Domestic Gas Meter Durability in Hydrogen and Natural Gas Mixtures

Abstract

:1. Introduction

2. Theory and Methods

3. Results

4. Discussion

- -

- The maximum WME values are −0.53 %, −0.76 % and −0.48 % for 2E/H15, 2E/H10 and 2E/H0 mixtures, respectively;

- -

- During each stage of the durability test (250, 3500, 5000, 8500 and 10,000 h), the WMEs never exceeded the maximum permissible value of ±1.2%;

- -

- The maximum difference in WME changes was equal to 0.42% after 2000 h, relating to 2E/H10 and 2E/H0 mixtures;

- -

- After 10,000 h the WME changes for the 2E/H15 and 2E/H0 mixtures are both equal to −0.82%.

4.1. Metrological Analysis

- -

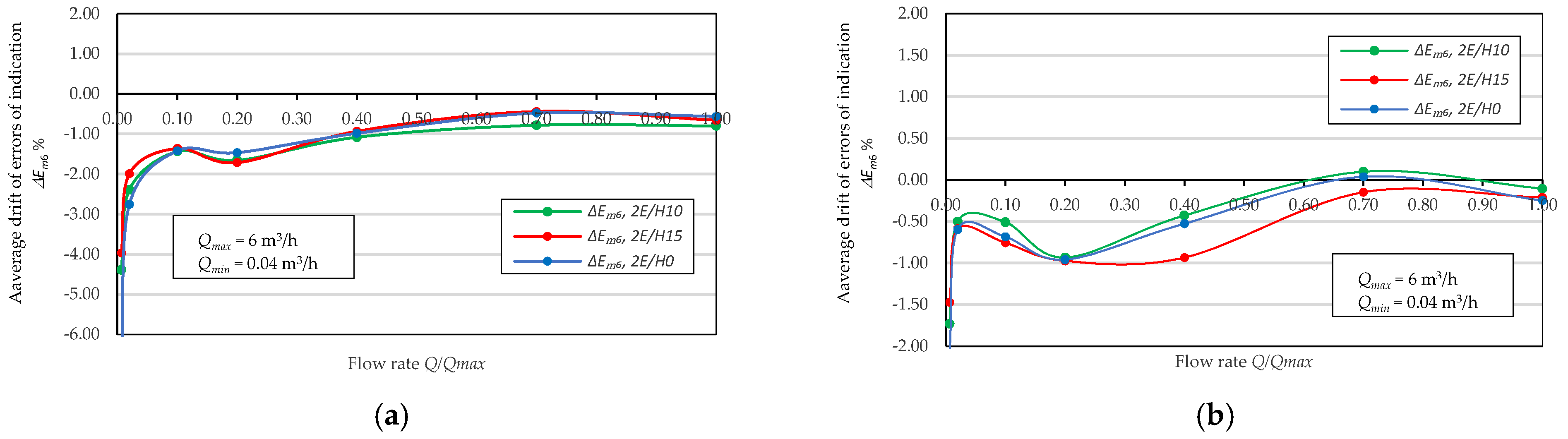

- After testing the durability of new diaphragm gas meters Type−1 and Type−2 and in-service gas meters Type−5 and Type−6 over 5000, 10,000 and 15,000 h with the addition of 10% and 15% H2, metrologically insignificant differences in the average drift of errors of indications in relation to the control sample 2E/H0 were found in flow rates from Qmin to Qmax.

- -

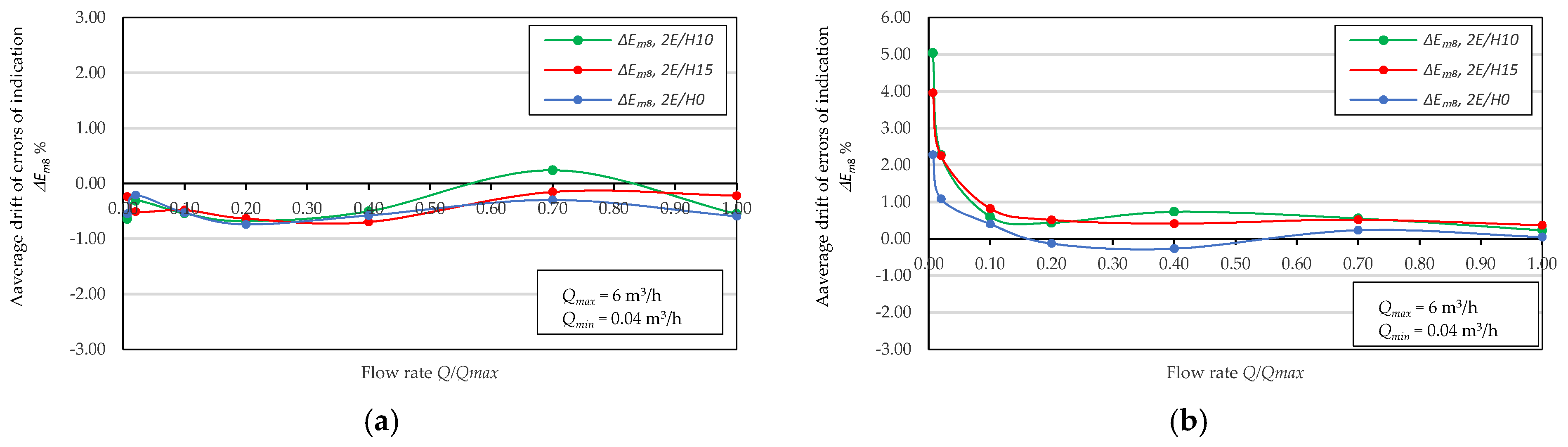

- After testing the durability of new diaphragm gas meters Type−3 and Type−4 and in-service gas meter Type−7 over 5000 and 10,000 h with the addition of 10% and 15% H2, metrologically insignificant differences in the average drift of errors of indications in relation to the control sample 2E/H0 were found in flow rates from Qmin to Qmax.

- -

- After testing the durability of new Type−8 thermal gas meters over 6000 and 7500 h with the addition of 15% H2, metrologically insignificant differences in the average drift of errors of indications in relation to the control sample 2E/H0 were found in flow rates from Qmin to Qmax.

- -

- After testing the durability of diaphragm and thermal gas meters over 10,000 and 15,000 h with the addition of 10% and 15% H2, there was no significant difference in WME changes in relation to the control sample 2E/H0. The maximum difference in WME changes after the durability test with the use of the 2E/H15 mixture in relation to the 2E/H0 mixture was 0.45% for the Type−6 gas meter, and after 15,000 h it was 0.44% for the Type−4 gas meter.

4.2. Statistical Analysis

- -

- For the new Type−1, Type−2, and Type−3 gas meters, as well as in-service Type−5 and Type−6 gas meters, after a durability test of 10,000 h, no statistically significant influence of the 15% hydrogen content in natural gas on the change in errors of indications was found.

- -

- For the new Type−4 gas meters, after a durability test of 10,000 h, a statistically significant influence of 15% hydrogen content in natural gas was found for the flow rates at 0.4Qmax and 0.7Qmax; however, when analyzing the values of these changes and their uncertainties, these differences were considered to be metrologically insignificant.

- -

- For in-service gas meters of Type−7, after a durability test of 10,000 h, a statistically significant influence of the 15% hydrogen content in natural gas was found for the flow rates at 3Qmin and Qmax; however, the difference in the average drift of the errors of indications is within the total measurement uncertainty and thus is metrologically insignificant.

- -

- For Type−8 thermal gas meters, after the 7500 h durability test, no statistically significant influence of 15% hydrogen content in natural gas on the change of errors of indications was found.

4.3. Leakage Test

5. Conclusions

- -

- For the test samples subjected to the durability tests, regardless of whether they were gas meters in service (after 10 years of operation) or new gas meters, no significant metrological influence of added hydrogen was found on the obtained average drift of errors of indications after the durability tests. Apart from single Type−1 gas meters tested in sample 2E/H0 (without hydrogen addition), in which most likely internal leakage occurred, the gas meters meet the metrological requirements for a durability test according to EN 1359 [18].

- -

- For the majority of diaphragm gas meters and for thermal gas meters, no statistically significant influence of the hydrogen content in the gas was found on the change in gas meter errors of indications after they were subjected to the durability tests. For the new Type−4 diaphragm gas meters and in-service Type−7 gas meters, after the 10,000 h durability test, statistically significant differences were found in the average drift of the errors of indications of gas meters subjected to the durability test with a 2E natural gas mixture with 15% hydrogen addition and 2E natural gas without hydrogen at flow rates 0.4Qmax and 0.7Qmax and 3Qmin and Qmax, respectively. Analyzing the average drift of errors of indications for the control sample 2E/H0 and the test sample 2E/H15, it can be concluded that the differences between these changes are smaller than the uncertainty of determining the difference, and therefore these should be considered metrologically insignificant.

- -

- For all types of gas meters subjected to the durability test after 10,000 h, no significant differences were found between the average weighted mean error (WME) changes for the tested gas mixtures, and almost all gas meter errors were within ±1.2%, except for single gas meters (four meters).

- -

- During the durability tests, no damage was found that would compromise operational safety. All gas meters—diaphragm or thermal—remained tight after the durability tests.

- -

- The tests carried out with the use of diaphragm gas meters, both new and after 10 years of operation, as well as thermal gas meters, indicate that they can be used for the settlement purposes of natural gas with the addition of hydrogen up to 15% concentration. Nevertheless, it should be noted that research in the field of flow metrology should still be carried out because the discussed results concern only a certain group of gas meters, which is not representative of all types of gas meters used.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature and Symbols

| E | error of indications of the gas meter (%) |

| Em | average errors of indications of the gas meter (%) |

| E0 | initial errors of indications of the gas meter (%) |

| Em01 | average initial errors of indications (for sample of three gas meters) (%) |

| Em02 | average initial errors of indications (for sample of six gas meters) (%) |

| Em1 | average errors of indications of the gas meters after 250 h of work |

| Em2 | average errors of indications of the gas meters after 2000 h of work (%) |

| Em3 | average errors of indications of the gas meters after 3500 h of work (%) |

| Em4 | average errors of indications of the gas meters after 5000 h of work (%) |

| Em5 Em5′ | average errors of indications of the gas meters after 8500 h of work (%) average errors of indications of the gas meters after 7500 h of work (%) |

| Em6 | average errors of indications of the gas meters after 10,000 h of work (%) |

| Em8 | average errors of indications of the gas meters after 15,000 h of work (%) |

| MPE | maximum permissible errors (%) |

| ΔEm1 | average drift of errors of indications of the gas meters after 250 h of work (%) |

| ΔEm2 | average drift of errors of indications of the gas meters after 2000 h of work (%) |

| ΔEm3 | average drift of errors of indications of the gas meters after 3500 h of work (%) |

| ΔEm4 | average drift of errors of indications of the gas meters after 5000 h of work (%) |

| ΔEm5 ΔEm5′ | average drift of errors of indications of the gas meters after 8500 h of work (%) average drift of errors of indications of the gas meters after 7500 h of work (%) |

| ΔEm6 | average drift of errors of indications of the gas meters after 10,000 h of work (%) |

| ΔEm8 | average drift of errors of indications of the gas meters after 15,000 h of work (%) |

| ΔEmH-m2E | difference of the average drifts of errors of indications of the gas meters tested for durability using a 2E/H5, 2E/H10 and 2E/H15 natural gas mixture with hydrogen and a 2E/H0 natural gas mixture without the addition of hydrogen (%) |

| Q | flow rate (m3/h) |

| U(ΔEmH-m2E) | uncertainty of determining the difference of the average drifts of errors of indications of the gas meters tested for durability using a 2E/H5, 2E/H10 and 2E/H15 natural gas mixture with hydrogen and a 2E/H0 natural gas mixture without the addition of hydrogen (%) |

| U(EmH) | uncertainty of determining the average drifts of errors of indications of the gas meters tested for durability using a 2E/H5, 2E/H10 and 2E/H15 natural gas mixture with hydrogen (%) |

| U(Em2E) | uncertainty of determining the average drifts of errors of indications of the gas meters tested for durability using a 2E/H0 natural gas mixture without the addition of hydrogen (%) |

| Abbreviations | |

| INiG-PIB | Oil and Gas Institute–National Research Institute |

| 2E | natural gas of group E of the second gas family (high-methane) described in EN 437 |

| 2E/H0 | 2E natural gas mixture without the addition of hydrogen |

| 2E/H5 | 2E natural gas mixture with 5% hydrogen content (V/V) |

| 2E/H10 | 2E natural gas mixture with 10% hydrogen content (V/V) |

| 2E/H15 | 2E natural gas mixture with 15% hydrogen content (V/V) |

References

- Castellani, B.; Gambelli, A.M.; Morini, E.; Nastasi, B.; Presciutti, A.; Filipponi, M.; Nicolini, A.; Rossi, F. Experimental Investigation on CO2 Methanation Process for Solar Energy Storage Compared to CO2-Based Methanol Synthesis. Energies 2017, 10, 855. [Google Scholar] [CrossRef]

- Perna, A.; Moretti, L.; Ficco, G.; Spazzafumo, G.; Canale, L.; Dell’Isola, M. SNG Generation via Power to Gas Technology: Plant Design and Annual Performance Assessment. Appl. Sci. 2020, 10, 8443. [Google Scholar] [CrossRef]

- Ozturk, M.; Ibrahim, D. A comprehensive review on power-to-gas with hydrogen options for cleaner applications. Int. J. Hydrogen Energy 2021, 46, 31511–31522. [Google Scholar] [CrossRef]

- European Committee for Standardization. EN 437:2021 Test Gases—Test Pressures—Appliance Categories; Technical Committee CEN/TC 238; European Committee for Standardization: Brussels, Belgium, 2018. [Google Scholar]

- Stetsenko, A.; Naumenko, V. Exploration of hydrogen influence on physical properties of natural gas and metrological characteristics of its metering systems. In Proceedings of the Flomeko 2019, Lisbon, Portugal, 26–28 June 2019. [Google Scholar]

- Buonanno, G. On field characterization of static domestic gas flowmeters. Measurement 2000, 27, 277–285. [Google Scholar] [CrossRef]

- Farzaneh-Gord, M.; Parvizi, S.; Arabkoohsar, A.; Machado, L.; Koury, R.N.N. Potential use of capillary tube thermal mass flow meters to measure residential natural gas consumption. J. Nat. Gas Sci. Eng. 2015, 22, 540–550. [Google Scholar] [CrossRef]

- Parvizi, S.; Arabkoohsar, A.; Farzaneh-Gord, M. Natural gas compositions variation effect on capillary tube thermal mass flow meter performance. Flow Meas. Instrum. 2016, 50, 229–236. [Google Scholar] [CrossRef]

- Huang, L. City Natural Gas Metering. In Natural Gas—Extraction to End Use; IntechOpen Ltd: London, UK, 2012; Chapter 9. [Google Scholar]

- Ficco, G. Metrological performance of diaphragm gas meter in distribution networks. Flow Meas. Instrum. 2014, 37, 65–67. [Google Scholar] [CrossRef]

- Ficco, G.; Celenza, L.; Dell’Isola, M.; Vigo, P. Experimental evaluation of thermal mass smart meters influence factors. J. Nat. Gas Sci. Eng. 2016, 32, 1–10. [Google Scholar] [CrossRef]

- Kułaga, P.; Jaworski, J.; Gacek, Z. Thermal gas meters in individual settlements. Characteristics and application perspectives. Gaz Woda Tech. Sanit. 2018, 11, 390–395. [Google Scholar]

- Jaworski, J.; Dudek, A. Study of the Effects of Changes in Gas Composition as Well as Ambient and Gas Temperature on Errors of Indications of Thermal Gas Meters. Energies 2020, 13, 5428. [Google Scholar] [CrossRef]

- Jaworski, J.; Kułaga, P.; Blacharski, T. Study of the Effect of Addition of Hydrogen to Natural Gas on Diaphragm Gas Meters. Energies 2020, 13, 3006. [Google Scholar] [CrossRef]

- Polman, E.A.; De Laat, J.C.; Crowther, M. Reduction of CO2 Emissions by Adding Hydrogen to Natural Gas; Gastech Tecnology BV: Apeldoorn, The Netherlands, 2003. [Google Scholar]

- Dehaeseleer, J. The Effects of Injecting Hydrogen (Renewable Gases); EASEE-Gas GMOM: Budapest, Hungary, 2018. [Google Scholar]

- International Organization of Legal Metrology. OIML D11. In General Requirements for Measuring Instruments—Environmental Conditions; International Organization of Legal Metrology: Paris, France, 2013. [Google Scholar]

- International Organization of Legal Metrology. OIML R1371&2:2012, Gas Meters Part 1: Metrological and Technical Requirements Part 2: Metrological Controls and Performance Tests; International Organization of Legal Metrology: Paris, France, 2012. [Google Scholar]

- European Committee for Standardization. EN 1359:2017 Gas Meters. Diaphragm Gas Meters and EN 1359:1998+A1:2006; European Committee for Standardization: Brussels, Belgium, 2017. [Google Scholar]

| Type of Gas Meter | Id. | New/ In-Service | Production Year | Cyclic Volume (dm3) | Size | Qmin (m3/h) | Qmax (m3/h) |

|---|---|---|---|---|---|---|---|

| Diaphragm | Type−1 | New | 2018 and 2019 | 1.2 | G4 | 0.04 | 6 |

| Type−2 | 2018 and 2019 | 1.2 | |||||

| Type−3 | 2019 | 1.2 | |||||

| Type−4 | 2019 | 2.0 | |||||

| Type−5 | In-service | 2009 | 2.0 | ||||

| Type−6 | 2008 | 2.2 | |||||

| Type−7 | 2009 | 2.0 | |||||

| Thermal | Type−8 | New | 2019 | - |

| Flow Rate Q | ||||||||

|---|---|---|---|---|---|---|---|---|

| Qmin | 3 Qmin | 0.1 Qmax | 0.2 Qmax | 0.4 Qmax | 0.7 Qmax | Qmax | ||

| Average errors (%) | WME (%) | |||||||

| Em01 | −1.22 | −0.57 | −0.10 | 0.30 | 0.61 | 0.10 | 0.13 | 0.22 |

| Em02 | 0.45 | 0.28 | 0.21 | 0.64 | 0.64 | 0.04 | 0.19 | 0.29 |

| Em1 | −2.10 | −1.52 | −0.82 | −0.28 | 0.09 | −0.54 | −0.29 | −0.35 |

| Em2 | −3.09 | −1.97 | −1.15 | −0.59 | −0.16 | −0.73 | −0.49 | −0.58 |

| Em3 | −2.18 | −1.51 | −0.89 | −0.60 | −0.16 | −0.39 | −0.30 | −0.39 |

| Em4 | −2.11 | −1.47 | −0.86 | −0.55 | −0.22 | −0.51 | −0.19 | −0.42 |

| Em5 | −3.52 | −1.65 | −1.17 | −0.95 | −0.10 | −0.30 | −0.49 | −0.44 |

| Em6 | −3.52 | −1.71 | −1.15 | −1.07 | −0.29 | −0.40 | −0.47 | −0.53 |

| Average drift of errors (%) | WME changes (%) | |||||||

| ΔEm1 | − 0.88 | − 0.96 | − 0.71 | − 0.58 | − 0.52 | − 0.64 | − 0.41 | − 0.57 |

| ΔEm2 | − 1.88 | − 1.40 | − 1.04 | − 0.89 | − 0.78 | − 0.83 | − 0.62 | − 0.80 |

| ΔEm3 | − 2.63 | − 1.79 | − 1.10 | − 1.24 | − 0.80 | − 0.43 | − 0.49 | − 0.67 |

| ΔEm4 | − 2.56 | − 1.75 | − 1.07 | − 1.19 | − 0.86 | − 0.56 | − 0.38 | − 0.70 |

| ΔEm5 | − 3.97 | − 1.93 | − 1.38 | − 1.60 | − 0.75 | − 0.34 | − 0.68 | − 0.73 |

| ΔEm6 | − 3.97 | − 2.00 | − 1.36 | − 1.72 | − 0.94 | − 0.44 | − 0.66 | − 0.82 |

| Volume Flow Q | Average Drift of Errors of Indications after the 10,000 h Test for Mixtures (%) | Differences in Average Drift of Errors (%) | Uncertainty in Average Drift of Errors (%) | Permitted Difference in Drift (%) | Metrological Assessment | |||

|---|---|---|---|---|---|---|---|---|

| ΔEm6 2E/H15 | ΔEm6 2E/H0 | ΔEmH-m2E | U(Em) | U(ΔEmH-m2E) | ||||

| 2E/H15 | 2E/H0 | |||||||

| Qmax | −0.66 | −0.56 | −0.10 | 0.18 | 0.19 | 0.53 | insignificant | |

| 0.7 Qmax | −0.44 | −0.48 | 0.04 | 0.17 | 0.16 | 0.60 | insignificant | |

| 0.4 Qmax | −0.94 | −0.99 | 0.05 | 0.18 | 0.19 | 0.52 | insignificant | |

| 0.2 Qmax | −1.72 | −1.47 | −0.25 | 0.18 | 0.14 | 0.63 | insignificant | |

| 0.1 Qmax | −1.36 | −1.42 | 0.06 | 0.16 | 0.23 | 0.58 | insignificant | |

| 3 Qmin | −2.00 | −2.76 | 0.76 | 0.39 | 0.71 | 1.62 | insignificant | |

| Qmin | −3.97 | −6.55 | 2.58 | 0.92 | 2.45 | 5.23 | insignificant | |

| Volume Flow Q | Brown–Forsythe Variance Homogeneity Test | Fisher–Snedecor Variance Equality Test | Tukey Post Hoc Test | ||

|---|---|---|---|---|---|

| Statistics | Significance Level | Statistics | Significance Level | ||

| Qmin | 2.856706 | 0.088879 | 1.546846 | 0.245036 | X |

| 3 Qmin | 1.171227 | 0.336787 | 1.361702 | 0.286142 | X |

| 0.1 Qmax | 1.110179 | 0.355114 | 0.069812 | 0.932871 | X |

| 0.2 Qmax | 0.939051 | 0.412817 | 0.796192 | 0.469211 | X |

| 0.4 Qmax | 2.783064 | 0.093765 | 0.162380 | 0.851593 | X |

| 0.7 Qmax | 3.172247 | 0.070964 | 0.818781 | 0.459740 | X |

| Qmax | 1.650751 | 0.224923 | 0.211673 | 0.811605 | X |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jaworski, J.; Kułaga, P.; Ficco, G.; Dell’Isola, M. Domestic Gas Meter Durability in Hydrogen and Natural Gas Mixtures. Energies 2021, 14, 7555. https://doi.org/10.3390/en14227555

Jaworski J, Kułaga P, Ficco G, Dell’Isola M. Domestic Gas Meter Durability in Hydrogen and Natural Gas Mixtures. Energies. 2021; 14(22):7555. https://doi.org/10.3390/en14227555

Chicago/Turabian StyleJaworski, Jacek, Paweł Kułaga, Giorgio Ficco, and Marco Dell’Isola. 2021. "Domestic Gas Meter Durability in Hydrogen and Natural Gas Mixtures" Energies 14, no. 22: 7555. https://doi.org/10.3390/en14227555

APA StyleJaworski, J., Kułaga, P., Ficco, G., & Dell’Isola, M. (2021). Domestic Gas Meter Durability in Hydrogen and Natural Gas Mixtures. Energies, 14(22), 7555. https://doi.org/10.3390/en14227555