Exploring of the Incompatibility of Marine Residual Fuel: A Case Study Using Machine Learning Methods

Abstract

:1. Introduction

2. Materials and Methods

3. Results

- Sample No.1—Compound oils grade A type 1(KMC).

- Sample No.2—Fuel for TSU-80 marine installations (RMD-80).

- Sample No.3—Fuel for TSU-380 marine installations (RMG-380).

- Sample No.4—Residual oil fuel M-100, low ash (RK-700).

- linear regression,

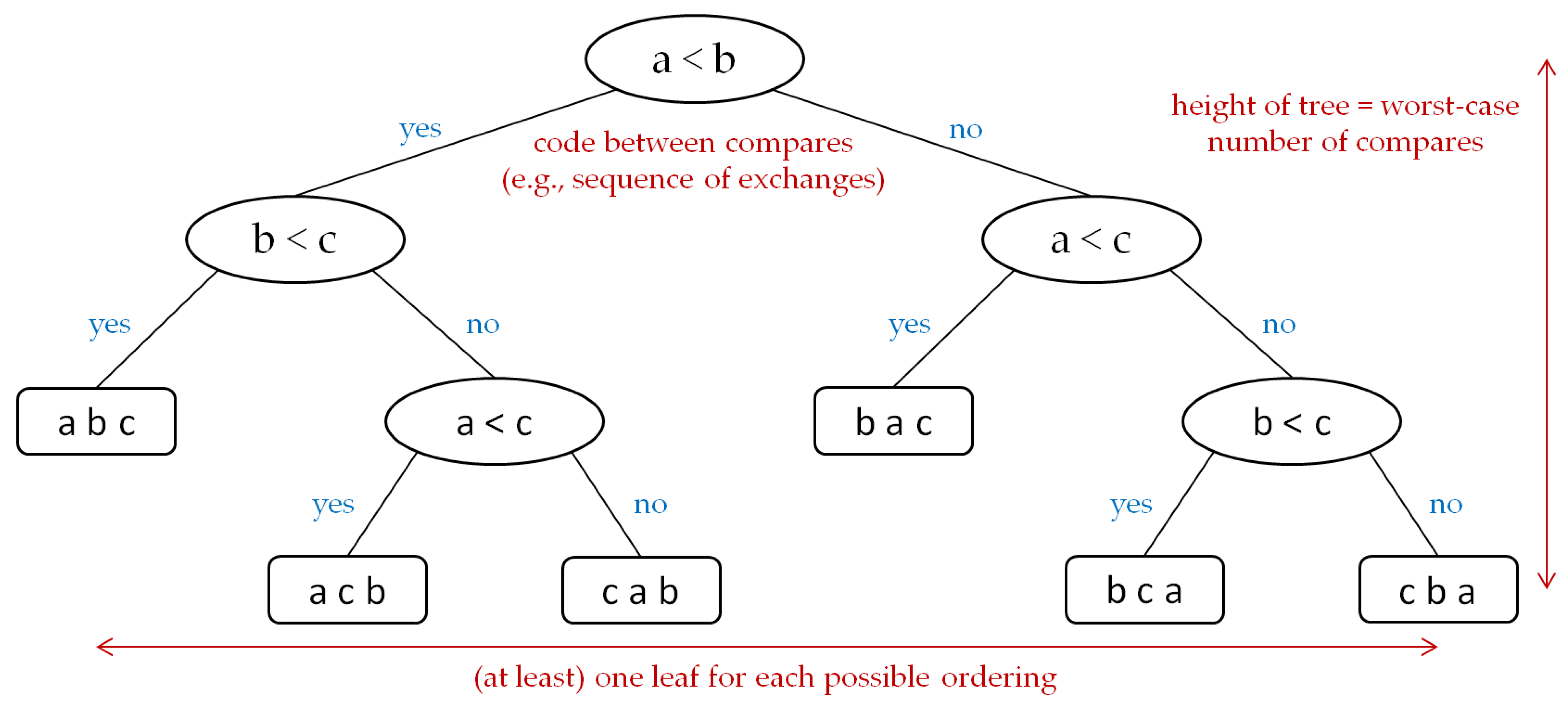

- decision tree,

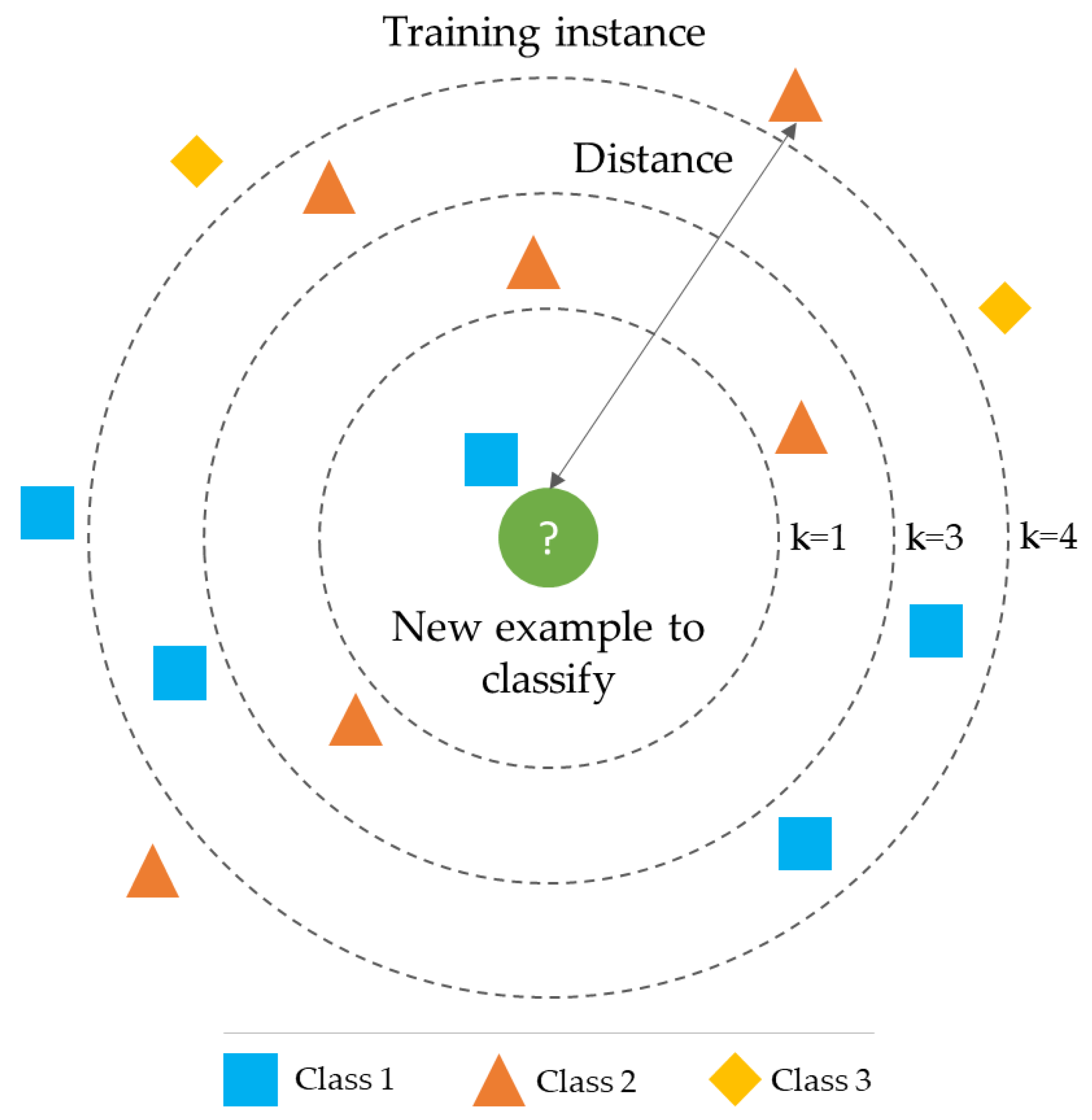

- k-NN,

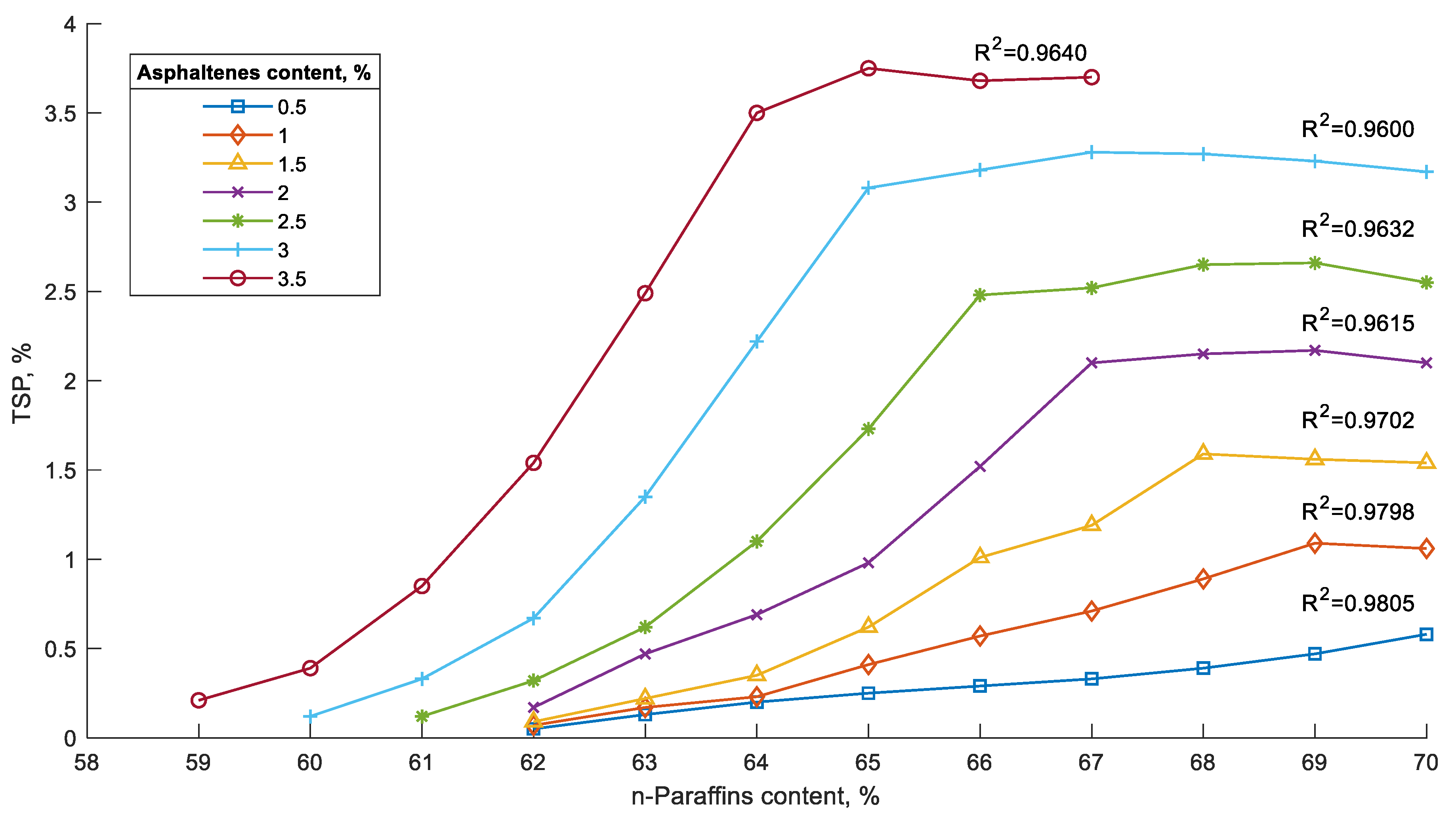

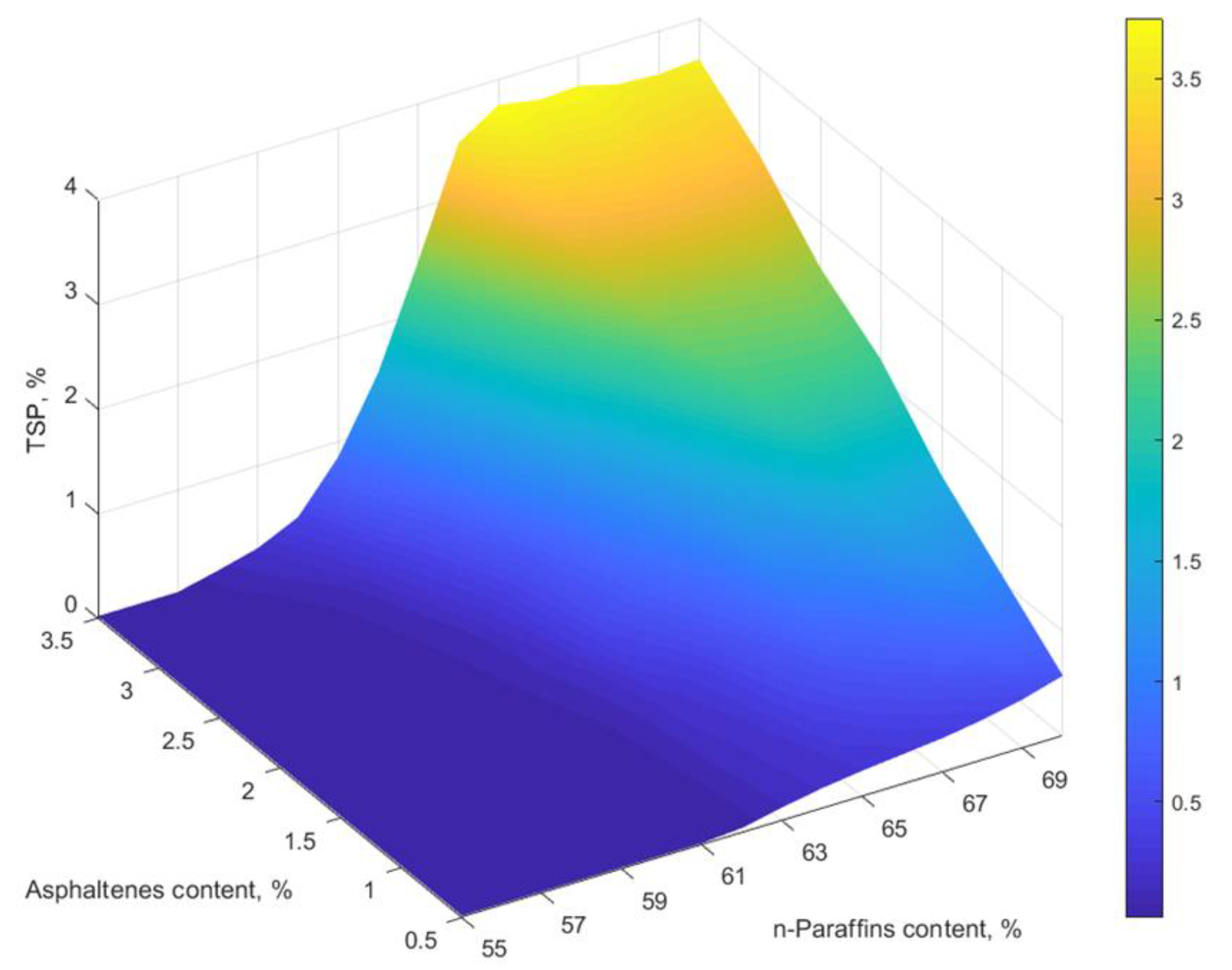

- finding a function of two variables by approximation.

| Procedure 1. Approximation of two variables |

| Input: n, m, data for i = 1 to ndo for j = 1 to m do Polyfit()the coefficients of the fifth-order polynomial Linspace() Polyval() calculating the ordinates of the approximating polynomial end for For each k = Ipolynomialcoefficients by xi Endfor |

| Procedure 2. k-NN method |

| Input: import pandas as pd from sklearn.neighbors import KNeighborsRegressor from sklearn.preprocessing import StandardScaler from sklearn.metrics import r2_score df = pd.read_csv(‘data.csv’, sep = ‘;’) X = df[[‘x’, ‘y’]] z = df[‘z’] scaler = StandardScaler()Normalized by StandardScaler X_sc = scaler.fit_transform(X) model_knn = KNeighborsRegressor(n_neighbors = 4) model_knn.fit(X_sc, z) z_pred = model_knn.predict(X_sc) r2_score(z, z_pred) x_new, y_newinput new variables new = scaler.transform([[x_new, y_new]]) model_knn.predict(new) array([0.02]) df[‘z_pred’] = z_pred df.to_csv(‘z_pred.csv’, sep = ‘;’, decimal = ‘,’) |

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| GOST | Russian government standard |

| ISO | International organization for standardization |

| IMO | International Maritime Organization |

| k-NN | k-nearest neighbors |

| SARA | Saturate, aromatic, resin, and asphaltene |

| TSA | Total sediment accelerated |

| TSP | Total sediment potential |

References

- 2050 Long-Term Strategy. Available online: https://ec.europa.eu/clima/eu-action/climate-strategies-targets/2050-long-term-strategy_en (accessed on 11 October 2021).

- Concepts for the Development of Hydrogen Energy in the Russian Federation. Available online: http://government.ru/docs/42971/ (accessed on 11 October 2021).

- On Approval of a Comprehensive Plan to Improve the Energy Efficiency of the Russian Economy. Available online: http://static.government.ru/media/files/rE6AtHAmGYeZUz51fpCeHYfmuyRzUGow.pdf (accessed on 11 October 2021).

- On Introducing a Draft Law on the Use of Subsoil Waste. Available online: http://static.government.ru/media/files/el8BjIdNpygksaGP3td60eqnQ1XvPfwz.pdf (accessed on 11 October 2021).

- Morenov, V.; Leusheva, E.; Buslaev, G.; Gudmestad, O.T. System of comprehensive energy-efficient utilization of associated petroleum gas with reduced carbon footprint in the field conditions. Energies 2020, 13, 4921. [Google Scholar] [CrossRef]

- Bykova, M.V.; Alekseenko, A.V.; Pashkevich, M.A.; Drebenstedt, C. Thermal desorption treatment of petroleum hydrocarbon-contaminated soils of tundra, taiga, and forest steppe landscapes. Environ. Geochem. Health 2021, 43, 2331–2346. [Google Scholar] [CrossRef]

- Litvinenko, V. The role of hydrocarbons in the global energy agenda: The focus on liquefied natural gas. Resources 2020, 9, 59. [Google Scholar] [CrossRef]

- Litvinenko, V.; Meyer, B. Syngas Production: Status and Potential for Implementation in Russian Industry; Springer International Publishing: Cham, Switzerland, 2017; pp. 1–161. [Google Scholar] [CrossRef]

- Zhukovskiy, Y.; Tsvetkov, P.; Buldysko, A.; Malkova, Y.; Stoianova, A.; Koshenkova, A. Scenario Modeling of Sustainable Development of Energy Supply in the Arctic. Resources 2021, 10, 124. [Google Scholar] [CrossRef]

- Korshunov, G.I.; Eremeeva, A.M.; Drebenstedt, C. Justification of the use of a vegetal additive to diesel fuel as a method of protecting underground personnel of coal mines from the impact of harmful emissions of diesel-hydraulic locomotives. J. Min. Inst. 2021, 247, 39–47. [Google Scholar] [CrossRef]

- Statistical Review of World Energy 2021 (70th edition). Available online: https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/statistical-review/bp-stats-review-2021-oil.pdf (accessed on 11 October 2021).

- Annual Report 2020. Available online: https://www.opec.org/opec_web/static_files_project/media/downloads/publications/AR%202020.pdf (accessed on 11 October 2021).

- Analysis and Forecast to 2026 (Oil 2021). Available online: https://iea.blob.core.windows.net/assets/1fa45234-bac5-4d89-a532-768960f99d07/Oil_2021-PDF.pdf (accessed on 11 October 2021).

- Schieldrop, B. IMO 2020 Report: Macro & FICC Research; Skandinaviska Enskilda Banken AB Publication: Stockholm, Sweden, 2018. [Google Scholar]

- Fetisov, V.; Mohammadi, A.H.; Pshenin, V.; Kupavykh, K.; Artyukh, D. Improving the economic efficiency of vapor recovery units at hydrocarbon loading terminals. Oil Gas Sci. Technol. Rev. IFP Energ. Nouv. 2021, 76, 38. [Google Scholar] [CrossRef]

- Fetisov, V.; Pshenin, V.; Nagornov, D.; Lykov, Y.; Mohammadi, A.H. Evaluation of pollutant emissions into the atmosphere during the loading of hydrocarbons in marine oil tankers in the Arctic region. J. Mar. Sci. Eng. 2020, 8, 917. [Google Scholar] [CrossRef]

- IMO. Reduction of GHG Emissions from Ships—Third IMO GHG Study 2014—Final Report; International Maritime Organization: London, UK, 2015. [Google Scholar]

- IMO. Annex VI Prevention of Air Pollution from Ships of International Convention for the Prevention of Pollution from Ships (MARPOL); International Maritime Organization: London, UK, 2005. [Google Scholar]

- Kunshin, A.A.; Dvoynikov, M.V.; Blinov, P.A. Topology and dynamic characteristics advancements of liner casing attachments for horizontal wells completion. In Proceedings of the VI Youth Forum of the World Petroleum Council–Future Leaders Forum; St. Petersburg, Russia, 23–28 June 2019, Taylor & Francis: London, UK, 2019; pp. 376–381. [Google Scholar]

- Li, C.; Yuan, Z.; Ou, J.; Fan, X.; Ye, S.; Xiao, T.; Shi, Y.; Huang, Z.; Ng, S.K.; Zhong, Z.; et al. An AIS-based high-resolution ship emission inventory and its uncertainty in Pearl River Delta region, China. Sci. Total Environ. 2016, 573, 1–10. [Google Scholar] [CrossRef]

- Liu, T.K.; Chen, Y.S.; Chen, Y.T. Utilization of vessel automatic identification system (AIS) to estimate the emission of air pollutant from merchant vessels in the port of Kaohsiung. Aerosol Air Qual. Res. 2019, 19, 2341–2351. [Google Scholar] [CrossRef]

- Miola, A.; Ciuffo, B.; Giovine, E.; Marra, M. Regulating Air Emissions from Ships: The State of the Art on Methodologies, Technologies and Policy Options; Publications Office of the European Union: Luxembourg, 2010. [Google Scholar]

- Lindstad, H.E.; Rehn, C.F.; Eskeland, G.S. Sulphur abatement globally in maritime shipping. Transp. Res. Part D Transp. Environ. 2017, 57, 303–313. [Google Scholar] [CrossRef] [Green Version]

- Kondrasheva, N.K.; Rudko, V.A.; Nazarenko, M.Y.; Gabdulkhakov, R.R. Influence of parameters of delayed asphalt coking process on yield and quality of liquid and solid-phase products. J. Min. Inst. 2020, 241, 97–104. [Google Scholar] [CrossRef]

- Gulvaeva, L.A.; Khavkin, V.A.; Shmelkova, O.I.; Mitusova, T.N.; Ershov, M.A.; Lobashova, M.M.; Nikulshin, P.A. Production technology for low-sulfur high-viscosity marine fuels. Chem. Technol. Fuels Oils 2019, 54, 759–765. [Google Scholar] [CrossRef]

- Dvoynikov, M.; Buslaev, G.; Kunshin, A.; Sidorov, D.A.; Kraslawski, A.; Budovskaya, M. New concepts of hydrogen production and storage in Arctic region. Resources 2021, 10, 3. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Rogachev, M.K.; Aleksandrov, A.N. A new approach to improving efficiency of gas-lift wells in the conditions of the formation of organic wax deposits in the Dragon field. J. Petrol. Explor. Prod. Technol. 2020, 10, 3663–3672. [Google Scholar] [CrossRef]

- Bai, J.; Jin, X.; Wu, J.T. Multifunctional anti-wax coatings for paraffin control in oil pipelines. Pet. Sci. 2019, 16, 619–631. [Google Scholar] [CrossRef] [Green Version]

- Coutinho, J.A.P.; Edmonds, B.; Moorwood, T.; Szczepanski, R.; Zhang, X. Reliable wax predictions for flow assurance. Energy Fuels 2006, 20, 1081–1088. [Google Scholar] [CrossRef]

- Kelbaliev, G.I.; Rasulov, S.R.; Ilyushin, P.Y.; Mustafaeva, G.R. Crystallization of paraffin from the oil in a pipe and deposition of asphaltene–paraffin substances on the pipe walls. J. Eng. Phys. Thermophy. 2018, 91, 1227–1232. [Google Scholar] [CrossRef]

- Rogachev, M.K.; Nguyen, V.T.; Aleksandrov, A.N. Technology for preventing the wax deposit formation in gas-lift wells at offshore oil and gas fields in Vietnam. Energies 2021, 14, 5016. [Google Scholar] [CrossRef]

- Wiehe, I.A.; Yarranton, H.W.; Akbarzadeh, К.; Rahimi, P.M.; Teclemariam, A. The paradox of asphaltene precipitation with normal paraffins. Energy Fuels 2005, 19, 1261–1267. [Google Scholar] [CrossRef]

- Prakoso, A.; Punase, A.; Klock, K.; Rogel, E.; Ovalles, C.; Hascakir, B. Determination of the stability of asphaltenes through physicochemical characterization of asphaltenes. In Proceedings of the SPE Western Regional Meeting, Anchorage, AK, USA, 23 May 2016; pp. 1–20. [Google Scholar]

- Wiehe, I.A.; Kennedy, R.J. The oil compatibility model and crude oil incompatibility. Energy Fuels 2000, 14, 56–59. [Google Scholar] [CrossRef]

- Mitusova, T.N.; Kondrasheva, N.K.; Lobashova, M.M.; Ershov, M.A.; Rudko, V.A. Influence of dispersing additives and blend composition on stability of marine high-viscosity fuels. J. Min. Inst. 2017, 228, 722–725. [Google Scholar]

- Stratiev, D.; Dinkov, R.; Shishkova, I.; Yordanov, D. Can we manage the process of asphaltene precipitation during the production of IMO 2020 fuel oil? Erdoel Erdgas Kohle/EKEP 2020, 12, 32–39. [Google Scholar]

- Stratiev, D.; Russell, C.; Sharpe, R.; Shishkova, I.; Dinkov, R.; Marinov, I.; Petkova, N.; Mitkova, M.; Botev, T.; Obryvalina, A.; et al. Investigation on sediment formation in residue thermal conversion based processes. Fuel Process. Technol. 2014, 128, 509–518. [Google Scholar] [CrossRef]

- Sultanbekov, R.; Islamov, S.; Mardashov, D.; Beloglazov, I.; Hemmingsen, T. Research of the influence of marine residual fuel composition on sedimentation due to incompatibility. J. Mar. Sci. Eng. 2021, 9, 1067. [Google Scholar] [CrossRef]

- Boikov, A.; Payor, V.; Savelev, R.; Kolesnikov, A. Synthetic data generation for steel defect detection and classification using deep learning. Symmetry 2021, 13, 1176. [Google Scholar] [CrossRef]

- Braidotti, L.; Valčić, M.; Prpić-Oršić, J. Exploring a flooding-sensors-agnostic prediction of the damage consequences based on machine learning. J. Mar. Sci. Eng. 2021, 9, 271. [Google Scholar] [CrossRef]

- Codjo, E.L.; Zad, B.B.; Toubeau, J.-F.; François, B.; Vallée, F. Machine learning-based classification of electrical low voltage cable degradation. Energies 2021, 14, 2852. [Google Scholar] [CrossRef]

- Zhang, Z.; Zheng, W.; Li, Y.; Cao, K.; Xie, M.; Wu, P. Monitoring sulfur content in marine fuel oil using ultraviolet imaging technology. Atmosphere 2021, 12, 1182. [Google Scholar] [CrossRef]

- Eyring, V.; Isaksen, I.S.A.; Berntsen, T.; Collins, W.J.; Corbett, J.J.; Endresen, O.; Grainger, R.G.; Moldanova, J.; Schlager, H.; Stevenson, D.S. Transport impacts on atmosphere and climate: Shipping. Atmos. Environ. 2010, 44, 4735–4771. [Google Scholar] [CrossRef]

- Zhao, J.; Fan, J.; Zhang, B.; Shi, Y. Satellite remote-sensing monitoring technology and the research advances of SO2 in the atmosphere. J. Saf. Environ. 2012, 4, 166–169. [Google Scholar]

- Yan, H.; Chen, L.; Tao, J.; Han, D.; Su, L.; Yu, C. SO2 long-term monitoring by satellite in the Pearl River Delta. J. Remote Sens. 2012, 2, 390–404. [Google Scholar]

- Huaxiang, S.; Minhua, Y. Effectiveness evaluation of SO2 emission reduction in Guizhou Province. Earth Environ. 2014, 5, 319–327. [Google Scholar]

- Huaxiang, S.; Minhua, Y. Analysis on effectiveness of SO2 emission reduction in Guangxi Zhuang Autonomous Region by satellite remote sensing. Chin. J. Environ. Eng. 2015, 3, 1361–1368. [Google Scholar]

- Li, B.; Ju, T.; Zhang, B.; Ge, J.; Zhang, J.; Tang, H. Satellite remote sensing monitoring and analysis of the causes of temporal and spatial variation characteristics of atmospheric SO2 Concentration in Tianshui. Environ. Monit. China 2016, 2, 134–140. [Google Scholar]

- Li, C. Emissions Characteristics and Future Trends of Non-Road Mobile Sources in China. Master Thesis, South China University, Guangdong, China, 2017. [Google Scholar]

- Breiman, L.; Friedman, J.; Olshen, R.A.; Stone, C.J. Classification and Regression Trees; CRC Press: Boca Raton, FL, USA, 1984. [Google Scholar]

- Noteworthy the Journal Blog. A Quick Introduction to K-Nearest Neighbors Algorithm. Available online: https://blog.usejournal.com/a-quick-introduction-to-k-nearest-neighbors-algorithm-62214cea29c7 (accessed on 11 October 2021).

- Nutskova, M.V.; Dvoynikov, M.V.; Budovskaya, M.E.; Sidorov, D.A.; Pantyukhin, A.A. Improving energy efficiency in well construction through the use of hydrocarbon-based muds and muds with improved lubricating properties. J. Phys. Conf. Ser. 2021, 1728, 012031. [Google Scholar] [CrossRef]

- Method of Determining Compatibility and Stability of Fuel Mixture Components. Available online: https://new.fips.ru/ofpstorage/Doc/IZPM/RUNWC1/000/000/002/733/748/%D0%98%D0%97-02733748-00001/document.pdf (accessed on 11 October 2021).

- Program for Calculating Kinematic Viscosity, Density, Sulfur and Water Content for a Mixture of Crude Oil and Petroleum Products. Available online: https://new.fips.ru/ofpstorage/Doc/PrEVM/RUNWPR/000/002/020/613/357/2020613357-00001/document.pdf (accessed on 11 October 2021).

- Savchenkov, S.; Kosov, Y.; Bazhin, V.; Krylov, K.; Kawalla, R. Microstructural Master Alloys Features of Aluminum–Erbium System. Crystals 2021, 11, 1353. [Google Scholar] [CrossRef]

- Leusheva, E.L.; Morenov, V.A. Development of combined heat and power system with binary cycle for oil and gas enterprises power supply. Neft. Khozyaystvo-Oil Ind. 104–106. [CrossRef]

- Filatova, I.; Nikolaichuk, L.; Zakaev, D.; Ilin, I. Public-private partnership as a tool of sustainable development in the oil-refining sector: Russian case. Sustainability 2021, 13, 5153. [Google Scholar] [CrossRef]

- Bazhin, V.Y.; Savchenkov, S.A.; Kosov, Y.I. Specificity of the titanium-powder alloying tablets usage in aluminium alloys. Non-Ferrous Met. 2016, 2, 52–56. [Google Scholar] [CrossRef]

- Sharikov, Y.V.; Sharikov, F.Y.; Krylov, K.A. Mathematical Model of Optimum Control for Petroleum Coke Production in a Rotary Tube Kiln. Theor. Found. Chem. Eng. 2021, 55, 711–719. [Google Scholar] [CrossRef]

| No. | Indicator Name | Unit of Measurement | Regulation of the Test Method | Result | |||

|---|---|---|---|---|---|---|---|

| Sample No.1 | Sample No.2 | Sample No.3 | Sample No.4 | ||||

| 1 | Density at 15 °C | kg/m3 | ISO 12185 | 833.5 | 901.0 | 956.0 | 976.0 |

| 2 | Kinematic viscosity at 50 °C | mm2/s | GOST 33 ISO 3104 | 12.1 | 34.5 | 321.5 | 680.1 |

| 3 | Flashpoint PMCC | °C | GOST R EN ISO 2719 | 181.0 | 110.0 | 98.0 | 110.0 |

| 4 | Sulfur mass fraction | % | GOST R 51947 ISO 8754 | 0.004 | 0.046 | 1.276 | 2.668 |

| 5 | Pourpoint | °C | ASTM D 6749 | 26.0 | 10.0 | 16.0 | 20.0 |

| 6 | Mass fraction of water | % | GOST R 51946 ISO 3733 | – | – | 0.05 | 0.1 |

| 7 | Total sediment accelerated (TSA) | % | GOST R 50837.6 ISO 10307-2 | 0.01 | 0.01 | 0.02 | 0.03 |

| 8 | Total sediment potential (TSP) | % | GOST R 50837.6 ISO 10307-2 | 0.01 | 0.01 | 0.02 | 0.04 |

| Fuel Samples | Asphaltenes, % wt. | n-Alkanes, % wt. | Isoalkane, % wt. | Naphthenes, % wt. | Alkenes, % wt. | Aromatic Hydrocarbons, % wt. | Resins, % wt. |

|---|---|---|---|---|---|---|---|

| No.1 | – | 71.93 | 18.35 | 2.62 | 5.55 | 1.55 | – |

| No.2 | – | 38.68 | 55.09 | 4.95 | – | 1.28 | – |

| No.3 | 2.53 | 54.14 | 22.74 | 5.43 | 0.57 | 14.12 | 0.47 |

| No.4 | 7.15 | 51.15 | 20.71 | 4.37 | 0.41 | 15.70 | 0.51 |

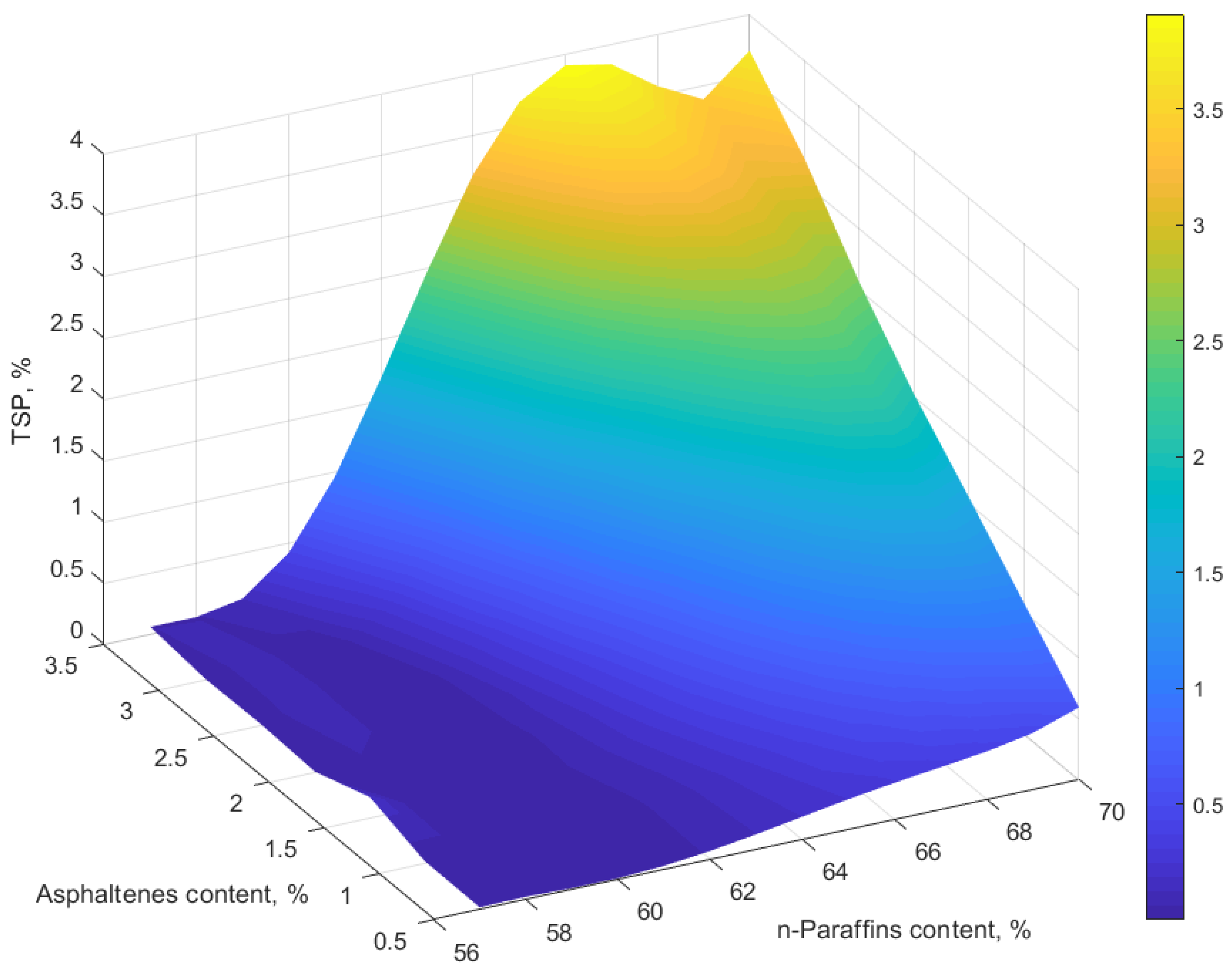

| n-Paraffins, % | Asphaltenes,% | ||||||

|---|---|---|---|---|---|---|---|

| 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | 3.5 | |

| 55 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| 56 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| 57 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| 58 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.11 |

| 59 | 0.02 | 0.02 | 0.02 | 0.03 | 0.02 | 0.05 | 0.21 |

| 60 | 0.02 | 0.02 | 0.02 | 0.04 | 0.06 | 0.12 | 0.39 |

| 61 | 0.02 | 0.02 | 0.04 | 0.08 | 0.12 | 0.33 | 0.85 |

| 62 | 0.05 | 0.07 | 0.09 | 0.17 | 0.32 | 0.65 | 1.54 |

| 63 | 0.13 | 0.17 | 0.22 | 0.47 | 0.62 | 1.28 | 2.49 |

| 64 | 0.20 | 0.23 | 0.35 | 0.69 | 1.10 | 2.22 | 3.50 |

| 65 | 0.25 | 0.41 | 0.62 | 0.98 | 1.73 | 3.08 | 3.75 |

| 66 | 0.29 | 0.57 | 1.01 | 1.52 | 2.48 | 3.19 | 3.68 |

| 67 | 0.33 | 0.71 | 1.19 | 2.18 | 2.55 | 3.25 | 3.70 |

| 68 | 0.39 | 0.89 | 1.59 | 2.20 | 2.59 | 3.22 | 3.60 |

| 69 | 0.47 | 1.11 | 1.56 | 2.22 | 2.63 | 3.22 | 3.58 |

| 70 | 0.58 | 1.06 | 1.54 | 2.17 | 2.57 | 3.17 | 3.61 |

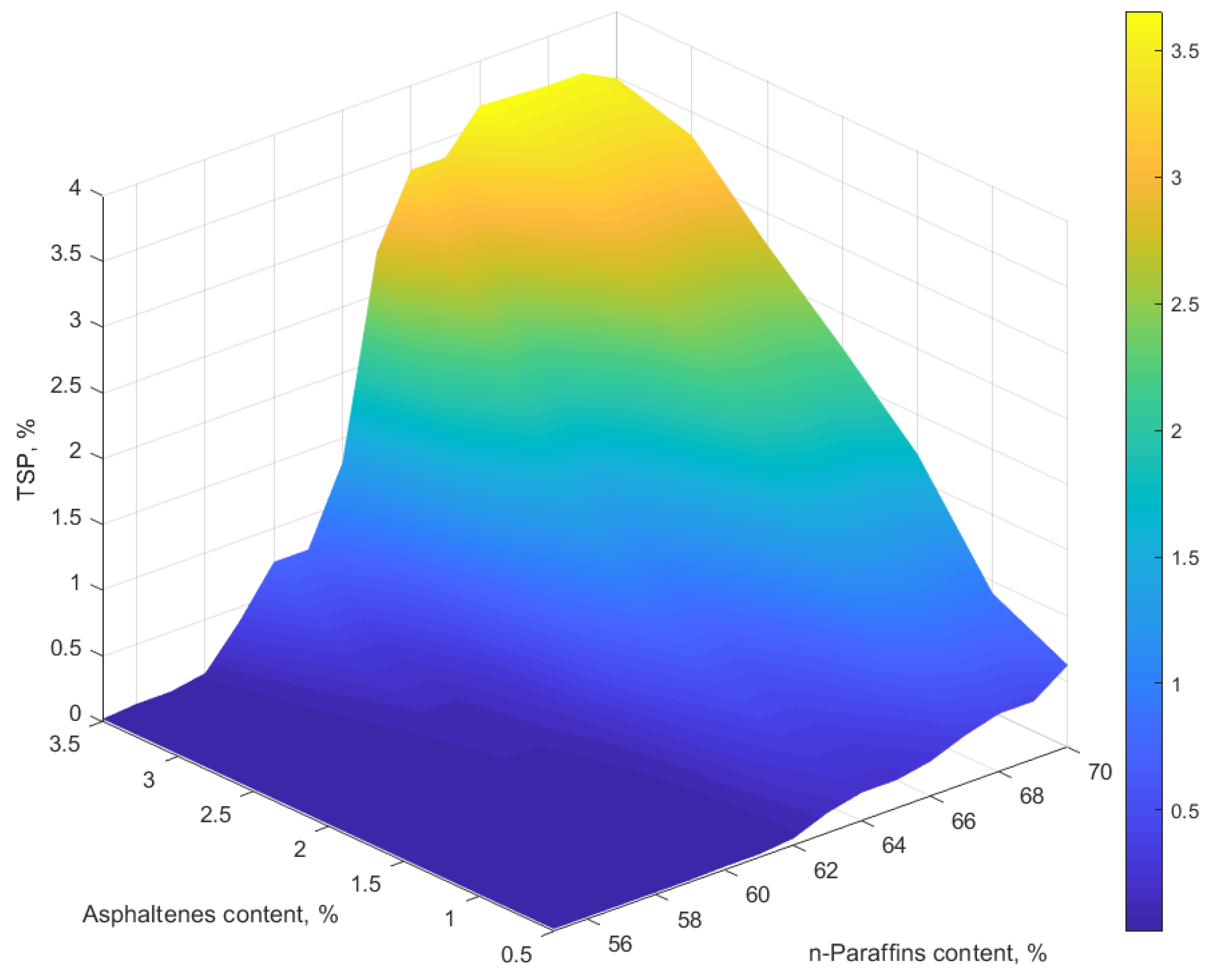

| n-Paraffins, % | Asphaltenes,% | ||||||

|---|---|---|---|---|---|---|---|

| 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | 3.5 | |

| 57 | 0.020 | 0.022 | 0.170 | 0.003 | 0.022 | 0.012 | 0.061 |

| 58 | 0.024 | 0.019 | 0.025 | 0.064 | 0.107 | 0.112 | 0.059 |

| 59 | 0.013 | 0.015 | 0.021 | 0.041 | 0.040 | 0.024 | 0.128 |

| 60 | 0.012 | 0.016 | 0.021 | 0.014 | 0.013 | 0.031 | 0.418 |

| 61 | 0.030 | 0.031 | 0.043 | 0.039 | 0.066 | 0.277 | 0.956 |

| 62 | 0.070 | 0.069 | 0.108 | 0.155 | 0.320 | 0.776 | 1.679 |

| 63 | 0.124 | 0.136 | 0.229 | 0.373 | 0.732 | 1.455 | 2.467 |

| 64 | 0.186 | 0.239 | 0.417 | 0.689 | 1.246 | 2.184 | 3.181 |

| 65 | 0.247 | 0.378 | 0.669 | 1.076 | 1.783 | 2.821 | 3.689 |

| 66 | 0.299 | 0.550 | 0.966 | 1.491 | 2.256 | 3.243 | 3.909 |

| 67 | 0.344 | 0.730 | 1.274 | 1.873 | 2.592 | 3.387 | 3.836 |

| 68 | 0.391 | 0.904 | 1.535 | 2.149 | 2.743 | 3.287 | 3.576 |

| 69 | 0.460 | 1.032 | 1.664 | 2.230 | 2.710 | 3.110 | 3.386 |

| 70 | 0.587 | 1.063 | 1.548 | 2.016 | 2.557 | 3.194 | 3.701 |

| n-Paraffins, % | Asphaltenes, % | ||||||

|---|---|---|---|---|---|---|---|

| 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | 3.5 | |

| 55 | 0.020 | 0.020 | 0.020 | 0.020 | 0.020 | 0.020 | 0.020 |

| 56 | 0.020 | 0.020 | 0.020 | 0.020 | 0.020 | 0.020 | 0.042 |

| 57 | 0.020 | 0.020 | 0.020 | 0.020 | 0.020 | 0.020 | 0.042 |

| 58 | 0.020 | 0.020 | 0.020 | 0.020 | 0.020 | 0.027 | 0.090 |

| 59 | 0.020 | 0.020 | 0.025 | 0.042 | 0.055 | 0.130 | 0.390 |

| 60 | 0.027 | 0.032 | 0.042 | 0.080 | 0.130 | 0.292 | 0.747 |

| 61 | 0.027 | 0.032 | 0.042 | 0.080 | 0.130 | 0.292 | 0.747 |

| 62 | 0.055 | 0.070 | 0.092 | 0.190 | 0.280 | 0.617 | 1.317 |

| 63 | 0.157 | 0.220 | 0.320 | 0.577 | 0.942 | 1.830 | 2.820 |

| 64 | 0.217 | 0.345 | 0.550 | 0.915 | 1.482 | 2.457 | 3.355 |

| 65 | 0.217 | 0.345 | 0.550 | 0.915 | 1.482 | 2.457 | 3.355 |

| 66 | 0.267 | 0.480 | 0.792 | 1.322 | 1.957 | 2.940 | 3.655 |

| 67 | 0.370 | 0.815 | 1.337 | 1.985 | 2.577 | 3.240 | 3.640 |

| 68 | 0.442 | 0.937 | 1.470 | 2.130 | 2.595 | 3.237 | 3.622 |

| 69 | 0.442 | 0.937 | 1.470 | 2.130 | 2.595 | 3.237 | 3.622 |

| 70 | 0.625 | 0.905 | 1.697 | 2.242 | 2.757 | 3.320 | 3.490 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sultanbekov, R.; Beloglazov, I.; Islamov, S.; Ong, M.C. Exploring of the Incompatibility of Marine Residual Fuel: A Case Study Using Machine Learning Methods. Energies 2021, 14, 8422. https://doi.org/10.3390/en14248422

Sultanbekov R, Beloglazov I, Islamov S, Ong MC. Exploring of the Incompatibility of Marine Residual Fuel: A Case Study Using Machine Learning Methods. Energies. 2021; 14(24):8422. https://doi.org/10.3390/en14248422

Chicago/Turabian StyleSultanbekov, Radel, Ilia Beloglazov, Shamil Islamov, and Muk Chen Ong. 2021. "Exploring of the Incompatibility of Marine Residual Fuel: A Case Study Using Machine Learning Methods" Energies 14, no. 24: 8422. https://doi.org/10.3390/en14248422