Abstract

Automatic clutch engagement control is essential for all kinds of vehicle power transmissions. The controllers for vehicle power transmissions may include model-based or model-free approaches and must provide high transmission efficiency, fast engagement and low jerk. Most vehicle automatic transmissions are using torque converters with transmission efficiencies up to 96%. This paper presents the use of fuzzy logic control for a dry clutch in parallel hybrid electric vehicles. This controller can minimize the loss of power transmission since it can offer a higher transmission efficiency, up to 99%, with faster engagement, lower jerk and, thus, higher driving comfortability with lower cost. Fuzzy logic control is one of the model-free schemes. It can be combined with AI algorithms, neuro networks and virtual reality technologies in future development. Fuzzy logic control can avoid the complex modelling while maintaining the system’s high stability amid uncertainties and imprecise information. Experiments show that fuzzy logic can reduce the clutch slip and vibration. The new system provides 2% faster engagement speed than the torque converter and eliminates 70% of noise and vibration less than the manual transmission clutch.

1. Introduction

Hybrid electric vehicles (HEVs) and plug-in hybrid electric vehicles (PHEVs) are rapidly popularizing due to the world commitment to reduce fossil fuels and CO2 emissions. HEVs provide CO2 emissions 40% fewer than the conventional internal combustion engine (ICE) vehicles in the same sizes and classes. In parallel, hybrid electric vehicles, the ICE and the main electric motor (EM) are installed independently. There are normally four driving modes (DMs): Pure electricity mode (DM1) at a low load and/or a low speed, only the main EM runs the vehicle; Pure combustion engine mode (DM2), at a higher load and/or a higher speed, the ICE is ignited by the starter/generator motor EM and the ICE runs the vehicle alone; Hybrid power mode 1 (DM3), at a very high load and/or speed, both main EM and ICE run the vehicle; Hybrid power mode 2 (DM4), at an extreme high load and/or maximum speed, all starter/generator, main EM, and ICE together run the vehicle. The vehicle battery can be charged from the plug-in cable and/or from the generator motor.

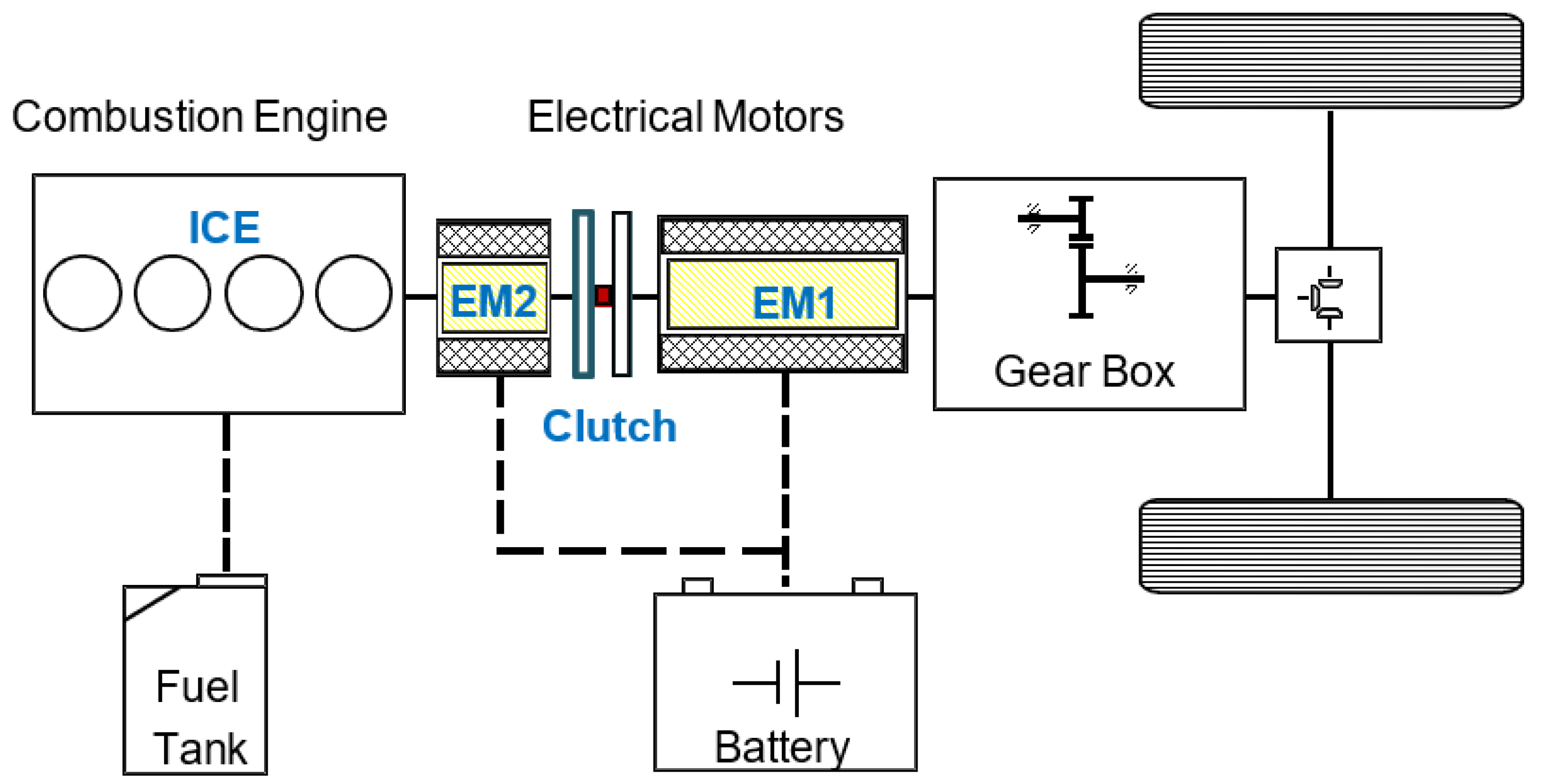

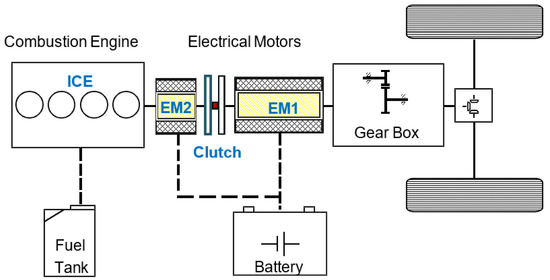

In 2021, Hyundai launched the latest version of the Sonata Hybrid as shown in Figure 1. This is a sedan middle class parallel hybrid electric vehicle. This HEV consists of one internal combustion engine (ICE) of four cylinders with multiple point injection, volume of 2.4 L, max power of 156 kW at 6000 rpm, and the peak torque of 265 Nm; one electric motor starter (EM2) with max power of 8 kW and max torque of 43 Nm; the main electric motor (EM1) with max power of 35 kW and max torque of 205 Nm; the battery HEV Li-ion with capacity of 6.1 Ah; the transmission gear box with full automated six speed and the friction clutch engagement are also fully automated. The vehicle curb weight is 1569 kg.

Figure 1.

Hyundai 2021 Sonata Hybrid.

The automatic transmission gearbox and torque converter determine the fast and smooth power transmissions. This paper starts with some comprehensive reviews of recent research on vehicle powertrain transmissions; development trends of HEV transmissions; research on clutch and braking systems in HEV energy management; modern clutch control strategies for HEV; HEV with dual clutch transmissions; and finally, control designs for clutch engagement.

The authors of [1] present a review of automatic transmission control in automotive powertrains including manual transmission (MT), automated manual transmission (AMT), dual-clutch transmission (DCT), conventional automatic transmission (AT), and continuous variable transmission (CVT). Another recent comprehensive review on HEV architectures and powertrain transmissions is referred to in [2], where the choices of different converters for obtaining high efficiency are introduced. A review of recent advances in energy management for HEV and PHEV is presented in [3], where different efficient operation techniques are introduced with the combination of electric traction and mechanical traction. Finally, global insights into future trends for HEV and PHEV are reviewed in [4].

Regarding recent studies on HEV powertrains, clutch and braking systems, the authors of [5] introduce development trends of transmissions of HEV using an optimizing energy management strategy. The effect of the engine start and clutch slip losses problem on the hybrid DCT powertrain is presented in [6]. The authors of [7] present control strategy of hydraulic regenerative braking of electrohydraulic HEV. Research on the optimization control of the regenerative braking system of HEV based on electrical variable transmission is introduced in [8].

Regarding the control strategy for HEV, the authors of [9] review different rule-based controls and optimization-based controls in order to improve the fuel economy for HEV. Other research on control strategy for clutch engagement during the switching mode of PHEV is presented in [10]. The authors of [11] present mode transition control for single-shaft PHEV using a model predictive control approach. The authors of [12] introduce multiphase mixed-integer nonlinear optimal control of HEV. The economic aspect of using different PHEVs in urban conditions is also reviewed in [13]. Finally, new optimized adaptive control for mode transition is presented in [14], where a mathematical model for clutch friction is developed for a PHEV during the mode transition.

There are more applications of DCT for HEV and PHEV because of its fast and smooth engagement. The authors of [15] present a new control algorithm for HEV with DCT configurations. The controller is used with a model reference adaptive controller (MRAC) to minimize the fuel consumption and reduce torque interruption. A cooperative control of clutch for HEV with DCT is presented in [16] where a robust multivariable control scheme using an H-infinity loop is proposed to improve the shift quality. The development of an engine start control method for P2 hybrid vehicles is considered in [17], where the pure electric motor switching to pure ICE mode is considered to prevent the driving torque variation at the time of the engine start. Optimal speed regulation control of hybrid DCT in the shift process is considered in [18] to shorten the torque interruption and reduce the wear of the synchronizer. Finally, the authors of [19] present the optimization of DCT for an axle-split HEV to minimize the fuel consumption.

Finally, an updated clutch strategy controls for HEV and PHEV are also reviewed. The authors of [20] present a clutch control strategy of the driving mode transition for P2 HEV, where a model-based coordinated control strategy is developed. A shift strategy is studied in [21] for a smooth and effective transmission, where the dynamic optimization scheme is used to extract the best economic shift strategy. A novel control method of clutch during mode transition of single shaft PHEV is introduced in [22], where an adaptive sliding mode control (ASMC) and a proportional integral (PI) observer are designed. An engine clutch engagement control for HEV with a transmission mounted electric device is presented in [23] for fast synchronization of the engine and motor speed. The authors of [24] present a double layer control of clutch during the vehicle starting up. Finally, the authors of [25] present the design, control and validation of two speed clutch for electric vehicle based on the coordinated control strategy to achieve the fast and smooth shifting. Recent vehicle advanced control technologies and simulations are referred to in [26,27,28,29,30,31,32,33].

Most of the clutch control strategies are presently used model-based control and there is still a lack of model-free control approaches related to fuzzy, AI or virtual reality techniques. The idea of this paper is arising from the successful use of fuzzy logic for the vehicle anti-lock braking system (ABS). Similar to the ABS, fuzzy logic control for the clutch system can allow the use of low-cost dry clutch plates and provide higher transmission efficiency, up to more than 99%. The controller design is tested with Matlab 2021b Simulink and experiments in our lab. Results indicate good performances, stability and the ability to reduce noise and vibration.

2. Modelling of Clutch Engagement

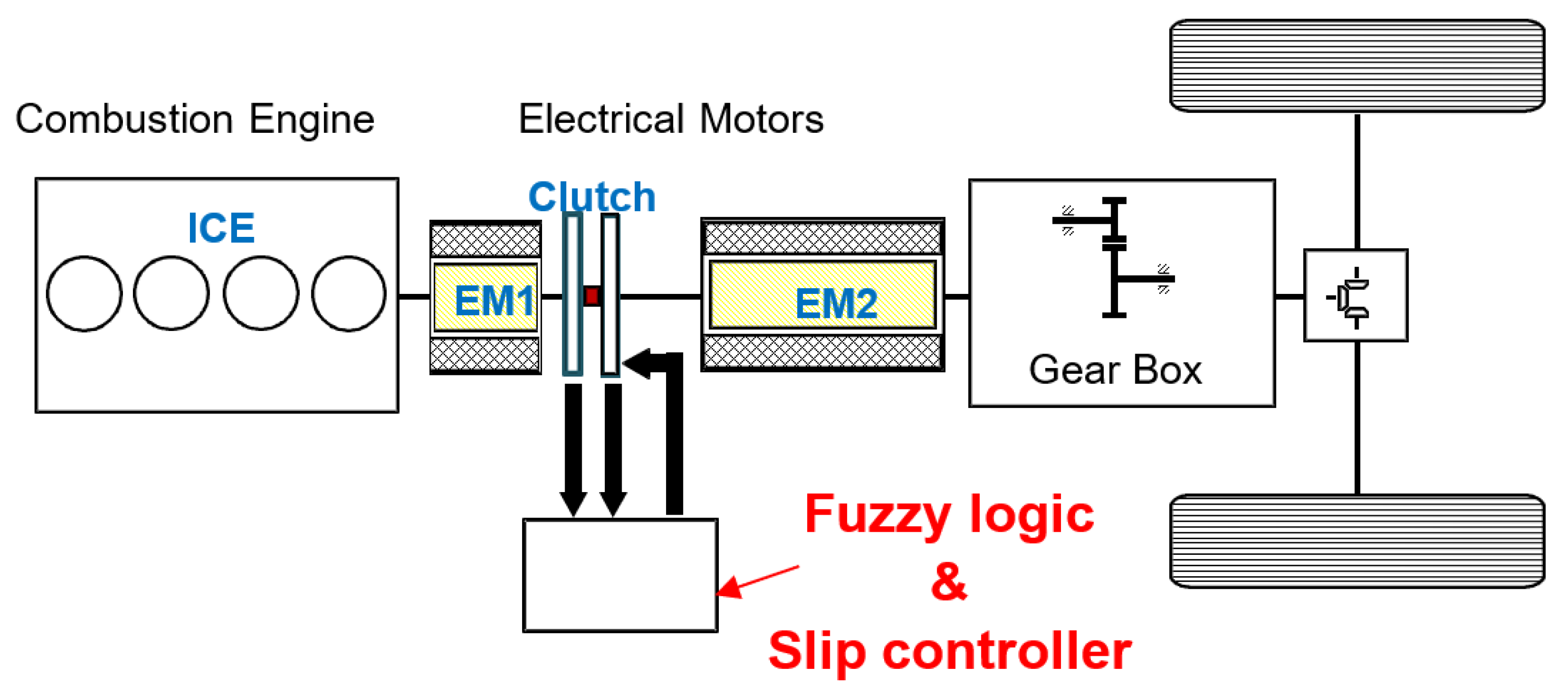

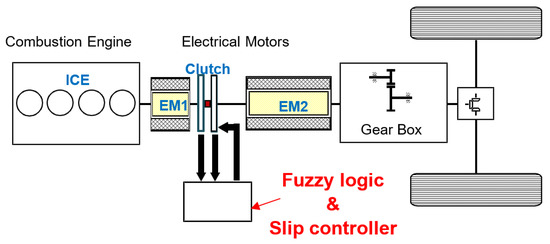

In this study, we use the vehicle dynamic formulas and clutch calculations from the textbook [34]. Real vehicle parameters are used in the updated 2021 Hyundai Sonata HEV. The fuzzy logic and slip controller are installed in the HEV clutch as shown in Figure 2.

Figure 2.

Fuzzy logic and slip controller.

In this HEV, the vehicle is driven by the rear wheels via an automatic gear box. At low loads and/or low speeds of less than 40 km/h, only the mail electric motor EM2 runs the vehicle. The clutch is open. At a higher torque and/or speeds higher than 40 km/h, the starter motor EM1 ignites the engine ICE. The clutch is closed and the ICE runs the vehicle.

The clutch system consists of two friction plates and is controlled by our fuzzy logic controller. Once clutch is engaged, the two dry friction plates are coupled and rotate on the same speed with fast engagement, low vibration and jerk. Design for this engagement is still a big challenge. In torque converters and/or in wet clutch systems, the clutch transmits torques coupling in oil and fluid. The friction plates and converters merge into lubricant oil. Oil provides better damping, less vibration, less jerk but the system becomes more complex and higher cost. However, the transmission efficiency is then reduced at a maximum of 95% due to the higher slipping ratio between the two plates. If we use the dry friction clutch, the system will be lower in cost and have a higher transmission efficiency of more than 99%. A fuzzy logic controller can help to regulate the switching mechanism at precise moments for the engagement.

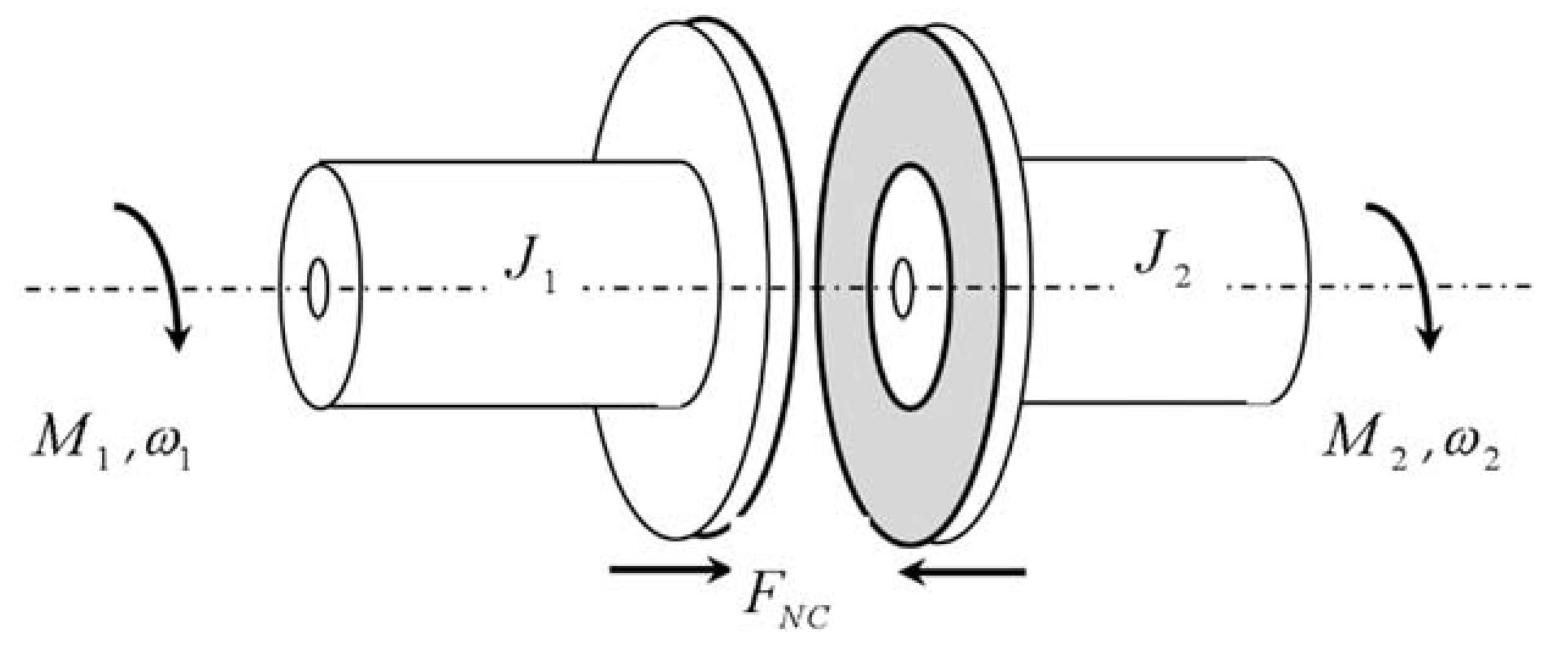

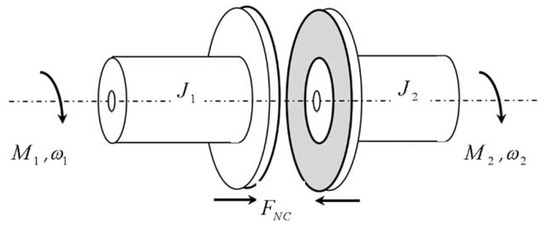

Figure 3 shows a simple scheme of a dry friction clutch: is the normal control force between the two dry friction plates—this force is generated by our fuzzy logic controller online; is the driving torque from ICE at the input shaft; is the transmitted torque to the output shaft; and are the lumped inertia moments; and are the damping coefficients; and are the friction coefficients; and are the angular velocities; and are the inner and outer radius of the friction plates; and is the clutch equivalent radius.

Figure 3.

Clutch scheme.

At the locked mode, the torque equation between the two friction plates is:

The maximum transmission torque is depending on the contact area or the plate radiuses , and , and the friction force :

At the slipping mode, , the transmission torque is depending on the difference of two angular velocities and the slipping friction coefficient :

At the locked mode, , the maximum friction torque is fully transferred and the two plates can be combined into one equation as:

or

The maximum friction torque maintains the locked mode until the friction torque being greater than the maximum static friction torque :

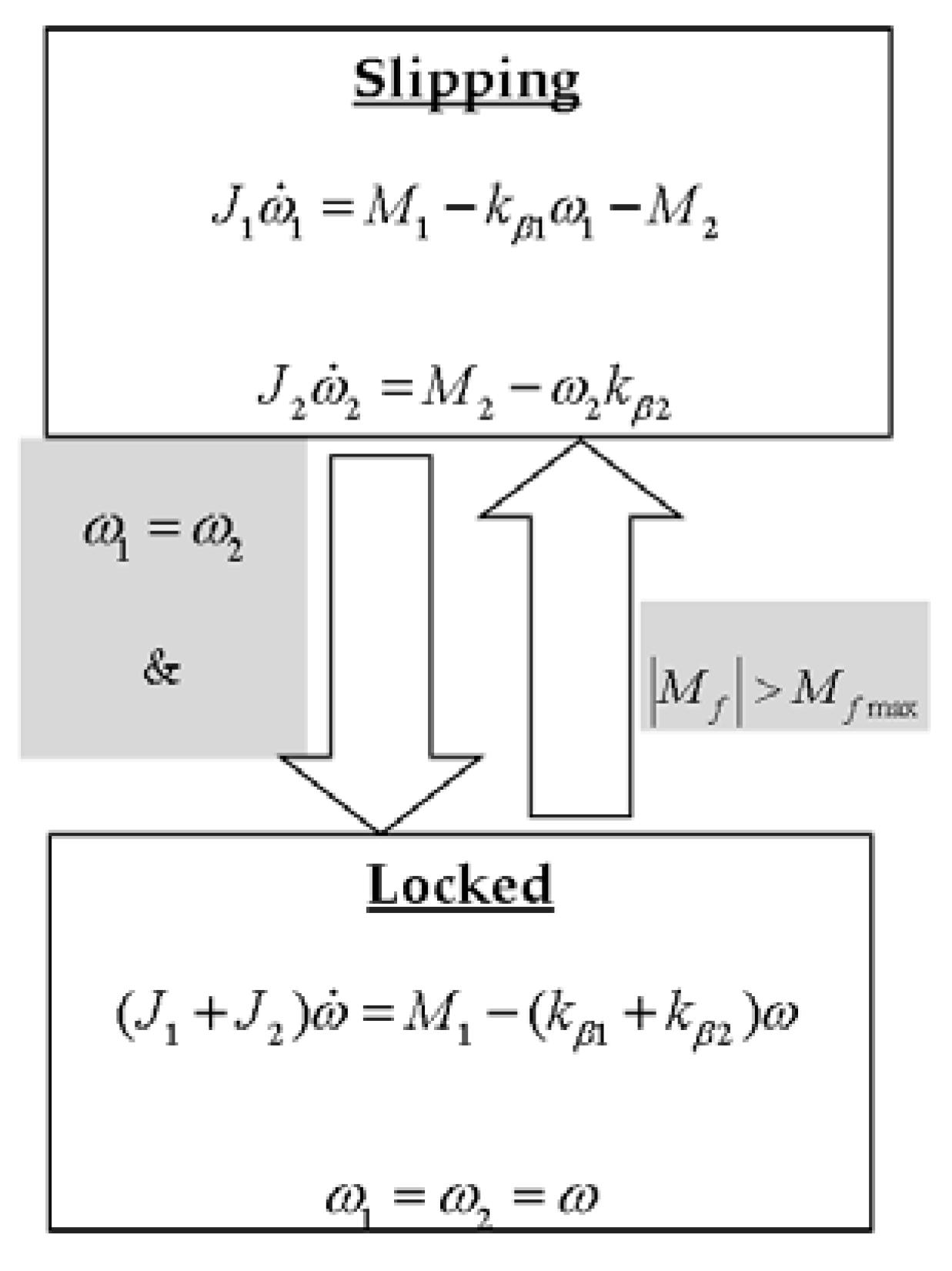

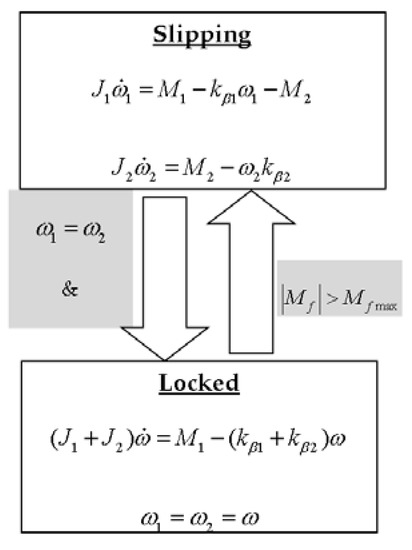

The shifting diagram for this clutch system is shown in Figure 4.

Figure 4.

Shifting diagram modes.

For a smoother engagement and lower jerk, the system must need a longer time to synchronize and lock the two plates. However, in reality, this proposal is not practical. A full clutch engagement must take place in very little time. The ideal time for a clutch engagement must not be more than 3 s. The longer engagement will lead to overheating and shorten the life-time. Therefore, we develop a fuzzy logic controller to synchronize the speed of the two plates with fast and smooth engagement.

3. Fuzzy Logic Controller Design

Automatic clutch engagement has become more popular. The driver now has only to control the brake and the accelerator pedal. Most of automatic transmission systems use torque converters and wet clutch systems since they are working in a good damping environment, then they can generate faster and smoother engagement with lower noise and vibration. However, due to also the damping liquid, they provide a higher slipping ratio, and hence a lower transmission efficiency, roughly 86–96%, and a higher cost of production and maintenance. While the dry friction clutch can offer a higher transmission efficiency of 97–99% and a lower cost of production and maintenance.

The main challenge for an automatic controller of a dry friction clutch is higher vibration and noise: how to balance the torque transmission efficiency versus the reduction of vibration and noise. The controller must always perform the two duty modes: switching connection and changing gears smoothly and correctly. The switching connection mode is the clutch being engaged or disengaged depending on the intention of the driver via his action on the accelerator pedal. The controller must determine the switching mode via the rate and the position of the accelerator operation. Similarly, the gears changing mode is determined by the current torque load and the vehicle speed to match the optimal energy management.

Based on the two duty modes requirements, fuzzy logic control rules are developed to regulate the slip ratio between the two plates. These fuzzy logic rules are designed and based on the slipping ratio between the input and the output speed and torque. This controller processes input data on engine, vehicle speed and the driver intention to generate the right output normal control force between the two plates. The clutch engagement takes place until the slipping ratio reduces to zero or the clutch is locked and matches the ICE speed.

A set of fuzzy logic rules is built based on the driver’s intention. For instance, a fast and aggressive pressure on the accelerator pedal can be understood as the driver wanting a fast and high normal control force and wishes to have full clutch engagement in a very short time. While gradual and slow pressure on the accelerator must be understood as the driver wanting to have a longer and smoother clutch engagement. Similarly, a fast release of the accelerator pedal will lead to a fast falling of ICE speed and an immediate interruption of the control force between the two plates. The clutch will be disengaged and the ICE will fall in the idle speed. The changing gears will take place accordingly depending on the vehicle’s speed and the output torque load conditions.

The followings are our fuzzy logic laws according to the position of the accelerator pedal: None (less than 1%), Little (1–20%), Medium (20–80%) and Large (more than 80%). And the accelerator rate: Slow (less than 20%/s), Medium (20–80%/s), and High (more than 80%/s). Similarly, the variable for the ICE speed is: Low or idling speed (less than 750 rpm), Upper (750–1830 rpm), Medium (1830–3540 rpm), and High (faster than 3540 rpm), and the variable for the ICE speed rate is: Falling Quickly (less than −2500 rpm/s), Falling Gently (from −2500–0 rpm/s), Constant (0 rpm/s), Rising Gently (0–2500 rpm/s), and Rising Quickly (greater than 2500 rpm/s).

A controller for this clutch is developed where the normal force between the two plates is a function of slipping ratio, slipping gain, and the above fuzzy logic laws. Variables for the slipping ratio re set up as: Null, Low, Medium and High. Variables for the slipping gain are set up as: Negative (less than −0.2), Gently Negative (less than −0.1), Null (=0), Low (at 0.025), Medium (at 0.075), and High (at 0.2). The fuzzy logic laws for controlling the slipping gain are presented in Table 1, Table 2, Table 3 and Table 4.

Table 1.

Accelerator laws.

Table 2.

ICE speed laws.

Table 3.

Driver intention laws.

Table 4.

Idling law.

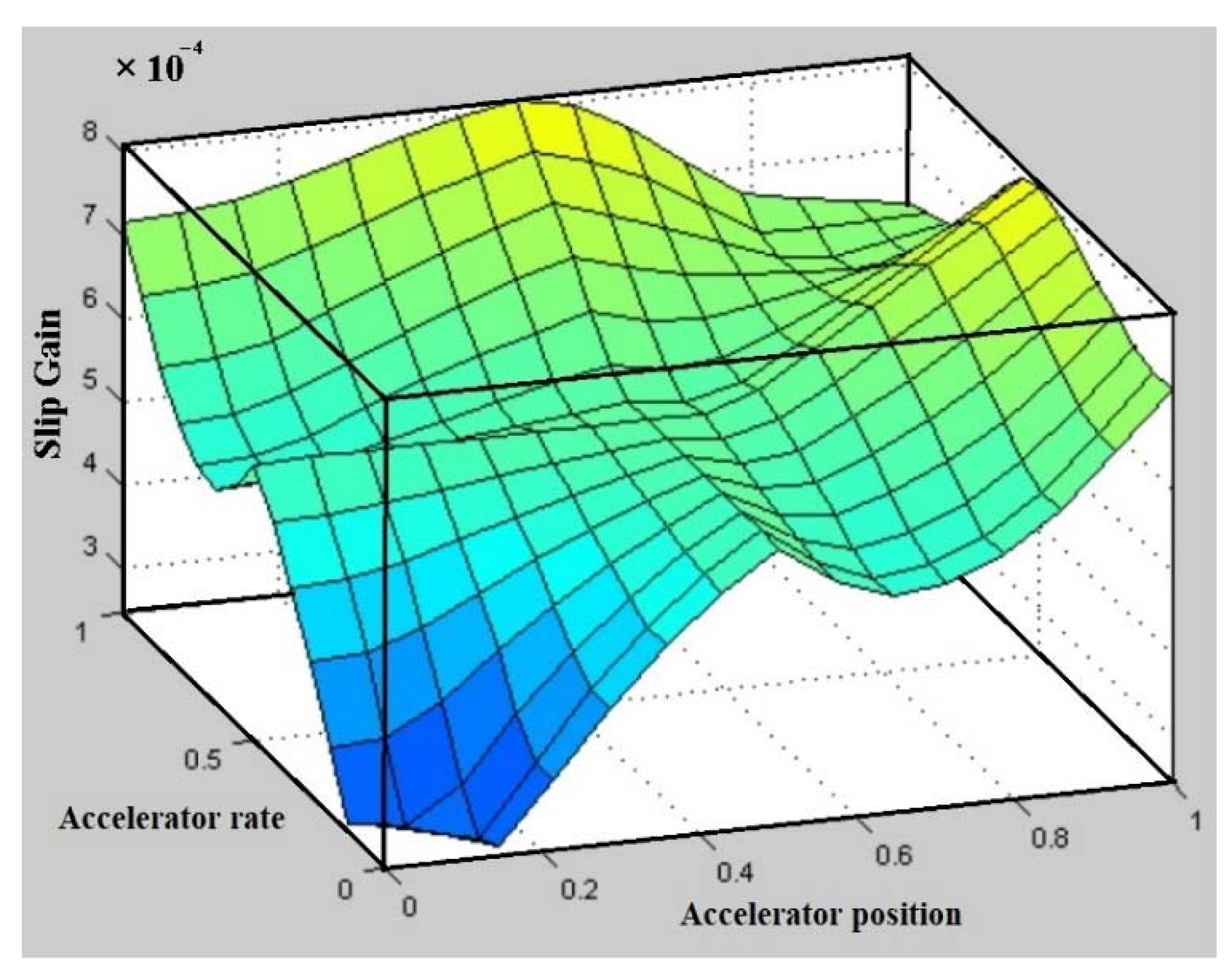

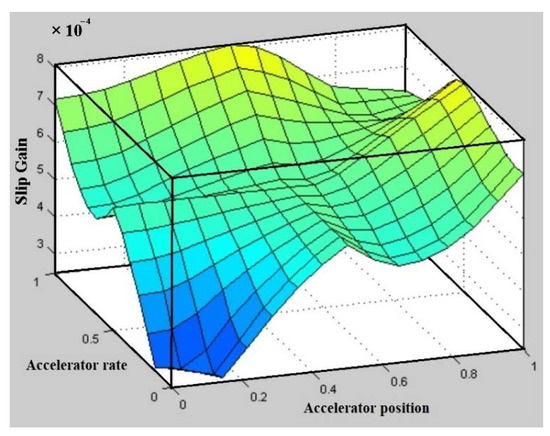

Figure 5.

Slipping gain, accelerator rate, and accelerator position.

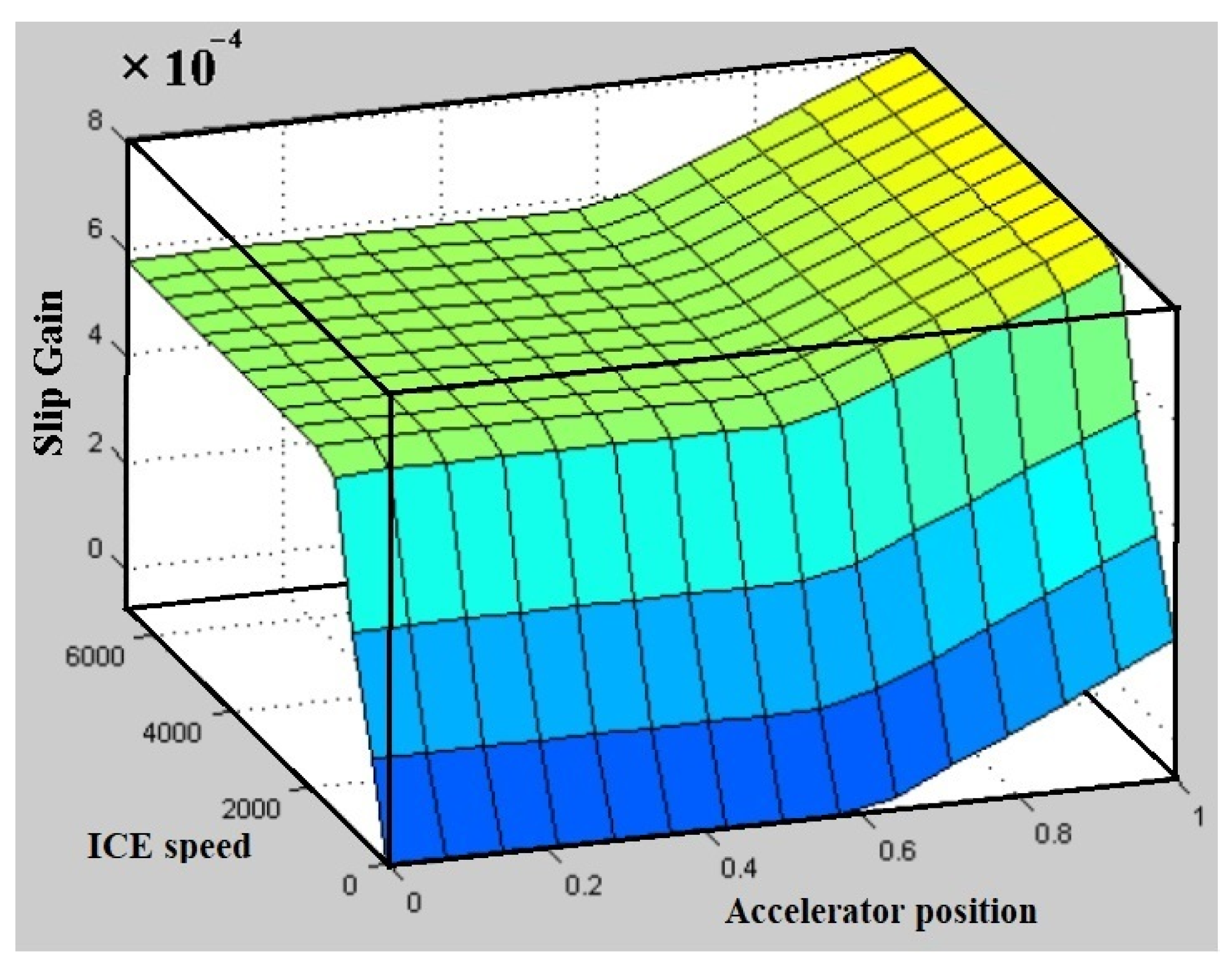

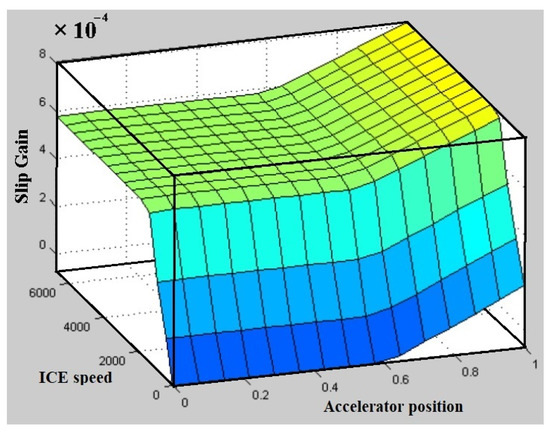

Figure 6.

Slipping gain, ICE speed, and acceleration position.

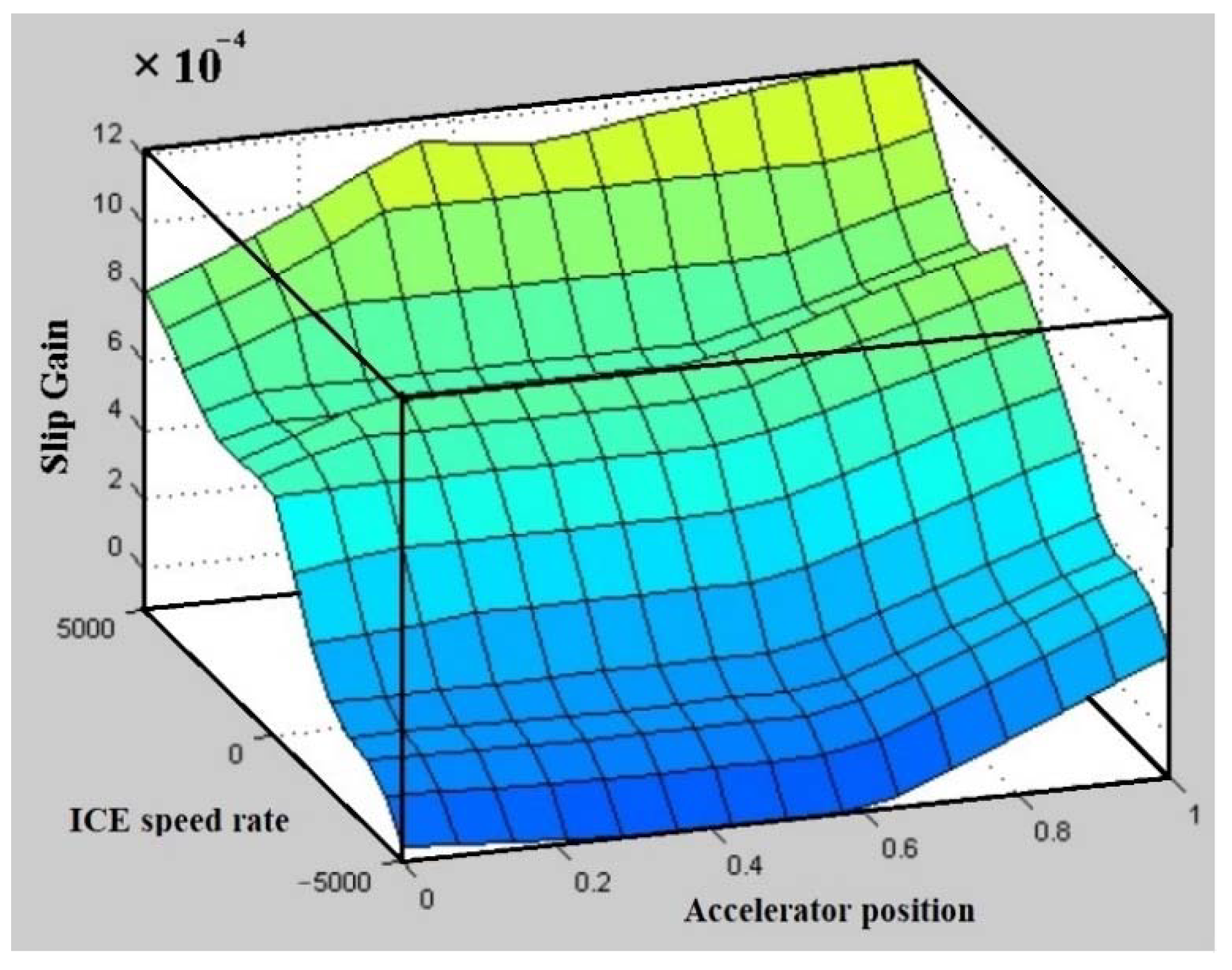

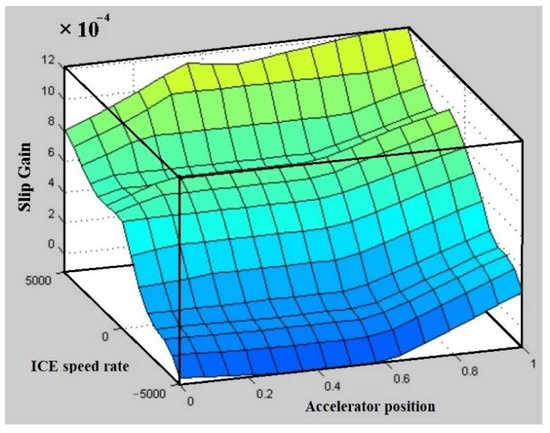

Figure 7.

Slipping gain, ICE speed rate, and acceleration position.

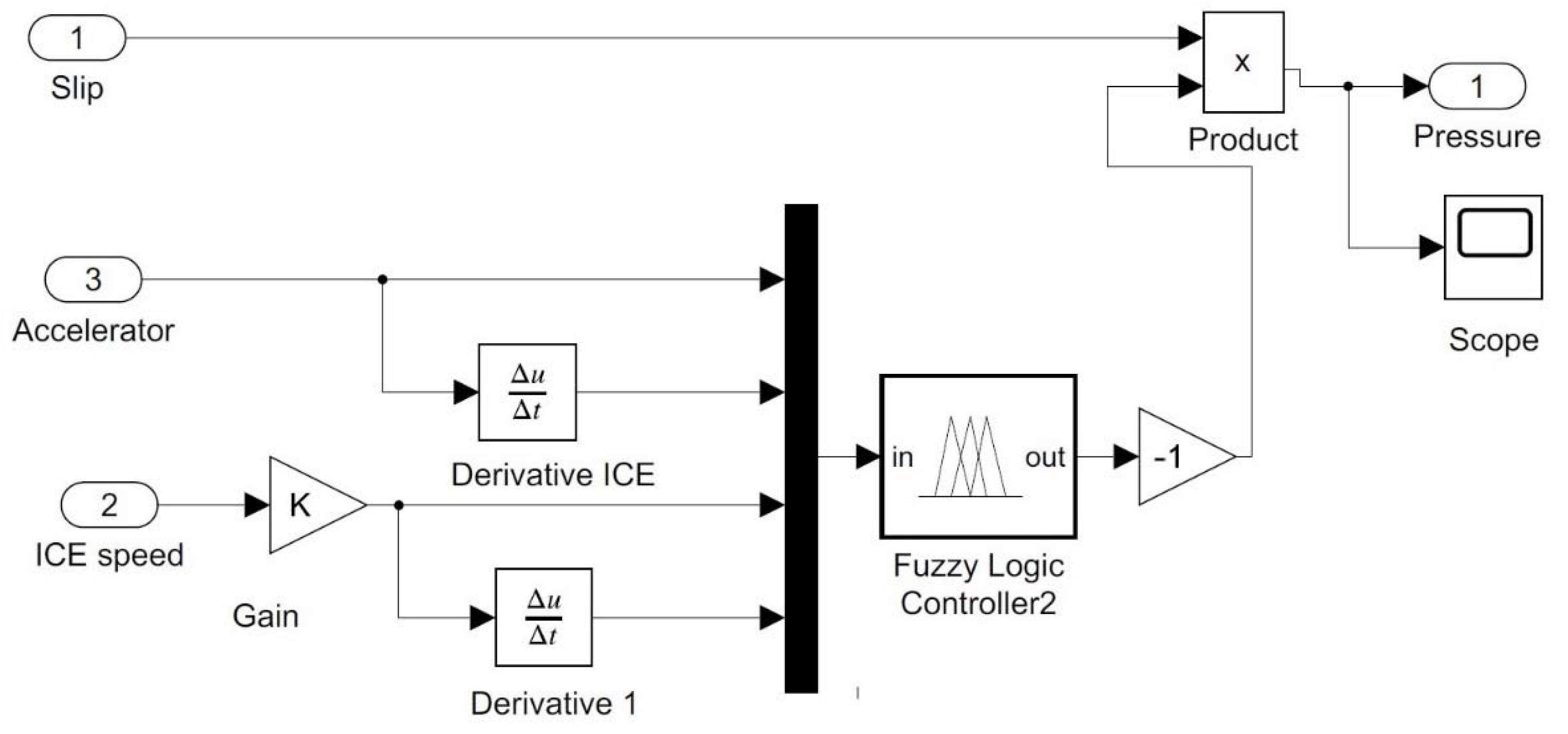

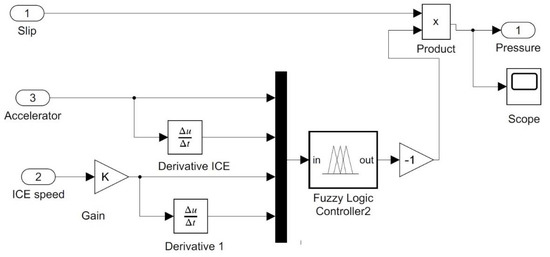

The full fuzzy logic controller on MATLAB Simulink R2021b is designed and shown in Figure 8. This controller receives and processes data in real-time from the accelerator position; accelerator rate; ICE speed; and ICE speed rate with the above fuzzy logic laws and generates the slipping gain values. The clutch normal force is now a product of slipping ratio from the angular slipping velocity sensors in the two clutch plates and the slipping gain values calculated from this fuzzy logic controller. The clutch engagement and vibration are now controlled by this normal control force.

Figure 8.

Fuzzy logic controller.

4. Simulink Simulations

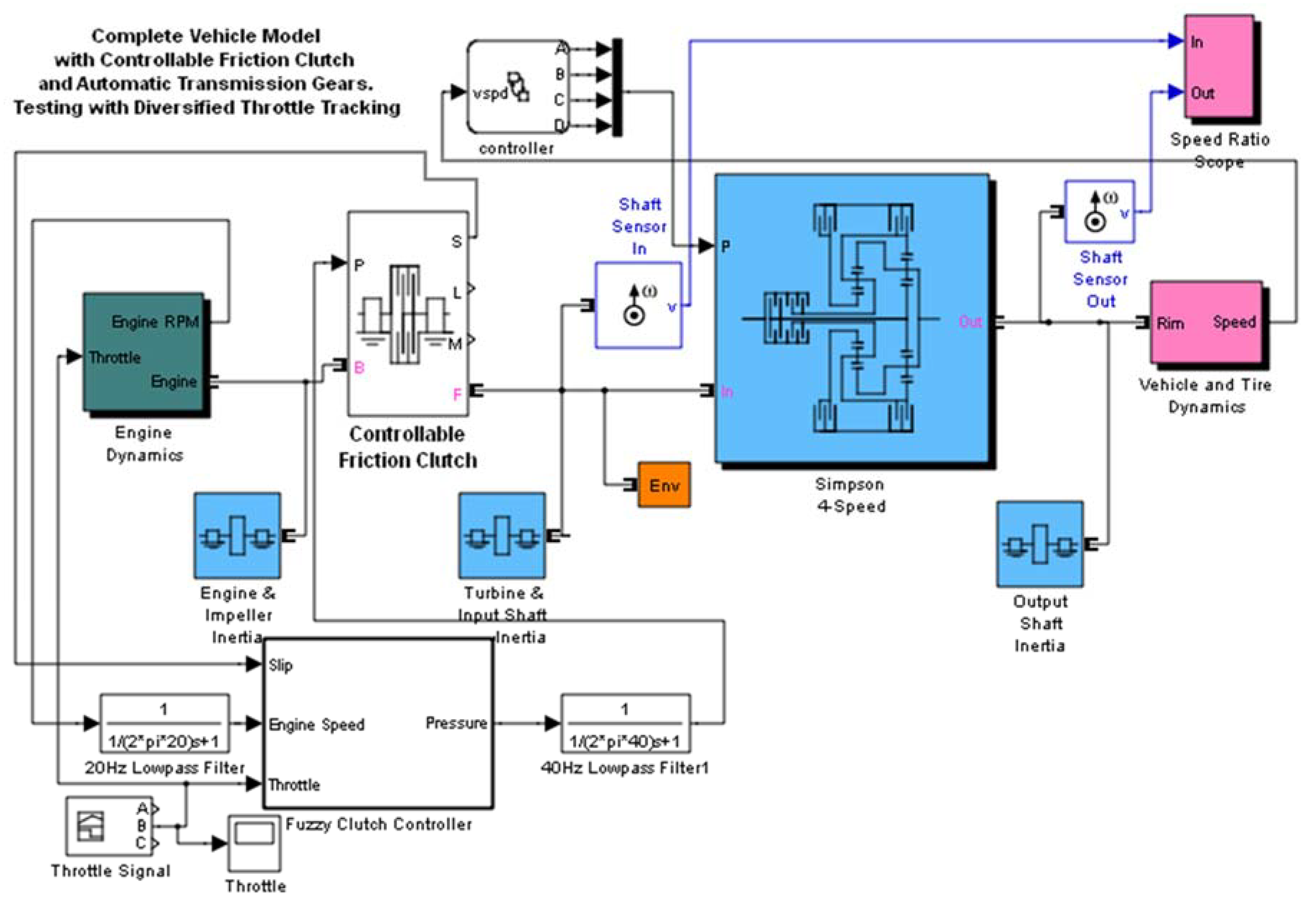

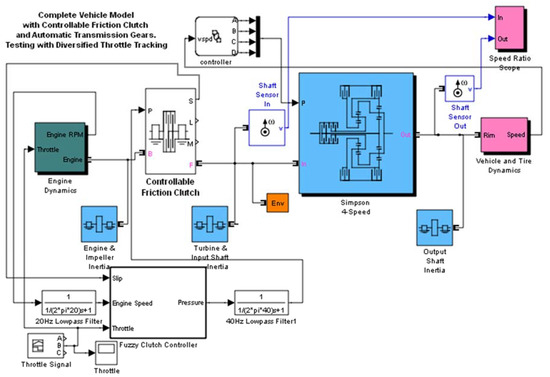

A comprehensive Simulink model of this parallel HEV is built in MATLAB 2021b and shown in Figure 9, including the ICE, fuzzy logic controller, main electric motor EM1, starter/generator EM2, six speeds automatic gearbox, tires, and vehicle dynamics.

Figure 9.

PHEV Simulink diagram.

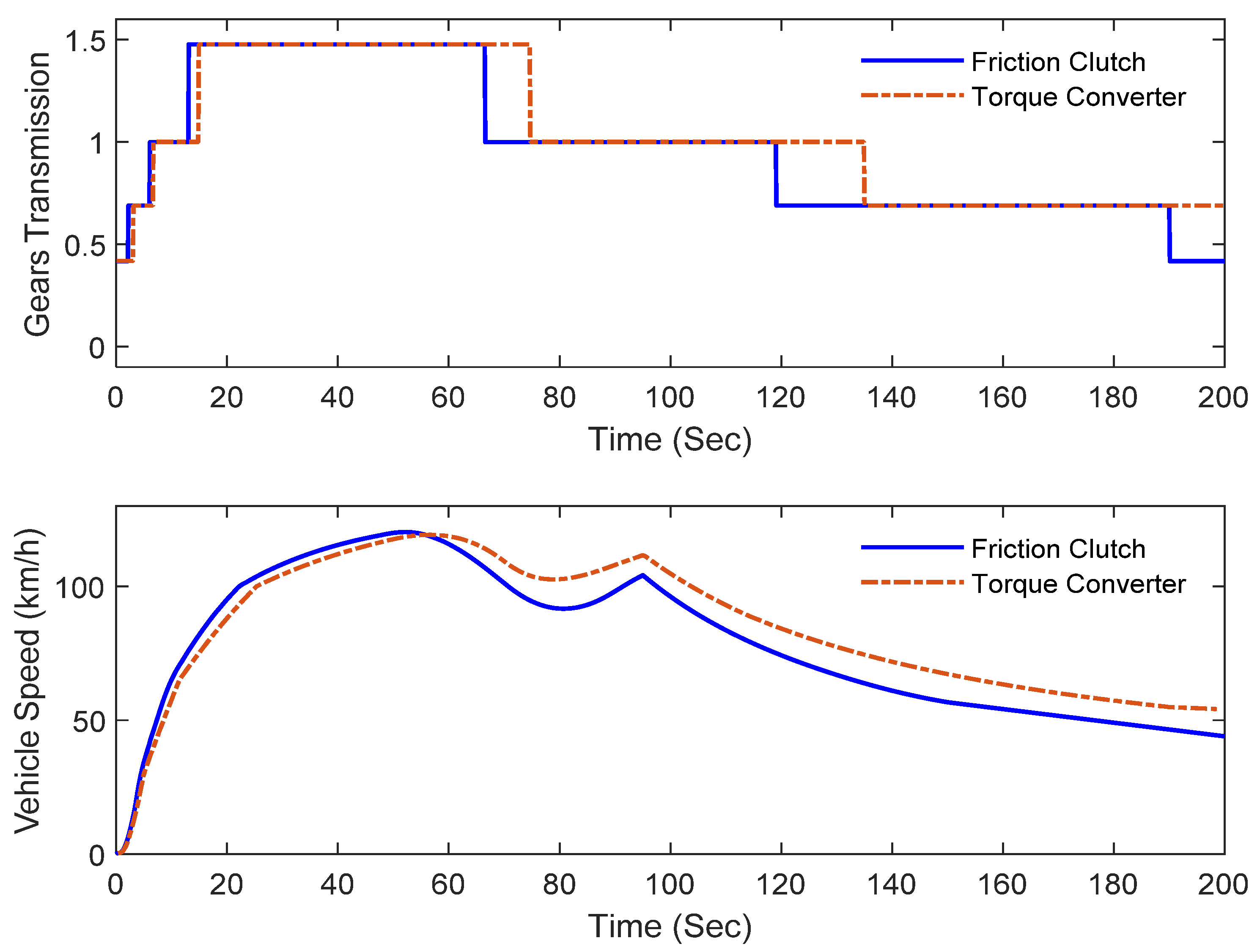

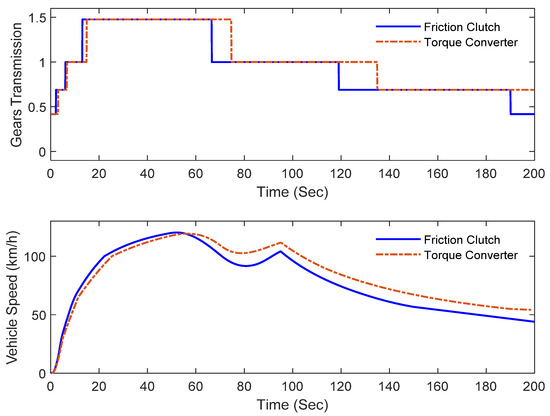

Simulations are run and compared between performances of the torque converter and our new friction clutch fuzzy logic controller over a fast-staring speed from 0 to 130 km/h with a full depression of the accelerator pedal in 5 s, then, keep it at full depression for 40 s, then, quickly release the accelerator pedal. The gears switching and the vehicle speed of the two simulations are shown in Figure 10.

Figure 10.

Full accelerator depression at starting time.

Figure 10 shows that the vehicle reaches the speed of 130 km/h in 50 s, the friction clutch system leads to automatic gear switching faster than the hydraulic torque converter and, hence, the vehicle reaches the maximum speed faster than the torque converter. With the sharp and full release of the accelerator pedal, the vehicle speed also reduces faster than the torque converter because of faster disengagement of the friction clutch than the torque converter.

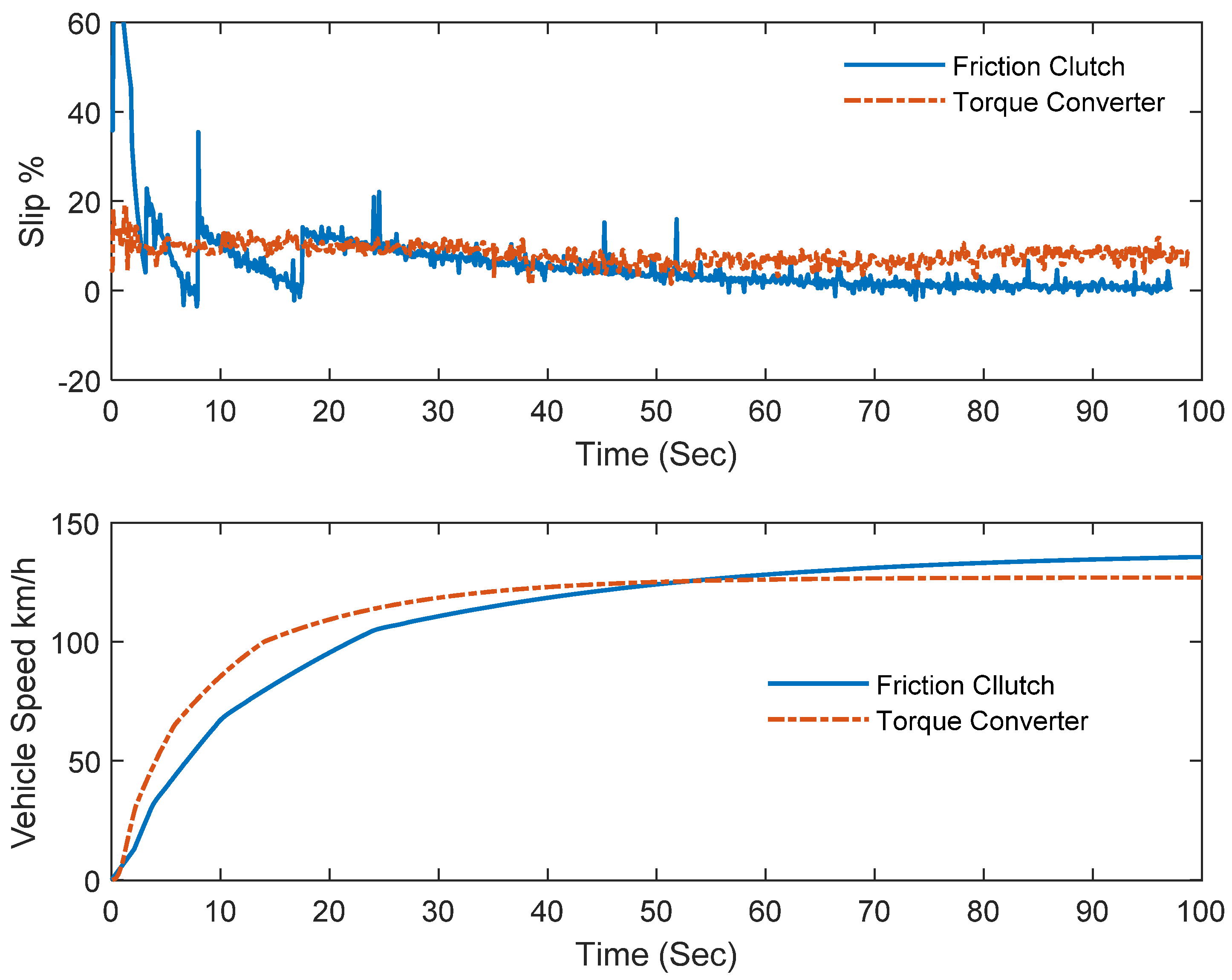

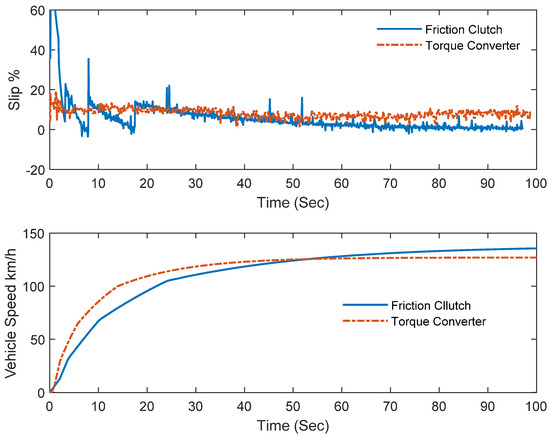

Now the vehicle is maintained, running at a stable speed of 130 km/h for a longer time. Figure 11 shows that, at this stable speed, the torque converter generates less transmission efficiency with a higher slipping ratio of more than 5%. While the slipping ration of the fiction clutch is gradually reduced to less than 1.5% after 100 s. The lower slipping ratio leads to higher torque transmission efficiency and, hence, the vehicle has a higher speed. However, the torque converter provides better damping in a fluid environment and, hence, generates lower vibration and noise. The vibration and noise of a dry clutch can be regulated by regulation of the normal force applied to the two plates and is presented in the next part.

Figure 11.

Slipping ratios and speeds.

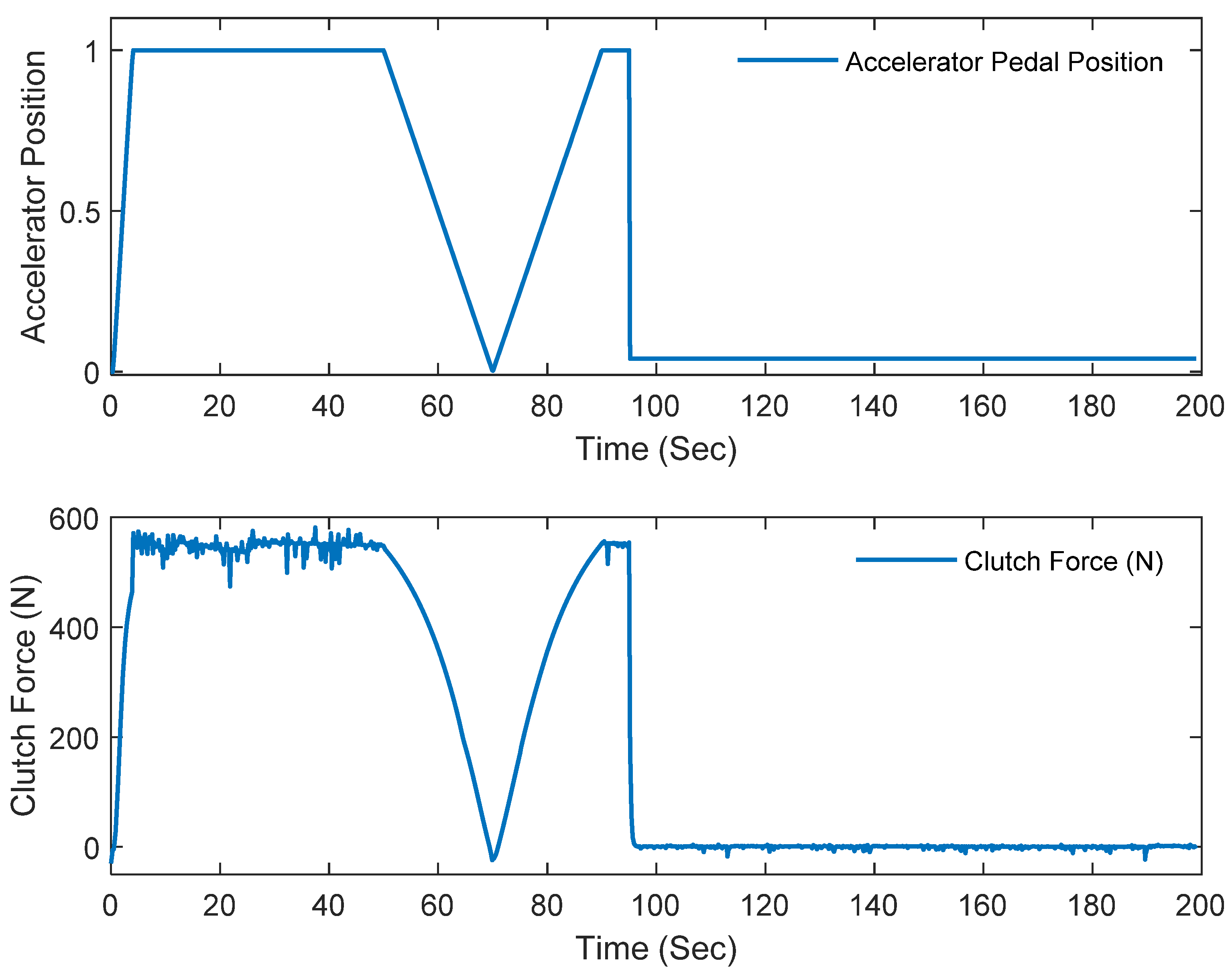

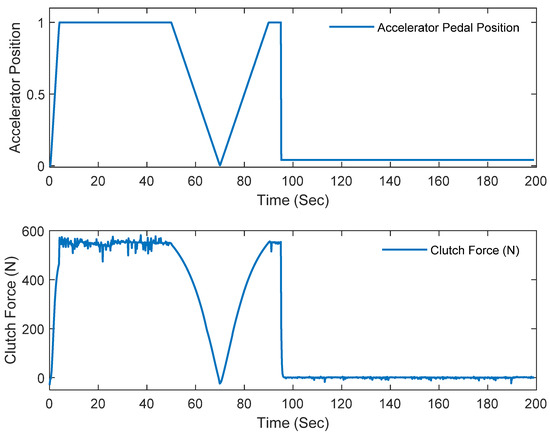

A full cycle test for this controller is conducted and is shown in Figure 12. The accelerator pedal is first pressed to its full position in 3 s. Then, it is kept in this full depression for 50 s. Then, we gradually release it over 20 s. Then, gradually press it again in 20 s. Then, keep it for 10 s. Then release it immediately and totally. The torque transmission between the two plates is stable at 590 N, then changes according to the accelerator position and rate. The clutch is totally disengaged when the accelerator pedal is released.

Figure 12.

Automatic friction clutch performance.

Figure 12 shows that the controller can manage the clutch engagement and disengagement well. The vehicle goes faster at the stable speed than with the use of the torque converter. This friction clutch is well controlled by the above fuzzy logic schemes. In the next section, we will conduct some real experiments to regulate the vibration and noise.

5. Experiments

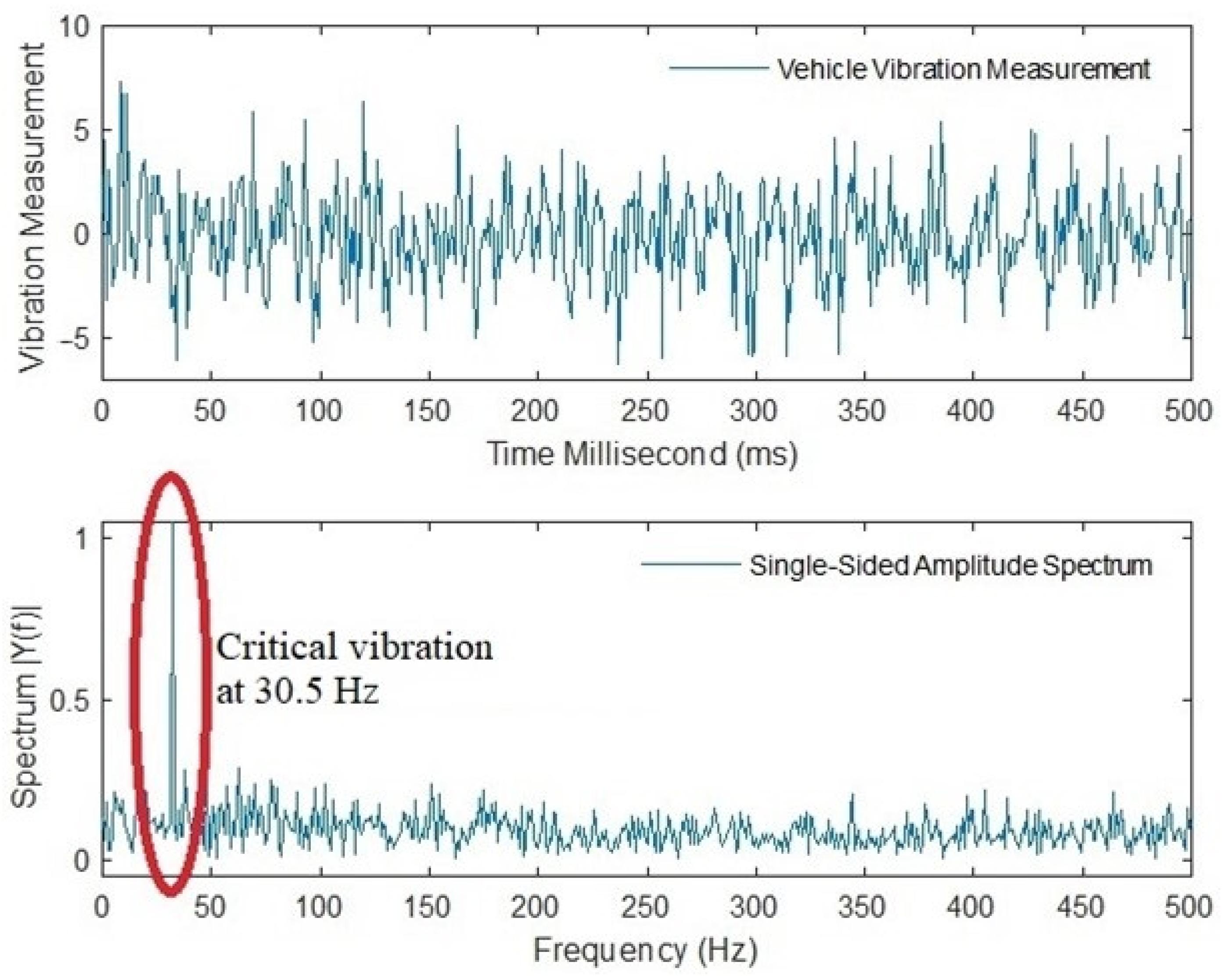

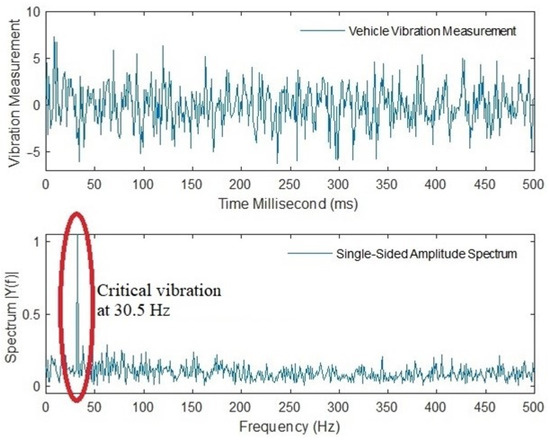

The vibration and noise of the friction clutch can be regulated by the normal force or by changing the clutch pressure. Real experiments show that the vehicle engine has a critical frequency at 30.5 Hz or at the engine angular speed of 1830 rpm, as shown in Figure 13.

Figure 13.

Critical vibration at 30.5 Hz.

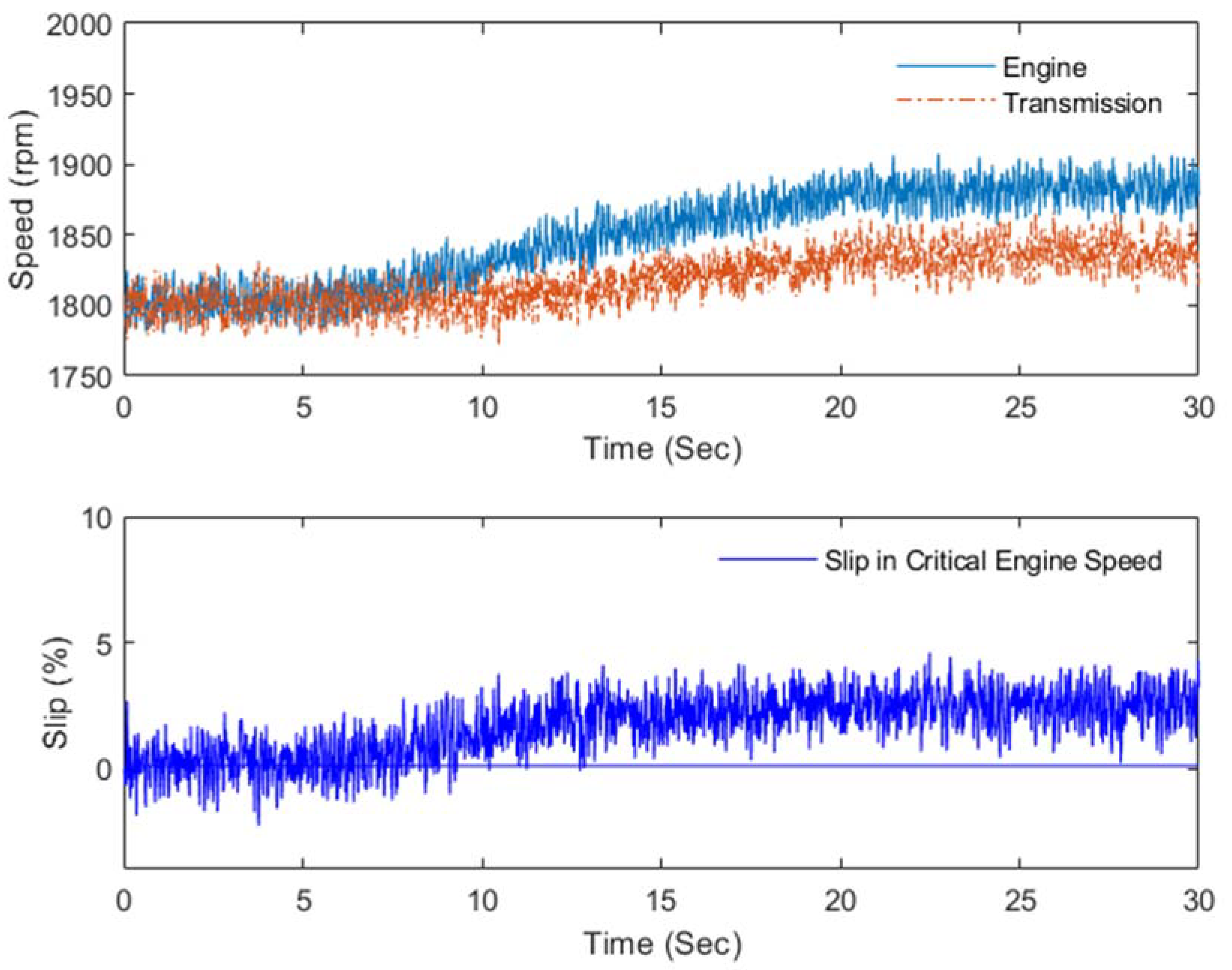

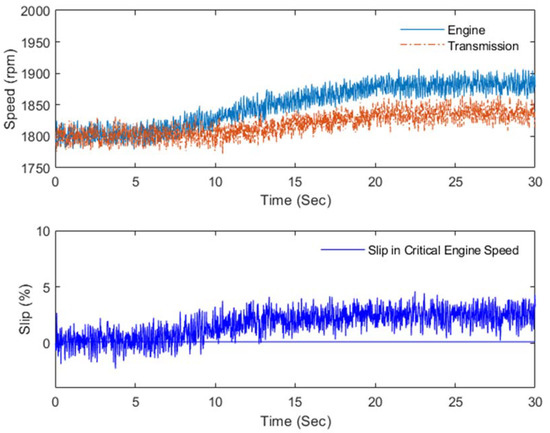

At a stable speed, the friction clutch always keeps the slipping ratio at less than 1.5%. In order to reduce the clutch vibration and noise at this critical frequency, we must reduce the normal force or the pressure on the plates. In this case, the slipping ratio increases to 4.5% or is equivalent to the slipping ratio at the stable speed of the torque converter. Figure 14 shows that the engine now runs at 1870 rpm and the output sharp runs at 1814 rpm or at roughly 3.5% of slipping ratio.

Figure 14.

Regulation of vibration.

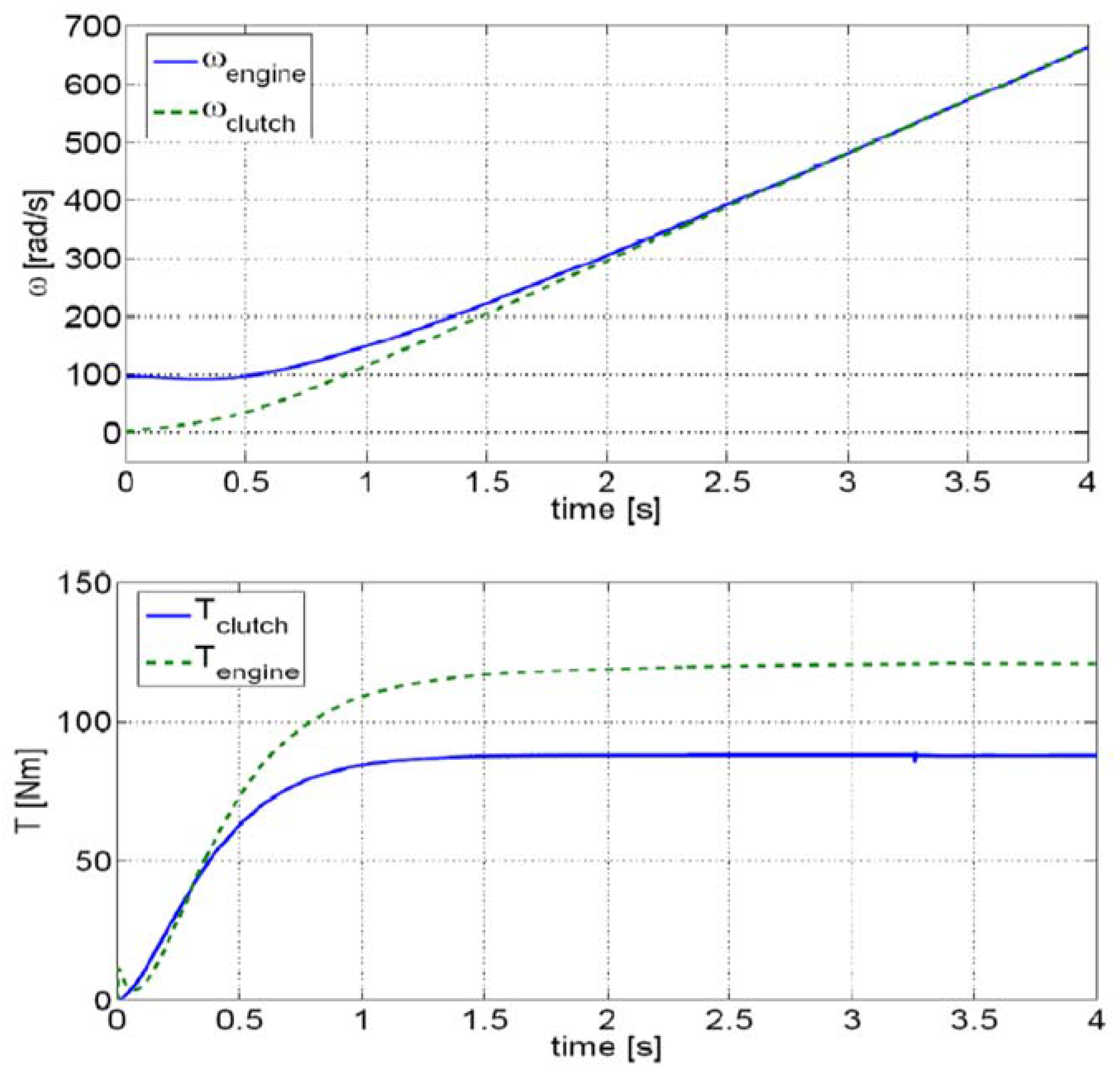

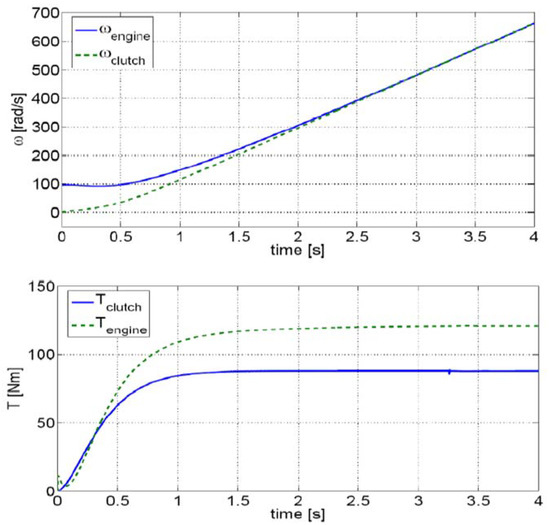

Figure 15 shows that full engagement takes place within 0.9 s when the clutch synchronizes more than 95% of the engine speed. The torque of the engine and the output shaft are kept in a stable condition accordingly.

Figure 15.

Clutch engagement and torque transmission.

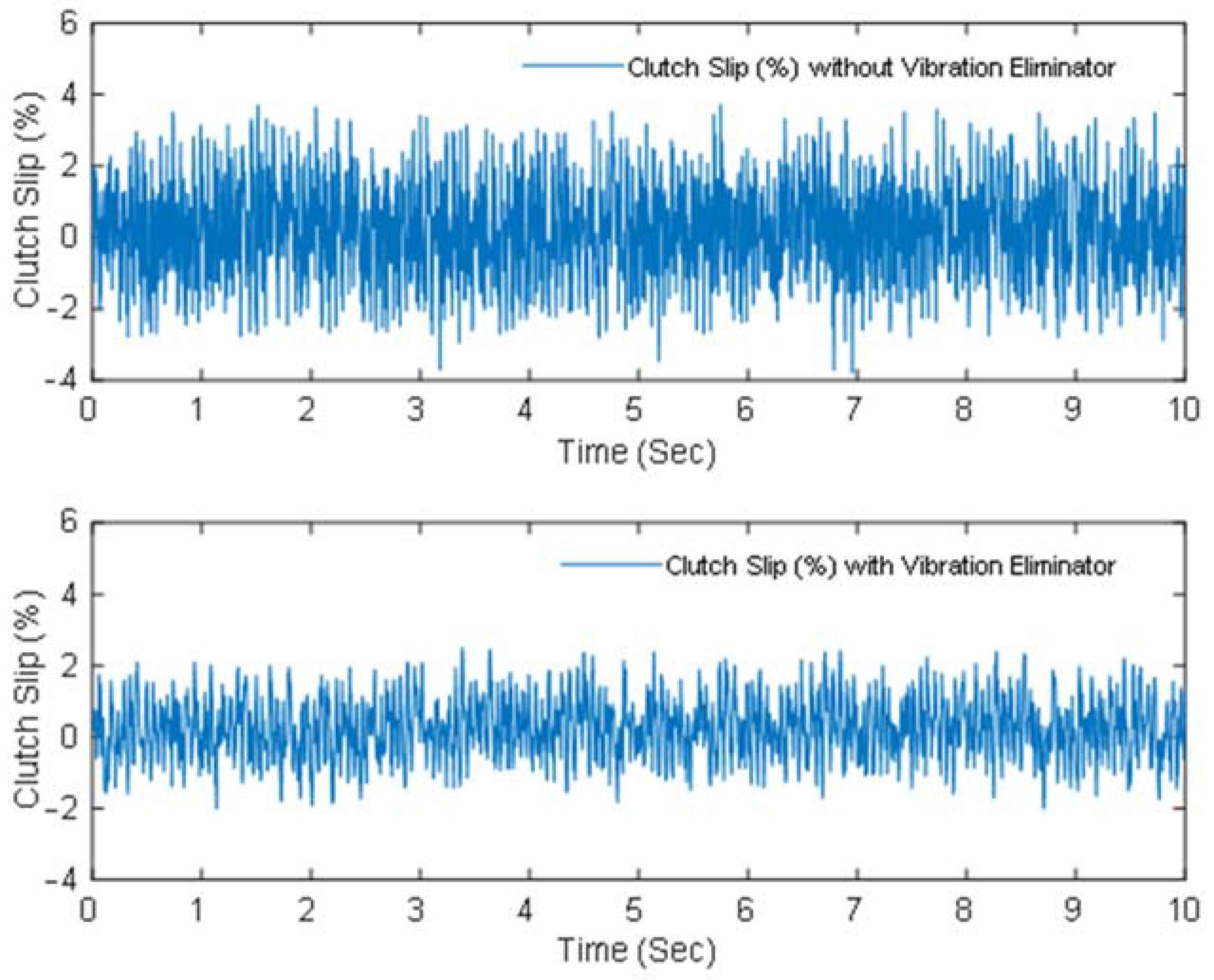

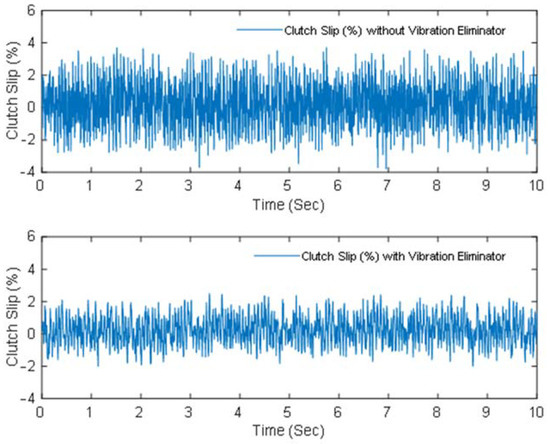

Figure 16 shows the vibration before and after having pressure regulation. At the high speed of 3540 rpm or at 59 Hz, the fuzzy logic clutch controller regulates the normal force and reduce the vibration at this high speed for 70% of vibration amplitude.

Figure 16.

Vibration before and after pressure regulation.

At the critical frequency of 1830 rpm and at high speeds of more than 3540 rpm, the fuzzy logic controller can regulate the normal force for better driving comfortability and lower vibration than the conventional manual transmission clutch system.

6. Conclusions

In this research, a complete fuzzy logic controller for a dry friction clutch is designed for a parallel HEV with a lower cost and a better performance. Simulations show that the dry friction clutch and the fuzzy logic controller can perform faster engagement and higher transmission efficiency than the use of torque converter. At a stable speed, the new system provides a 2% faster speed than the torque converter. Simulations also show that the dry friction clutch with fuzzy logic control can be used to replace torque converters. Experiments with normal force regulation by fuzzy logic control can eliminate the vibration and noise at critical and at high frequencies. The new system can eliminate 70% less noise and vibration than the manual transmission clutch. This research offers novel theoretical and experimental contributions to the development of parallel HEVs in the future.

Author Contributions

Conceptualization, T.M.V.; methodology, T.M.V.; formal analysis, T.M.V. and R.M.; writing—original draft preparation, T.M.V. and R.M.; writing—review and editing, R.M. and J.C.; supervision, J.H. and M.P. All authors have read and agreed to the published version of the manuscript.

Funding

The result was obtained through financial support from the Ministry of Education, Youth and Sports in Czechia and the European Union in the framework of the project “Modular platform for autonomous chassis of specialized electric vehicles for freight and equipment transportation”, Reg. No. CZ.02.1.01/0.0/0.0/16_025/0007293. This work also was partly supported by the Student Grant Scheme at the Technical University of Liberec through project nr. SGS-2021-3059.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data are available from the corresponding author upon request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Tamada, S.; Bhattacharjee, D.; Dan, P.K. Review on automatic transmission control in electric and non-electric automotive powertrain. Int. J. Veh. Perform. 2020, 6, 98–128. [Google Scholar] [CrossRef]

- Singh, K.V.; Bansal, H.O.; Singh, D. A comprehensive review on hybrid electric vehicles: Architectures and components. J. Mod. Transport. 2019, 27, 77–107. [Google Scholar] [CrossRef] [Green Version]

- Yang, C.; Zha, M.; Wang, W.; Liu, K.; Xiang, C. Efficient energy management strategy for hybrid electric vehicles/plug-in hybrid electric vehicles: Review and recent advances under intelligent transportation system. IET Intell. Transp. Syst. 2020, 14, 702–711. [Google Scholar] [CrossRef]

- Tung, S.C.; Woydt, M.; Shah, R. Global Insights on Future Trends of Hybrid/EV Driveline Lubrication and Thermal Management. Front. Mech. Eng. 2020, 6, 74. [Google Scholar] [CrossRef]

- Shi, T.; Zhao, F.; Hao, H.; Liu, Z. Development Trends of Transmissions for Hybrid Electric Vehicles Using an Optimized Energy Management Strategy. Automot. Innov. 2018, 1, 291–299. [Google Scholar] [CrossRef] [Green Version]

- Galvagno, E.; Guercioni, G.; Rizzoni, G.; Velardocchia, M.; Vigliani, A. Effect of engine start and clutch slip losses on the energy management problem of a hybrid DCT powertrain. Int. J. Automot. Technol. 2020, 21, 953–969. [Google Scholar] [CrossRef]

- Zhao, Q.; Zhang, H.; Xin, Y. Research on Control Strategy of Hydraulic Regenerative Braking of Electrohydraulic Hybrid Electric Vehicles. Math. Probl. Eng. 2021, 2021. [Google Scholar] [CrossRef]

- Xu, Q.; Wang, F.; Zhang, X.; Cui, S. Research on the Efficiency Optimization Control of the Regenerative Braking System of Hybrid Electrical Vehicle Based on Electrical Variable Transmission. IEEE Access 2019, 7, 116823–116834. [Google Scholar] [CrossRef]

- Yao, Z.; Yoon, H.S. Control Strategy for Hybrid Electric Vehicle Based on Online Driving Pattern Classification. SAE Int. J. Alt. Power 2019, 8, 91–102. [Google Scholar] [CrossRef]

- Sim, K.; Oh, S.M.; Namkoong, C.; Lee, J.S.; Han, K.S.; Hwang, S.H. Control Strategy of Clutch Engagement during Mode Change of Plug-in Hybrid Electric Vehicle. Int. J. Automot. Technol. 2017, 18, 901–909. [Google Scholar] [CrossRef]

- Wang, S.; Xia, B.; He, C.; Zhang, S.; Shi, D. Mode transition control for single-shaft parallel hybrid electric vehicle using model predictive control approach. Adv. Mech. Eng. 2018, 10, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Robuschi, N.; Zeile, C.; Sager, S.; Braghin, F. Multiphase mixed-integer nonlinear optimal control of hybrid electric vehicles. Automatica 2021, 123, 109325. [Google Scholar] [CrossRef]

- Wróblewski, P.; Kupiec, J.; Drozdz, W.; Lewicki, W.; Jaworski, J. The Economic Aspect of Using Different Plug-In Hybrid Driving Techniques in Urban Conditions. Energies 2021, 14, 3543. [Google Scholar] [CrossRef]

- He, R.; Yan, Y.; Hu, D. Optimised adaptive control methodology for mode transition of hybrid electric vehicle based on the dynamic characteristics analysis. Veh. Syst. Dyn. 2021, 59, 1282–1303. [Google Scholar] [CrossRef]

- Elzaghir, W.; Zhang, Y.; Natarajan, N.; Massey, F.; Mi, C. Control of a hybrid electric vehicle with dual clutch transmission configurations during mode transition. Int. J. Electr. Hybrid Veh. 2018, 10, 1–25. [Google Scholar] [CrossRef]

- Kim, S.; Choi, S.B. Cooperative Control of Drive Motor and Clutch for Gear Shift of Hybrid Electric Vehicles with Dual-Clutch Transmission. ASME Trans. Mechatron. 2020, 25, 1578–1588. [Google Scholar] [CrossRef]

- Ning, J.; Zhu, G.; Qu, B. Development of a engine start control method for P2 hybrid vehicles in launch situation. IFAC PapersOnLine 2018, 51, 7–10. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, J.; Huang, J.; Yin, C.; Wang, L. Optimal Speed Regulation Control of the Hybrid Dual Clutch Transmission Shift Process. World Electr. Veh. J. 2020, 11, 11. [Google Scholar] [CrossRef] [Green Version]

- Cao, X.; Du, C.; Yan, F.; Xu, H.; He, B.; Sui, Y. Parameter Optimization of Dual Clutch Transmission for an Axle-split Hybrid Electric Vehicle. IFAC PapersOnLine 2019, 52, 423–430. [Google Scholar] [CrossRef]

- Wang, S.; Liu, Y.; Cai, T. Clutch Control Strategy of Driving Mode Transition for P2 Hybrid Electric Vehicle. IOP Conf. Ser. Mater. Sci. Eng. 2019, 470, 012003. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, X.; Yang, J.; Yang, W. Shift Strategy Optimization for Automatic Transmission of Heavy Trucks Based on Dynamic Programming Algorithm. Appl. Sci. 2021, 11, 5555. [Google Scholar] [CrossRef]

- Ding, J.; Jiao, X. A Novel Control Method of Clutch During Mode Transition of Single-Shaft Parallel Hybrid Electric Vehicles. Electronics 2020, 9, 54. [Google Scholar] [CrossRef] [Green Version]

- Bang, J.S.; Choi, S.H.; Ko, Y.K.; Kim, T.S.; Kim, S. The Engine Clutch Engagement Control for Hybrid Electric Vehicles. In Proceedings of the 2018 IEEE Conference on Control Technology and Applications (CCTA), Copenhagen, Denmark, 21–24 August 2018; pp. 1448–1453. [Google Scholar]

- Song, M.; Wang1, H.; Liu, H.; Peng, P.; Wang, X.; Pi, D.; Yang, C.; He, G. Double-layer Control of an Automatic Mechanical Transmission Clutch during Commercial Vehicle Start-up. J. Mech. Eng. 2019, 65, 515–524. [Google Scholar] [CrossRef]

- Liu, Y.; Xie, J.; Qin, D.; Zhang, Y.; Chen, Z.; Li, G.; Zhang, Y. Design, Control and Validation of Two-Speed Clutch-less Automatic Transmission for Electric Vehicle. IEEE/ASME Trans. Mechatron. 2021, 1–11. [Google Scholar]

- Minh, V.T.; Pumwa, J. Feasible Path Planning for Autonomous Vehicles. Math. Probl. Eng. 2014, 2014. [Google Scholar] [CrossRef]

- Minh, V.T.; Mohd Hashim, F.B.; Awang, M. Development of a real-time clutch transition strategy for a parallel hybrid electric vehicle. Proc. Inst. Mech. Eng. Part I J. Syst. Control. Eng. 2012, 226, 188–203. [Google Scholar] [CrossRef]

- Minh, V.T.; Afzulpurkar, N.; Muhamad, W.W. Fault detection model-based controller for process systems. Asian J. Control. 2011, 13, 382–397. [Google Scholar] [CrossRef]

- Minh, V.T.; Hashim, F.B.M. Tracking setpoint robust model predictive control for input saturated and softened state constraints. Int. J. Control. Autom. Syst. 2011, 9, 958–965. [Google Scholar] [CrossRef]

- Minh, V.T.; Afzulpurkar, N.; Muhamad, W.M.W. Fault detection and control of process systems. Math. Probl. Eng. 2007, 2007, 080321. [Google Scholar] [CrossRef]

- Minh, V.T.; Moezzi, R.; Dhoska, K.; Pumwa, J. Model Predictive Control for Autonomous Vehicle Tracking. Int. J. Innov. Technol. Interdiscip. Sci. 2021, 4, 560–603. [Google Scholar]

- Ovchinnikov, I.; Kovalenko, P. Predictive Control Model to Simulate Humanoid Gait: Predictive Control Model to Simulate Humanoid Gait. Int. J. Innov. Technol. Interdiscip. Sci. 2019, 1, 9–17. [Google Scholar]

- Pumwa, J. Time Variant Predictive Control of Autonomous Vehicles: Time Variant Predictive Control of Autonomous Vehicles. Int. J. Innov. Technol. Interdiscip. Sci. 2019, 2, 62–77. [Google Scholar]

- Minh, V.T. Advanced Vehicle Dynamics; Universiti of Malaya Press: Kuala Lumpur, Malaysia, 2012; 265p. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).