1. Introduction

To develop a sustainable future for all people, changes must be implemented in all industrial sectors. The construction industry in particular is responsible for a large percentage of resource consumption, grey energy, and emissions [

1]. Emissions and required energy caused by buildings can be divided in two different parts: on the one hand operational energy, which includes heating, cooling, and electricity and on the other hand embodied energy, which includes the production, transport, and disposal of building materials [

2]. In the last decades a lot of research projects focused on the development regarding operational energy, but recent studies show that it is very important to reduce embodied energy as well. This is possible with the use of building materials based on renewable resources.

Fibers from renewable resources represent a potential alternative to many synthetic materials and at the same time open up a diverse market for the further utilization of by-products from agriculture and the timber industry. Plant-based natural fibers, which can be found in many different countries and are usually a low cost renewable alternative for conventional fibers used in composites, predominantly have much lower emissions in production and processing [

3]. An industrial interest also lies in the use of agricultural residues, since a sustainable cascade use of raw materials is becoming increasingly important with the higher use of renewable raw materials.

The use of agricultural residues reduces the environmental impact and the cost of cement-based composites. Resulting material mixes however often yield only limited mechanical performance and are more sensitive to moisture than conventional cementitious building products [

4]. However, it has been shown that the addition of natural fibers can reduce the amount of cracks and enhances the flexural strength and the tensile strength of the concrete [

5]. Many different natural fibers were investigated in several research projects over the last years [

3]. To increase adhesion between wheat straw and cement, chemical pretreatment of the fibers with NaOH has been proven successful [

4]. It is not yet known whether this method is applicable to other natural fibers.

Blast furnace slag is an industrial by-product that until recently was disposed of in landfills, but is now increasingly being used as an additive in the production of building materials such as cement. After it is granulated, blast furnace slag can partially replace cement in the concrete mix. Since 2006, EN 15167 “Blast furnace slag for use in concrete, mortar and grout” has been a harmonized European material standard for using granulated blast furnace slag in concrete mixes. Granulated blast furnace slag (GBFS) can be used to partially replace cement up to 50% in concrete without affecting its compressive strength [

6]. This fact was taken as a basis to design an ecologically optimized concrete recipe.

Adding industrial and agricultural by-products to the concrete recipe are two approaches to reduce the environmental impact of concrete. These two approaches have not been combined yet. The design of ecologically optimized concrete with granulated blast furnace slag with the addition of NaOH-treated rice straw fibers could reduce both the embodied carbon and embodied energy of the building material, provide a sustainable cascade use of agricultural residues and could therefore be a low-cost alternative to conventional concrete. However, it is very important that the mechanical and physical properties do not deteriorate, which is why various experiments must be carried out.

Hence, the main goal of this project was

to find an ecological optimized concrete recipe that can be used as the basis for the rice straw concrete,

to investigate the effect of sodium hydroxide (NaOH) treatment on the characterization of rice straw, and

to investigate the physical and mechanical properties of the developed rice straw concrete.

2. Materials and Methods

First an ecologically optimized concrete mixture was created, that was used as a basis for the further investigations with either untreated or pretreated rice straw particles. Before the concrete recipe was designed, several experiments for investigating a suitable mortar were made.

2.1. Materials

The investigated concrete mixtures are composed of cement, water, fillers, sand, aggregates, additives, and rice straw. The properties of the materials used are characterized as follows. Local tap water with a pH value of 7.0 was used. Natural river sand with 100% sieve passage on sieve no. 3/8 and at least 80% sieve passage on sieve no. 4 was used. The crushed aggregate used had a retention capacity of at least 20% on sieve no. 4.

The binders used are Portland cement, gypsum and blast furnace slag, each mixed with varying proportions of limestone powder and silica fume. CEM I 52.5N was used as Ordinary Portland cement (OPC) according to Egyptian standard ES 4756 and European standard EN 197. The oxide compositions of the cement used are shown in

Table 1. The Silica fume powder (SF), which meets the requirements of ASTM C 1240 contained an average of 92.85% SiO2. Granulated blast furnace slag (GBFS) was grinded to a size of 0.15–0.20 mm. Local limestone powder CaCO3 (LSP) retained on sieve no. 200 with a specific weight of 2.61 kg/cm

3.

To improve the workability of fresh concrete, a commercially available superplasticizer according to ASTM C 494, type G was used. Sodium hydroxide (NaOH) in flakes or pellets with a purity of 97%–98% was dissolved in water to produce a 1% lye. This lye was used to treat the rice straw particles to reduce their inhibitory effect on cement hydration.

Figure 1 shows the local Egyptian rice straw, on the left side it is untreated and on the right side it is pretreated with the NaOH lye.

2.2. Examined Mortar Mixtures

Table 2 shows the investigated mortar mixes. The indicated weight of the materials refers to the dry weight. OPC was replaced in varying proportions by LSP, SF, gypsum(G), and GBFS. The amount of sand and water remained the same in all tests. A control test specimen consists exclusively of OPC, sand and water. The mixtures differ in the different addition of GBFS, which replaces the OPC. The OPC GBFS binders were mixed with sand in a weight ratio of 1:3. The respective materials were mixed together to form a homogeneous mixture, then water was added. Afterwards, the mixture was mixed further for two minutes until a paste with the required workability was obtained. This was filled into a cubic cavity with a side length of 50 mm according to ASTM C 109, covered with a cling film to prevent moisture evaporation and cured for 24 h at room temperature. After 24 h, the specimens were demolded and stored under water at 25 °C in the laboratory until the time of testing.

2.3. The Effect of Chemical Pretreatment on Morphological and Structural Surface of Rice Straw

A scanning electron microscopy (SEM) was used in order to find out how the chemical pretreatment affects the morphology and structure of the rice straw particles. Observing the surface morphology of the straw provides information on the degree of interfacial adhesion between the rice straw fiber and the matrix.

According to ASTM D1109-84 [

7], the treated rice straw was prepared by soaking it in a 1% NaOH solution for 24 h and afterwards was filtered through a 2 mm sieve. The ratio between rice straw and soaking solution was 1:10 by weight. The rice straw was rinsed with tap water until the water became lucent. After the pretreated rice straw was dried in an oven at 105 ± 2 °C it was separated into 1–30 mm long particles by cutting and packed in polyethylene bags to keep out moisture.

2.4. The Influence of Pretreated Rice Straw on the Physical and Mechanical Properties of Rice Straw Concrete

2.4.1. Concrete Design

The concrete mix was designed according to the standard BS5328. Part 2 [

8], M-25 grade concrete. Normal-density aggregates were used, the unit weight of concrete was assumed to be 2400 kg/m

3. The aggregate was chosen to represent 77% of the mass. The aggregates have been selected so that they correspond to the standard grading curves. For instance, the coarse aggregates (65%) comprise 590 kg/m

3 (50%) of 20 mm aggregates, 590 kg/m

3 (50%) of 10 mm aggregates, and 650 kg/m

3 (35%) of fine aggregate, according to the standard grading curves. The water-binding material ratio is defined as 0.55. The mass of binding material amounts 370 kg/m

3, the mass of the used water amounts 200 kg/m

3.

The second step was to design the rice straw content. Since no code provision is available for a concrete mixture with rice straw, the M-25 mix was defined as a control sample for the other rice straw concrete mixes. Ten different rice straw concrete mixtures were obtained by replacing the OPC with different weight percentage of untreated and treated (1% NaOH solution) rice straw particles, namely, 3, 6, 9, 12, and 15%. The different recipes of the M-25 concrete with untreated and treated rice straw particles are presented in

Table 3.

2.4.2. Preparation of the Test Samples

The materials for the concrete mixtures were first weighed and mixed in a dry state for 3 to 4 min. Water and superplasticizer were then added to the dry mixture to improve the processing properties. Mixing was continued for about 6 to 8 min and the fresh concrete was divided into two identical test specimens.

The first part was used to measure the fresh concrete properties, the second part was placed in different steel moulds, compacted and covered with a diffusion-proof foil. After 24 h, the specimens were demoulded and stored in water at 25 °C in the laboratory until the time of testing.

2.4.3. Test Procedure

The fresh concrete was tested according to ASTM C231-03 [

9]. The hardened concrete was tested according to BS 1881:Part 114 [

10].

The porosity was calculated after 28 days using the following equation:

where P: Saturated porosity, %, w

a: Sample weight of the saturated sample in air, g., w

d: Dry weight of the sample after 24 h in the oven at 105 ± 5 °C, g., w

w: Sample weight in water, g.

This method was used for the measurement of the porosity of cement-based materials according to [

11,

12,

13].

The compressive, splitting tensile and flexural strength were measured in accordance to BS 1881:Part 108 [

14], ASTM C 496 [

15] and ASTM C 293 [

16] and respectively, using a universal testing machine. Cube specimens with dimensions of 150 mm for concrete and 50 mm for mortar were used to measure the compressive strength. The splitting tensile strength was measured with a cylindrical specimen of 150 mm diameter and 300 mm height. The flexural strength was also carried out on a prism sample with dimensions of 100 × 100 × 400 mm. The compressive, splitting tensile and flexural strength tests were carried out after 28 days. Three specimens were tested for each material property.

3. Results and Discussion

3.1. Morphological and Structural Surface of Rice Straw Particles

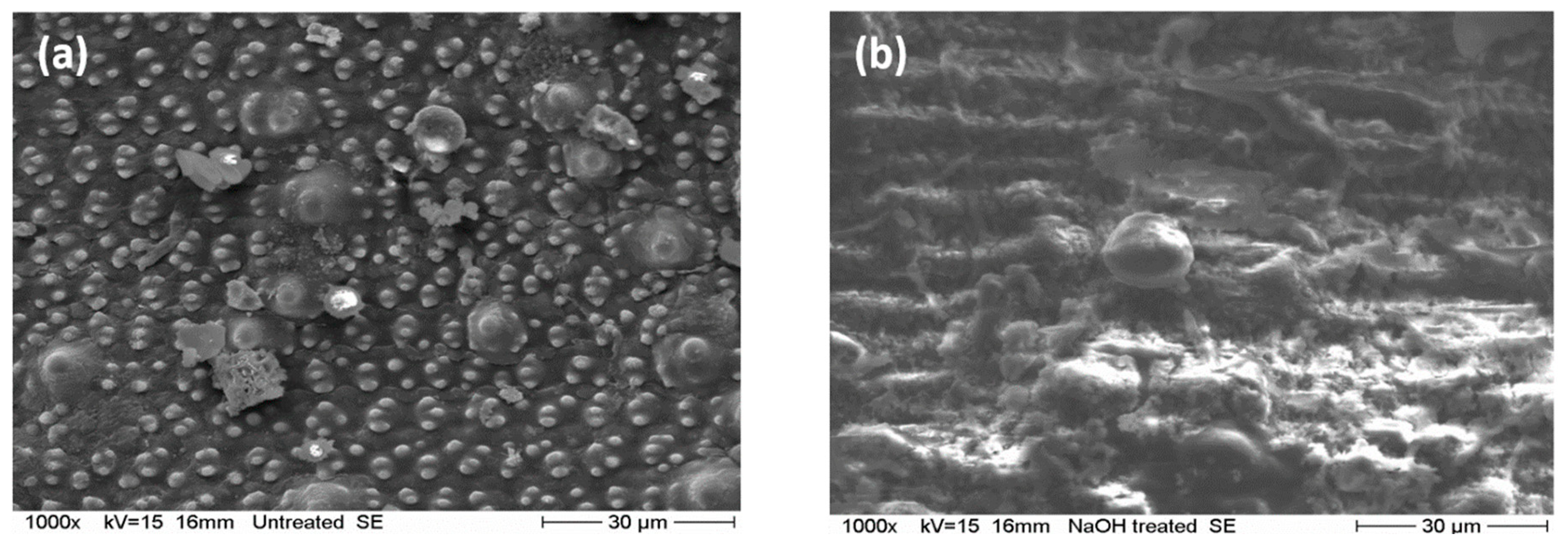

It was expected that the surface morphology of untreated straw fibers would differ from the surface morphology of treated straw fibers in terms of smoothness and roughness. The SEM images of untreated fibers in

Figure 2a show that the initial condition of rice straw has a regular and compact surface structure. In addition, the surface is covered with a layer of oils, waxes and extracts, which are part of the natural constitution of the lignocellulose fiber. This layer was also detected by [

17,

18] in the analysis of untreated coconut fiber, sugar cane bagasse and brown coconut fiber. The micrographs in

Figure 2b show the treatment of straw fibers with NaOH, which produced a rough surface. According to Troedec et al. [

19], treatment with NaOH removes the extractives, waxes, oils, and amorphous components such as hemicellulose and lignin from the fiber surface, thus increasing the overall roughness of the surface. With the removal of these substances, the presence of parenchyma cells, which are the natural component of lignocellulose fibers, as well as the presence of spherical protuberances, which are fat deposits known as “tyloses”, can be detected [

20].

Figure 2b shows the rough surface of the NaOH-treated fiber and thus creates a basis for the assumption that the connection to the cement matrix will be better than with untreated fibers.

3.2. Influence of Blast Furnace Slag on the Compressive Strength

The results of the tests on the compressive strength of OPC and OPC with 10, 20, 30, and 40% GBFS mixtures after 3, 7, and 28 days are shown in

Figure 3. All mixtures showed a continuous increase in compressive strength with increasing curing time. The diagram also illustrates that all mixtures containing up to 20% GBFS showed higher compressive strength values than the control sample. The samples with more than 30% GBFS showed a decrease in compressive strength. The maximum compressive strength of 61 MPa was achieved after 28 days using a GBFS content of 10%. The minimum compressive strength of 13.3 MPa was achieved using a GBFS content of 40% after three days. After 28 days the compressive strength values of 39, 52.5, 58.9, and 61 MPa were achieved using the mix with GBFS rations of 40%, 30%, 20%, and 10%, respectively. The aim was to use as much GBFS as possible without significantly reducing the compressive strength. This is achieved when the OPC is substituted with 30% GBFS. Therefore, a GBFS-OPC mixture with a GBFS content of 30% was chosen for the next part of the investigation.

The increased compressive strength of mixtures with a GBFS replacement content of up to 20% could be explained due to the following combined reasons:

To sum up, the concrete recipes with a replacement of OPC with 30% GBFS shows the highest amount of GBFS without a significant reduction of strength compared to the reference sample.

3.3. Influence of the Rice Straw Content and Its Chemical Pretreatment on the Properties of the Mortar Mixture

In the following chapters the properties of the investigated concrete with pre-treated and untreated rice straw fibers are shown. In every experiment a control sample was tested to compare the findings with the performance of a conventional concrete. The values of these control samples are shown in the following figures at 0% rice straw content.

3.3.1. Air Content

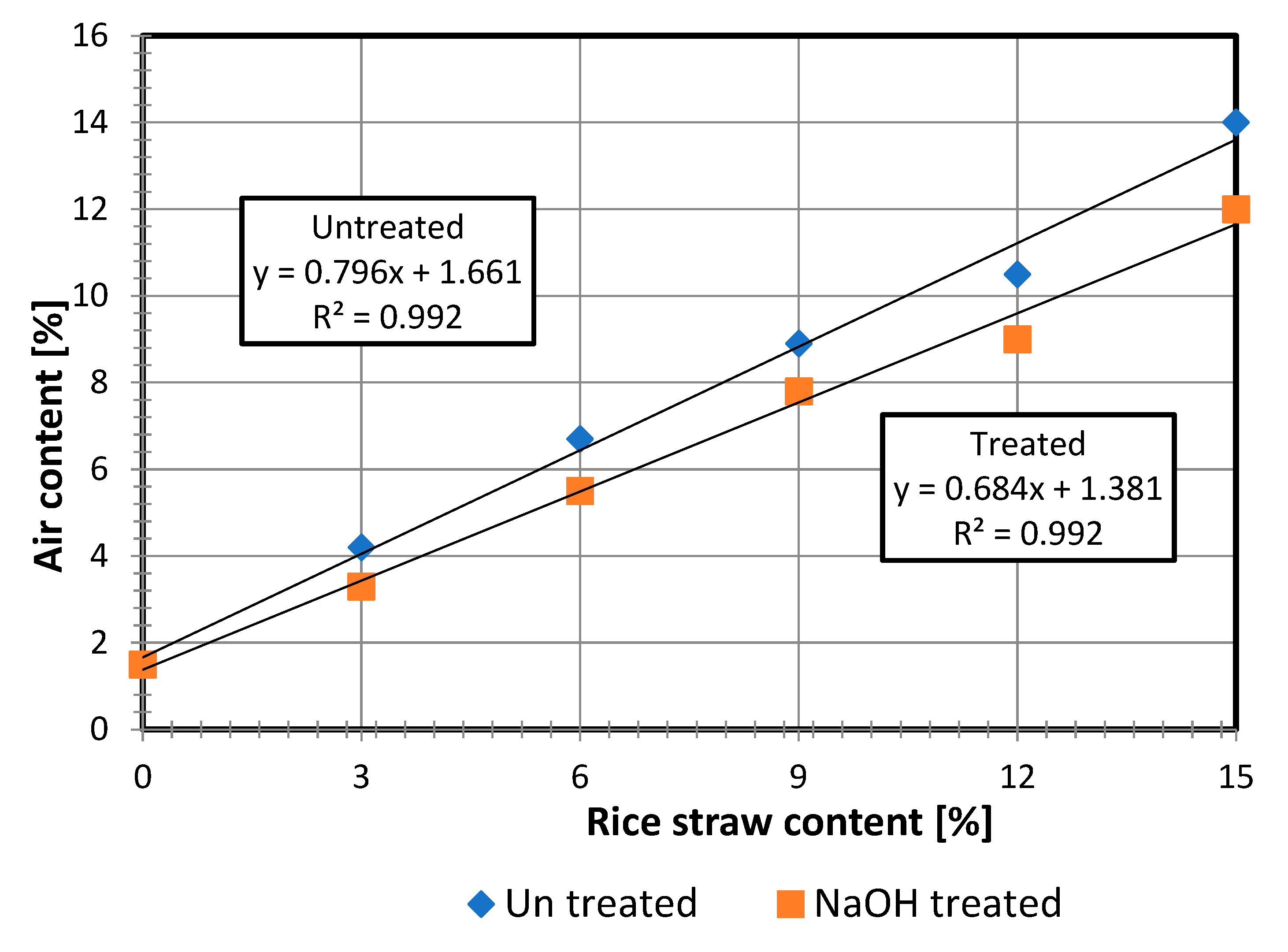

The results of the tests carried out are illustrated in

Figure 4 and clearly show that the addition of straw particles increased the air content. The values vary from 1.5% for the control sample to 14% for concrete with untreated straw fibers. The compaction of concrete with straw fibers becomes difficult at high contents, as air voids are inserted. The addition of treated rice straw fibers increases the workability compared to untreated rice straw fibers, which explains the lower air content. However, it must be emphasized that the air content depends on many variables, such as the mixing process, composition, grain size distribution, physical and chemical properties of the cement used, and many other complex parameters [

24].

A higher air content leads to a lower density, but at the same time the weight can be reduced, which normally leads to a lower environmental impact as transport is minimized. A higher air content can also improve the insulating effect of the building material.

3.3.2. Dry Weight

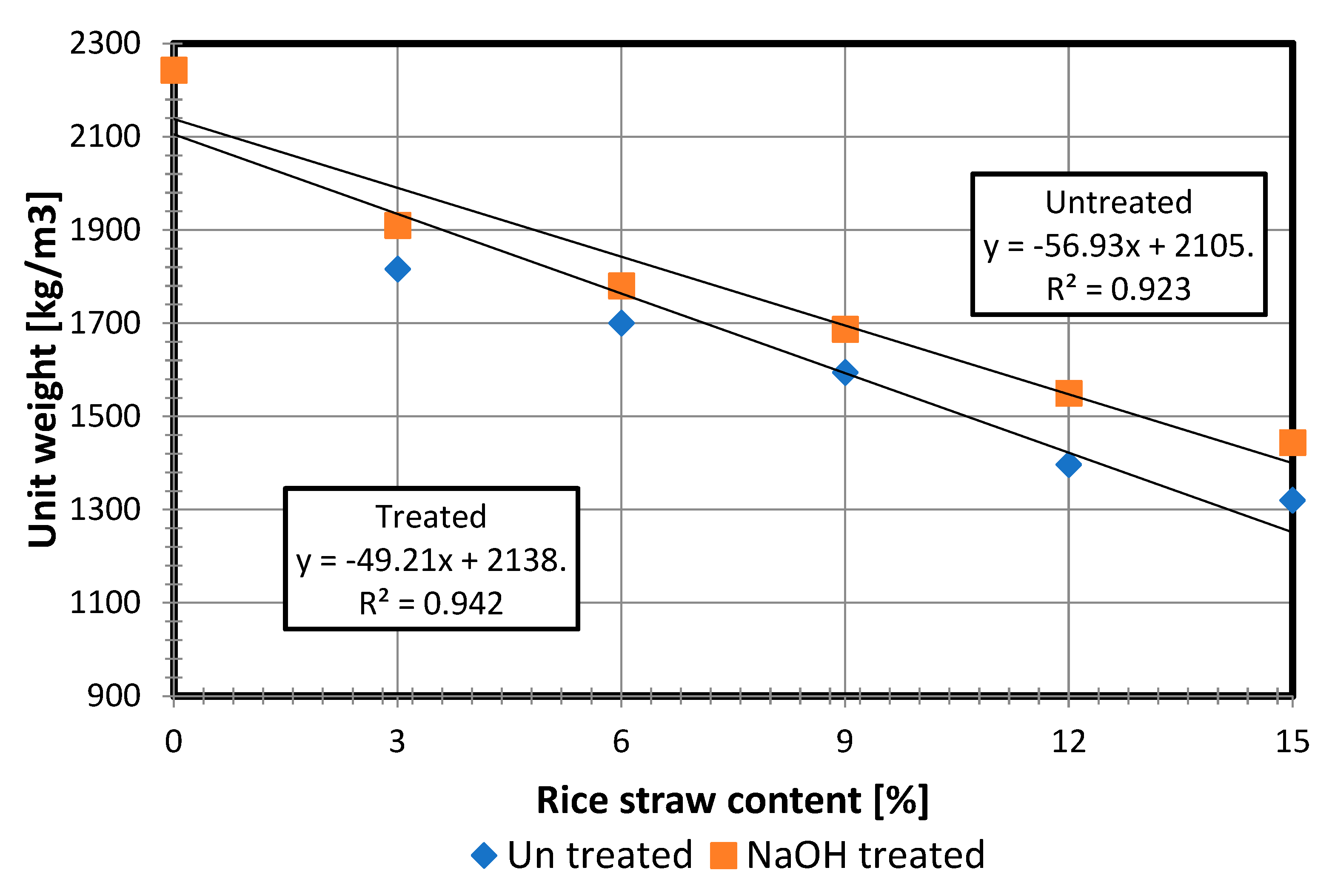

The dry unit weights of untreated and pretreated rice straw concrete with different straw contents are shown in

Figure 5. The values for the dry weight units decrease from 2243 kg/m

3 for the control sample to 1444 kg/m

3 and 1320 kg/m

3 for concrete mixes containing 15% pretreated and untreated straw fibers respectively. These values correspond to reductions of up to approximately 35.6% for treated and 41% for untreated straw particles respectively. In general, the higher the straw content, the lower the density of the composite material. This property is also frequently observed with composite materials made of wood and cement, as wood particles generally have lower bulk densities than cement. The treated particles tend to have smaller particle sizes and are therefore probably better able to bond to the cement matrix, which minimizes air voids [

22]. The NaOH-treated rice straw concrete shows a higher dry weight at every tested rice straw concrete.

The Egyptian standard specification No 1349-1991 state a dry density of 2 g/cm3 for cementitious sandstones. Based on this value, the rice straw content of 0–9% is acceptable for cementitious sandstones.

3.3.3. Porosity

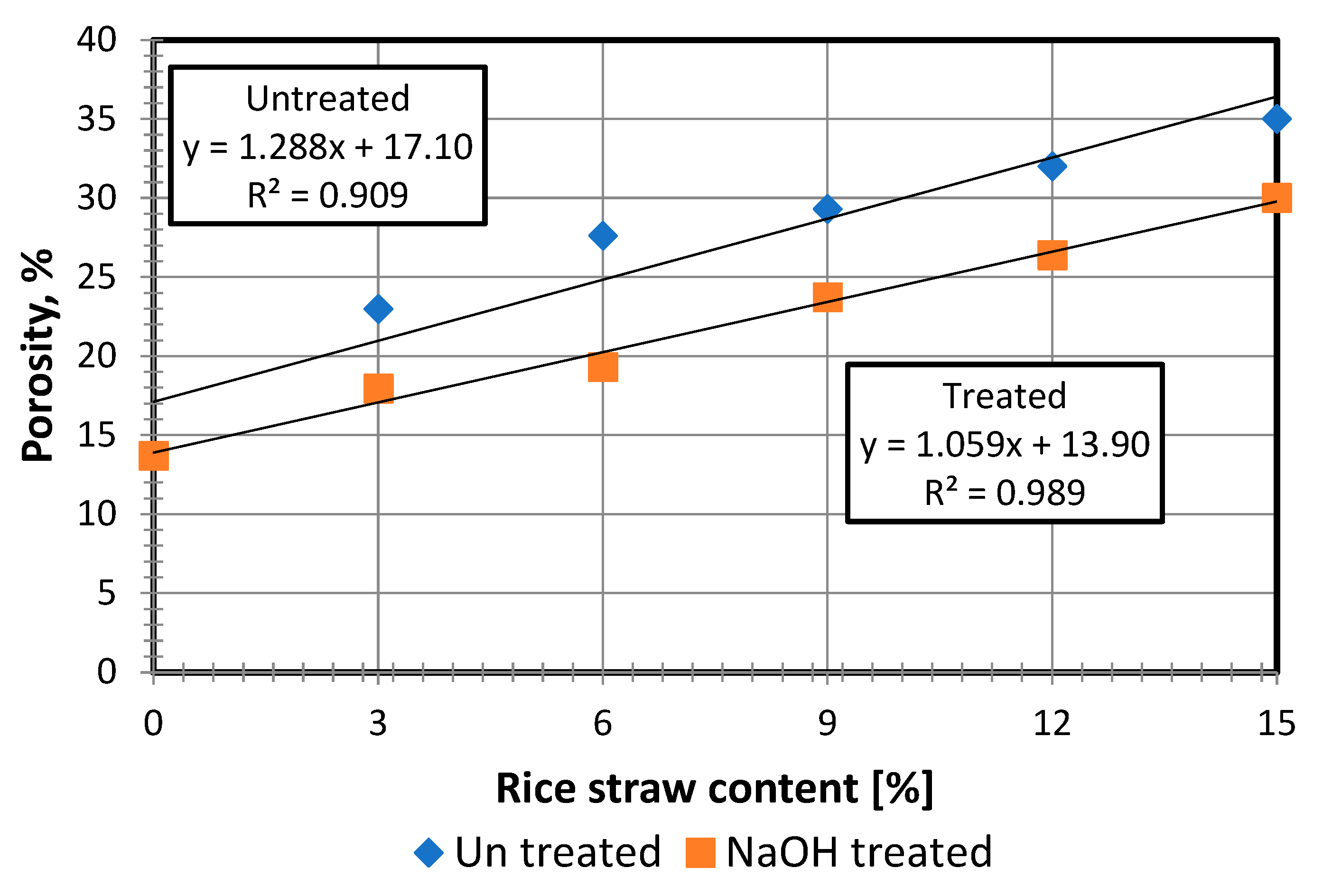

The correlation between the porosity of the tested material samples and the straw content is shown in

Figure 6. In general, the porosity of the material increases when the straw content is increased. Overall, the porosity varies between 13.7% at 0% straw content by weight and 32.05% at 15% untreated straw content. The samples with NaOH-treated rice straw fibers show a lower porosity than the samples with untreated rice straw fibers.

The addition of a certain amount of straw fibers (up to 20%) leads to an accumulation of voids, especially when untreated straw particles are used. This effect offers the possibility to reduce the composite compressive strength. A regression analysis was carried out to determine the relationship between straw content and porosity, as shown in

Figure 6.

3.3.4. Compression Strength

Figure 7 shows the compressive strength of the concrete in relation to the straw fiber content and treatment over a period of 28 days. The results show that the compressive strength decreases with an increasing straw fiber content. The compressive strength of the untreated straw concrete was lower than the strength of the treated straw concrete at the same straw content.

The compressive strength value for the reference concrete decreased from 32 MPa to 3.44 MPa for untreated and 3.7 MPa for treated straw concrete, respectively, at 15% straw content. This corresponds to an 89% and 88% decrease in compressive strength for untreated and treated straw concrete at 15% straw content. The compressive strength values are in the range of the values given by [

22] for composite materials containing straw particles. A possible explanation for this situation is provided by [

24], where the influence of different fibers on the compressive strength of cement-like materials is described. The porosity of the materials largely determines the strength properties of cementitious materials. At low contents (0.5–1.0 vol%) fibers improve the compressive strength by minimizing crack growth. However, a higher fiber content increases the porosity of the composite and leads to a loss of compressive strength [

22]. Other reasons for an increase in porosity at higher straw contents may be a higher water content and poorer compaction [

24]. The decrease in compressive strength is also attributed to the physical properties of the straw particles because they are not as stiff as the cement matrix. Under high loads, cracks form around the particles, which subsequently accelerate the failure of the cement matrix.

An interesting finding is the relative high difference between the compressive strength of the untreated and NaOH-treated rice straw concrete at a rice straw content of 3% compared to the almost identical results at a rice straw content of 15%.

Compared to other studies, the relationship between the compressive strength of concrete made from rice straw fibers is closely related to the cement composites made from cotton straw produced by [

25]. According to the Egyptian standard, specification number 1349-1991 the compressive strength of cementitious sandstones should not be less than 7 MPa for load-bearing and not less than 2.5 MPa for non-load-bearing stones. Due to this fact, the cement specimens made of rice straw with up to 9% straw content are suitable for load-bearing structures.

3.3.5. Splitting Tensile Strength

Figure 8 shows the effect of rice-straw on the splitting tensile strength of hardened concrete over the time period of 28 days. The results show that it decreases by increasing the rice straw percentage, for both treated and untreated rice-straw samples. The splitting tensile strength ranges of 2.65–1.17 for treated and 2.52–1.03 MPa for untreated rice straw were obtained by using a concrete mix with a rice straw content of 3–15%, respectively. The control sample obtained a splitting tensile strength of 2.78 MPa.

Similar to the previous experiments, the results of the NaOH-treated samples show an improved performance compared to the untreated samples.

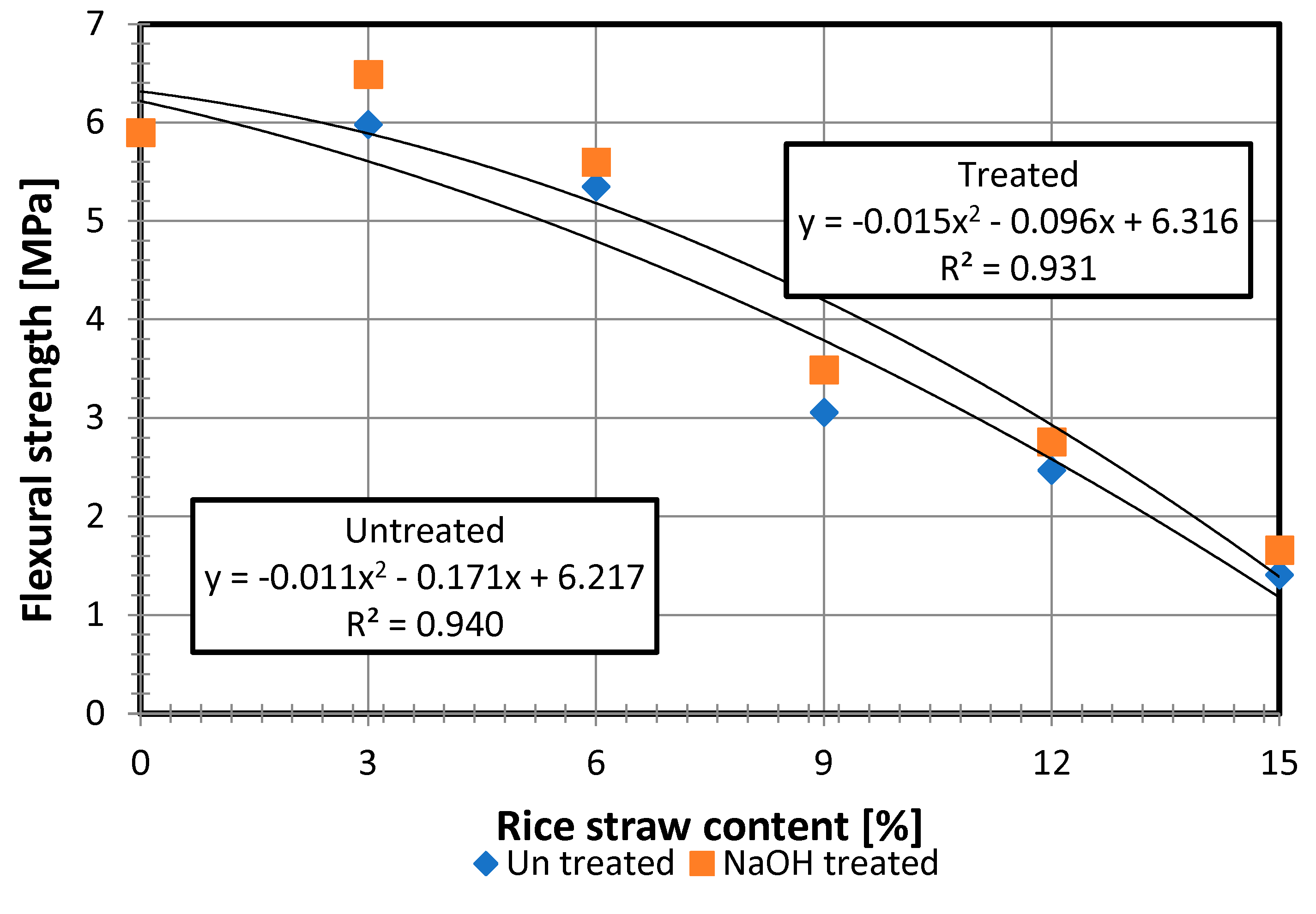

3.3.6. Flexural Strength

The flexural strength is shown in

Figure 9. The results show that the flexural strength ranges of 6.49–1.66 for pretreated and 5.98–1.41 MPa for untreated rice straw were obtained by using concrete mixtures with a straw content of 3–15%. The control specimen obtained a flexural strength of 5.9 MPa.

According to the Egyptian standard, specification number 1349-1991 states that the flexural strength should not be less than 3 MPa. Due to this fact, the cement specimens made of rice straw with up to 9% straw content are suitable for loadbearing structures. In general, a better performance could be observed in the tests with treated rice straw fibers.

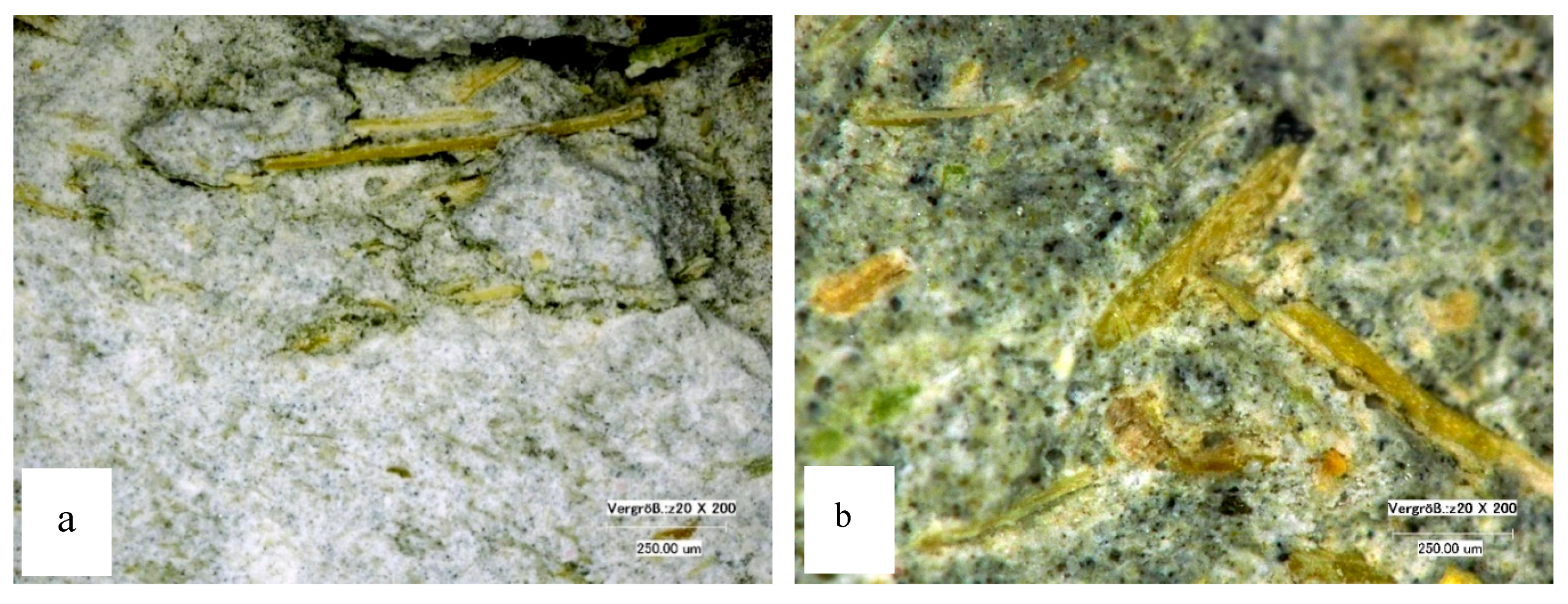

3.3.7. Microscopic Morphological Fracture Surface

Figure 10 shows the microscopic morphological fracture surface between untreated and treated rice straw and concrete at 15% rice straw content. A gap between untreated straw and the rest of the material mix is visible, which indicates a defective bond. This may be due to the fact that the alkaline properties of rice straw impair the hydration phase of the cement. The more untreated rice straw was added, the greater the impairment to the hydration phase and the worse the bonding of the different composites. Due to the removal of the alkaline surfaces by the lye, no gap is visible between treated rice straw and the rest of the material mixture. Therefore, SEM pictures verify the hypothesis that the degree of bonding between the rice straw and the concrete mix is increased when rice straw is treated with an NaOH solution.

4. Conclusions

The carried out experimental studies determine the physical and mechanical properties of an ecologically optimized rice straw concrete with granulated blast furnace slag (GBFS). It was possible to design a concrete mix with a substitution of 30% OPC with GBFS. A lower content of GBFS would have led to a higher compressive strength, but the aim was to use as much GBFS as possible to lower the environmental impact.

In general, the use of rice straw fibers as an aggregate in concrete minimizes weight as well as the compressive and splitting tensile strength. The porosity increases with the additional use of straw fibers. The flexural strength of rice straw concrete has been increased by increasing the straw content up to 3%. To sum up, the addition of the organic component reduces the engineering parameters of the concrete mix, with the exception of the flexural strength. As an advantage the higher air content could improve the thermal insulation. In addition, the use of industrial and agricultural by-products such as GBFS and rice straw contributes to resource protection and a sustainable cascade use of raw materials.

The mechanical tests in which the rice straw was treated with NaOH achieved a higher density, a lower porosity, a higher compressive strength, splitting tensile strength and flexural strength than tests with untreated straw fibers. The degree of bonding between the rice straw and the concrete mix is increased when rice straw is treated with a NaOH solution. In general, the performance of the rice straw concrete increases, when the rice straw particles are treated with a NaOH solution. The initial hypothesis whether the treatment of NaOH also improves the performance of rice straw as an additive in concrete can be answered with yes.

The specimens containing 9% straw particles show great potential in the application for load bearing structures.

The results validate that rice straw concrete can provide a basis for the development of constructions in hot and dry climates, as [

26] also investigated with barley straws sand concrete. Further research could also investigate the ability of increased vibration damping, as organo-mineral cements often show this ability.

Overall, it could be shown that rice straw concrete is a potential ecologically optimized building material.

Author Contributions

T.A.: conceptualization, methodology, investigation, writing—original draft preparation; M.M.: conceptualization, methodology, investigation, writing—original draft preparation; M.K.: conceptualization, methodology, investigation, supervision; M.O.: conceptualization, investigation, methodology, writing—original draft preparation; I.Y.: methodology, editing, supervision; H.F.: extension of the research idea; rewriting the manuscript, correcting English language and managing the manuscript; E.S.: correcting English language; A.K.: head of team; support in sharpening the research idea. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The authors acknowledge the Open Access Funding by TU Wien.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- International Energy Agency. 2019 Global Status Report for Buildings and Construction. Towards a Zero-Emisisions, Efficient and Resilient Buildings and Construction Sector; IEA: Paris, France, 2019. [Google Scholar]

- Pomponi, F.; Moncaster, A. Scrutinising embodied carbon in buildings: The next performance gap made manifest. Renew. Sustain. Energy Rev. 2018, 81, 2431–2442. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Banthia, N. Plant-based natural fibre reinforced cement composites: A review. Cem. Concr. Compos. 2016, 68, 96–108. [Google Scholar] [CrossRef]

- Silva, J.V.F.; Bianchi, N.A.; Oliveira, C.A.B.; Caraschi, J.C.; Duarte de Souza, A.J.; Molina, J.C.; Campos, C.I. Characterization of composite formed by cement and wheat straw treated with sodium hydroxide. Bioresources 2019, 14, 2. [Google Scholar]

- Shrestha, R. Effect of Treated Straw Fibers on the Mechanical and Durability Characteristics of Concrete. Ph.D. Thesis, Thapar Institute of Engineering and Technology, Patiala, India, 2019. [Google Scholar]

- Singh, A.; Bhadauria, S.S.; Kushwah, S.S.; Tare, K. The study on optimization of cement and fine aggregate by blast furnace slag in concrete. AIP Conf. Proc. 2019, 2158. [Google Scholar] [CrossRef]

- ASTM D1109-84(2013). Standard Test Method for 1 % Sodium Hydroxide Solubility of Wood; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- BSI Group. Concrete: Methods for Specifying Concrete Mixes; BSI Group: London, UK, 1997. [Google Scholar]

- ASTM C231 / C231M-17a. Standard Test Method for Air Content of Freshly Mixed Concrete by the Pressure Method; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- BSI Group. Testing Concrete. Methods for Determination of Density of Hardened Concrete; BSI Group: London, UK, 1983. [Google Scholar]

- Papadakis, V.G.; Fardis, M.N.; Vayenas, C.G. Hydration and Carbonation of Pozzolanic Cements. ACI Mater. J. 1992, 89, 119–130. [Google Scholar] [CrossRef]

- Rossignolo, J.A.; Agnesini, M.V. Durability of polymer-modified lightweight aggregate concrete. Cem. Concr. Compos. 2004, 26, 375–380. [Google Scholar] [CrossRef]

- Gonen, T.; Yazicioglu, S. The influence of compaction pores on sorptivity and carbonation of concrete. Constr. Build. Mater. 2007, 21, 1040–1045. [Google Scholar] [CrossRef]

- BSI Group. Testing Concrete Method for Making Test Cubes from Fresh Concrete; BSI Group: London, UK, 1983. [Google Scholar]

- ASTM C496 / C496M-17. Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM C78 / C78M-18. Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading); ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Carvalho, K.C.C.; Mulinari, D.R.; Voorwald, H.J.C.; Cioffi, M.O.H. Chemical modification effect on the mechanical properties of HIPS/ coconut fibers composites. Bioresources 2010, 5, 1143–1155. [Google Scholar]

- Vilay, V.; Mariatti, M.; Taib, R.M.; Todo, M. Effect of fiber surface treatment and fiber loading on the properties of bagasse fiber–reinforced unsaturated polyester composites. Compos. Sci. Technol. 2008, 68, 631–638. [Google Scholar] [CrossRef]

- Le Troedec, M.; Sedan, D.; Peyratout, C.; Bonnet, J.P.; Smith, A.; Guinebretiere, R.; Gloaguen, V.; Krausz, P. Influence of various chemical treatments on the composition and structure of hemp fibres. Compos. Part A: Appl. Sci. Manuf. 2008, 39, 514–522. [Google Scholar] [CrossRef]

- Villar-Cociña, E.; Valencia-Morales, E.; González-Rodríguez, R.; Hernández-Ruíz, J. Kinetics of the pozzolanic reaction between lime and sugar cane straw ash by electrical conductivity measurement: A kinetic-diffusive model. Cem. Concr. Res. 2003, 33, 517–524. [Google Scholar] [CrossRef]

- Vuk, T.; Tinta, V.; Gabrovšek, R.; Kaučič, V. The effects of limestone addition, clinker type and fineness on properties of Portland cement. Cem. Concr. Res. 2001, 31, 135–139. [Google Scholar] [CrossRef]

- Morsy, M.I.N. Properties of Rice Straw Cementitious Composite; Technische Universität Darmstadt: Darmstadt, Germany, 2011. [Google Scholar]

- Okino, E.Y.; De Souza, M.R.; Santana, M.A.; Alves, M.V.S.; De Sousa, M.E.; Teixeira, D.E. Physico-mechanical properties and decay resistance of Cupressus spp. cement-bonded particleboards. Cem. Concr. Compos. 2005, 27, 333–338. [Google Scholar] [CrossRef]

- Karade, S.R.; Irle, M.; Maher, K. Assessment of Wood-Cement Compatibility: A New Approach. Holzforschung. 2003, 57, 672–680. [Google Scholar] [CrossRef]

- Safiuddin, M.; Jumaat, M.Z.; Salam, M.A.; Islam, M.S.; Hashim, R. Utilization of solid wastes in construction materials. Int. J. Phys. Sci. 2010, 5, 1952–1963. [Google Scholar]

- Belhadj, B.; Bederina, M.; Dheilly, R.; Mboumba-Mamboundou, L.; Quéneudec, M. Evaluation of the thermal performance parameters of an outside wall made from lignocellulosic sand concrete and barley straws in hot and dry climatic zones. Energy Build. 2020, 225, 110348. [Google Scholar] [CrossRef]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).