Effect of Pyrolysis Temperature and Wood Species on the Properties of Biochar Pellets

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.1.1. Preparation of Treated Wood Fibers

2.1.2. Preparation of Pyrolytic Lignin

2.2. Characterization of Raw Material

2.3. Pelletization Process

2.4. Characterization of Wood Pellets

2.5. Data Analysis

3. Results and Discussion

3.1. Properties of Wood Residues and Pyrolytic Lignin

3.1.1. Particle Size Distribution

3.1.2. Elemental Analysis and Chemical Composition and Chemical Properties

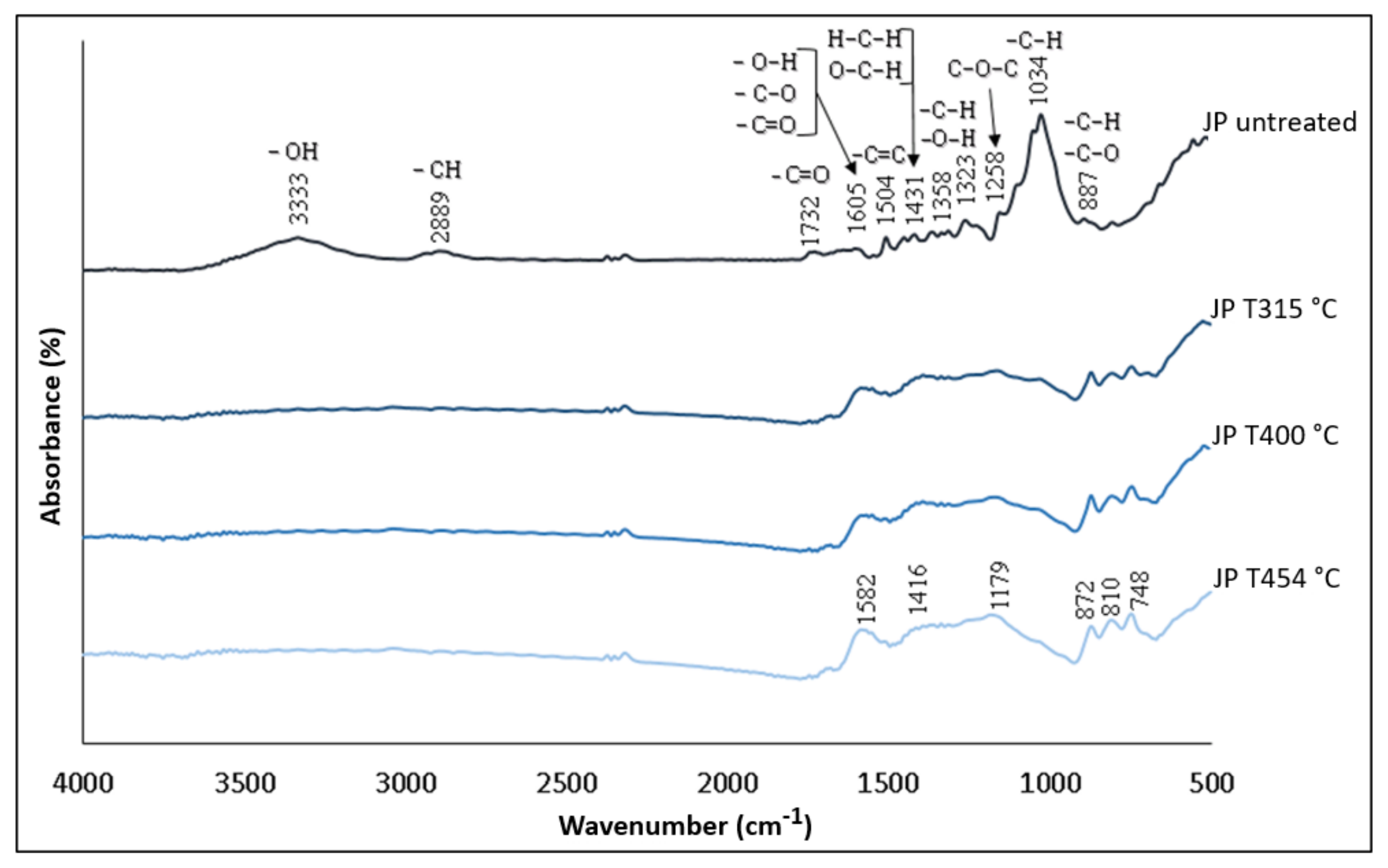

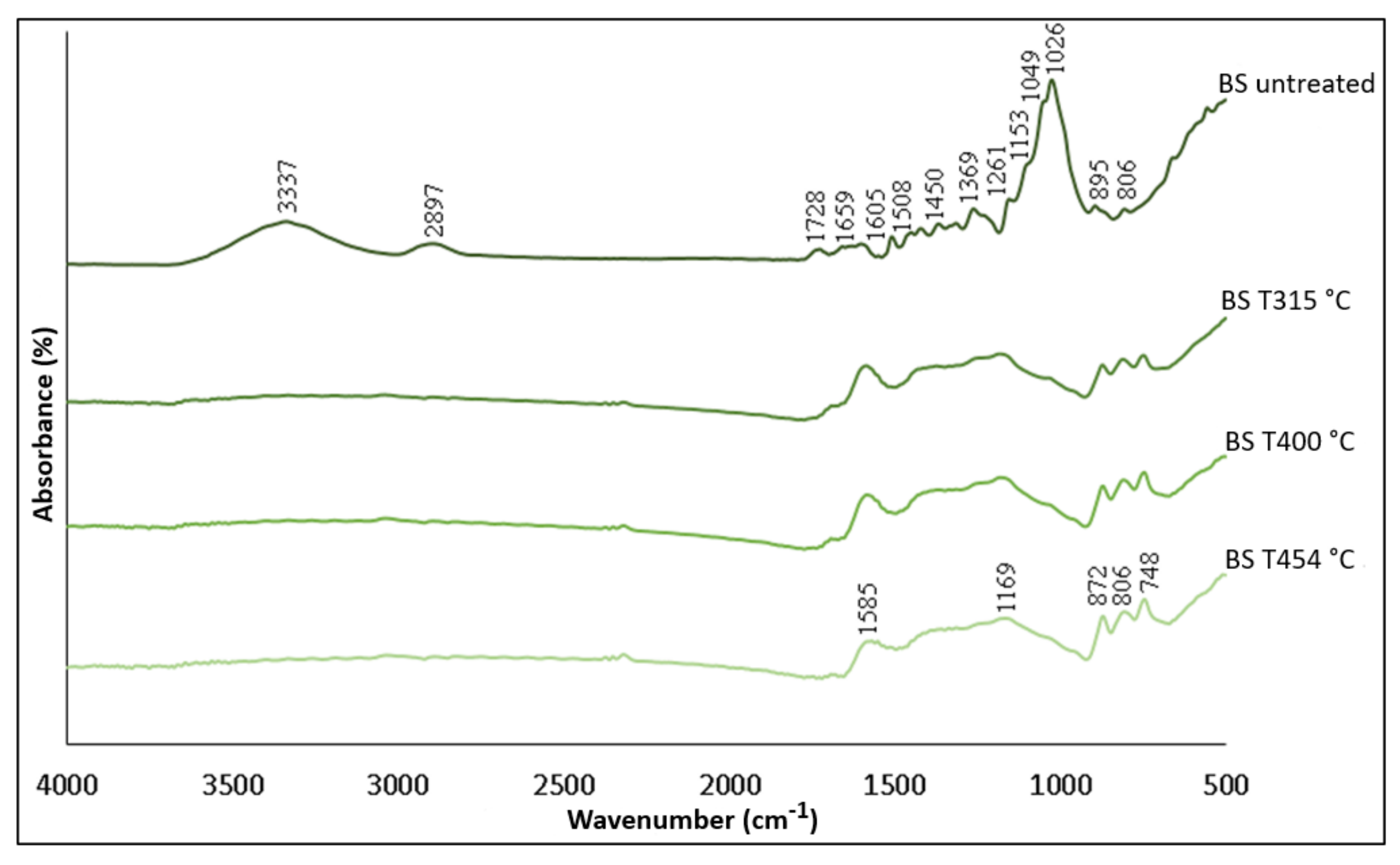

3.1.3. FTIR Characterization

3.2. Properties of Pellets

3.2.1. Thermal Degradation of Pellets

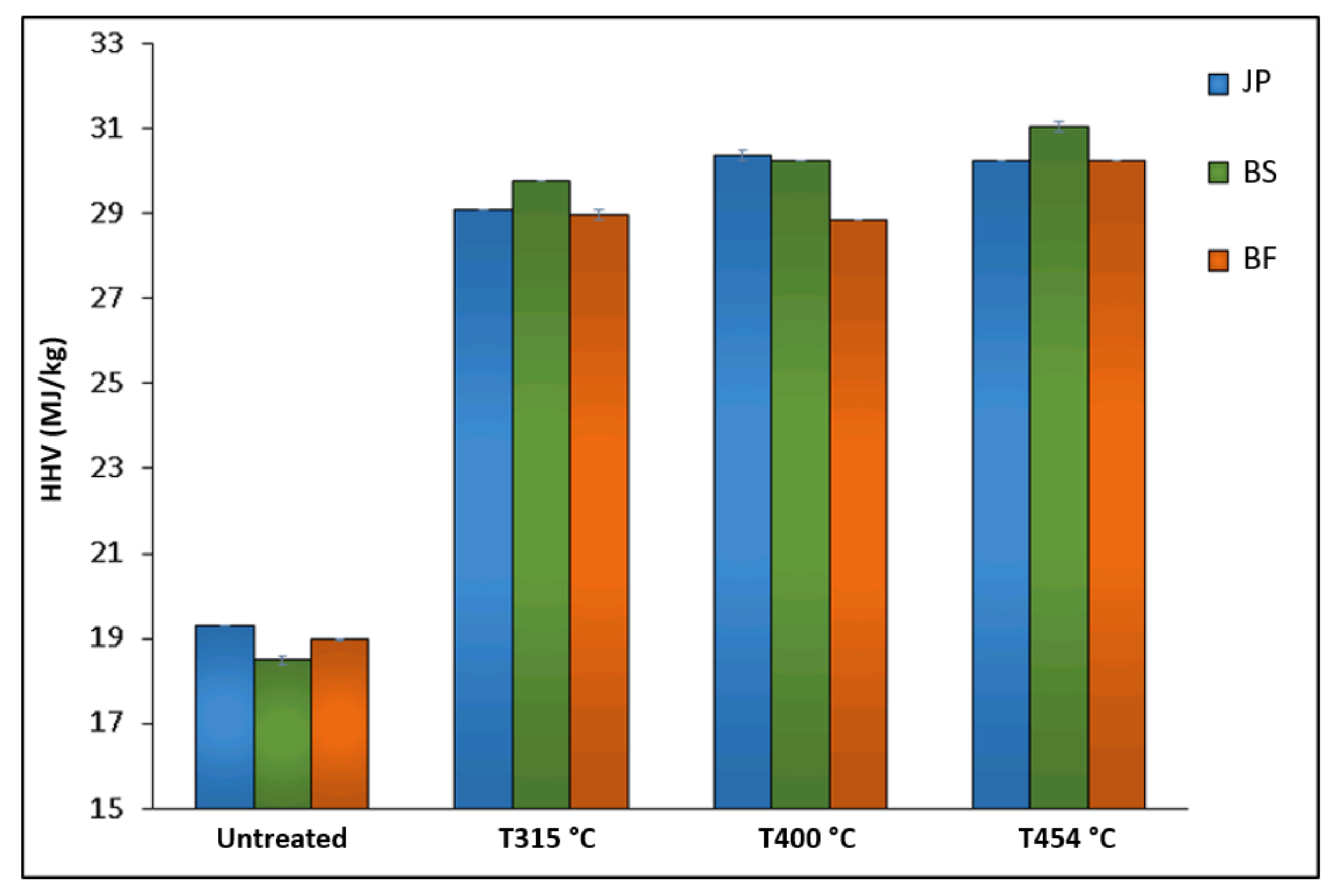

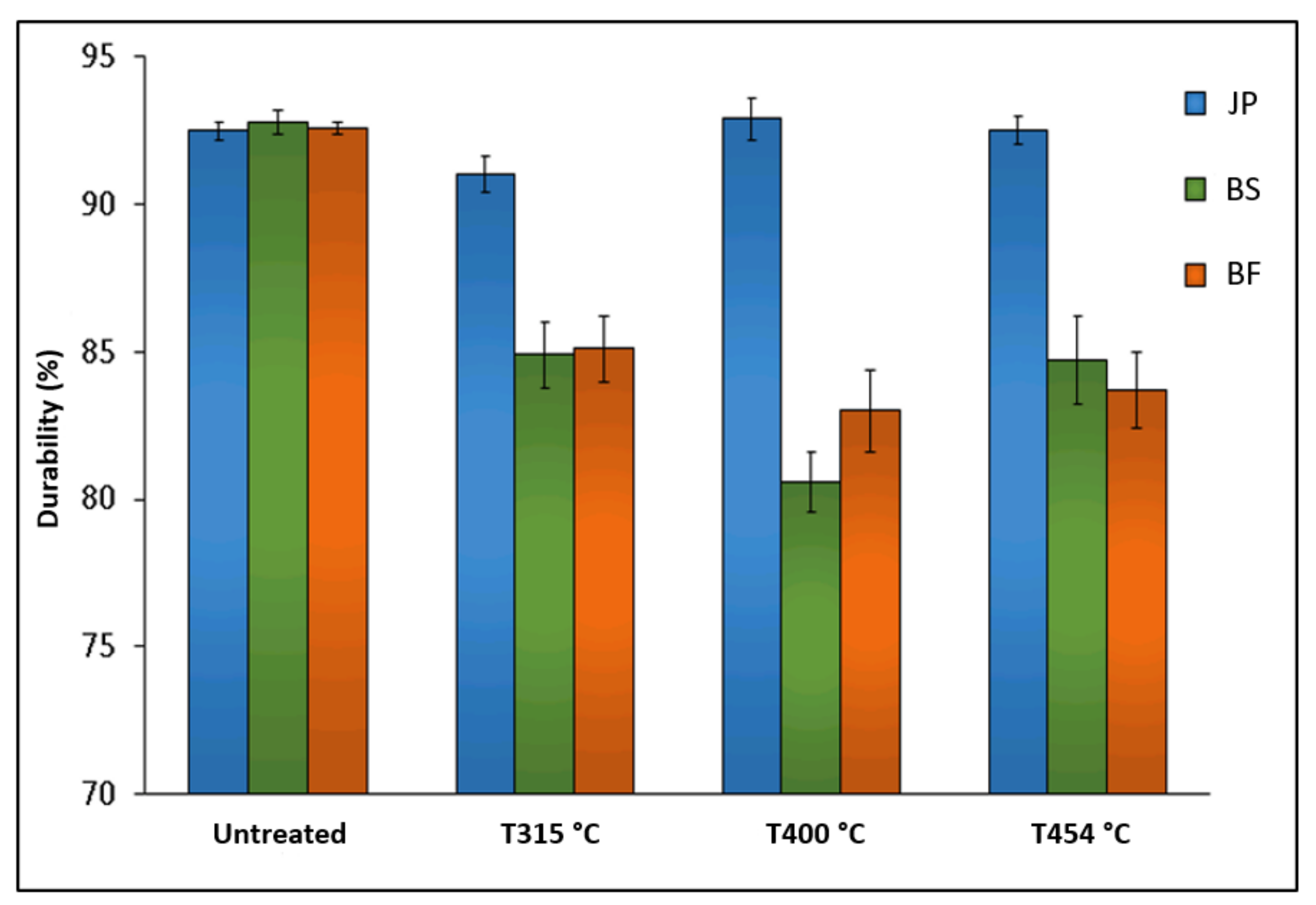

3.2.2. Physical and Mechanical Characteristics of Pellets

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Salmon, D. Ressources et Industries Forestières du Québec: Portrait Statistique Édition 2017. Ministère des Forêts, de la Faune et des Parcs. Québec, QC. Available online: https://mffp.gouv.qc.ca/wp-content/uploads/portrait-statistique-2017.pdf (accessed on 8 May 2019).

- Haykırı-Açma, H. Combustion characteristics of different biomass materials. Energy Convers. Manag. 2003, 44, 155–162. [Google Scholar] [CrossRef]

- Van der Stelt, M.; Gerhauser, H.; Kiel, J.; Ptasinski, K. Biomass upgrading by torrefaction for the production of biofuels: A review. Biomass Bioenergy 2011, 35, 3748–3762. [Google Scholar] [CrossRef]

- Chen, W.H.; Kuo, P.C. A study on torrefaction of various biomass materials and its impact on lignocellulosic structure simulated by a thermogravimetry. Energy 2010, 35, 2580–2586. [Google Scholar] [CrossRef]

- Weber, K.; Quicker, P. Properties of biochar. Fuel 2018, 217, 240–261. [Google Scholar] [CrossRef]

- Solomatnikova, O.; Douville, G.; Carriere, N.; Vallée, V.; Trudel, F.; Duchesne, M.; Gaudreault, A. Profil des Produits Forestiers: Technologies de Bioénergies Abase de Biomasse Forestiere 2011. Ministère des Ressources Naturelles et de la Faune. Québec, QC. Available online: https://visionbiomassequebec.org/wp-content/uploads/2015/03/Technologies-de-bioe%CC%81nergies-a%CC%80-base-de-biomasse-forestie%CC%80re_2011-1.pdf (accessed on 8 May 2019).

- Chen, W.H.; Kuo, P.C. Torrefaction and co-torrefaction characterization of hemicellulose, cellulose and lignin as well as torrefaction of some basic constituents in biomass. Energy 2011, 36, 803–811. [Google Scholar] [CrossRef]

- Rodrigues, T.O.; Rousset, P.L.A. Effects of torrefaction on energy properties of Eucalyptus Grandis wood. Cerne 2015, 15, 446–452. [Google Scholar]

- Pach, M.; Zanzi, R.; Björnbom, E. Torrefied biomass a substitute for wood and charcoal. In Proceedings of the 6th Asia-Pacific International Symposium on Combustion and Energy Utilization, Kuala Lumpur, Malaysia, 20–22 May 2002. [Google Scholar]

- Järvinen, T.; Agar, D. Experimentally determined storage and handling properties of fuel pellets made from torrefied whole-tree pine chips, logging residues and beech stem wood. Fuel 2014, 129, 330–339. [Google Scholar] [CrossRef]

- Stevens, J.; Gardner, D.J. Enhancing the fuel value of wood pellets with the addition of lignin. Wood Fiber Sci. 2010, 42, 439–443. [Google Scholar]

- Alakangas, E. New European pellets standards. In Proceedings of the World Sustainable Energy Days, European Pellets Conference, Jyväskylä, Finland, 3–4 March 2010. [Google Scholar]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. Fuel pellets from biomass: The importance of the pelletizing pressure and its dependency on the processing conditions. Fuel 2011, 90, 3285–3290. [Google Scholar] [CrossRef]

- Stelte, W.; Sanadi, A.R.; Shang, L.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.B. Recent developments in biomass pelletization—A review. BioResources 2012, 7, 4451–4490. [Google Scholar] [CrossRef]

- García, R.; González-Vázquez, M.P.; Pevida, C.; Rubiera, F. Pelletization properties of raw and torrefied pine sawdust: Effect of co-pelletization, temperature, moisture content and glycerol addition. Fuel 2018, 215, 290–297. [Google Scholar] [CrossRef]

- Zhu, G.; Yang, L.; Gao, Y.; Xu, J.; Chen, H.; Zhu, Y.; Wang, Y.; Liao, C.; Lu, C.; Zhu, C. Characterization and pelletization of cotton stalk hydrochar from HTC and combustion kinetics of hydrochar pellets by TGA. Fuel 2019, 244, 479–491. [Google Scholar] [CrossRef]

- Xing, X.; Fan, F.; Jiang, W. Characteristics of biochar pellets from corn straw under different pyrolysis temperatures. R. Soc. Open Sci. 2018, 5, 172–346. [Google Scholar] [CrossRef] [PubMed]

- Abedi, A.; Dalai, A.K. Study on the quality of oat hull fuel pellets using bio-additives. Biomass Bioenergy 2017, 106, 166–175. [Google Scholar] [CrossRef]

- Kong, L.; Tian, S.; Li, Z.; Luo, R.; Chen, D.; Tu, Y.; Xiong, Y. Conversion of recycled sawdust into high HHV and low NOx emission bio-char pellets using lignin and calcium hydroxide blended binders. Renew. Energy 2013, 60, 559–565. [Google Scholar] [CrossRef]

- Saosee, P.; Sajjakulnukit, B.; Gheewala, S.H. Life Cycle Assessment of Wood Pellet Production in Thailand. Sustainability 2020, 12, 6996. [Google Scholar] [CrossRef]

- Reed, D.; Bergman, R.; Kim, J.-W.; Tayler, A.; Harper, D.; Jones, D.; Knowles, C.; Puettmann, M.E. Cradle-to-gate life-cycle inventory and impact assessment of wood fuel pellet manufacturing from hardwood flooring residues in the Southeastern United States. For. Prod. J. 2012, 62, 280–288. [Google Scholar] [CrossRef]

- Loriers, A.; Planchon, V.; Godin, B.; Delcarte, J.; Stilmant, D.; Van Stappen, F. Comparative life cycle assessment of torrefied pellet production from five lignocellulosic biomass types. In Proceedings of the 25th European Biomass Conference and Exhibition, Stockholm, Sweden, 12–15 June 2017; pp. 1781–1787. [Google Scholar]

- Zhang, S.Y.; Koubaa, A. Softwoods of Eastern Canada: Their Silvics Characteristics, Manufacturing and End-Uses; Special Publication SP-526E; FPInnovations: Québec, QC, Canada, 2008; 400p. [Google Scholar]

- Zhang, M.; Wu, H. Pyrolytic lignin from fast pyrolysis bio-oil via cold-water precipitation: Optimal separation conditions and properties. Fuel 2019, 242, 580–586. [Google Scholar] [CrossRef]

- Mao, A.; He, Z.; Wan, H.; Li, Q. Preparation, properties, and bonding utilization of pyrolysis bio-oil. In Bio-Based Wood Adhesives, 1st ed.; Zhongqi, H., Ed.; CRC Press: Boca Raton, FL, USA, 2017; Volume 366, pp. 260–279. [Google Scholar]

- Technical Association of Pulp and Paper Industry (TAPPI). Carbohydrate composition of extractive-free wood and wood pulp by gas-liquid chromatography (T-249 cm-85). In TAPPI Test Method; TAPPI Press: Atlanta, GA, USA, 1985; Volume 1, pp. 1–5. [Google Scholar]

- Sheng, C.; Azevedo, J. Estimating the higher heating value of biomass fuels from basic analysis data. Biomass Bioenergy 2005, 28, 499–507. [Google Scholar] [CrossRef]

- Technical Association of Pulp and Paper Industry (TAPPI). Preparation of wood for chemical analysis (T264 om-88). In TAPPI Test Method; TAPPI Press: Atlanta, GA, USA, 1989; Volume 1. [Google Scholar]

- Bouslimi, B.; Koubaa, A.; Bergeron, Y. Effects of biodegradation by brown-rot decay on selected wood properties in eastern white cedar (Thuja occidentalis L.). Int. Biodeterior. Biodegrad. 2014, 87, 87–98. [Google Scholar] [CrossRef]

- Technical Association of Pulp and Paper Industry (TAPPI). Acid Insoluble lignin in wood and pulp (T-222 OM-88). In TAPPI Test Method; TAPPI Press: Atlanta, GA, USA, 1989; Volume 1. [Google Scholar]

- Technical Association of Pulp and Paper Industry (TAPPI). Solvent extractives of wood and pulp (T-204 OM-88). In TAPPI Test Method; TAPPI Press: Atlanta, GA, USA, 1989; Volume 1. [Google Scholar]

- Samuelsson, R.; Larsson, S.H.; Thyrel, M.; Lestander, T.A. Moisture content and storage time influence the binding mechanisms in biofuel wood pellets. Appl. Energy 2012, 99, 109–115. [Google Scholar] [CrossRef]

- Nielsen, N.P.K.; Gardner, D.J.; Poulsen, T.; Felby, C. Importance of temperature, moisture content, and species for the conversion process of wood residues into fuel pellets. Wood Fiber Sci. 2009, 41, 414–425. [Google Scholar]

- Belhadef, W. Développement de Granules Énergétiques Améliorées à Base de Bouleau Blanc et de Graines de Canola. Master’s Thesis, Université du Québec en Abitibi-Témiscamingue, Rouyn-Noranda, QC, Canada, 2016. [Google Scholar]

- SAS. Getting Started with SAS; SAS Institute Inc.: Cary, NC, USA, 2008. [Google Scholar]

- Manouchehrinejad, M.; van Giesen, I.; Mani, S. Grindability of torrefied wood chips and wood pellets. Fuel Process. Technol. 2018, 182, 45–55. [Google Scholar] [CrossRef]

- Pelaez-Samaniego, M.R.; Yadama, V.; Garcia-Perez, M.; Lowell, E.; McDonald, A.G. Effect of temperature during wood torrefaction on the formation of lignin liquid intermediates. J. Anal. Appl. Pyrolysis 2014, 109, 222–233. [Google Scholar] [CrossRef]

- Arias, B.; Pevida, C.; Fermoso, J.; Plaza, M.; Rubiera, F.; Pis, J. Influence of torrefaction on the grindability and reactivity of woody biomass. Fuel Process. Technol. 2008, 89, 169–175. [Google Scholar] [CrossRef]

- Phanphanich, M.; Mani, S. Impact of torrefaction on the grindability and fuel characteristics of forest biomass. Bioresour. Technol. 2011, 102, 1246–1253. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Peng, J.; Li, H.; Bi, X.T.; Legros, R.; Lim, C.; Sokhansanj, S. Oxidative torrefaction of biomass residues and densification of torrefied sawdust to pellets. Bioresour. Technol. 2013, 127, 318–325. [Google Scholar] [CrossRef] [PubMed]

- Ghiasi, B.; Kumar, L.; Furubayashi, T.; Lim, C.J.; Bi, X.; Kim, C.S.; Sokhansanj, S. Densified biocoal from woodchips: Is it better to do torrefaction before or after densification? Appl. Energy 2014, 134, 133–142. [Google Scholar] [CrossRef]

- Peng, J.; Bi, X.; Sokhansanj, S.; Lim, C. Torrefaction and densification of different species of softwood residues. Fuel 2013, 111, 411–421. [Google Scholar] [CrossRef]

- Mullen, C.A.; Boateng, A.A. Characterization of water-insoluble solids isolated from various biomass fast pyrolysis oils. J. Anal. Appl. Pyrolysis 2011, 90, 197–203. [Google Scholar] [CrossRef]

- Kim, K.H.; Kim, J.Y.; Cho, T.S.; Choi, J.W. Influence of pyrolysis temperature on physicochemical properties of biochar obtained from the fast pyrolysis of pitch pine (Pinus rigida). Bioresour. Technol. 2012, 118, 158–162. [Google Scholar] [CrossRef]

- Harun, N.Y.; Afzal, M.T. Thermal decomposition kinetics of forest residue. J. Appl. Sci. 2010, 10, 1122–1127. [Google Scholar] [CrossRef][Green Version]

- Bouafif, H.; Koubaa, A.; Perré, P.; Cloutier, A.; Riedl, B. Analysis of among-species variability in wood fiber surface using DRIFTS and XPS: Effects on esterification efficiency. J. Wood Chem. Technol. 2008, 28, 296–315. [Google Scholar] [CrossRef]

- Santos, L.B.; Striebeck, M.V.; Crespi, M.S.; Ribeiro, C.A.; De Julio, M. Characterization of biochar of pine pellet. J. Therm. Anal. Calorim. 2015, 122, 21–32. [Google Scholar] [CrossRef]

- Stelte, W.; Clemons, C.; Holm, J.K.; Sanadi, A.R.; Ahrenfeldt, J.; Shang, L.; Henriksen, U.B. Pelletizing properties of torrefied spruce. Biomass Bioenergy 2011, 35, 4690–4698. [Google Scholar] [CrossRef]

- Angın, D. Effect of pyrolysis temperature and heating rate on biochar obtained from pyrolysis of safflower seed press cake. Bioresour. Technol. 2013, 128, 593–597. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Cao, J.; Wang, J. Pyrolytic characteristics of pine wood in a slowly heating and gas sweeping fixed-bed reactor. J. Anal. Appl. Pyrolysis 2009, 84, 179–184. [Google Scholar] [CrossRef]

- Yang, H.; Huang, L.; Liu, S.; Sun, K.; Sun, Y. Pyrolysis process and characteristics of products from sawdust briquettes. BioResources 2016, 11, 2438–2456. [Google Scholar] [CrossRef][Green Version]

- Al-Wabel, M.I.; Al-Omran, A.; El-Naggar, A.H.; Nadeem, M.; Usman, A.R. Pyrolysis temperature-induced changes in characteristics and chemical composition of biochar produced from conocarpus wastes. Bioresour. Technol. 2013, 131, 374–379. [Google Scholar] [CrossRef]

- Mimmo, T.; Panzacchi, P.; Baratieri, M.; Davies, C.; Tonon, G. Effect of pyrolysis temperature on miscanthus (Miscanthus × giganteus) biochar physical, chemical and functional properties. Biomass Bioenergy 2014, 62, 149–157. [Google Scholar] [CrossRef]

- Wu, W.; Yang, M.; Feng, Q.; McGrouther, K.; Wang, H.; Lu, H.; Chen, Y. Chemical characterization of rice straw-derived biochar for soil amendment. Biomass Bioenergy 2012, 47, 268–276. [Google Scholar] [CrossRef]

- Esteves, B.; Velez Marques, A.; Domingos, I.; Pereira, H. Chemical changes of heat treated pine and eucalypt wood monitored by FTIR. Maderas Cienc. Tecnol. 2013, 15, 245–258. [Google Scholar] [CrossRef]

- Özgenç, Ö.; Durmaz, S.; Boyaci, I.H.; Eksi-Kocak, H. Determination of chemical changes in heat-treated wood using ATR-FTIR and FT Raman spectrometry. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2017, 171, 395–400. [Google Scholar] [CrossRef]

- Chupin, L.; Motillon, C.; Charrier-El Bouhtoury, F.; Pizzi, A.; Charrier, B. Characterisation of maritime pine (Pinus pinaster) bark tannins extracted under different conditions by spectroscopic methods, FTIR and HPLC. Ind. Crop. Prod. 2013, 49, 897–903. [Google Scholar] [CrossRef]

- Jiang, L.B.; Yuan, X.Z.; Li, H.; Chen, X.H.; Xiao, Z.H.; Liang, J.; Leng, L.J.; Guo, Z.; Zeng, G.M. Co-pelletization of sewage sludge and biomass: Thermogravimetric analysis and ash deposits. Fuel Process. Technol. 2016, 145, 109–115. [Google Scholar] [CrossRef]

- Wang, Q.; Han, K.; Gao, J.; Li, H.; Lu, C. The pyrolysis of biomass briquettes: Effect of pyrolysis temperature and phosphorus additives on the quality and combustion of bio-char briquettes. Fuel 2017, 199, 488–496. [Google Scholar] [CrossRef]

- Wang, S.; Lin, H.; Ru, B.; Sun, W.; Wang, Y.; Luo, Z. Comparison of the pyrolysis behavior of pyrolytic lignin and milled wood lignin by using TG–FTIR analysis. J. Anal. Appl. Pyrolysis 2014, 108, 78–85. [Google Scholar] [CrossRef]

- Hu, Q.; Shao, J.; Yang, H.; Yao, D.; Wang, X.; Chen, H. Effects of binders on the properties of bio-char pellets. Appl. Energy 2015, 157, 508–516. [Google Scholar] [CrossRef]

- Hu, Q.; Yang, H.; Yao, D.; Zhu, D.; Wang, X.; Shao, J.; Chen, H. The densification of bio-char: Effect of pyrolysis temperature on the qualities of pellets. Bioresour. Technol. 2016, 200, 521–527. [Google Scholar] [CrossRef]

- Manouchehrinejad, M.; Mani, S. Torrefaction after pelletization (TAP): Analysis of torrefied pellet quality and co-products. Biomass Bioenergy 2018, 118, 93–104. [Google Scholar] [CrossRef]

- Azargohar, R.; Soleimani, M.; Nosran, S.; Bond, T.; Karunakaran, C.; Dalai, A.K.; Tabil, L.G. Thermo-physical characterization of torrefied fuel pellet from co-pelletization of canola hulls and meal. Ind. Crop. Prod. 2019, 128, 424–435. [Google Scholar] [CrossRef]

- Cheng, J.; Zhou, F.; Si, T.; Zhou, J.; Cen, K. Mechanical strength and combustion properties of biomass pellets prepared with coal tar residue as a binder. Fuel Process. Technol. 2018, 179, 229–237. [Google Scholar] [CrossRef]

- Shang, L.; Nielsen, N.P.K.; Stelte, W.; Dahl, J.; Ahrenfeldt, J.; Holm, J.K.; Arnavat, M.P.; Bach, L.S.; Henriksen, U.B. Lab and bench-scale pelletization of torrefied wood chips—Process optimization and pellet quality. Bioenergy Res. 2014, 7, 87–94. [Google Scholar] [CrossRef]

- Thrän, D.; Witt, J.; Schaubach, K.; Kiel, J.; Carbo, M.; Maier, J.; Ndibe, C.; Koppejan, J.; Alakangas, E.; Majer, S. Moving torrefaction towards market introduction–Technical improvements and economic-environmental assessment along the overall torrefaction supply chain through the SECTOR project. Biomass Bioenergy 2016, 89, 184–200. [Google Scholar] [CrossRef]

- Föhr, J.; Ranta, T.; Suikki, J.; Soininen, H. Manufacturing of torrefied pellets without a binder from different raw wood materials in the pilot plant. Wood Res. 2017, 62, 481–494. [Google Scholar]

| Type | JP | BS | BF | PL | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T (°C) | Raw | 315 | 400 | 454 | Raw | 315 | 400 | 454 | Raw | 315 | 400 | 454 | 450 |

| Elemental analysis (%) | |||||||||||||

| C | 46.96 | 65.21 | 77 | 80.7 | 45.85 | 75.6 | 80.55 | 85.92 | 46.46 | 70.01 | 71.19 | 83.45 | 57.18 |

| H | 6.55 | 1.27 | 2.48 | 3.34 | 6.42 | 3.14 | 3.03 | 2.81 | 6.67 | 3.34 | 3.32 | 2.77 | 6.11 |

| N | 0.05 | 0.2 | 0.26 | 0.21 | 0.05 | 0.2 | 0.11 | 0.1 | 0.02 | 0.17 | 0.16 | 0.12 | 1.51 |

| S | 1.09 | 0.35 | 0.47 | 0.58 | 1.16 | 0.62 | 0.52 | 0.47 | 1.07 | 0.59 | 0.69 | 0.56 | 0.59 |

| O | 45.35 | 32.97 | 19.79 | 15.17 | 46.52 | 20.44 | 15.79 | 10.70 | 45.78 | 25.89 | 24.64 | 13.1 | 33.61 |

| Calorific value (MJ/kg) | |||||||||||||

| HHV * | 19.4 | 21.0 | 25.2 | 26.8 | 19.0 | 25.2 | 26.5 | 27.9 | 19.3 | 23.8 | 22.2 | 27.2 | 21.9 |

| Type | JP | BS | BF | |||||

|---|---|---|---|---|---|---|---|---|

| Type | JP | BF | ||||||

| T(°C) | Raw | 315 | 400 | 454 | Raw | 400 | Raw | 400 |

| BS | ||||||||

| Chemical composition (%) | ||||||||

| Cellulose | 45.00 (0.30) | 17.13 (0.52) | 13.82 (0.06) | 2.72 (0.01) | 44.66 (3.44) | 9.55 (0.03) | 40.72 (6.39) | 9.9 (0.12) |

| Hemicellulose | 17.88 (0.30) | 1.98 (0.17) | 0.42 (0.06) | 0.02 (0.01) | 23.2 (3.44) | 0.28 (0.03) | 31.99 (6.39) | 0.17 (0.11) |

| Lignin | 34.06 (2.24) | 80.55 (2.91) | 83.65 (2.69) | 96.76 (1.25) | 28.83 (1.77) | 89.59 (0.80) | 24.29 (0.86) | 89.11 (0.09) |

| Extractives | 3.06 (0.13) | 1.03 (0.06) | 0.61 (0.01) | 0.50 (0.04) | 3.31 (0.21) | 0.57 (0.06) | 3.00 (0.10) | 0.79 (0.04) |

| Density | HHV | Durability | |

|---|---|---|---|

| Type of wood (A) | 35756.6 ** | 71.74 ** | 62.05 ** |

| Temperature (B) | 24260.8 ** | 13952 ** | 36.75 ** |

| (A) → × (B) | 1042.9 ** | 45.29 ** | 9.26 ** |

| R2 | 0.96 | 0.99 | 0.99 |

| Pellets | Humidity (%) | Ash (%) | Density (kg/m3) |

|---|---|---|---|

| Untreated JP | 7.7 | 0.12 | 1390.57 (0.04) |

| JP T315 °C | 4.80 | 7.31 | 1438.37 (0.04) |

| JP T400 °C | 4.30 | 4.29 | 1392.50 (0.07) |

| JP T454 °C | 4.50 | 1.46 | 1344.63 (0.42) |

| Untreated BF | 7.08 | 0.52 | 1395.00 (0.07) |

| BF T315 °C | 5.49 | 1.72 | 1343.10 (0.07) |

| BF T400 °C | 5.16 | 2.56 | 1334.10 (0.13) |

| BF T454 °C | 5.43 | 2.32 | 1337.40 (0.93) |

| Untreated BS | 6.85 | 0.38 | 1390.07 (0.04) |

| BS T315 °C | 5.28 | 2.69 | 1334.90 (0.07) |

| BS T400 °C | 5.29 | 2.20 | 1316.60 (0.33) |

| BS T454 °C | 4.02 | 1.98 | 1331.10 (0.47) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arous, S.; Koubaa, A.; Bouafif, H.; Bouslimi, B.; Braghiroli, F.L.; Bradai, C. Effect of Pyrolysis Temperature and Wood Species on the Properties of Biochar Pellets. Energies 2021, 14, 6529. https://doi.org/10.3390/en14206529

Arous S, Koubaa A, Bouafif H, Bouslimi B, Braghiroli FL, Bradai C. Effect of Pyrolysis Temperature and Wood Species on the Properties of Biochar Pellets. Energies. 2021; 14(20):6529. https://doi.org/10.3390/en14206529

Chicago/Turabian StyleArous, Safa, Ahmed Koubaa, Hassine Bouafif, Besma Bouslimi, Flavia Lega Braghiroli, and Chedly Bradai. 2021. "Effect of Pyrolysis Temperature and Wood Species on the Properties of Biochar Pellets" Energies 14, no. 20: 6529. https://doi.org/10.3390/en14206529

APA StyleArous, S., Koubaa, A., Bouafif, H., Bouslimi, B., Braghiroli, F. L., & Bradai, C. (2021). Effect of Pyrolysis Temperature and Wood Species on the Properties of Biochar Pellets. Energies, 14(20), 6529. https://doi.org/10.3390/en14206529