Adaptive Neuro-Fuzzy Inference System-Based Maximum Power Tracking Controller for Variable Speed WECS

Abstract

:1. Introduction

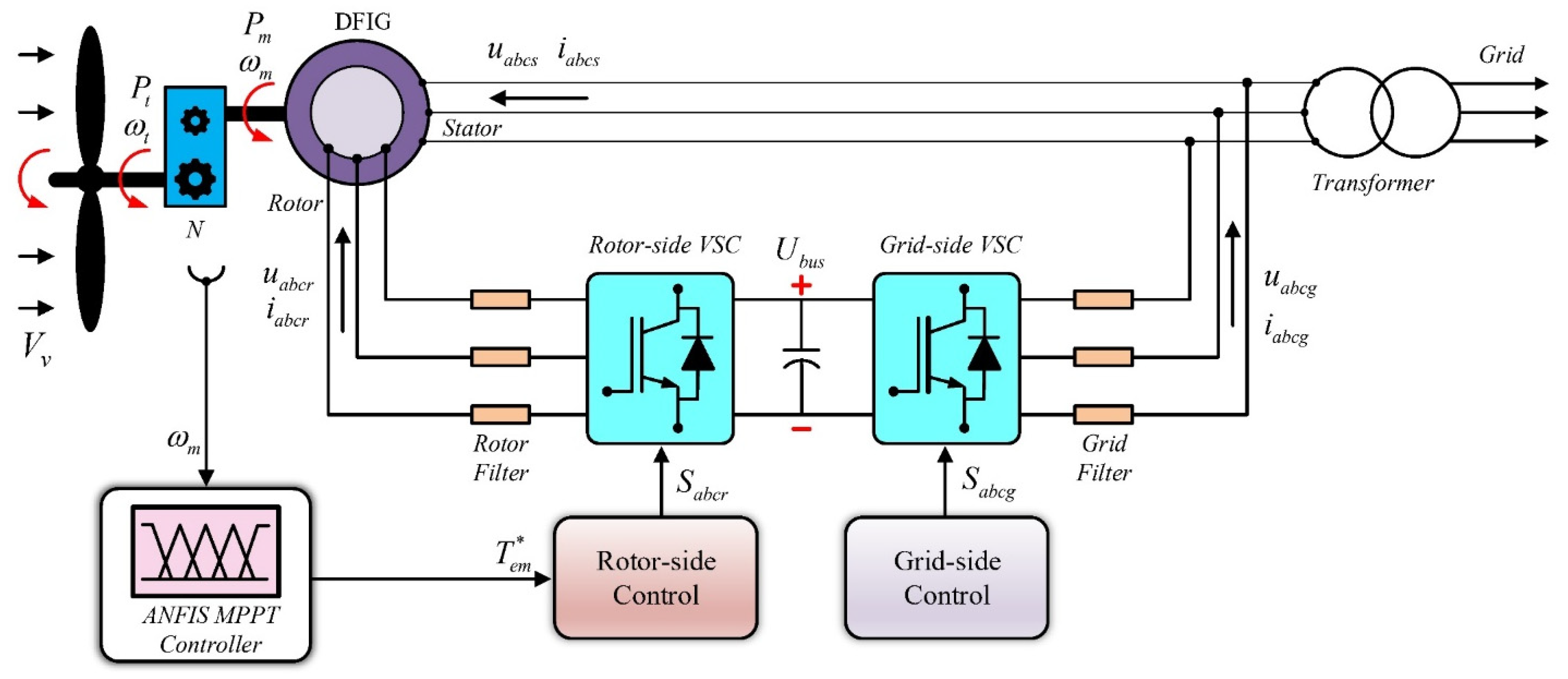

2. Modeling of Doubly Fed Induction Generator-Based WECS

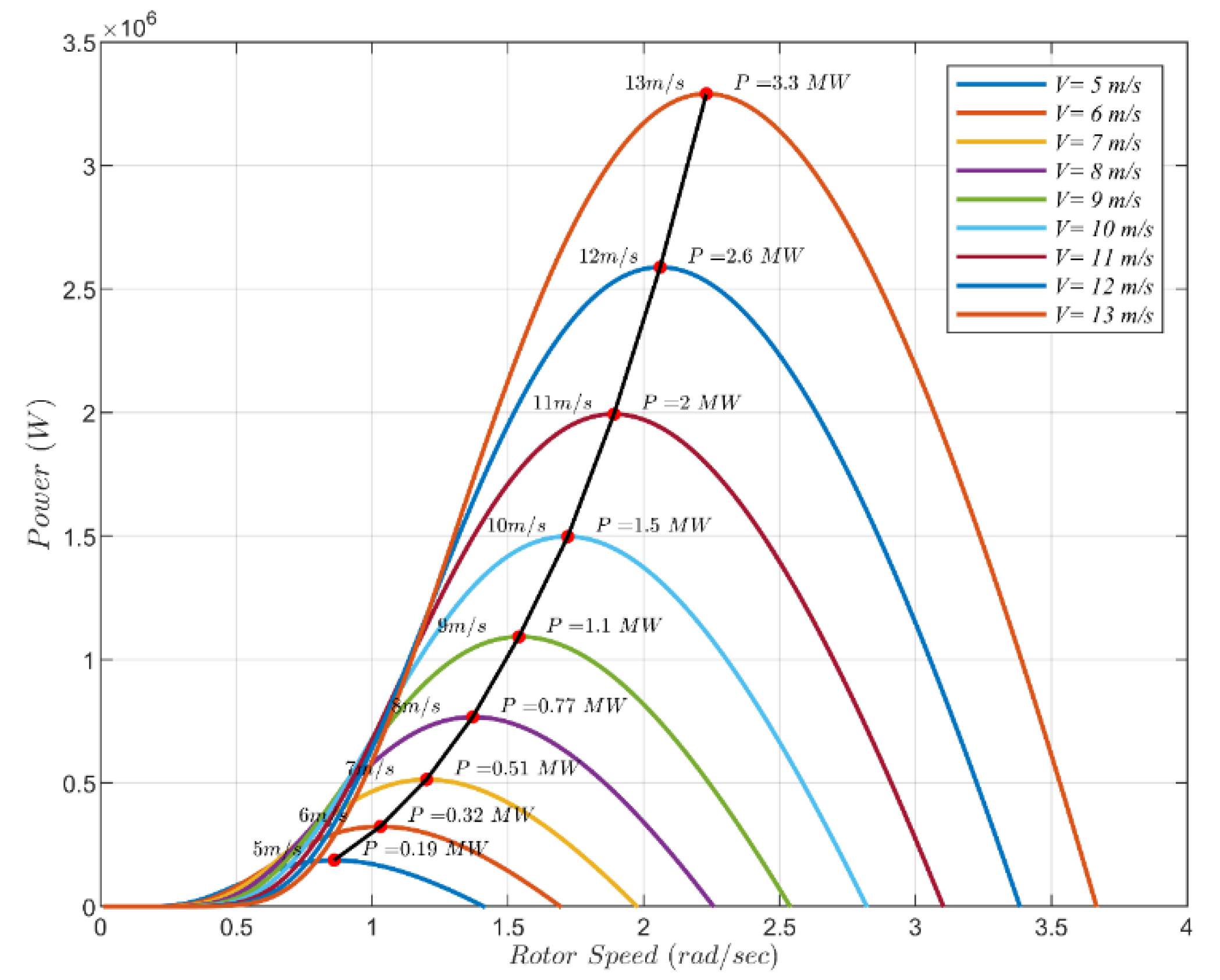

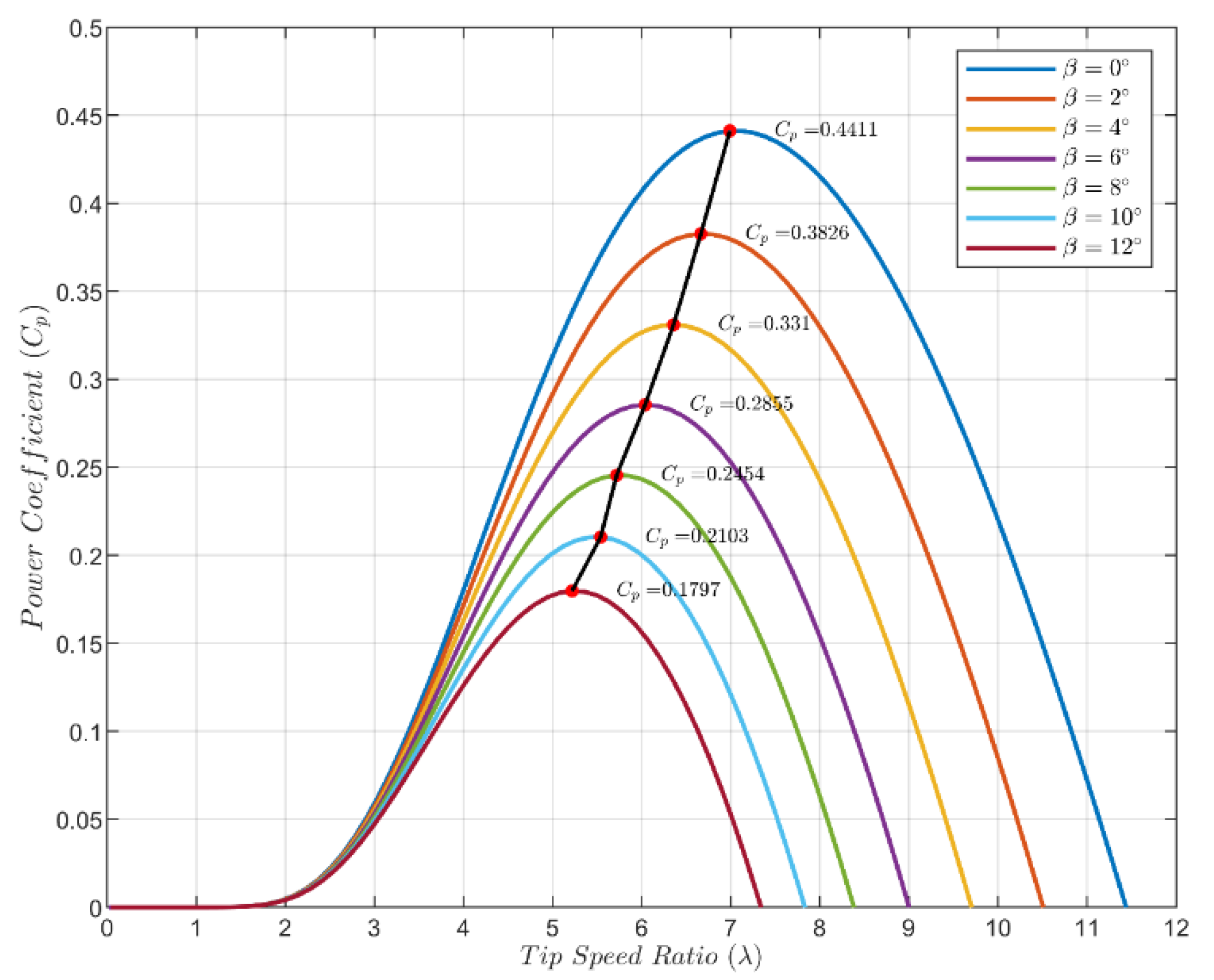

2.1. Wind Turbine Modeling

2.2. DFIG Modeling

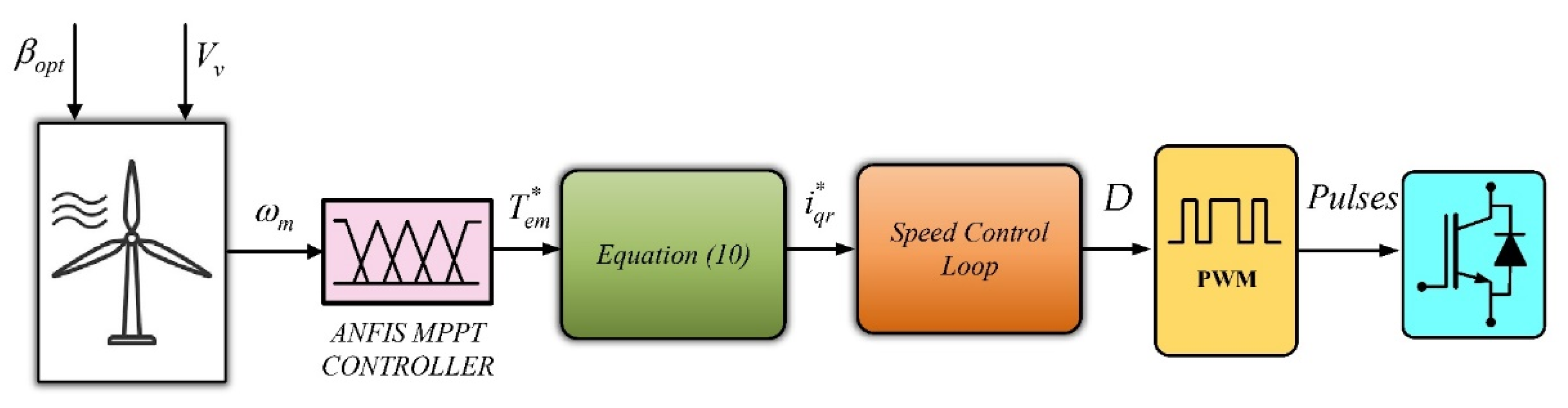

3. Rotor Side Control with Maximum Power Point Tracking

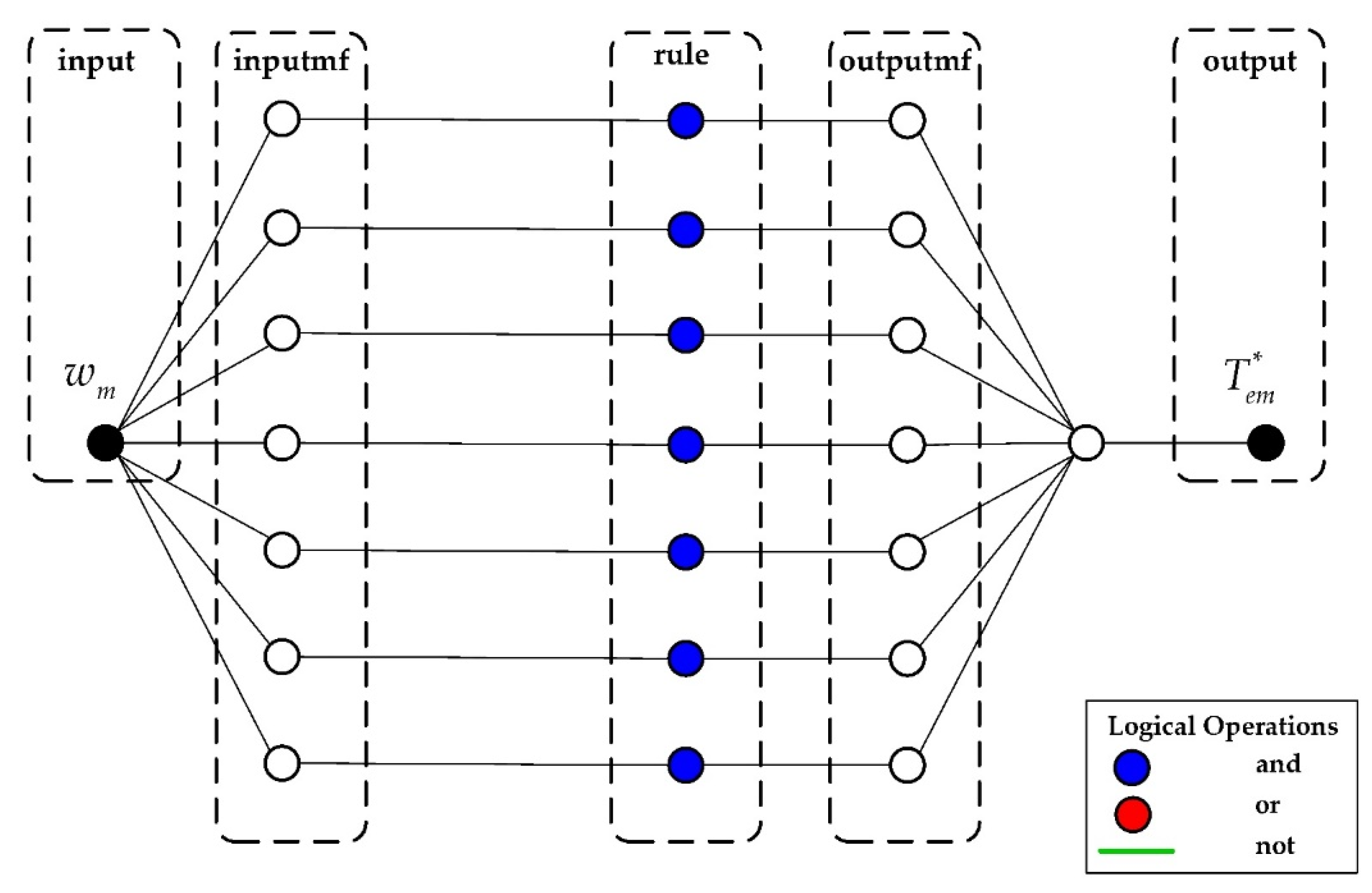

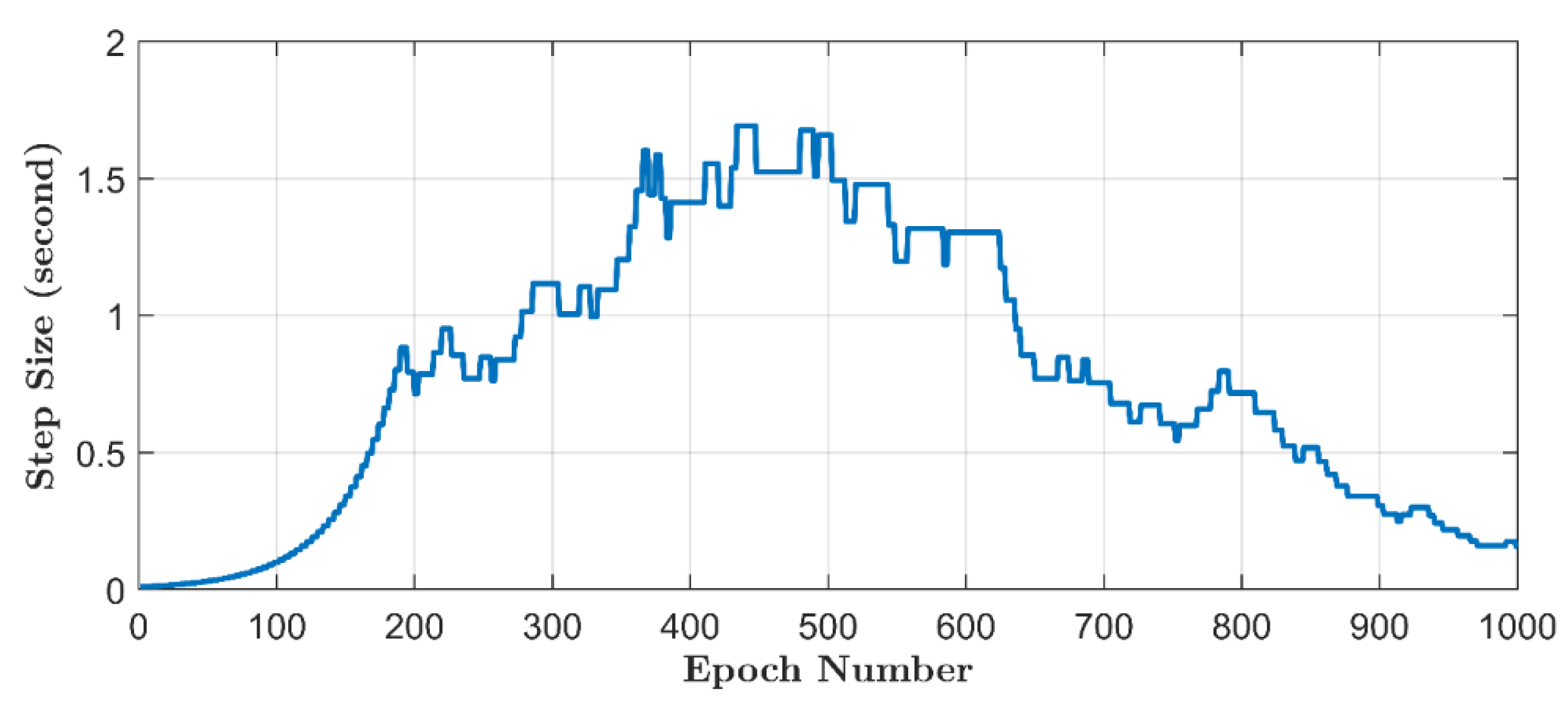

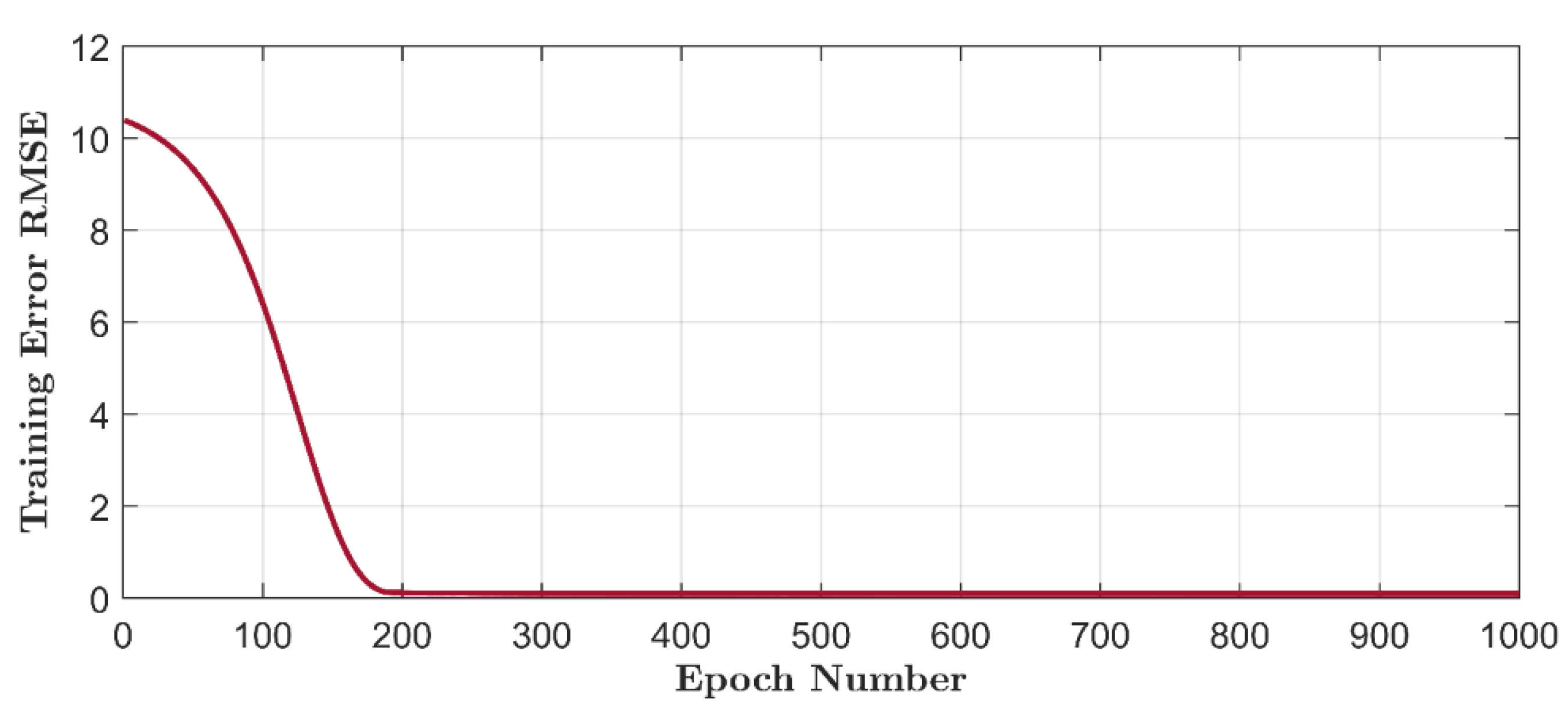

4. ANFIS Maximum Power Point Tracking Control

- Layer 1, the adaptive fuzzification layer is composed of user-specified input variables and membership functions (MF).

- Layer 2, the fuzzy rule layer checks the degree of MF, and the corresponding fuzzy set is selected and input to the next layer.

- Layer 3, the firing strength normalization layer evaluates weight for each normalized node.

- Layer 4, the adaptive implication layer outputs values in accordance with inference rules, and each neuron is normalized.

- Layer 5, the output layer adds all of the inputs from layer 4 and transforms the fuzzy values to a crisp value.

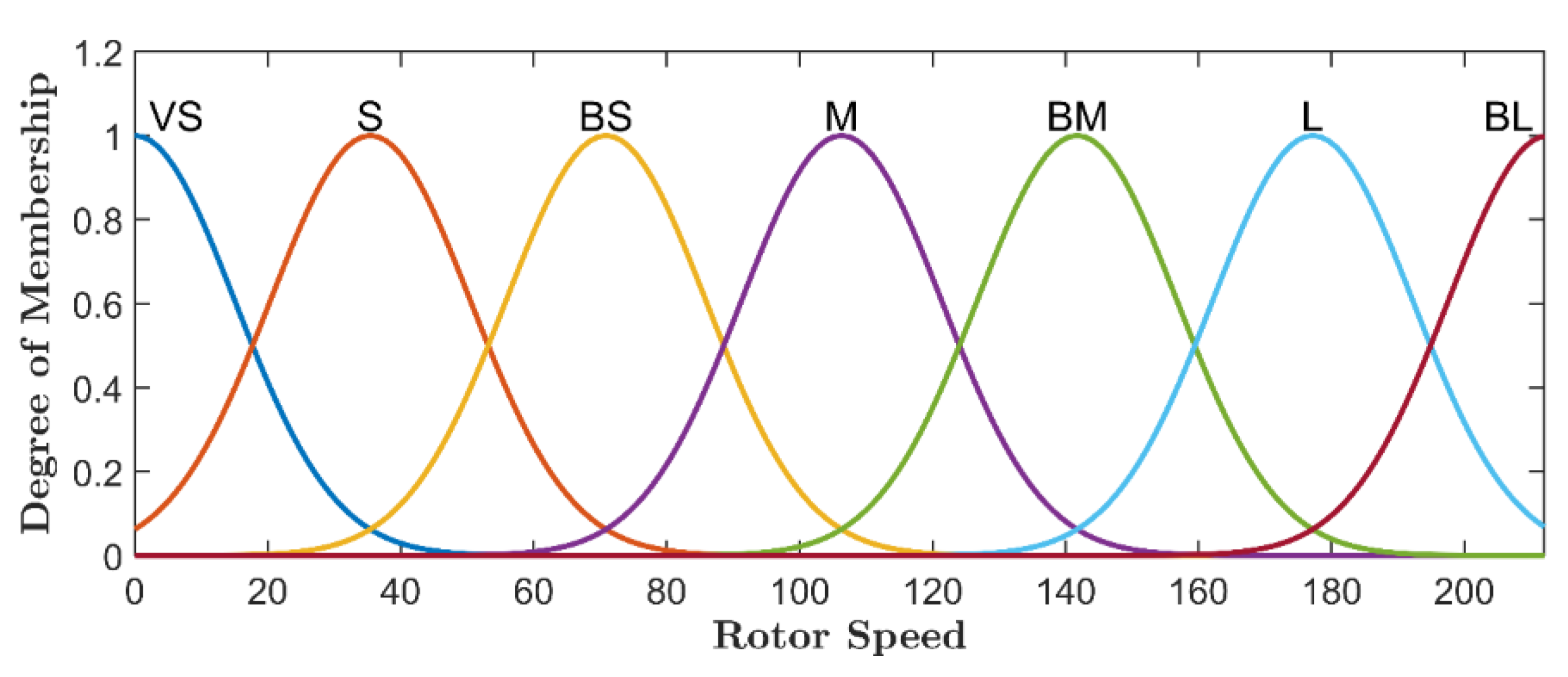

- The first layer consists of an input node as the variable. This layer is responsible for transform in input value to the next layer. Here, seven gaussian MFs with minimum = 0 and maximum = 1 are utilized, and corresponding node equations are given (17):where i = 1, 2, … 7, is the output of ith node in layer one, is the linguistic label, is the input to the node.

- The second layer verifies the weights of individual MFs. It accepts the first layer’s input values and serves as the MF for the corresponding input variables fuzzy sets. The second layer has non-adaptive nodes that multiply incoming signals and output the result as in (18):where i = 1, 2, … 7 and j = 1, 2, … 7. The output from each node represents the firing strength of a rule.

- Each node in the third layer computes the activation level of each fuzzy rule, with the number of layers equal to the number of fuzzy rules. Each node of these layers generates the normalized weights. Each node calculates the ratio of the rule’s firing strength to the total of all rules’ firing strengths, that is, the normalized firing strength given in (19):where j = 1, 2, … 7.

- The fourth layer contains the output values obtained through rule inference. Node function of the fourth layer is given in (20):

- If is and is then ;

- If is and is then ;

- If is and is then ,

- The fifth layer is the output layer; it aggregates all of the fourth layer’s inputs and converts the fuzzy classification results into a crisp representation. This layer has a non-adaptive nature, having a single node with the output given in (21):

5. Simulation Result and Discussion

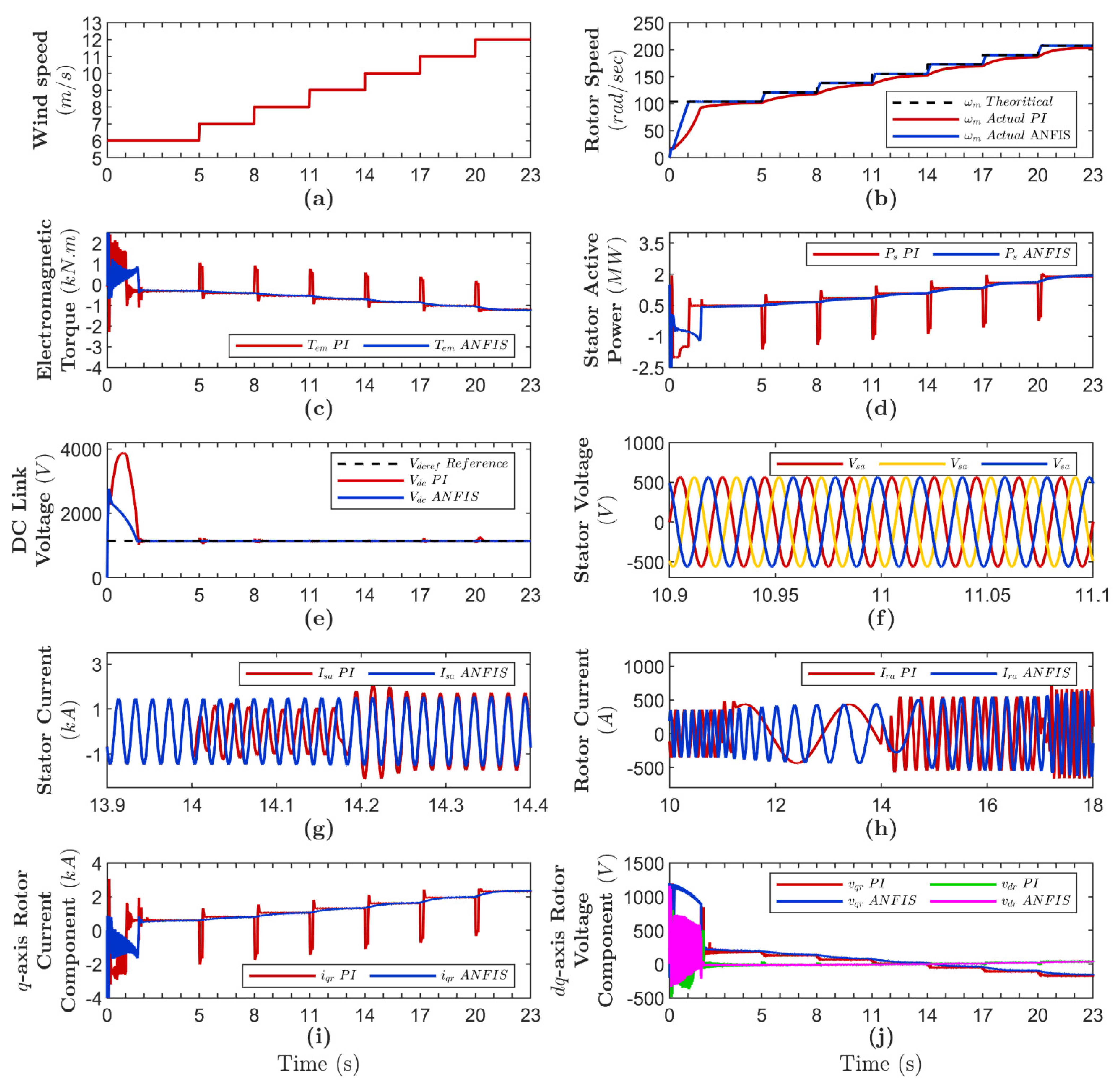

5.1. Case-I: Step Increase in Input Wind Speed

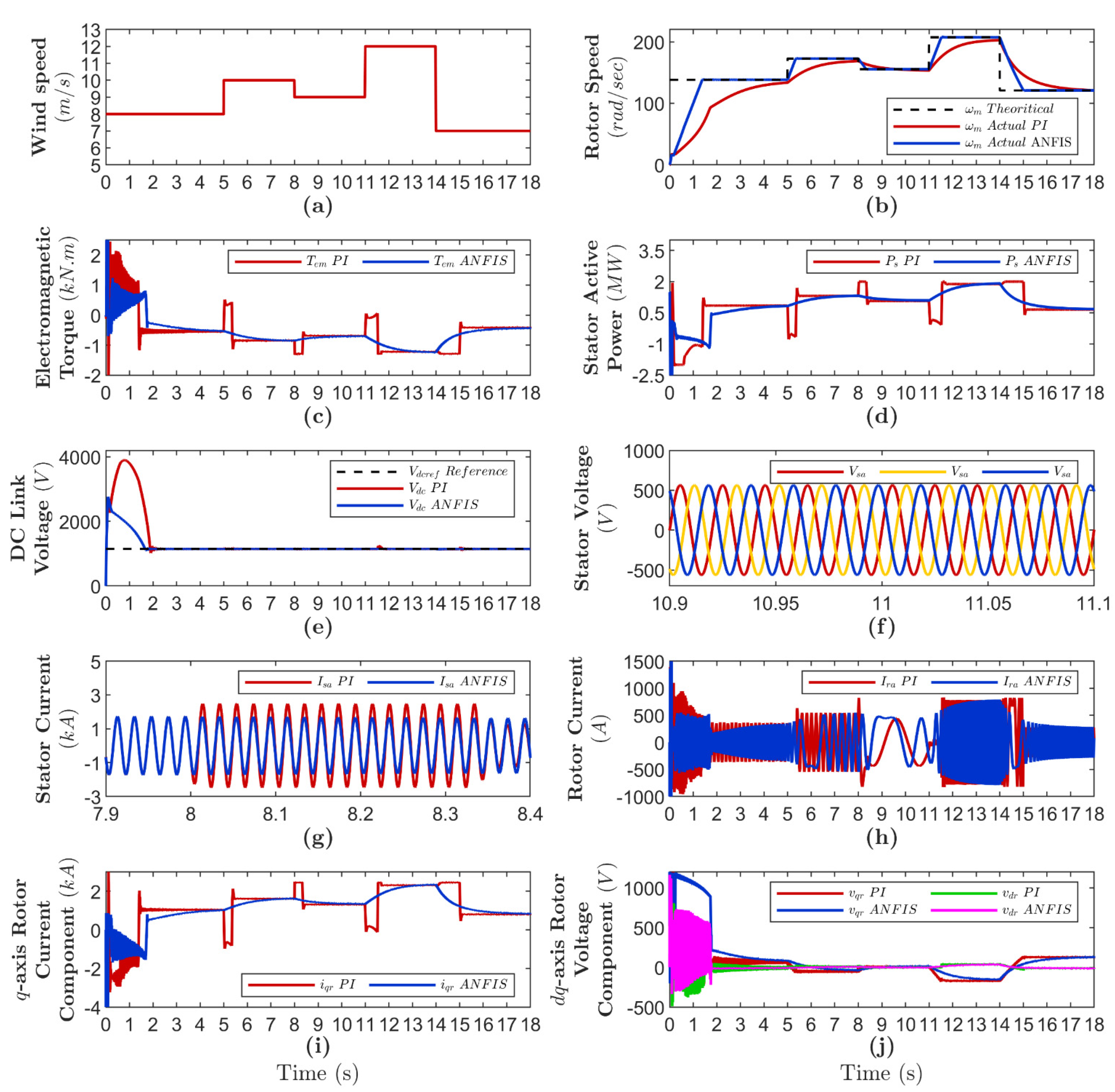

5.2. Case-II: Step Decrease in Input Wind Speed

5.3. Case-III: Intermittent Change in Input Wind Speed

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qazi, A.; Hussain, F.; Rahim, N.A.B.D.; Hardaker, G.; Alghazzawi, D.; Shaban, K.; Haruna, K. Towards Sustainable Energy: A Systematic Review of Renewable Energy Sources, Technologies, and Public Opinions. IEEE Access 2019, 7, 63837–63851. [Google Scholar] [CrossRef]

- Chhipa, A.A.; Vyas, S.; Kumar, V.; Joshi, R.R. Role of Power Electronics and Optimization Techniques in Renewable Energy Systems. In Intelligent Algorithms for Analysis and Control of Dynamical Systems; Kumar, R., Singh, V.P., Akhilesh, M., Eds.; Springer: Singapore, 2021; pp. 167–175. [Google Scholar] [CrossRef]

- Wang, H.; Di Pietro, G.; Wu, X.; Lahdelma, R.; Verda, V.; Haavisto, I. Renewable and Sustainable Energy Transitions for Countries with Different Climates and Renewable Energy Sources Potentials. Energies 2018, 11, 3523. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.; Yin, M.; Zou, Y.; Meng, K.; Dong, Z.Y. Maximum Wind Energy Extraction for Variable Speed Wind Turbines with Slow Dynamic Behavior. IEEE Trans. Power Syst. 2017, 32, 3321–3322. [Google Scholar] [CrossRef]

- Rodríguez-Amenedo, J.L.; Arnaltes, S.; Rodríguez, M.A. Operation and Coordinated Control of Fixed and Variable Speed Wind Farms. Renew. Energy 2008, 33, 406–414. [Google Scholar] [CrossRef]

- Portillo, R.C.; Prats, M.Á.M.; Leon, J.I.; Sánchez, J.A.; Carrasco, J.M.; Galván, E.; Franquelo, L.G. Modeling Strategy for Back-to-Back Three-Level Converters Applied to High-Power Wind Turbines. IEEE Trans. Ind. Electron. 2006, 53, 1483–1491. [Google Scholar] [CrossRef]

- Valenciaga, F.; Puleston, P.F.; Battaiotto, P.E. Variable structure system control design method based on a differential geometric approach: Application to a wind energy conversion subsystem. IEE Proc. Control. Theory Appl. 2004, 151, 6–12. [Google Scholar] [CrossRef]

- Zhou, F.; Liu, J. A Robust Control Strategy Research on PMSG-Based WECS Considering the Uncertainties. IEEE Access 2018, 6, 51951–51963. [Google Scholar] [CrossRef]

- Mesemanolis, A.; Mademlis, C.; Kioskeridis, I. Optimal Efficiency Control Strategy in Wind Energy Conversion System with Induction Generator. IEEE J. Emerg. Sel. Top. Power Electron. 2013, 1, 238–246. [Google Scholar] [CrossRef]

- Akhmatov, V. Variable-Speed Wind Turbines with Doubly-Fed Induction Generators Part III: Model with the Back-to-Back Converters. Wind Eng. 2003, 27, 79–91. [Google Scholar] [CrossRef]

- Naidu, N.K.S.; Singh, B. Grid-Interfaced DFIG-Based Variable Speed Wind Energy Conversion System with Power Smoothening. IEEE Trans. Sustain. Energy 2017, 8, 51–58. [Google Scholar] [CrossRef]

- Cheng, M.; Zhu, Y. The State of the Art of Wind Energy Conversion Systems and Technologies: A Review. Energy Convers. Manag. 2014, 88, 332–347. [Google Scholar] [CrossRef]

- Lin, W.M.; Hong, C.M. Intelligent Approach to Maximum Power Point Tracking Control Strategy for Variable-Speed Wind Turbine Generation System. Energy 2010, 35, 2440–2447. [Google Scholar] [CrossRef]

- Hosseinzadeh, M.; Salmasi, F.R. Analysis and detection of a wind system failure in a micro-grid. J. Renew. Sustain. Energy 2016, 8, 043301–043317. [Google Scholar] [CrossRef]

- Tripathi, S.M.; Tiwari, A.N.; Singh, D. Grid-Integrated Permanent Magnet Synchronous Generator Based Wind Energy Conversion Systems: A Technology Review. Renew. Sustain. Energy Rev. 2015, 51, 1288–1305. [Google Scholar] [CrossRef]

- Abdullah, M.A.; Yatim, A.H.M.; Tan, C.W.; Saidur, R. A Review of Maximum Power Point Tracking Algorithms for Wind Energy Systems. Renew. Sustain. Energy Rev. 2012, 16, 3220–3227. [Google Scholar] [CrossRef]

- Kumar, D.; Chatterjee, K. A Review of Conventional and Advanced MPPT Algorithms for Wind Energy Systems. Renew. Sustain. Energy Rev. 2016, 55, 957–970. [Google Scholar] [CrossRef]

- Apata, O.; Oyedokun, D.T.O. An Overview of Control Techniques for Wind Turbine Systems. Sci. Afr. 2020, 10, e00566. [Google Scholar] [CrossRef]

- Lalouni, S.; Rekioua, D.; Idjdarene, K.; Tounzi, A. Maximum Power Point Tracking Based Hybrid Hill-Climb Search Method Applied to Wind Energy Conversion System. Electr. Power Compon. Syst. 2015, 43, 1028–1038. [Google Scholar] [CrossRef]

- Hua, A.C.-C.; Cheng, B.C.-H. Design and Implementation of Power Converters for Wind Energy Conversion System. In Proceedings of the 2010 International Power Electronics Conference—ECCE ASIA, Sapporo, Japan, 21–24 June 2010; pp. 323–328. [Google Scholar] [CrossRef]

- Femia, N.; Granozio, D.; Petrone, G.; Spagnuolo, G.; Vitelli, M. Predictive Amp; Adaptive MPPT Perturb and Observe Method. IEEE Trans. Aerosp. Electron. Syst. 2007, 43, 934–950. [Google Scholar] [CrossRef]

- Urtasun, A.; Sanchis, P.; San Martín, I.; López, J.; Marroyo, L. Modeling of Small Wind Turbines Based on PMSG with Diode Bridge for Sensorless Maximum Power Tracking. Renew. Energy 2013, 55, 138–149. [Google Scholar] [CrossRef] [Green Version]

- Xia, Y.; Ahmed, K.H.; Williams, B.W. Wind Turbine Power Coefficient Analysis of a New Maximum Power Point Tracking Technique. IEEE Trans. Ind. Electron. 2013, 60, 1122–1132. [Google Scholar] [CrossRef]

- Abdullah, M.A.; Yatim, A.H.M.; Tan, C.W. An Online Optimum-Relation-Based Maximum Power Point Tracking Algorithm for Wind Energy Conversion System. In Proceedings of the 2014 Australasian Universities Power Engineering Conference, AUPEC 2014—Proceedings, Perth, WA, Australia, 28 September–1 October 2014. [Google Scholar] [CrossRef]

- Bendib, B.; Belmili, H.; Krim, F. A Survey of the Most Used MPPT Methods: Conventional and Advanced Algorithms Applied for Photovoltaic Systems. Renew. Sustain. Energy Rev. 2015, 45, 637–648. [Google Scholar] [CrossRef]

- Hosseini, S.H.; Farakhor, A.; Haghighian, S.K. Novel Algorithm of Maximum Power Point Tracking (MPPT) for Variable Speed PMSG Wind Generation Systems through Model Predictive Control. In Proceedings of the ELECO 2013—8th International Conference on Electrical and Electronics Engineering, Bursa, Turkey, 28–30 November 2013; pp. 243–247. [Google Scholar] [CrossRef]

- Yu, K.N.; Liao, C.K. Applying Novel Fractional Order Incremental Conductance Algorithm to Design and Study the Maximum Power Tracking of Small Wind Power Systems. J. Appl. Res. Technol. 2015, 13, 238–244. [Google Scholar] [CrossRef] [Green Version]

- Hohm, D.P.; Ropp, M.E. Comparative Study of Maximum Power Point Tracking Algorithms. Prog. Photovolt. Res. Appl. 2003, 11, 47–62. [Google Scholar] [CrossRef]

- Pagnini, L.C.; Burlando, M.; Repetto, M.P. Experimental Power Curve of Small-Size Wind Turbines in Turbulent Urban Environment. Appl. Energy 2015, 154, 112–121. [Google Scholar] [CrossRef]

- Hilloowala, R.M.; Sharaf, A.M. A Rule-Based Fuzzy Logic Controller for a PWM Inverter in a Stand Alone Wind Energy Conversion Scheme. IEEE Trans. Ind. Appl. 1996, 32, 57–65. [Google Scholar] [CrossRef]

- Galdi, V.; Piccolo, A.; Siano, P. Designing an Adaptive Fuzzy Controller for Maximum Wind Energy Extraction. IEEE Trans. Energy Convers. 2008, 23, 559–569. [Google Scholar] [CrossRef]

- Galdi, V.; Piccolo, A.; Siano, P. Exploiting Maximum Energy from Variable Speed Wind Power Generation Systems by Using an Adaptive Takagi-Sugeno-Kang Fuzzy Model. Energy Convers. Manag. 2009, 50, 413–421. [Google Scholar] [CrossRef]

- Ata, R. Artificial Neural Networks Applications in Wind Energy Systems: A Review. Renew. Sustain. Energy Rev. 2015, 49, 534–562. [Google Scholar] [CrossRef]

- Thongam, J.S.; Bouchard, P.; Ezzaidi, H.; Ouhrouche, M. Artificial Neural Network-Based Maximum Power Point Tracking Control for Variable Speed Wind Energy Conversion Systems. In Proceedings of the IEEE International Conference on Control Applications, St. Petersburg, Russia, 8–10 July 2009; pp. 1667–1671. [Google Scholar] [CrossRef]

- Patyra, M.J.; Grantner, J.L.; Koster, K. Digital Fuzzy Logic Controller: Design and Implementation. IEEE Trans. Fuzzy Syst. 1996, 4, 439–459. [Google Scholar] [CrossRef]

- Jang, J.-S.R. ANFIS: Adaptive-Network-Based Fuzzy Inference System. IEEE Trans. Syst. Man. Cybern. 1993, 23, 665–685. [Google Scholar] [CrossRef]

- Abad, G.; López, J.; Rodríguez, M.A.; Marroyo, L.; Iwanski, G. Doubly Fed Induction Machine: Modeling and Control for Wind Energy Generation; Institute of Electrical and Electronics Engineers: Piscataway, NJ, USA, 2011. [Google Scholar] [CrossRef]

- Biswas, D.; Sahoo, S.S.; Tripathi, P.M.; Chatterjee, K. Maximum Power Point Tracking for Wind Energy System by Adaptive Neural-Network Based Fuzzy Inference System. In Proceedings of the 2018 4th International Conference on Recent Advances in Information Technology (RAIT), Dhanbad, India, 15–17 March 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Asghar, A.B.; Liu, X. Adaptive Neuro-Fuzzy Algorithm to Estimate Effective Wind Speed and Optimal Rotor Speed for Variable-Speed Wind Turbine. Neurocomputing 2018, 272, 495–504. [Google Scholar] [CrossRef]

- Kumar, A.; Giribabu, D. Performance Improvement of DFIG Fed Wind Energy Conversion System Using ANFIS Controller. In Proceedings of the 2016 2nd International Conference on Advances in Electrical, Electronics, Information, Communication and Bio-Informatics (AEEICB), Chennai, India, 27–28 February 2016; pp. 202–206. [Google Scholar] [CrossRef]

- Mathworks. Available online: https://www.mathworks.com/products/hdl-coder.html (accessed on 21 August 2021).

| Gains | REG-1 | REG-2 | REG-3 |

|---|---|---|---|

| Proportional | 10,160 | 0.5771 | 0.5771 |

| Integral | 406,400 | 491.5995 | 491.5995 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Number of nodes | 32 | Total number of parameters | 28 |

| Number of linear parameters | 14 | Number of training data pairs | 10,000,001 |

| Number of nonlinear parameters | 14 | Number of fuzzy rules | 7 |

| Membership Function Name | Type | Parameter | |

|---|---|---|---|

| Standard Deviation | Mean | ||

| Very Small (VS) | Gaussian | 15.047 | −3.3549 × 10−13 |

| Small (S) | Gaussian | 15.047 | 35.433 |

| Big Small (BS) | Gaussian | 15.047 | 70.865 |

| Medium (M) | Gaussian | 15.047 | 106.3 |

| Big Medium (BM) | Gaussian | 15.047 | 141.73 |

| Large (L) | Gaussian | 15.047 | 177.16 |

| Big Large (BL) | Gaussian | 15.047 | 212.6 |

| Membership Function Name | Type | Parameter | |

|---|---|---|---|

| Standard Deviation | Mean | ||

| Very Small (VS) | Gaussian | 26.909 | 5.1594 |

| Small (S) | Gaussian | 30.952 | 33.765 |

| Big Small (BS) | Gaussian | 63.437 | 89.457 |

| Medium (M) | Gaussian | 34.224 | 107.28 |

| Big Medium (BM) | Gaussian | 33.967 | 138.56 |

| Large (L) | Gaussian | 35.116 | 183.63 |

| Big Large (BL) | Gaussian | 41.65 | 199.36 |

| Membership Function Name | Type | Parameter | |

|---|---|---|---|

| Lower Limit | Upped Limit | ||

| Very Small (VS) | Linear | 1.9856 | 1145.1 |

| Small (S) | Linear | 7.3276 | 1244.4 |

| Big Small (BS) | Linear | −4.8424 | −5088.7 |

| Medium (M) | Linear | −124.22 | 9248 |

| Big Medium (BM) | Linear | −143.49 | 15,022 |

| Large (L) | Linear | −98.038 | 7647.7 |

| Big Large (BL) | Linear | −149.91 | 17,393 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Nominal wind speed | 11 m/s | Frequency | 50 Hz |

| Air density | 1.225 kg/m3 | Rated torque | 12,732 N·m |

| Tip-speed ratio | 7 | Pole pair | 2 |

| Pitch angle | 0° | Inertia | 127 kg·m2 |

| Power coefficient | 0.4411 | Gear ratio | 100 |

| Nominal power | 2 MW | Radius of turbine | 42 m |

| Time Duration (s) | Input Wind Speed (m/s) | ||

|---|---|---|---|

| Case-I | Case-II | Case-III | |

| 0–5 | 6 | 12 | 8 |

| 5–8 | 7 | 11 | 10 |

| 8–11 | 8 | 10 | 9 |

| 11–14 | 9 | 9 | 12 |

| 14–17 | 10 | 8 | 7 |

| 17–20 | 11 | 7 | 7 |

| 20–23 | 12 | 6 | 7 |

| Case Study | Simulation Time Instant (sec) | Wind Speed | Rotor Speed (rad/sec) | Stator Active Power (MW) | Percentage Improvement in Power (%) | ||

|---|---|---|---|---|---|---|---|

| PI | ANFIS | PI | ANFIS | ||||

| Case-I | 4 | 6 | 100.6 | 103.7 | 0.4786 | 0.4878 | 1.89 |

| 7 | 7 | 115.9 | 120.9 | 0.6261 | 0.6372 | 1.74 | |

| 10 | 8 | 133.4 | 138.2 | 0.8386 | 0.8491 | 1.24 | |

| 13 | 9 | 151.1 | 155.5 | 1.0562 | 1.0683 | 1.13 | |

| 16 | 10 | 168.2 | 172.8 | 1.3150 | 1.3320 | 1.28 | |

| 19 | 11 | 185.4 | 190.2 | 1.5860 | 1.6140 | 1.73 | |

| 22 | 12 | 202.5 | 207.3 | 1.8830 | 1.9200 | 1.93 | |

| Case-II | 4 | 12 | 195.2 | 207.3 | 1.7732 | 1.8740 | 5.38 |

| 7 | 11 | 187.3 | 190.2 | 1.5860 | 1.6380 | 3.17 | |

| 10 | 10 | 170.5 | 172.8 | 1.3150 | 1.3620 | 3.45 | |

| 13 | 9 | 153.7 | 155.5 | 1.0680 | 1.1120 | 3.96 | |

| 16 | 8 | 137.1 | 138.2 | 0.8479 | 0.8894 | 4.67 | |

| 19 | 7 | 120.2 | 120.9 | 0.6533 | 0.6928 | 5.70 | |

| 22 | 6 | 101.1 | 103.7 | 0.4939 | 0.5236 | 5.67 | |

| Case-III | 4 | 8 | 129.1 | 138.2 | 0.7889 | 0.8478 | 6.95 |

| 7 | 10 | 165.9 | 172.8 | 1.3127 | 1.3265 | 1.04 | |

| 10 | 9 | 153.8 | 155.5 | 1.0680 | 1.0970 | 2.64 | |

| 13 | 12 | 199.9 | 207.3 | 1.8830 | 1.9070 | 1.26 | |

| 17 | 7 | 120.9 | 123.4 | 0.6531 | 0.7071 | 7.64 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chhipa, A.A.; Kumar, V.; Joshi, R.R.; Chakrabarti, P.; Jasinski, M.; Burgio, A.; Leonowicz, Z.; Jasinska, E.; Soni, R.; Chakrabarti, T. Adaptive Neuro-Fuzzy Inference System-Based Maximum Power Tracking Controller for Variable Speed WECS. Energies 2021, 14, 6275. https://doi.org/10.3390/en14196275

Chhipa AA, Kumar V, Joshi RR, Chakrabarti P, Jasinski M, Burgio A, Leonowicz Z, Jasinska E, Soni R, Chakrabarti T. Adaptive Neuro-Fuzzy Inference System-Based Maximum Power Tracking Controller for Variable Speed WECS. Energies. 2021; 14(19):6275. https://doi.org/10.3390/en14196275

Chicago/Turabian StyleChhipa, Abrar Ahmed, Vinod Kumar, Raghuveer Raj Joshi, Prasun Chakrabarti, Michal Jasinski, Alessandro Burgio, Zbigniew Leonowicz, Elzbieta Jasinska, Rajkumar Soni, and Tulika Chakrabarti. 2021. "Adaptive Neuro-Fuzzy Inference System-Based Maximum Power Tracking Controller for Variable Speed WECS" Energies 14, no. 19: 6275. https://doi.org/10.3390/en14196275

APA StyleChhipa, A. A., Kumar, V., Joshi, R. R., Chakrabarti, P., Jasinski, M., Burgio, A., Leonowicz, Z., Jasinska, E., Soni, R., & Chakrabarti, T. (2021). Adaptive Neuro-Fuzzy Inference System-Based Maximum Power Tracking Controller for Variable Speed WECS. Energies, 14(19), 6275. https://doi.org/10.3390/en14196275