Sliding Mean Value Subtraction-Based DC Drift Correction of B-H Curve for 3D-Printed Magnetic Materials

Abstract

1. Introduction

- (1)

- (2)

- The removal of DC drift by subtracting an approximate polynomial data fitting function from the signal [17] does not consider all cycles separately. It can give good results when the number of measured cycles is high enough, which is difficult to obtain under low-frequency measurements—furthermore, the presence of switching noise increases approximation.

2. The Proposed Algorithm

2.1. Data Acquisition and Initial Processing

- Measure the input primary current I [n] and output secondary voltage V [n] with reasonable sampling frequency Fs. If spectrum analysis is also required along with the B-H curve, the minimum sampling frequency should follow the Nyquist criterion.

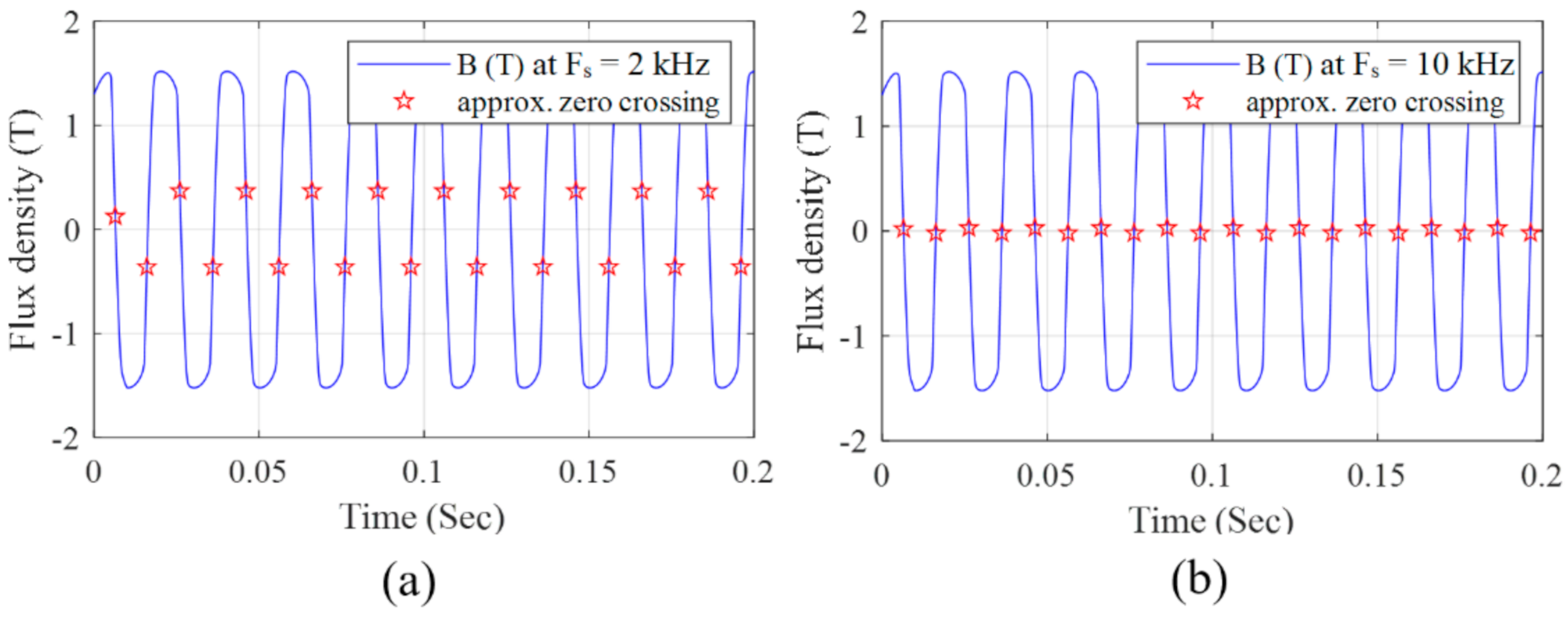

- The sampling frequency can be improved by data interpolation. Linear interpolation to increase sampling frequency from Fs to kFs can have less impact on the signal’s shape. An increase in the sampling frequency is necessary to recover zero crossings in the signal. If the sampling rate is not good enough, the approximate zero-crossings would be away from the actual zero line, as shown in Figure 2. This may lead to signal processing-related problems, such as spectral leakage or increased ripples due to bandpass filters. However, very powerful data acquisition devices are available these days, and data interpolation can make the algorithm suitable for implementation in on-board processors.

- Random noise, such as additive white gaussian noise (AWGN), is inevitable in homemade B-H tracers. This is because of the high frequency switching noise if digital signal generators and power supplies are used. Moreover, this noise also occurs because of the mismatched impedances between various components of the experimental setup. Although AWGN noise does not significantly contribute to the DC drift, it causes random movement of the B and H intercept points, mainly if the signal to noise ratio (SNR) is low. Being random, AWGN noise cannot be eliminated completely; however, its impact can be minimized by attenuating the high-frequency noise components using an IIR low pass filter. IIR filters are the right choice because of their narrow transition band and fewer passband ripples.

- The magnetic field strength (H(t)) and magnetic field density (B(t)) can be calculated using the following formulas.where N1 and N2 are the number of primary and secondary turns, respectively, i1(t) is the current in the primary winding, l is the average length of the toroid taken at the center, Ac is the core cross-sectional area, v2(t) is the secondary induced voltage, and ti and tf represent the measurement interval and signal length, respectively. It is important to know that the measured induced voltage contains the drift signal acting as a constant of integration.

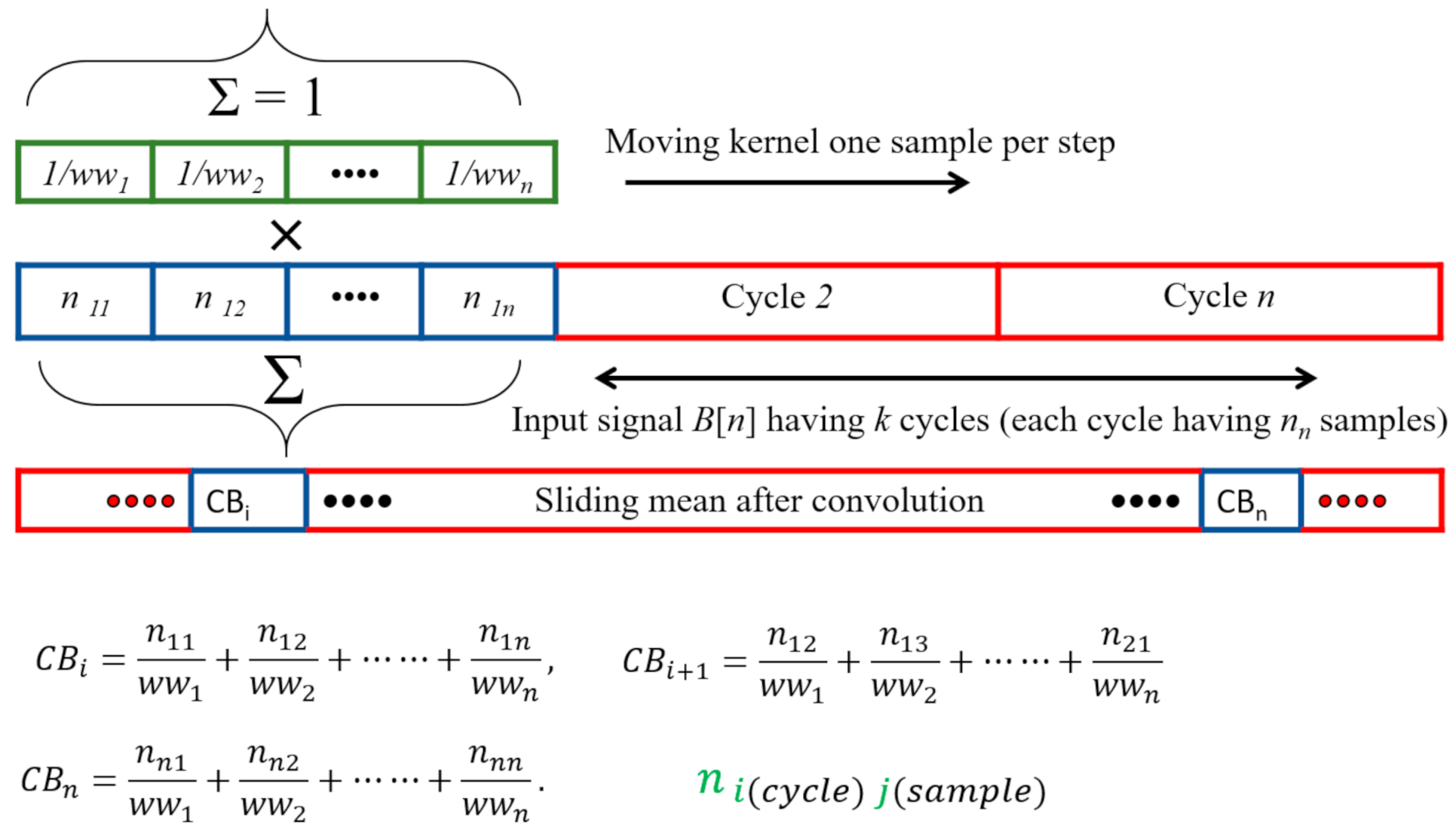

2.2. Defining Kernel Function and the Removal of the DC Drift

2.3. Zero-Crossing Detection

3. Measurement Setup

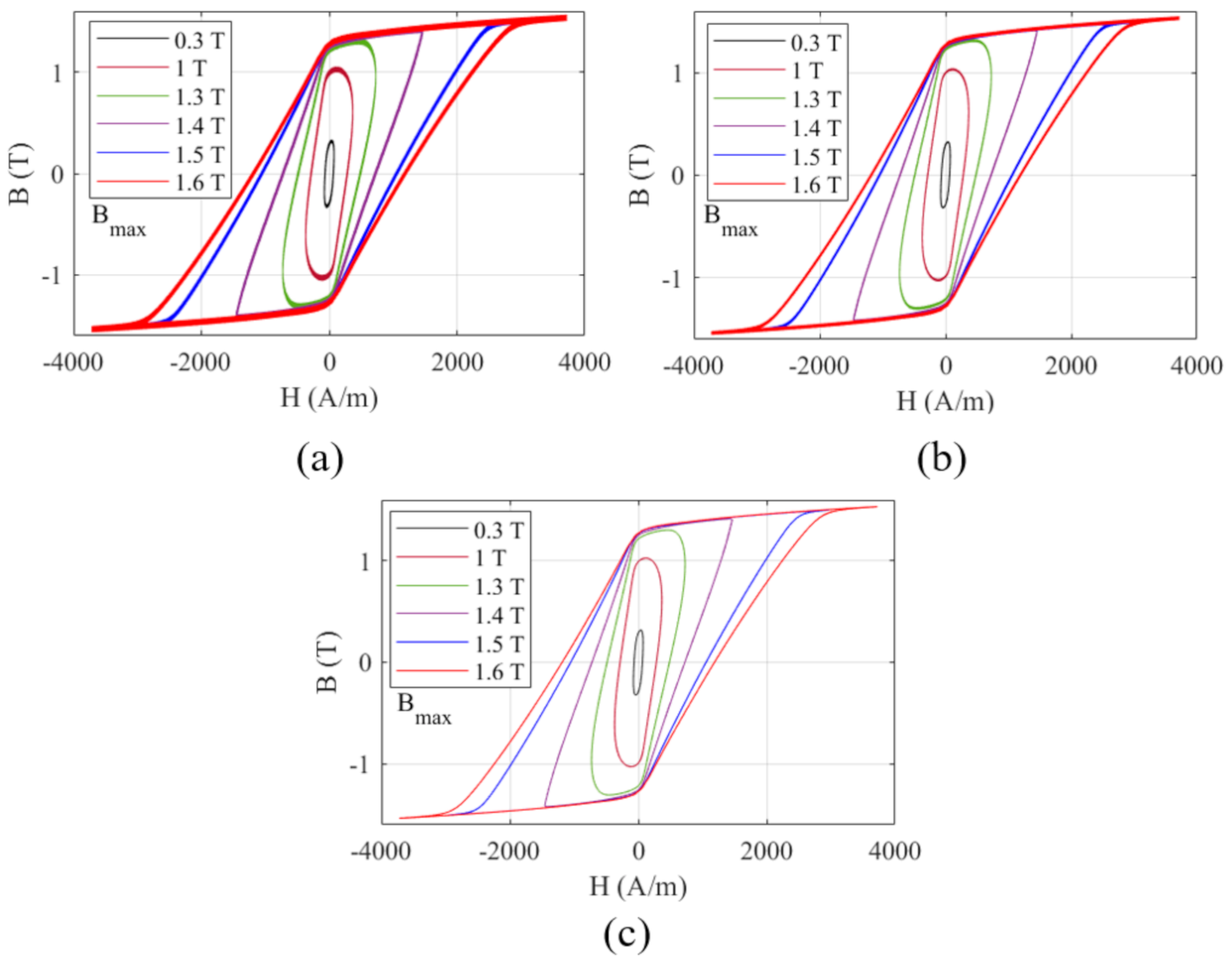

4. Results and Discussion

5. Conclusions

- The proposed algorithm can work on the least number of measured current or voltage cycles compared to the corresponding data fitting-based correction algorithm.

- The higher-order noise components because of switching frequency, AWGN, and the impedance mismatch are effectively removed using the IIR low-pass filter. However, it can be avoided if the signal has a high signal to noise ratio (SNR).

- The increase in the sampling rate using data interpolation makes the algorithm suitable to plot good magnetic characteristics from the data measured at a low sampling frequency. This makes algorithms convenient, even if the data acquisition devices are not very powerful.

- The zero-crossing detection helps to count the integral number of cycles and removes the filter-based transient intervals. The removal of the transient interval is very crucial to getting a smooth B-H curve. Additionally, it reduces the spectral leakage if the frequency spectrum analysis is required.

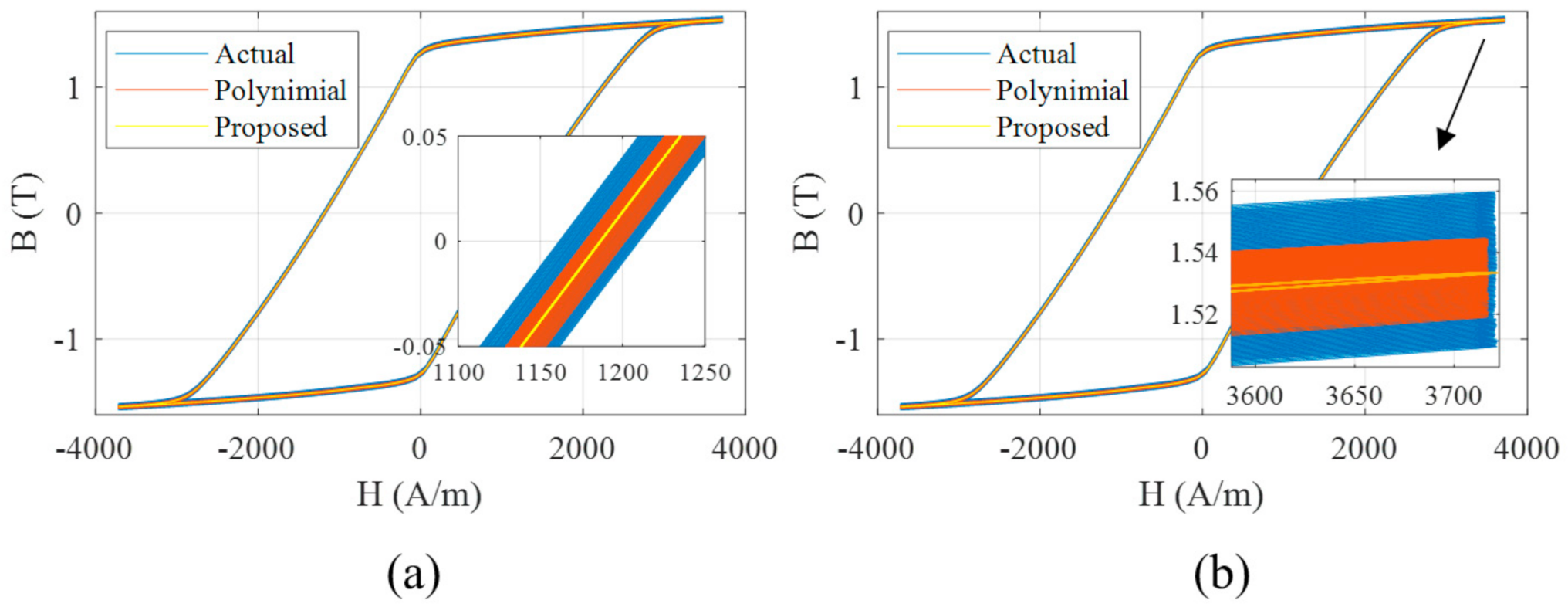

- The proposed algorithm gives a very narrow band intercept across the B and H axis, which reduces the error considerably.

Author Contributions

Funding

Conflicts of Interest

References

- Lammers, S.; Adam, G.; Schmid, H.J.; Mrozek, R.; Oberacker, R.; Hoffmann, M.J.; Quattrone, F.; Ponick, B. Additive Manufacturing of a lightweight rotor for a permanent magnet synchronous machine. In Proceedings of the 2016 6th International Electric Drives Production Conference, EDPC 2016-Proceedings, Nuremberg, Germany, 30 November–1 December 2016; pp. 41–45. [Google Scholar] [CrossRef]

- Garibaldi, M.; Gerada, C.; Ashcroft, I.; Hague, R. Free-Form Design of Electrical Machine Rotor Cores for Production Using Additive Manufacturing. J. Mech. Des. 2019, 141, 1–27. [Google Scholar] [CrossRef]

- Metsä-Kortelainen, S.; Lindroos, T.; Savolainen, M.; Jokinen, A.; Revuelta, A.; Pasanen, A.; Ruusuvuori, K.; Pippuri, J. Manufacturing of topology optimized soft magnetic core through 3D printing. In Proceedings of the NAFEMS Exploring the Design Freedom of Additive Manufacturing through Simulation, Helsinki, Finland, 22–23 November 2016. [Google Scholar]

- Garibaldi, M. Laser additive Manufacturing of Soft Magnetic Cores for rotating Electrical Machinery: Materials Development and Part Design. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2018. [Google Scholar]

- Lorenz, F.; Rudolph, J.; Wemer, R. Design of 3D Printed High Performance Windings for Switched Reluctance Machines. In Proceedings of the 23rd International Conference on Electrical Machines, ICEM 2018, Alexandroupoli, Greece, 3–6 September 2018; pp. 2451–2457. [Google Scholar] [CrossRef]

- Simpson, N.; Mellor, P.H. Additive manufacturing of shaped profile windings for minimal AC loss in gapped inductors. In Proceedings of the 2017 IEEE International Electric Machines and Drives Conference (IEMDC), Miami, FL, USA, 21–24 May 2017; pp. 1–7. [Google Scholar] [CrossRef]

- Richardson, B.; Love, L.; Tate, J.G. Additive Manufacturing for Low Volume Bearings. 2017. Available online: http://www.osti.gov/scitech/ (accessed on 24 November 2020).

- Wrobel, R.; Hussein, A. Design Considerations of Heat Guides Fabricated Using Additive Manufacturing for Enhanced Heat Transfer in Electrical Machines. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition, ECCE 2018, Portland, OR, USA, 23–27 September 2018; pp. 6506–6513. [Google Scholar] [CrossRef]

- Sixel, W.; Liu, M.; Nellis, G.; Sarlioglu, B. Cooling of Windings in Electric Machines via 3D Printed Heat Exchanger. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition, ECCE 2018, Portland, OR, USA, 23–27 September 2018; pp. 229–235. [Google Scholar] [CrossRef]

- Silbernagel, C.; Gargalis, L.; Ashcroft, I.; Hague, R.; Galea, M.; Dickens, P. Electrical resistivity of pure copper processed by medium-powered laser powder bed fusion additive manufacturing for use in electromagnetic applications. Addit. Manuf. 2019, 29, 100831. [Google Scholar] [CrossRef]

- Silbernagel, C.; Ashcroft, I.; Dickens, P.; Galea, M. Electrical resistivity of additively manufactured AlSi10Mg for use in electric motors. Addit. Manuf. 2018, 21, 395–403. [Google Scholar] [CrossRef]

- Goll, D.; Schuller, D.; Martinek, G.; Kunert, T.; Schurr, J.; Sinz, C.; Schubert, T.; Bernthaler, T.; Riegel, H.; Schneider, G. Additive manufacturing of soft magnetic materials and components. Addit. Manuf. 2019, 27, 428–439. [Google Scholar] [CrossRef]

- Garibaldi, M.; Ashcroft, I.; Lemke, J.; Simonelli, M.; Hague, R. Effect of annealing on the microstructure and magnetic properties of soft magnetic Fe-Si produced via laser additive manufacturing. Scr. Mater. 2018, 142, 121–125. [Google Scholar] [CrossRef]

- Plotkowski, A.; Pries, J.; List, F.; Nandwana, P.; Stump, B.; Carver, K.; Dehoff, R. Influence of scan pattern and geometry on the microstructure and soft-magnetic performance of additively manufactured Fe-Si. Addit. Manuf. 2019, 29, 100781. [Google Scholar] [CrossRef]

- Riipinen, T.; Metsä-Kortelainen, S.; Lindroos, T.; Keränen, J.S.; Manninen, A.; Pippuri-Mäkeläinen, J. Properties of soft magnetic Fe-Co-V alloy produced by laser powder bed fusion. Rapid Prototyp. J. 2019, 25, 699–707. [Google Scholar] [CrossRef]

- Kang, N.; El Mansori, M.; Guittonneau, F.; Liao, H.; Fu, Y.; Aubry, E. Controllable mesostructure, magnetic properties of soft magnetic Fe-Ni-Si by using selective laser melting from nickel coated high silicon steel powder. Appl. Surf. Sci. 2018, 455, 736–741. [Google Scholar] [CrossRef]

- Garcia, J.; Rivas, M. A quasi-static magnetic hysteresis loop measurement system with drift correction. IEEE Trans. Magn. 2006, 42, 15–17. [Google Scholar] [CrossRef]

- Horn, J.L.; Grimes, C.A. A 0.1–500 Hz analog thin film BH hysteresis loop tracer with automatic Y-axis drift correction. Rev. Sci. Instrum. 1997, 68, 1346–1347. [Google Scholar] [CrossRef]

- Franco, V.; Ramos-Martos, J.; Conde, A. Autocalibrating quasistatic M-H hysteresis loop tracer with negligible drift. Rev. Sci. Instrum. 1996, 67, 4167–4170. [Google Scholar] [CrossRef]

- Krings, A.; Soulard, J.; Wallmark, O. PWM Influence on the Iron Losses and Characteristics of a Slotless Permanent-Magnet Motor with SiFe and NiFe Stator Cores. IEEE Trans. Ind. Appl. 2015, 51, 1475–1484. [Google Scholar] [CrossRef]

- Krings, A.; Nategh, S.; Wallmark, O.; Soulard, J. Influence of the Welding Process on the Performance of Slotless PM Motors With SiFe and NiFe Stator Laminations. IEEE Trans. Ind. Appl. 2014, 50, 296–306. [Google Scholar] [CrossRef]

- Asad, B.; Vaimann, T.; Belahcen, A.; Kallaste, A.; Rassõlkin, A.; Iqbal, M.N. Broken rotor bar fault detection of the grid and inverter-fed induction motor by effective attenuation of the fundamental component. IET Electr. Power Appl. 2019, 13, 2005–2014. [Google Scholar] [CrossRef]

- Asad, B.; Vaimann, T.; Kallaste, A.; Rassõlkin, A.; Belahcen, A.; Iqbal, M.N. Improving Legibility of Motor Current Spectrum for Broken Rotor Bars Fault Diagnostics. Electr. Control. Commun. Eng. 2019, 15, 1–8. [Google Scholar] [CrossRef]

- Tiismus, H.; Kallaste, A.; Belahcen, A.; Vaimann, T.; Rassõlkin, A.; Lukichev, D.V. Hysteresis measurements and numerical losses segregation of additively manufactured silicon steel for 3d printing electrical machines. Appl. Sci. 2020, 10, 6515. [Google Scholar] [CrossRef]

- Tiismus, H.; Kallaste, A.; Belahcen, A.; Rassolkin, A.; Vaimann, T. Hysteresis Loss Evaluation of Additively Manufactured Soft Magnetic Core. In Proceedings of the 2020 International Conference on Electrical Machines (ICEM), Kärdla, Estonia, 12–15 June 2019; pp. 1657–1661. [Google Scholar] [CrossRef]

- EN IEC 60404-6:2018-Magnetic Materials-Part 6: Methods of Measurement of the Magnetic Properties of Magnetically Soft Metallic and Powder Materials at Frequencies in the Range 20 Hz to 100 kHz by the Use of Ring Specimens. Available online: https://standards.iteh.ai/catalog/standards/clc/0f265b9d-6454-4597-aa62-9290d0e03700/en-iec-60404-6-2018 (accessed on 27 November 2020).

- EN 60404-4:1997-Magnetic Materials-Part 4: Methods of Measurement of d.c. Magnetic Properties of Magnetically Soft Materials. Available online: https://standards.iteh.ai/catalog/standards/clc/a53d9e5b-537f-4e4d-87d2-a4fceadb1534/en-60404-4-1997 (accessed on 27 November 2020).

| Sr. No. | Technique | B-Axis Intercept Range at H = 0 (Error) |

|---|---|---|

| 1 | Measured | 0.05 T (5%) |

| 2 | Polynomial adjustment based | 0.02 T (2%) |

| 3 | Proposed | 0.0002 T (0.02%) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Asad, B.; Tiismus, H.; Vaimann, T.; Belahcen, A.; Kallaste, A.; Rassõlkin, A.; Ghafarokhi, P.S. Sliding Mean Value Subtraction-Based DC Drift Correction of B-H Curve for 3D-Printed Magnetic Materials. Energies 2021, 14, 284. https://doi.org/10.3390/en14020284

Asad B, Tiismus H, Vaimann T, Belahcen A, Kallaste A, Rassõlkin A, Ghafarokhi PS. Sliding Mean Value Subtraction-Based DC Drift Correction of B-H Curve for 3D-Printed Magnetic Materials. Energies. 2021; 14(2):284. https://doi.org/10.3390/en14020284

Chicago/Turabian StyleAsad, Bilal, Hans Tiismus, Toomas Vaimann, Anouar Belahcen, Ants Kallaste, Anton Rassõlkin, and Payam Shams Ghafarokhi. 2021. "Sliding Mean Value Subtraction-Based DC Drift Correction of B-H Curve for 3D-Printed Magnetic Materials" Energies 14, no. 2: 284. https://doi.org/10.3390/en14020284

APA StyleAsad, B., Tiismus, H., Vaimann, T., Belahcen, A., Kallaste, A., Rassõlkin, A., & Ghafarokhi, P. S. (2021). Sliding Mean Value Subtraction-Based DC Drift Correction of B-H Curve for 3D-Printed Magnetic Materials. Energies, 14(2), 284. https://doi.org/10.3390/en14020284