Towards Sustainable Heat Supply with Decentralized Multi-Energy Systems by Integration of Subsurface Seasonal Heat Storage

Abstract

:1. Introduction

1.1. Goal and Approach

1.2. Structure

2. Materials and Methods

2.1. HT-ATES Model

2.1.1. Modelling Approach

- -

- Spatial discretization. The spatial discretization in the horizontal direction is 0.5 m close to the well location. Because flow velocity decreases with the radial distance from the well, the cell size may increase outwards. This was done logarithmically to a maximum of 50 m at the model domain boundary. To prevent boundary conditions from influencing simulation results, several test runs were carried out. The test runs showed that outcomes did not change significantly (<1%) with an increasing grid size of 1500 m around the well. This was therefore set as the outer model boundary distance. To allow for sufficient detail/insight in the vertical (free convection) flow component, the vertical layers are also discretized at high resolution; 0.5 m thickness. Further refining of the modelling grid did not result in different results. The discretization was therefore assessed to be sufficient.

- -

- Temporal discretization. Internal time steps of the SEAWAT model are limited because of the courant number that is implemented in the advection package. We use a value of 0.8, meaning that the maximal distance that advection will be allowed in one internal transport time step is 0.8 cell length; the length of the time step is automatically adjusted accordingly. Model input and output is changed and transferred with the multi-energy system model with a daily time step. This means that the flow in/out of the wells is changed once a day and evenly divided for this timespan.

- -

- Boundary conditions. The boundary conditions are set as constant head and constant temperature at the outer boundary of the modelling domain. The top and bottom of the model are set as constant temperature and no-flow boundary. The constant temperature is equal to the starting temperature of the aquifer groundwater, Tamb = 12 °C. Therefore, water enters the model via the well or via the outer model boundary (at 1500 m distance). Heat can leave the model domain via the top, bottom, and outer model boundaries.

- -

- Subsurface characterization and hydrogeology. The characterization of the subsurface parameters follows the subsurface model presented in [24], which is a 30 m thick homogeneous aquifer. The model consists of an aquifer confined by 25 m thick aquitards at the top and bottom. Aquifer horizontal hydraulic conductivity is 35 m/d, aquitard horizontal hydraulic conductivity is 0.05 m/d, and hydraulic conductivity anisotropy was used as Kh/Kv = 5 for both the aquifer and the aquitard.

- -

- Well implementation. The simulated wells have a fully penetrating well screen (Lwell = 30 m). The well screen consists of multiple grid cells based on the vertical discretization. The flow for each well screen cell is calculated proportionally to the transmissivity distribution along the layers belonging to the cells. For the modelled homogeneous aquifer, this results in equal flow distribution over the well screen length. The extraction temperature of each well cell is calculated by SEAWAT as the average well temperature at the well screen during extraction or injection.

- -

- -

- Solvers. The groundwater flow is solved using the Preconditioned Conjugate Gradient 2 package. The standard finite-difference method with upstream or central-in-space weighting is applied in the advection package.

| Parameter | Value | Used for Package Class [35] |

|---|---|---|

| Water heat capacity | 4.18 kJ/kg/°C | RCT |

| Solid heat capacity * | 710 kJ/kg °C | RCT |

| Water reference density | 1000 kg/m3 | RCT |

| Solid density * | 2640 kg/m3 | RCT |

| Water thermal conductivity | 0.58 W/m/°C | RCT |

| Solid thermal conductivity | 3 W/m/°C | RCT |

| Thermal distribution coefficient # | 1.7 × 10−4 m3/kg | RCT |

| Thermal retardation + | 2.21 | RCT |

| Porosity | 0.3 | BTN |

| Specific storage aquifer | 6 × 10−4/m | LPF |

| Longitudinal dispersion | 0.5 m | DSP |

| Transversal dispersion | 0.05 m | DSP |

| Vertical dispersion | 0.005 m | DSP |

| Effective molecular diffusion heat # | 0.157 m2/day | DSP |

| Effective molecular diffusion salt | 8.6 × 10−6 m2/day | DSP |

2.1.2. Implementation of Variable Viscosity and Density

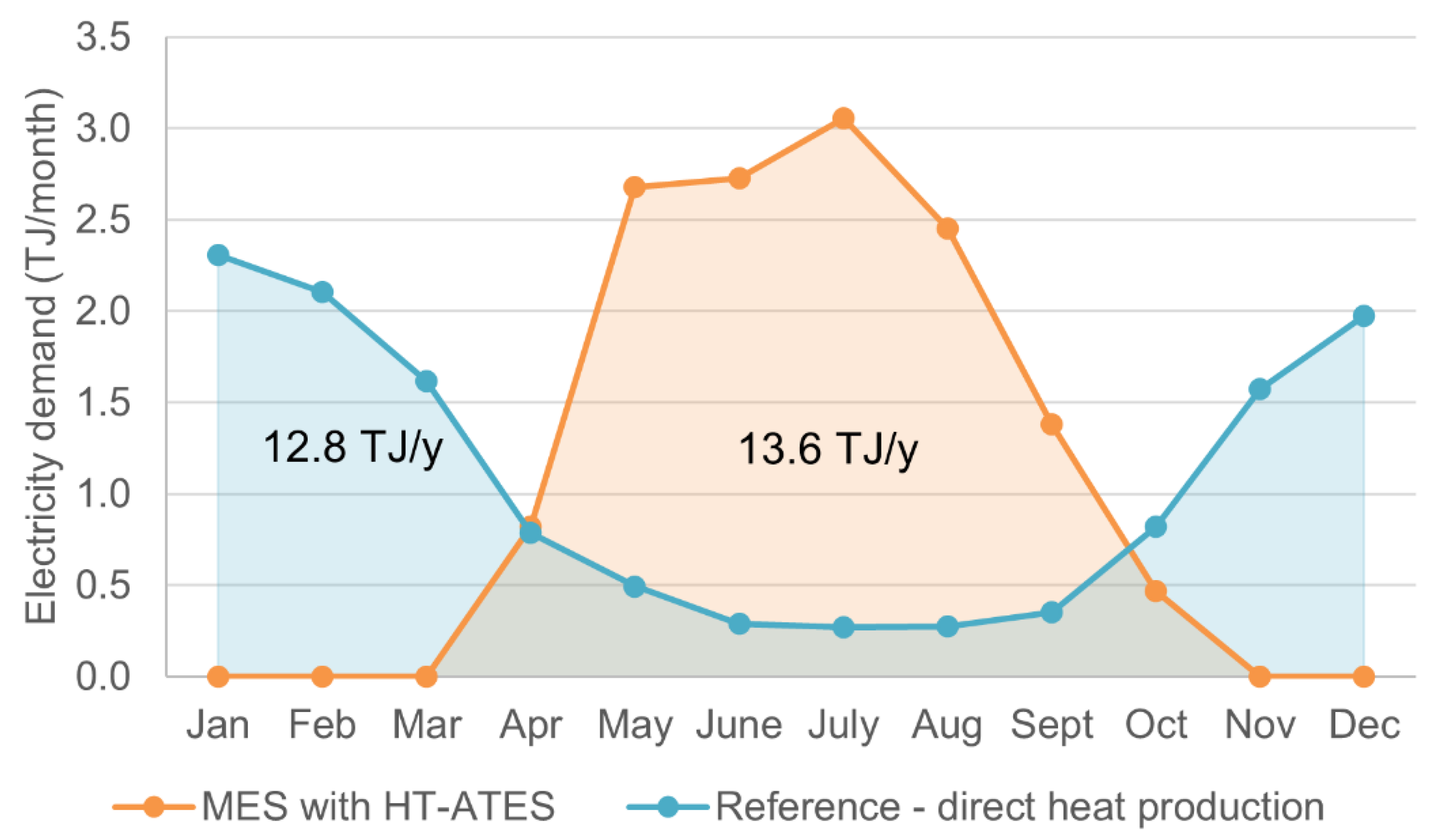

2.2. Multi-Energy System Model

2.2.1. COP Heat Pump

2.2.2. Heat Demand Pattern

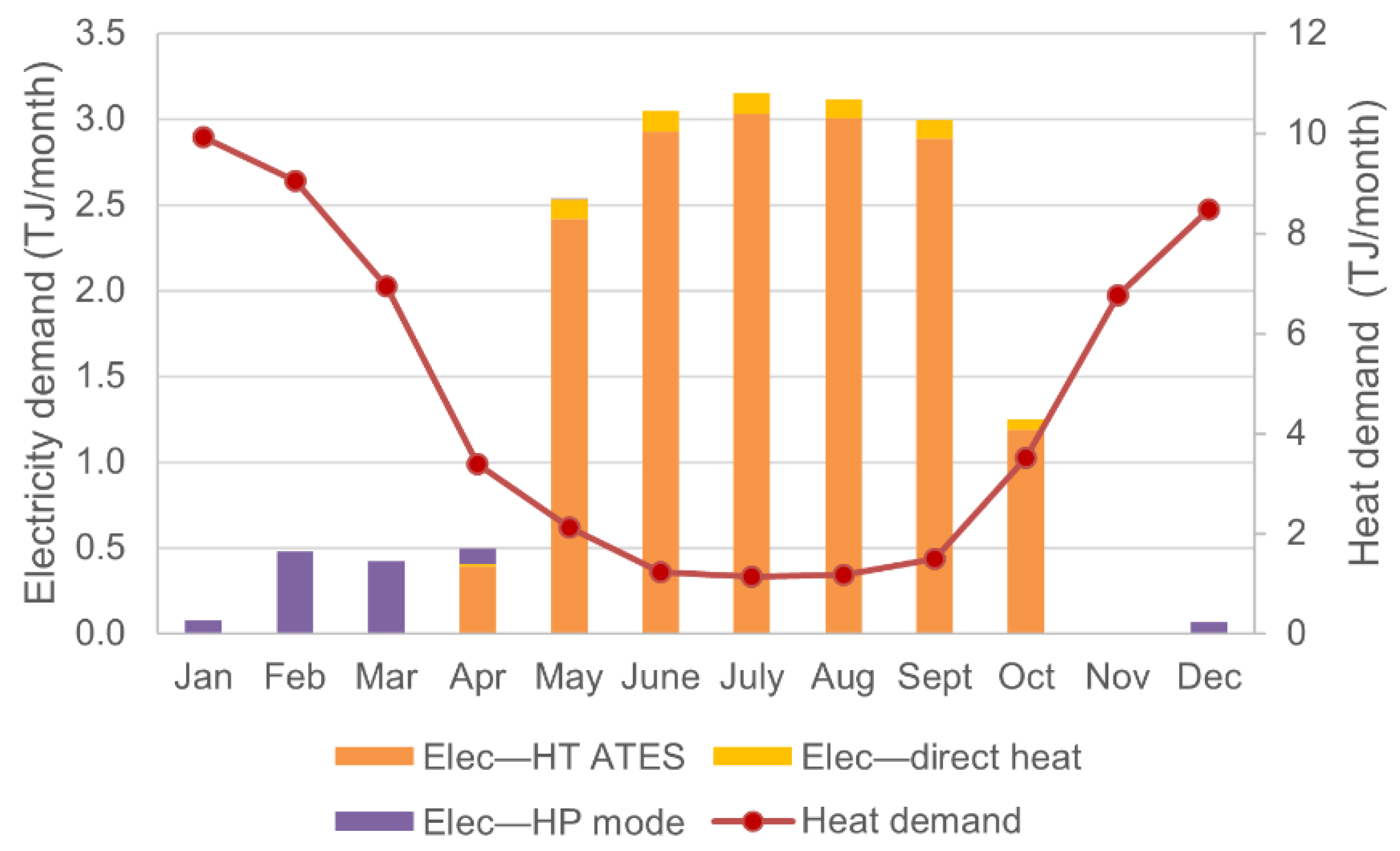

2.2.3. Heat Supply Pattern

2.2.4. Coupling of the HT-ATES Model and the Multi-Energy System-Model

2.3. Application of the Multi-Energy System Model in a Case Study

2.3.1. Case Description; Nieuwegein, The Netherlands

2.3.2. Modes of Operation for the Heat Pump and HT-ATES

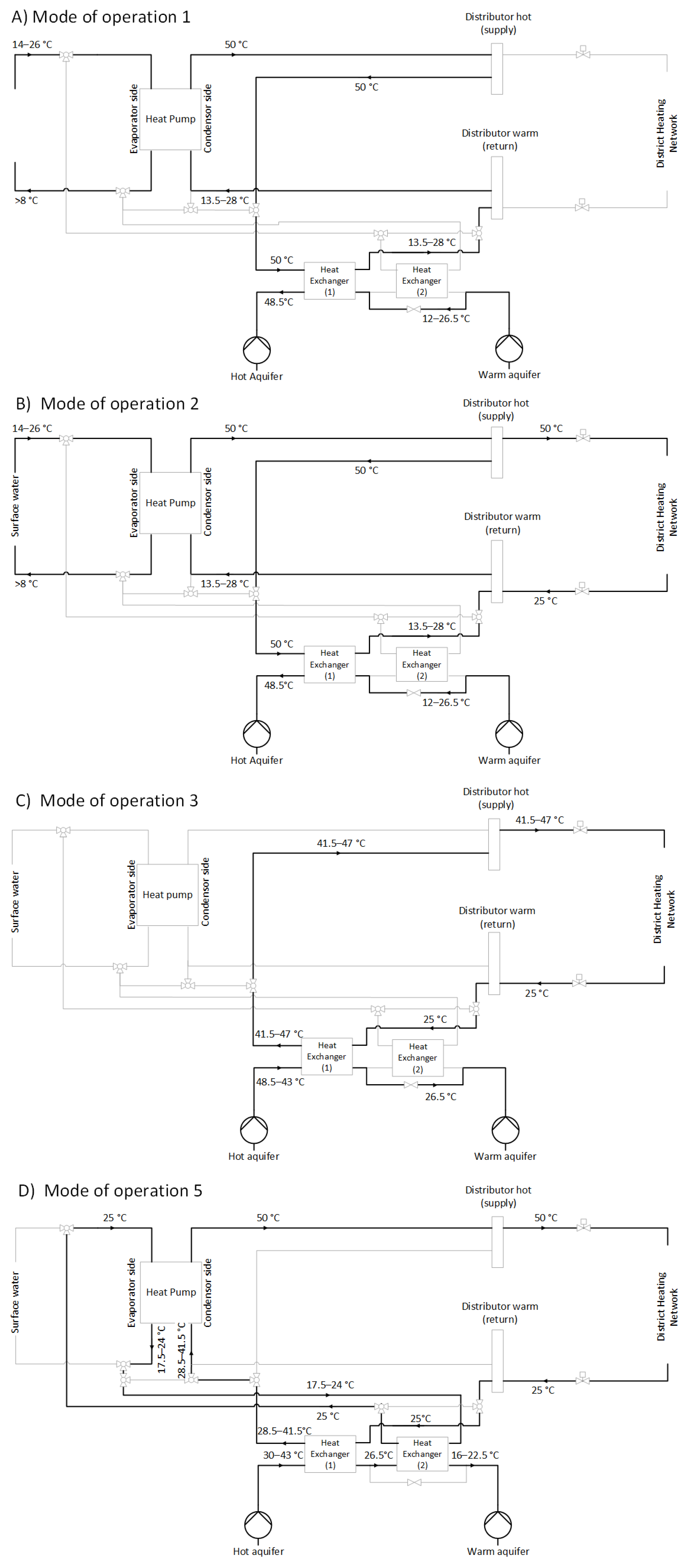

- Heat production and storage in the HT-ATES (no heat demand)In this mode of operation, heat is produced with surface water (14–26 °C) as input during the summer months (see Figure 3A). Heat is injected into the hot aquifer at 48.5 °C (assumed 1.5 °C loss over the heat exchanger).

- Simultaneous heat production and deliveryIf there is a heat demand at a time when the heat pump is producing heat (during summer), the heat demand is fulfilled directly from the heat pump (50 °C) via the hot distributor (see Figure 3B). After fulfilling the heat demand, the remainder of the heat is injected into the hot aquifer at 48.5 °C.

- Heat delivery from the HT-ATES above the inlet temperature of the district heating network (hot well > 43 °C)In the period from October–April (approximately), the heat pump is not able to produce heat with surface water as the surface water temperature is too low (<14 °C). Heat demand from the multi-energy system is now fulfilled by extracting heat from the hot aquifer of the HT-ATES system (see Figure 3C). Water from the hot well (43–48.5 °C) is extracted and exchanged with the return flow from the DHN (25 °C) and subsequently injected into the warm well (at 26.5 °C). The heat supply flow of the DHN is heated to 41.5–47 °C.

- HT-ATES is shut off. (Hot well under threshold temperature < 43 °C)In this mode of operation, the temperature of the hot aquifer has dropped below the threshold temperature (43 °C) to guarantee heat delivery at 40 °C. The HT-ATES system is now shut off and cannot be used to fulfil the heat demand of the multi-energy system.In this case, heat must be delivered from another (external) source, such as a peak boiler or a sustainable heat source. This is not included in this analysis.

- 5.

- HT-ATES feeds heat pump mode; heat delivery from the HT-ATES with alternative threshold temperature (hot well temperature between 30 °C and 43 °C)To prolong heat delivery from the HT-ATES system, we designed an extra mode of operation for the heat pump and HT-ATES. In this mode of operation, the heat delivery from the HT-ATES continues when the temperature of the hot well is below 43 °C but above 30 °C. This is possible because of additional heat exchange with the HT-ATES in combination with a heat lift by the heat pump (see Figure 3D). First, the return flow of the DHN is exchanged with water from the hot well (30–43 °C) and thereby the return flow is heated to 28.5–41.5 °C. This already heated return flow of the DHN is then fed to the condenser side of the heat pump and raised to 50 °C. The flow from the hot aquifer is thus first exchanged with the return flow of the DHN, which results in a temperature of 26.5 °C. Then, the same flow is led to a second heat exchanger, to extract more heat by a (closed) loop that is connected to the evaporator side of the heat pump (inlet temperature of 25 °C). The return flow from the evaporator side of the heat pump is then finally exchanged with the flow that is injected in the warm well (at 16–22.5 °C). In this way, the heat from the hot well is exchanged in two stages before being injected into the warm well, making the heat exchange more efficient. Moreover, the injection temperature in the warm well is decreased, creating a larger ΔT between the wells which could be beneficial for the HT-ATES efficiency. The electricity demand of the heat pump in this mode is retrieved directly from local RES (renewable energy systems) when possible, or from the grid when no electricity from local RES is available.

2.4. Scenarios

2.5. Assessment Framework

2.5.1. Fulfilment of Heat Demand

2.5.2. HT-ATES Performance

2.5.3. MES Performance

2.5.4. Economic Analysis/Levelized Cost of Energy

3. Results

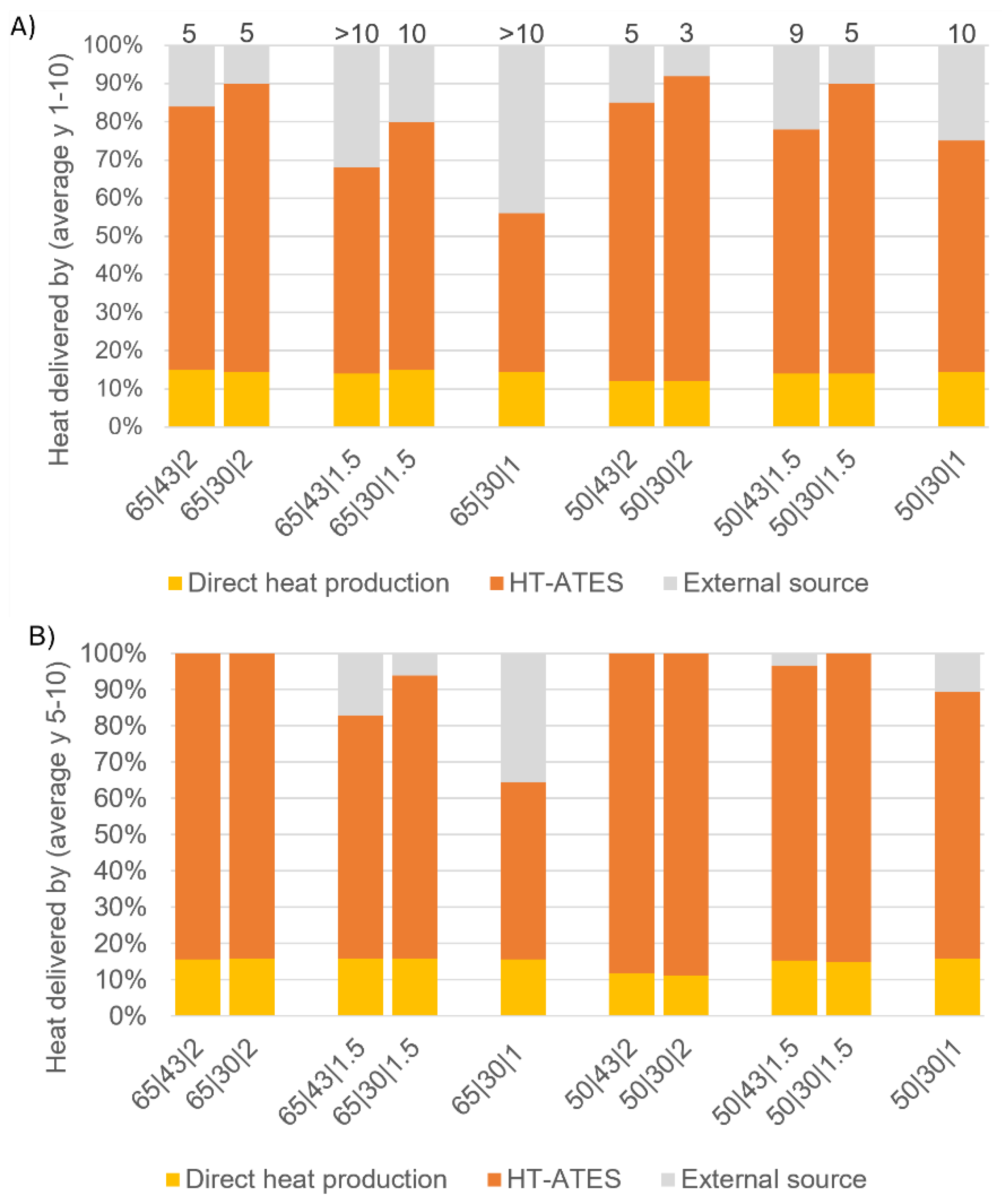

3.1. Fulfillment of Heat Demand with HT-ATES

3.2. HT-ATES Performance

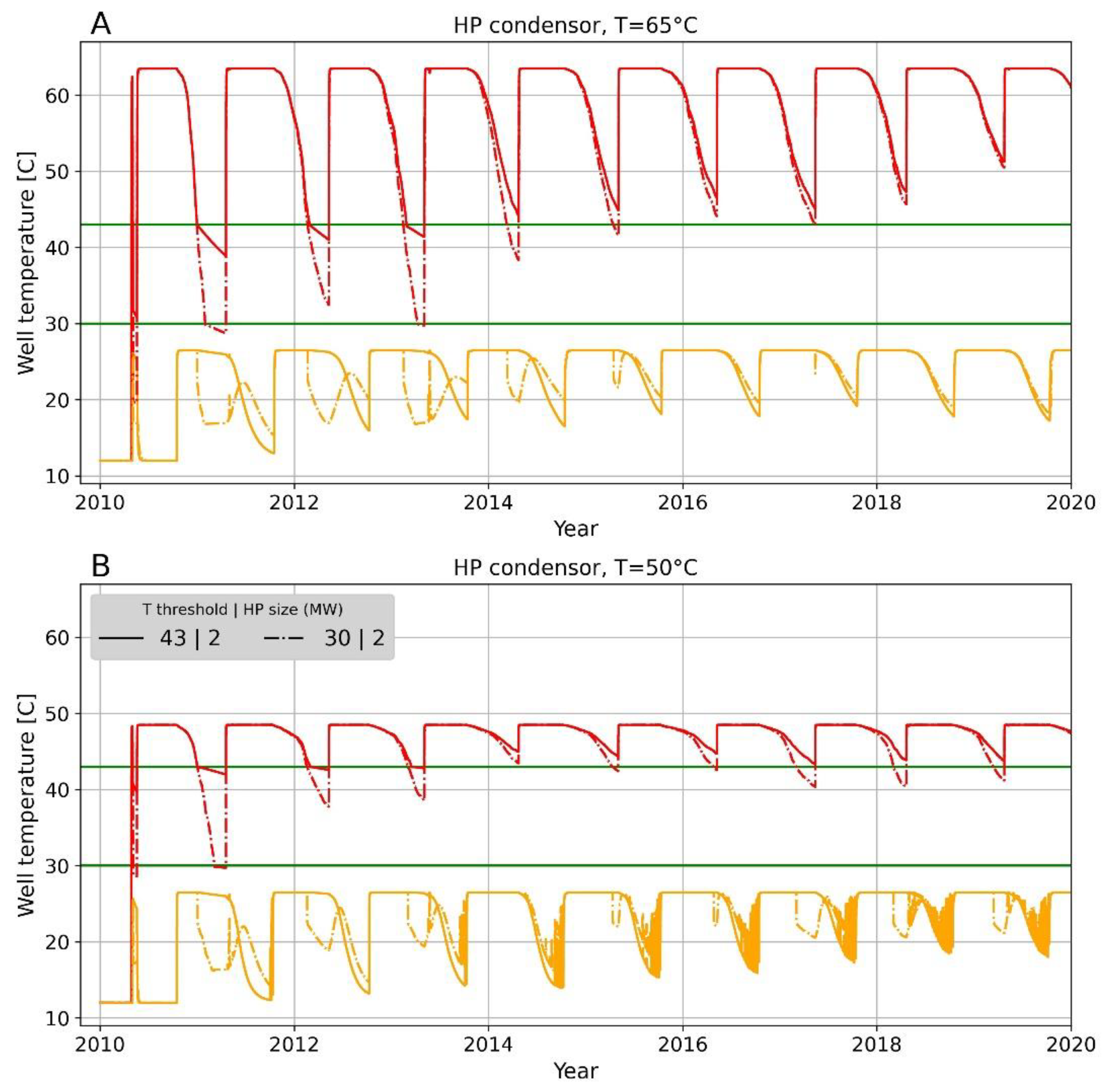

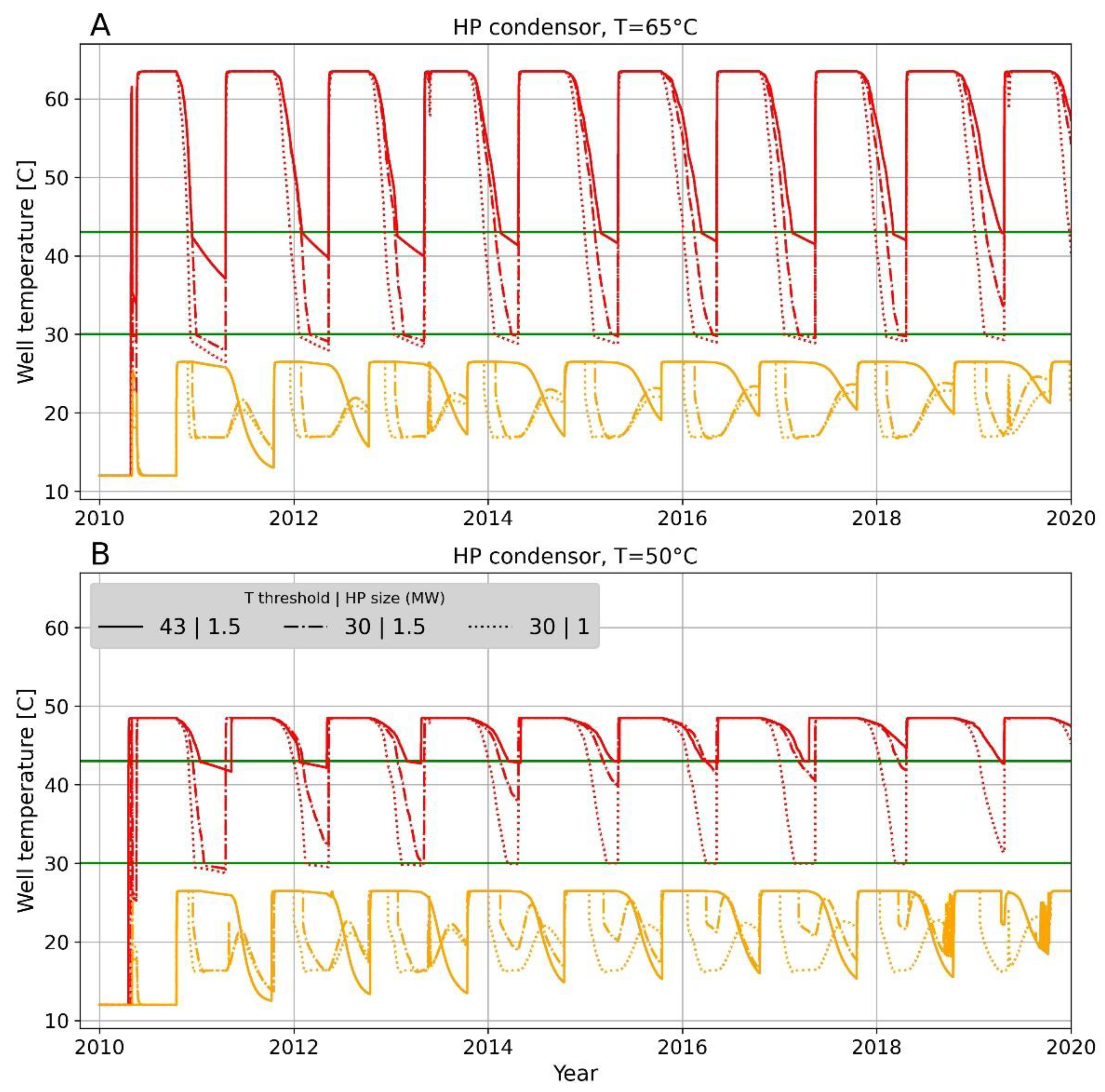

3.2.1. Well Temperature Development

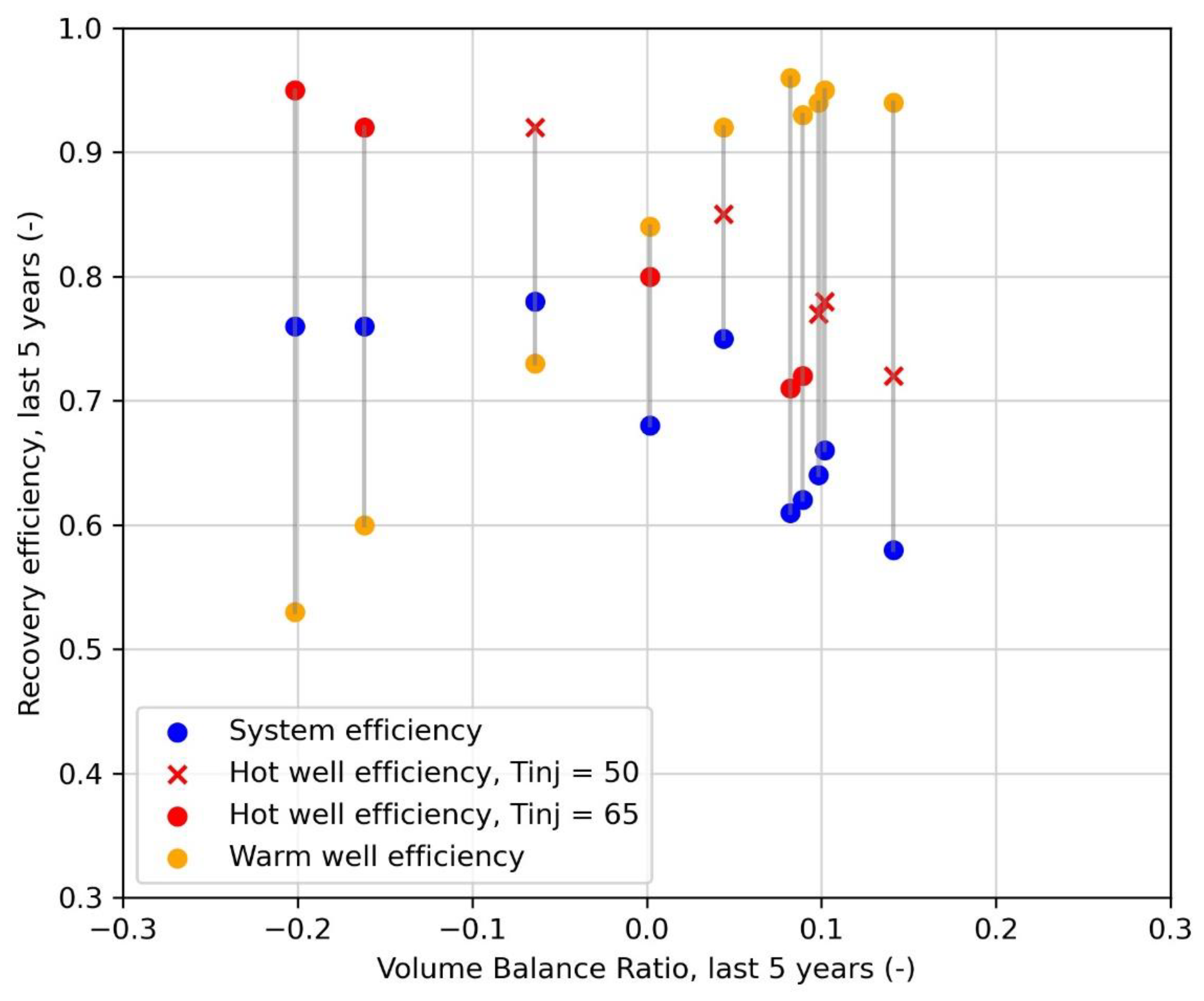

3.2.2. HT-ATES Performance Results

3.3. LCOE of Heat Production and Storage

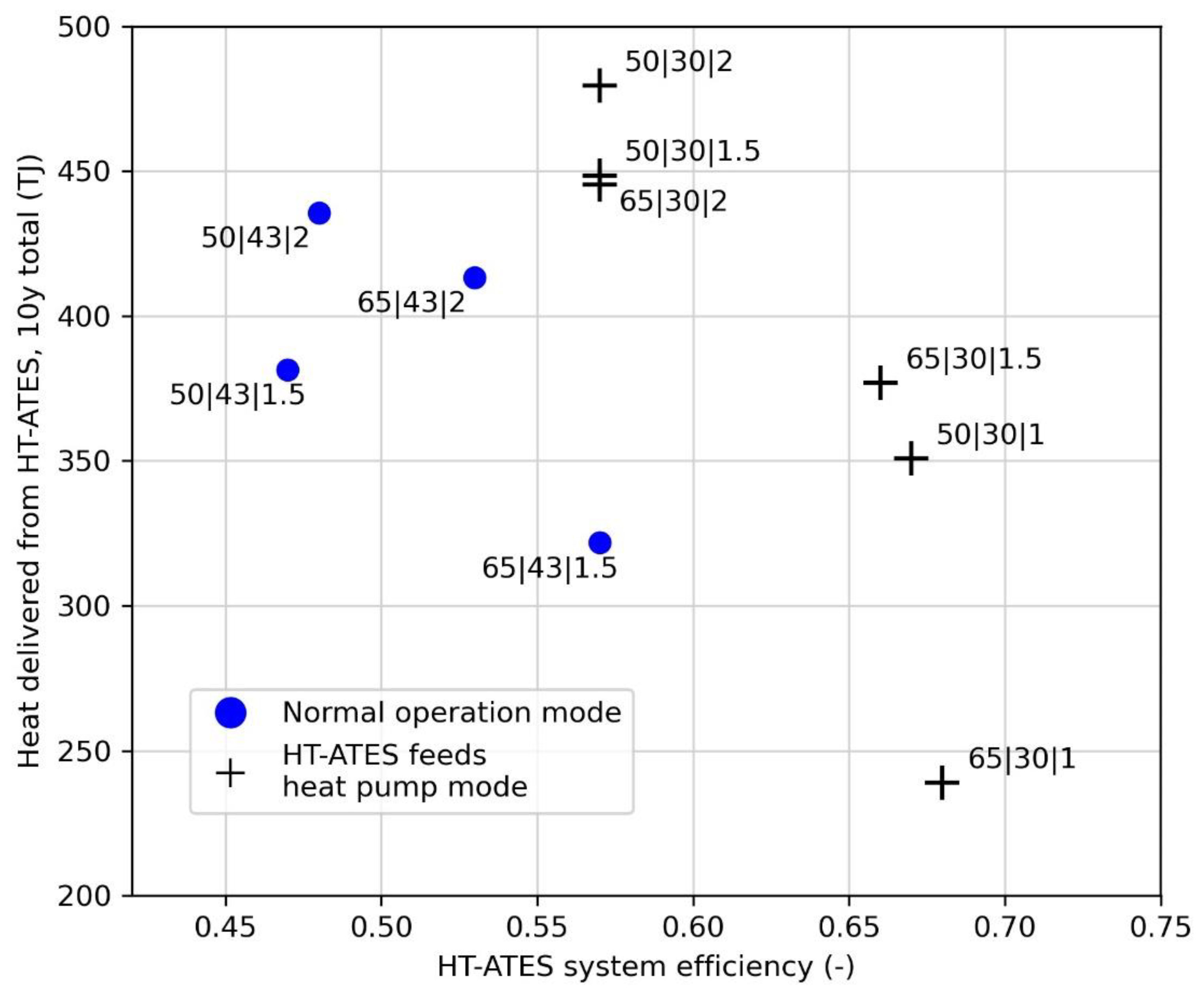

3.4. Overall Performance: An Integral View on Heat Delivery, System Efficiency and Costs

- -

- At a small heat pump size and a high storage temperature (65|30|1), a relatively small amount of the total heat demand can be delivered to the multi-energy system (0.56) and LCOE does not decrease compared to a 1.5 MWel heat pump scenario (both around 16.6 €/GJ). However, decreasing the storage temperature to 50 °C has a large positive effect for this small heat pump scenario (50|30|1); the LCOE strongly decreases (16.7 to 12.2 €/GJ) and the delivered amount of heat increases to 75%.

- -

- Overall, the 50 °C storage temperature ensures lower costs and higher fulfilment of heat demand to the neighbourhood. This is probably caused because the heat pump is cheaper and more effective, which results in larger amounts of stored heat. This has a stronger effect than the increase in costs due to the needed number of wells.

- -

- For all scenarios, the HT-ATES system feeds heat pump mode (43 °C vs. 30 °C shut-off temperature) has a strong positive effect on all assessment criteria: the LCOE decreases, the fulfilment of heat demand increases, and the MES efficiency increases. Hence, this mode of operation has a high potential to be integrated into future HT-ATES systems. With only a small amount of electricity use in winter (not more than 2–6% of the total electricity use), the amount of heat delivered from the HT-ATES increases by 6–12%.

- -

- The most optimal scenario for this neighbourhood, based on all assessment criteria, is the 50|30|1.5 MW scenario. This scenario can provide 100% of the heat demand year-round to the neighbourhood within the first five years, while the LCOE is 13.8 €/GJ, the second cheapest system.

4. Discussion

4.1. The Functioning of a HT-ATES within a Multi-Energy System

4.2. The Impact of HT-ATES in a Multi-Energy System

4.3. The LCOE Placed in Perspective

4.4. Prolonged Lifetime of the Multi-Energy System with HT-ATES

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | Definition | Unit |

| CAPEXi | Total capital expenditure for system component i | € |

| COP | Coefficient Of Performance | - |

| COP10y avg | Average COP of the heat pump over the run time (10 year average) | - |

| COPHP | Coefficient of performance of a heat pump | - |

| cw | Specific volumetric heat capacity of water | kJ/K/m3 |

| DHN | District Heating Network | - |

| Ecost,i | Costs of energy (in this case electricity) for the system | €/year |

| el | electric power | - |

| Eldem,10y avg | Average electricity demand of the total heat system over the run time (10 year average) | TJ/y |

| Endel,10y avg | Average amount of delivered heat to the neighbourhood (10 year average) | TJ/y |

| Espaceheat,total | Total space heat demand over a run period | MJ |

| hDH_i | Number of degree hours at hour t | - |

| HP | Heat Pump | - |

| HT-ATES | High Temperature Aquifer Thermal Energy Storage | - |

| LCOEheat | Levelized cost of heat production | €/GJ |

| Li | Lifetime of a system component i | years |

| MES | Multi-Energy System | - |

| OPEXi | Operational expenditures and maintenance of system component i | €/year |

| PtH | Power-to-Heat | - |

| PV | Photovoltaic | - |

| Qheat,delivered | Part of the heat demand delivered by MES (HT-ATES + heat pump) | GJ/year |

| Qspaceheat,i | Heat demand at time t | MJ |

| r | Discount rate | % |

| RES | Renewable Energy Systems | - |

| rVB | Volume balance ratio | - |

| T | Water temperature | °C |

| Tair,i | Outside air temperature at time t | °C |

| Tambient | Background temperature of the aquifer | °C |

| Tbase | Base temperature for heating | °C |

| th | thermal power | - |

| Thot | Temperature of the hot well of the HT-ATES | °C |

| THP,cond | Outgoing temperature heat pump condenser | °C |

| THP,evap | Ingoing temperature heat pump evaporator | °C |

| Tinj | Injected storage temperature | °C |

| Twarm | Temperature of the warm well of the HT-ATES | °C |

| Vheatproduction | Yearly total extraction volume | m3 |

| Vheatstorage | Yearly total storage volume | m3 |

| vin | Flow of water into the hot well | m3/h |

| vout | Flow of water out of the warm well | m3/h |

| α | Capital recovery factor | - |

| ∑HDH | Sum of heat degree hours over a run period | - |

| η | (recovery) Efficiency | % |

| ηMES | MES efficiency | % |

| ρ | Density of water | kg/m3 |

| ρ0 | Density of water at ambient groundwater temperature | kg/m3 |

References

- European Energy Agency. Trends and Projections in Europe 2019; Publications Office of the European Union: Luxembourg, 2019; ISBN 9789294801036. [Google Scholar]

- IEA. Power Systems in Transition; IEA: Paris, France, 2020. [Google Scholar]

- REN21. Renewables Global Futures Report; REN21: Paris, France, 2017; ISBN 9783981810745. [Google Scholar]

- United Nations Adoption of the Paris Agreement. In Proceedings of the Conference of the Parties on Its Twenty-First Session, Paris, France, 12 December 2015; p. 32.

- IRENA. Electricity Storage and Renewables: Costs and Markets to 2030; IRENA: Abu Dhabi, United Arab Emirates, 2017. [Google Scholar]

- European Commission; The Fuell Cell and Hydrogen Joint Undertaking (FCH JU). Commercialisation of Energy Storage; FCH JU: Brussels, Belgium, 2015. [Google Scholar]

- IEA. Technology Roadmap: Energy Storage; IEA: Paris, France, 2014. [Google Scholar]

- European Commission. Powering a Climate-Neutral Economy: An EU Strategy for Energy System Integration; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Lund, H.; Connolly, D. Energy Storage and Smart Energy Systems. Int. J. Sustain. Energy Plan. Manag. 2016, 11, 3–4. [Google Scholar] [CrossRef]

- Mathiesen, B.V.; Lund, H.; Connolly, D.; Wenzel, H.; Ostergaard, P.A.; Möller, B.; Nielsen, S.; Ridjan, I.; KarnOe, P.; Sperling, K.; et al. Smart Energy Systems for coherent 100% renewable energy and transport solutions. Appl. Energy 2015, 145, 139–154. [Google Scholar] [CrossRef]

- Böckl, B.; Greiml, M.; Leitner, L.; Pichler, P.; Kriechbaum, L.; Kienberger, T. HyFloW—A hybrid load flow-modelling framework to evaluate the effects of energy storage and sector coupling on the electrical load flows. Energies 2019, 12, 956. [Google Scholar] [CrossRef] [Green Version]

- Murray, P.; Orehounig, K.; Grosspietsch, D.; Carmeliet, J. A comparison of storage systems in neighbourhood decentralized energy system applications from 2015 to 2050. Appl. Energy 2018, 231, 1285–1306. [Google Scholar] [CrossRef]

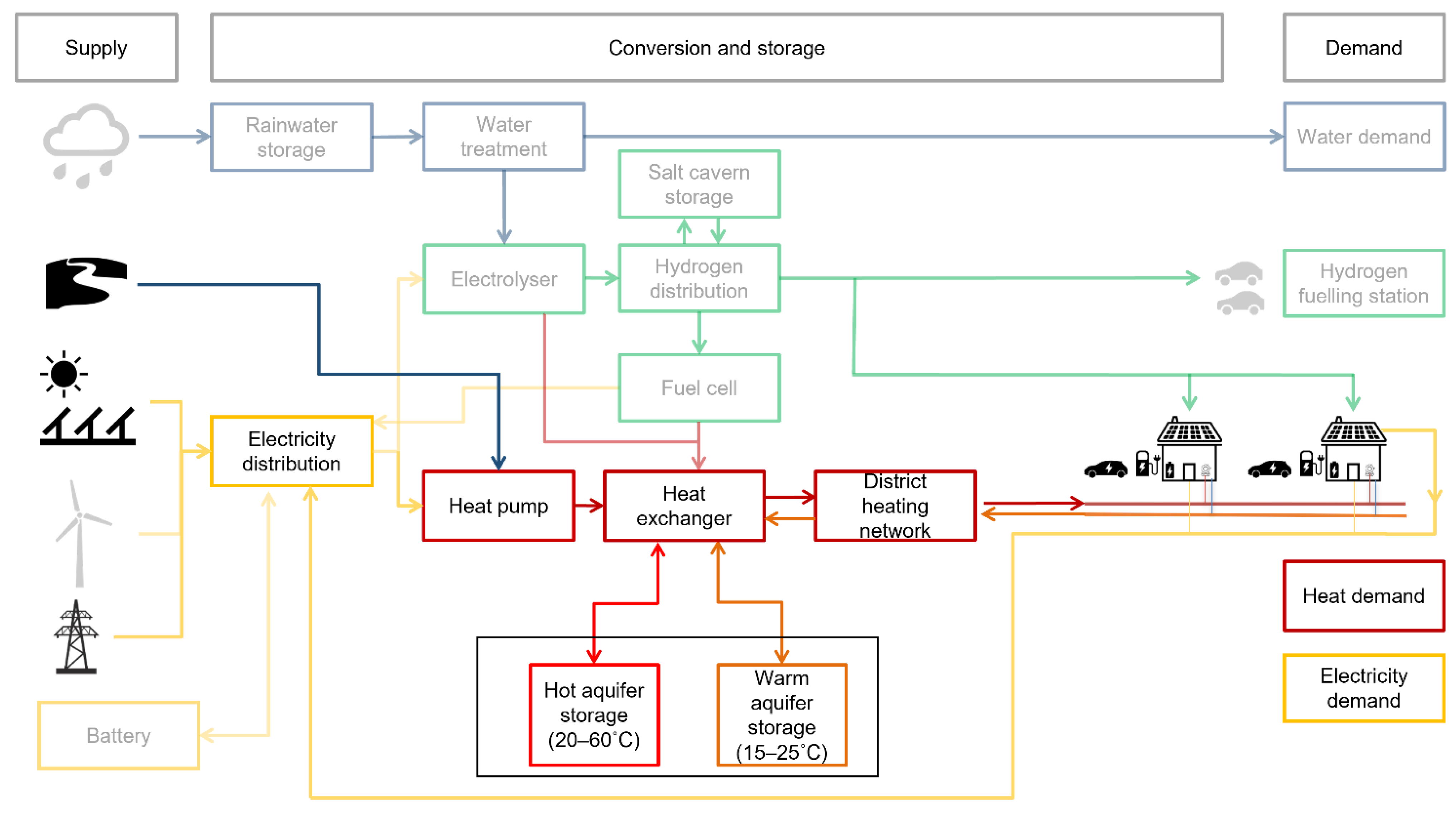

- van der Roest, E.; Snip, L.; Fens, T.; van Wijk, A. Introducing Power-to-H3: Combining renewable electricity with heat, water and hydrogen production and storage in a neighbourhood. Appl. Energy 2020, 257, 114024. [Google Scholar] [CrossRef]

- Gabrielli, P.; Gazzani, M.; Martelli, E.; Mazzotti, M. Optimal design of multi-energy systems with seasonal storage. Appl. Energy 2018, 219, 408–424. [Google Scholar] [CrossRef]

- Maroufmashat, A.; Fowler, M.; Sattari Khavas, S.; Elkamel, A.; Roshandel, R.; Hajimiragha, A. Mixed integer linear programing based approach for optimal planning and operation of a smart urban energy network to support the hydrogen economy. Int. J. Hydrogen Energy 2016, 41, 7700–7716. [Google Scholar] [CrossRef]

- Robinius, M.; Otto, A.; Heuser, P.; Welder, L.; Syranidis, K.; Ryberg, D.; Grube, T.; Markewitz, P.; Peters, R.; Stolten, D. Linking the Power and Transport Sectors—Part 1: The Principle of Sector Coupling. Energies 2017, 10, 956. [Google Scholar] [CrossRef] [Green Version]

- David, A.; Mathiesen, B.V.; Averfalk, H.; Werner, S.; Lund, H. Heat Roadmap Europe: Large-scale electric heat pumps in district heating systems. Energies 2017, 10, 578. [Google Scholar] [CrossRef] [Green Version]

- Kallesøe, A.J.; Vangkilde-Pedersen, T. (Eds.) HEATSTORE Underground Thermal Energy Storage (UTES)—State-of-the Art, Example Cases and Lessons Learned; HEATSTORE Project Report; GEOTHERMICA—ERA NET Cofund Geothermal, 2019. [Google Scholar]

- Brown, T.; Schlachtberger, D.; Kies, A.; Schramm, S.; Greiner, M. Synergies of sector coupling and transmission reinforcement in a cost-optimised, highly renewable European energy system. Energy 2018, 160, 720–739. [Google Scholar] [CrossRef] [Green Version]

- Bloess, A.; Schill, W.P.; Zerrahn, A. Power-to-heat for renewable energy integration: A review of technologies, modeling approaches, and flexibility potentials. Appl. Energy 2018, 212, 1611–1626. [Google Scholar] [CrossRef]

- Drijver, B.; Van Aarssen, M.; Zwart, B. De High-temperature aquifer thermal energy storage (HT-ATES): Sustainable and multi-usable. In Proceedings of the Innostock 2012—12th International Conference on Energy Storage, Lleida, Spain, 16–18 May 2012; Volume 1, pp. 1–10. [Google Scholar]

- Wesselink, M.; Liu, W.; Koornneef, J.; van den Broek, M. Conceptual market potential framework of high temperature aquifer thermal energy storage—A case study in The Netherlands. Energy 2018, 147, 477–489. [Google Scholar] [CrossRef]

- Hartog, N.; Bloemendal, M.; Slingerland, E.; van Wijk, A. Duurzame Warmte Gaat Ondergronds; KWR: Nieuwegein, The Netherlands, 2016. [Google Scholar]

- Van der Roest, E.; Snip, L.; Bloemendal, M.; van Wijk, A. Power-to-X; KWR 2018.032; KWR: Nieuwegein, The Netherlands, 2018. [Google Scholar]

- Van der Roest, E.; Fens, T.; Bloemendal, M.; Beernink, S.; van der Hoek, J.P.; van Wijk, A.J.M. The Impact of System Integration on System Costs of a Neighborhood Energy and Water System. Energies 2021, 14, 2616. [Google Scholar] [CrossRef]

- Van der Roest, E. Systeemontwerp Power to X; KWR 2020.004; KWR: Nieuwegein, The Netherlands, 2020. [Google Scholar]

- Van Wijk, A.; van der Roest, E.; Boere, J. Solar Power to the People (ENG); IOS Press BV: Amsterdam, The Netherlands, 2017; ISBN 9781614998310. [Google Scholar]

- Bloemendal, M. The Hidden Side of Cities: Methods for Governance, Planning and Design for Optimal Use of Subsurface Space with ATES. Ph.D. Thesis, TU Delft, Delft, The Netherlands, 2018. [Google Scholar]

- Fleuchaus, P.; Schüppler, S.; Bloemendal, M.; Guglielmetti, L.; Opel, O.; Blum, P. Risk analysis of High-Temperature Aquifer Thermal Energy Storage (HT-ATES). Renew. Sustain. Energy Rev. 2020, 133, 110153. [Google Scholar] [CrossRef]

- Van Lopik, J.H.; Hartog, N.; Zaadnoordijk, W.J. The use of salinity contrast for density difference compensation to improve the thermal recovery efficiency in high-temperature aquifer thermal energy storage systems. Hydrogeol. J. 2016, 1255–1271. [Google Scholar] [CrossRef] [Green Version]

- Schout, G.; Drijver, B.; Gutierrez-Neri, M.; Schotting, R. Analysis of recovery efficiency in high-temperature aquifer thermal energy storage: A Rayleigh-based method. Hydrogeol. J. 2014, 22, 281–291. [Google Scholar] [CrossRef]

- Langevin, C.D.; Shoemaker, W.B.; Guo, W. MODFLOW-2000, the USGS Modular Groundwater Model—Documentation of the SEAWAT-2000 Version with Variable Density Flow Process and Integrated MT3DMS Transport Process; Report; USGS, 2003.

- Zheng, C.; Wang, P.P. MT3DMS: A Modular Three-Dimensional Multispecies Transport Model for Simulation of Advection, Dispersion, and Chemical Reactions of Contaminants in Groundwater Systems; Documentation and User’s Guide; US Army Corps of Engineers, 1999.

- Langevin, C.D.; Thorne, D.T.; Dausman, A.M.; Sukop, M.C.; Guo, W. SEAWAT Version 4: A Computer Program for Simulation of Multi-Species Solute and Heat Transport; Report; USGS, 2008.

- Bakker, M.; Post, V.; Langevin, C.D.; Hughes, J.D.; White, J.T.; Starn, J.J.; Fienen, M.N. Scripting MODFLOW Model Development Using Python and FloPy. Groundwater 2016, 54, 733–739. [Google Scholar] [CrossRef]

- Beernink, S.; Bloemendal, M.; Hartog, N. Prestaties en Thermische Effecten van Ondergrondse Warmteopslagsystemen. WINDOW Fase 1 (C2).; KWR 2020.146; KWR: Nieuwegein, The Netherlands, 2020. [Google Scholar]

- Langevin, C.D. Modeling axisymmetric flow and transport. Ground Water 2008, 46, 579–590. [Google Scholar] [CrossRef] [PubMed]

- Hecht-Mendez, J.; Molina-Giraldo, N.; Blum, P.; Bayer, P. Evaluating MT3DMS for Heat Transport Simulation of Closed Geothermal Systems. Ground Water 2010, 48, 741–756. [Google Scholar] [CrossRef]

- Voss, C. A Finite-Element Simulation Model for Saturated-Unsaturated, Fluid-Density-Dependent Groundwater Flow with Energy Transport or Chemically-Reactive Single-Species Solute Transport. Water Resour. Investig. Rep. 1984, 84, 4369. [Google Scholar]

- Zeghici, R.M.; Oude Essink, G.H.P.; Hartog, N.; Sommer, W. Integrated assessment of variable density-viscosity groundwater flow for a high temperature mono-well aquifer thermal energy storage (HT-ATES) system in a geothermal reservoir. Geothermics 2015, 55, 58–68. [Google Scholar] [CrossRef]

- Arpagaus, C.; Bless, F.; Uhlmann, M.; Schiffmann, J.; Bertsch, S.S. High temperature heat pumps: Market overview, state of the art, research status, refrigerants, and application potentials. Energy 2018, 152, 985–1010. [Google Scholar] [CrossRef] [Green Version]

- Calculating Degree Days. Available online: https://www.degreedays.net/calculation (accessed on 9 March 2021).

- KNMI Database—Daggegevens van Het Weer in Nederland. Available online: https://www.knmi.nl/nederland-nu/klimatologie/daggegevens (accessed on 4 July 2020).

- Warmtepompinfo Graaddagen. Available online: https://www.warmtepomp-info.nl/tapwaterkosten/graaddagen/ (accessed on 12 April 2017).

- D’Agostino, D.; Mazzarella, L. What is a Nearly zero energy building? Overview, implementation and comparison of definitions. J. Build. Eng. 2019, 21, 200–212. [Google Scholar] [CrossRef]

- Schepers, B.; Naber, N.; van den Wijngaart, R.; van Polen, S.; van der Molen, F.; Langeveld, T.; van Bemmel, B.; Oei, A.; Hilferink, M.; van Beek, M. Functioneel Ontwerp Vesta 4.0; CE Delft: Delft, The Netherlands, 2019. [Google Scholar]

- KNMI Klimatologie—Uurgegevens van Het Weer in Nederland. Available online: http://projects.knmi.nl/klimatologie/uurgegevens/selectie.cgi (accessed on 21 February 2020).

- Beernink, S.; Hartog, N.; Bloemendal, M.; van der Meer, M. ATES systems performance in practice: Analysis of operational data from ATES systems in the province of Utrecht, The Netherlands. In Proceedings of the European Geothermal Congress 2019, Den Haag, The Netherlands, 11–14 June 2019. [Google Scholar]

- CBS Aardgas en Elektriciteit, Gemiddelde Prijzen van Eindverbruikers. Available online: https://opendata.cbs.nl/#/CBS/nl/dataset/81309NED/table?dl=59C6 (accessed on 19 January 2021).

- Zwamborn, M. Berekening Onrendabele Top Voor Bodemenergiesystemen; KWA: Amersfoort, The Netherlands, 2018. [Google Scholar]

- TNO; ISPT. Cost Reduction Industrial Heat Pumps (CRUISE); ISPT: Amersfoort, The Netherlands, 2019. [Google Scholar]

- Collignon, M.; Klemetsdal, Ø.S.; Møyner, O.; Alcanié, M.; Rinaldi, A.P.; Nilsen, H.; Lupi, M. Evaluating thermal losses and storage capacity in high-temperature aquifer thermal energy storage (HT-ATES) systems with well operating limits: Insights from a study-case in the Greater Geneva Basin, Switzerland. Geothermics 2020, 85, 101773. [Google Scholar] [CrossRef]

- Jeon, J.S.; Lee, S.R.; Pasquinelli, L.; Fabricius, I.L. Sensitivity analysis of recovery efficiency in high-temperature aquifer thermal energy storage with single well. Energy 2015, 90, 1349–1359. [Google Scholar] [CrossRef] [Green Version]

- Zwamborn, M.; Kleinlugenbelt, R. Window Fase 1—A1. Notitie Vergelijking en Selectie Locaties Voor Ondergrondse Warmteopslag; KWR 2020.148; KWR: Nieuwegein, The Netherlands, 2020. [Google Scholar]

- SKAO; Stimular; Connekt; Milieu Centraal; Ministerie van Infrastructuur en Milieu. CO2 Emissiefactoren. Available online: https://co2emissiefactoren.nl/ (accessed on 31 March 2020).

| Terraced House | Apartment | Total | |

|---|---|---|---|

| Number of houses | 1000 | 1000 | 2000 |

| People per household | 2.4 | 2 | - |

| Energy demand domestic hot water | 7.9 GJ/y | 6.6 GJ/y | 14.5 TJ/y |

| Space heat demand | 24.4 GJ/y | 17.6 GJ/y | 42 TJ/y |

| Heat Pump Condenser Temperature | HT-ATES Threshold Temperature | Heat Pump Size | |

|---|---|---|---|

| 65|43|2 | 65 °C | 43 °C | 2 MWel |

| 50|43|2 | 50 °C | 43 °C | 2 MWel |

| 65|30|2 | 65 °C | 30 °C | 2 MWel |

| 50|30|2 | 50 °C | 30 °C | 2 MWel |

| 65|43|1.5 | 65 °C | 43 °C | 1.5 MWel |

| 50|43|1.5 | 50 °C | 43 °C | 1.5 MWel |

| 65|30|1.5 | 65 °C | 30 °C | 1.5 MWel |

| 50|30|1.5 | 50 °C | 30 °C | 1.5 MWel |

| 65|30|1 | 65 °C | 30 °C | 1 MWel |

| 50|30|1 | 50 °C | 30 °C | 1 MWel |

| System Component | CAPEX (in €) | OPEX (%) | Lifetime |

|---|---|---|---|

| Aquifers and equipment a | (75,860 × ln(kWth/6.69) − 115,000) × 1.25 | 4% | 30 |

| Heat exchanger b | 1500 × √kWth × 1.1 | 2% | 20 |

| Heat pump—65 °C condenser temp. c | 600 €/kWth | 1% | 20 |

| Heat pump—50 °C condenser temp. c | 400 €/kWth | 1% | 20 |

| Scenario | Vhot Injection 10y Average (103 m3/y) | Vhot Extraction 10y Average (103 m3/y) | Volume Balance Ratio (rVB) | Hot Well Recovery Efficiency 10y Average (-) | Warm Well Recovery Efficiency 10y Average (-) | HT-ATES Heat Delivered 10y Total (Endel,10 y avg in TJ) | HT-ATES Heat Stored 10y Total (TJ) | HT-ATES System Recovery Efficiency 10y Average (-) | MES Efficiency 10y Average (ηMES ) |

|---|---|---|---|---|---|---|---|---|---|

| 65|43|2 | 446 | 339 | 0.14 | 0.64 | 0.88 | 413 | 778 | 0.53 | 0.53 |

| 65|30|2 | 450 | 397 | 0.06 | 0.69 | 0.85 | 445 | 780 | 0.57 | 0.56 |

| 65|43|1.5 | 330 | 282 | 0.08 | 0.70 | 0.82 | 322 | 569 | 0.57 | 0.57 |

| 65|30|1.5 | 315 | 389 | −0.10 | 0.83 | 0.59 | 377 | 568 | 0.66 | 0.63 |

| 65|30|1 | 193 | 259 | −0.15 | 0.86 | 0.51 | 239 | 354 | 0.68 | 0.64 |

| 50|43|2 | 774 | 509 | 0.21 | 0.63 | 0.92 | 436 | 900 | 0.48 | 0.48 |

| 50|30|2 | 736 | 570 | 0.13 | 0.71 | 0.89 | 480 | 838 | 0.57 | 0.55 |

| 50|43|1.5 | 692 | 450 | 0.21 | 0.62 | 0.90 | 381 | 810 | 0.47 | 0.48 |

| 50|30|1.5 | 680 | 540 | 0.11 | 0.71 | 0.87 | 448 | 785 | 0.57 | 0.55 |

| 50|30|1 | 432 | 441 | −0.01 | 0.83 | 0.69 | 351 | 522 | 0.67 | 0.61 |

| Scenario | Average COP Heat Pump (COP10 y avg) | Max. Capacity Infiltrated (MWth) | Max. Capacity Delivered (MWth) | Amount of Doublets | Average Electricity Demand—10y Average (Eldem,10 y avg in TJ/y) | % of Heat Demand Delivered by the HT-ATES/Heat Pump | Heat Production Costs (LCOE in €/GJ) |

|---|---|---|---|---|---|---|---|

| 65|43|2 * | 4 | 8.8 | 11.7 | 6 | 21.8 | 84% | 19.6 |

| 65|30|2 * | 4 | 8.8 | 11.7 | 6 | 22.2 | 90% | 18.6 |

| 65|43|1.5 | 4 | 6.5 | 10 | 6 | 16.5 | 68% | 18.5 |

| 65|30|1.5 | 4 | 6.5 | 11 | 7 | 17.7 | 80% | 16.6 |

| 65|30|1 | 4 | 4.3 | 8.3 | 6 | 12.0 | 56% | 16.7 |

| 50|43|2 * | 5.5 | 12.6 | 11.7 | 7 | 17.6 | 85% | 17.1 |

| 50|30|2 * | 5.5 | 12.6 | 11.7 | 7 | 16.7 | 92% | 15.7 |

| 50|43|1.5 | 5.5 | 9.4 | 11.8 | 8 | 16.3 | 78% | 15.5 |

| 50|30|1.5 * | 5.5 | 9.5 | 11.6 | 8 | 16.3 | 90% | 13.8 |

| 50|30|1 | 5.6 | 6.2 | 10.9 | 7 | 12.6 | 75% | 12.2 |

| Heat Production Costs (LCOE) in €/GJ—10 Years | Heat Production Costs (LCOE) in €/GJ—30 Years | |

|---|---|---|

| 65|43|2 | 19.6 | 17.4 |

| 65|30|2 | 18.6 | 17.4 |

| 65|43|1.5 | 18.5 | 14.3 |

| 65|30|1.5 | 16.6 | 14.3 |

| 65|30|1 | 16.7 | 11.1 |

| 50|43|2 | 17.1 | 14.6 |

| 50|30|2 | 15.7 | 14.2 |

| 50|43|1.5 | 15.5 | 13.0 |

| 50|30|1.5 | 13.8 | 12.3 |

| 50|30|1 | 12.2 | 10.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

van der Roest, E.; Beernink, S.; Hartog, N.; van der Hoek, J.P.; Bloemendal, M. Towards Sustainable Heat Supply with Decentralized Multi-Energy Systems by Integration of Subsurface Seasonal Heat Storage. Energies 2021, 14, 7958. https://doi.org/10.3390/en14237958

van der Roest E, Beernink S, Hartog N, van der Hoek JP, Bloemendal M. Towards Sustainable Heat Supply with Decentralized Multi-Energy Systems by Integration of Subsurface Seasonal Heat Storage. Energies. 2021; 14(23):7958. https://doi.org/10.3390/en14237958

Chicago/Turabian Stylevan der Roest, Els, Stijn Beernink, Niels Hartog, Jan Peter van der Hoek, and Martin Bloemendal. 2021. "Towards Sustainable Heat Supply with Decentralized Multi-Energy Systems by Integration of Subsurface Seasonal Heat Storage" Energies 14, no. 23: 7958. https://doi.org/10.3390/en14237958

APA Stylevan der Roest, E., Beernink, S., Hartog, N., van der Hoek, J. P., & Bloemendal, M. (2021). Towards Sustainable Heat Supply with Decentralized Multi-Energy Systems by Integration of Subsurface Seasonal Heat Storage. Energies, 14(23), 7958. https://doi.org/10.3390/en14237958