Deployment and Optimisation of a Pilot-Scale IASBR System for Treatment of Dairy Processing Wastewater

Abstract

:1. Introduction

2. Materials and Methods

2.1. Aim and Objectives

- Provide a thorough evaluation of the technology’s applicability to treating dairy wastewater at a larger scale under real world conditions;

- Quantitatively evaluate the removal capabilities of the system for nitrogen and phosphorus;

- Optimise reactor operation to maximise throughput, maintain high removal rates and improve energy efficiency.

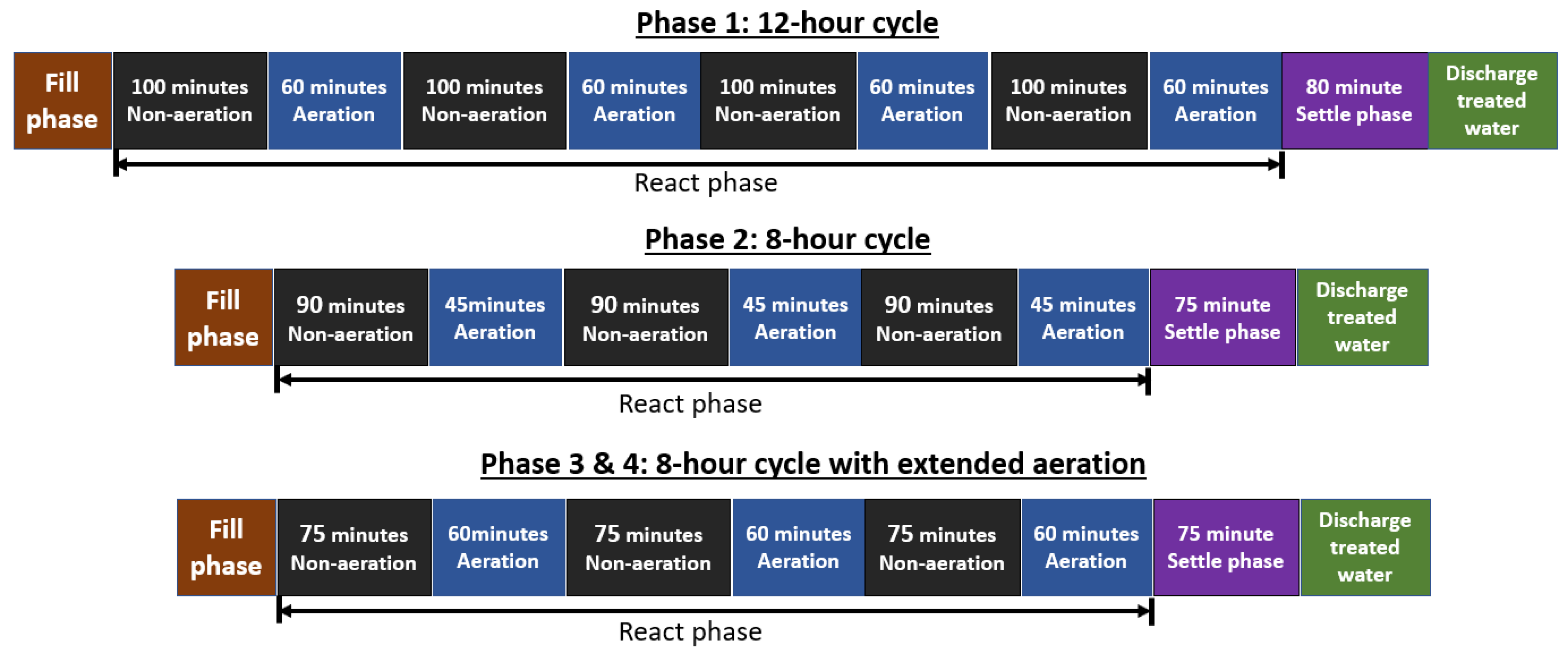

2.2. IASBR Design and Operation

2.3. Sampling and Analytical Methods

2.4. Energy Optimisation Analysis

3. Results and Discussion

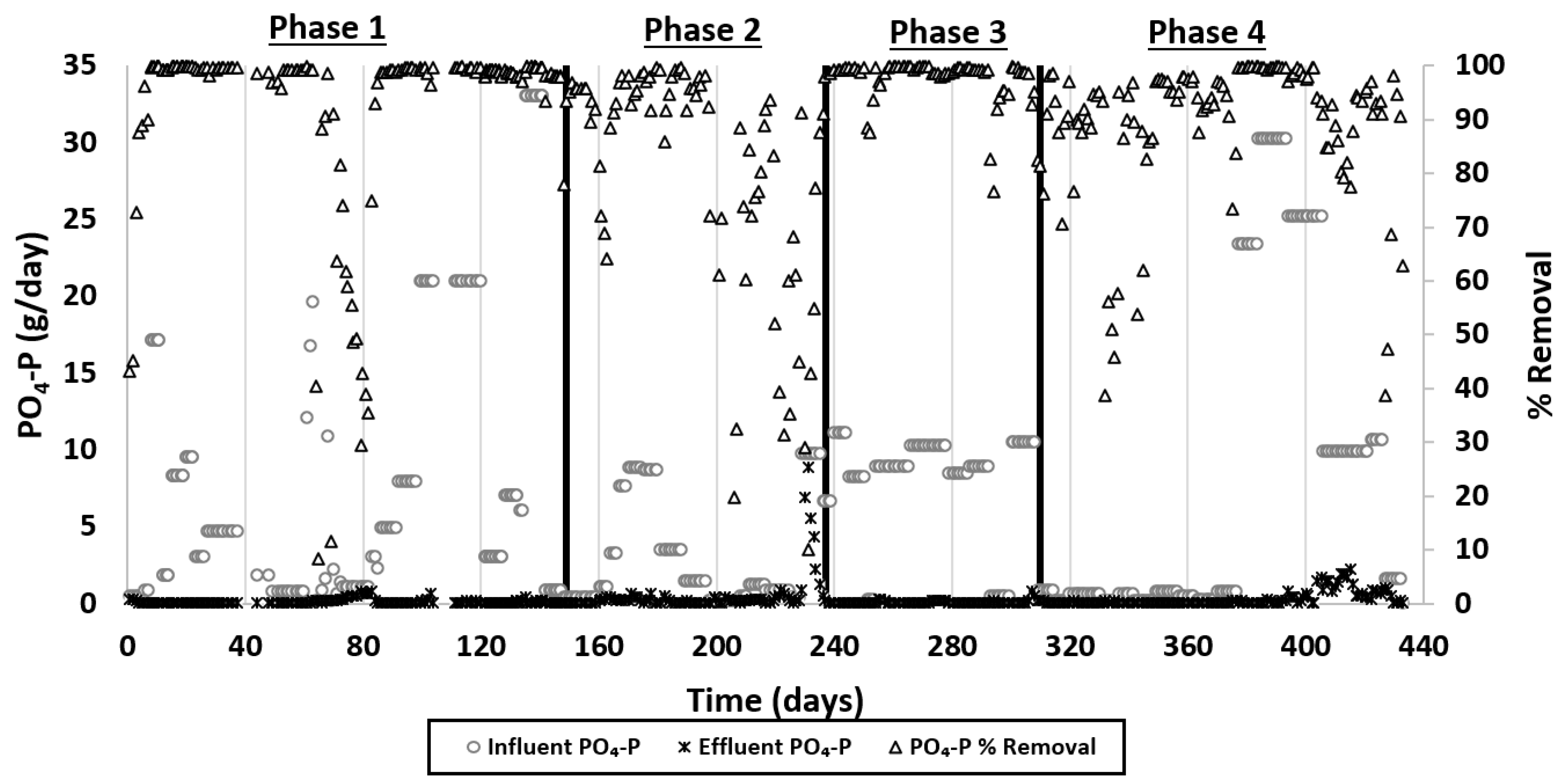

3.1. Overview of Contaminant Removal throughout the Study

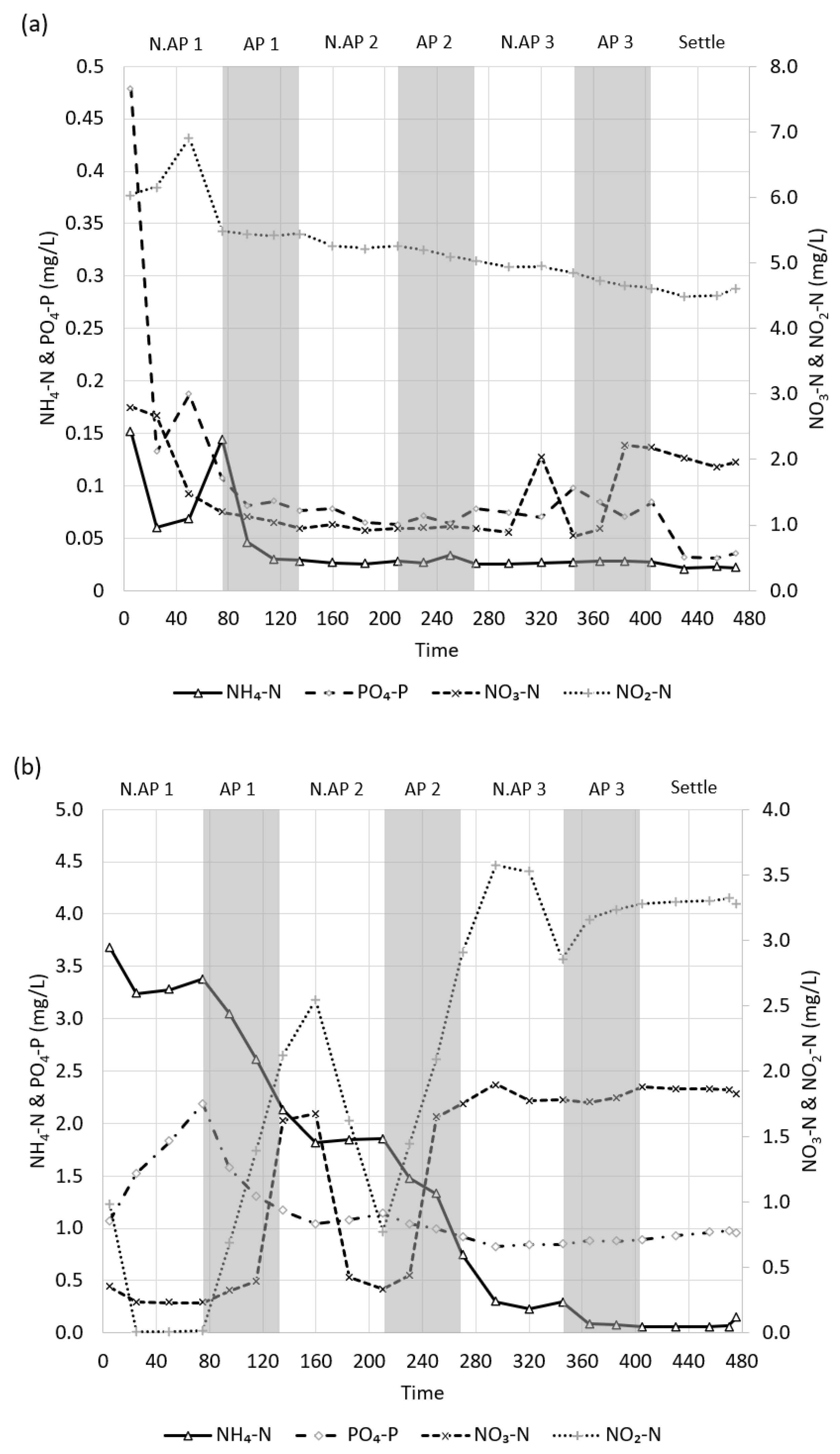

3.2. Phase Performance and High-Resolution Studies

3.2.1. Phase 1

3.2.2. Phase 2

3.2.3. Phase 3

3.2.4. Phase 4

3.2.5. Modelled Operation

3.3. Operational Savings

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Milk Statistics: Intake of Cows Milk by Creameries and Pasteurisers; Central Statics Office (CSO): Cork, Ireland, 2021; Available online: https://www.cso.ie/ (accessed on 15 July 2021).

- Yan, M.-J.; Holden, N.M. Water use efficiency of Irish dairy processing. J. Dairy Sci. 2019, 102, 9525–9535. [Google Scholar] [CrossRef]

- Slavov, A.K. Dairy Wastewaters—General Characteristics and Treatment Possibilities—A Review. Food Technol. Biotechnol. 2017, 55, 14–28. [Google Scholar] [CrossRef] [PubMed]

- Lateef, A.; Chaudhry, M.N.; Ilyas, S. Biological treatment of dairy wastewater using activated sludge. Sci. J. Sci. Soc. Thail. 2013, 39, 179–185. [Google Scholar] [CrossRef] [Green Version]

- Zhan, X.; Hu, Z.; Wu, G. Greenhouse Gas Emission and Mitigation in Municipal Wastewater Treatment Plants, 1st ed.; IWA Publishing: London, UK, 2018; p. 160. [Google Scholar] [CrossRef]

- Kushwaha, J.P.; Srivastava, V.C.; Mall, I.D. An Overview of Various Technologies for the Treatment of Dairy Wastewaters. Crit. Rev. Food Sci. Nutr. 2011, 51, 442–452. [Google Scholar] [CrossRef] [PubMed]

- Britz, T.J.; Schalkwyk, C. Treatment of Dairy Processing Wastewaters; CRC Press: Boca Raton, FL, USA, 2004; pp. 1–28. [Google Scholar] [CrossRef]

- Irish Environmental Protection Agency. Draft BAT Guidance Note on Best Available Techniques for the Slaughtering Sector; Irish Environmental Protection Agency: Wexford, Ireland, 2006.

- Irish Environmental Protection Agency. BAT Guidance Note on Best Available Techniques for the Dairy Processing Sector; Irish Environmental Protection Agency: Wexford, Ireland, 2008.

- Zhang, Y.; Li, M.; Dong, J.; Yang, H.; Van Zwieten, L.; Lu, H.; Alshameri, A.; Zhan, Z.; Chen, X.; Jiang, X.; et al. A Critical Review of Methods for Analyzing Freshwater Eutrophication. Water 2021, 13, 225. [Google Scholar] [CrossRef]

- Yang, X.-E.; Wu, X.; Hao, H.-L.; He, Z.-L. Mechanisms and assessment of water eutrophication. J. Zhejiang Univ. Sci. B 2008, 9, 197–209. [Google Scholar] [CrossRef] [PubMed]

- Yapıcıoğlu, P.; Yeşilnacar, M.I. Energy cost assessment of a dairy industry wastewater treatment plant. Environ. Monit. Assess. 2020, 192, 536. [Google Scholar] [CrossRef]

- Ashekuzzaman, S.M.; Forrestal, P.; Richards, K.; Fenton, O. Dairy industry derived wastewater treatment sludge: Generation, type and characterization of nutrients and metals for agricultural reuse. J. Clean. Prod. 2019, 230, 1266–1275. [Google Scholar] [CrossRef]

- Ahn, C.H.; Park, J.K. Critical factors affecting biological phosphorus removal in dairy wastewater treatment plants. KSCE J. Civ. Eng. 2008, 12, 99–107. [Google Scholar] [CrossRef]

- Li, J.; Healy, M.G.; Zhan, X.; Norton, D.; Rodgers, M. Effect of Aeration Rate on Nutrient Removal from Slaughterhouse Wastewater in Intermittently Aerated Sequencing Batch Reactors. Water Air Soil Pollut. 2008, 192, 251–261. [Google Scholar] [CrossRef]

- Mohamed, A.Y.A.; Welles, L.; Siggins, A.; Healy, M.G.; Brdjanovic, D.; Rada-Ariza, A.M.; Lopez-Vazquez, C.M. Effects of substrate stress and light intensity on enhanced biological phosphorus removal in a photo-activated sludge system. Water Res. 2021, 189, 116606. [Google Scholar] [CrossRef]

- Leonard, P.; Tarpey, E.; Finnegan, W.; Zhan, X. Efficient treatment of dairy processing wastewater in a laboratory scale Intermittently Aerated Sequencing Batch Reactor (IASBR). J. Dairy Res. 2018, 85, 379–383. [Google Scholar] [CrossRef] [PubMed]

- Tchobanoglous, G.; Burton, F.L.; Stensel, H.D. Wastewater Engineering: Treatment and Reuse, 4th ed.; Metcalf & Eddy: New York, NY, USA, 2003. [Google Scholar]

- Song, X.; Liu, R.; Chen, L.; Dong, B.; Kawagishi, T. Advantages of intermittently aerated SBR over conventional SBR on nitrogen removal for the treatment of digested piggery wastewater. Front. Environ. Sci. Eng. 2017, 11, 13. [Google Scholar] [CrossRef]

- Pan, M.; Chen, T.; Hu, Z.; Zhan, X. Assessment of nitrogen and phosphorus removal in an intermittently aerated sequencing batch reactor (IASBR) and a sequencing batch reactor (SBR). Water Sci. Technol. 2013, 68, 400–405. [Google Scholar] [CrossRef]

- Aslan, S.; Miller, L.; Dahab, M. Ammonium oxidation via nitrite accumulation under limited oxygen concentration in sequencing batch reactors. Bioresour. Technol. 2009, 100, 659–664. [Google Scholar] [CrossRef]

- Yan, L.; Liu, S.; Liu, Q.; Zhang, M.; Liu, Y.; Wen, Y.; Chen, Z.; Zhang, Y.; Yang, Q. Improved performance of simultaneous nitrification and denitrification via nitrite in an oxygen-limited SBR by alternating the DO. Bioresour. Technol. 2019, 275, 153–162. [Google Scholar] [CrossRef]

- Peng, Y.; Zhu, G. Biological nitrogen removal with nitrification and denitrification via nitrite pathway. Appl. Microbiol. Biotechnol. 2006, 73, 15–26. [Google Scholar] [CrossRef]

- Simon-Várhelyi, M.; Tomoiagă, C.; Brehar, M.A.; Cristea, V.M. Dairy wastewater processing and automatic control for waste recovery at the municipal wastewater treatment plant based on modelling investigations. J. Environ. Manag. 2021, 287, 112316. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.; Zhang, T.; Wang, B.; Xu, Z.; Zhang, L.; Peng, Y. Advanced nitrogen removal of low C/N ratio sewage in an anaerobic/aerobic/anoxic process through enhanced post-endogenous denitrification. Chemosphere 2020, 252, 126624. [Google Scholar] [CrossRef]

- Garcia-Ochoa, F.; Gomez, E. Bioreactor scale-up and oxygen transfer rate in microbial processes: An overview. Biotechnol. Adv. 2009, 27, 153–176. [Google Scholar] [CrossRef] [PubMed]

- United States Environmental Protection Agency. Biological Nutrient Removal Processes and Costs; U.S. EPA: Washington, DC, USA, 2007.

- Khalaf, A.H.; Ibrahim, W.A.; Fayed, M.; Eloffy, M.G. Comparison between the performance of activated sludge and sequence batch reactor systems for dairy wastewater treatment under different operating conditions. Alex. Eng. J. 2021, 60, 1433–1445. [Google Scholar] [CrossRef]

- Ahmad, T.; Aadil, R.M.; Ahmed, H.; ur Rahman, U.; Soares, B.C.V.; Souza, S.L.Q.; Pimentel, T.C.; Scudino, H.; Guimarães, J.T.; Esmerino, E.A.; et al. Treatment and utilization of dairy industrial waste: A review. Trends Food Sci. Technol. 2019, 88, 361–372. [Google Scholar] [CrossRef]

- Sinha, S.; Srivastava, A.; Mehrotra, T.; Singh, R.; Jindal, T. A Review on the Dairy Industry Waste Water Characteristics, Its Impact on Environment and Treatment Possibilities. In Emerging Issues in Ecology and Environmental Science, 1st ed.; Springer: Cham, Germany, 2019; pp. 73–84. [Google Scholar] [CrossRef]

- Zhao, K.; Wu, Y.W.; Young, S.; Chen, X.J. Biological Treatment of Dairy Wastewater: A Mini Review. J. Environ. Inform. Lett. 2020, 4, 22–31. [Google Scholar] [CrossRef]

- Goli, A.; Shamiri, A.; Khosroyar, S.; Talaiekhozani, A.; Sanaye, R.; Azizi, K. A Review on Different Aerobic and Anaerobic Treatment Methods in Dairy Industry Wastewater. J. Environ. Treat. Tech. 2019, 7, 113–141. [Google Scholar]

- Federation, W.E.; American Public Health Association. Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 2012; Volume 22. [Google Scholar]

- Janczukowicz, W.; Zieliński, M.; Dębowski, M. Biodegradability evaluation of dairy effluents originated in selected sections of dairy production. Bioresour. Technol. 2008, 99, 4199–4205. [Google Scholar] [CrossRef]

- Pan, M.; Henry, L.G.; Liu, R.; Huang, X. Nitrogen removal from slaughterhouse wastewater through partial nitrification followed by denitrification in intermittently aerated sequencing batch reactors at 11 °C. Environ. Technol. 2014, 35, 470–477. [Google Scholar] [CrossRef]

- Dan, N.H.; Rene, E.R.; Le Luu, T. Removal of Nutrients from Anaerobically Digested Swine Wastewater Using an Intermittent Cycle Extended Aeration System. Front. Microbiol. 2020, 11, 576438. [Google Scholar] [CrossRef] [PubMed]

- Bickers, P.O.; Bhamidimarri, R.; Shepherd, J.; Russell, J. Biological phosphorus removal from a phosphorus-rich dairy processing wastewater. Water Sci. Technol. 2003, 48, 43–51. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Yao, B.; Cong, S.; Ma, T.; Zou, D. Optimization of Wastewater Phosphorus Removal in Winter Temperatures Using an Anaerobic–Critical Aerobic Strategy in a Pilot-Scale Sequencing Batch Reactor. Water 2019, 12, 110. [Google Scholar] [CrossRef] [Green Version]

- Energy in Ireland, 2019 Report; Sustainable Energy Authority of Ireland (SEAI): Dublin, Ireland, 2019.

- Clifford, E.; Nielsen, M.; Sørensen, K.; Rodgers, M. Nitrogen dynamics and removal in a horizontal flow biofilm reactor for wastewater treatment. Water Res. 2010, 44, 3819–3828. [Google Scholar] [CrossRef] [PubMed]

- Sedlack, R. Phosphorus and Nitrogen Removal from Municipal Wastewater Principles and Practice, 2nd ed.; CRC Press: Boca Raton, FL, USA, 1991. [Google Scholar]

| Energy User | Rated Power (kW) |

|---|---|

| Mixer (Novair 200) | 0.28 |

| Blower (EL-S-300W) | 0.32 |

| Fill Pump (Domo 7vx) | 0.79 |

| Discharge Pump (Doc 3) | 0.31 |

| Sludge Pump (Doc 3) | 0.31 |

| Phase 1 (min) | Phase 2 (min) | Phase 3 (min) | Phase 4 (min) | Optimised Phase 4 Model (min) | |

|---|---|---|---|---|---|

| Fill | 5 | 7.5 | 7.5 | 7.5 | 7.5 |

| Mixer On | 1280 | 1215 | 1215 | 1215 | 675 |

| Blower On | 480 | 405 | 540 | 270 | 180 |

| Sludge Removal | 6 | 6 | 6 | 6 | 6 |

| Discharge | 5 | 7.5 | 7.5 | 7.5 | 7.5 |

| Contaminant (mg/L) | NH4-N | NO3-N | PO4-P | TSS |

|---|---|---|---|---|

| Phase 1 (750 L/day) | ||||

| Influent | 19.68 (11.91) | 1.03 (1.99) | 11.26 (12.68) | 676.46 (239.13) |

| Effluent | 0.64 (1.25) | 1.34 (3.08) | 0.14 (0.21) | 14.40 (14.62) |

| % Reduction a | 96.0 | - | 93.0 | 97.7 |

| Phase 2 (1125 L/day) | ||||

| Influent | 13.72 (7.86) | 3.42 (7.64) | 2.78 (3.08) | 558.17 (180.96) |

| Effluent | 4.50 (4.51) | 0.46 (0.62) | 0.46 (1.21) | 16.71 (16.18) |

| % Reduction | 75.2 | - | 81.7 | 96.7 |

| Phase 3 (1125 L/day) | ||||

| Influent | 1.88 (1.17) | 4.91 (8.04) | 7.09 (3.06) | 417.27 (152.74) |

| Effluent | 0.07 (0.16) | 0.63 (1.52) | 0.08 (0.10) | 11.47 (14.33) |

| % Reduction | 95.7 | - | 97.3 | 96.8 |

| Phase 4 (1125 L/day) | ||||

| Influent | 16.48 (18.70) | 4.20 (9.61) | 7.41 (9.58) | 792.14 (575.01) |

| Effluent | 3.05 (5.64) | 1.09 (1.97) | 0.27 (0.43) | 5.23 (4.64) |

| % Reduction | 86.4 | - | 89.57 | 98.8 |

| Overall Operation | ||||

| Influent | 14.76 (14.02) | 2.99 (7.14) | 7.86 (9.85) | 641.49 (370.33) |

| Effluent | 1.97 (4.01) | 0.98 (2.26) | 0.23 (0.61) | 11.90 (13.74) |

| % Reduction | 89.5 | - | 90.62 | 97.6 |

| Study | Wastewater Type | Scale | m3 Treated/Day/m3 Reactor | HRT (Days) | NH4-N Removal * |

|---|---|---|---|---|---|

| Leonard et al., 2018. [17] | Real Dairy | Laboratory | 0.25 | 4.0 | 92.3% |

| Li et al., 2008. [15] | Real Slaughterhouse | Laboratory | 0.30 | 3.3 | 94% (TN) |

| Pan et al., 2014 (Phase 1). [35] | Real Slaughterhouse | Laboratory | 0.15 | 6.7 | 44.2% |

| Pan et al., 2014 (Phase 2). [35] | Real Slaughterhouse | Laboratory | 0.10 | 10.0 | 97.6% |

| This study Phase 1. | Real Dairy | Pilot | 0.25 | 4.0 | 96.0% |

| This study: Phases 2–4. | Real Dairy | Pilot | 0.38 | 2.7 | 85.8% |

| Phase Study | Sample | NH4-N (mg/L) | NO3-N (mg/L) | NO2-N (mg/L) | PO4-P (mg/L) | Reactor Temperature a (°C) | Reactor pH a |

|---|---|---|---|---|---|---|---|

| 1 | Influent | 4.86 | 3.42 | 7.14 | 4.16 | 21.7 (0.4) | 8.7 (0.1) |

| Effluent | 0.06 | 0.58 | 0.01 | 0.05 | |||

| 2 | Influent | 17.04 | 0.01 | 0.07 | 0.84 | 13.8 (0.2) | 8.4 (0.1) |

| Effluent | 15.02 | 0.04 | 0.06 | 0.05 | |||

| 3 | Influent | 2.03 | 6.09 | 3.01 | 9.41 | 8.2 (0.1) | 8.4 (0.2) |

| Effluent | 0.02 | 1.96 | 4.61 | 0.04 | |||

| 4 | Influent | 13.03 | 0.36 | 0.53 | 1.44 | 20.9 (0.3) | 8.3 (0.1) |

| Effluent | 0.15 | 1.83 | 3.28 | 0.96 |

| Operation | kWh/Day | kWh/m3 Treated | Specific Energy Reduction (from P1) | Kg CO2 */Day | Kg CO2 */m3 Treated |

|---|---|---|---|---|---|

| P1 | 8.79 | 11.72 | Baseline | 3.30 | 4.40 |

| P2 | 8.41 | 7.48 | 36.19% | 3.15 | 2.80 |

| P3 | 8.88 | 7.89 | 32.69% | 3.33 | 2.96 |

| P4 | 7.52 | 6.68 | 42.97% | 2.82 | 2.51 |

| Energy optimised P4 (Modelled; +/−5.2% **) | 4.28 | 3.80 | 67.55% | 1.60 | 1.43 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leonard, P.; Clifford, E.; Finnegan, W.; Siggins, A.; Zhan, X. Deployment and Optimisation of a Pilot-Scale IASBR System for Treatment of Dairy Processing Wastewater. Energies 2021, 14, 7365. https://doi.org/10.3390/en14217365

Leonard P, Clifford E, Finnegan W, Siggins A, Zhan X. Deployment and Optimisation of a Pilot-Scale IASBR System for Treatment of Dairy Processing Wastewater. Energies. 2021; 14(21):7365. https://doi.org/10.3390/en14217365

Chicago/Turabian StyleLeonard, Peter, Eoghan Clifford, William Finnegan, Alma Siggins, and Xinmin Zhan. 2021. "Deployment and Optimisation of a Pilot-Scale IASBR System for Treatment of Dairy Processing Wastewater" Energies 14, no. 21: 7365. https://doi.org/10.3390/en14217365

APA StyleLeonard, P., Clifford, E., Finnegan, W., Siggins, A., & Zhan, X. (2021). Deployment and Optimisation of a Pilot-Scale IASBR System for Treatment of Dairy Processing Wastewater. Energies, 14(21), 7365. https://doi.org/10.3390/en14217365