The Use of Multivariate Data Analysis (HCA and PCA) to Characterize Ashes from Biomass Combustion

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Examination of Ash Composition

2.3. Statistical Analyses

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jasinskas, A.; Mieldažys, R.; Jotautienė, E.; Domeika, R.; Vaiciukevičius, E.; Marks, M. Technical, Environmental, and Qualitative Assessment of the Oak Waste Processing and Its Usage for Energy Conversion. Sustainability 2020, 12, 8113. [Google Scholar] [CrossRef]

- Jandačka, J.; Holubčík, M. Emissions Production from Small Heat Sources Depending on Various Aspects. Mob. Netw. Appl. 2020, 25, 904–912. [Google Scholar] [CrossRef]

- Yao, X.; Zhao, Z.; Li, J.; Zhang, B.; Zhou, H.; Xu, K. Experimental Investigation of Physicochemical and Slagging Characteristics of Inorganic Constituents in Ash Residues from Gasification of Different Herbaceous Biomass. Energy 2020, 198, 117367. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An Overview of the Composition and Application of Biomass Ash.: Part 2. Potential Utilisation, Technological and Ecological Advantages and Challenges. Fuel 2013, 105, 19–39. [Google Scholar] [CrossRef]

- Zając, G.; Szyszlak-Bargłowicz, J.; Dudziak, A.; Kuranc, A.; Wasilewski, J. Ash Composition and Deposition Tendencies of Selected Biomass Types; Department of Machinery Exploitation and Management of Production Processes: Lublin, Poland, 2017; ISBN 839374332X. [Google Scholar]

- Zając, G.; Szyszlak-Bargłowicz, J.; Szczepanik, M. Influence of Biomass Incineration Temperature on the Content of Selected Heavy Metals in the Ash Used for Fertilizing Purposes. Appl. Sci. 2019, 9, 1790. [Google Scholar] [CrossRef] [Green Version]

- Jandacka, J.; Caban, J.; Nieoczym, A.; Holubcik, M.; Vrabel, J. Possibilities of Using Wood Waste for the Production of Fuel Briquettes. PRZEMYSL Chem. 2021, 100, 367–374. [Google Scholar]

- Carević, I.; Baričević, A.; Štirmer, N.; Šantek Bajto, J. Correlation between Physical and Chemical Properties of Wood Biomass Ash and Cement Composites Performances. Constr. Build. Mater. 2020, 256, 119450. [Google Scholar] [CrossRef]

- Munawar, M.A.; Khoja, A.H.; Naqvi, S.R.; Mehran, M.T.; Hassan, M.; Liaquat, R.; Dawood, U.F. Challenges and Opportunities in Biomass Ash Management and Its Utilization in Novel Applications. Renew. Sustain. Energy Rev. 2021, 150, 111451. [Google Scholar] [CrossRef]

- Ciesielczuk, T.; Kusza, G.; Nems, A. Fertilization with Biomass Ashes as a Source of Trace Elements for Soils. Environ. Prot. Nat. Resour. 2011, 49, 219–227. [Google Scholar]

- Maschowski, C.; Zangna, M.C.; Trouvé, G.; Gieré, R. Bottom Ash of Trees from Cameroon as Fertilizer. Appl. Geochem. 2016, 72, 88–96. [Google Scholar] [CrossRef]

- Pesonen, J.; Kuokkanen, V.; Kuokkanen, T.; Illikainen, M. Co-Granulation of Bio-Ash with Sewage Sludge and Lime for Fertilizer Use. J. Environ. Chem. Eng. 2016, 4, 4817–4821. [Google Scholar] [CrossRef]

- Schiemenz, K.; Eichler-Löbermann, B. Biomass Ashes and Their Phosphorus Fertilizing Effect on Different Crops. Nutr. Cycl. Agroecosys. 2010, 87, 471–482. [Google Scholar] [CrossRef] [Green Version]

- Meller, E.; Bilenda, E. Effects of Biomass Ash on the Physicochemical Properties of Light Soil. Energy Policy J. 2012, 15, 287–292. [Google Scholar]

- Poluszyńska, J.; Ślęzak, E. Characteristics of Fly Ash from the Combustion of Biomass as Stabilizer of Sewage Sludge. Sci. Works Inst. Ceram. Build. Mater. 2015, 8, 71–78. [Google Scholar]

- Haustein, E.; Grabarczyk, L. The Biomass and Coal Co-Incineration Impacts on the Selected Properties of Fly Ashes. Energy Policy J. 2012, 15, 87–101. [Google Scholar]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An Overview of the Composition and Application of Biomass Ash. Part 1. Phase–Mineral and Chemical Composition and Classification. Fuel 2013, 105, 40–76. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G.; Baxter, D. Trace Element Concentrations and Associations in Some Biomass Ashes. Fuel 2014, 129, 292–313. [Google Scholar] [CrossRef]

- Zając, G.; Szyszlak-Bargłowicz, J.; Gołębiowski, W.; Szczepanik, M. Chemical Characteristics of Biomass Ashes. Energies 2018, 11, 2885. [Google Scholar] [CrossRef] [Green Version]

- Eriksson, J.-E.; Khazraie, T.; Hupa, L. Different Methods for the Characterization of Ash Compositions in Co-Firing Boilers; Springer: Berlin/Heidelberg, Germany, 2018; pp. 253–263. [Google Scholar]

- Izenman, A.J. Modern Multivariate Statistical Techniques; Springer Texts in Statistics; Springer: New York, NY, USA, 2008. [Google Scholar]

- Jolliffe, I.T.; Cadima, J. Principal Component Analysis: A Review and Recent Developments. Philos. Trans. R. Soc. Math. Phys. Eng. Sci. 2016, 374, 20150202. [Google Scholar] [CrossRef] [PubMed]

- Tabachnick, B.G.; Fidell, L.S. Using Multivariate Statistics, 7th ed.; Pearson: Boston, MA, USA, 2019; Volume 5. [Google Scholar]

- Trendafilov, N.; Gallo, M. Principal component analysis (PCA). In Multivariate Data Analysis on Matrix Manifolds: (With Manopt); Trendafilov, N., Gallo, M., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 89–139. ISBN 978-3-030-76974-1. [Google Scholar]

- Strandberg, A.; Holmgren, P.; Broström, M. Predicting Fuel Properties of Biomass Using Thermogravimetry and Multivariate Data Analysis. Fuel Process. Technol. 2017, 156, 107–112. [Google Scholar] [CrossRef]

- de Paula Protásio, T.; Bufalino, L.; Junior, M.G.; Tonoli, G.H.D.; Trugilho, P.F. Multivariate Techniques Applied to Evaluation of Lignocellulosic Residues for Bioenergy Production. Ciênc. Florest. 2013, 23, 771–781. [Google Scholar]

- Sgarbossa, A.; Costa, C.; Menesatti, P.; Antonucci, F.; Pallottino, F.; Zanetti, M.; Grigolato, S.; Cavalli, R. A Multivariate SIMCA Index as Discriminant in Wood Pellet Quality Assessment. Renew. Energy 2015, 76, 258–263. [Google Scholar] [CrossRef]

- Tao, G.; Lestander, T.A.; Geladi, P.; Xiong, S. Biomass Properties in Association with Plant Species and Assortments I: A Synthesis Based on Literature Data of Energy Properties. Renew. Sustain. Energy Rev. 2012, 16, 3481–3506. [Google Scholar] [CrossRef]

- Jolliffe, I.T. (Ed.) Principal Component Analysis for Time Series and Other Non-Independent Data. In Principal Component Analysis; Springer Series in Statistics; Springer: New York, NY, USA, 2002; pp. 299–337. ISBN 978-0-387-22440-4. [Google Scholar]

- Yeomans, K.A.; Golder, P.A. The Guttman-Kaiser Criterion as a Predictor of the Number of Common Factors. J. R. Stat. Soc. Ser. Stat. 1982, 31, 221–229. [Google Scholar] [CrossRef]

- Voshell, S.; Mäkelä, M.; Dahl, O. A Review of Biomass Ash Properties towards Treatment and Recycling. Renew. Sustain. Energy Rev. 2018, 96, 479–486. [Google Scholar] [CrossRef]

| Biomass | Moisture | Ash | VM | C | H | N |

|---|---|---|---|---|---|---|

| % | ||||||

| Miscanthus | 6.53 ± 0.04 | 2.98 ± 0.05 | 71.9 ± 0.1 | 43.1 ± 0.1 | 6.53 ± 0.03 | 0.53 ± 0.04 |

| Oak | 5.58 ± 0.05 | 0.25 ± 0.02 | 74.6 ± 0.2 | 46.3 ± 0.1 | 6.42 ± 0.01 | 0.11 ± 0.02 |

| Pine | 4.11 ± 0.05 | 0.52 ± 0.06 | 73.4 ± 0.2 | 48.1 ± 0.1 | 4.11 ± 0.05 | 0.12 ± 0.03 |

| Sunflower husk | 7.79 ± 0.09 | 2.91 ± 0.05 | 69.5 ± 0.2 | 43.6 ± 0.3 | 6.42 ± 0.09 | 1.67 ± 0.07 |

| Wheat straw | 6.25 ± 0.07 | 2.97 ± 0.04 | 73.5 ± 0.3 | 43.5 ± 0.2 | 5.24 ± 0.03 | 0.52 ± 0.07 |

| Willow | 6.82 ± 0.04 | 0.38 ± 0.07 | 78.4 ± 0.2 | 45.3 ± 0.2 | 5.97 ± 0.06 | 0.54 ± 0.03 |

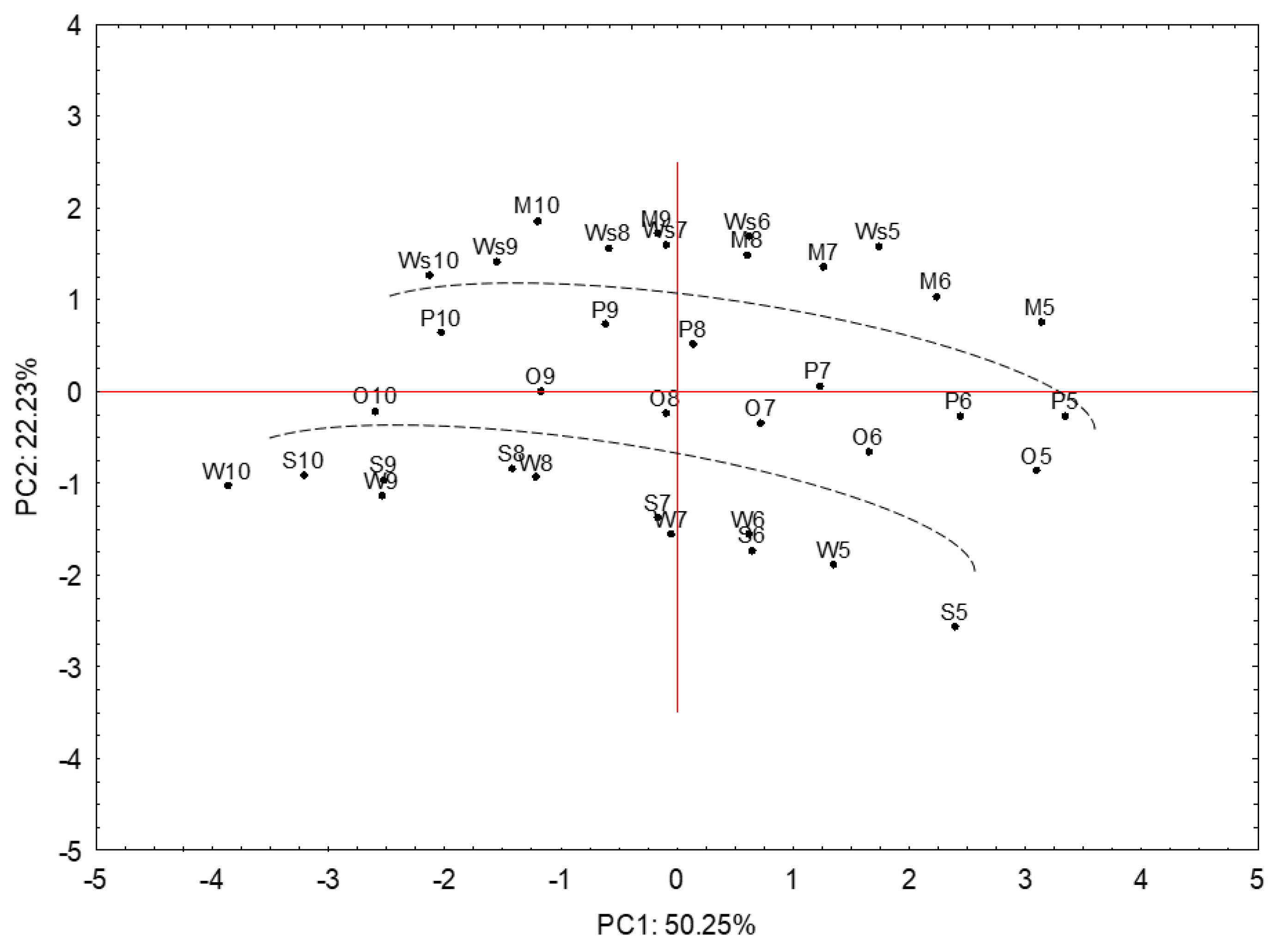

| Biomass | Temp | Code | Cd | Cr | Cu | Fe | Ni | Pb | Zn |

|---|---|---|---|---|---|---|---|---|---|

| °C | mg·kg−1 | ||||||||

| Miscanthus | 500 | M5 | 7.68 | 25.7 | 58.77 | 5390 | 16.4 | 9.69 | 716 |

| Oak | 500 | O5 | 8.26 | 22.41 | 307 | 4059 | 19.17 | 12.21 | 300 |

| Pine | 500 | P5 | 8.06 | 18.87 | 203 | 4250 | 21.69 | 12.91 | 430 |

| Sunflower husk | 500 | S5 | 9.93 | 50.09 | 358 | 5736 | 59.37 | 6.78 | 647 |

| Wheat straw | 500 | Ws5 | 5.42 | 32.25 | 72.54 | 5315 | 14.17 | 8.52 | 336 |

| Willow | 500 | W5 | 7.5 | 39.93 | 190 | 1568 | 75.51 | 10.23 | 922 |

| Miscanthus | 600 | M6 | 6.36 | 27.14 | 58.55 | 4271 | 16.82 | 9.36 | 617 |

| Oak | 600 | O6 | 5.92 | 34.92 | 304 | 3665 | 35.08 | 11.18 | 251 |

| Pine | 600 | P6 | 7.16 | 28.3 | 196 | 3814 | 31.67 | 12.04 | 401 |

| Sunflower husk | 600 | S6 | 7.24 | 53.95 | 333 | 4200 | 61.77 | 5.93 | 412 |

| Wheat straw | 600 | Ws6 | 4.91 | 43.6 | 57.94 | 4450 | 17.44 | 7.01 | 235 |

| Willow | 600 | W6 | 7.13 | 44.45 | 155 | 1485 | 83 | 9.27 | 758 |

| Miscanthus | 700 | M7 | 4.91 | 30.99 | 57.24 | 3781 | 18.67 | 7.6 | 592 |

| Oak | 700 | O7 | 4.98 | 38.19 | 266 | 3534 | 50.37 | 9.9 | 155 |

| Pine | 700 | P7 | 6.25 | 32.61 | 151 | 3566 | 51.34 | 10.14 | 253 |

| Sunflower husk | 700 | S7 | 6.57 | 59.39 | 284 | 3572 | 65.71 | 4.89 | 383 |

| Wheat straw | 700 | Ws7 | 4.31 | 48.75 | 54.24 | 3944 | 28.49 | 6.46 | 204 |

| Willow | 700 | W7 | 6.9 | 55.8 | 141 | 1452 | 89.33 | 8.43 | 699 |

| Miscanthus | 800 | M8 | 4.12 | 33.33 | 55.83 | 2803 | 18.73 | 7.42 | 538 |

| Oak | 800 | O8 | 4.85 | 40.2 | 242 | 3199 | 62.38 | 7.86 | 67.26 |

| Pine | 800 | P8 | 4.49 | 36.88 | 134 | 3141 | 56.58 | 8.58 | 210 |

| Sunflower husk | 800 | S8 | 4.88 | 69.76 | 263 | 2934 | 68.9 | 4.73 | 149 |

| Wheat straw | 800 | Ws8 | 4.04 | 51.29 | 53.03 | 3226 | 31.13 | 5.93 | 185 |

| Willow | 800 | W8 | 4.55 | 60.14 | 131 | 1338 | 96.67 | 7.55 | 550 |

| Miscanthus | 900 | M9 | 3.65 | 37.11 | 54.74 | 2669 | 21.03 | 5.58 | 402 |

| Oak | 900 | O9 | 3.9 | 44.18 | 220.33 | 2242 | 66.83 | 5.94 | 46.29 |

| Pine | 900 | P9 | 4.17 | 40.88 | 102 | 2591 | 59.49 | 6.74 | 201 |

| Sunflower husk | 900 | S9 | 3.62 | 81.92 | 254.67 | 2859 | 94.23 | 4.53 | 53.97 |

| Wheat straw | 900 | Ws9 | 3.61 | 57.46 | 46.48 | 2593 | 45.08 | 4.2 | 163 |

| Willow | 900 | W9 | 4.11 | 71.53 | 129 | 871 | 116.67 | 5.16 | 444 |

| Miscanthus | 1000 | M10 | 3.17 | 50.43 | 51.27 | 1928 | 21.49 | 5.43 | 155.67 |

| Oak | 1000 | O10 | 3.45 | 73.52 | 164.67 | 1603 | 84.56 | 5.38 | 31.69 |

| Pine | 1000 | P10 | 3.45 | 65.95 | 85.63 | 1764 | 66.26 | 6.04 | 95.3 |

| Sunflower husk | 1000 | S10 | 3.36 | 91.47 | 215 | 2788 | 106.67 | 3.76 | 22.13 |

| Wheat straw | 1000 | Ws10 | 3.51 | 68.02 | 41.96 | 2356 | 50.32 | 3.45 | 152.67 |

| Willow | 1000 | W10 | 3.5 | 96.90 | 95.1 | 712.67 | 126.33 | 4.71 | 236 |

| Cd | Cr | Cu | Fe | Ni | Pb | |

|---|---|---|---|---|---|---|

| Cr | −0.53 * | |||||

| Cu | 0.50 * | 0.04 | ||||

| Fe | 0.54 * | −0.57 * | 0.21 | |||

| Ni | −0.22 | 0.79 * | 0.28 | −0.68 * | ||

| Pb | 0.67 * | −0.79 * | 0.21 | 0.37 * | −0.42 * | |

| Zn | 0.66 * | −0.40 * | −0.05 | 0.10 | −0.10 | 0.44 * |

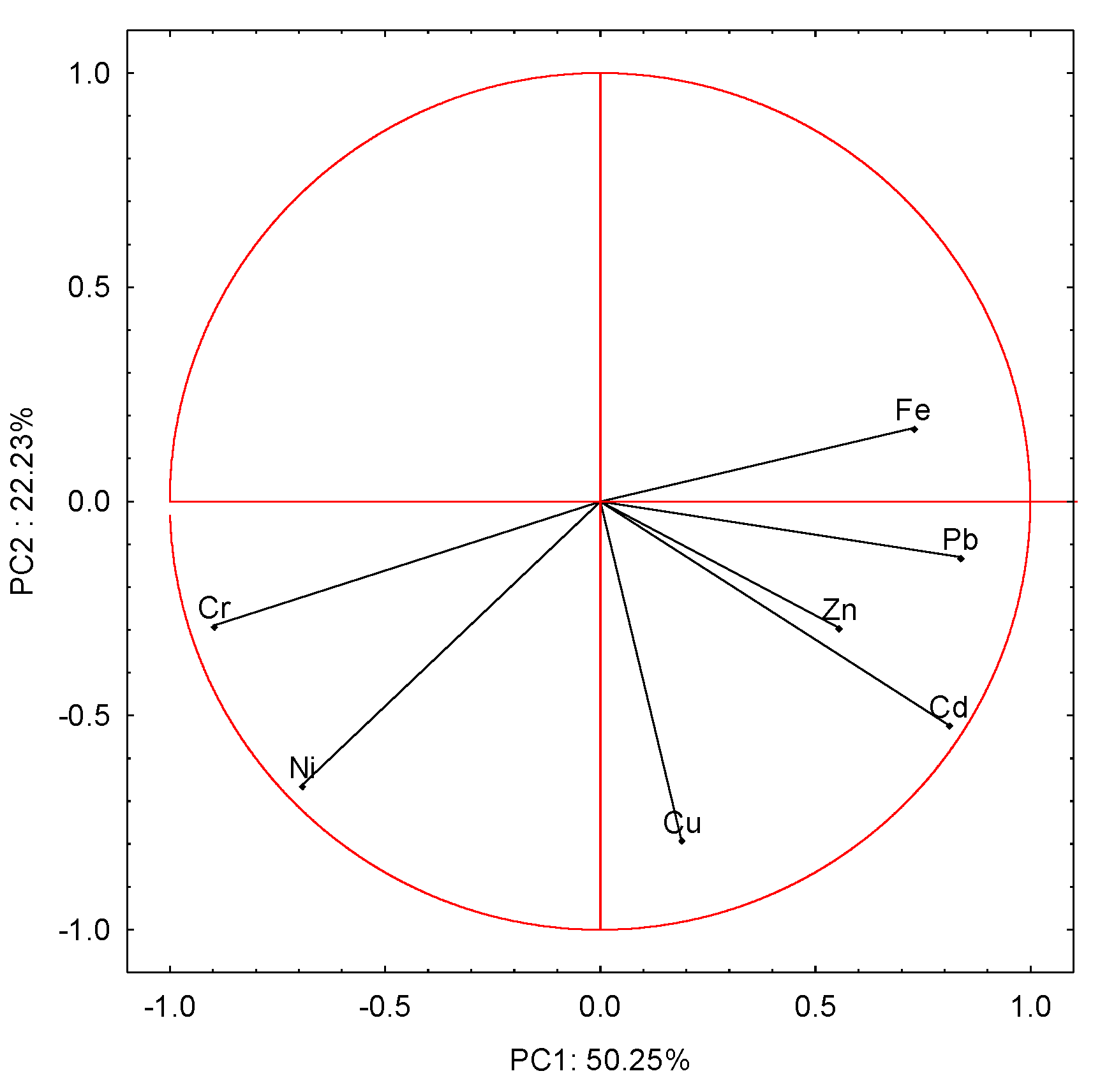

| Element | PC1 | PC2 | PC3 |

|---|---|---|---|

| Cd | 0.81 | −0.52 | −0.04 |

| Cr | −0.90 | −0.29 | 0.06 |

| Cu | 0.19 | −0.79 | 0.54 |

| Fe | 0.73 | 0.17 | 0.51 |

| Ni | −0.69 | −0.66 | −0.16 |

| Pb | 0.84 | −0.13 | −0.13 |

| Zn | 0.55 | −0.30 | −0.70 |

| Eigenvalue | 3.52 | 1.56 | 1.10 |

| Variance % | 50.25 | 22.23 | 15.65 |

| Cumulative variance % | 50.25 | 72.48 | 88.13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szczepanik, M.; Szyszlak-Bargłowicz, J.; Zając, G.; Koniuszy, A.; Hawrot-Paw, M.; Wolak, A. The Use of Multivariate Data Analysis (HCA and PCA) to Characterize Ashes from Biomass Combustion. Energies 2021, 14, 6887. https://doi.org/10.3390/en14216887

Szczepanik M, Szyszlak-Bargłowicz J, Zając G, Koniuszy A, Hawrot-Paw M, Wolak A. The Use of Multivariate Data Analysis (HCA and PCA) to Characterize Ashes from Biomass Combustion. Energies. 2021; 14(21):6887. https://doi.org/10.3390/en14216887

Chicago/Turabian StyleSzczepanik, Małgorzata, Joanna Szyszlak-Bargłowicz, Grzegorz Zając, Adam Koniuszy, Małgorzata Hawrot-Paw, and Artur Wolak. 2021. "The Use of Multivariate Data Analysis (HCA and PCA) to Characterize Ashes from Biomass Combustion" Energies 14, no. 21: 6887. https://doi.org/10.3390/en14216887

APA StyleSzczepanik, M., Szyszlak-Bargłowicz, J., Zając, G., Koniuszy, A., Hawrot-Paw, M., & Wolak, A. (2021). The Use of Multivariate Data Analysis (HCA and PCA) to Characterize Ashes from Biomass Combustion. Energies, 14(21), 6887. https://doi.org/10.3390/en14216887