Turbine Design and Optimization for a Supercritical CO2 Cycle Using a Multifaceted Approach Based on Deep Neural Network

Abstract

:1. Introduction

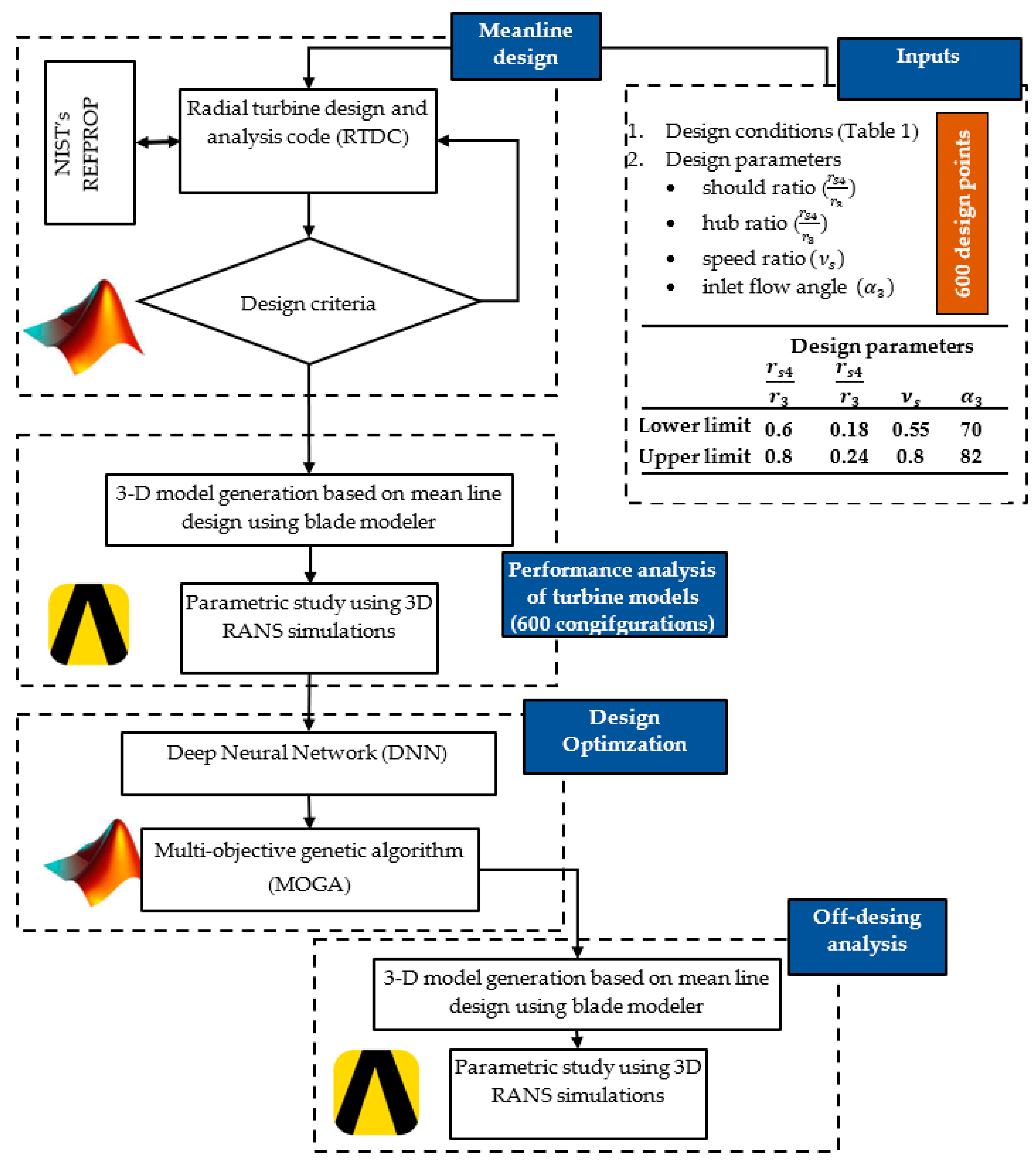

2. Methodology

3. Meanline Design Procedure

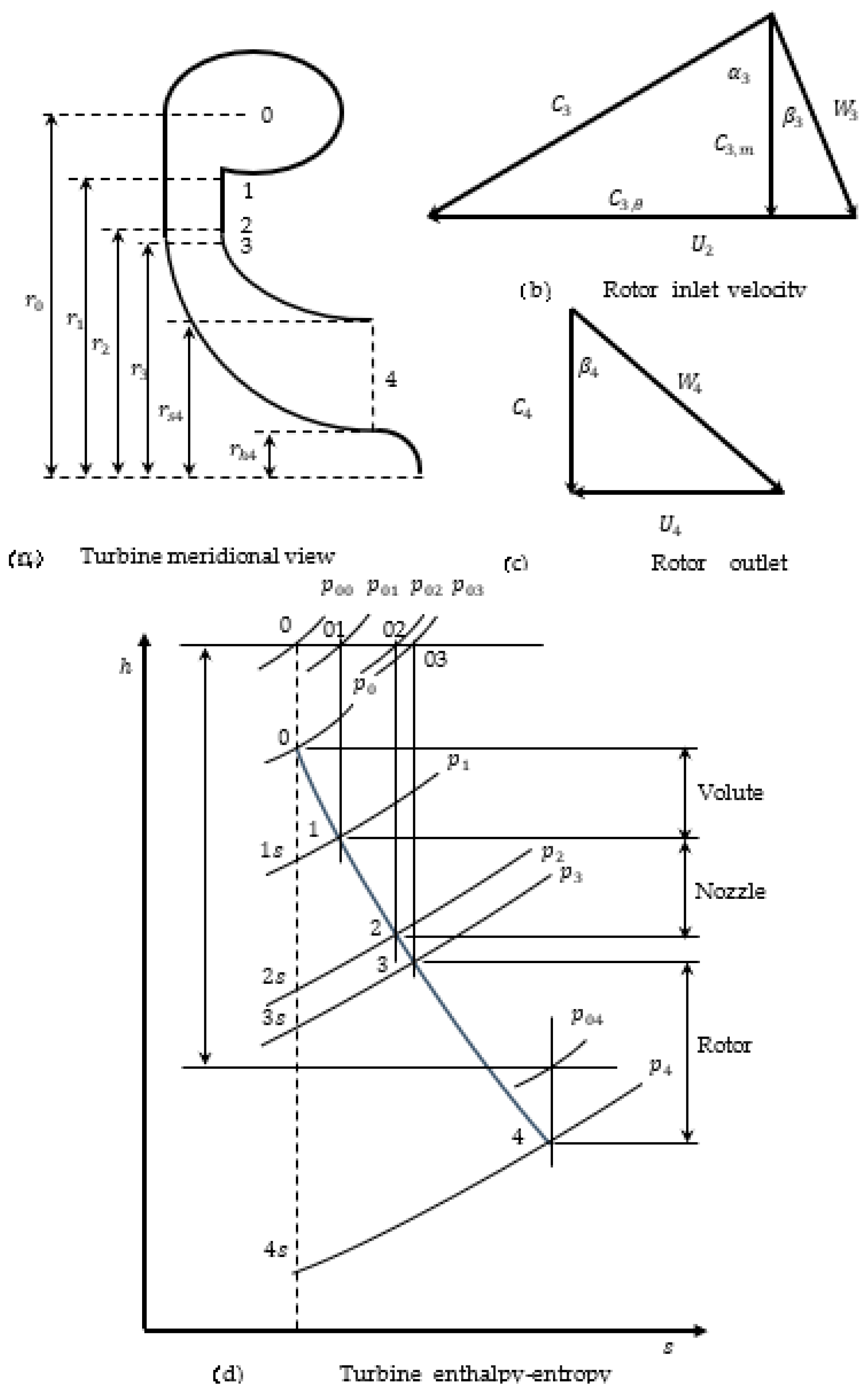

- Volute (0–1): dispenses the flow evenly to each blade passage and converts pressure head to velocity head to some extent.

- Nozzle (1–2): converts pressure head to velocity head and aligns the flow with the rotor at the required angle.

- Rotor (3–4): the kinetic energy of the working fluid is transformed into mechanical work.

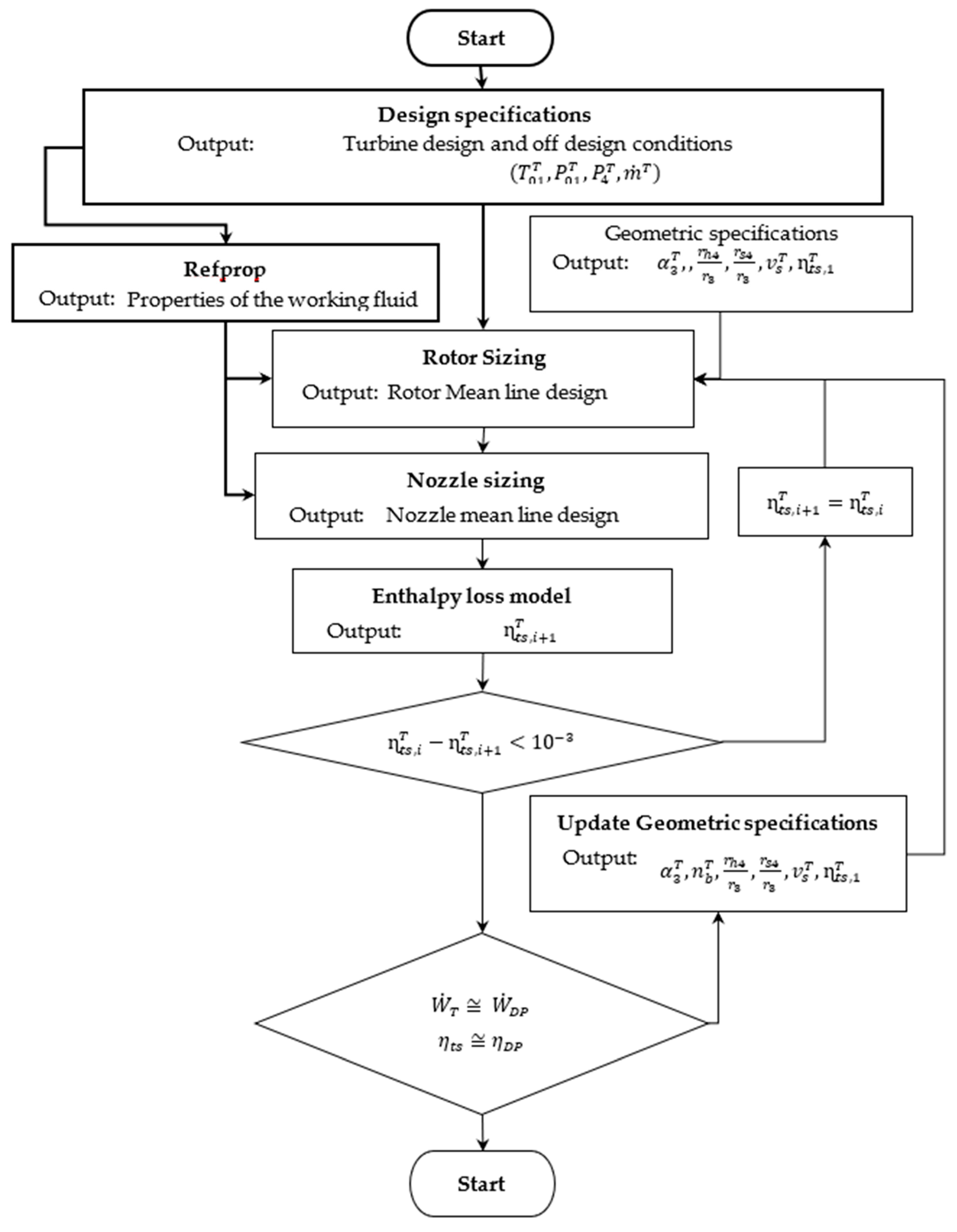

3.1. Radial Turinbe Rotor Desing Code (RTRDC)

3.2. Efficiency Correction

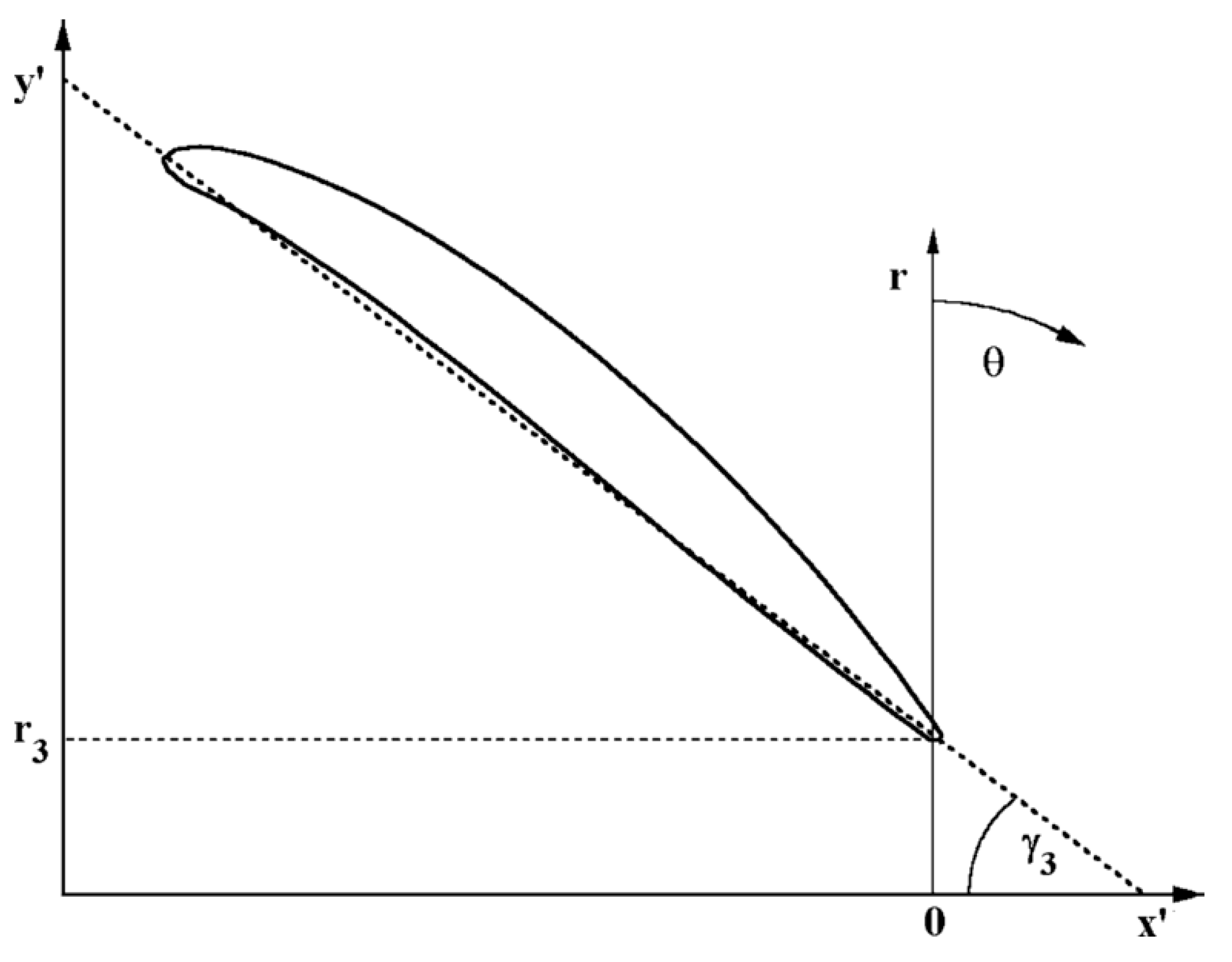

3.3. Nozzle Geometry

4. CFD Model

Geometrical Model and Mesh

5. Machine Learning Model

5.1. Training Data Details

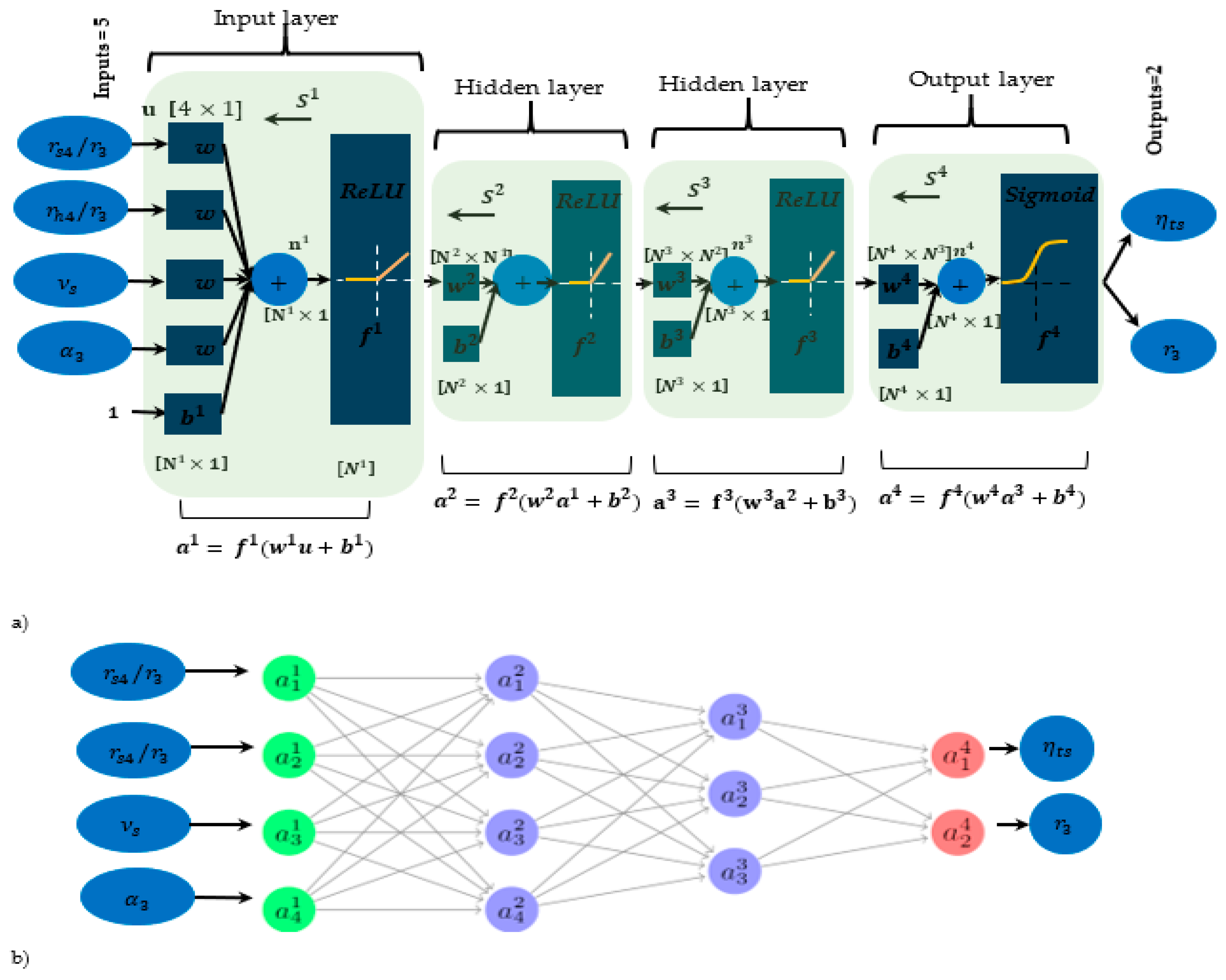

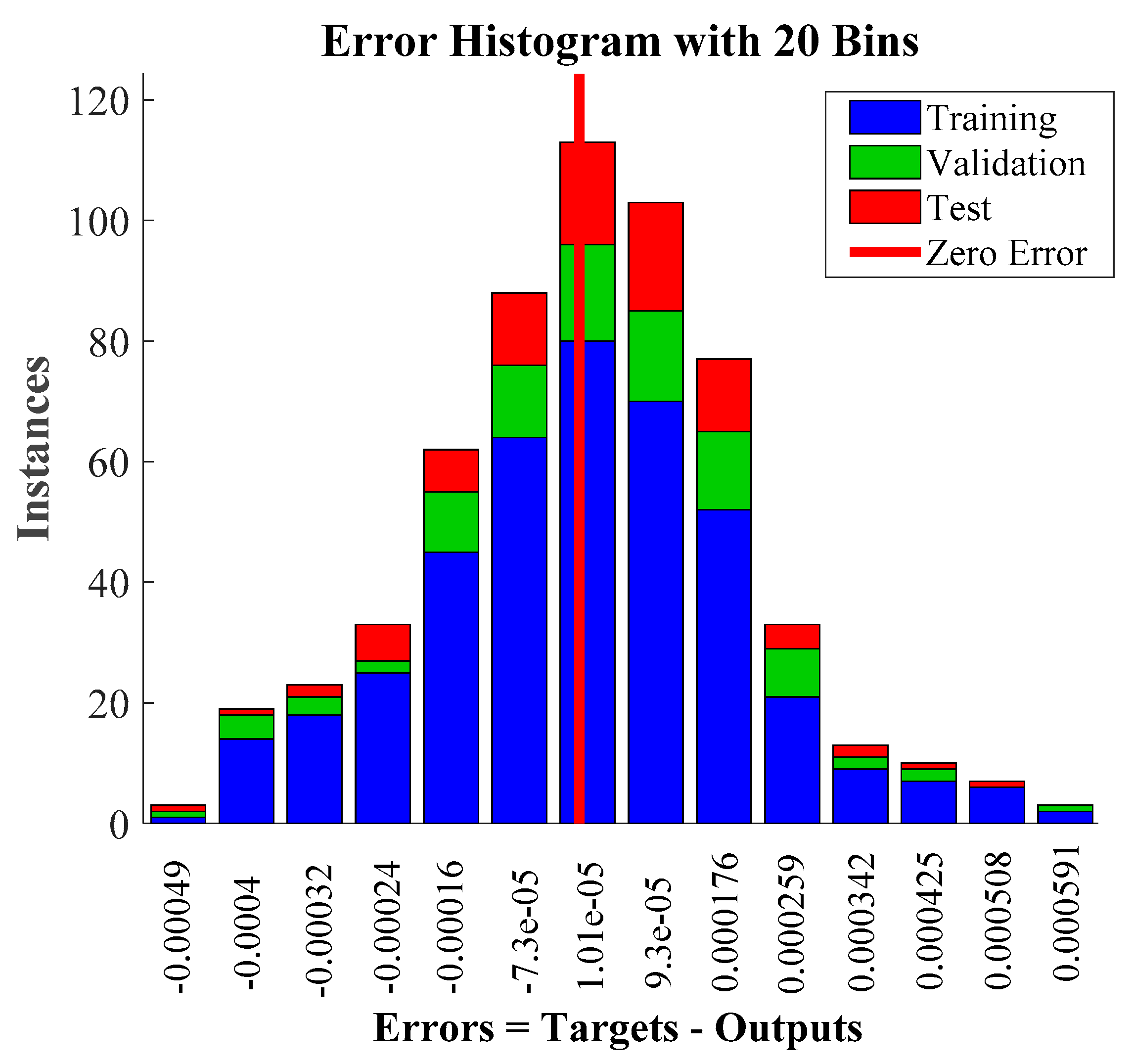

5.2. The Deep Neural Network

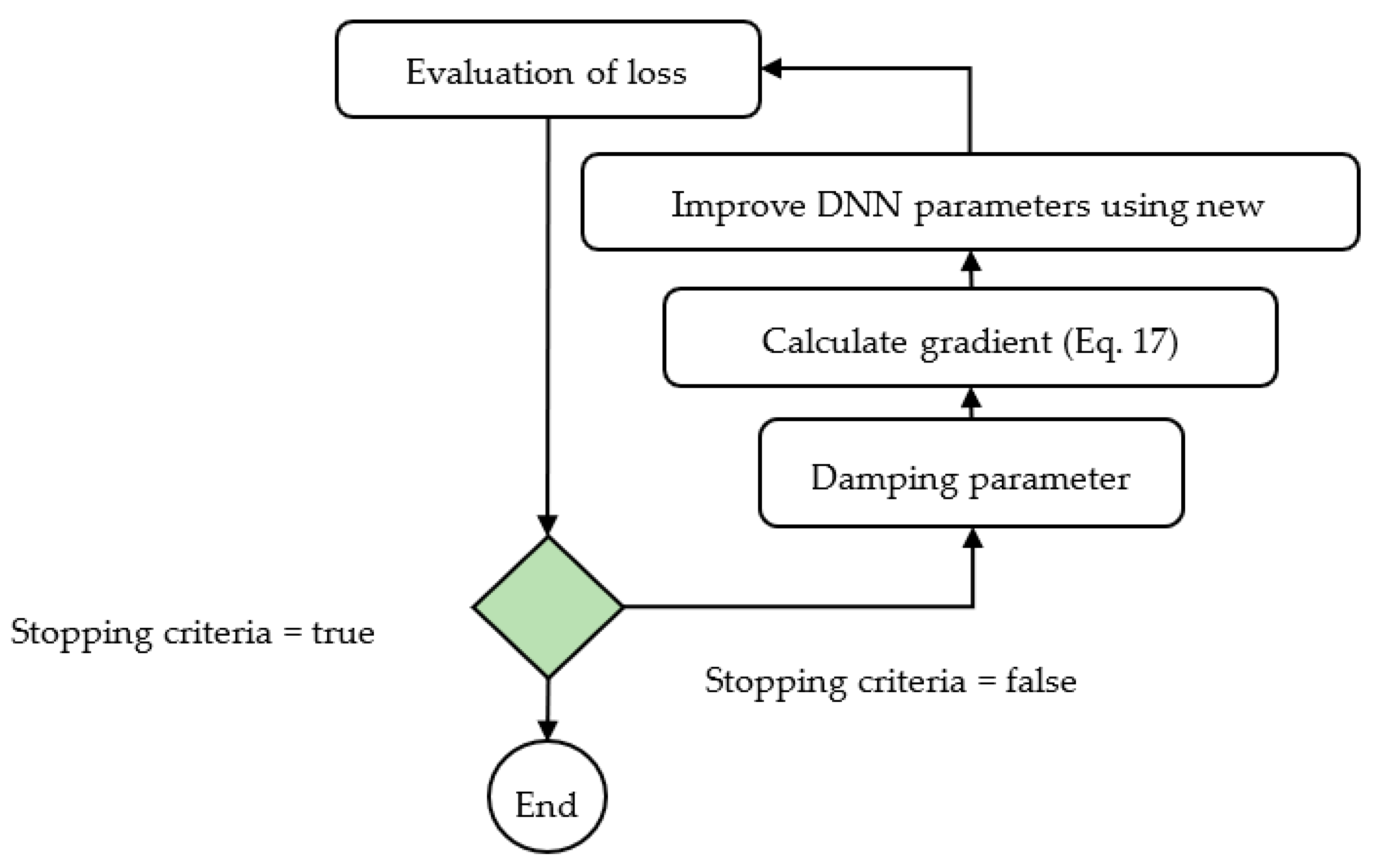

DNN Optimization Methodology

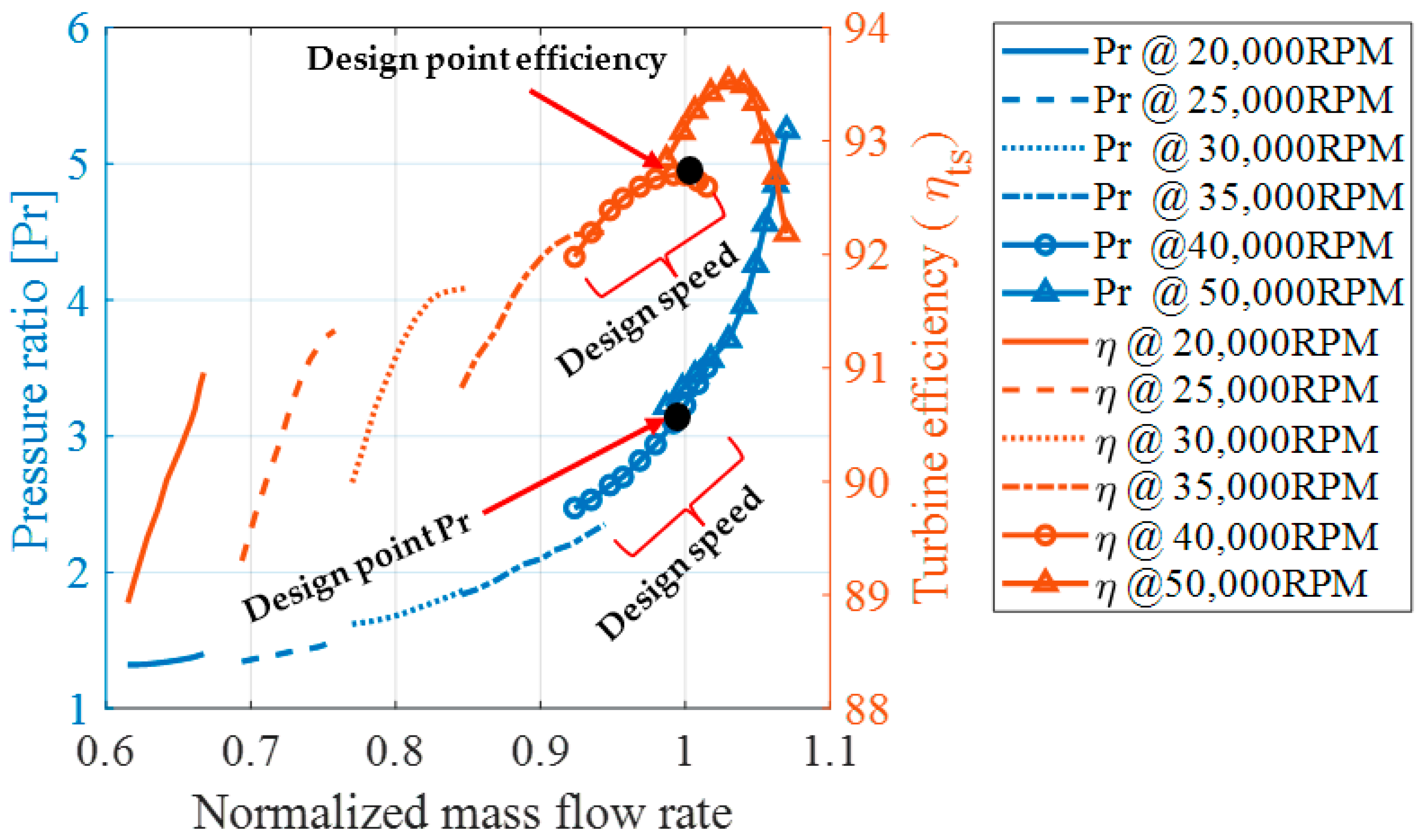

6. Optimization of the Turbine Geometry

7. Results

8. Conclusions

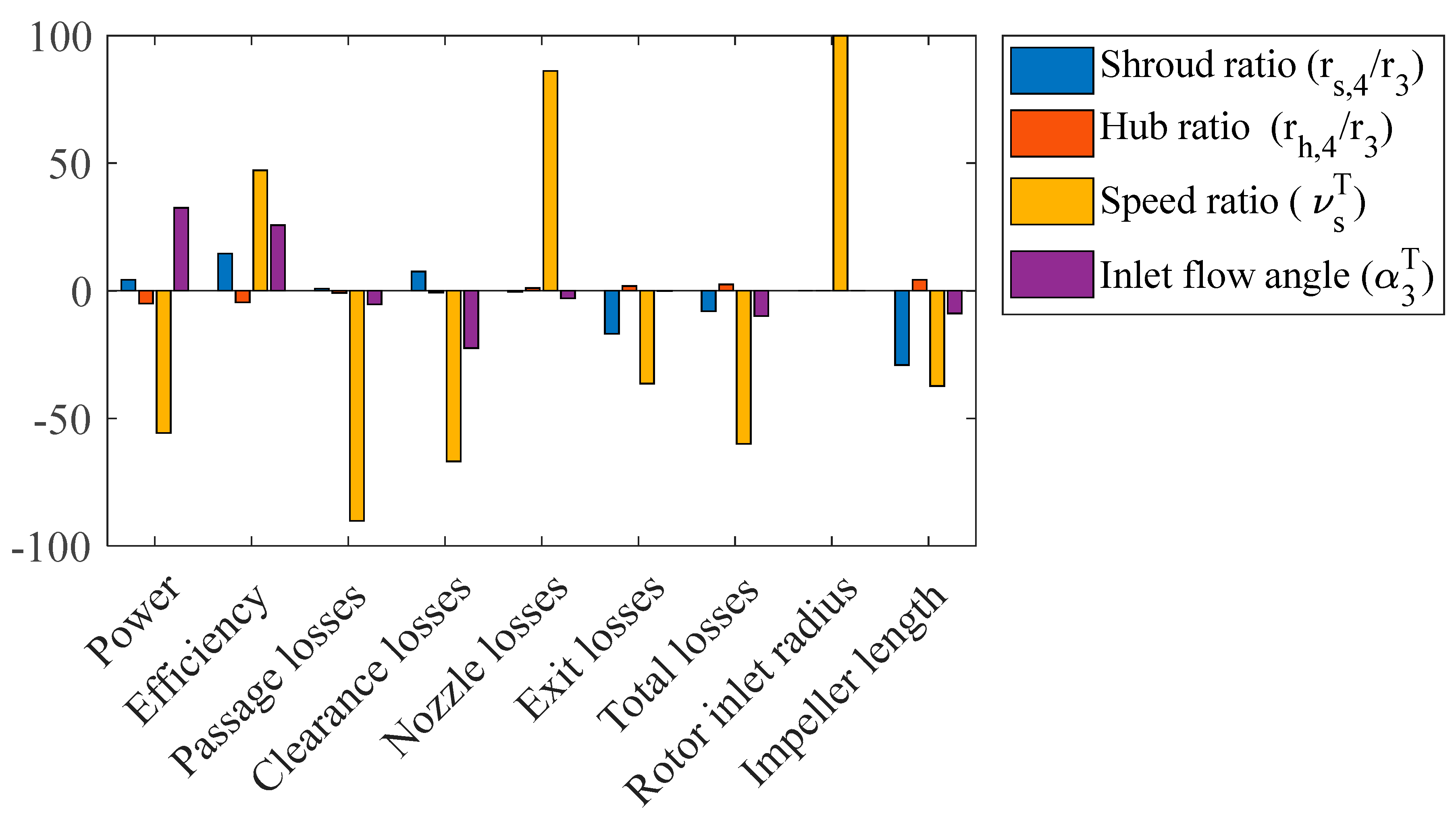

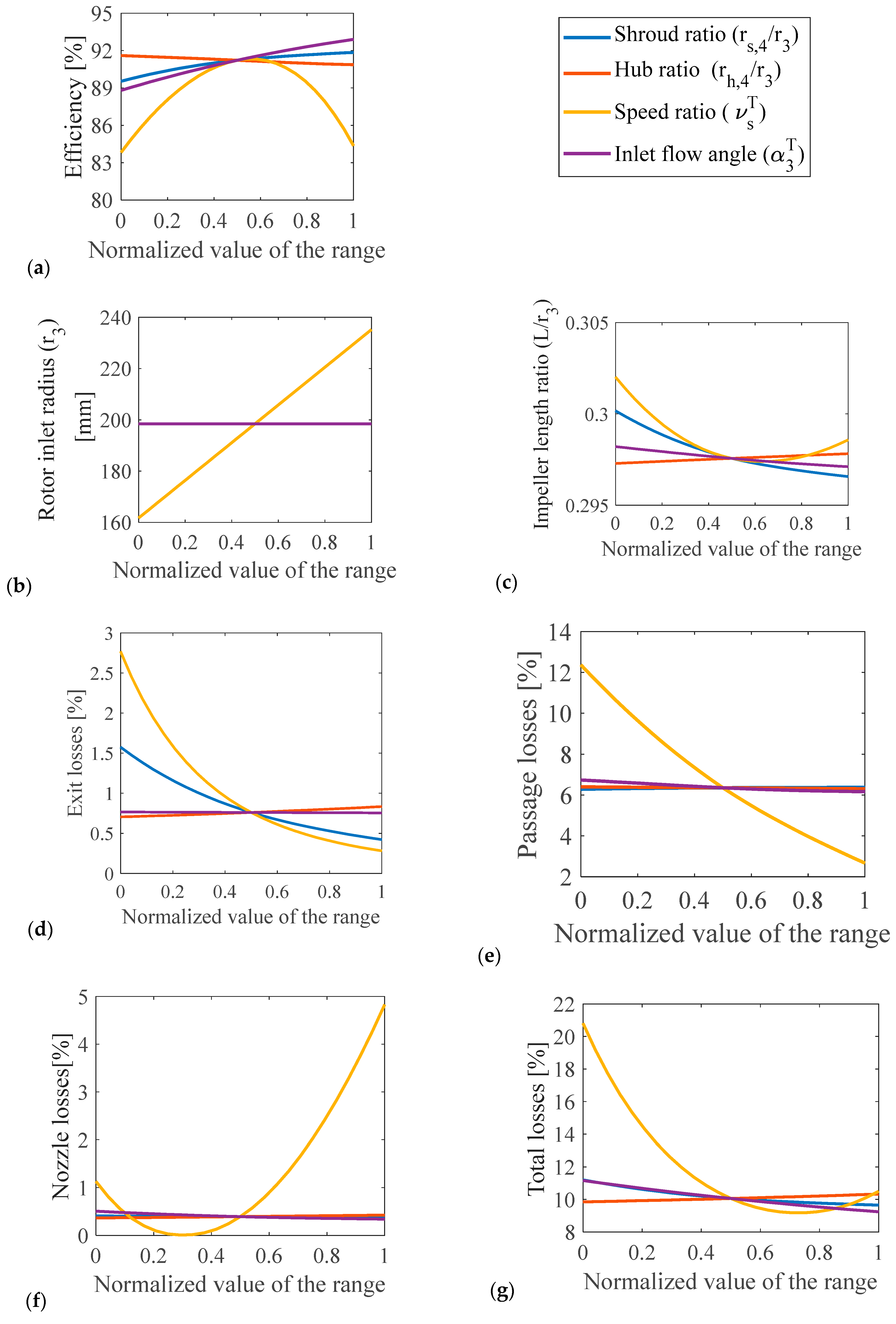

- It is noted that the turbine’s performance parameters (power, efficiency, various types of losses, rotor radius, and impellor length) are most sensitive to the speed ratio () followed by the inlet flow angle (). At the same time, the turbine’s performance is observed to be least sensitive to the turbine’s hub ratio.

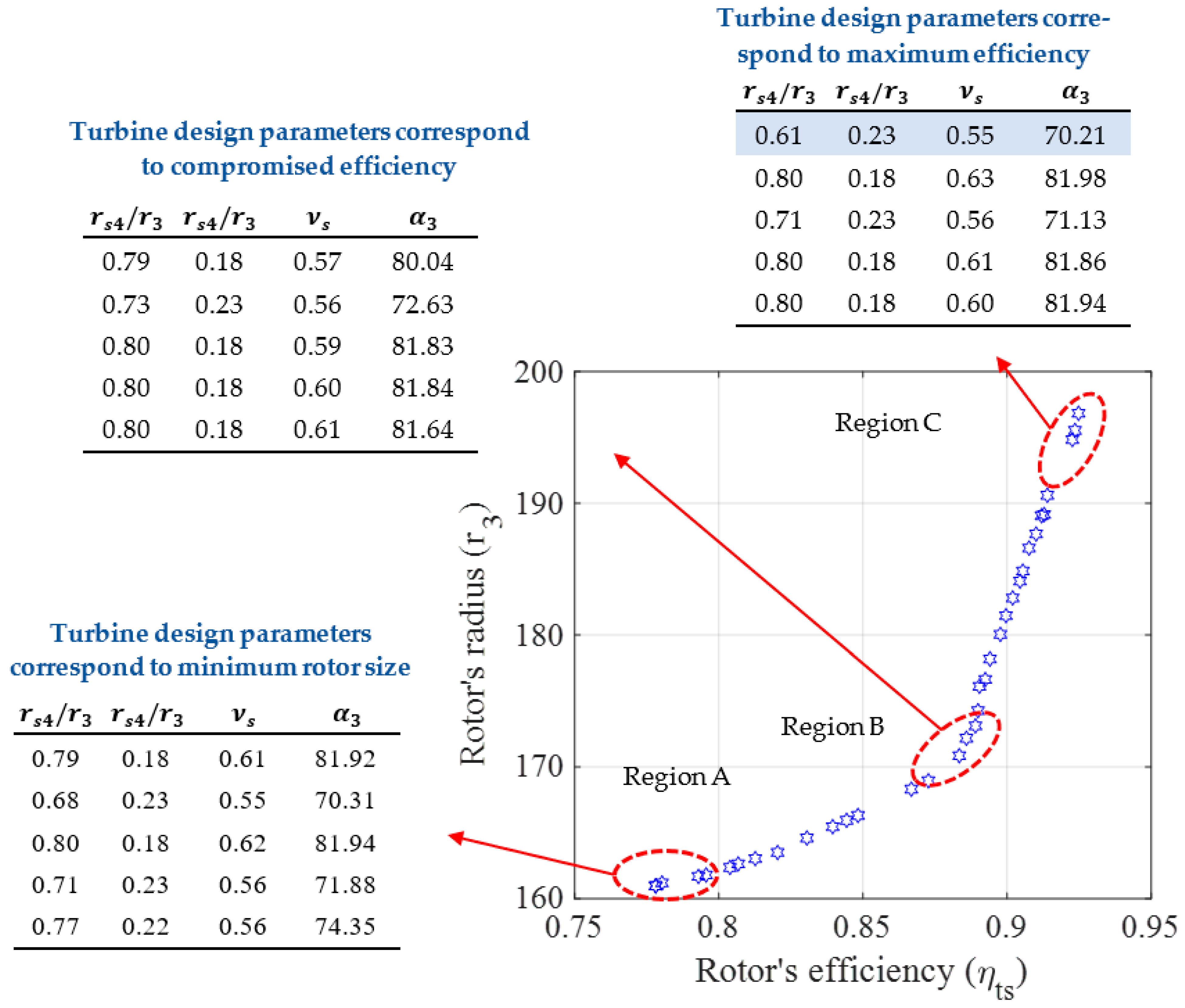

- It is found that the rotor’s efficiency changes considerably by changing the design parameters, i.e., shroud ratio ( hub ratio (, speed ratio and inlet flow angle . Conversely, the rotor’s size is only affected by the speed ratio i.e., rotor inlet radius , which rises considerably by increasing the value of the speed ratio, although, shroud ratio ( hub ratio ( and inlet flow angle do not impart any significant impact on the rotor’s size.

- Optimization results suggest that the dependence of design input parameters on the performance and sizing of the turbine is quite complex, and it is difficult to conclude the effect of individual parameters without contemplating their combined effect. Therefore, the design and analysis of the turbine would require multifaceted techniques such as the one used in the current study to understand the absolute behavior of any individual turbine design parameter.

- It is found that the turbine’s minimum size corresponds to the design with the lowest efficiency; however, the turbine’s efficiency can be improved at the cost of the increased size of the turbine’s rotor. Heat exchangers are the largest components in the sCO2-BC [4] and take up most of its layout space; therefore, design of the turbine with higher efficiency is recommended, despite the fact that it will increase the size of the turbine, as it will not impact the overall layout size of the sCO2-BC.

- Analysis of a range of design variables consumes a huge amount of computational time and resources. Therefore, by combining computational fluid dynamics with machine learning algorithms, efficient and cost-effective methods for design optimization can be achieved. In this study, the computational cost is reduced substantially by utilizing trained DNN and MOGA optimization processes, and this DNN-MOGA methodology can be extended to other applications of design optimization. However, it is to be noted here that data used for the training in this work is limited to an 8-Megawatt turbine system for sCO2-BC and cannot be used for expander systems with different power outputs.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Mach number | |

| Absolute velocity | |

| Specific heat capacity at constant pressure | |

| Diameter | |

| Body force | |

| Conversion factor | |

| Specific enthalpy | |

| Mach number | |

| Mass flow rate | |

| Specific speed | |

| N | Rotor rpm |

| Number of blades | |

| Pressure | |

| R | Gas constant |

| Power ratio | |

| Temperature | |

| Time | |

| U | Blade velocity |

| Velocity | |

| Work | |

| Relative velocity | |

| Y-plus | |

| Greek symbols | |

| Flow angle of absolute velocity vector | |

| Flow angle of relative velocity vector | |

| Heat capacity ratio | |

| Efficiency | |

| Density ] | |

| Slip velocity | |

| Angular speed | |

| Sub and superscript | |

| 1 | Nozzle inlet |

| 2 | Nozzle outlet |

| 3 | Rotor inlet |

| 4 | Rotor outlet |

| hub | |

| min | minimum |

| Stagnation value | |

| radial | |

| relative | |

| shroud | |

| static | |

| tangential | |

| Total to static | |

References

- UNFCCC. The Paris Agreement. Available online: http://unfccc.int/paris_agreement/items/9485.php (accessed on 16 October 2021).

- World Energy Council. World Energy Resources, 2016. Available online: https://www.worldenergy.org/wp-content/uploads/2016/10/World-Energy-Resources-Full-report-2016.10.03.pdf (accessed on 16 October 2021).

- Fundamentals and Applications of Supercritical Carbon Dioxide (sCO2) Based Power Cycles; Brun, K.; Friedman, P.; Dennis, R. (Eds.) Woodhead Publishing: Sawston, Cambridge, MA, UK, 2017. [Google Scholar]

- Saeed, M.; Awais, A.A.; Berrouk, A.S. CFD aided design and analysis of a precooler with zigzag channels for supercritical CO2 power cycle. Energy Convers. Manag. 2021, 236, 114029. [Google Scholar] [CrossRef]

- Saeed, M.; Khatoon, S.; Kim, M.-H. Design optimization and performance analysis of a supercritical carbon dioxide recompression Brayton cycle based on the detailed models of the cycle components. Energy Convers. Manag. 2019, 196, 242–260. [Google Scholar] [CrossRef]

- Sienicki, J.; Moisseytsev, A.; Fuller, R.L.; Wright, S.A.; Pickard, P.S. Scale dependencies of supercritical carbon dioxide brayton cycle technologies and the optimal size for a next-Step supercritical CO2 cycle demonstration. In Proceedings of the sCO2 Power Cycle Symposium, Boulder, CO, USA, 24–25 May 2011. [Google Scholar]

- Dostal, V.; Michael, J.D.; Hejzlar, P. A Supercritical Carbon Dioxide Cycle for Next Generation Nuclear Reactors, MIT-ANP-TR-100, Advanced Nuclear Power Technology Program Report. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2004. [Google Scholar]

- Zhang, H.; Zhao, H.; Deng, Q.; Feng, Z. Aerothermodynamic design and numerical investigation of supercritical carbon dioxide turbine. In Proceedings of the ASME Turbo Expo, Montréal, QC, Canada, 15–19 June 2015. [Google Scholar]

- Odabaee, M.; Sauret, E.; Hooman, K. CFD simulation of a supercritical carbon dioxide radial-inflow turbine, comparing the results of using real gas equation of estate and real gas property file. Appl. Mech. Mater. 2016, 846, 85–90. [Google Scholar] [CrossRef]

- Luo, D.; Liu, Y.; Sun, X.; Huang, D. The design and analysis of supercritical carbon dioxide centrifugal turbine. Appl. Therm. Eng. 2017, 127, 527–535. [Google Scholar] [CrossRef]

- Kalra, C.; Sevincer, E.; Brun, K.; Hofer, D.; Moore, J. Development of high efficiency hot gas turbo-expander for optimized CSP supercritical CO2 power block operation. In Proceedings of the 4th International Symposium Supercritical CO2 Power Cycles, Pittsburgh, PA, USA, 9–10 September 2014. [Google Scholar]

- Lindqvist, K.; Wilson, Z.T.; Næss, E.; Sahinidis, N.V. A machine learning approach to correlation development applied to fin-tube bundle heat exchangers. Energies 2018, 11, 3450. [Google Scholar] [CrossRef] [Green Version]

- Song, J.; Tian, W.; Xu, X.; Wang, Y.; Li, Z. Thermal performance of a novel ultrasonic evaporator based on machine learning algorithms. Appl. Therm. Eng. 2019, 148, 438–446. [Google Scholar] [CrossRef]

- Longo, G.A.; Mancin, S.; Righetti, G.; Zilio, C.; Ortombina, L.; Zigliotto, M. Application of an Artificial Neural Network (ANN) for predicting low-GWP refrigerant boiling heat transfer inside Brazed Plate Heat Exchangers (BPHE). Int. J. Heat Mass Transf. 2020, 160, 119824. [Google Scholar] [CrossRef]

- Zhao, X.; Shirvan, K.; Salko, R.K.; Guo, F. On the prediction of critical heat flux using a physics-informed machine learning-aided framework. Appl. Therm. Eng. 2020, 164, 114540. [Google Scholar] [CrossRef]

- Zhang, A. Machine Learning-Based Design Optimization of Centrifugal Impellers. In The Global Power and Propulsion Society; 2021. [Google Scholar]

- Omidi, M.; Liu, S.J.; Mohtaram, S.; Lu, H.T.; Zhang, H.C. Improving centrifugal compressor performance by optimizing the design of impellers using genetic algorithm and computational fluid dynamics methods. Sustainability 2019, 11, 5409. [Google Scholar] [CrossRef] [Green Version]

- Shi, D.; Sun, L.; Xie, Y. Off-design performance prediction of a S-CO2 turbine based on field reconstruction using deep-learning approach. Appl. Sci. 2020, 10, 4999. [Google Scholar] [CrossRef]

- Ilmini, K.; Fernando, T. Persons’ Personality Traits Recognition using Machine Learning Algorithms and Image Processing Techniques. Adv. Comput. Sci. Int. J. 2016, 5, 40–44. [Google Scholar]

- Saeed, M.; Kim, M. Analysis of a recompression supercritical carbon dioxide power cycle with an integrated turbine design/optimization algorithm. Energy 2018, 165, 93–111. [Google Scholar] [CrossRef]

- Massimiani, A.; Palagi, L.; Sciubba, E.; Tocci, L. Neural networks for small scale ORC optimization. Energy Procedia 2017, 129, 34–41. [Google Scholar] [CrossRef]

- Villarrubia, G.; de Paz, J.F.; Chamoso, P.; De la Prieta, F. Artificial neural networks used in optimization problems. Neurocomputing 2018, 272, 10–16. [Google Scholar] [CrossRef]

- Aungier, A.H. Turbine Aerodynamics: Axial-Flow and Radial-Flow Turbine Design and Analysis; ASME: New York, NY, USA, 2006; pp. 10016–15990. [Google Scholar]

- Moustapha, H. Axial and Radial Turbines, 1st ed.; Concepts NREC: VT, USA, 2003; Available online: https://www.researchgate.net/publication/238778854_Axial_and_Radial_Turbines (accessed on 16 October 2021).

- Fouad, W.A.; Berrouk, A.S. Prediction of H2S and CO2 Solubilities in Aqueous Triethanolamine Solutions Using a Simple Model of Kent-Eisenberg Type. Ind. Eng. Chem. Res. 2012, 51, 6591–6597. [Google Scholar] [CrossRef]

- Althuluth, M.; Berrouk, A.S.; Kroon, M.C.; Peters, C.J. Modeling solubilities of gases in the ionic liquid 1-ethyl-3-methylimidazolium tris (pentafluoroethyl) trifluorophosphate using the Peng–Robinson equation of state. Ind. Eng. Chem. Res. 2014, 53, 11818–11821. [Google Scholar] [CrossRef]

- Lemmon, E.; Linden, M.M.; Huber, M. NIST Reference Fluid Thermodynamic and Transport Properties Database: REFPROP Version 9.1, NIST Standard Reference Database 23, 2013., n.d. Available online: http://www.boulder.nist.gov (accessed on 25 December 2017).

- Watanabe, I.; Ariga, I.; Mashimo, T. Effect of Dimensional Parameters of Impellers on Performance Characteristics of a Radial-Inflow Turbine. J. Eng. Power 1971, 93, 81–102. [Google Scholar] [CrossRef]

- Saeed, M.; Alawadi, K.; Kim, S.C. Performance of Supercritical CO2 Power Cycle and Its Turbomachinery with the Printed Circuit Heat Exchanger with Straight and Zigzag Channels. Energies 2021, 14, 62. [Google Scholar] [CrossRef]

- Saeed, M.; Berrouk, A.S.; Siddiqui, M.S.; Awais, A.A. Effect of Printed Circuit Heat Exchanger’s Different Designs on the Performance of Supercritical Carbon Dioxide Brayton Cycle. Appl. Therm. Eng. 2020, 179, 115758. [Google Scholar] [CrossRef]

- Saeed, M.; Berrouk, A.S.; AlShehhi, M.S.; AlWahedi, Y.F. Numerical investigation of the thermohydraulic characteristics of microchannel heat sinks using supercritical CO2 as a coolant. J. Supercrit. Fluids 2021, 176, 105306. [Google Scholar] [CrossRef]

- Abadi, M.; Agarwal, A.; Barham, P.; Brevdo, E.; Chen, Z.; Citro, C.; Corrado, G.S.; Davis, A.; Dean, J.; Devin, M.; et al. TensorFlow: Large-Scale Machine Learning on Heterogeneous Distributed Systems. In Proceedings of the 12th USENIX Symposium on Operating Systems Design and Implementation, Savannah, GA, USA, 2–4 November 2016. [Google Scholar]

- Saeed, M.; Radaideh, M.I.; Berrouk, A.S.; Alawadhi, K. Machine Learning-based Efficient Multi-layered Precooler Design Approach for Supercritical CO2 Cycle. Energy Convers. Manag. X 2021, 11, 100104. [Google Scholar] [CrossRef]

- Rebai, N.; Hadjadj, A.; Benmounah, A.; Berrouk, A.S.; Boualleg, S.M. Prediction of Natural Gas Hydrates Formation Using a Combination of Thermodynamic and Neural Network Modelling. J. Petrol. Sci. Eng. 2019, 182, 10627. [Google Scholar] [CrossRef]

- Chu, Y.M.; Ibrahim, M.; Saeed, T.; Berrouk, A.S.; Algehyne, E.A.; Kalbasi, R. Examining Rheological Behavior of MWCNT-TiO2/5W40 Hybrid Nanofluid Based on Experiment and RSM/ANN Modeling. J. Mol. Liq. 2021, 333, 115969. [Google Scholar] [CrossRef]

- Goldberg, D.E.; Samtani, M.P. Engineering Optimization via Genetic Algorithm. In Electronic Computation; ASCE: Reston, VA, USA; Washington, DC, USA, 1986; pp. 471–482. Available online: https://www.researchgate.net/publication/246069860_Engineering_optimization_via_genetic_algorithm (accessed on 16 October 2021).

- Siddiqui, M.S.; Latif, S.T.M.; Saeed, M.; Rahman, M.; Badar, A.W.; Hasan, S.M. Reduced order model of offshore wind turbine wake by proper orthogonal decomposition. Int. J. Heat Fluid Flow 2020, 82, 108554. [Google Scholar] [CrossRef]

- Siddiqui, M.S.; Hamza, M.; Waheed, A.; Saeed, M. Parametric Analysis Using CFD to Study Impact of Geometric and Numerical Modeling on the Performance of Small-Scale Horizontal Axis Wind Turbine, (n.d.). Available online: https://www.mdpi.com/1996-1073/13/15/3880/htm (accessed on 16 October 2021).

- Saeed, M.; Berrouk, A.S.; Siddiqui, M.S.; Awais, A.A. Numerical investigation of thermal and hydraulic characteristics of sCO2-water printed circuit heat exchangers with zigzag channels. Energy Convers. Manag. 2020, 224, 113375. [Google Scholar] [CrossRef]

- Saeed, M.; Berrouk, A.S.; Singh, M.P.; Alawadhi, K. Analysis of Supercritical CO2 Cycle Using Zigzag Channel Pre-Cooler: A Design Optimization Study Based on Deep. Energies 2021, 14, 6227. [Google Scholar] [CrossRef]

| Items | Symbols | Values |

|---|---|---|

| The mass flow rate of exhaust CO2 | 50 [kg s−1] | |

| Temperate of exhaust gases | 983 [K] | |

| Expansion ratio | 3 | |

| The desired value of total to static efficiency | 0.90 | |

| Desired turbine output power | 8 [MW] | |

| Rotational speed | ω | 40,000 [rpm] |

| Mesh | Number of Nodes in Streamwise Direction | Span Wise Direction | Theta Direction | CPU Time/10 Iterations [s] | Memory Consumed [MB] | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Inlet Domain | Nozzle Blade | Nozzle Rotor Gap | Rotor Blade | Outlet Domain | Along with Blade | Tip Clearance Region | |||||

| M1 | 25 | 35 | 20 | 45 | 25 | 70 | 11 | 45 | 318 | 5612 | 82.32 |

| M2 | 35 | 40 | 25 | 55 | 35 | 80 | 15 | 65 | 672 | 9653 | 87.57 |

| M3 | 40 | 50 | 30 | 70 | 40 | 90 | 19 | 85 | 1548 | 2578 | 91.31 |

| M4 | 50 | 60 | 35 | 80 | 50 | 100 | 23 | 95 | 2347 | 3517 | 91.19 |

| Input Parameters | Output Parameter | |||||

|---|---|---|---|---|---|---|

| S. No. | ||||||

| 1 | 0.6 | 0.18 | 0.55 | 70 | 0.77 | 161.71 |

| 2 | 0.6 | 0.18 | 0.55 | 73 | 0.78 | 161.71 |

| 3 | 0.6 | 0.18 | 0.55 | 76 | 0.78 | 161.71 |

| 4 | 0.6 | 0.18 | 0.55 | 79 | 0.79 | 161.71 |

| 5 | 0.6 | 0.18 | 0.55 | 82 | 0.79 | 161.71 |

| 6 | 0.6 | 0.18 | 0.6 | 70 | 0.82 | 176.41 |

| 7 | 0.6 | 0.18 | 0.6 | 73 | 0.83 | 176.41 |

| 8 | 0.6 | 0.18 | 0.6 | 76 | 0.83 | 176.41 |

| . | . | . | . | . | . | . |

| . | . | . | . | . | . | . |

| . | . | . | . | . | . | . |

| 600 | 0.8 | 0.24 | 0.8 | 82 | 0.82 | 270.49 |

| Design Parameters | Objective Function | |||||

|---|---|---|---|---|---|---|

| Lower limit | 0.6 | 0.18 | 0.55 | 70 | Maximize | Minimize |

| Upper limit | 0.8 | 0.24 | 0.8 | 82 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saeed, M.; Berrouk, A.S.; Burhani, B.M.; Alatyar, A.M.; Wahedi, Y.F.A. Turbine Design and Optimization for a Supercritical CO2 Cycle Using a Multifaceted Approach Based on Deep Neural Network. Energies 2021, 14, 7807. https://doi.org/10.3390/en14227807

Saeed M, Berrouk AS, Burhani BM, Alatyar AM, Wahedi YFA. Turbine Design and Optimization for a Supercritical CO2 Cycle Using a Multifaceted Approach Based on Deep Neural Network. Energies. 2021; 14(22):7807. https://doi.org/10.3390/en14227807

Chicago/Turabian StyleSaeed, Muhammad, Abdallah S. Berrouk, Burhani M. Burhani, Ahmed M. Alatyar, and Yasser F. Al Wahedi. 2021. "Turbine Design and Optimization for a Supercritical CO2 Cycle Using a Multifaceted Approach Based on Deep Neural Network" Energies 14, no. 22: 7807. https://doi.org/10.3390/en14227807

APA StyleSaeed, M., Berrouk, A. S., Burhani, B. M., Alatyar, A. M., & Wahedi, Y. F. A. (2021). Turbine Design and Optimization for a Supercritical CO2 Cycle Using a Multifaceted Approach Based on Deep Neural Network. Energies, 14(22), 7807. https://doi.org/10.3390/en14227807