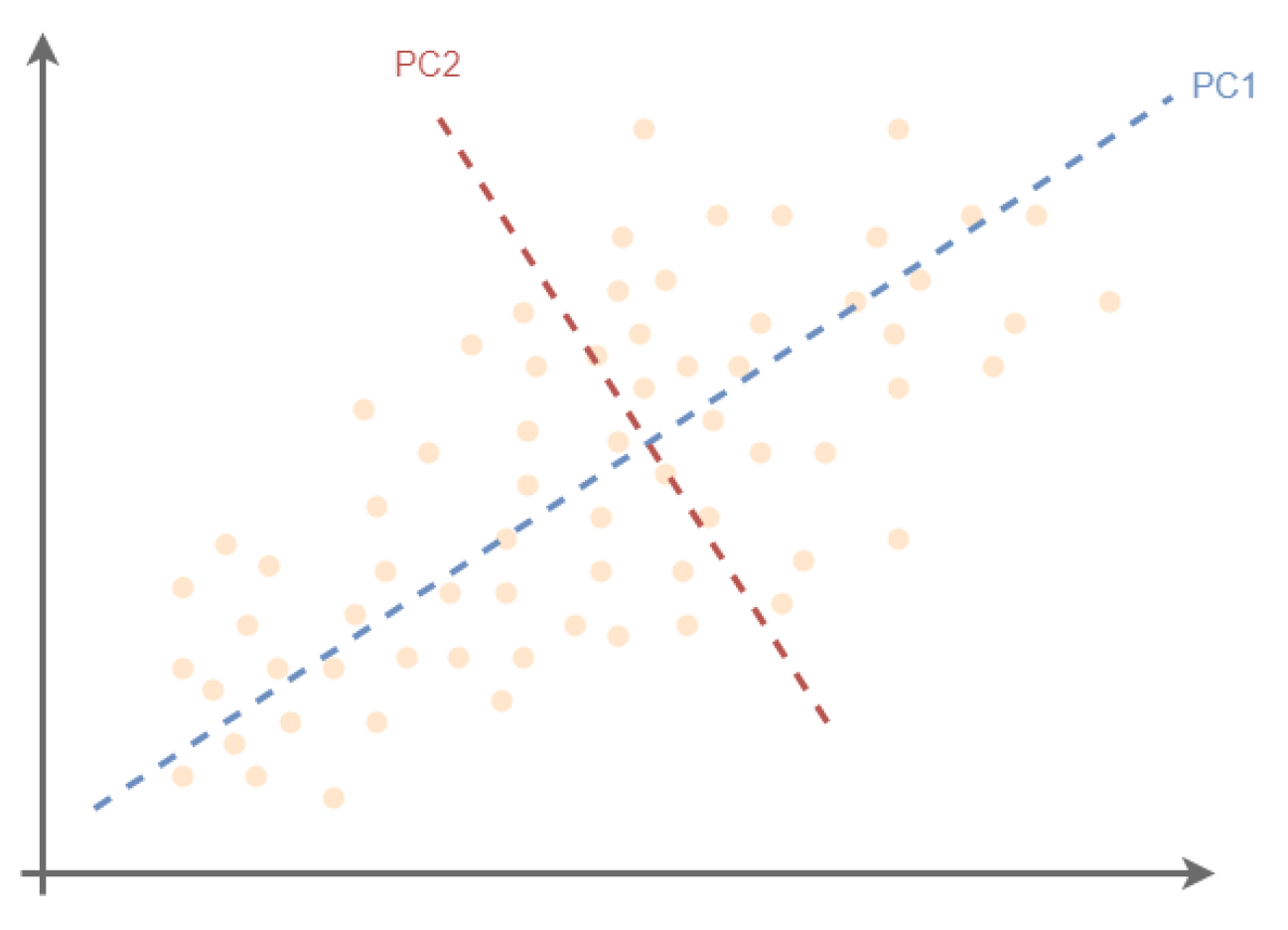

3.3.7. Principal Component Analysis

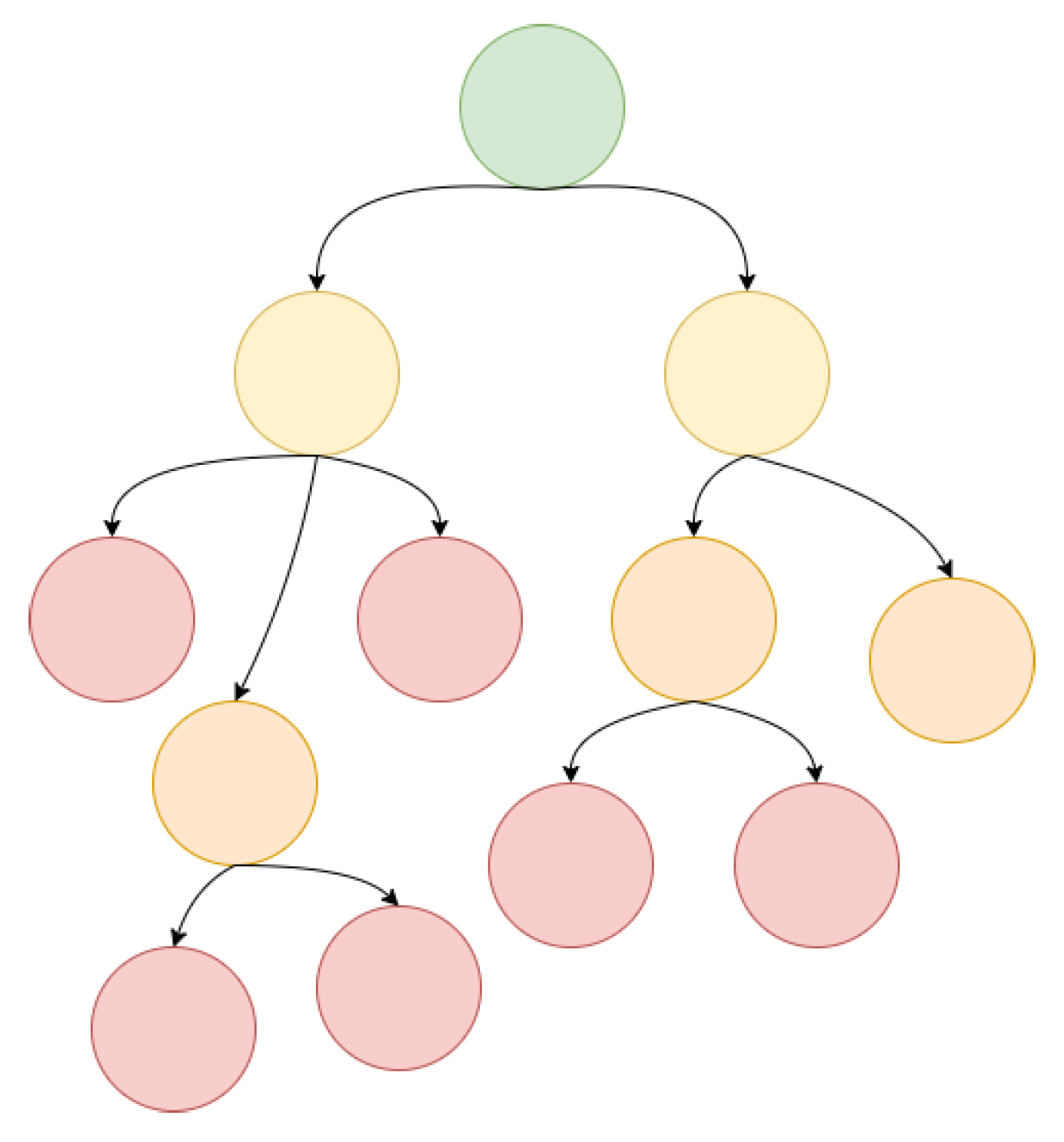

3.3.8. Decision Tree Algorithm

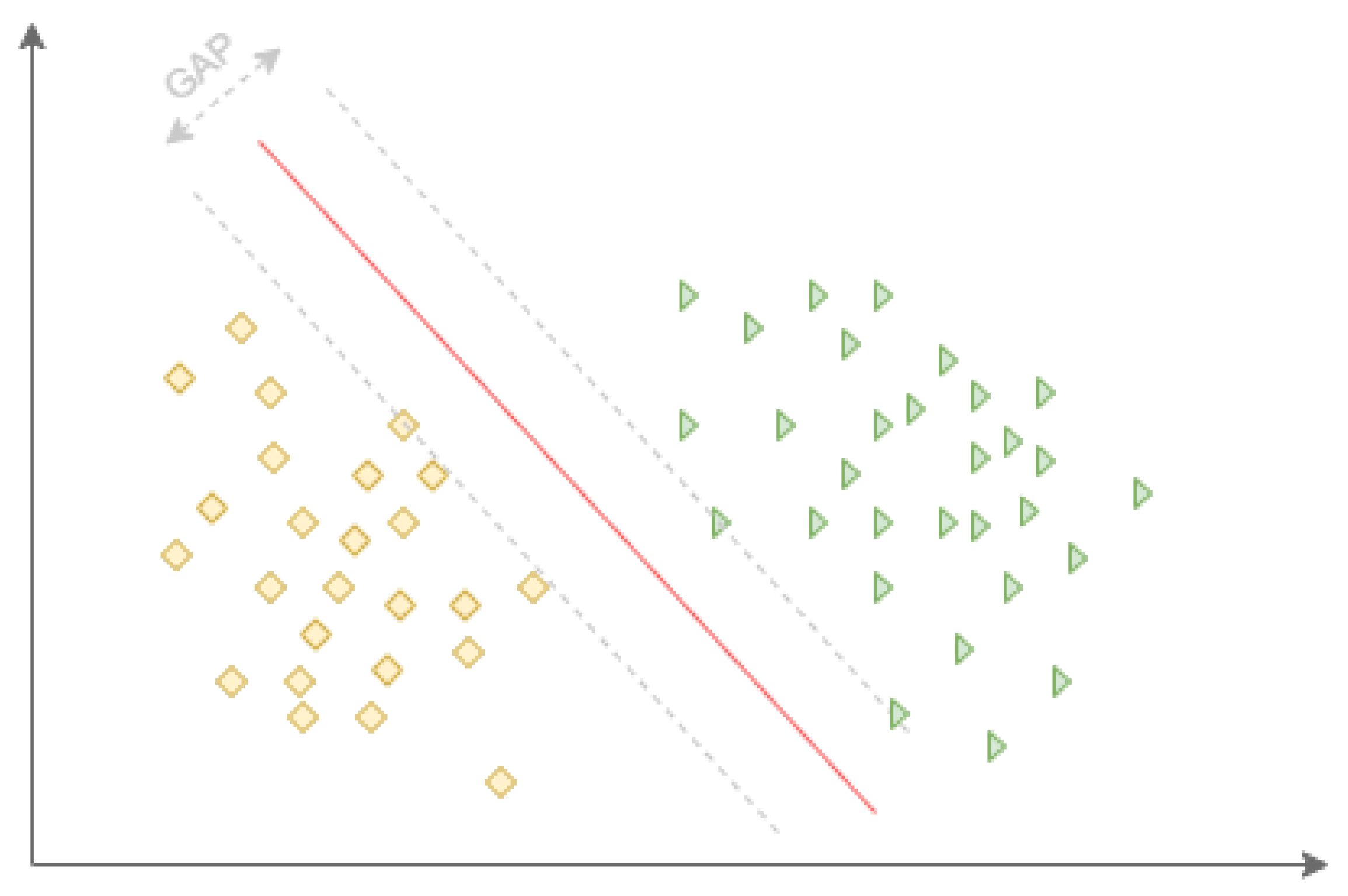

3.3.9. Support Vector Machine

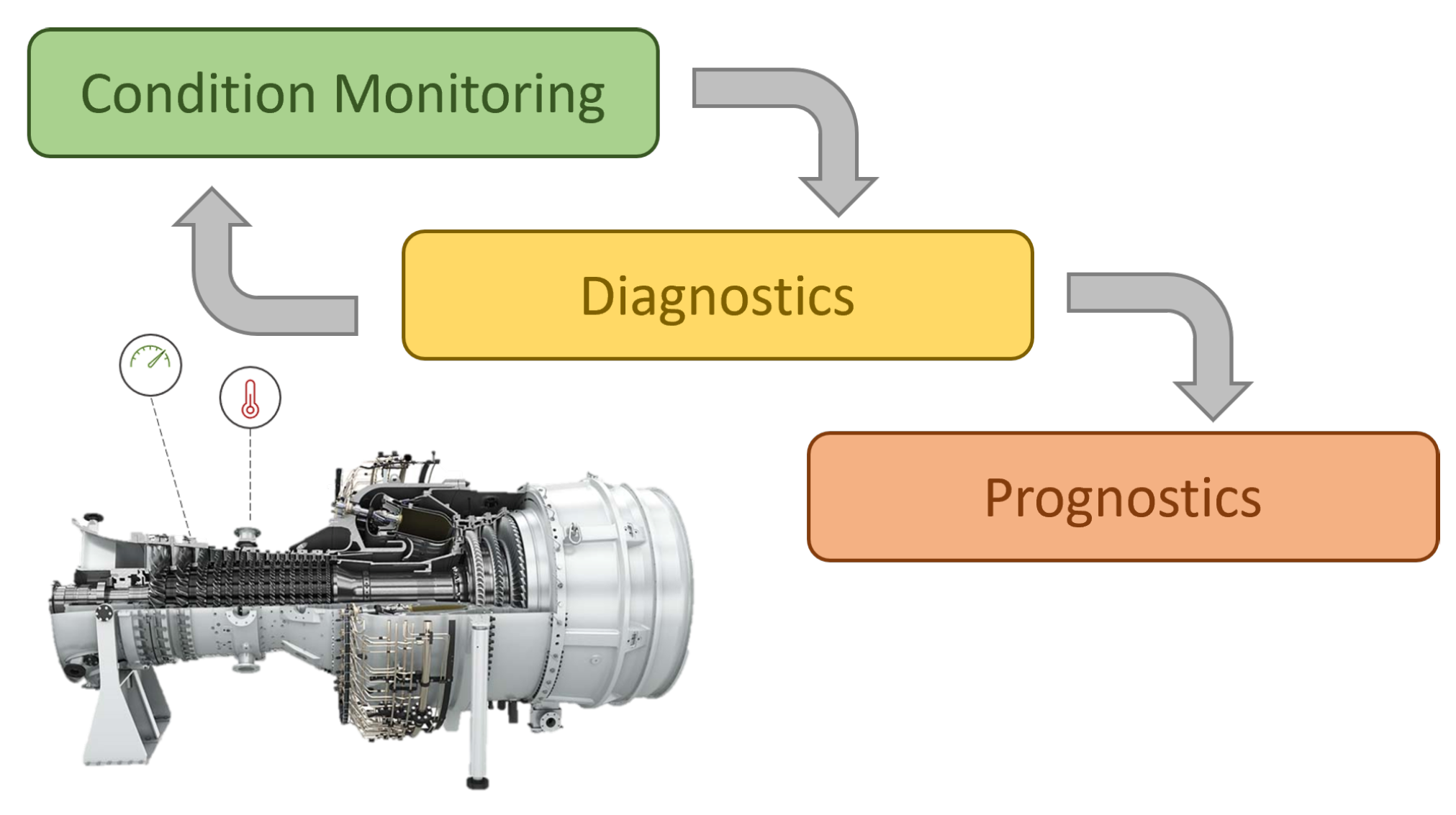

4. Condition Monitoring

4.1. Health Status

4.2. Anomaly Detection

5. Diagnostics

5.1. Fault Detection

5.2. Sensor Faults

6. Prognostics

7. Comparative Analysis of ML Models

8. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Prakash, G.; Yuan, X.X.; Hazra, B.; Mizutani, D. Toward a big data-based approach: A review on degradation models for prognosis of critical infrastructure. J. Nondestruct. Eval. Diagn. Progn. Eng. Syst. 2021, 4, 021005. [Google Scholar] [CrossRef]

- Lei, Y.; Yang, B.; Jiang, X.; Jia, F.; Li, N.; Nandi, A.K. Applications of machine learning to machine fault diagnosis: A review and roadmap. Mech. Syst. Signal Process. 2020, 138, 106587. [Google Scholar] [CrossRef]

- Carvalho, T.P.; Soares, F.A.; Vita, R.; Francisco, R.d.P.; Basto, J.P.; Alcalá, S.G. A systematic literature review of machine-learning methods applied to predictive maintenance. Comput. Ind. Eng. 2019, 137, 106024. [Google Scholar] [CrossRef]

- Qiu, J.; Wu, Q.; Ding, G.; Xu, Y.; Feng, S. A survey of machine learning for big data processing. Eurasip J. Adv. Signal Process. 2016, 2016, 67. [Google Scholar] [CrossRef] [Green Version]

- Volponi, A.J. Gas turbine engine health management: Past, present, and future trends. J. Eng. Gas Turbines Power 2014, 136, 051201. [Google Scholar] [CrossRef]

- Daily, J.; Peterson, J. Predictive maintenance: How big data analysis can improve maintenance. In Supply Chain Integration Challenges in Commercial Aerospace; Springer: Berlin/Heidelberg, Germany, 2017; pp. 267–278. [Google Scholar]

- Fentaye, A.D.; Baheta, A.T.; Gilani, S.I.; Kyprianidis, K.G. A Review on gas turbine gas-path diagnostics. Aerospace 2019, 6, 83. [Google Scholar] [CrossRef] [Green Version]

- Boyce, M.P. Gas Turbine Engineering Handbook; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Kurz, R.; Brun, K. Degradation in Gas Turbine Systems. J. Eng. Gas Turbines Power 2000, 123, 70–77. [Google Scholar] [CrossRef] [Green Version]

- Alqallaf, J.; Ali, N.; Teixeira, J.A.; Addali, A. Solid Particle Erosion Behaviour and Protective Coatings for Gas Turbine Compressor Blades—A Review. Processes 2020, 8, 984. [Google Scholar] [CrossRef]

- De León Hijes, F.C.G.; Cartagena, J.J.R. Maintenance strategy based on a multicriterion classification of equipments. Reliab. Eng. Syst. Saf. 2006, 91, 444–451. [Google Scholar] [CrossRef]

- Wang, Y.; Deng, C.; Wu, J.; Wang, Y.; Xiong, Y. A corrective maintenance scheme for engineering equipment. Eng. Fail. Anal. 2014, 36, 269–283. [Google Scholar] [CrossRef]

- Swanson, L. Linking maintenance strategies to performance. Int. J. Prod. Econ. 2001, 70, 237–244. [Google Scholar] [CrossRef]

- Shirmohammadi, A.H.; Zhang, Z.G.; Love, E. A computational model for determining the optimal preventive maintenance policy with random breakdowns and imperfect repairs. IEEE Trans. Reliab. 2007, 56, 332–339. [Google Scholar] [CrossRef]

- Lee, C.K.M.; Cao, Y.; Ng, K.H. Chapter Big Data Analytics for Predictive Maintenance Strategies. In Supply Chain Management in the Big Data Era; IGI Global: Hershey, PA, USA, 2017; pp. 50–74. [Google Scholar] [CrossRef] [Green Version]

- Tinga, T.; Loendersloot, R. Aligning PHM, SHM and CBM by understanding the physical system failure behaviour. In Proceedings of the European Conference on the Prognostics and Health Management Society, Fort Worth, TX, USA, 29 September–2 October 2014. [Google Scholar]

- Zonta, T.; da Costa, C.A.; da Rosa Righi, R.; de Lima, M.J.; da Trindade, E.S.; Li, G.P. Predictive maintenance in the Industry 4.0: A systematic literature review. Comput. Ind. Eng. 2020, 150, 106889. [Google Scholar] [CrossRef]

- Li, E.Y. Artificial neural networks and their business applications. Inf. Manag. 1994, 27, 303–313. [Google Scholar] [CrossRef]

- Dong, G.; Liao, G.; Liu, H.; Kuang, G. A review of the autoencoder and its variants: A comparative perspective from target recognition in synthetic-aperture radar images. IEEE Geosci. Rem. Sens. Mag. 2018, 6, 44–68. [Google Scholar] [CrossRef]

- Lawrence, S.; Giles, C.L.; Tsoi, A.C.; Back, A.D. Face recognition: A convolutional neural-network approach. IEEE Trans. Neural Netw. 1997, 8, 98–113. [Google Scholar] [CrossRef] [Green Version]

- Huang, G.B.; Zhu, Q.Y.; Siew, C.K. Extreme learning machine: Theory and applications. Neurocomputing 2006, 70, 489–501. [Google Scholar] [CrossRef]

- Goodfellow, I.; Pouget-Abadie, J.; Mirza, M.; Xu, B.; Warde-Farley, D.; Ozair, S.; Courville, A.; Bengio, Y. Generative adversarial nets. Adv. Neural Inf. Process. Syst. 2014, 13. [Google Scholar] [CrossRef]

- Dyer, C.; Kuncoro, A.; Ballesteros, M.; Smith, N.A. Recurrent neural network grammars. arXiv 2016, arXiv:1602.07776. [Google Scholar]

- Gregor, K.; Danihelka, I.; Graves, A.; Rezende, D.; Wierstra, D. Draw: A recurrent neural network for image generation. In Proceedings of the International Conference on Machine Learning, Lille, France, 7–9 July 2015; pp. 1462–1471. [Google Scholar]

- Bernardo, J.M.; Smith, A.F. Bayesian Theory; John Wiley & Sons: Hoboken, NJ, USA, 2009; Volume 405. [Google Scholar]

- Zadeh, L.A. Fuzzy sets. In Fuzzy Sets, Fuzzy Logic, and Fuzzy Systems: Selected Papers by Lotfi a Zadeh; World Scientific: Singapore, 1996; pp. 394–432. [Google Scholar]

- Yager, R.R.; Zadeh, L.A. An Introduction to Fuzzy Logic Applications in Intelligent Systems; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; Volume 165. [Google Scholar]

- Langdon, W.B.; Poli, R. Foundations of Genetic Programming; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Jiang, L.; Cai, Z.; Wang, D.; Jiang, S. Survey of improving k-nearest-neighbor for classification. In Proceedings of the Fourth International Conference on Fuzzy Systems and Knowledge Discovery (FSKD 2007), Haikou, China, 24–27 August 2007; Volume 1, pp. 679–683. [Google Scholar]

- Yadav, J.; Sharma, M. A Review of K-mean Algorithm. Int. J. Eng. Trends Technol. 2013, 4, 2972–2976. [Google Scholar]

- Khan, K.; Rehman, S.U.; Aziz, K.; Fong, S.; Sarasvady, S. DBSCAN: Past, present and future. In Proceedings of the Fifth International Conference on the Applications of Digital Information and Web Technologies (ICADIWT 2014), Bangalore, India, 17–19 February 2014; pp. 232–238. [Google Scholar]

- Fraley, C.; Raftery, A.E. Model-based clustering, discriminant analysis, and density estimation. J. Am. Stat. Assoc. 2002, 97, 611–631. [Google Scholar] [CrossRef]

- Blasques, F.; Koopman, S.J.; Lucas, A. Nonlinear autoregressive models with optimality properties. Econom. Rev. 2020, 39, 559–578. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Song, X. Nonlinear system identification based on NARX network. In Proceedings of the 2015 10th Asian Control Conference (ASCC), Kota Kinabalu, Malaysia, 31 May–3 June 2015; pp. 1–6. [Google Scholar]

- Tlili, B. Identification and Control of Non Linear Systems Using the NARMA Type Models. J. Européen Des Systèmes Automatisés 2008, 42, 1279–1309. [Google Scholar] [CrossRef]

- Chen, S.; Billings, S.A.; Luo, W. Orthogonal least squares methods and their application to nonlinear system identification. Int. J. Control 1989, 50, 1873–1896. [Google Scholar] [CrossRef]

- Abdi, H.; Williams, L.J. Principal component analysis. Wiley Interdiscip. Rev. Comput. Stat. 2010, 2, 433–459. [Google Scholar] [CrossRef]

- Myles, A.J.; Feudale, R.N.; Liu, Y.; Woody, N.A.; Brown, S.D. An introduction to decision tree modeling. J. Chemom. A J. Chemom. Soc. 2004, 18, 275–285. [Google Scholar] [CrossRef]

- Breiman, L. Random forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef] [Green Version]

- Somvanshi, M.; Chavan, P.; Tambade, S.; Shinde, S. A review of machine-learning techniques using decision tree and support vector machine. In Proceedings of the 2016 International Conference on Computing Communication Control and Automation (ICCUBEA), Pune, India, 12–13 August 2016; pp. 1–7. [Google Scholar]

- Noble, W.S. What is a support vector machine? Nat. Biotechnol. 2006, 24, 1565–1567. [Google Scholar] [CrossRef] [PubMed]

- De Castro-Cros, M.; Rosso, S.; Bahilo, E.; Velasco, M.; Angulo, C. Condition Assessment of Industrial Gas Turbine Compressor Using a Drift Soft Sensor Based in Autoencoder. Sensors 2021, 21, 2708. [Google Scholar] [CrossRef]

- Pogorelov, G.I.; Kulikov, G.G.; Abdulnagimov, A.I.; Badamshin, B.I. Application of Neural Network Technology and High-performance Computing for Identification and Real-time Hardware-in-the-loop Simulation of Gas Turbine Engines. Procedia Eng. 2017, 176, 402–408. [Google Scholar] [CrossRef]

- Giorgi, M.G.D.; Campilongo, S.; Ficarella, A. A diagnostics tool for aero-engines health monitoring using machine learning technique. Energy Procedia 2018, 148, 860–867. [Google Scholar] [CrossRef]

- Farahani, H.S.; Fatehi, A.; Shoorehdeli, M.A. On the Application of Domain Adversarial Neural Network to Fault Detection and Isolation in Power Plants. In Proceedings of the 19th IEEE International Conference on Machine Learning and Applications, ICMLA 2020, Miami, FL, USA, 14–17 December 2020; pp. 1132–1138. [Google Scholar] [CrossRef]

- Zhang, Y.; Bingham, C.; Gallimore, M.; Chen, J. Steady-state and transient operation discrimination by Variational Bayesian Gaussian Mixture Models. In Proceedings of the IEEE International Workshop on Machine Learning for Signal Processing, MLSP, Southampton, UK, 22–25 September 2013; pp. 6–10. [Google Scholar] [CrossRef]

- Zhandos, A.; Guo, J. An approach based on decision tree for analysis of behaviour with combined cycle power plant. In Proceedings of the 2017 International Conference on Progress in Informatics and Computing, PIC 2017, Nanjing, China, 15–17 December 2017; pp. 415–419. [Google Scholar] [CrossRef]

- Tan, Y.; Tian, H.; Jiang, R.; Lin, Y.; Zhang, J. A comparative investigation of data-driven approaches based on one-class classifiers for condition monitoring of marine machinery system. Ocean Eng. 2020, 201, 107174. [Google Scholar] [CrossRef]

- Asgari, H.; Chen, X.Q.; Morini, M.; Pinelli, M.; Sainudiin, R.; Spina, P.R.; Venturini, M. NARX models for simulation of the start-up operation of a single-shaft gas turbine. Appl. Therm. Eng. 2016, 93, 368–376. [Google Scholar] [CrossRef]

- Fontes, C.H.; Pereira, O. Pattern recognition in multivariate time series—A case study applied to fault detection in a gas turbine. Eng. Appl. Artif. Intell. 2016, 49, 10–18. [Google Scholar] [CrossRef]

- Enríquez-Zárate, J.; Trujillo, L.; de Lara, S.; Castelli, M.; Z-Flores, E.; Muñoz, L.; Popovič, A. Automatic modeling of a gas turbine using genetic programming: An experimental study. Appl. Soft Comput. 2017, 50, 212–222. [Google Scholar] [CrossRef]

- Liu, J.; Liu, J.; Yu, D.; Kang, M.; Yan, W.; Wang, Z.; Pecht, M.G. Fault detection for gas turbine hot components based on a convolutional neural network. Energies 2018, 11, 2149. [Google Scholar] [CrossRef] [Green Version]

- Bhavani, N.P.; Sujatha, K.; Reddy, T.K. Condition monitoring of gas turbine power plant using image processing (CMGTPPIP). In Proceedings of the 2016 International Conference on Electrical, Electronics, and Optimization Techniques (ICEEOT), Chennai, India, 3–5 March 2016; pp. 3809–3814. [Google Scholar]

- Sujatha, G.K.; Priyadarshini, I.; Jhansi, G.; Bhavani, N.P.; Jayachitra, N.; Karthikeyan, V.; Ram Kumar, K.S.; Kumar, K.S. Clean coal technology using inventive materials for monitoring SO2 emissions in smart power plants. AIP Conf. Proc. 2019, 2105. [Google Scholar] [CrossRef]

- Gangopadhyay, T.; Ramanan, V.; Akintayo, A.; K Boor, P.; Sarkar, S.; Chakravarthy, S.R.; Sarkar, S. 3D convolutional selective autoencoder for instability detection in combustion systems. Energy AI 2021, 4, 100067. [Google Scholar] [CrossRef]

- Verma, M.; Kumar, A. A novel general approach to evaluating the reliability of gas turbine system. Eng. Appl. Artif. Intell. 2014, 28, 13–21. [Google Scholar] [CrossRef]

- Majdani, F.; Petrovski, A.; Doolan, D. Evolving ANN-based sensors for a context-aware cyber physical system of an offshore gas turbine. Evol. Syst. 2018, 9, 119–133. [Google Scholar] [CrossRef] [Green Version]

- Somehsaraei, H.N.; Ghosh, S.; Maity, S.; Pramanik, P.; De, S.; Assadi, M. Automated data filtering approach for ANN modeling of distributed energy systems: Exploring the application of machine learning. Energies 2020, 13, 3750. [Google Scholar] [CrossRef]

- Lee, G.; Jung, M.; Song, M.; Choo, J. Unsupervised anomaly detection of the gas turbine operation via convolutional auto-encoder. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, PHM, Virtual, Detroit, MI, USA, 8–10 June 2020. [Google Scholar] [CrossRef]

- Fu, S.; Zhong, S.; Lin, L.; Zhao, M. A re-optimized deep auto-encoder for gas turbine unsupervised anomaly detection. Eng. Appl. Artif. Intell. 2021, 101, 104199. [Google Scholar] [CrossRef]

- Luo, H.; Zhong, S. Gas turbine engine gas path anomaly detection using deep learning with Gaussian distribution. In Proceedings of the 2017 Prognostics and System Health Management Conference, PHM-Harbin 2017, Harbin, China, 9–12 July 2017. [Google Scholar] [CrossRef]

- Yan, W. One-class extreme learning machines for gas turbine combustor anomaly detection. In Proceedings of the International Joint Conference on Neural Networks, Vancouver, BC, Canada, 24–29 July 2016; pp. 2909–2914. [Google Scholar] [CrossRef]

- Yan, W. Detecting Gas Turbine Combustor Anomalies Using Semi-supervised Anomaly Detection with Deep Representation Learning. Cogn. Comput. 2020, 12, 398–411. [Google Scholar] [CrossRef]

- Xu, R.; Yan, W. A Comparison of GANs-Based Approaches for Combustor System Fault Detection. In Proceedings of the International Joint Conference on Neural Networks, Glasgow, UK, 19–24 July 2020. [Google Scholar] [CrossRef]

- Loboda, I.; Yepifanov, S.; Feldshteyn, Y. An integrated approach to gas turbine monitoring and diagnostics. Turbo Expo Power Land Sea Air 2008, 43123, 359–367. [Google Scholar]

- Loboda, I.; Injeti, G. Gas Turbine Condition Monitoring and Diagnostics; Gas Turbines, IntechOpen: Rijeka, Croatia, 2010. [Google Scholar] [CrossRef] [Green Version]

- Batayev, N. Gas turbine fault classification based on machine learning supervised techniques. In Proceedings of the 14th International Conference on Electronics Computer and Computation, ICECCO 2018, Kaskelen, Kazakhstan, 28 November–1 December 2018; pp. 206–212. [Google Scholar] [CrossRef]

- Maragoudakis, M.; Loukis, E. Using Ensemble Random Forests for the extraction and exploitation of knowledge on gas turbine blading faults identification. Insight 2012, 25, 80–104. [Google Scholar] [CrossRef]

- Amozegar, M.; Khorasani, K. An ensemble of dynamic neural network identifiers for fault detection and isolation of gas turbine engines. Neural Netw. 2016, 76, 106–121. [Google Scholar] [CrossRef] [PubMed]

- Wong, P.K.; Yang, Z.; Vong, C.M.; Zhong, J. Real-time fault diagnosis for gas turbine generator systems using extreme learning machine. Neurocomputing 2014, 128, 249–257. [Google Scholar] [CrossRef]

- Pang, S.; Yang, X.; Zhang, X. Aero Engine Component Fault Diagnosis Using Multi-Hidden-Layer Extreme Learning Machine with Optimized Structure. Int. J. Aerosp. Eng. 2016, 2016, 1329561. [Google Scholar] [CrossRef]

- Lu, F.; Jiang, J.; Huang, J. Gas Turbine Engine Gas-path Fault Diagnosis Based on Improved SBELM Architecture. Int. J. Turbo Jet Engines 2018, 35, 351–363. [Google Scholar] [CrossRef]

- Sun, X.L.; Wang, N. Gas turbine fault diagnosis using intuitionistic fuzzy fault Petri nets. J. Intell. Fuzzy Syst. 2018, 34, 3919–3927. [Google Scholar] [CrossRef]

- Montazeri-Gh, M.; Yazdani, S. Application of interval type-2 fuzzy logic systems to gas turbine fault diagnosis. Appl. Soft Comput. J. 2020, 96, 106703. [Google Scholar] [CrossRef]

- Sina Tayarani-Bathaie, S.; Sadough Vanini, Z.N.; Khorasani, K. Dynamic neural network-based fault diagnosis of gas turbine engines. Neurocomputing 2014, 125, 153–165. [Google Scholar] [CrossRef]

- Tahan, M.; Muhammad, M.; Abdul Karim, Z.A. A multi-nets ANN model for real-time performance-based automatic fault diagnosis of industrial gas turbine engines. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 2865–2876. [Google Scholar] [CrossRef]

- Abbasi Nozari, H.; Aliyari Shoorehdeli, M.; Simani, S.; Dehghan Banadaki, H. Model-based robust fault detection and isolation of an industrial gas turbine prototype using soft computing techniques. Neurocomputing 2012, 91, 29–47. [Google Scholar] [CrossRef]

- Amare, D.F.; Aklilu, T.B.; Gilani, S.I. Gas path fault diagnostics using a hybrid intelligent method for industrial gas turbine engines. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 1–17. [Google Scholar] [CrossRef]

- Zhao, L.; Mo, C.; Sun, T.; Huang, W. Aero engine gas-path fault diagnose based on multimodal deep neural networks. Wirel. Commun. Mob. Comput. 2020, 2020, 8891595. [Google Scholar] [CrossRef]

- Mohtasham Khani, M.; Vahidnia, S.; Ghasemzadeh, L.; Ozturk, Y.E.; Yuvalaklioglu, M.; Akin, S.; Ure, N.K. Deep-learning-based crack detection with applications for the structural health monitoring of gas turbines. Struct. Health Monit. 2020, 19, 1440–1452. [Google Scholar] [CrossRef]

- Hong, J.; Wang, Q.; Qiu, X.; Chan, H.L. Remaining Useful Life Prediction Using Time-Frequency Feature and Multiple Recurrent Neural Networks. In Proceedings of the IEEE International Conference on Emerging Technologies and Factory Automation, ETFA, Zaragoza, Spain, 10–13 September 2019; pp. 916–923. [Google Scholar] [CrossRef]

- Bai, M.; Liu, J.; Ma, Y.; Zhao, X.; Long, Z.; Yu, D. Long short-term memory network-based normal pattern group for fault detection of three-shaft marine gas turbine. Energies 2021, 14, 13. [Google Scholar] [CrossRef]

- Shen, Y.; Khorasani, K. Hybrid multi-mode machine learning-based fault diagnosis strategies with application to aircraft gas turbine engines. Neural Netw. 2020, 130, 126–142. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Liu, J.; Ma, Y.; Zhou, W.; Yu, D. A coupling diagnosis method for sensor faults detection, isolation and estimation of gas turbine engines. Energies 2020, 13, 4976. [Google Scholar] [CrossRef]

- Sun, R.; Shi, L.; Yang, X.; Wang, Y.; Zhao, Q. A coupling diagnosis method of sensors faults in gas turbine control system. Energy 2020, 205, 117999. [Google Scholar] [CrossRef]

- Hu, Y.; Zhu, J.; Sun, Z.; Gao, L. Sensor fault diagnosis of gas turbine engines using an integrated scheme based on improved least squares support vector regression. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2020, 234, 607–623. [Google Scholar] [CrossRef]

- Maleki, S.; Bingham, C. Robust hierarchical clustering for novelty identification in sensor networks: With applications to industrial systems. Appl. Soft Comput. 2019, 85, 105771. [Google Scholar] [CrossRef]

- Maleki, S.; Bingham, C.; Zhang, Y. Development and realization of changepoint analysis for the detection of emerging faults on industrial systems. IEEE Trans. Ind. Inform. 2016, 12, 1180–1187. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Wang, J.; Shen, Y. Research on Verification of Sensor Fault Diagnosis Based on BP Neural Network. In Proceedings of the 11th International Conference on Prognostics and System Health Management, Jinan, China, 23–25 October 2020; pp. 456–460. [Google Scholar] [CrossRef]

- Olsson, T.; Ramentol, E.; Rahman, M.; Oostveen, M.; Kyprianidis, K. A data-driven approach for predicting long-term degradation of a fleet of micro gas turbines. Energy AI 2021, 4, 100064. [Google Scholar] [CrossRef]

- Kiakojoori, S.; Khorasani, K. Dynamic neural networks for gas turbine engine degradation prediction, health monitoring and prognosis. Neural Comput. Appl. 2016, 27, 2157–2192. [Google Scholar] [CrossRef]

- Rengasamy, D.; Rothwell, B.; Figueredo, G.P. Asymmetric Loss Functions for Deep Learning Early Predictions of Remaining Useful Life in Aerospace Gas Turbine Engines. In Proceedings of the International Joint Conference on Neural Netw, Glasgow, UK, 19–24 July 2020. [Google Scholar] [CrossRef]

- Zaidan, M.A.; Harrison, R.F.; Mills, A.R.; Fleming, P.J. Bayesian Hierarchical Models for aerospace gas turbine engine prognostics. Expert Syst. Appl. 2015, 42, 539–553. [Google Scholar] [CrossRef]

- Liu, Z.; Karimi, I.A. Gas turbine performance prediction via machine learning. Energy 2020, 192, 116627. [Google Scholar] [CrossRef]

- Ravichandran, T.; Liu, Y.; Kumar, A.; Srivastava, A.; Hanachi, H.; Heppler, G. Data-Driven Performance Prediction Using Gas Turbine Sensory Signals. In Proceedings of the Canadian Conference on Electrical and Computer Engineering, London, ON, Canada, 26–29 April 2020. [Google Scholar] [CrossRef]

- Alketbi, S.; Nassif, A.B.; Eddin, M.A.; Shahin, I.; Elnagar, A. Predicting the power of a combined cycle power plant using machine learning methods. In Proceedings of the 2020 IEEE International Conference on Communications, Computing, Cybersecurity, and Informatics, CCCI 2020, Virtual, Sharjah, United Arab Emirates, 3–5 November 2020. [Google Scholar] [CrossRef]

- Tüfekci, P. Prediction of full load electrical power output of a base load operated combined cycle power plant using machine-learning methods. Int. J. Electr. Power Energy Syst. 2014, 60, 126–140. [Google Scholar] [CrossRef]

- Wankhede, A.; Ghate, V. Prediction of power of a combine gas and steam turbine using artificial neural network. In Proceedings of the 2018 3rd IEEE International Conference on Recent Trends in Electronics, Information and Communication Technology, RTEICT 2018, Bangalore, India, 18–19 May 2018; pp. 1103–1108. [Google Scholar] [CrossRef]

- De Giorgi, M.G.; Quarta, M. Hybrid MultiGene Genetic Programming—Artificial neural networks approach for dynamic performance prediction of an aeroengine. Aerosp. Sci. Technol. 2020, 103, 105902. [Google Scholar] [CrossRef]

- Abdul-Wahab, S.A.; Omer, A.S.M.; Yetilmezsoy, K.; Bahramian, M. Modelling the clogging of gas turbine filter houses in heavy-duty power generation systems. Math. Comput. Model. Dyn. Syst. 2020, 26, 119–143. [Google Scholar] [CrossRef]

- Park, Y.; Choi, M.; Kim, K.; Li, X.; Jung, C.; Na, S.; Choi, G. Prediction of operating characteristics for industrial gas turbine combustor using an optimized artificial neural network. Energy 2020, 213, 118769. [Google Scholar] [CrossRef]

- Koleini, I.; Roudbari, A.; Marefat, V. EGT prediction of a micro gas turbine using statistical and artificial intelligence approach. IEEE Aerosp. Electron. Syst. Mag. 2018, 33, 4–13. [Google Scholar] [CrossRef]

- Ferrero, A.; Larocca, F.; Pennecchi, F.R. Uncertainty propagation in field inversion for turbulence modelling in turbomachinery. In Proceedings of the 2020 IEEE International Workshop on Metrology for AeroSpace, Pisa, Italy, 22–24 June 2020; pp. 303–308. [Google Scholar] [CrossRef]

| Reference | Year | ML Model | Application |

|---|---|---|---|

| Yu Xhang et al. [46] | 2013 | VBGMM | Determine operational change between steady-state and transients |

| Manjit Verma and Amit Kumar [56] | 2014 | PN | Qualitative and quantitative analysis for modelling and analysing machine behaviour |

| Hamid Asgari et al. [49] | 2016 | NARX | Gas turbine’s start-up dynamics’ assessment |

| Cristiano Hora Fontes and Otacílio Pereira [50] | 2016 | SPCA + Fuzzy C-means | Operational pattern recognition |

| Nallamilli P. G. Bhavani et al. [53] | 2016 | ANN | Intelligent sensor to monitor and control combustion quality |

| Pogorelov G.I et al. [43] | 2017 | RNN | Dynamic performance assessment |

| Abshukirov Zhandos and Jian Guo [47] | 2017 | Decision tree | Behaviour analysis based on temperature evolution |

| Josué Enríquez-Zárate et al. [51] | 2017 | GSGP | Model parameters’ estimation |

| Maria Grazia De Giorgi et al. [44] | 2018 | ANN, SVM | Model comparison for health status monitoring |

| Jiao Liu et al. [52] | 2018 | CNN | Abnormal operation detection |

| Farzan Majdani et al. [57] | 2018 | ANN | Inferential sensor for machine status assessment |

| K. Sujatha, G. et al. [54] | 2019 | ANN + PSO | Exhaust gas estimation |

| Hossein Shahabadi Farahani et al. [45] | 2020 | TL | Improvement of health monitoring system |

| Yanghui Tan et al. [48] | 2020 | OCSVM, SVDD, GKNN, LOF, IForest, and ABOD | Evaluation of operation conditions |

| Tryambak Gangopadhyay et al. [55] | 2021 | 3DCSAE | Operational transition detection in a combustion system |

| Reference | Year | ML Model | Application |

|---|---|---|---|

| Weizhong Yan [62] | 2016 | ELM | Combustor anomaly detection |

| Hui Luo and Shisheng Zhong [61] | 2017 | AE | Improvement of anomaly detection performance |

| Homam Nikpey Somehsaraei et al. [58] | 2020 | ANN | Enhancing model performance by filtering and detecting outliers |

| Geunbae Lee et al. [59] | 2020 | CAE | Anomalies’ identification in a monitoring system |

| Weizhong Yan [63] | 2020 | ELM | Enhancement of anomaly detection in a combustor |

| Rui Xu and Weizhong Yan [64] | 2020 | GAN | Faulty data detection |

| Song Fu et al. [60] | 2021 | R-DAE | Anomaly detection improvement with a novel model |

| Reference | Year | ML Model | Application |

|---|---|---|---|

| Manolis Maragoudakis and Euripides Loukis [68] | 2012 | RF | Blade faults’ identification |

| Hasan AbbasiNozari et al. [77] | 2012 | LLNF | Fault detection and isolation working at different operational points |

| S. Sina Tayarani-Bathaie et al. [75] | 2014 | DNN | Fault detection from model residuals |

| M. Amozegar and K. Khorasani [69] | 2016 | Ensemble ANN | Fault identification framework |

| Xinyi Yang et al. [71] | 2016 | Q-ELM | Fault detection using quantum-behaved swarm optimisation |

| Mohammadreza Tahan et al. [76] | 2017 | ANN | Compressor faults’ detection |

| Feng Lu et al. [72] | 2018 | SBELM | Fast fault diagnosis working under noisy anduncertain conditions |

| D. F. Amare et al. [78] | 2018 | AANN | Simultaneous fault diagnosis |

| Xiao-Ling Sun and Ning Wang [73] | 2018 | IFFPNs | Fault diagnosis with uncertainty information |

| Jihoon Hong et al. [81] | 2019 | RNN | Improvement of a degradation detection system |

| Nurlan Batayev [67] | 2019 | RF, k-NN, Logisticregression | Supervised fault detection |

| Mahtab Mohtasham Khani et al. [80] | 2020 | CNN | Boosting inspection by applying a filter to image data |

| Morteza Montazeri-Gh and Shabnam Yazdani [74] | 2020 | IT2FLSs | Fault diagnosis at various operation conditions |

| Yanyan Shen and Khashayar Khorasani [83] | 2020 | RNN + SOM | Hybrid strategy to improve fault diagnosis performance |

| Liang Zhao et al. [79] | 2020 | CNN + ANN | Multiple neural net fusion for diagnostic enhancement |

| Mingliang Bai et al. [82] | 2021 | LSTM | Gas path faults’ identification |

| Reference | Year | ML Model | Application |

|---|---|---|---|

| Sepehr Maleki and Chris Bingham [87] | 2019 | Hierarchical clustering | One-class sensor fault detection |

| Linhai Zhu et al. [84] | 2020 | SRCKF + DBSCAN | Sensor faults’ identification in harsh conditions |

| Rongzhuo Sun et al. [85] | 2020 | RNN | Coupling diagnosis method for sensor fault identification |

| Yu Hu et al. [86] | 2020 | GA-RRLSSVR | Online diagnosis for gas path sensor faults |

| Ying Liu et al. [89] | 2020 | ANN | Sensor fault detection and verification ina digital simulation platform |

| Reference | Year | ML Model | Application |

|---|---|---|---|

| Pınar Tüfekci [97] | 2014 | Several ML algorithms | Full-load electrical power prediction |

| Martha A. Zaidan et al. [93] | 2015 | Bayesian hierarchical model | RUL inference |

| S. Kiakojoori and K. Khorasani [91] | 2016 | NARX, Elman NN | Estimation of compressor fouling and turbine erosion dynamic degradation |

| Apeksha Wankhede and Vilas Ghate [98] | 2018 | ANN | Electrical power prediction |

| Iman Koleini et al. [102] | 2018 | MRP, ANN | EGT prediction based on shaft velocity |

| Divish Rengasamy et al. [92] | 2020 | DNN, CNN, LSTM | RUL prediction |

| Zuming Liu and Iftekhar A. Karimi [94] | 2020 | HDMR + ANN | Compressor and turbine operationcharacteristics prediction |

| Thambirajah Ravichandran et al. [95] | 2020 | OLS + MCDM | Short- and long-term degradation estimation |

| Salama Alketbi et al. [96] | 2020 | RF | Electrical power prediction |

| Maria Grazia De Giorgi and Marco Quarta [99] | 2020 | MGGP + NARX | EGT prediction |

| Sabah Ahmed Abdul-Wahab et al. [100] | 2020 | MISO fuzzy logic | Pressure difference of GT filter estimation |

| Yeseul Park et al. [101] | 2020 | ANN | Combustor performance prediction |

| Tomas Olsson et al. [90] | 2021 | RNN | Micro-GT degradation prediction |

| Algorithms | Accuracy | Model Complexity | Treat with Uncertainties | Computational Time | Robustness | Observations |

|---|---|---|---|---|---|---|

| ANN | Reasonably high | Reasonable | Low | Reasonably low | Reasonably low | The performance can be improved with a large amount of accurate data |

| AE | High | Reasonably high | Reasonable | Reasonably low | Reasonable | Good generalisation properties |

| CNN | High | High | Reasonable | Reasonably high | Reasonable | - |

| ELM | Reasonably high | Reasonably low | Low | Low | Low | - |

| GAN | Low | High | Reasonably low | Reasonable | Reasonable | - |

| RNN | High | High | Reasonably low | Reasonable | Reasonably high | Large amount of and sequential data |

| Bayesian Models | High | Reasonable | Reasonably high | Reasonable | Reasonably high | - |

| Clustering | Reasonably high | Reasonable | Reasonable | Reasonably high | Reasonably high | The performance can be improved by having an accurate dataset |

| Decision Tree | High | Reasonable | Reasonable | Reasonably low | Reasonably high | - |

| Fuzzy Logic | High | Reasonably high | Reasonably high | Reasonably low | High | Generalisation properties with a reasonable amount of data; expertise in the field is needed |

| Genetic Programming | High | High | Reasonably low | High | High | - |

| L and NL Regression | Reasonable | Low | Low | Low | Reasonably low | Regulation can help to generalise the solution |

| PCA | Low | Low | Reasonably low | Low | Low | It works well only with linear data. Good performance in pre-processing data |

| SVM | Reasonably high | Reasonably low | Reasonable | Low | Reasonably low | The performance can be improved by using more sophisticated kernels |

| Algorithms | Condition Monitoring | Diagnostics | Prognostics | ||

|---|---|---|---|---|---|

| ANN | [44,45,53,54,56,57] | - | [69,75,76,77,78,79] | [89] | [91,92,94,96,97,98,101,102] |

| AE | [42,55] | [59,60,61,63] | - | - | - |

| CNN | [52] | [59] | [79,80] | - | - |

| ELM | - | [62,63] | [70,71,72] | - | - |

| GAN | - | [64] | - | - | - |

| RNN | [43] | - | [82,83,103] | - | - |

| Bayesian Models | [46] | - | - | - | [93] |

| Clustering | [48] | [58,63] | - | [84,87,88] | [96] |

| Decision Tree | [47,48,56] | - | [67,68] | - | [96] |

| Fuzzy Logic | - | - | [73,74] | - | [100] |

| Genetic Programming | [51] | - | - | [86] | [99] |

| Linear and Nonlinear Regression | [49] | - | - | - | [90,91,95] |

| PCA | [50] | - | - | - | - |

| SVM | [44,48] | - | - | [85] | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Castro-Cros, M.; Velasco, M.; Angulo, C. Machine-Learning-Based Condition Assessment of Gas Turbines—A Review. Energies 2021, 14, 8468. https://doi.org/10.3390/en14248468

de Castro-Cros M, Velasco M, Angulo C. Machine-Learning-Based Condition Assessment of Gas Turbines—A Review. Energies. 2021; 14(24):8468. https://doi.org/10.3390/en14248468

Chicago/Turabian Stylede Castro-Cros, Martí, Manel Velasco, and Cecilio Angulo. 2021. "Machine-Learning-Based Condition Assessment of Gas Turbines—A Review" Energies 14, no. 24: 8468. https://doi.org/10.3390/en14248468

APA Stylede Castro-Cros, M., Velasco, M., & Angulo, C. (2021). Machine-Learning-Based Condition Assessment of Gas Turbines—A Review. Energies, 14(24), 8468. https://doi.org/10.3390/en14248468