Long-Term Performance Analysis Using TRNSYS Software of Hybrid Systems with PV-T

Abstract

:1. Introduction

2. Materials and Methods

2.1. Location and Meteorological Data

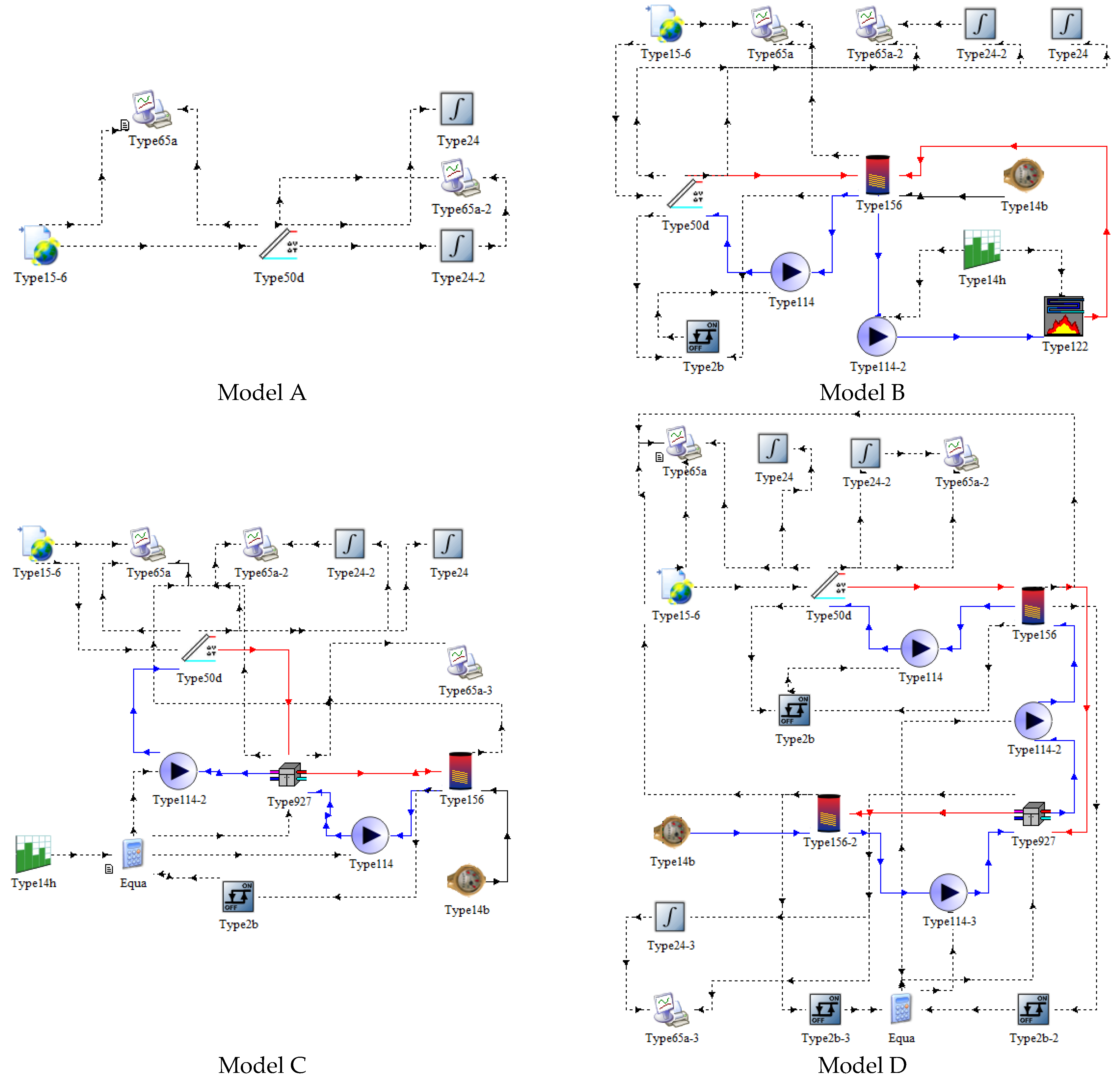

2.2. Transient Models with PV-T

2.3. Parameters of PV-T

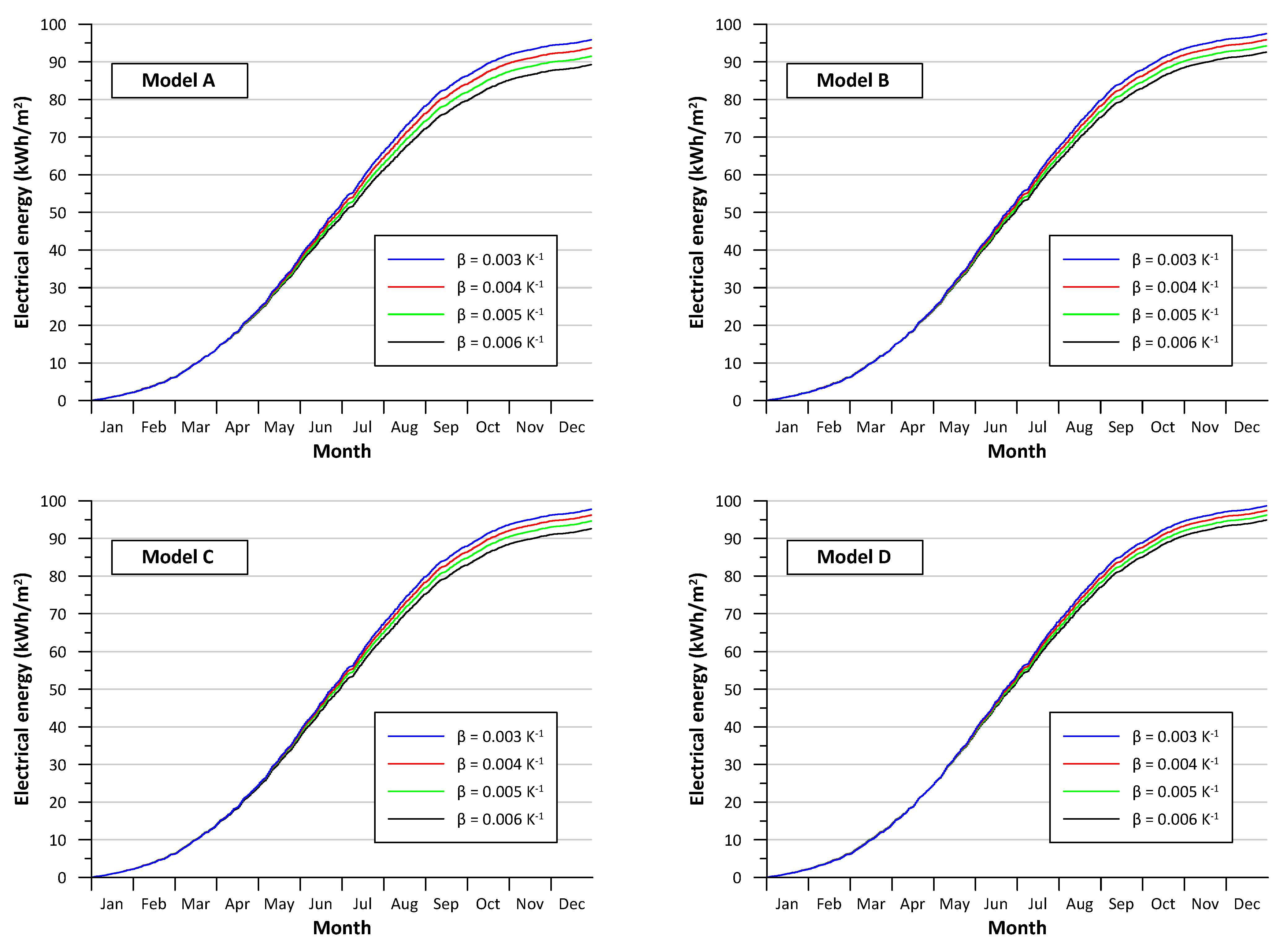

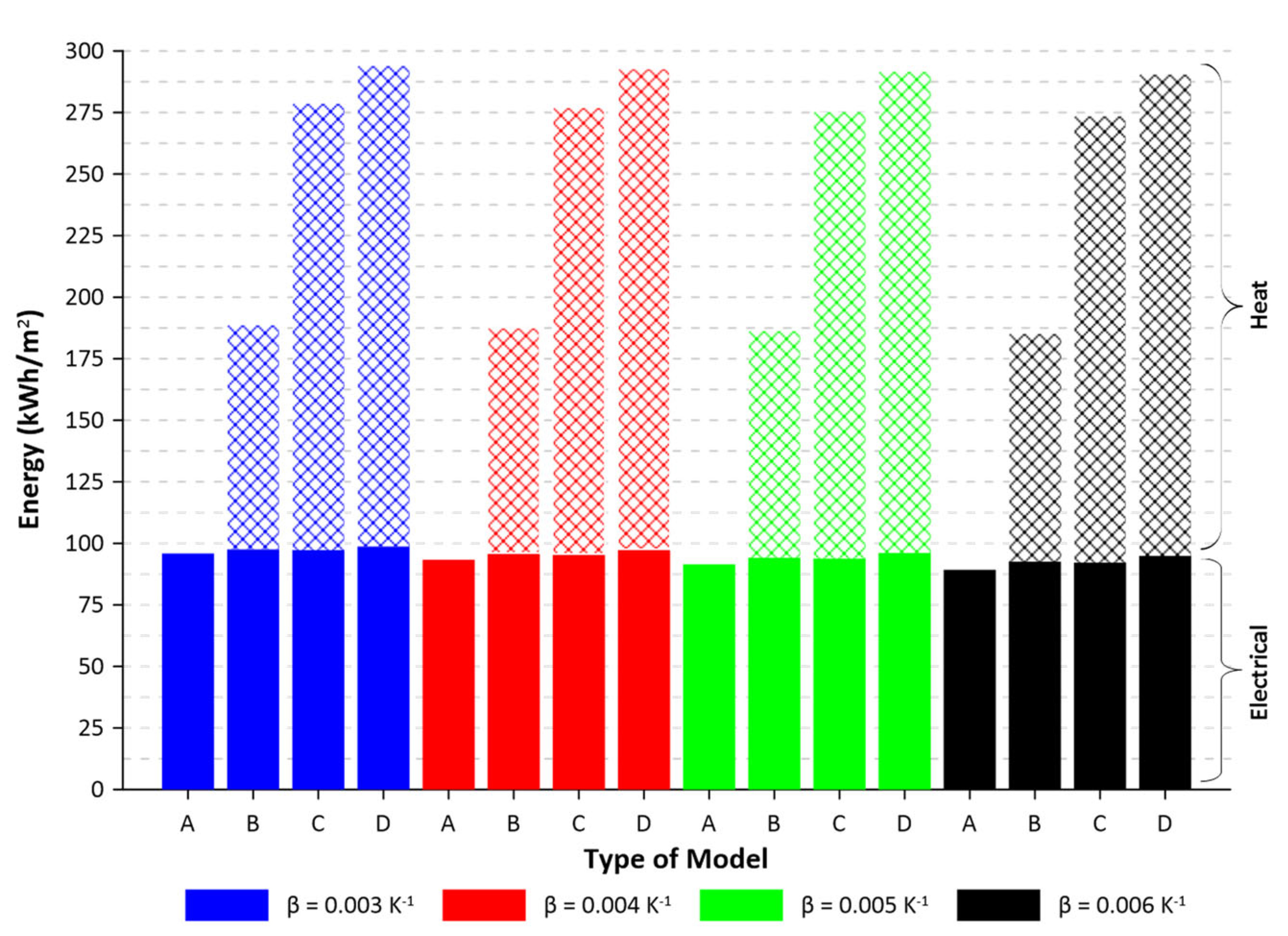

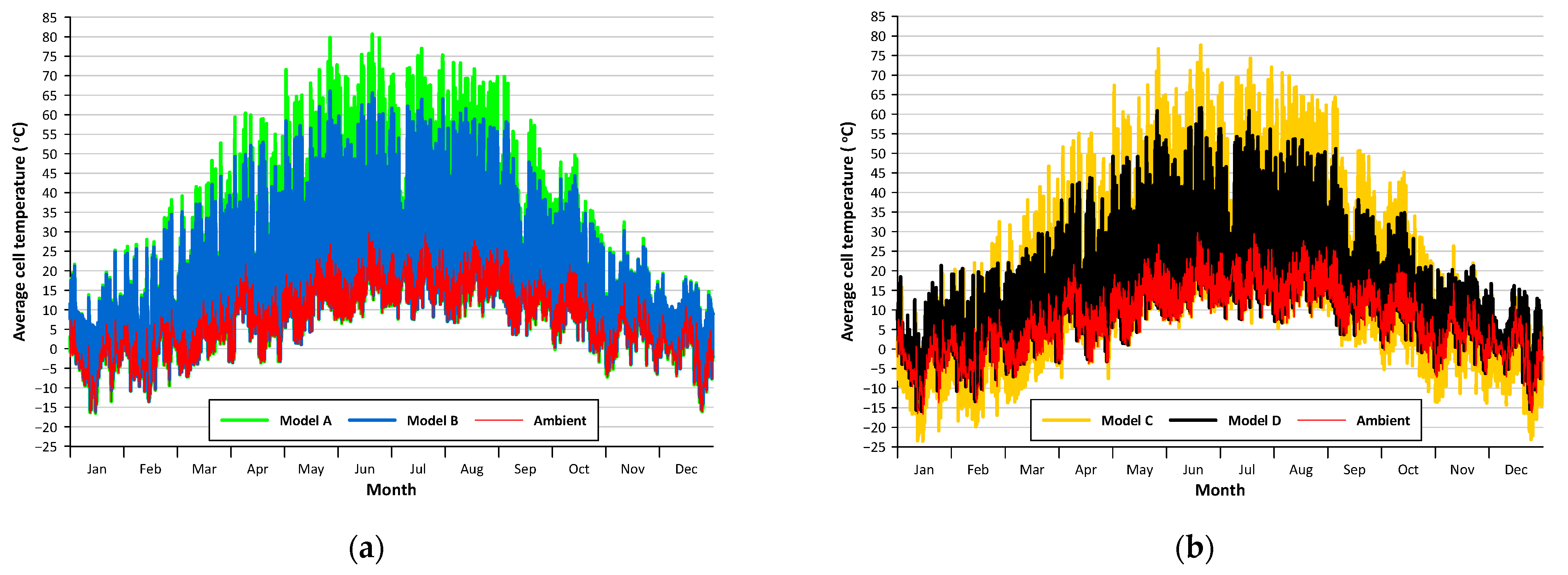

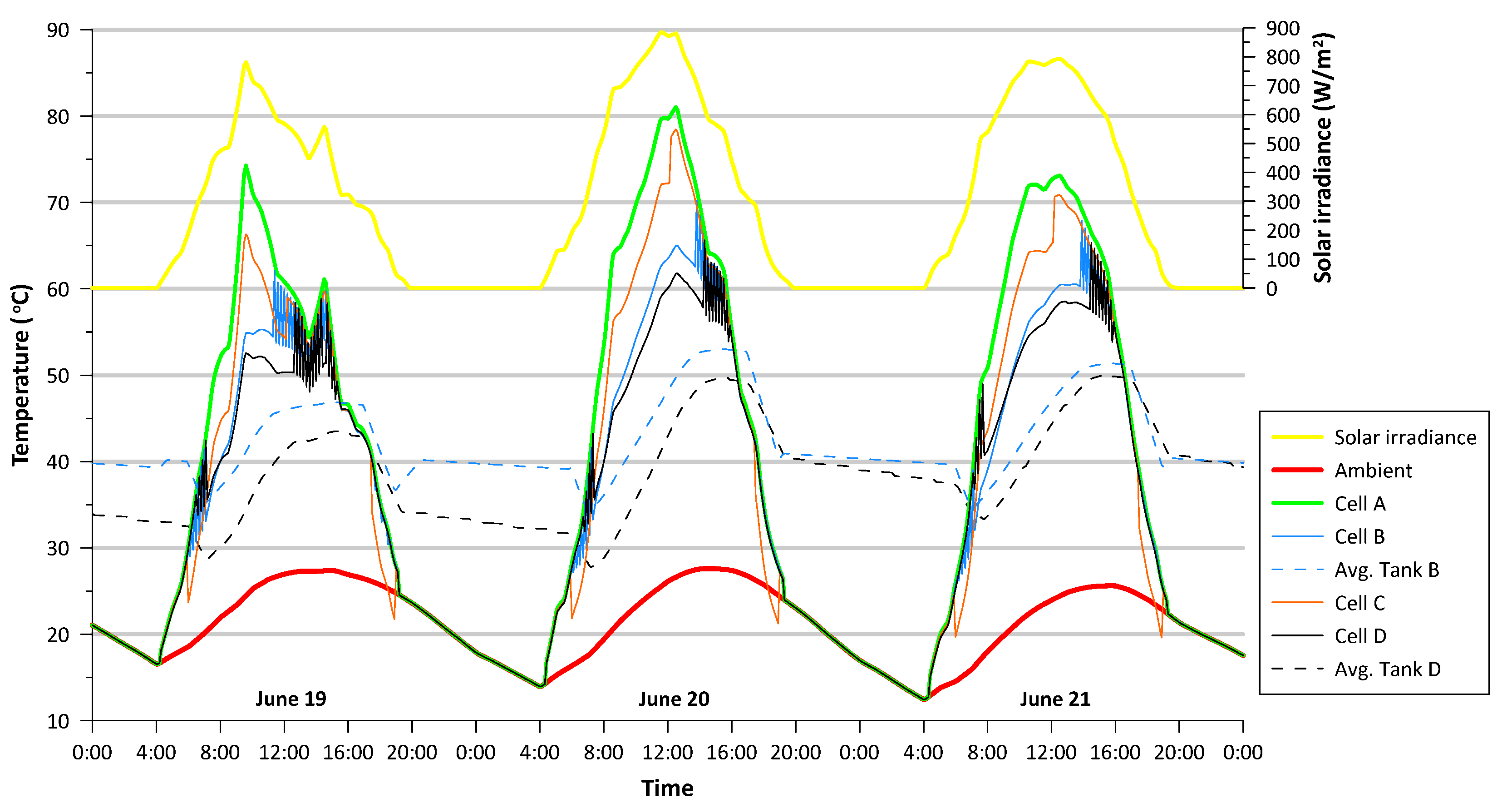

3. Results and Discussion

4. Conclusions

- The absence of heat received from the solar fluid, particularly in the summer period, leads to cell temperatures even several times higher than the outside temperature;

- Models C and D, in which the PV-T cooperated with a heat pump, allow for obtaining more heat and electricity from the PV-T in the long run than Model B, in which heat energy from the PV-T is transferred directly to the DHW tank;

- Intensification of the heat collection process from the PV-T using a heat pump resulted in an increase in electricity production by 6% compared to the base model A.

- For each installation model, the highest values of electricity production were obtained for K−1, and the lowest—for K−1.

- The type of cell used may reduce the production of electricity from PV-T by up to 7% on an annual basis.

- In temperate oceanic climate (Dfb sub-group in Köppen–Geiger climate classification system) the highest impact of on electricity production in PV-T is visible in the months from May to September, i.e., during the highest daily total horizontal radiation achieved and the highest air temperatures.

- A key element to improve the efficiency of the heat pump and increase the value of the seasonal COP is the appropriate adjustment of the devices in the hybrid installation.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Temperature coefficient, K−1 | |

| COP | Coefficient Of Performance |

| DHW | Domestic Hot Water |

| PV electrical efficiency | |

| is the module’s electrical efficiency at the reference temperature | |

| PV | Photovoltaic Panels |

| PV-T | hybrid PhotoVoltaic-Thermal collector |

| STC | Standard Test Conditions |

| PV cell temperature | |

| reference temperature |

Appendix A

| Component | Short Description |

|---|---|

| Equa | The equations statement allows variables to be defined as algebraic functions of constants, previously defined variables, and outputs. |

| Type 2b | Differential controller generates a control function (1 or 0) chosen as a function of the difference between upper and lower temperatures, compared with two dead band temperature differences. |

| Type14b | The time-dependent forcing function specifies the value of the water drawn at various times throughout one cycle. |

| Type14h | Time-dependent forcing function has a behavior characterized by a repeated pattern. It is responsible for PV-T working priority during the day. |

| Type 15-6 | Weather data processor allows reading data at regular time intervals from an external weather data file and making it available to other TRNSYS components. |

| Type 24 | This component integrates a series of specified quantities over a period of time. |

| Type 50d | It simulates a PV-T with high complexity in the heat losses calculation. |

| Type 65a | The online graphics component displays chosen system variables during the simulation. Additionally, data sent to the online plotter are automatically once per time step saved in a defined external file. |

| Type 114 | These component models a single (constant) speed pump that is able to maintain a constant fluid outlet mass flow rate. |

| Type 122 | This component models a fluid boiler (auxiliary heater). |

| Type 156 | It simulates a fluid-filled, vertical, cylindrical, constant volume storage tank with an immersed coiled-tube heat exchanger. |

| Type 927 | These component models a single-stage water-to-water heat pump based on user-supplied data. |

References

- Herez, A.; El Hage, H.; Lemenand, T.; Ramadan, M.; Khaled, M. Review on photovoltaic/thermal hybrid solar collectors: Classifications, applications and new systems. Sol. Energy 2020, 207, 1321–1347. [Google Scholar] [CrossRef]

- Pietrzak, M.B.; Igliński, B.; Kujawski, W.; Iwański, P. Energy Transition in Poland—Assessment of the Renewable Energy Sector. Energies 2021, 14, 2046. [Google Scholar] [CrossRef]

- Canales, F.A.; Jadwiszczak, P.; Jurasz, J.; Wdowikowski, M.; Ciapała, B.; Kaźmierczak, B. The impact of long-term changes in air temperature on renewable energy in Poland. Sci. Total Environ. 2020, 729, 138965. [Google Scholar] [CrossRef] [PubMed]

- Pounraj, P.; Prince Winston, D.; Kabeel, A.E.; Praveen Kumar, B.; Manokar, A.M.; Sathyamurthy, R.; Christabel, S.C. Experimental investigation on Peltier based hybrid PV/T active solar still for enhancing the overall performance. Energy Convers. Manag. 2018, 168, 371–381. [Google Scholar] [CrossRef]

- Calise, F.; Figaj, R.; Vanoli, L. Experimental and Numerical Analyses of a Flat Plate Photovoltaic/Thermal Solar Collector. Energies 2017, 10, 491. [Google Scholar] [CrossRef] [Green Version]

- Lämmle, M.; Hermann, M.; Kramer, K.; Panzer, C.; Piekarczyk, A.; Thoma, C.; Fahr, S. Development of highly efficient, glazed PVT collectors with overheating protection to increase reliability and enhance energy yields. Sol. Energy 2018, 176, 87–97. [Google Scholar] [CrossRef]

- Chow, T.T. Performance analysis of photovoltaic-thermal collector by explicit dynamic model. Sol. Energy 2003, 75, 143–152. [Google Scholar] [CrossRef]

- Barbu, M.; Darie, G.; Siroux, M. A Parametric Study of a Hybrid Photovoltaic Thermal (PVT) System Coupled with a Domestic Hot Water (DHW) Storage Tank. Energies 2020, 13, 6481. [Google Scholar] [CrossRef]

- Bandaru, S.H.; Becerra, V.; Khanna, S.; Radulovic, J.; Hutchinson, D.; Khusainov, R. A Review of Photovoltaic Thermal (PVT) Technology for Residential Applications: Performance Indicators, Progress, and Opportunities. Energies 2021, 14, 3853. [Google Scholar] [CrossRef]

- Ul Abdin, Z.; Rachid, A. A Survey on Applications of Hybrid PV/T Panels. Energies 2021, 14, 1205. [Google Scholar] [CrossRef]

- Fu, Z.; Li, Y.; Liang, X.; Lou, S.; Qiu, Z.; Cheng, Z.; Zhu, Q. Experimental investigation on the enhanced performance of a solar PVT system using micro-encapsulated PCMs. Energy 2021, 228, 120509. [Google Scholar] [CrossRef]

- Klugmann-Radziemska, E.; Wcisło-Kucharek, P. Photovoltaic module temperature stabilization with the use of phase change materials. Sol. Energy 2017, 150, 538–545. [Google Scholar] [CrossRef]

- Hemmat Esfe, M.; Kamyab, M.H.; Valadkhani, M. Application of nanofluids and fluids in photovoltaic thermal system: An updated review. Sol. Energy 2020, 199, 796–818. [Google Scholar] [CrossRef]

- Abbas, N.; Awan, M.B.; Amer, M.; Ammar, S.M.; Sajjad, U.; Ali, H.M.; Zahra, N.; Hussain, M.; Badshah, M.A.; Jafry, A.T. Applications of nanofluids in photovoltaic thermal systems: A review of recent advances. Phys. A Stat. Mech. Its Appl. 2019, 536, 122513. [Google Scholar] [CrossRef]

- Adun, H.; Mukhtar, M.; Adedeji, M.; Agwa, T.; Ibrahim, K.H.; Bamisile, O.; Dagbasi, M. Synthesis and application of ternary nanofluid for photovoltaic-thermal system: Comparative analysis of energy and exergy performance with single and hybrid nanofluids. Energies 2021, 14, 4434. [Google Scholar] [CrossRef]

- Sakellariou, E.I.; Wright, A.J.; Axaopoulos, P.; Oyinlola, M.A. PVT based solar assisted ground source heat pump system: Modelling approach and sensitivity analyses. Sol. Energy 2019, 193, 37–50. [Google Scholar] [CrossRef]

- Jonas, D.; Lämmle, M.; Theis, D.; Schneider, S.; Frey, G. Performance modeling of PVT collectors: Implementation, validation and parameter identification approach using TRNSYS. Sol. Energy 2019, 193, 51–64. [Google Scholar] [CrossRef]

- Rezvanpour, M.; Borooghani, D.; Torabi, F.; Pazoki, M. Using CaCl2·6H2O as a phase change material for thermo-regulation and enhancing photovoltaic panels’ conversion efficiency: Experimental study and TRNSYS validation. Renew. Energy 2020, 146, 1907–1921. [Google Scholar] [CrossRef]

- Zarrella, A.; Emmi, G.; Vivian, J.; Croci, L.; Besagni, G. The validation of a novel lumped parameter model for photovoltaic thermal hybrid solar collectors: A new TRNSYS type. Energy Convers. Manag. 2019, 188, 414–428. [Google Scholar] [CrossRef]

- Atmaca, M.; Pektemir, İ.Z. An Investigation on the Effect of the Total Efficiency of Water and Air Used Together as a Working Fluid in the Photovoltaic Thermal Systems. Processes 2019, 7, 516. [Google Scholar] [CrossRef] [Green Version]

- Khalili, N.N.W.; Othman, M.; Abu Bakar, M.N.; Abdullah, L. Modelling of a Single Passage Air PV/T Solar Collector: Experimental and Simulation Design. Processes 2020, 8, 763. [Google Scholar] [CrossRef]

- Pater, S. Field measurements and energy performance analysis of renewable energy source devices in a heating and cooling system in a residential building in southern Poland. Energy Build. 2019, 199, 115–125. [Google Scholar] [CrossRef]

- Mazzeo, D.; Oliveti, G.; Baglivo, C.; Congedo, P.M. Energy reliability-constrained method for the multi-objective optimization of a photovoltaic-wind hybrid system with battery storage. Energy 2018, 156, 688–708. [Google Scholar] [CrossRef]

- He, W.; Tao, L.; Han, L.; Sun, Y.; Campana, P.E.; Yan, J. Optimal analysis of a hybrid renewable power system for a remote island. Renew. Energy 2021, 179, 96–104. [Google Scholar] [CrossRef]

- Ammari, C.; Belatrache, D.; Touhami, B.; Makhloufi, S. Sizing, optimization, control and energy management of hybrid renewable energy system—A review. Energy Built Environ. 2021. [Google Scholar] [CrossRef]

- Tripathi, R.; Bhatti, T.S.; Tiwari, G.N. Effect of packing factor on electrical and overall energy generation through low concentrated photovoltaic thermal collector in composite climate condition. Mater. Today Proc. 2020, 31, 449–453. [Google Scholar] [CrossRef]

- Ji, J.; Han, J.; Chow, T.T.; Yi, H.; Lu, J.; He, W.; Sun, W. Effect of fluid flow and packing factor on energy performance of a wall-mounted hybrid photovoltaic/water-heating collector system. Energy Build. 2006, 38, 1380–1387. [Google Scholar] [CrossRef]

- Farghally, H.M.; Ahmed, N.M.; El-Madany, H.T.; Atia, D.M.; Fahmy, F.H. Design and Sensitivity Analysis of Photovoltaic/Thermal Solar Collector. Int. Energy J. 2015, 15, 21–32. [Google Scholar]

- Pokorny, N.; Matuška, T. Glazed photovoltaic-thermal (PVT) collectors for domestic hotwater preparation in multifamily building. Sustainability 2020, 12, 6071. [Google Scholar] [CrossRef]

- Myhan, R.; Szturo, K.; Panfil, M.; Szwejkowski, Z. The Influence of Weather Conditions on the Optimal Setting of Photovoltaic Thermal Hybrid Solar Collectors—A Case Study. Energies 2020, 13, 4612. [Google Scholar] [CrossRef]

- Piliougine, M.; Oukaja, A.; Sidrach-de-Cardona, M.; Spagnuolo, G. Temperature coefficients of degraded crystalline silicon photovoltaic modules at outdoor conditions. Prog. Photovolt. Res. Appl. 2021, 29, 558–570. [Google Scholar] [CrossRef]

- Kamkird, P.; Ketjoy, N.; Rakwichian, W.; Sukchai, S. Investigation on Temperature Coefficients of Three Types Photovoltaic Module Technologies under Thailand Operating Condition. Procedia Eng. 2012, 32, 376–383. [Google Scholar] [CrossRef] [Green Version]

- Dupré, O.; Vaillon, R.; Green, M.A. Physics of the temperature coefficients of solar cells. Sol. Energy Mater. Sol. Cells 2015, 140, 92–100. [Google Scholar] [CrossRef]

- Smith, P. Study of temperature coefficients for parameters of photovoltaic cells. Int. J. Photoenergy 2018, 2018, 77–86. [Google Scholar] [CrossRef] [Green Version]

- Dubey, S.; Sarvaiya, J.N.; Seshadri, B. Temperature Dependent Photovoltaic (PV) Efficiency and Its Effect on PV Production in the World—A Review. Energy Procedia 2013, 33, 311–321. [Google Scholar] [CrossRef] [Green Version]

- Solar Energy Laboratory. Volume 3 Component Library Overview. In Trnsys 18-a. TRaNsient SYstem Simulation Program; University of Wisconsin-Madison and Thermal Energy System Specialists: Madison, WI, USA, 2017. [Google Scholar]

- Solar Energy Laboratory. Volume 4 Mathematical Reference. In Trnsys 18-a. TRaNsient SYstem Simulation Program; University of Wisconsin-Madison and Thermal Energy System Specialists: Madison, WI, USA, 2017. [Google Scholar]

| Parameters | Value | Unit |

|---|---|---|

| Collector area | 6 | m2 |

| Collector efficiency factor | 0.7 | - |

| Collector plate absorptance | 0.9 | - |

| Number of glass covers | 1 | - |

| Loss coefficient for bottom and edge losses | 5.56 | W/(m2·K) |

| Collector slope | 34 | ° |

| Packing factor | 0.6 | - |

| Cell efficiency at reference conditions | 0.2 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pater, S. Long-Term Performance Analysis Using TRNSYS Software of Hybrid Systems with PV-T. Energies 2021, 14, 6921. https://doi.org/10.3390/en14216921

Pater S. Long-Term Performance Analysis Using TRNSYS Software of Hybrid Systems with PV-T. Energies. 2021; 14(21):6921. https://doi.org/10.3390/en14216921

Chicago/Turabian StylePater, Sebastian. 2021. "Long-Term Performance Analysis Using TRNSYS Software of Hybrid Systems with PV-T" Energies 14, no. 21: 6921. https://doi.org/10.3390/en14216921

APA StylePater, S. (2021). Long-Term Performance Analysis Using TRNSYS Software of Hybrid Systems with PV-T. Energies, 14(21), 6921. https://doi.org/10.3390/en14216921