CFD Study on the Ventilation Effectiveness in a Public Toilet under Three Ventilation Methods

Abstract

:1. Introduction

2. Methods

2.1. Physical Model

2.2. Experimental Setup

2.3. CFD Setup

2.3.1. Numerical Method

2.3.2. Boundary Conditions

2.4. Evaluation Index

2.5. Validation of the CFD Simulation Method

3. Results and Discussion

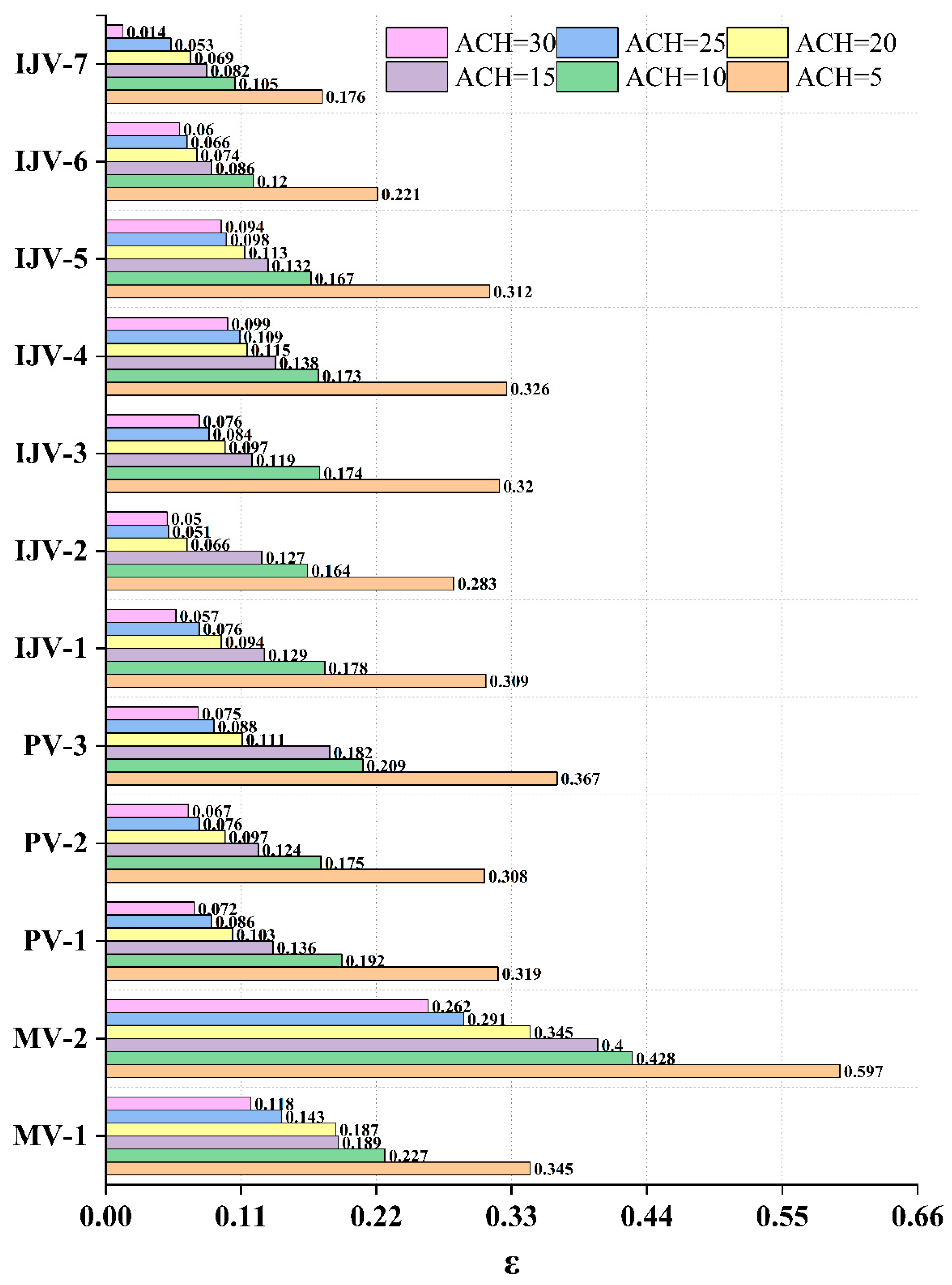

3.1. Performance of MV, PV, and IJV with Ammonia in the Occupied Zone

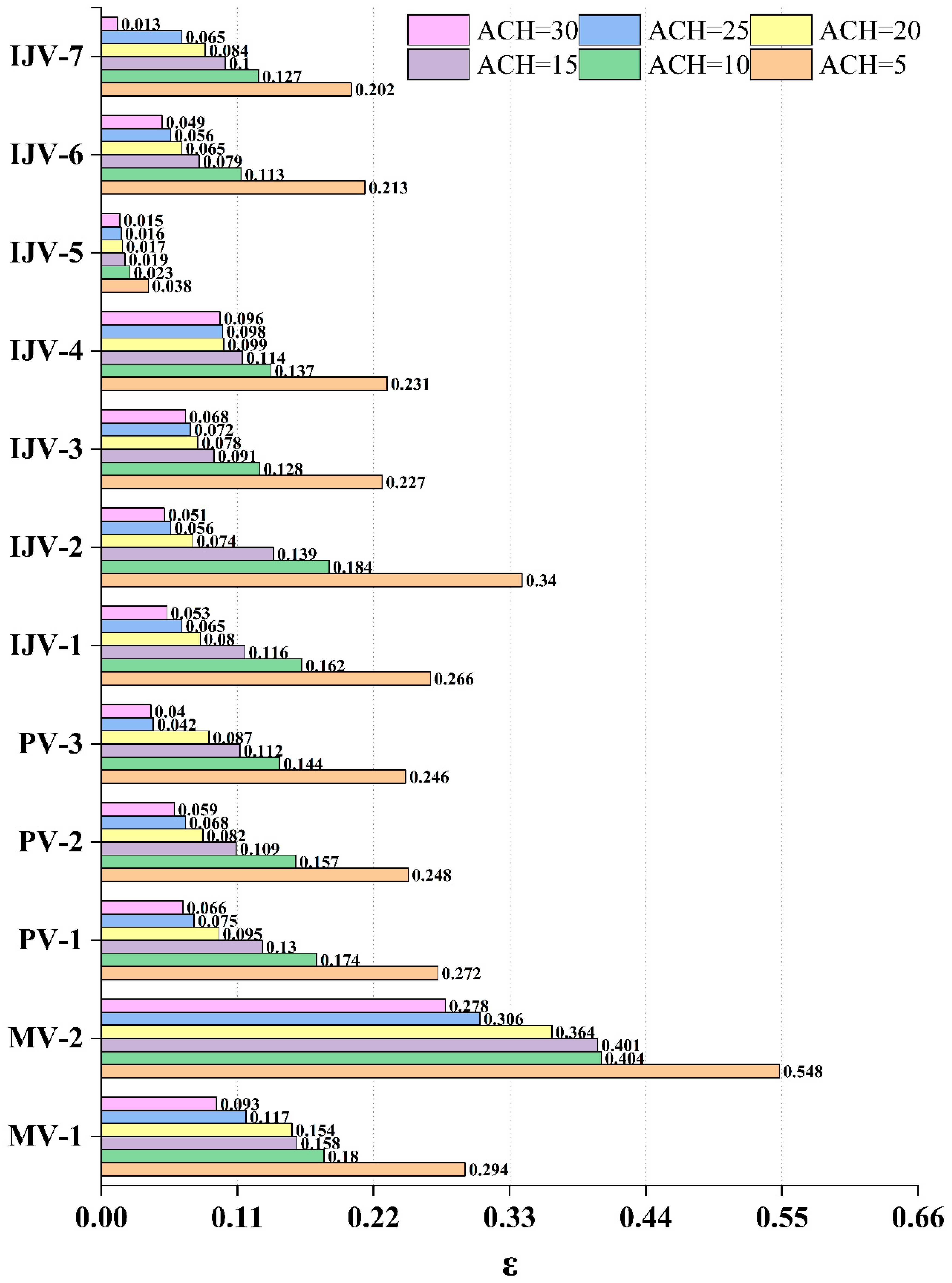

3.2. Performance of MV, PV, and IJV with Hydrogen Sulfide in the Occupied Zone

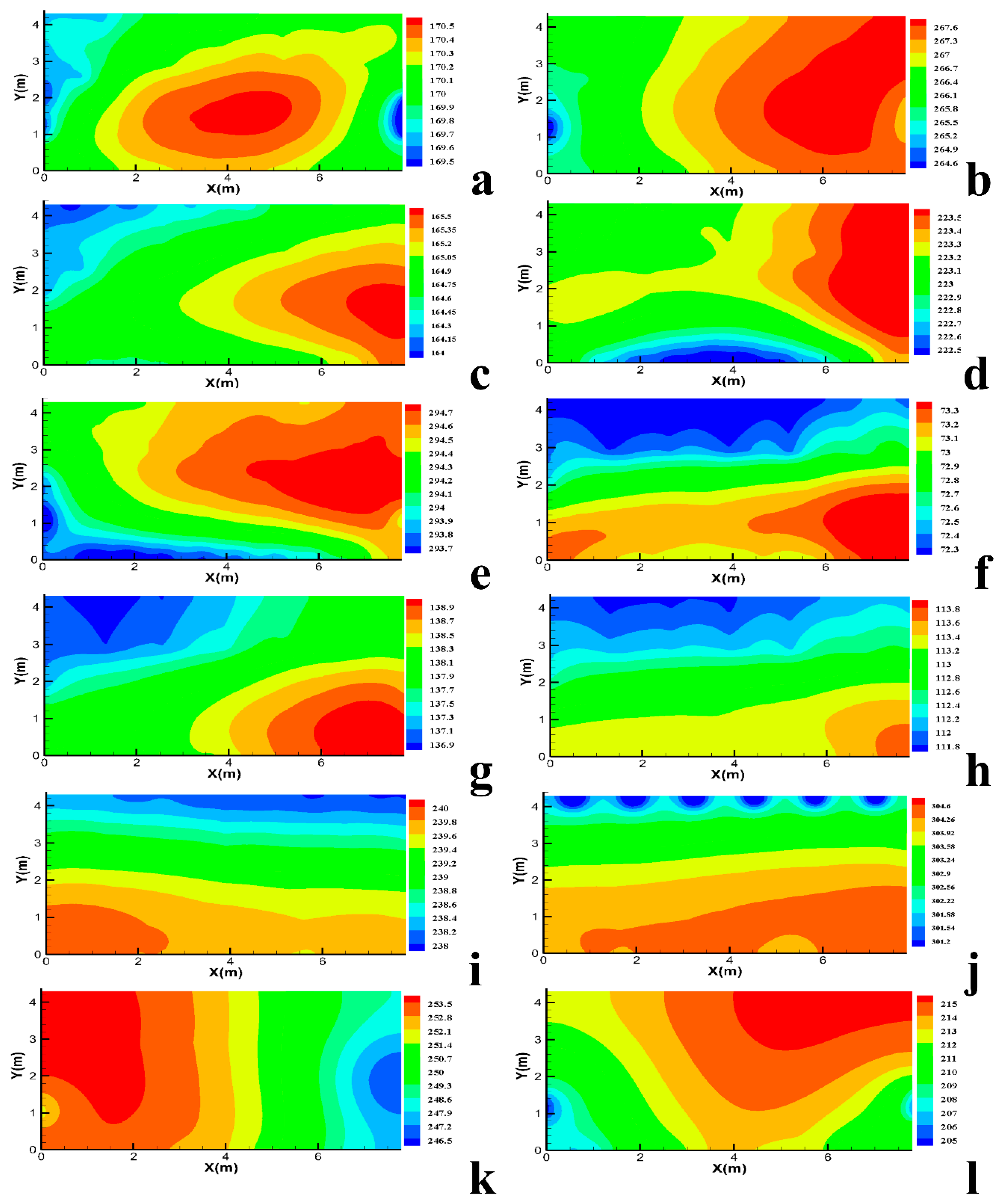

3.3. Air Age in the Occupied Zone under MV, PV, and IJV

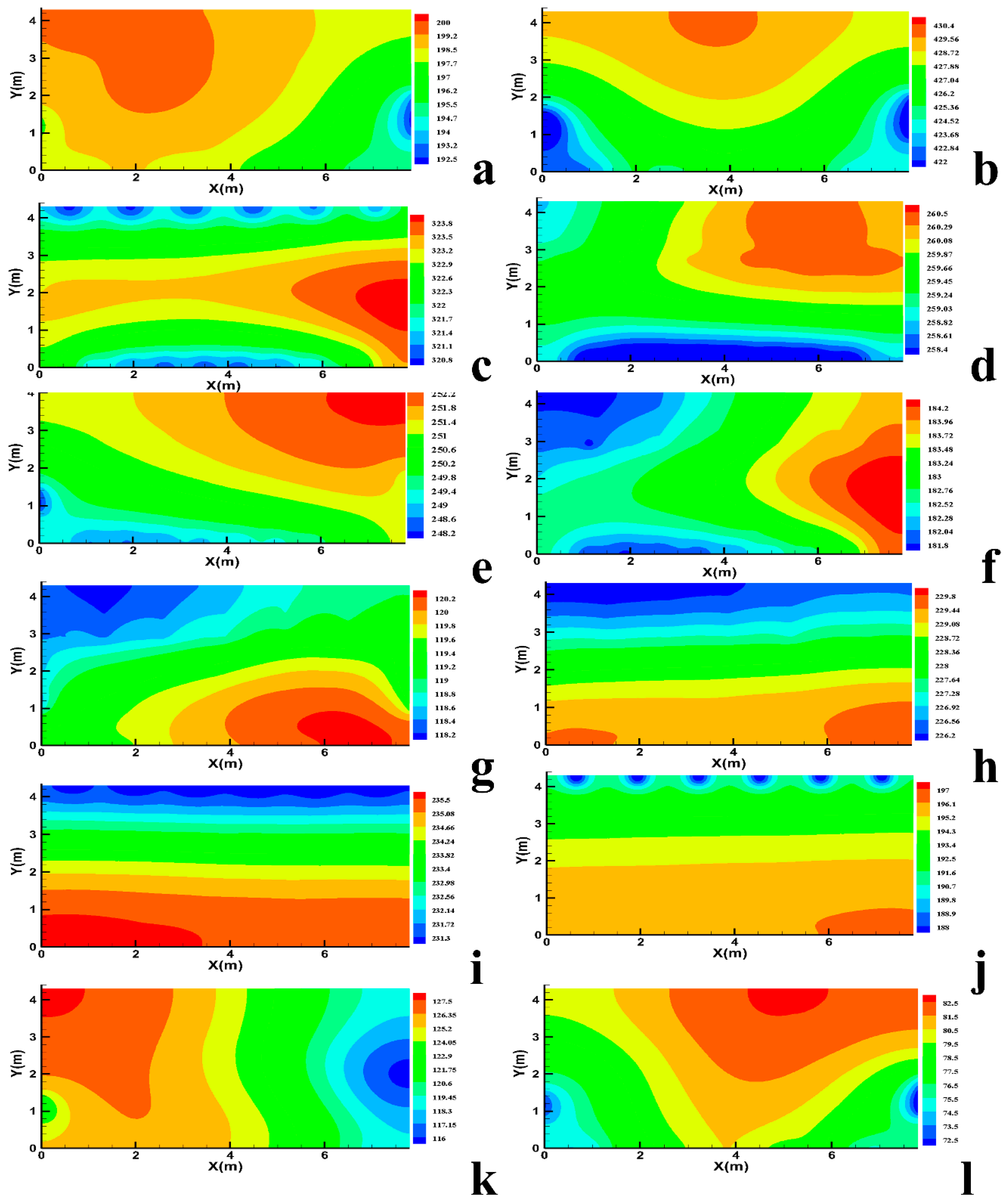

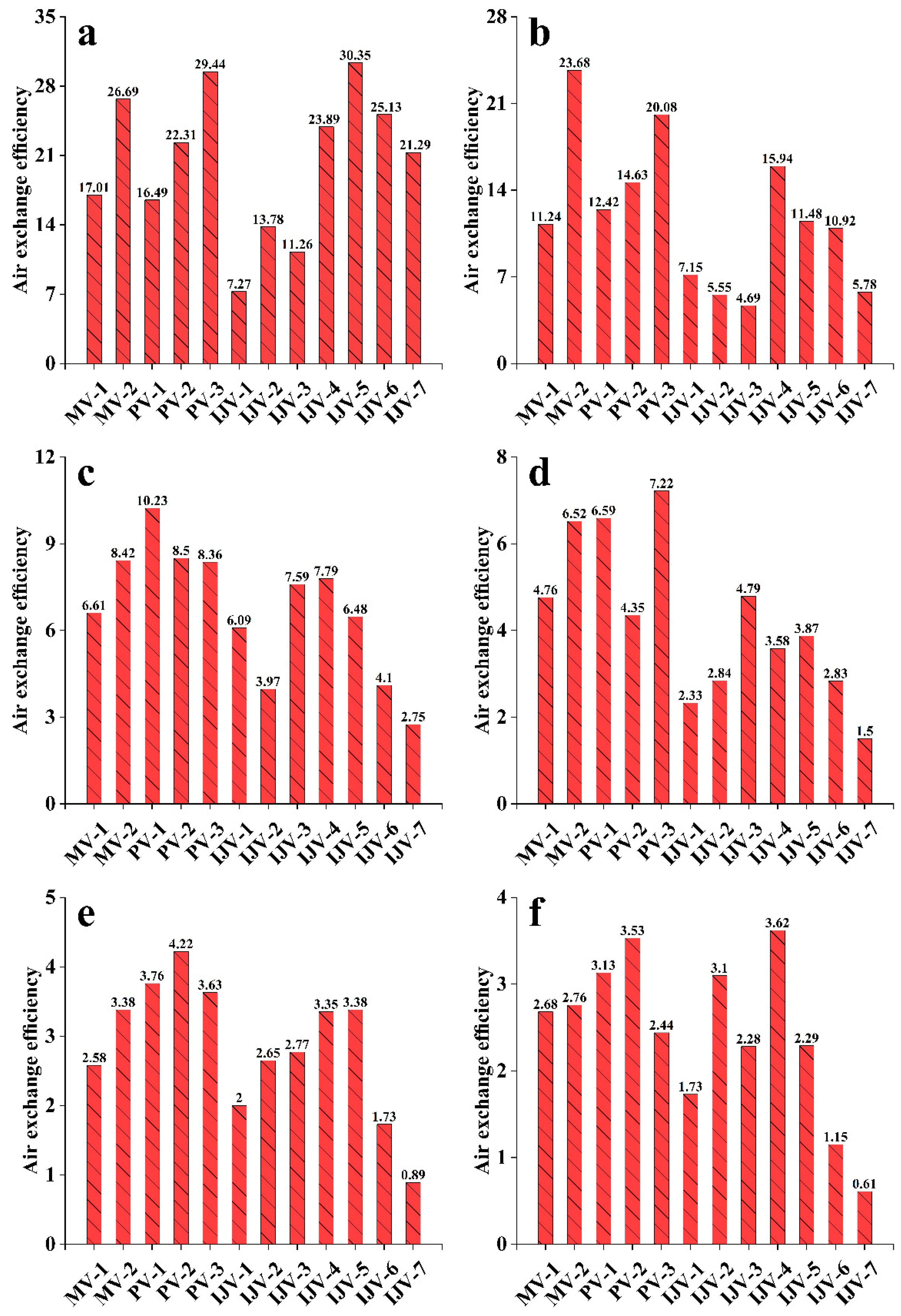

3.4. Air Exchange Efficiency in MV, PV, and IJV

4. Conclusions

- This study investigated the normalized concentrations of ammonia and hydrogen sulfide gas at the monitoring face under six ACHs (5h−1, 10 h−1, 15 h−1, 20 h−1, 25 h−1, and 30 h−1). The results show that the ventilation method, position of the air outlet and the supply air, and the ACH affect the concentration of pollutants. Increasing the ACH can reduce the normalized concentration of pollutants and improve the IAQ in public toilets.

- The mixed ventilation scheme is ineffective in removing pollutants, and IJV has advantages in reducing pollutants over PV and MV. IJV-7 performs best in reducing the normalized concentration of ammonia, and IJV-5 has an advantage in reducing the normalized concentration of hydrogen sulfide.

- Increasing the number of air changes may lead to a longer MAA. The IJV-7 program has the shortest MAA and the freshest air but the smallest AEE value. Therefore, it is vital to choose the correct number of air changes for different ventilation schemes.

- The research results of this paper supply a theoretical basis for improving ventilation efficiency. From the perspective of improving public health and the prevention of infectious diseases, this research is of great significance.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| C | Average concentration of contaminants in the immediate environment (mg·m−3) |

| Ce | Concentration of contaminants at the exhaust outlet (mg·m−3) |

| Cin | Concentration of contaminants at the air supply outlet (mg·m−3) |

| IAQ | Indoor air quality |

| CFD | Computational fluid dynamics |

| MV | Mixing ventilation |

| PV | Personalized ventilation |

| IJV | Impinging jet ventilation |

| MAA | Mean age of air |

| AEE | Air exchange efficiency |

| ACH | Air change rate per hour (h−1) |

References

- Zhu, S.; Zheng, X.; Stevanovic, S.; Wang, L.; Wang, H.; Gao, J.; Xiang, Z.; Ristovski, Z.; Liu, J.; Yu, M. Investigating particles, VOCs, ROS produced from mosquito-repellent incense emissions and implications in SOA formation and human health. Build. Environ. 2018, 143, 645–651. [Google Scholar] [CrossRef]

- Lim, S.S.; Vos, T.; Flaxman, A.D.; Danaei, G.; Shibuya, K.; Adair-Rohani, H.; AlMazroa, M.A.; Amann, M.; Anderson, H.R.; Andrews, K.G.; et al. A comparative risk assessment of burden of disease and injury attributable to 67 risk factors and risk factor clusters in 21 regions, 1990–2010: A systematic analysis for the Global Burden of Disease Study 2010. Lancet 2012, 380, 2224–2260. [Google Scholar] [CrossRef] [Green Version]

- He, X.; Zhou, G.; Ma, Y.; Li, L.; Luo, B. Winter vacation, indoor air pollution and respiratory health among rural college students: A case study in Gansu Province. China Build. Environ. 2020, 188, 107481. [Google Scholar] [CrossRef]

- Murga, A.; Long, Z.; Yoo, S.J.; Sumiyoshi, E.; Ito, K. Decreasing inhaled contaminant dose of a factory worker through a hybrid Emergency Ventilation System: Performance evaluation in worst-case scenario. Energy Built Environ. 2020, 1, 319–326. [Google Scholar] [CrossRef]

- Peng, B.Y.; Su, Y.; Chen, Z.; Chen, J.; Zhou, X.; Benbow, M.E.; Griddle, C.S.; Wu, W.M.; Zhang, Y. Biodegradation of Polystyrene by Dark (Tenebrio obscurus) and Yellow (Tenebrio molitor) Mealworms (Coleoptera: Tenebrionidae). Environ. Sci. Technol. 2019, 53, 5256–5265. [Google Scholar] [CrossRef]

- Steinemann, A.; Wargocki, P.; Rismanchi, B. Ten questions concerning green buildings and indoor air quality. Build. Environ. 2016, 112, 351–358. [Google Scholar] [CrossRef] [Green Version]

- Ben-David, T.; Rackes, A.; Lo, L.J.; Wen, J.; Waring, M.S. Optimizing ventilation: Theoretical study on increasing rates in offices to maximize occupant productivity with constrained additional energy use. Build. Environ. 2019, 166, 106314.1–106314.13. [Google Scholar] [CrossRef]

- Boots, A.W.; Berkel, J.V.; Dallinga, J.W.; Smolinska, A.; Wouters, E.; Schooten, F.V. The versatile use of exhaled volatile organic compounds in human health and disease. J. Breath Res. 2012, 6, 027108. [Google Scholar] [CrossRef]

- Sato, H.; Hirose, T.; Kimura, T.; Moriyama, Y.; Nakashima, Y. Analysis of malodorous volatile substances of human waste: Feces and urine. J. Health Sci. 2001, 47, 483–490. [Google Scholar] [CrossRef] [Green Version]

- Ao, Y.; Wang, L.; Jia, X.; Gu, C. Numerical Simulation of Pollutant Diffusion Law in Bathroom and Optimization of the Locations and Ways of Exhaust Outlet and Makeup Air, Shenyang Jianzhu Daxue Xuebao (Ziran Kexue Ban). J. Shenyang Jianzhu Univ. 2011, 27, 720–724. [Google Scholar]

- Sun, X.G. Hygienic Standards for Communal Toilet in City; Domestic-National Standards-State Administration for Market Regulation: Beijing, China, 1998.

- Zhang, S.; Cheng, Y.; Oladokun, O.; Wu, Y.; Lin, Z. Improving Predicted Mean Vote with Inversely Determined Metabolic Rate. Sustain. Cities Soc. 2019, 53, 101870. [Google Scholar] [CrossRef]

- Perez-Lombard, L.; Ortiz, J.; Maestre, I.R. The map of energy flow in HVAC systems. Appl. Energy 2011, 88, 5020–5031. [Google Scholar] [CrossRef]

- Zhang, S.; Lin, Z.; Ai, Z.; Wang, F.; Cheng, Y.; Huang, C. Effects of operation parameters on performances of stratum ventilation for heating mode. Build. Environ. 2019, 148, 55–66. [Google Scholar]

- Lin, Y.P. Natural Ventilation of Toilet Units in K–12 School Restrooms Using CFD. Energies 2021, 14, 4792. [Google Scholar] [CrossRef]

- Tung, Y.C.; Hu, S.C.; Tsai, T.I.; Chang, I.L. An experimental study on ventilation efficiency of isolation room. Build. Environ. 2009, 44, 271–279. [Google Scholar] [CrossRef]

- Tung, Y.C.; Hu, S.C.; Tsai, T.Y. Influence of bathroom ventilation rates and toilet location on odor removal. Build. Environ. 2009, 44, 1810–1817. [Google Scholar] [CrossRef]

- Tung, Y.C.; Shih, Y.C.; Hu, S.C.; Chang, Y.L. Experimental performance investigation of ventilation schemes in a private bathroom. Build. Environ. 2010, 45, 243–251. [Google Scholar] [CrossRef]

- Chung, S.C.; Lin, Y.P.; Yang, C.; Lai, C.M. Natural Ventilation Effectiveness of Awning Windows in Restrooms in K-12 Public Schools. Energies 2019, 12, 2414. [Google Scholar] [CrossRef] [Green Version]

- Haghshenaskashani, S.; Sajadi, B. Evaluation of Thermal Comfort, IAQ and Energy Consumption in an Impinging Jet Ventilation (IJV) System with/without Ceiling Exhaust. J. Build. Eng. 2018, 18, 142–153. [Google Scholar] [CrossRef]

- Lt, A.; Jg, A.; Zl, B.; Li, W.A.; Lz, A.; Gl, A.; Yw, A. A novel flow-guide device for uniform exhaust in a central air exhaust ventilation system. Build. Environ. 2019, 149, 134–145. [Google Scholar]

- Zeng, L.; Liu, G.; Gao, J.; Du, B.; Wang, Y. A circulating ventilation system to concentrate pollutants and reduce exhaust volumes: Case studies with experiments and numerical simulation for the rubber refining process. J. Build. Eng. 2020, 35, 101984. [Google Scholar] [CrossRef]

- Sui, X.; Tian, Z.; Liu, H.; Chen, H.; Wang, D. Field measurements on indoor air quality of a residential building in Xi’an under different ventilation modes in winter. J. Build. Eng. 2021, 42, 103040. [Google Scholar] [CrossRef]

- Gautam, K.R.; Rong, L.; Iqbal, A.; Zhang, G. Full-scale CFD simulation of commercial pig building and comparison with porous media approximation of animal occupied zone. Comput. Electron. Agric. 2021, 186, 106206. [Google Scholar] [CrossRef]

- Lv, L.; Zeng, L.; Wu, Y.; Gao, J.; Zhang, J. Effects of Human Walking on the Capture Efficiency of Range Hood in Residential Kitchen. Build. Environ. 2021, 196, 107821. [Google Scholar] [CrossRef]

- Lv, L.; Gao, J.; Zeng, L.; Cao, C.; He, L. Performance assessment of air curtain range hood using contaminant removal efficiency: An experimental and numerical study. Build. Environ. 2020, 188, 107456. [Google Scholar] [CrossRef]

- Sa, A.; Wc, A.; Ch, B.; Kg, C.; Ng, C. Influence of mixed and displacement air distribution systems’ design on concentrations of micro-particles emitted from floor or generated by breathing. J. Build. Eng. 2019, 26, 100855. [Google Scholar]

- Cao, G.; Nilssen, A.M.; Cheng, Z.; Stenstad, L.I.; Radtke, A.; Skogås, J. Laminar airflow and mixing ventilation: Which is better for operating room airflow distribution near an orthopedic surgical patient? Am. J. Infect. Control 2019, 47, 737–743. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Dai, X.; Wei, J.; Ai, Z.; Fan, Y.; Tang, L.; Jin, T.; Ge, J. Numerical comparison of the efficiency of mixing ventilation and impinging jet ventilation for exhaled particle removal in a model intensive care unit. Build. Environ. 2021, 200, 107955. [Google Scholar] [CrossRef]

- Xue, T.; Bla, B.; Ym, C.; Dong, L.C.; Yla, B.; Yong, C. Experimental study of local thermal comfort and ventilation performance for mixing, displacement and stratum ventilation in an office. Sustain. Cities Soc. 2019, 50, 101630. [Google Scholar]

- Fange, P.O. Human requirements in future air-conditioned environments. In Advances in Building Technology; Elsevier: Amsterdam, The Netherlands, 2002; pp. 29–38. [Google Scholar]

- Schiavon, S.; Melikov, A.K.; Sekhar, C. Energy analysis of the personalized ventilation system in hot and humid climates. Energy Build. 2010, 42, 699–707. [Google Scholar] [CrossRef]

- Shen, C.; Gao, N.; Wang, T. CFD study on the transmission of indoor pollutants under personalized ventilation. Build. Environ. 2013, 63, 69–78. [Google Scholar] [CrossRef]

- Cermak, R.; Melikov, A.K. Protection of occupants from exhaled infectious agents and floor material emissions in rooms with personalized and underfloor ventilation. Hvac&R Res. 2007, 13, 23–38. [Google Scholar]

- Gao, N.; Zhang, H.; Niu, J. Investigating indoor air quality and thermal comfort using a numerical thermal manikin. Indoor Built Environ. 2007, 16, 7–17. [Google Scholar] [CrossRef]

- He, Q.; Niu, J.; Gao, N.; Zhu, T.; Wu, J. CFD study of exhaled droplet transmission between occupants under different ventilation strategies in a typical office room. Build. Environ. 2011, 46, 397–408. [Google Scholar] [CrossRef]

- Cermak, R.; Melikov, A.K.; Forejt, L.; Kovar, O. Performance of personalized ventilation in conjunction with mixing and displacement ventilation. Hvac&R Res. 2006, 12, 295–311. [Google Scholar]

- Nielsen, P.V. Control of airborne infectious diseases in ventilated spaces. J. R. Soc. Interface 2009, 6, S747–S755. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ameen, A.; Cehlin, M.; Larsson, U.; Karimipanah, T. Experimental Investigation of the Ventilation Performance of Different Air Distribution Systems in an Office Environment—Heating Mode. Energies 2019, 12, 1835. [Google Scholar] [CrossRef] [Green Version]

- Karimipanah, T.; Awbi, H.B. Theoretical and experimental investigation of impinging jet ventilation and comparison with wall displacement ventilation. Build. Environ. 2002, 37, 1329–1342. [Google Scholar] [CrossRef]

- Qin, C.; Lu, W.Z. Effects of ceiling exhaust location on thermal comfort and age of air in room under impinging jet supply scheme. J. Build. Eng. 2021, 35, 101966. [Google Scholar] [CrossRef]

- Ye, X.; Zhu, H.; Kang, Y.; Zhong, K. Heating energy consumption of impinging jet ventilation and mixing ventilation in large-height spaces: A comparison study. Energy Build. 2016, 130, 697–708. [Google Scholar] [CrossRef]

- Ye, X.; Kang, Y.; Yang, F.; Zhong, K. Comparison study of contaminant distribution and indoor air quality in large-height spaces between impinging jet and mixing ventilation systems in heating mode. Build. Environ. 2019, 160, 106159. [Google Scholar] [CrossRef]

- Chen, H.J.; Moshfegh, B.; Cehlin, M. Numerical investigation of the flow behavior of an isothermal impinging jet in a room. Build. Environ. 2012, 49, 154–166. [Google Scholar] [CrossRef]

- Chen, H.; Moshfegh, B.; Cehlin, M. Computational investigation on the factors influencing thermal comfort for impinging jet ventilation. Build. Environ. 2013, 66, 29–41. [Google Scholar] [CrossRef]

- Ameen, A.; Cehlin, M.; Larsson, U.; Karimipanah, T. Experimental Investigation of the Ventilation Performance of Different Air Distribution Systems in an Office Environment—Cooling Mode. Energies 2019, 12, 1354. [Google Scholar] [CrossRef] [Green Version]

- Yao, S.; Yong, G.; Nan, J.; Liu, J. Experimental investigation of the flow behavior of an isothermal impinging jet in a closed cabin. Build. Environ. 2015, 84, 238–250. [Google Scholar] [CrossRef]

- Cooper, D.; Jackson, C.D.; Launder, E.B.; Liao, X.G. Impinging jet studies for turbulence model assessment—I. Flow-field experiments. Int. J. Heat Mass Transf. 1993, 36, 2675–2684. [Google Scholar] [CrossRef]

- Shi, Z.; Chen, Q. Experimental and computational investigation of wall-mounted displacement induction ventilation system. Energy Build. 2021, 241, 110937. [Google Scholar] [CrossRef]

- Li, X.; Li, D.; Yang, X.; Yang, J. Total air age: An extension of the air age concept. Build. Environ. 2003, 38, 1263–1269. [Google Scholar] [CrossRef]

- Aziz, M.A.; Gad, I.; Mohammed, E.; Mohammed, R.H. Experimental and numerical study of influence of air ceiling diffusers on room air flow characteristics. Energy Build. 2012, 55, 738–746. [Google Scholar] [CrossRef]

- Jurelionis, A.; Gagytė, L.; Prasauskas, T.; Čiužas, D.; Krugly, E.; Šeduikytė, L.; Martuzevičius, D. The impact of the air distribution method in ventilated rooms on the aerosol particle dispersion and removal: The experimental approach. Energy Build. 2015, 86, 305–313. [Google Scholar] [CrossRef]

- Buratti, C.; Palladino, D. Mean Age of Air in Natural Ventilated Buildings: Experimental Evaluation and CO2 Prediction by Artificial Neural Networks. Appl. Sci. 2020, 10, 1730. [Google Scholar] [CrossRef] [Green Version]

- Ning, M.; Mengjie, S.; Mingyin, C.; Dongmei, P.; Shiming, D. Computational fluid dynamics (CFD) modelling of air flow field, mean age of air and CO2 distributions inside a bedroom with different heights of conditioned air supply outlet. Appl. Energy 2016, 164, 906–915. [Google Scholar] [CrossRef]

- Chanteloup, V.; Mirade, P.-S. Computational fluid dynamics (CFD) modelling of local mean age of air distribution in forced-ventilation food plants. J. Food Eng. 2009, 90, 90–103. [Google Scholar] [CrossRef]

- Ng, K.C.; Ng, E.Y.K.; Yusoff, M.Z.; Lim, T.K. Applications of high-resolution schemes based on normalized variable formulation for 3D indoor airflow simulations. Int. J. Numer. Methods Eng. 2010, 73, 948–981. [Google Scholar] [CrossRef]

- Niachou, K.; Hassid, S.; Santamouris, M.; Livada, I. Experimental performance investigation of natural, mechanical and hybrid ventilation in urban environment. Build. Environ. 2008, 43, 1373–1382. [Google Scholar] [CrossRef]

- Liu, M.; Chang, D.; Liu, J.; Ji, S.; Lin, C.H.; Wei, D.; Long, Z.; Zhang, T.; Shen, X.; Cao, Q.; et al. Experimental investigation of air distribution in an airliner cabin mockup with displacement ventilation. Build. Environ. 2021, 191, 107577. [Google Scholar] [CrossRef]

- Gilani, S.; Montazeri, H.; Blocken, B. CFD simulation of stratified indoor environment in displacement ventilation: Validation and sensitivity analysis. Build. Environ. 2015, 95, 299–313. [Google Scholar] [CrossRef]

- Shaojie, J.; Jinfeng, M. Pollutant Concentration Research of Toilet in Natural Ventilation Conditions. Contam. Control. Air Cond. Technol. 2012, 4, 22–24. [Google Scholar]

- Yang, X.; Yang, H.; Ou, C.; Luo, Z.; Hang, J. Airborne transmission of pathogen-laden expiratory droplets in open outdoor space. Sci. Total Environ. 2021, 773, 145537. [Google Scholar] [CrossRef]

- Etheridge, D.W.; Sandberg, M. Building Ventilation: Theory and Measurement; Wiley: Chichester, UK, 1996. [Google Scholar]

- Lu, Y. HVAC HVAC Design Guidelines; China Construction Industry Press: Beijing, China, 1996. [Google Scholar]

- Desta, T.Z.; Buggenhout, S.V.; Brecht, A.V.; Meyers, J.; Aerts, J.M.; Baelmans, M.; Berckmans, D. Modelling mass transfer phenomena and quantification of ventilation performance in a full scale installation. Build. Environ. 2005, 40, 1583–1590. [Google Scholar] [CrossRef]

- Zhang, L.; Chow, T.T.; Fong, K.F.; Tsang, C.F.; Wang, Q. Comparison of performances of displacement and mixing ventilations. Part II: Indoor air quality. Int. J. Refrig. 2005, 28, 288–305. [Google Scholar]

- Simons, M.W.; Waters, J.R. Ventilation effectiveness parameters resulting from mechanical ventilation with recirculation. Int. J. Ventil. 2002, 1, 119–126. [Google Scholar] [CrossRef]

- Bartak, M.; Cermak, M.; Clarke, J.; Denev, J.; Drkal, F.; Lain, M.; Macdonald, I.; Majer, M.; Stankov, P. Experimental and numerical study of local mean age of air. In Proceedings of the 7th International Building Performance Simulation Association Conference, Rio de Janeiro, Brazil, 13–15 August 2001. [Google Scholar]

| Parts of the Model | Geometric Data (m) |

|---|---|

| Public toilet | 7.8 × 4.3 × 2.6 |

| Test chamber | 0.96 × 0.96 × 2.2 |

| Pollution source | 0.5 × 0.2 |

| M1 | (X) 0.2 × (Y) 0.2 |

| M2 | (Y) 0.4 × (Z) 0.4 |

| U1 | (X) 0.2 × (Z) 0.2 |

| S1 | (X) 0.2 × (Z) 0.2 |

| S3 | (X) 0.2 × (Z) 0.2 |

| J1 | (X) 0.2 × (Y) 0.2 |

| J6, J7 | (Y) 0.3 × (Z) 0.06 |

| Urinal | r = 0.1 |

| Stall | (X) 0.2 × (Y) 0.3 |

| Window-1 | (X) 0.965 × (Z) 0.6 |

| Window-2 | (Y) 0.55 × (Z) 1.4 |

| Door | (Y) 1.2 × (Z) 2.1 |

| Case | Exhaust Fan Position | ACH (h−1) |

|---|---|---|

| MV-1 | M1 | 5, 10, 15, 20, 25, 30 |

| MV-2 | M2 | 5, 10, 15, 20, 25, 30 |

| PV-1 | U1, S1 | 2.5, 5, 7.5, 10, 12.5, 15 |

| PV-2 | U1, S2 | 2.5, 5, 7.5, 10, 12.5, 15 |

| PV-3 | U1, S3 | 2.5, 5, 7.5, 10, 12.5, 15 |

| IJV-1 | U1, J1 | 2.5, 5, 7.5, 10, 12.5, 15 |

| IJV-2 | U1, J1 | 2.5, 5, 7.5, 10, 12.5, 15 |

| IJV-3 | J1 | 5, 10, 15, 20, 25, 30 |

| IJV-4 | J2 | 5, 10, 15, 20, 25, 30 |

| IJV-5 | J3 | 5, 10, 15, 20, 25, 30 |

| IJV-6 | J6 | 5, 10, 15, 20, 25, 30 |

| IJV-7 | J7 | 5, 10, 15, 20, 25, 30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Zeng, L.; Shi, H.; Liu, H.; Yin, W.; Shen, H.; Yang, L.; Gao, J.; Wang, L.; Zhang, Y.; et al. CFD Study on the Ventilation Effectiveness in a Public Toilet under Three Ventilation Methods. Energies 2021, 14, 8379. https://doi.org/10.3390/en14248379

Zhang Z, Zeng L, Shi H, Liu H, Yin W, Shen H, Yang L, Gao J, Wang L, Zhang Y, et al. CFD Study on the Ventilation Effectiveness in a Public Toilet under Three Ventilation Methods. Energies. 2021; 14(24):8379. https://doi.org/10.3390/en14248379

Chicago/Turabian StyleZhang, Zhonghua, Lingjie Zeng, Huixian Shi, Hua Liu, Wenjun Yin, Haowen Shen, Libin Yang, Jun Gao, Lina Wang, Yalei Zhang, and et al. 2021. "CFD Study on the Ventilation Effectiveness in a Public Toilet under Three Ventilation Methods" Energies 14, no. 24: 8379. https://doi.org/10.3390/en14248379

APA StyleZhang, Z., Zeng, L., Shi, H., Liu, H., Yin, W., Shen, H., Yang, L., Gao, J., Wang, L., Zhang, Y., & Zhou, X. (2021). CFD Study on the Ventilation Effectiveness in a Public Toilet under Three Ventilation Methods. Energies, 14(24), 8379. https://doi.org/10.3390/en14248379