Fault Detection in PV Tracking Systems Using an Image Processing Algorithm Based on PCA

Abstract

:1. Introduction

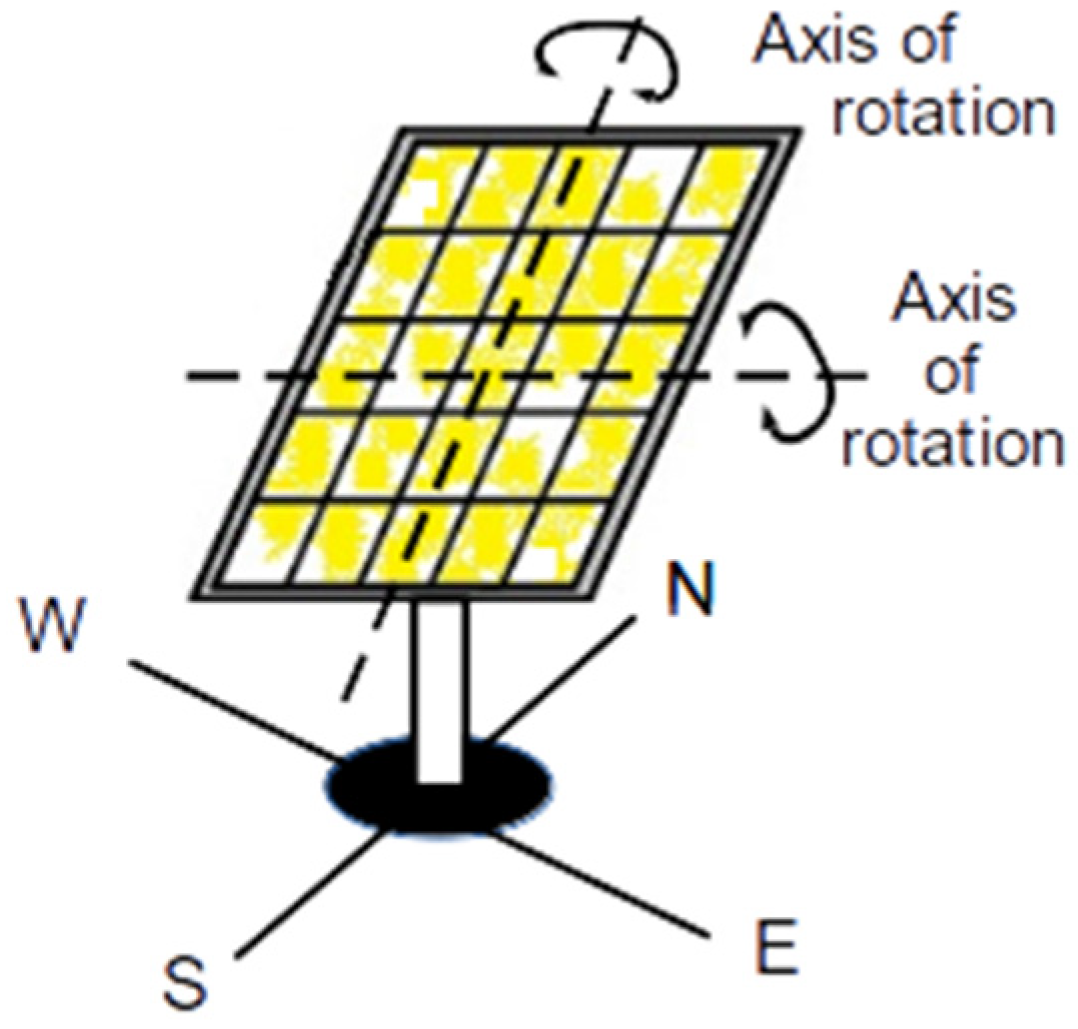

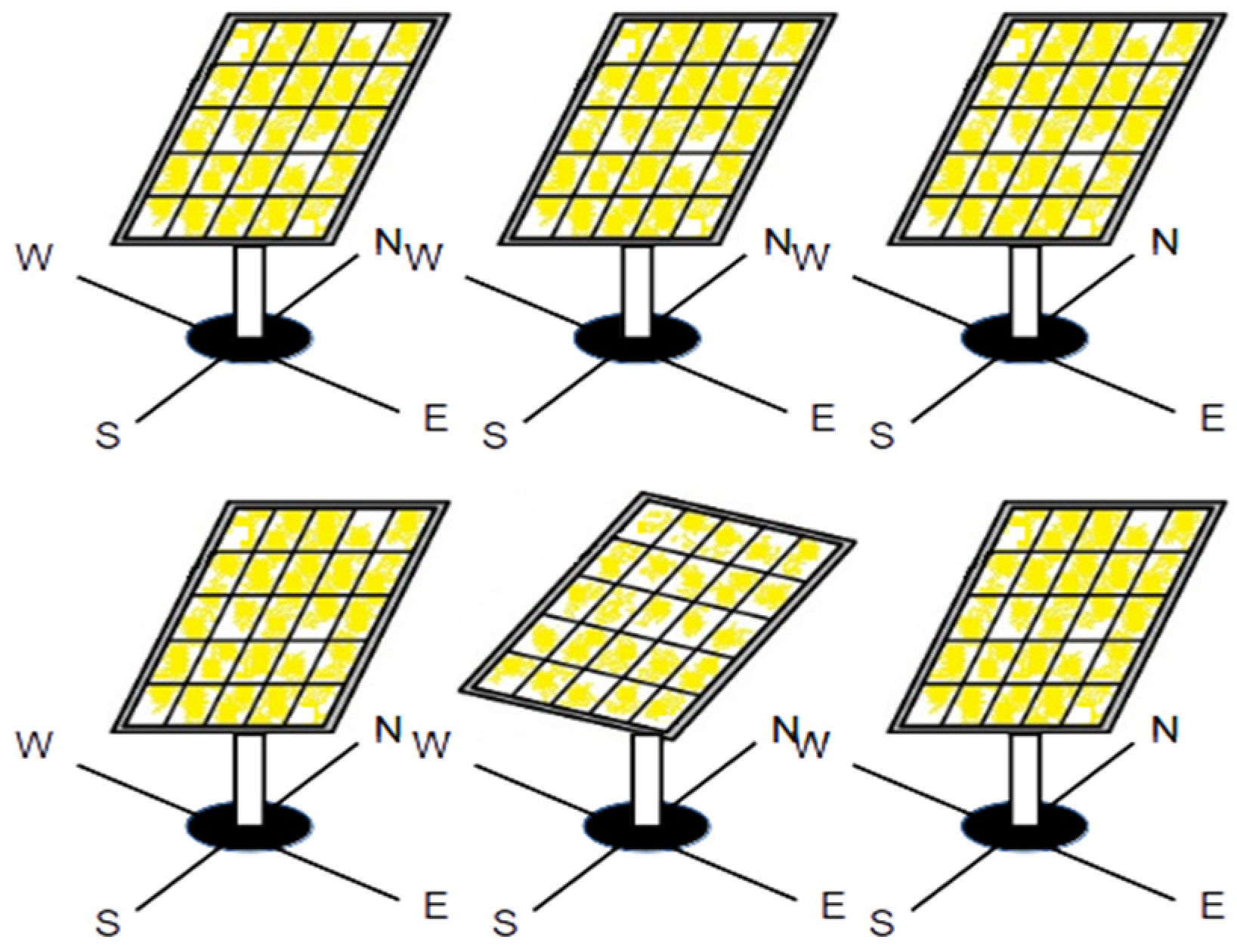

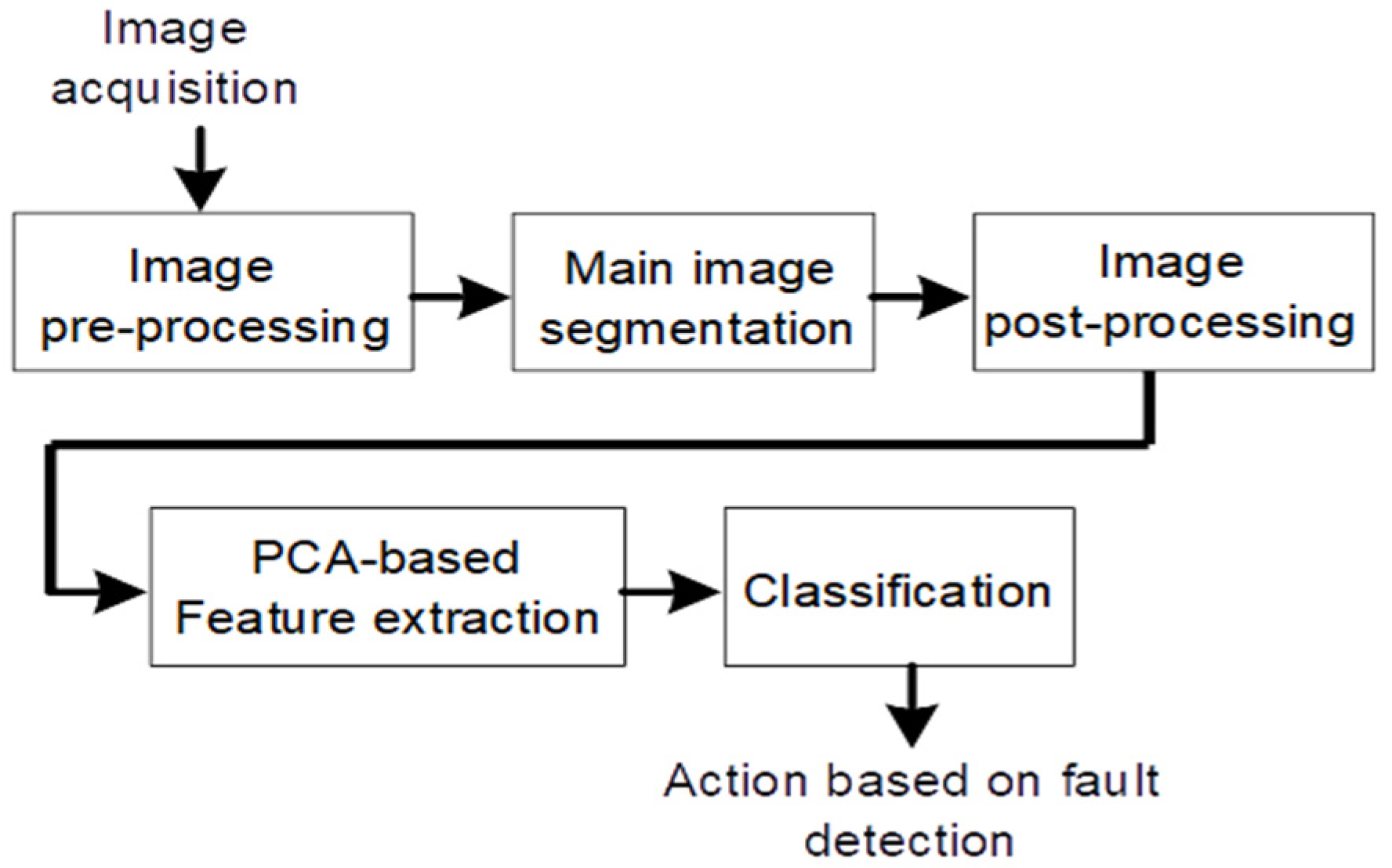

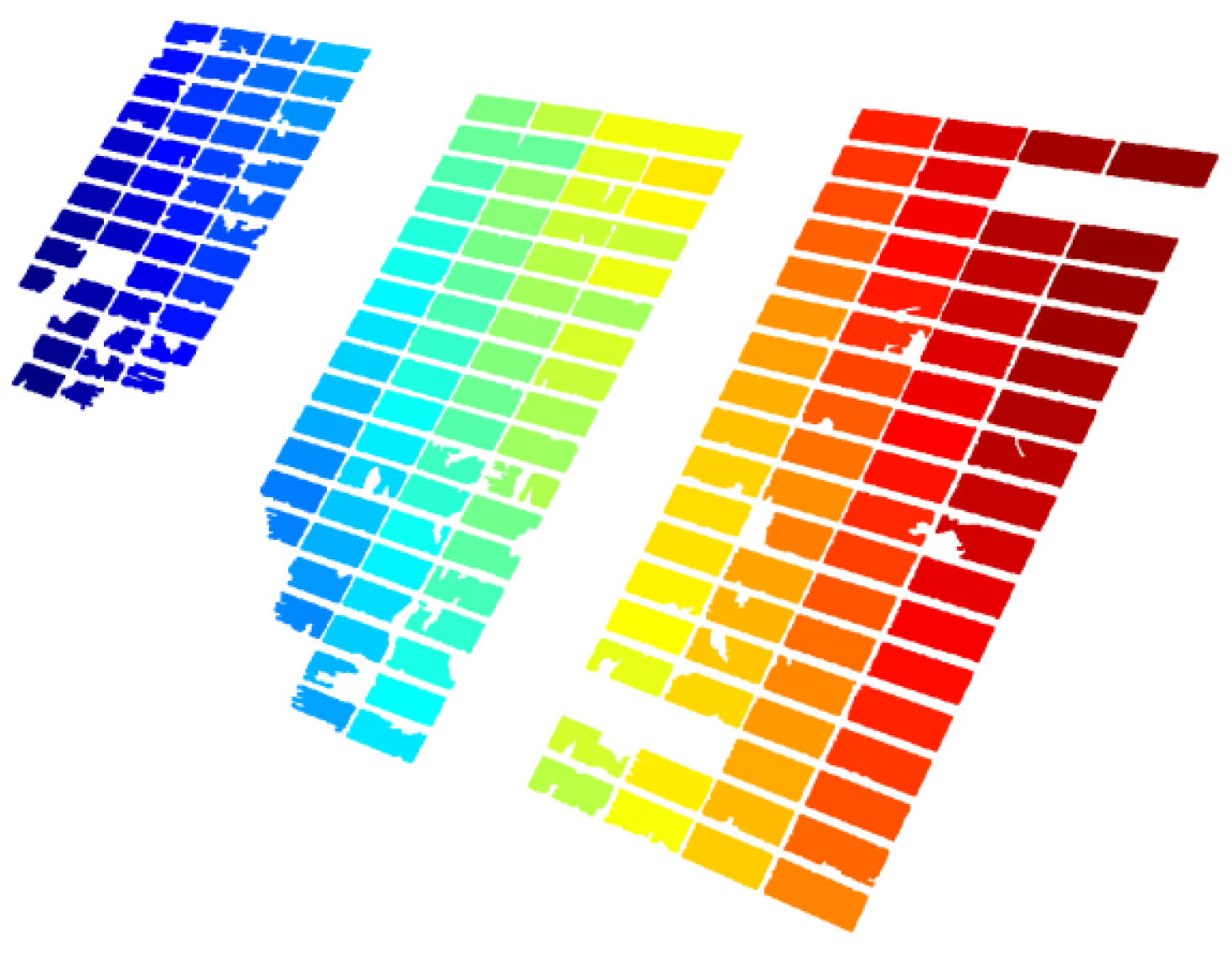

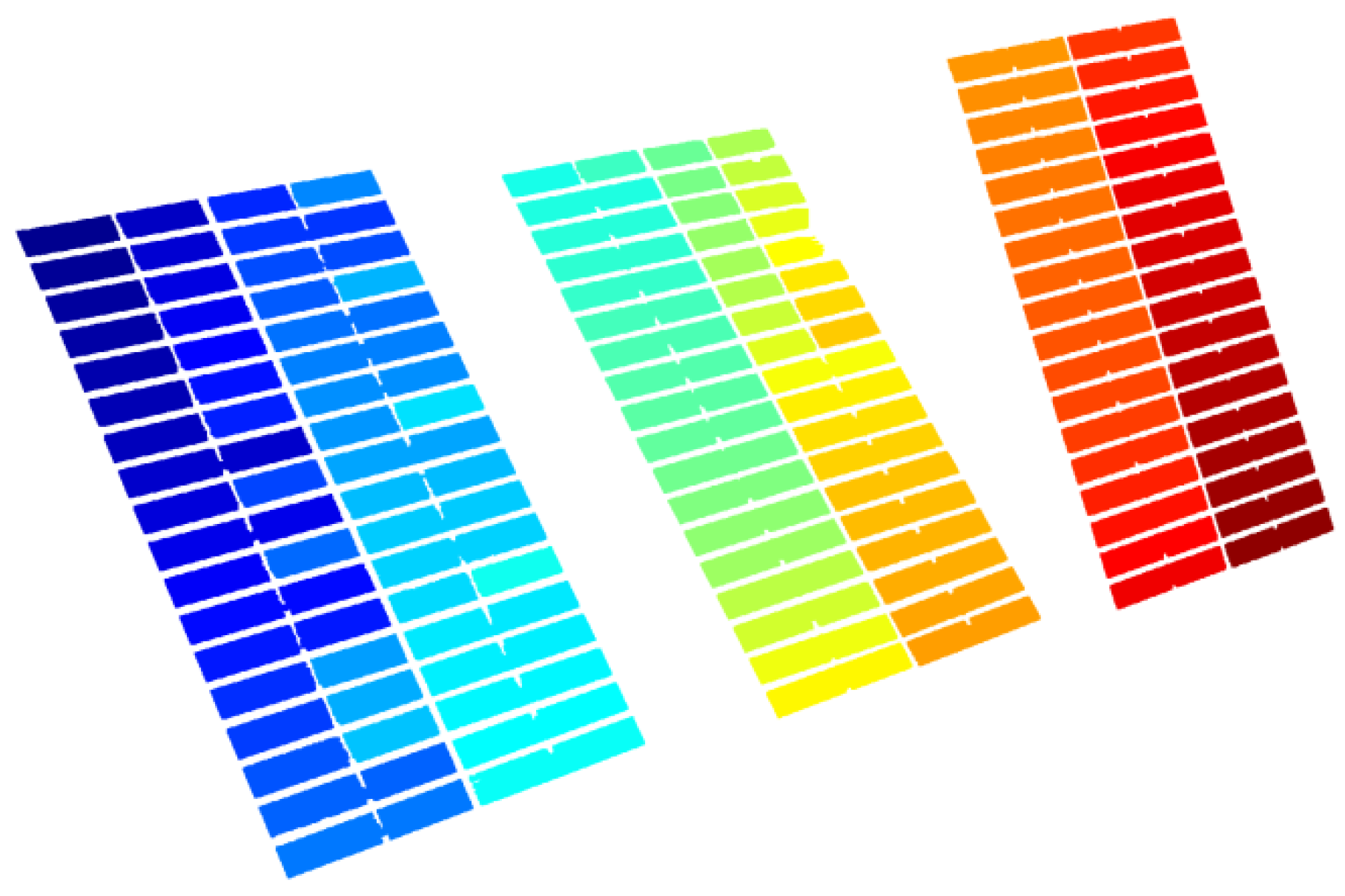

2. Proposed Image Processing Algorithm for Fault Detection of Tracking Systems

2.1. Proposed Strategy

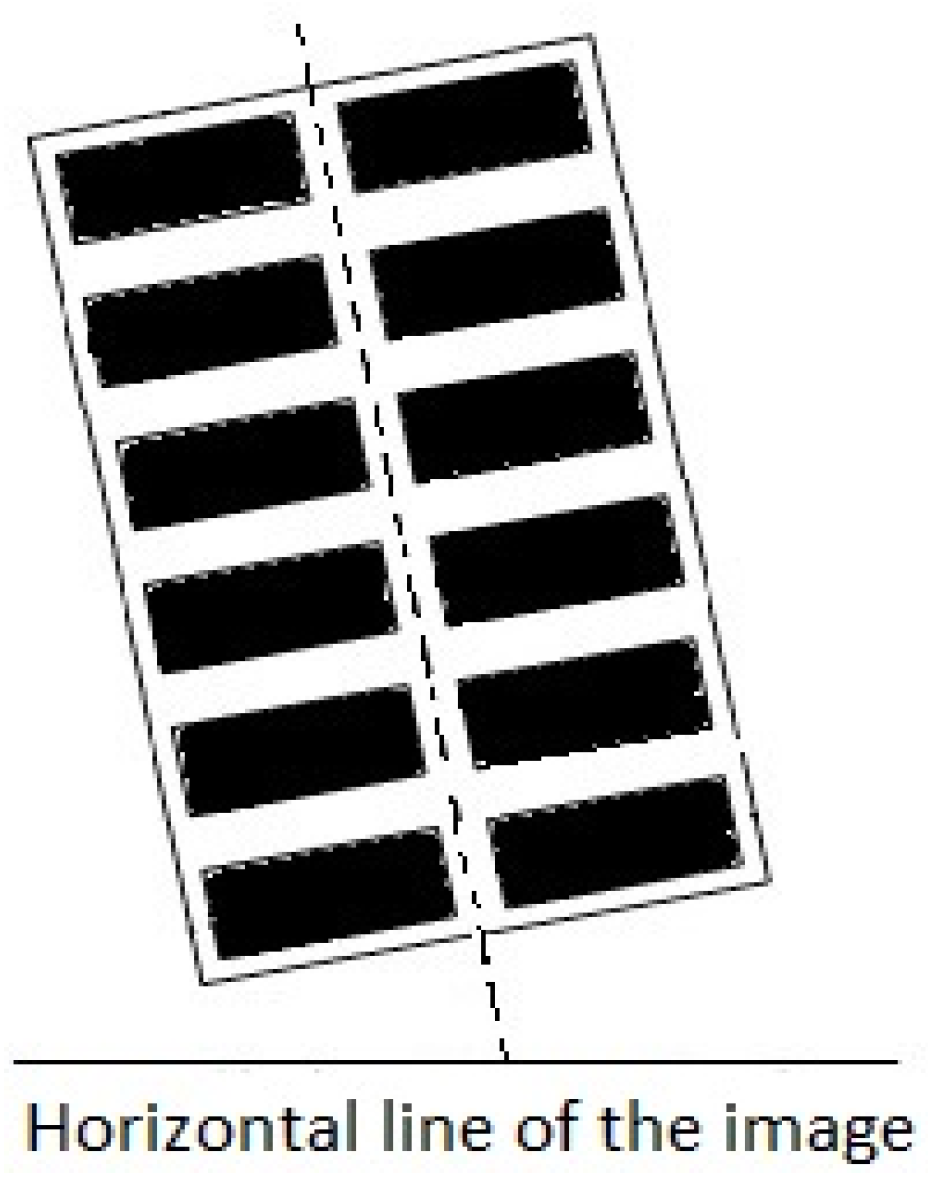

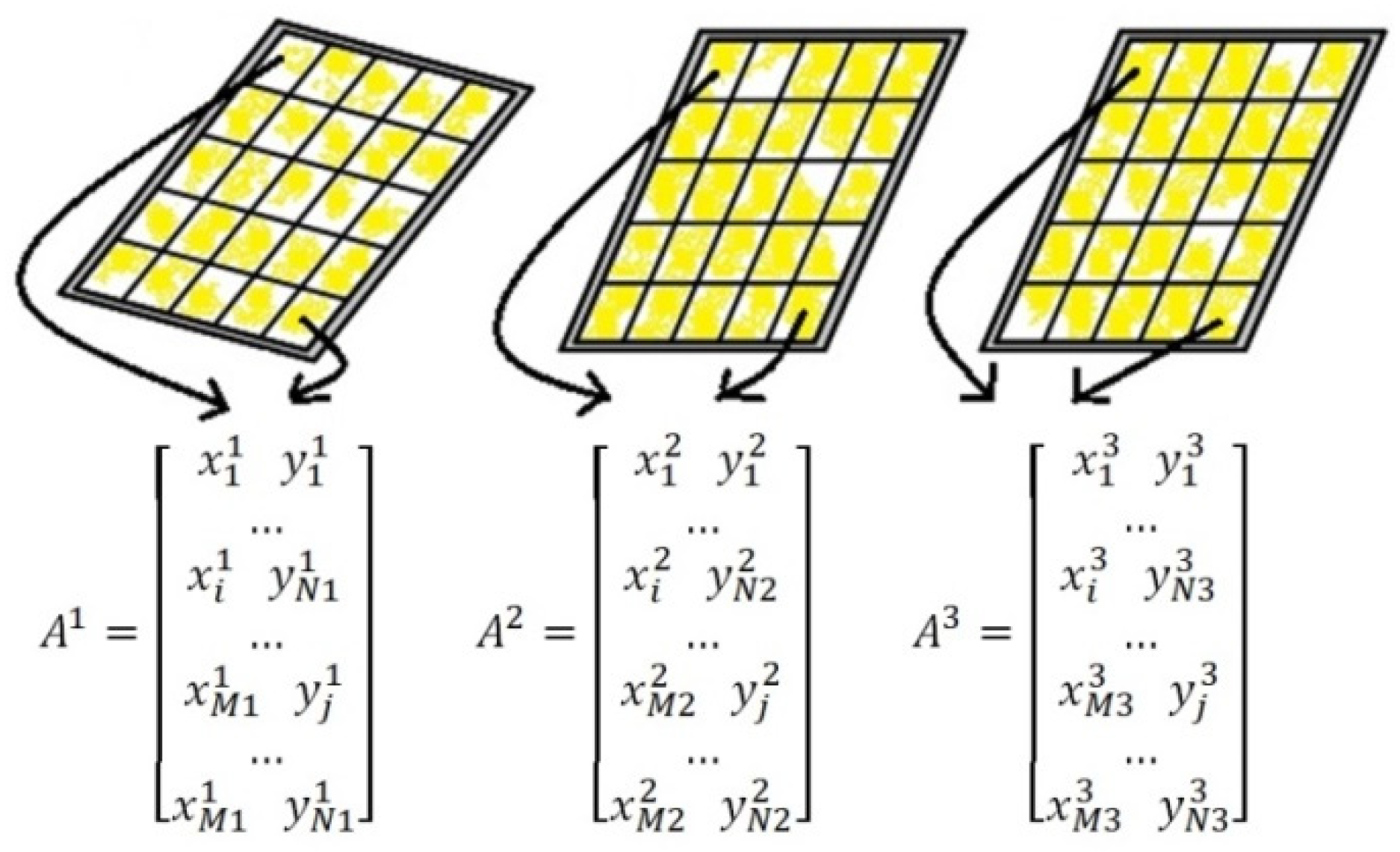

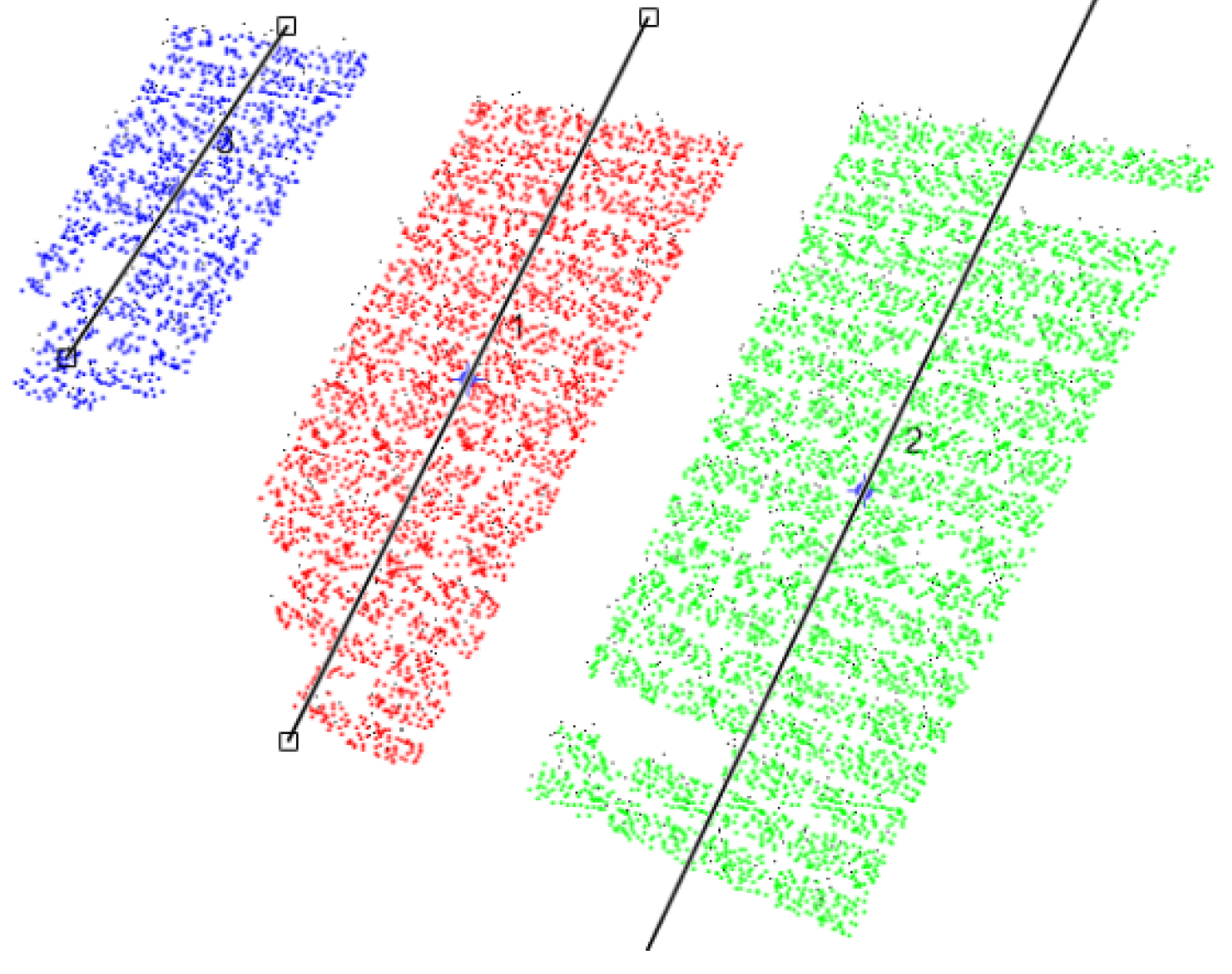

2.2. Image Processing Approach Using PCA

- Step 1: Determine the average value of the orientation using (10);

- Step 2: For each panel under analysis determine the corresponding orientation and deviation index using (9) and (11), respectively;

- Step 3: Compare the deviation index (DI) of each panel with the predefined threshold value, Th:

- Step 3 (a)—If DIi ≤ Th, then the ith panel are in healthy condition;

- Step 3 (b)—If DIi > Th, then the ith panel is considered with a fault in their tracker—the ith panel is removed from analysis and return to Step 1.

3. Results

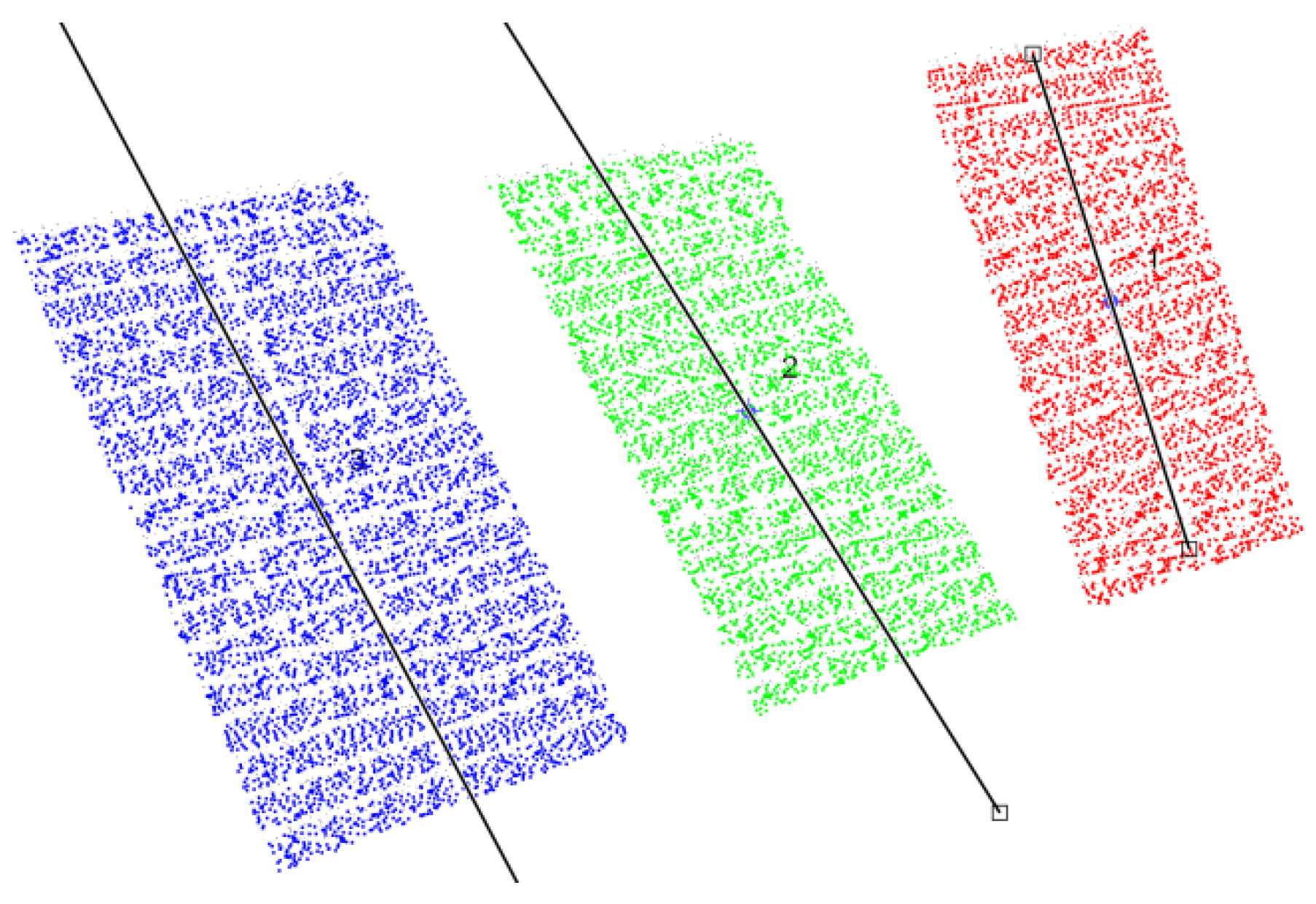

3.1. Trackers of the PV Panels with No Fault

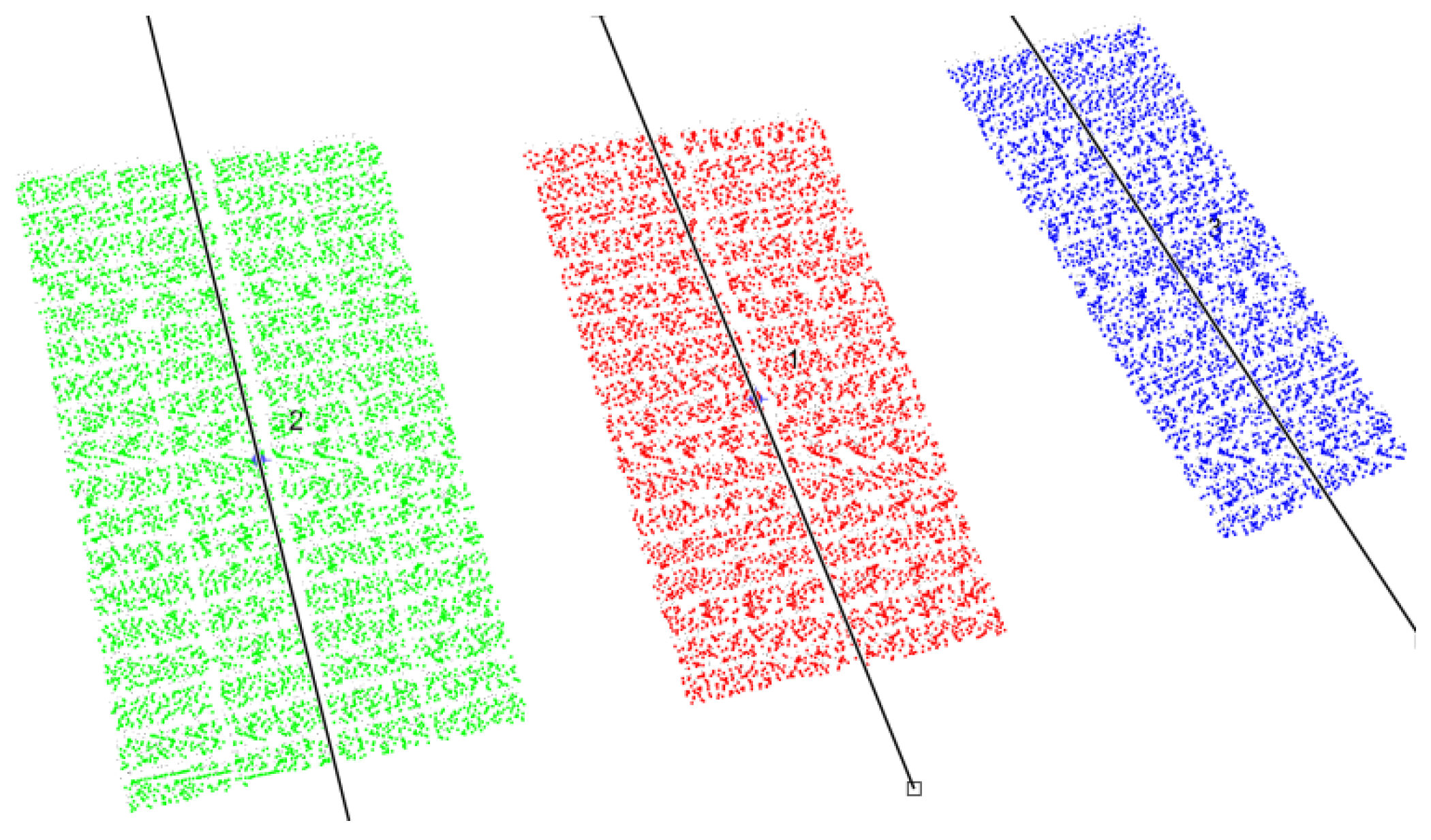

3.2. One of the Trackers with a Vertical Fault

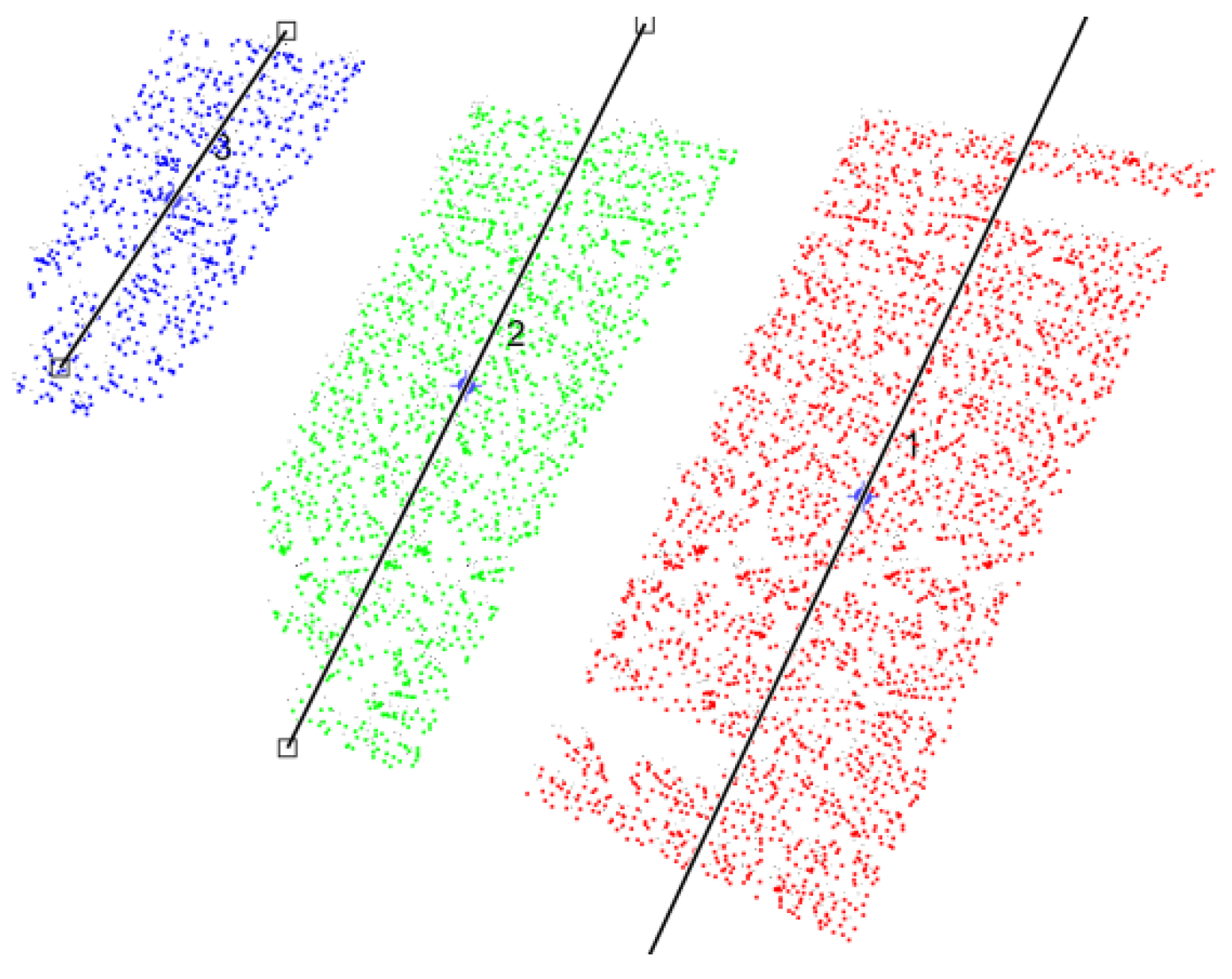

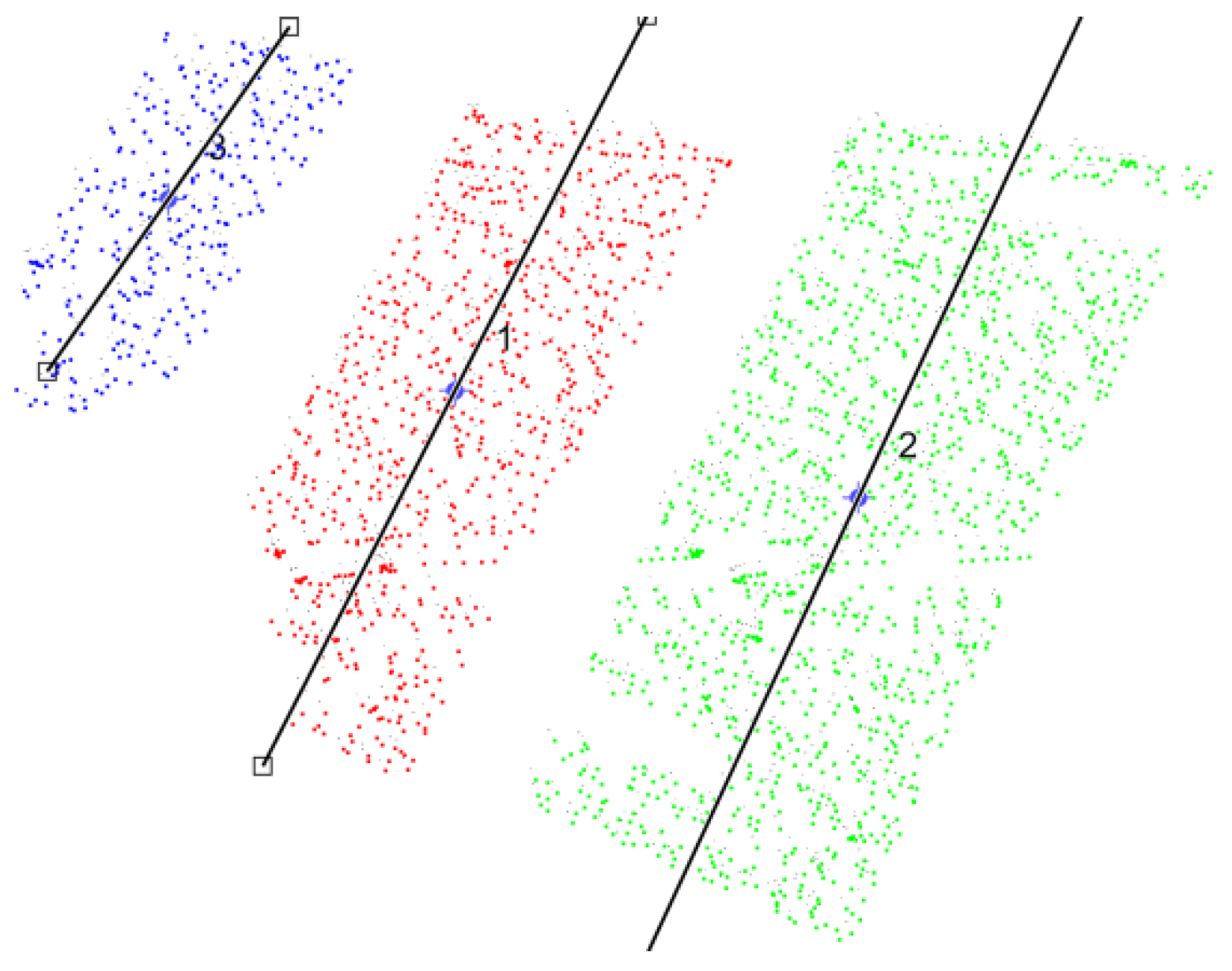

3.3. One of the Trackers with a Horizontal Fault

3.4. Comparison

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| Ai | Matrix i |

| Average matrix across each dimension | |

| Matrix i with mean zero | |

| a-Si | Amorphous silicon |

| Ci | Cluster i |

| Symmetric covariance matrix | |

| Minimum distance between pixels | |

| DI | Deviation index |

| Distance between two pixels | |

| Eigenvalues of matrix i | |

| m-Si | Monocrystalline |

| Mi | Number of rows of matrix Ai |

| MPPT | Maximum power point tracking |

| Number of pixels that belongs to cluster i | |

| PCA | Principal component analysis |

| Pixel j belonging to cluster i | |

| p-Si | Polycrystalline |

| PV | Photovoltaic systems |

| RGB | Red/green/blue |

| Threshold distance level | |

| Eigenvectors of matrix i | |

| Highest eigenvalue | |

| Eigenvalue i | |

| Eigenvector values associated with eigenvalue i | |

| X-Y coordinates of pixel j belonging to cluster i | |

| PV module | |

| Mean angle of the PV modules |

References

- Soytaş, U.; Sarı, M. Handbook of Energy Economics; Taylor and Francis Group: Abingdon, UK, 2019; 620p. [Google Scholar]

- Zhu, R.; Guo, W.; Gong, X. Short-Term Photovoltaic Power Output Prediction Based on k-Fold Cross-Validation and an Ensemble Model. Energies 2019, 12, 1220. [Google Scholar] [CrossRef] [Green Version]

- Venkateswari, R.; Sreejith, S. Factors influencing the efficiency of photovoltaic system. Renew. Sustain. Energy Rev. 2019, 101, 376–394. [Google Scholar] [CrossRef]

- Kishor, N.; Villalva, M.G.; Mohanty, S.R.; Ruppert, E. Modeling of PV module with consideration of environmental factors. In Proceedings of the IEEE PES Innovative Smart Grid Technologies Conference Europe, Gothenburg, Sweden, 11–13 October 2010; pp. 1–5. [Google Scholar]

- Zhang, W.; Dang, H.; Simoes, R. A new solar power output prediction based on hybrid forecast engine and decomposition model. ISA Trans. 2018, 81, 313–326. [Google Scholar] [CrossRef] [PubMed]

- Hafez, A.Z.; Soliman, A.; El-Metwally, K.A.; Ismail, I.M. Tilt and azimuth angles in solar energy applications—A review. Renew. Sustain. Energy Rev. 2017, 77, 147–168. [Google Scholar] [CrossRef]

- Lee, C.-Y.; Chou, P.-C.; Chiang, C.-M.; Lin, C.-F. Sun tracking systems: A review. Sensors 2009, 9, 3875–3890. [Google Scholar] [CrossRef] [PubMed]

- Mousazadeh, H.; Keyhani, A.; Javadi, A.; Mobli, H.; Abrinia, K.; Sharif, A. A review of principle and sun-tracking methods for maximizing solar systems output. Renew. Sustain. Energy Rev. 2019, 13, 1800–1818. [Google Scholar] [CrossRef]

- Zhu, Y.; Liu, J.; Yang, X. Design and performance analysis of a solar tracking system with a novel single-axis tracking structure to maximize energy collection. Appl. Energy 2019, 264, 114647. [Google Scholar] [CrossRef]

- Hafez, A.Z.; Yousef, A.M.; Harag, N.M. Solar tracking systems: Technologies and trackers drive types—A review. Renew. Sustain. Energy Rev. 2018, 91, 754–782. [Google Scholar] [CrossRef]

- Zsiborács, H.; Baranyai, N.H.; Vincze, A.; Háber, I.; Weihs, P.; Oswald, S.; Gützer, C.; Pintér, G. Changes of Photovoltaic Performance as a Function of Positioning Relative to the Focus Points of a Concentrator PV Module: Case Study. Appl. Sci. 2019, 9, 3392. [Google Scholar] [CrossRef] [Green Version]

- Zsiborács, H.; Baranyai, N.H.; Vincze, A.; Weihs, P.; Schreier, S.F.; Gützer, C.; Revesz, M.; Pintér, G. The Impacts of Tracking System Inaccuracy on CPV Module Power. Processes 2020, 8, 1278. [Google Scholar] [CrossRef]

- Fathabadi, H. Comparative study between two novel sensorless and sensor based dual-axis solar trackers. Sol. Energy 2016, 138, 67–76. [Google Scholar] [CrossRef]

- Sidek, M.H.M.; Azis, N.; Hasan, W.Z.W.; Ab Kadir, M.Z.A.; Shafie, S.; Radzi, M.A.M. Automated positioning dual-axis solar tracking system with precision elevation and azimuth angle control. Energy 2017, 124, 160–177. [Google Scholar] [CrossRef]

- Iftikhar, H.; Sarquis, E.; Branco, P.J.C. Why Can Simple Operation and Maintenance (O&M) Practices in Large-Scale Grid-Connected PV Power Plants Play a Key Role in Improving Its Energy Output? Energies 2021, 14, 3798. [Google Scholar]

- Dienst, S.; Schmidt, J.; Kuhne, S. Case Study: Condition Assessment of a Photovoltaic Power Plant using Change-Point Analysis. In Proceedings of the International Conference on Smart Grids and Green IT Systems (SMARTGREENS), Aachen, Germany, 9–10 May 2013; Volume 1, pp. 1–6. [Google Scholar]

- Camargo, A.; Smith, J.S. Image pattern classification for the identification of disease causing agents in plants. Comput. Electron. Agric. 2009, 66, 121–125. [Google Scholar] [CrossRef]

- Malayil, M.; Vedhanayagam, M. A novel image scaling based reversible watermarking scheme for secure medical image transmission. ISA Trans. 2021, 108, 269–281. [Google Scholar] [CrossRef] [PubMed]

- Hofer, M.; Marana, A. Dental Biometrics: Human Identification. In Proceedings of the Dental Work Information XX Brazilian Symposium on Computer Graphics and Image Processing, Minas Gerais, Brazil, 7–10 October 2007; pp. 281–286. [Google Scholar]

- Karimi, M.; Asemani, D. Surface defect detection in tiling Industries using digital image processing methods: Analysis and evaluation. ISA Trans. 2014, 53, 834–844. [Google Scholar] [CrossRef]

- Asokan, A.; Anitha, J. Adaptive Cuckoo Search based optimal bilateral filtering for denoising of satellite images. ISA Trans. 2020, 100, 308–321. [Google Scholar] [CrossRef] [PubMed]

- Martins, J.F.; Pires, V.F.; Amaral, T. Induction motor fault detection and diagnosis using a current state space pattern recognition. Pattern Recognit. Lett. 2011, 32, 321–328. [Google Scholar] [CrossRef]

- Deabes, W.; Abdelrahman, M. A nonlinear fuzzy assisted image reconstruction algorithm for electrical capacitance tomography. ISA Trans. 2010, 49, 10–18. [Google Scholar] [CrossRef]

- Kim, T.-H.; Cho, T.-H.; Moon, Y.S.; Park, S.H. Visual inspection system for the classification of solder joints. Pattern Recognit. 1999, 32, 565–575. [Google Scholar] [CrossRef]

- Hajihosseini, P.; Anzehaee, M.M.; Behnam, B. Fault detection and isolation in the challenging Tennessee Eastman process by using image processing techniques. ISA Trans. 2018, 79, 137–146. [Google Scholar] [CrossRef] [PubMed]

- Berenguel, M.; Rubio, F.R.; Valverde, A.; Lara, P.J.; Arahal, M.R.; Camacho, E.F.; Lopez, M. An artificial vision-based control system for automatic heliostat positioning offset correction in a central receiver solar power plant. Sol. Energy 2004, 76, 523–653. [Google Scholar] [CrossRef]

- Camacho, E.F.; Berenguel, M.; Gallego, A.J. Control of thermal solar energy plants. J. Process Control 2014, 24, 332–340. [Google Scholar] [CrossRef]

- Najera, Y.; Reed, D.R.; Grady, W.M. Image processing methods for predicting the time of cloud shadow arrivals to photovoltaic systems. In Proceedings of the 37th IEEE Photovoltaic Specialists Conference, Seattle, WA, USA, 19–24 June 2011; pp. 188–191. [Google Scholar]

- Chu, Y.; Pedro, H.T.C.; Coimbra, C.F.M. Hybrid intra-hour DNI forecasts with sky image processing enhanced by stochastic learning. Sol. Energy 2013, 98, 592–603. [Google Scholar] [CrossRef]

- Gallardo-Saavedra, S.; Hernández-Callejo, L.; Duque-Perez, O. Technological review of the instrumentation used in aerial thermographic inspection of photovoltaic plants. Renew. Sustain. Energy Rev. 2018, 93, 566–579. [Google Scholar] [CrossRef]

- Simon, M.; Meyer, E.L. Detection and analysis of hot-spot formation in solar cells. Sol. Energy Mater. Sol. Cells 2010, 94, 106–113. [Google Scholar] [CrossRef]

- Mahmoud, Y.; El-Saadany, E.F. A Novel MPPT Technique Based on an Image of PV Modules. IEEE Trans. Energy Convers. 2017, 32, 213–221. [Google Scholar] [CrossRef]

- Lee, C.-D.; Huang, H.-C.; Yeh, H.-Y. The Development of Sun-Tracking System Using Image Processing. Sensors 2013, 13, 5448–5459. [Google Scholar] [CrossRef] [Green Version]

- Jaffery, Z.A.; Dubey, A.K.; Haque, I.A. Scheme for predictive fault diagnosis in photo-voltaic modules using thermal imaging. Infrared Phys. Technol. 2017, 83, 182–187. [Google Scholar] [CrossRef]

- Tsanakas, J.A.; Chrysostomou, D.; Botsaris, P.N.; Gasteratos, A. Fault diagnosis of photovoltaic modules through image processing and Canny edge detection on field thermographic measurements. Int. J. Sustain. Energy 2015, 34, 351–372. [Google Scholar] [CrossRef]

- Amaral, T.G.; Pires, V.F. Fault Detection in Trackers for PV Systems Based on a Pattern Recognition Approach. Int. Trans. Electr. Energy Syst. 2019, 29, e2771. [Google Scholar] [CrossRef]

- Moore, L.M.; Post, H.N. Five years of operating experience at a large, utility-scale photovoltaic generating plant. Prog. Photovolt. Res. Appl. 2008, 16, 249–259. [Google Scholar] [CrossRef]

- Oozeki, T.; Yamada, T.; Otani, K.; Takashima, T.; Kato, K. An analysis of reliability in the early stages of photovoltaic systems in japan. Prog. Photovolt. Res. Appl. 2010, 18, 363–370. [Google Scholar] [CrossRef]

- Papadakis, K.; Koutroulis, E.; Kalaitzakis, K. A server database system for remote monitoring and operational evaluation of renewable energy sources plants. Renew. Energy 2005, 30, 1649–1669. [Google Scholar] [CrossRef]

- Arena, E.; Corsini, A.; Ferulano, R.; Iuvara, D.; Miele, E.S.; Celsi, L.R.; Sulieman, N.A.; Villari, M. Anomaly Detection in Photovoltaic Production Factories via Monte Carlo Pre-Processed Principal Component Analysis. Energies 2021, 14, 3951. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, X.; Qian, P. Wind Turbine Fault Detection and Identification Through PCA-Based Optimal Variable Selection. IEEE Trans. Sustain. Energy 2018, 9, 1627–1635. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Tang, Q.; Lin, Y.; Tang, Y. Fault detection of feed water treatment process using PCA-WD with parameter optimization. ISA Trans. 2017, 68, 313–326. [Google Scholar] [CrossRef]

- Pires, V.F.; Amaral, T.G.; Martins, J.F. Power Quality Disturbances Classification Using the 3-D Space Representation and PCA based Neuro-Fuzzy Approach. Expert Syst. Appl. 2011, 38, 11911–11917. [Google Scholar] [CrossRef]

- Otsu, N. A threshold selection method from gray-level histogram. IEEE Trans. Syst. Man Cybern. 1978, 9, 62–66. [Google Scholar] [CrossRef] [Green Version]

- Ballard, D.; Brown, C. Computer Vision; Prentice-Hall, Inc.: Englewood Clifs, NJ, USA, 1982. [Google Scholar]

- Rohlf, F.J. 12 Single-link clustering algorithms. In Handbook of Statistics; Elsevier: Amsterdam, The Netherlands, 1982; Volume 2, pp. 267–284. [Google Scholar]

- Pandit, S.; Gupta, S. A comparative study on distance measuring approaches for clustering. Int. J. Res. Comput. Sci. 2011, 2, 29–31. [Google Scholar] [CrossRef] [Green Version]

- Race, A.M.; Steven, R.T.; Palmer, A.D.; Styles, I.B.; Bunch, J. Memory Efficient Principal Component Analysis for the Dimensionality Reduction of Large Mass Spectrometry Imaging Data Sets. Anal. Chem. 2013, 85, 3071–3078. [Google Scholar] [CrossRef]

- Khatun, T. Measuring environmental degradation by using principal component analysis. Environ. Dev. Sustain. 2009, 11, 439–457. [Google Scholar] [CrossRef]

- Cherkassky, V.; Mulier, F. Learning from Data; John Wiley & Sons, Inc.: New York, NY, USA, 1998. [Google Scholar]

- Jolliffe, I.T. Principal Component Analysis; Springer: New York, NY, USA, 1986. [Google Scholar]

| PV Module 1 | PV Module 2 | PV Module 3 | |

|---|---|---|---|

| θi | 61.5° | 62.7° | 58.3° |

| DI | 0.37 | 1.03 | 1.40 |

| PV Module 1 | PV Module 2 | PV Module 3 | |

|---|---|---|---|

| θi | 107.5° | 121.0° | 118.9° |

| DI | 6.91 | 0.58 | 0.58 |

| PV Mod. 1 | PV Mod. 2 | PV Mod. 3 | |

|---|---|---|---|

| θi | 110.1° | 106.0° | 123.3° |

| DI | 1.13 | 1.13 | 8.47 |

| Images | Computation Time [ms] | ||

|---|---|---|---|

| 1:40:N | 1:160:N | 1:240:N | |

| Case 1 | 0.747 | 0.160 | 0.120 |

| Case 2 | 0.792 | 0.187 | 0.110 |

| Case 3 | 0.672 | 0.132 | 0.096 |

| Manually | Method [36] | Proposed Method | |

|---|---|---|---|

| θi | 112.6 | 113.5 | 112.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amaral, T.G.; Pires, V.F.; Pires, A.J. Fault Detection in PV Tracking Systems Using an Image Processing Algorithm Based on PCA. Energies 2021, 14, 7278. https://doi.org/10.3390/en14217278

Amaral TG, Pires VF, Pires AJ. Fault Detection in PV Tracking Systems Using an Image Processing Algorithm Based on PCA. Energies. 2021; 14(21):7278. https://doi.org/10.3390/en14217278

Chicago/Turabian StyleAmaral, Tito G., Vitor Fernão Pires, and Armando J. Pires. 2021. "Fault Detection in PV Tracking Systems Using an Image Processing Algorithm Based on PCA" Energies 14, no. 21: 7278. https://doi.org/10.3390/en14217278

APA StyleAmaral, T. G., Pires, V. F., & Pires, A. J. (2021). Fault Detection in PV Tracking Systems Using an Image Processing Algorithm Based on PCA. Energies, 14(21), 7278. https://doi.org/10.3390/en14217278