Abstract

A very important aspect of proper preparation of the coal mixture for the coking process is its appropriate grinding. One of the parameters describing the energy input required for grinding is the Hardgrove index. This research was undertaken to determine the dependence of the Hardgrove grindability index on selected physicochemical properties of coal. The Hardgrove grindability index was determined using the available methods described in the standards, and the dependence on selected parameters was examined. A clear positive correlation with calorific value and smaller (also positive) correlations with moisture content and free swelling index was obtained. A slight negative correlation was also obtained with sulfur content.

1. Introduction

Due to its use in metallurgical processes, coking coal is included in the list of 30 critical raw materials of the EU [1]. Hard coal extraction in Poland in 2020 amounted to 54.7 million tonnes [2], including more than 12 million tonnes of coking coal [3]. A significant share of coal imports with various technical parameters is the reason for the strict determination of coal’s technical parameters. One of the parameters for assessing the quality of coal for the industry is determining its grindability [4]: the energy intensity of the grinding of energy media mixtures. Coal extraction in the world (including hard and bituminous coal) in 2020 amounted to 159 billion tons [5], including export and import of coal amounted to 36 billion tons–coal prices are determined by the calorific value (price related to coal with a calorific value of 6000 kcal/ton, i.e., 25 MJ/kg, sulfur content below 1%, ash content 11–15%, moisture content 11–15%, volatile matter content 22–37%) [6]. Grindability is an important parameter for the assessment of the suitability of coal for coking or power generation [7].

Research on the grindability of hard coal is carried out in Poland at AGH University of Science and Technology [8,9], at Central Mining Institute (GIG) [10] and at the Institute for Chemical Processing of Coal (IChPW) [11].

A detailed description of the coal grinding process in various devices has been presented in several dozen publications [12,13,14,15,16].

The paper [11] presented the results of a study on the influence of selected parameters of coal on the Hardgrove Grindability Index (HGI). The samples used in the investigation came from a Polish coking-coal mine. It was found that the mean random vitrinite reflectance value, a measure of the coal rank, was the parameter that had the most significant positive effect on coal grindability.

Ambar Nath Sengupta [17] developed a correlation of HGI with the simple analytical composition of coal. A new index named as Statistical Grindability Index (SGI) was introduced. SGI derived from proximate analysis of coal. SGI may be used to predict HGI with reasonable accuracy where the facility of HGI determination is not available.

In the study [18], a total of 96 hard coal samples from Zonguldak Coal Basin (Turkey) were analyzed initially with the standard method of coal grindability (HGI values were determined). In addition, an alternative method (ring mill with Malvern Mastersizer) was proposed in the study.

Investigations into the effects of moisture and coal blending on the Hardgrove grindability index were carried out on Collie coal from Western Australia [19].

A new method of estimation of the Hardgrove grindability index of Turkish coals by neural networks was proposed by [20]. Data from 163 sub-bituminous coals from Turkey were used, featuring 11 coal parameters (proximate analysis, group maceral analysis and rank). Results indicate that a hybrid neural network gave the most accurate HGI prediction.

In the study [21], the variable importance measurements (proximate and ultimate analysis, petrography) processed by Random Forest models were used for the prediction of the Hardgrove grindability index based on Kentucky coal samples.

Fundamental evaluation of petrographic effects on coal grindability by seasonal autoregressive integrated moving average (SARIMA) was done by Dindarloo et al. [22].

Investigation into the applicability of Bond Work Index (BWI) and Hardgrove Grindability Index (HGI) tests for biomass compared to Colombian coal was done by Williams et al. [23].

The paper [24] described the prediction of coal grindability based on petrography, proximate and ultimate analysis using multiple regression and artificial neural network models.

Prediction of grindability with multivariable regression and a neural network in Chinese coal is shown in Reference [25].

In this work, research was undertaken to determine the dependence of the parameter characterizing the grindability (the Hardgrove index) on the selected physicochemical properties of coal.

2. The Hardgrove Method for the Determination of Grindability

“Grindability” means the resistance of the crushed material to grinding. It depends on the hardness, compactness (consistency), texture and structure of the material, type of the crystal lattice, contents of minerals and other physical and chemical properties. The grindability of coal depends on the petrographic composition of the organic mass and the mineral composition of the non-flammable particle. It affects the grinding capacity and efficiency in the process of preparing energy media mixtures. The higher the grindability index, the better the performance of the process and, therefore, the less energy needed for the grinding.

One of the standard methods for determining the grindability of coal is the Hardgrove method. The method was developed in 1932, primarily to test the grindability of hard coals. In 1945, it was introduced to the industry by the American Society for Testing Materials (ASTM), designated as method “ASTM D. 409”. In 1951, this method was recognized as a standard test used in many countries (PN/G 04530, DIN 51 742, ISO 5074) [26,27,28].

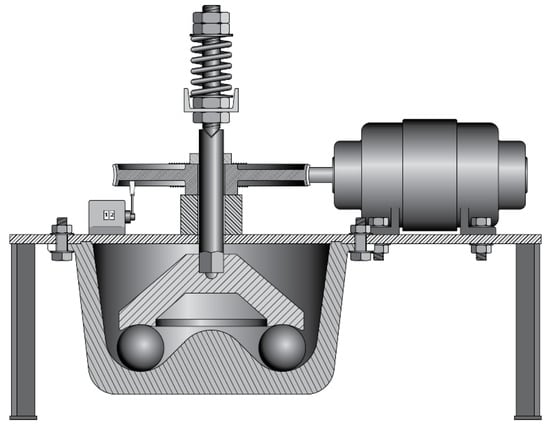

Figure 1 shows a diagram of the Hardgrove index measuring device built in 1932 by the author of the method.

Figure 1.

The system built in 1932 by R.M. Hardgrove to determine the grindability index. Self-prepared based on [29].

Assuming that the energy input on grinding is proportional to the newly formed surface (according to Rithinger’s law), this method compares the change in the surface of the tested coal sample with the change in the surface of the standard coal. In the Hardgrove method, the reference material is coal from the Kittanning deposit of the St. Jerome mine (Somerset, PA, USA), for which the Hardgrove grindability index is equal to 100.

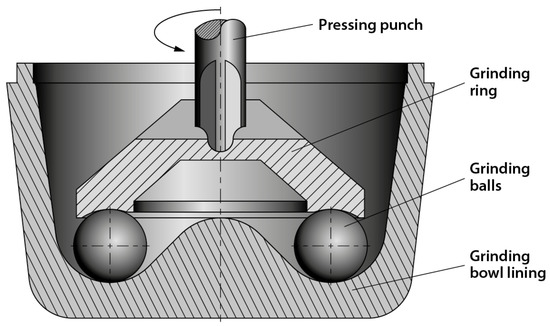

The device built by Hardgrove is a ball-ring mill. Figure 2 schematically shows the grinding components of this device. The Hardgrove mill consists of the following components [12]:

Figure 2.

A cross-section of the Hardgrove ball-ring mill. Self-prepared based on [30].

- An adequately shaped bowl, which is also a grinding race;

- Eight steel grinding balls with a diameter of 25.4 ± 0.13 mm;

- A rotating grinding ring made of steel, with an external diameter of 98.4 mm and a weight of 1.1 kg, acting simultaneously as the element driving the balls and pressing them to the grinding race;

- A clamping punch together with a toothed reduction gear with a total weight of 2.0 kg, acting also as the shaft driving the grinding ring;

- Three lead weights with a total weight of 25.9 kg (not shown in the figure).

The total weight of the grinding ring pressing the grinding balls, three weights and the punch with the toothed wheel should be 29.0 ± 0.2 kg. The rotational speed of the upper grinding element should be between 19 and 21 rpm.

In order to carry out the test, a test sample weighing 50 ± 0.01 g with a grain size of 0.60–1.19 mm is ground in the test mill. After the rotating grinding ring has made 60 ± 0.25 revolutions, the ground sample is sipped on a sieve with a mesh size of 0.075 mm. The resulting mass of G75 grains larger than the mesh size is the basis for determining the Hardgrove grindability index.

where is the mass (in grams) of the grain class exceeding 0.075 mm.

The above formula is valid only for the given grain class and for the test material concerned. The Hardgrove index is determined only by one point on the grain composition curve.

The benefits that can be obtained by using the Hardgrove test are:

- Small amount of material needed for analysis;

- Simplicity of the procedure;

- Short testing time and quick result.

Coal that requires large energy inputs during grinding has a low Hardgrove index value. The high values of the Hardgrove index testify to the ease of grinding the coal. There is also no simple relationship between the value of the Hardgrove index and the energy needed to grind a given coal sample. The value of the grindability index, GrH, equal to 100 does not indicate that twice less energy was used for grinding it than for grinding a sample with a Hardgrove index value of 50.

The values of the Hardgrove index (GrH or HGI) for coal used in the power industry range from 30 to 100, occasionally exceeding 100.

The disadvantage of the Hardgrove method is that it is not possible to determine directly (from the measurements made) the energy that needs to be used to fragment the tested sample. Test results can be translated into parameters relevant to the industrial conditions is possible if certain requirements are met. Practical operating conditions can be simulated by correlating the Hardgrove index with the Bond work index Wi by dependency [15]:

where GrH is the Hardgrove index.

3. Results of the Investigation

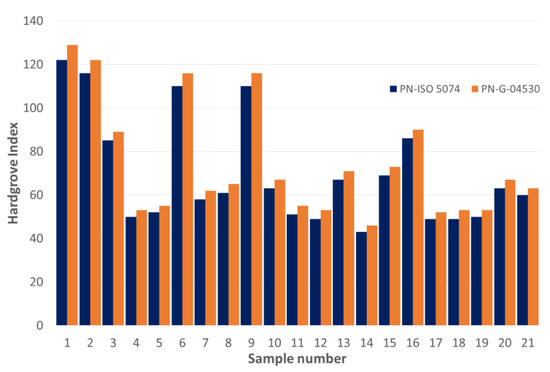

The research was carried out on 21 samples of coal obtained from various sources to determine their Hardgrove grindability index values (Figure 3), ash contents, moisture contents, sulfur contents, coking properties, free swelling index (FSI) values, dilatation, phosphorus contents and calorific values. The results are presented in Figure 4, Figure 5, Figure 6 and Figure 7.

Figure 3.

Comparison of Hardgrove index values calculated based on PN-ISO 5074 and PN-G-04530 standards.

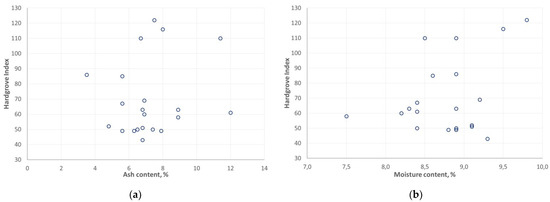

Figure 4.

The value of the Hardgrove index depending on the results of proximate analysis of the tested coals: (a) ash content and (b) moisture content.

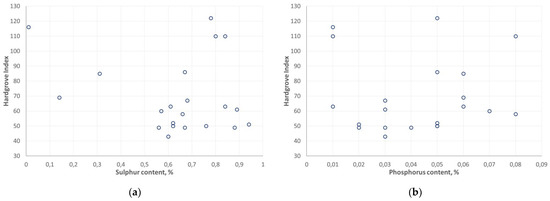

Figure 5.

The value of the Hardgrove index as a function of the content of selected elements in the coals studied: (a) sulfur and (b) phosphorus.

Figure 6.

The value of Hardgrove index as a function of coking parameters of the coals studied: (a) Roga index, (b) free swelling index and (c) dilation.

Figure 7.

Hardgrove index values versus caloric values of tested coals.

Calculation of Hardgrove index values using the method presented in PN-G-04530 [26] standard gives results about 5–8% higher than when using ISO 5074 standard [27].

4. The Determination of the Correlation of Selected Physicochemical Parameters of Coal with the Value of the Hardgrove Index

The research was carried out on 21 samples of coal obtained from Poland, Czech Republic and Russia and on mixtures of these coals.

The correlation between the parameters studied and the Hardgrove index was determined using Pearson’s correlation coefficient determined by the following equation:

where and are the values of the tested parameter and the Hardgrove index for the i-th coal sample, respectively, while and are the average values of the tested parameter and the Hardgrove index calculated for all samples, respectively; n is the number of samples.

Table 1 shows the results of the correlation calculation between selected parameters and the Hardgrove index.

Table 1.

Pearson correlation coefficient between selected parameter and Hardgrove index.

For the proximate analysis results, a slight positive correlation can be observed for moisture content. The ash content does not correlate with the Hardgrove index. There is a very weak negative correlation for sulfur content analysis results. Phosphorus content does not correlate with the Hardgrove index. Analyzing the influence of coking indices, one can observe a significant influence of free swelling index (higher Hardgrove index value with higher free swelling indices). Dilatation and Roga indices do not show any correlation. The only parameter that correlated very clearly with the Hardgrove index is the calorific value. At higher calorific values, we observe higher Hardgrove index values, i.e., more calorific coals require less grinding effort.

5. Conclusions

Determining the properties of coal, in particular, the grindability, is of great importance because coal graining plays a huge role in each use of coal: combustion, gasification, enrichment and pyrolysis. The energy consumption for breaking up (grinding) coal is significant and amounts to 5–15 kWh/t.

The mechanical properties of coal, such as the modulus of elasticity, compressibility, strength and microhardness, are not sufficient to determine the grindability. The heterogeneous nature of coal makes it difficult to predict HGI values. To determine the behavior of different coals in the grinding process, grindability tests are used.

Low-carbon coals behave differently in the grinding process (they are harder to comminute) than high-carbon coals. Coals with medium and low content of volatile parts are the easiest to grind.

For proximate analysis results, we observed a slight positive correlation for moisture content. The moisture content of 7–8.5% is correlated with a low value of the Hardgrove index. The ash content does not correlate with the Hardgrove index.

In the final analysis of results, we observed that HGI decreases when the sulfur content increases. Phosphorus content does not correlate with the Hardgrove index.

Analyzing the influence of coking indices, one can observe a significant influence of the free swelling index (higher Hardgrove index value with higher free swelling indices). Dilatation and Roga indices do not show any correlation.

The only parameter that correlated very strongly with the Hardgrove index is the calorific value. At higher calorific values, we observe higher Hardgrove index values, i.e., more calorific coals require less grinding effort.

In the next stage of the study, an analysis of the influence of the petrographic composition of coal samples on the value of the Hardgrove index will be presented.

Author Contributions

Conceptualization, B.T. and D.K.; methodology, B.T. and V.C.; validation, R.P. and T.S.; formal analysis, D.M.F.; investigation, K.K.; resources, P.M.; data curation, B.T.; writing—original draft preparation, B.T., R.P. and K.K.; writing—review and editing, K.K., R.P. and B.T.; visualization, K.K.; supervision, B.T.; project administration, B.T.; funding acquisition, B.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was co-financed by the Research Subsidy of the AGH University of Science and Technology for the Faculty of Energy and Fuels (No. 16.16.210.476) and by the Faculty of Civil Engineering and Resource Management (No. 16.16.100.215).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- European Commission. Study on the EU’s List of Critical Raw Materials (2020) Final Report; European Commission: Brussels, Belgium, 2021. [Google Scholar] [CrossRef]

- Statistics Poland, Enterprises Department, Energy and Raw Materials Balanced Section. Energy 2021; Statistics Poland: Warszawa, Poland, 2021. [Google Scholar]

- JSW SA Annual Report. 2020. Available online: https://www.jsw.pl/raportroczny-2020/nasze-otoczenie/otoczenie-rynkowe-i-konkurencyjne#rynek_koksu-tab (accessed on 27 November 2021).

- Olkuski, T. Polish energy policy concerning hard coal mining economy after 1989. Inżynieria Miner. J. Polish Miner. Eng. Soc. 2020, 2, 101–110. Available online: http://www.potopk.com.pl/Full_text/2020_n2_v2_full/IM%202-2020-v2-a15.pdf (accessed on 3 December 2021). [CrossRef]

- BP. Statistical Review of World Energy, 70th ed.; BP: London, UK, 2021. [Google Scholar]

- International Energy Agency (IEA). Coal 2020, Analysis and Forecast to 2025; IEA Publications: Paris, France, 2021. [Google Scholar]

- Olkuski, T.; Sikora, A.; Sikora, M.P.; Szurlej, A. Forecasts of Production, Consumption, and the Trade Balance of Primary Energy and Fuels in the USA. Inżynieria Miner. J. Polish Miner. Eng. Soc. 2019, 2, 327–334. Available online: https://www.potopk.com.pl/Full_text/2019_full/IM%202-2019-a51.pdf (accessed on 3 December 2021). [CrossRef]

- Tora, B. Model of the Grinding Process (In Polish: Model Procesu Mielenia); VSB TU: Ostrava, Czech Republic, 2001. [Google Scholar]

- Tora, B.; Kogut, K. Energy Coal Mixtures. Properties, Milling, Combustion (In Polish: Węglowe Mieszanki Energetyczne. Właściwości, Mielenie, Spalanie); Uczelniane Wydawnictwo Naukowo-Dydaktyczne AGH: Kraków, Poland, 2005. [Google Scholar]

- Róg, L. Factors determining of grindability of hard coals (in polish: Czynniki wpływające na podatność przemiałową węgli kamiennych). In Research Reports of Mining and Environment; No 3; GIG: Katowice, Poland, 2007; pp. 39–53. [Google Scholar]

- Rejdak, M.; Micorek, T.; Hower, J.C. Influence of selected factors of Polish coking coals on the Hardgrove Grindability Index (HGI). Int. J. Coal Prep. Util. 2021, 41, 789–802. [Google Scholar] [CrossRef]

- Nawrocki, J.; Ryncarz, A.; Węglarczyk, J. Grinding Theory and Practice (In Polish: Teoria i Praktyka Rozdrabniania); Dział Wydawnictw Politechniki Śląskiej: Gliwice, Poland, 1989. [Google Scholar]

- Drzymała, Z. Research and Fundamentals of Special Mill Design (In Polish: Badania i Podstawy Konstrukcji Młynów Specjalnych), 1st ed.; Wydawnictwo Naukowe PWN: Warszawa, Poland, 1992. [Google Scholar]

- Ryncarz, A. Coal milling susceptibility tests by the Bond work index and Hardgrove index methods (in polish: Badania podatności na mielenie węgla metodą indeksu pracy Bonda i wskaźnika Hardgrove’a). Przegląd Górniczy 1994, 9, 21–24. [Google Scholar]

- Woyciechowski, W. Investigations into the Grinding Behavior of Coals and Coal Mixtures (In Deutsch: Untersuchungen zum Mahlverhalten von Kohlen und Kohlenmischungen). Ph.D. Thesis, Technische Universität Clausthal, Clausthal-Zellerfeld, Germany, 1995. [Google Scholar]

- Żelkowski, J.; Woyciechowski, W.; Strugała, A. Determination of grindability by Hardgrove’s method—A review of experiments (in polish: Oznaczanie podatności przemiałowej metodą Hardgrove’a–przegląd doświadczeń). In Zeszyty Naukowe Politechniki Śląskiej, seria Górnictwo; Dział Wydawnictw Politechniki Śląskiej: Gliwice, Poland, 1996; p. 231. [Google Scholar]

- Sengupta, A.N. An assessment of grindability index of coal. Fuel Process Technol 2002, 76, 1–10. [Google Scholar] [CrossRef]

- Yilmaz, S. A new approach for the testing method of coal grindability. Adv. Powder Technol. 2019, 30, 1932–1940. [Google Scholar] [CrossRef]

- Vuthaluru, H.B.; Brooke, R.J.; Zhang, D.K.; Yan, H.M. Effects of moisture and coal blending on Hardgrove Grindability Index of Western Australian coal. Fuel Process Technol. 2003, 81, 67–76. [Google Scholar] [CrossRef]

- Özbayoğlu, G.; Özbayoğlu, A.M.; Özbayoğlu, M.E. Estimation of Hardgrove grindability index of Turkish coals by neural networks. Int. J. Min. Process 2008, 85, 93–100. [Google Scholar] [CrossRef]

- Matin, S.S.; Hower, J.C.; Farahzadi, L.; Chelgani, S.C. Explaining relationships among various coal analyses with coal grindability index by Random Forest. Int. J. Min. Process 2016, 155, 140–146. [Google Scholar] [CrossRef]

- Dindarloo, S.; Hower, J.C.; Bagherieh, A.H.; Trimble, A.S. Fundamental evaluation of petrographic effects on coal grindability by seasonal autoregressive integrated moving average (SARIMA). Int. J. Min. Process 2016, 154, 94–99. [Google Scholar] [CrossRef]

- Williams, O.; Eastwick, C.; Kingman, S.; Giddings, D.; Lormor, S.; Lester, E. Investigation into the applicability of Bond Work Index (BWI) and Hardgrove Grindability Index (HGI) tests for several biomasses compared to Colombian La Loma coal. Fuel 2015, 158, 379–387. [Google Scholar] [CrossRef]

- Chelgani, S.C.; Hower, J.C.; Jorjani, E.; Mesroghli, S.; Bagherieh, A.H. Prediction of coal grindability based on petrography, proximate and ultimate analysis using multiple regression and artificial neural network models. Fuel Process Technol. 2008, 89, 13–20. [Google Scholar] [CrossRef]

- Li, P.; Xiong, Y.; Yu, D.; Sun, X. Prediction of grindability with multivariable regression and neural network in Chinese coal. Fuel 2005, 84, 2384–2388. [Google Scholar] [CrossRef]

- Polish Standard. Hard Coal, Determination of Grindability by the Hardgrove Method (In Polish: Węgiel Kamienny. Oznaczanie Podatności Przemiałowej Metodą Hardgrove’a); PN-78/G-04530; Polish Standard: Warszawa, Poland, 1978. [Google Scholar]

- ISO Standard. Hard Coal, Determination of Hardgrove Grindability Index; ISO 5074; ISO Standard: Geneva, Switzerland, 2015. [Google Scholar]

- German Industry Standard. Determination of the Hardgrove Grindability Index of Hard Coal (In Deutsch: Prüfung Fester Brennstoffe-Bestimmung der Mahlbarkeit von Steinkohle nach Hardgrove); DIN 51472; German Industry Standard: Berlin, Germany, 2001. [Google Scholar]

- Beke, B. The Process of Fine Grinding, 1st ed.; Akadémiai Kiadó: Budapest, Hungary, 1981. [Google Scholar]

- Su, O.; Toroglu, I.; Akcin, N.A. An Evaluation of the Impact Strength Index as a Criterion of Grindability. Energy Source Part A 2010, 32, 1671–1678. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).