Abstract

Sludge dewatering is a key element in sludge’s processing and management. Solid-phase separation, sludge volume reduction and the separation of a high-quality supernatant are the main tasks of the dewatering devices. The effectiveness of this task, in turn, results from the selection of the dewatering method and conditioning of the sludge before dewatering. The aim of the research was to determine the influence of conditioning substances (polyelectrolyte, fly ash and zeolite) on the efficiency of dewatering at variable filtration pressure. The use of polyelectrolyte in sludge conditioning was a solution that increased the efficiency of the filtration process. On the contrary, the use of structure-forming substances (fly ash and zeolite) slows the process but reduces the hydration of the filter cake. The same trends were obtained in dual conditioning combining dosing of polyelectrolyte and ash or zeolite. It was also shown that the dewatering efficiency of conditioned sludge with these two different substances (ash and zeolite) was the same. The use of zeolite in independent or dual conditioning was important for the quality of the supernatant.

1. Introduction

Municipal sewage sludge is a compressible material whose property can deteriorate the effects of drainage filtration. Laheij et al. proved that, at the filtration pressure of 300–400 kPa, it is possible to obtain 35–40% of the dry matter content in the filter cake [1]. It is also possible, depending on the type and characteristics of the sludge, that better dewatering effects can be obtained by increasing the pressure and filtration time [2]. Using variable pressure in the process of pressure filtration, a fundamental difference in final water content was obtained already at the stage of dewatering of raw sludge. Between the lowest (0.25 MPa) and the highest (0.75 MPa) applied pressure, a water content difference of up to 3.7% (80.4% for 0.25 MPa pressure and 76.7% for 0.75 MPa pressure) was obtained. It was also noted that, with increased pressure, filtration resistance decreased slightly from 1.13 × 1013 m/kg (0.25 MPa) to 0.82 × 1013 m/kg (0.75 MPa) [3]. A two-fold increase in filtration efficiency was also observed at the highest pressure. Zhao and Bache [2] found that, depending on the type and properties of the sludge, there is an optimal pressure and filtration time. This is confirmed by the studies of Wu et al. [4], which indicate the need to determine the threshold filtration pressure, beyond which the dewatering efficiency deteriorates.

The use of chemical additives, especially polyelectrolytes, for the conditioning of sewage sludge to ensure the proper functioning of many processes of separation of the solid phase from hydrated sludge is now of key importance. The type of polyelectrolyte used and its doses may vary during the examinations of the process. These changes may lead to its improper use. However, progress in understanding the processes of flocculation of suspensions and sludge allows for the development of a scientific strategy for optimization of these procedures. Polyelectrolytes have been used in the conditioning of sewage sludge due to two major mechanisms: neutralization of the surface charge and formation of intermolecular bridges [5]. Control of the polyelectrolyte dose is required for sludge conditioning, since overdosing increases costs and reduces the effects of sludge dewatering. The optimal dose of a polyelectrolyte is usually associated with a decrease in electrokinetic potential and the formation of large flocs of sludge [6]. There is no practical algorithm related to the properties of polyelectrolytes in order to calculate the most favorable dose at which the best dewatering effects are obtained. The dose is chosen experimentally. This is confirmed by the studies of other researchers [7,8,9]. When using polyelectrolytes to condition sewage sludge, important factors include the polyelectrolyte preparation method, concentration and flocculation time. Sorensen et al. [10] found that the high compressibility of the sludge conditioned with polyelectrolyte has an inhibitory effect on the filtration rate that is strongly correlated with the filtration pressure. Therefore, the main task in the dewatering of biological sludge is the reduction of compressibility, which enables the reduction of the process time and the increase of dry matter in the dewatered sludge. This task can be achieved by adding structure-forming substances, for example, cement, to the sludge before dewatering [3].

The efficiency of mechanical dewatering of sewage sludge mainly depends on sludge properties, e.g., the amount of extracellular polymeric substances, water content, size of sludge particles, the content of dry mass, etc. Before mechanical dewatering, sludge is subjected to preparation in order to change its properties and, consequently, improve conditions of water release. In practice, chemical conditioning is most often used. The role of the chemical mechanism in sewage sludge conditioning is to destroy the colloidal system of sludge and sludge flocculation by the addition of chemical substances such as polyelectrolyte, iron chlorides, etc. Chemical reagents used in sewage sludge conditioning are expensive and contribute significantly to the overall cost of sludge management. Therefore, it is critical to find a cost-effective and efficient way to condition sewage sludge. In the present study, the requirements are met by such chemical substances as fly ash and zeolite. Fly ash particles from hard coal combustion are characterized by their spherical and rough structure. The particle size of fly ash ranges from 0.01 to 0.1 mm. Large contents of SiO2 and Al2O3 from hard coal combustion present in ashes lead to the formation of active spots on the particle surfaces. Substantial specific area of fly ash particles leads to the adsorption of sludge particles and, consequently, the formation of greater aggregates and the increase in the efficiency of sewage sludge dewatering. A high amount of negatively charged sludge particles leads to the repulsion of particles, due to the electrostatic effect and formation of a stable system that impacts on low efficiency during dewatering of sewage sludge. Dosing the fly ashes to sewage sludge with negative electrokinetic potential leads to the increase in the value of 0 mV. A negative charge of sewage sludge is destabilized by positive charges of aluminum, iron or calcium silicates contained in the fly ash. Consequently, this leads to the destruction of stability of colloidal particles and their approaching to each other. With the intermolecular effect of Van der Waals forces, colloidal particles are clustered into greater aggregates, thus significantly improving the dewatering capacity of the conditioned sewage sludge and the clarity of the obtained supernatant.

As a result of the mechanical dewatering of sludge, a highly polluting supernatant is formed, especially with an organic substance. The supernatant from sludge treatment is recirculated, mainly without pretreatment, to the technological wastewater-treatment line. This has an adverse effect on the operating conditions of biological reactors by increasing the load of activated sludge. There are also unfavorable proportions between biologically degradable organic compounds and the content of nutrients [11]. The amount of supernatant is about 0.4–12% of the volume of wastewater flowing into the treatment plant [12,13,14], and even 20% [15,16]. In addition, the supernatant quality is highly variable and depends on the sludge characteristics and treatment methods [16,17,18,19,20,21,22]. For example, the supernatant from the primary sludge thickening is characterized by a high concentration of the dissolved fraction above 20% of total chemical oxygen demand (COD) of raw wastewater [23,24]. Supernatant from mechanical thickening of excessive sludge is characterized by a significant share of non-biodegradable fraction in the range from 69 to 87% of total COD [25].

The aim of the study was to compare the effect of polyelectrolyte and structure-forming substances—conditioners (fly ash and zeolites)—on the efficiency of the pressure filtration process. In the study, we tested independent and dual methods of conditioning and the effect of pressure on the separation efficiency of solid phase and the quality of the supernatant.

2. Materials and Methods

Mixed sludge (primary and excess sludge in the volume ratio about 1:1) from the municipal wastewater treatment plant in Poland was used in the research. The average daily wastewater inflow to the treatment plant is 40,000 m3/d. The mixture was taken from a buffer tank before mechanical-dewatering-station belt presses operating in parallel.

The dry solids (DSs) and volatile solids (VSs) of mixed sludge were, respectively, 29.1% (±0.2%) and 70.9% (±0.6%). The water content in mixed sludge was 97.1%. The pH of the collected sludge was in the range 7.0–7.4.

Cationic Superfloc C-496 polyelectrolyte, zeolite 13X-B1 and fly ash were used as the conditioning substances. Fly ash, in sludge conditioning, is classified as a structure-forming substance. Zeolite is classified similarly, bearing in mind that the final use of the waste zeolite is possible based on its physical properties and not the sorption capacity of commercial zeolite. The fly ash was derived from the combustion of hard coal (coal-fired power plant in Poland) (Table 1). Zeolite 13X-B1 (JALON) is an adsorbent with large pores and high capacity, and it is especially effective for removing air pollutants (Table 2).

Table 1.

Chemical composition of fly ashes from hard-coal combustion (without flue gas desulphurization).

Table 2.

Characteristics of zeolite 13X-B1 mixed with sludge.

Superfloc C–494 high cationic polyelectrolyte (Brenntag) was used at a concentration of 0.1%. The optimal doses of polyelectrolyte C–496 were determined by the capillary suction time test and were 4.0 g/kgDS ± 0.2 g/kgDS (CSK = 38 s). Mixing of the tested sludge with conditioning agents was carried by using a paddle stirrer in a glass vessel. The sludge was stirred with the C-494 dose for 20 s and 250 rpm (G~600 s−1).

After sludge conditioning, mechanical dewatering was carried out in the pressure filtration process, for four different pressures, namely 0.25, 0.5, 0.75 and 1.0 MPa. The tested samples of conditioned sludge had a volume of 100 mL. Ten main combinations were tested in the study, taking into account a variable dose of conditioning substances, dual conditioning and variable filtration pressure (Table 3).

Table 3.

Research combinations tested in the study.

Dry solids (DSs), volatile solids (VSs), capillary suction time (CST) and filtration efficiency were measured according to standard methods [26]. In the supernatant, after sludge filtration, the soluble chemical oxygen demand fraction (CODS) was measured. Hach test tubes and a spectrophotometer Hach Lange DR 5000 were used to measure CODS. The supernatant samples, before CODS measurement, were centrifuged for 15 min at 12,100 rcf and filtered through a membrane filter (0.45 μm, cellulose acetate).

In terms of mathematical analysis, the R2 coefficient of determination of linear regression (of the tested parameters as a function of pressure change) was calculated. In terms of statistical analysis, ANOVA was performed (Statistica 13.3). Combinations 1–10 were tested. Since the ANOVA was negative, that is, not all sets (combinations) were created equal, the Tukey’s post hoc test was performed. The adopted alpha significance level was 0.05. Combinations that differed in the effects of conditioning are marked with letters (a, b, c, d and e) in the graphs.

3. Results

Research on the process of pressure filtration of sewage sludge was carried out for a number of selected combinations of sewage sludge conditioning. During the analysis of the results of the pressure filtration process, the greatest attention was focused on the parameter of filtration efficiency and the sludge dewatering effect directly related to efficiency. The diagrams below present a summary of the most favorable values achieved for individual methods of sludge conditioning.

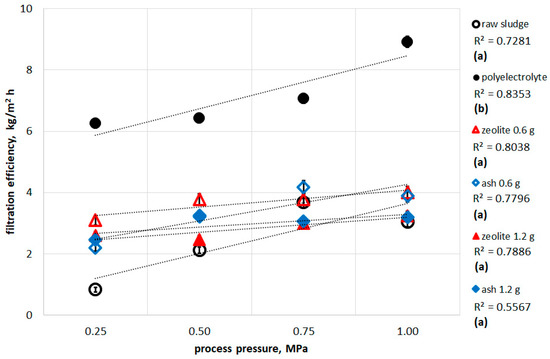

The analysis of the results presented in the graph in Figure 1 reveals that the highest efficiency (ca. 9 kg/m2h) occurred for the sludge conditioned with polyelectrolyte dewatered at the highest filtration pressure. With sludge prepared by using polyelectrolyte, followed by the filtration process, the process efficiency increased with the increasing pressure. A similar tendency was observed when analyzing other samples subjected to filtration. Generally, the factor determining the increase in the filtration-process efficiency for each combination of sludge conditioning was the pressure used. The lowest filtration efficiency was documented for raw sludge samples (from 0.8 kg/m2h for the pressure of 0.25 MPa to 3.08 kg/m2h for the pressure of 1.0 MPa). Statistical analysis showed, that for all conditioning methods, except for polyelectrolyte conditioning (group b), the filtration efficiency was the same (group a).

Figure 1.

The efficiency of filtration of the sludge conditioned with polyelectrolyte or structure-forming substances (Statistical groups a and b).

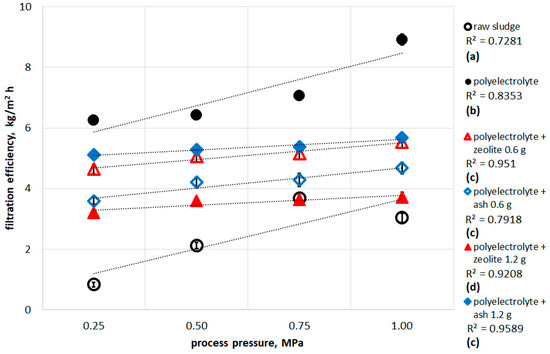

The graph in Figure 2 compares the results of the process efficiency where combined methods were used to condition sewage sludge before the filtration process, using two conditioning factors: polyelectrolyte and zeolite or ash.

Figure 2.

The filtration efficiency of sludge conditioned in combinations using structure-forming substances and polyelectrolyte (Statistical groups a, b, c and d).

Supporting zeolite conditioning with the previous application of polyelectrolyte resulted in an increase in filtration efficiency of sludge prepared in this way. During filtration at the pressure of 1.0 Mpa of these sludge samples (polyelectrolyte + zeolite 0.6 g), an increase in process efficiency was obtained, from 4.01 to 5.54 kg/m2h. A similar tendency was observed in the case of sludge conditioning with ash, preceded by polyelectrolyte dosing (polyelectrolyte + ash 1.2 g), with the growth ranging from 3.19 to 5.68 kg/m2h. The linear trend of increasing the process efficiency depending on the filtration pressure was also maintained. In the case of the dual-conditioning polyelectrolyte-forming substance, significant differences occurred in the case of using polyelectolite + zeolite 1.2 g (group d). The other dual conditioning combinations did not change the filtration efficiency (group c).

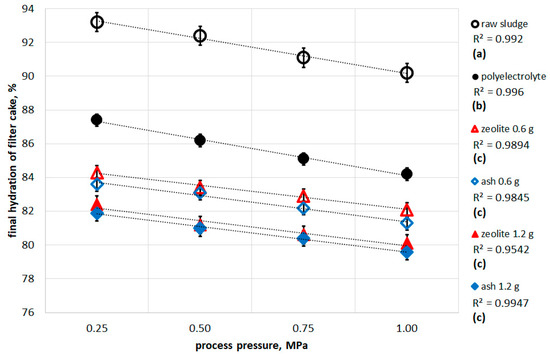

The effects of sewage sludge dewatering are presented in the diagrams in Figure 3 and Figure 4. The highest water content of 93.2% (Figure 3; pressure used in the process, 0.25 MPa) was found for dewatering raw (unprepared) sludge. Lower water content was found for increasing the process pressure, with a final water content of 90.2% obtained for the highest pressure of 1.0 MPa. Using polyelectrolyte for conditioning as an independent conditioning factor, at the highest applied pressure, we found that the final water content was at the level of 84.2%. Significantly better dewatering effects were observed when 0.6 g of ash was added to the samples. Compared to water content in the raw sludge after the process (90.2%), the obtained water content of 81.3% was reduced by ca. 9 percentage points. Increasing the addition of ash (1.2 g) to the sludge before the filtration process led to the decrease of the final water content to the level of 79.6%. A similar pattern was observed in the case of addition of zeolite to the sludge before dewatering in the amount of 6 and 1.2 g. The final water content after the filtration process was 82.1 and 80.1%, respectively (Figure 3).

Figure 3.

Final water content obtained after filtration of the sludge conditioned with polyelectrolyte or structure-forming substances (Statistical groups a, b and c).

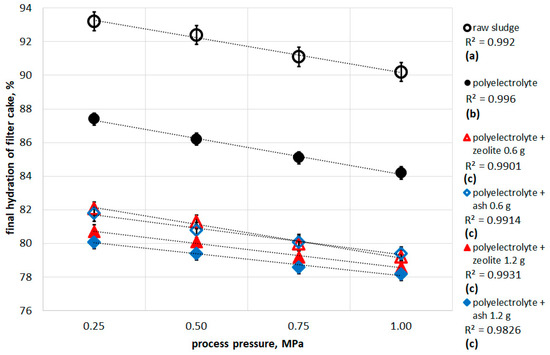

Figure 4.

Final hydration of filter cake of sludge conditioned in combinations using structure-forming substances and polyelectrolyte (Statistical groups a, b and c).

Considering the effects of dewatering of sewage sludge conditioned by a combined method in different variations by using polyelectrolyte and then adding zeolite or ash, it was found that lower water content was obtained in each case compared to dewatering of sludge conditioned by using independent factors (Figure 4). The lowest final water content of 78.2% was obtained by dewatering of sludge samples conditioned by means of a combined method, using polyelectrolyte and 1.2 g of ash (Figure 4).

Regardless of the independent or dual conditioning, the addition of structure-forming substances did not have a statistically significant effect on the change in final hydration (group c).

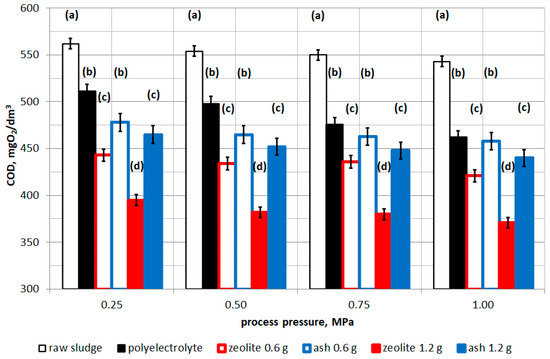

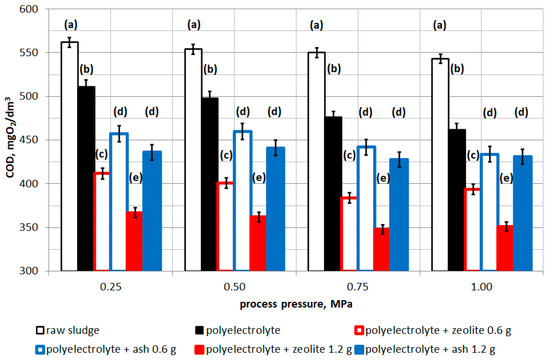

In the supernatant after sludge dewatering, regardless of the filtration pressure, there were no clear changes in the concentration of organic compounds expressed as CODS 4 (Figure 5 and Figure 6). Conditioning of sludge with polyelectrolyte/zeolite/ash caused a decrease in CODS, along with an increase in the pressure used in the filtration process (Figure 5 and Figure 6). Through the use of zeolite for sludge conditioning, the best quality of supernatant after dewatering was obtained. The CODS for raw sludge (non-conditioned) was on average 550 mgO2/L. The sludge conditioning by addition of zeolite at a dose of 12 g/L resulted in a two-fold decrease in CODS to an average of 380 mgO2/L (Figure 5). By using dual conditioning polyelectrolyte + zeolite or ash (Figure 6), a very similar CODS was obtained as in the case of using the single method (Figure 5). The most advantageous combination of conditioning was the use of polyelectrolyte and zeolite (12 g/L), where, at a filtration pressure of 0.75 MPa, a CODS of 348 mg O2/L was obtained.

Figure 5.

Soluble chemical oxygen demand fraction (CODS) changes in supernatant after filtration of sludge conditioned with polyelectrolyte or structuring substances (Statistical groups a, b, c and d).

Figure 6.

CODS changes in supernatant after filtration of conditioned sludge in combination with the use of structuring agents and polyelectrolyte (Statistical groups a, b, c, d and e).

Statistically, the type and dose of the forming substance influenced the quality of sludge liquids. Generally, the use of zeolites in the independent or dual conditioning was significantly different from other methods, and the effect on the quality of the supernatant was different.

4. Discussion

Due to the specific properties of chemical substances added to sewage sludge that lead to destabilization of the colloidal systems of the sludge, mineral particles act as a core for aggregation of sludge flocs on them. Adding fly ash and zeolite led to the formation of microzones with sludge flocs concentrated around particles (cores) of the added chemical substances. This resulted in an increase of the floc size and the bridging of the remaining microspheres, leading to the formation of large reinforced aggregates of sludge flocs which were resistant to structural damage caused by high pressure during filtration. Apart from the destabilization of sludge floc systems, conditioning of sewage sludge with chemical substances used in the above examinations leads to the formation of their structure, which is a permeable and rigid structure that remains porous under high pressure and also changes sludge compressibility. Furthermore, the rough surface of fly ash and zeolite particles is likely to ensure more microchannels that stop solid particles in sewage sludge and enhance the release of free water, thus enhancing the dewatering effect [3].

At all times, the disposal of sewage sludge is a problem for sewage-treatment plants. Regardless of the adopted direction of sludge disposal, combustion or natural use, the most important thing is quick and effective dehydration, which allows the energy demand for water evaporation to be reduced. Theoretically, any waste that does not generate an additional pollutant load on the sludge can be used as a conditioner. The advantage of using energy waste for sludge conditioning is the possibility of recycling by-products of combustion (fly ash), as well as flue gas cleaning (waste zeolites), which, in countries based on coal energy, poses problems with proper disposal. The solution of adding structure-forming substances also seems appropriate in the case of highly contaminated sludge, for which the only disposal option is incineration. A more advantageous solution that can be used for mineralized sludge (by adding fly ash or zeolites) is its use in the construction industry, as an environmentally safe method of sludge disposal [27]. It is estimated that, in the production of building materials such as bricks, ceramic materials and lightweight aggregates, it is possible to replace up to 20% of natural materials [28].

5. Conclusions

The use of polyelectrolyte in sludge conditioning and dewatering was the most advantageous solution in terms of the efficiency (process speed) of sludge pressure filtration. Much lower filtration efficiency was achieved during the dewatering of sludge conditioned with fly ash or zeolite. Dual conditioning based on dosing of polyelectrolyte and ash or zeolite also failed as a method of increasing the efficiency of the process. On the contrary, by the use of structure-forming substances, it was possible to increase the efficiency of solid-phase separation and to reduce the hydration of the filter cake. This phenomenon was correlated with an increase in filtration pressure from 0.25 to 1.0 MPa, as well as with a higher dosage of the forming substances. On the other hand, the zeolite-conditioning method made it possible to reduce contamination of the jet liquid from dewatering that results from the sorption capacity of this material. On the other hand, the zeolite-conditioning method made it possible to reduce the contamination of the supernatant, which results from the sorption capacity of this material. Finally, it should be stated that the use of forming substances in sludge conditioning (especially dual conditioning) intensified the removal of water from the sludge, but the process becomes slower, i.e., more time-consuming.

Author Contributions

M.K. was responsible for conceptualization, methodology, software, investigation, validation, data curation, writing—original draft, writing—review and editing, visualization and supervision. T.K. was responsible for investigation, validation, data curation, resources and writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

The scientific research was funded by the statute subvention of Czestochowa University of Technology, Faculty of Infrastructure and Environment.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Laheij, E.J.; Kerkhof, P.J.A.M.; Hewijn, A.J.M.; Coumans, W.J. Fundamental aspects of sludge filtration and expression. Water Res. 1996, 30, 697–703. [Google Scholar] [CrossRef]

- Zhao, Y.Q.; Bache, D.H. Integrated effects of applied pressure, time, and polymer doses on alum sludge dewatering behaviour. Waste Manage. 2002, 22, 813–819. [Google Scholar] [CrossRef]

- Kowalczyk, M. Enhancement of Processes for Sewage Sludge Dewatering; Technical University of Czestochowa: Czestochowa, Poland, 2012. (In Polish) [Google Scholar]

- Wu, R.M.; Lee, D.J.; Wang, C.H.; Chen, J.P.; Tan, R.B. Novel cake characteristics of waste-activated sludge. Water Res. 2001, 35, 1358–1362. [Google Scholar] [CrossRef]

- Böhm, N.; Kulicke, W.M. Optimization of the use of polyelectrolytes for dewatering industrial sludge of various origins. Colloid Polym. Sci. 1997, 275, 73–81. [Google Scholar] [CrossRef]

- Christensen, J.R.; Sorensen, P.B.; Christensen, G.L.; Hansen, J.A. Mechanisms for overdosing in sludge conditioning. J. Environ. Eng. 1993, 119, 159–171. [Google Scholar] [CrossRef]

- Dentel, S.K.; Dursun, D. Shear sensitivity of digested sludge: Comparison of methods and application in conditioning and dewatering. Water Res. 2009, 43, 4617–4625. [Google Scholar] [CrossRef]

- Dentel, S.K.; Abu-Orf, M.M.; Walker, C.A. Optimization of slurry flocculation and dewatering based on electrokinetic and rheological phenomena. Chem. Eng. J. 2000, 80, 65–72. [Google Scholar] [CrossRef]

- Buyukkamaci, N.; Kucukselek, E. Improvement of dewatering capacity of a petrochemical sludge. J. Hazard. Mater. 2007, 144, 323–327. [Google Scholar] [CrossRef]

- Sorensen, P.B.; Moldrup, P.; Hansen, J.A.A. Filtration and expression of compressible cakes. Chem. Engng. Sci. 1996, 51, 967–979. [Google Scholar] [CrossRef]

- Torà, J.A.; Lafuente, J.; Garcia-Belinchón, C.; Bouchy, L.; Carrera, J.; Baeza, J.A. High-throughput nitritation of reject water with a novel ammonium control loop: Stable effluent generation for anammox or heterotrophic denitritation. Chem. Eng. J. 2014, 243, 265–271. [Google Scholar] [CrossRef]

- Ryzińska, J. The problem of reject water and the possibility of their treatment in Poland. GazWoda I Tech. Sanit. 2006, 7–8, 58–62. (In Polish) [Google Scholar]

- Gajewska, M.; Obarska-Pempkowiak, H. Effect of recycling of reject waters from dewatering the sludges on the operation efficiency of a wastewater treatment plant. Przemysł Chem. 2008, 87, 448–451. (In Polish) [Google Scholar]

- Guo, C.H.; Stabnikov, V.; Ivanov, V. The removal of nitrogen and phosphorus from reject water of municipal wastewater treatment plant using ferric and nitrate bioreductions. Bioresour. Technol. 2010, 101, 3992–3999. [Google Scholar] [CrossRef] [PubMed]

- Dąbrowski, W. A study of the digestion process of sewage sludge from dairy WWTP to determine the composition and load of reject water. Water Pr. Technol. 2014, 9, 71–78. [Google Scholar] [CrossRef]

- Morales, N.; Val del Río, A.; Vázquez-Padín, J.R.; Méndez, R.; Mosquera-Corral, A.; Campos, J.L. Integration of the Anammox process to the rejection water and mainstream lines of WWTPs. Chemosphere 2015, 140, 99–105. [Google Scholar] [CrossRef]

- Li, Z.; Ma, Y.; Hira, D.; Fujii, T.; Furukawa, K. Factors affecting the treatment of reject water by the anammox process. Bioresour. Technol. 2011, 102, 5702–5708. [Google Scholar] [CrossRef]

- Erdirençelebi, D.; Küçükhemek, M. Diagnosis of the anaerobic reject water effects on WWTP operational characteristics as a precursor of bulking and foaming. Water Sci. Technol. 2015, 71, 572–579. [Google Scholar] [CrossRef]

- Gajewska, M.; Obarska-Pempkowiak, H. The role of SSVF and SSHF beds in concentrated wastewater treatment, design recommendation. Water Sci. Technol. 2011, 64, 431–439. [Google Scholar] [CrossRef]

- Wäger-Baumann, F.; Fuchs, W. Process variant for the treatment of anaerobic digester effluent with a membrane bioreactor. Environ. Eng. Sci. 2011, 28, 611–627. [Google Scholar] [CrossRef]

- Wett, B.; Podmirseg, S.B.; Gomez-Brandon, M.; Hell, M.; Nyhuis, G.; Bott, C.; Murthy, S. Expanding DEMON sidestream deammonification technology towards mainstream application. Water Env. Res. 2015, 87, 2084–2089. [Google Scholar] [CrossRef]

- Dąbrowski, W.; Karolinczak, B.; Gajewska, M.; Wojciechowska, E. Application of subsurface vertical flow constructed wetlands to reject water treatment in dairy wastewater treatment plant. Env. Technol. 2017, 38, 175–182. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Song, Y.; Liu, R.; Pan, H.; Xiang, L.; Qian, F. Identifying changes in dissolved organic matter content and characteristics by fluorescence spectroscopy coupled with self-organizing map and classification and regression tree analysis during wastewater treatment. Chemosphere 2014, 113, 79–86. [Google Scholar] [CrossRef]

- Hocaoglu, S.M.; Insel, G.; Cokgor, E.U.; Baban, A.; Orhon, D. COD fractionation and biodegradation kinetics of segregated domestic wastewater: Black and grey water fractions. J. Chem. Technol. Biotechnol. 2010, 85, 1241–1249. [Google Scholar] [CrossRef]

- Szaja, A.; Aguilar, J.A.; Łagód, G. Estimation of chemical oxygen demand fractions of municipal wastewater by respirometric method—Case study. Annu. Set Environ. Prot. 2015, 17, 289–299. [Google Scholar]

- APHA. Standard Methods for the Examination of Water and Wastewater, 21st ed.; American Public Health Association; American Water Works Association; Water Environment Federation: Washington, DC, USA, 2005. [Google Scholar]

- Świerczek, L.; Cieślik, B.M.; Konieczka, P. The potential of raw sewage sludge in construction industry—A review. J. Clean. Prod. 2018, 200, 342–356. [Google Scholar] [CrossRef]

- Chang, Z.; Long, G.; Zhou, J.L.; Ma, C. Valorization of sewage sludge in the fabrication of construction and building materials: A review. Resour. Conserv. Recycl. 2020, 154, 104606. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).