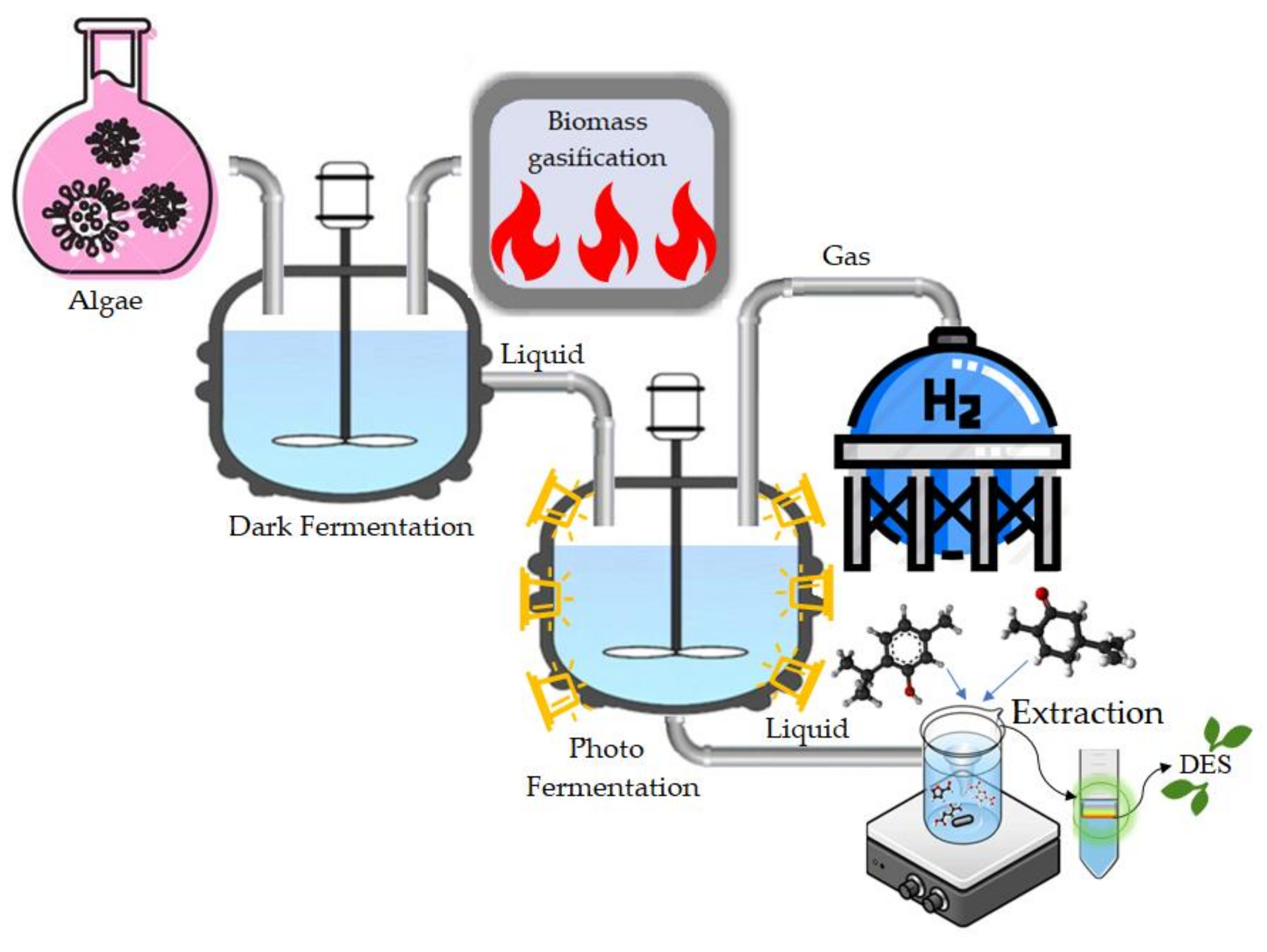

Management of Dark Fermentation Broth via Bio Refining and Photo Fermentation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Analytical Methods

- The mono sugars (glucose, xylose) and the HMF, FF and LA conversion product concentrations in samples were confirmed by analysis using HPLC (Merck—Hitachi, Germany) equipped with a YMC-Pack ODS-2 column (5 µm, 250 × 4.6 mm, YMC, Co, Ltd. Japan, Inc. USA), refractometric detector (RID-RI Detector 2100-Knauer, Germany) and a spectrophotometric (UV-VIS-DAD) detector (L-7450-Merck-Hitachi, Germany) at 284 nm. The samples were filtered through a syringe filter with a PA membrane with a pore diameter of 0.45 µm. A filtered sample of the hydrolysate in a volume of 20 µL was analyzed by HPLC. The mobile phase was 1% sulfuric acid—methanol (85:15 v/v) at a flow rate of 0.6 mL/min. The HPLC column was maintained at room temperature.

- Gaseous products of photo fermentation (H2, O2 and CO2) were analyzed using a gas chromatograph (Autosystem XL) coupled with a thermal conductivity detector (TCD) (PerkinElmer, Waltham, MA, USA) and packed column Porapack Q 100–120 mesh, OD 3.2 mm × 6.5 m (Sigma-Aldrich, Merck, Darmstadt, Germany). The oven temperature was at 60 °C. In the investigations, the TurboChrom 6.1 software (PerkinElmer, Waltham, MA, USA), was used. Gas samples were analyzed after the photo fermentation, on the 10th day of bacterial growth.

- The pH during photo fermentation was continuously monitored during the fermentation (Arduino Microcontroller data-logger, Continuous pH regulative system developed at the Gdańsk University of Technology, Gdańsk, Poland). The growth of R. rubrum culture was monitored by measuring the OD at λ = 600 nm (optical density of culture).

- The protein concentration was measured using UV-VIS spectrophotometry at 750 nm and Folin—Ciocalteu method on Hach Lange DR 5000 apparatus [30].

2.2. Model Photo Fermentation Broth Characterization

2.3. Photo Fermentation

2.4. DES Separation

3. Results and Discussion

3.1. Design of Experiment

3.2. Analysis of Model Post-Fermentation Broth

3.3. Optimization of the Residual Mono Sugars Conversion Process

3.4. Photo Fermentation Course Analysis

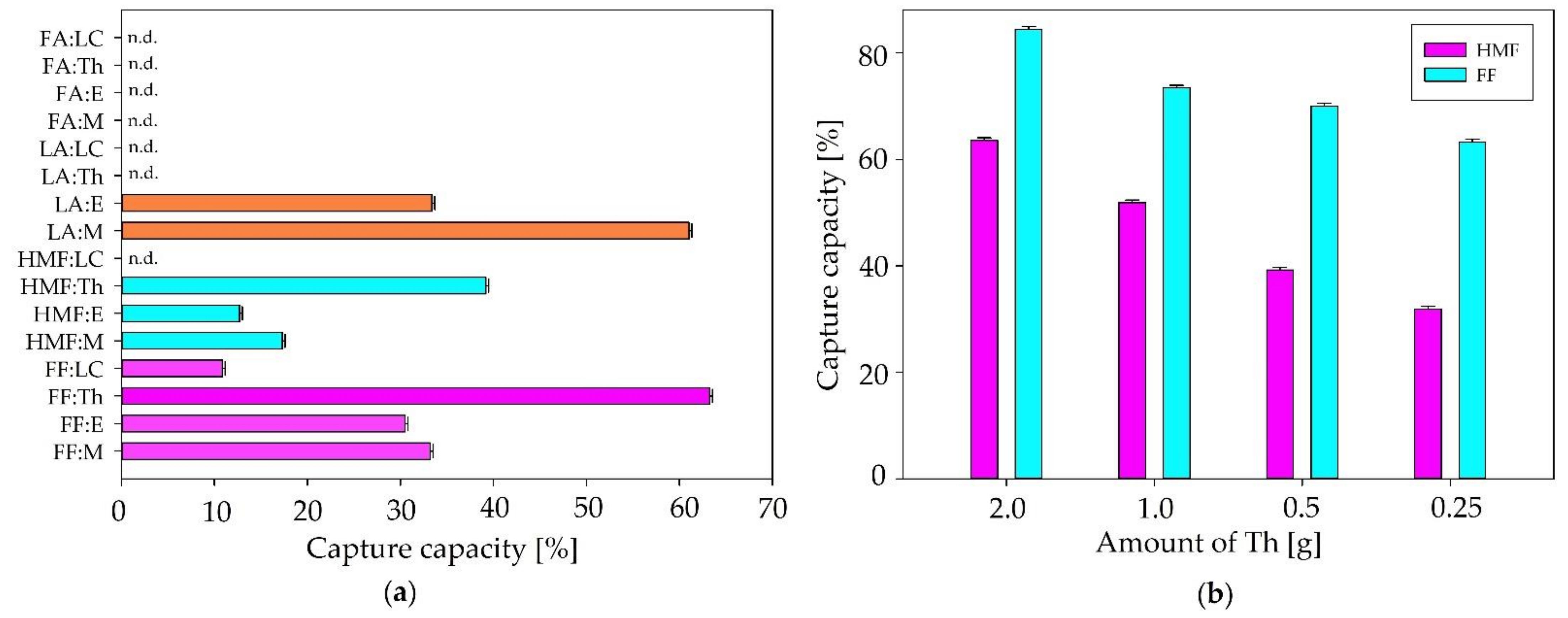

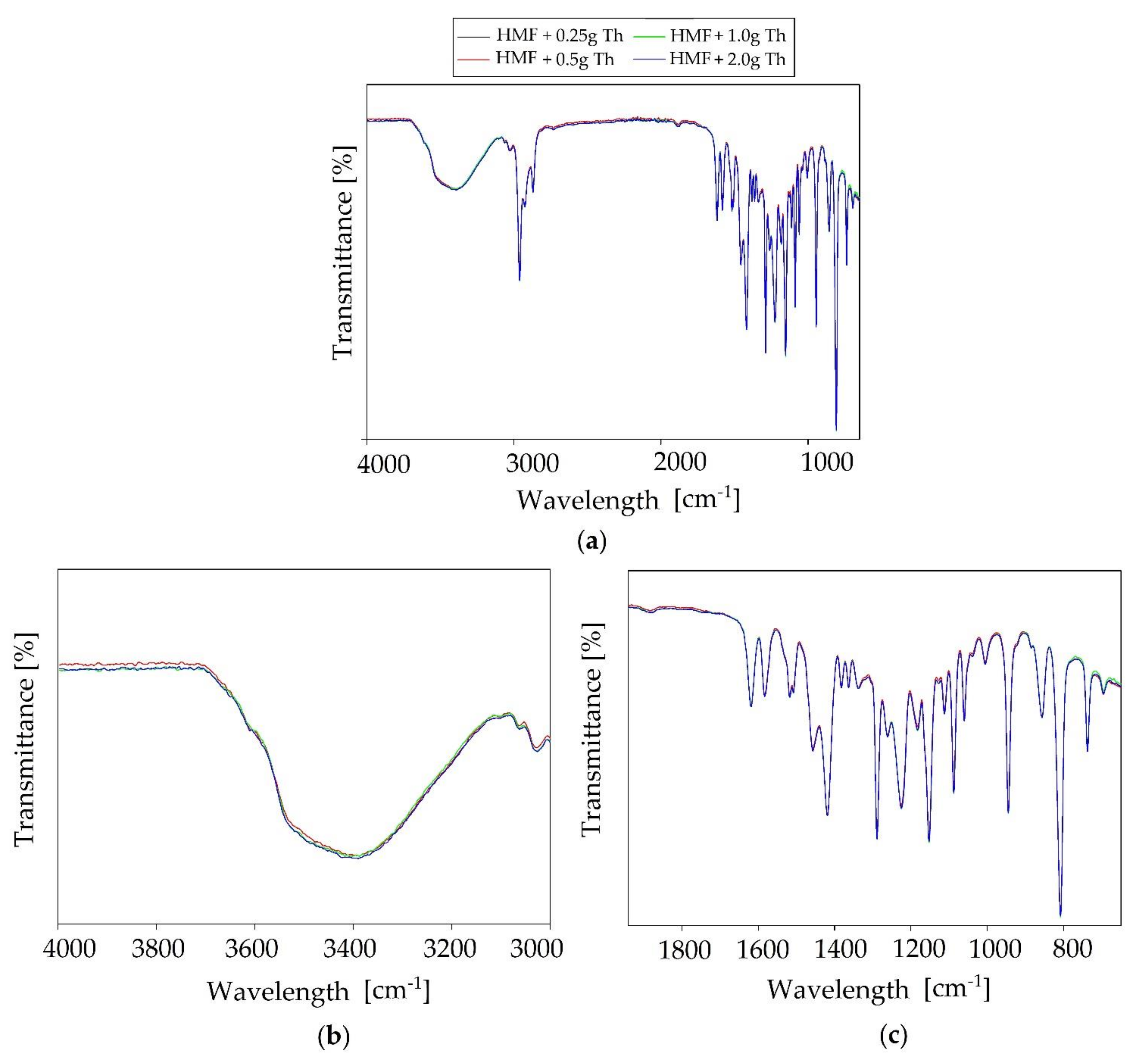

3.5. Biorefining—DES Separation

- hydrophobic to form a water-insoluble eutectic mixture;

- HBD must form stable eutectic mixtures with DES precursors;

- selectively bind to DES precursors;

- the DES formed should have a lower density than that of water for easier separation.

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Vijayaraghavan, K.; Ahmad, D. Biohydrogen generation from palm oil mill effluent using anaerobic contact filter. Int. J. Hydrog. Energy 2006, 31, 1284–1291. [Google Scholar] [CrossRef]

- Dincer, I.; Acar, C. Review and evaluation of hydrogen production methods for better sustainability. Int. J. Hydrog. Energy 2015, 40, 11094–11111. [Google Scholar] [CrossRef]

- Tang, G.-L.; Huang, J.; Sun, Z.-J.; Tang, Q.-Q.; Yan, C.-H.; Liu, G.-Q. Biohydrogen production from cattle wastewater by enriched anaerobic mixed consortia: Influence of fermentation temperature and pH. J. Biosci. Bioeng. 2008, 106, 80–87. [Google Scholar] [CrossRef] [PubMed]

- Kucharska, K.; Hołowacz, I.; Konopacka-Łyskawa, D.; Rybarczyk, P.; Kamiński, M. Key issues in modeling and optimization of lignocellulosic biomass fermentative conversion to gaseous biofuels. Renew. Energy 2018, 129, 384–408. [Google Scholar] [CrossRef]

- Słupek, E.; Makoś, P.; Kucharska, K.; Gębicki, J. Mesophilic and thermophilic dark fermentation course analysis using sensor matrices and chromatographic techniques. Chem. Pap. 2020, 74, 1573–1582. [Google Scholar] [CrossRef]

- Singh, R.; White, D.; Demirel, Y.; Kelly, R.; Noll, K.; Blum, P. Uncoupling fermentative synthesis of molecular hydrogen from biomass formation in Thermotoga maritima. Appl. Environ. Microbiol. 2018, 84, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Zheng, Y.; Zhao, J.; Xu, F.; Li, Y. Pretreatment of lignocellulosic biomass for enhanced biogas production. Prog. Energy Combust. Sci. 2014, 42, 35–53. [Google Scholar] [CrossRef]

- Łukajtis, R.; Hołowacz, I.; Kucharska, K.; Glinka, M.; Rybarczyk, P.; Przyjazny, A.; Kamiński, M. Hydrogen production from biomass using dark fermentation. Renew. Sustain. Energy Rev. 2018, 91, 665–694. [Google Scholar] [CrossRef]

- Łukajtis, R.; Rybarczyk, P.; Kucharska, K.; Konopacka-Łyskawa, D.; Słupek, E.; Wychodnik, K.; Kamiński, M. Optimization of saccharification conditions of lignocellulosic biomass under alkaline pre-treatment and enzymatic hydrolysis. Energies 2018, 11, 886. [Google Scholar] [CrossRef] [Green Version]

- Kucharska, K.; Łukajtis, R.; Słupek, E.; Cieśliński, H.; Rybarczyk, P.; Kamiński, M. Hydrogen production from energy poplar preceded by MEA pre-treatment and enzymatic hydrolysis. Molecules 2018, 23, 3029. [Google Scholar] [CrossRef] [Green Version]

- Mussatto, S.I.; Fernandes, M.; Mancilha, I.M.; Roberto, I.C. Effects of medium supplementation and pH control on lactic acid production from brewer’s spent grain. Biochem. Eng. J. 2008, 40, 437–444. [Google Scholar] [CrossRef]

- Yokoi, H.; Saitsu, A.; Uchida, H.; Hirose, J.; Hayashi, S.; Takasaki, Y. Microbial hydrogen production from sweet potato starch residue. J. Biosci. Bioeng. 2001, 91, 58–63. [Google Scholar] [CrossRef]

- Redondas, V.; Gómez, X.; García, S.; Pevida, C.; Rubiera, F.; Morán, A.; Pis, J.J. Hydrogen production from food wastes and gas post-treatment by CO2 adsorption. Waste Manag. 2012, 32, 60–66. [Google Scholar] [CrossRef]

- Cheng, J.; Ding, L.; Xia, A.; Lin, R.; Li, Y.; Zhou, J.; Cen, K. Hydrogen production using amino acids obtained by protein degradation in waste biomass by combined dark- and photo-fermentation. Bioresour. Technol. 2015, 179, 13–19. [Google Scholar] [CrossRef] [PubMed]

- Xing, Y.; Li, Z.; Fan, Y.; Hou, H. Biohydrogen production from dairy manures with acidification pretreatment by anaerobic fermentation. Environ. Sci. Pollut. Res. 2010, 17, 392–399. [Google Scholar] [CrossRef] [PubMed]

- Azbar, N.; Dokgöz, F.T.; Keskin, T.; Eltem, R.; Korkmaz, K.S.; Gezgin, Y.; Akbal, Z.; Öncel, S.; Dalay, M.C.; Gönen, Ç.; et al. Comparative Evaluation of Bio-Hydrogen Production From Cheese Whey Wastewater Under Thermophilic and Mesophilic Anaerobic Conditions. Int. J. Green Energy 2009, 6, 192–200. [Google Scholar] [CrossRef]

- Levin, D.B.; Islam, R.; Cicek, N.; Sparling, R. Hydrogen production by Clostridium thermocellum 27405 from cellulosic biomass substrates. Int. J. Hydrog. Energy 2006, 31, 1496–1503. [Google Scholar] [CrossRef]

- Li, Q.; Yang, M.; Wang, D.; Li, W.; Wu, Y.; Zhang, Y.; Xing, J.; Su, Z. Efficient conversion of crop stalk wastes into succinic acid production by Actinobacillus succinogenes. Bioresour. Technol. 2010, 101, 3292–3294. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.Y.; Yim, S.C.; Lee, P.C.; Lee, W.G.; Lee, S.Y.; Chang, H.N. Batch and continuous fermentation of succinic acid from wood hydrolysate by Mannheimia succiniciproducens MBEL55E. Enzyme Microbial Technol. 2004, 35, 348–653. [Google Scholar] [CrossRef]

- Jönsson, L.J.; Martín, C. Pretreatment of lignocellulose: Formation of inhibitory by-products and strategies for minimizing their effects. Bioresour. Technol. 2016, 199, 103–112. [Google Scholar] [CrossRef] [Green Version]

- Lay, J.J.; Lee, Y.J.; Noike, T. Feasibility of biological hydrogen production from organic fraction of municipal solid waste. Water Res. 1999, 33, 2579–2586. [Google Scholar] [CrossRef]

- Evvyernie, D.; Yamazaki, S.; Morimoto, K.; Karita, S.; Kimura, T.; Sakka, K.; Ohmiya, K. Identification and characterization of Clostridium paraputrificum M-21, a chitinolytic, mesophilic and hydrogen-producing bacterium. J. Biosci. Bioeng. 2000, 89, 596–601. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, J.; Dong, C.; Miller, C.; Li, Y.; Wang, L.; Yao, W. Continuous biohydrogen production from liquid swine manure supplemented with glucose using an anaerobic sequencing batch reactor. Int. J. Hydrogen Energy 2009, 34, 6636–6645. [Google Scholar] [CrossRef]

- Karmann, S.; Panke, S.; Zinn, M. Fed-Batch Cultivations of Rhodospirillum rubrum Under Multiple Nutrient-Limited Growth Conditions on Syngas as a Novel Option to Produce Poly(3-Hydroxybutyrate) (PHB). Front. Bioeng. Biotechnol. 2019, 7, 59. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ghimire, A.; Frunzo, L.; Pirozzi, F.; Trably, E.; Escudie, R.; Lens, P.N.L.; Esposito, G. A review on dark fermentative biohydrogen production from organic biomass: Process parameters and use of by-products. Appl. Energy 2015, 144, 73–95. [Google Scholar] [CrossRef]

- He, D.; Bultel, Y.; Magnin, J.P.; Roux, C.; Willison, J.C. Hydrogen photosynthesis by Rhodobacter capsulatus and its coupling to a PEM fuel cell. J. Power Sources 2005, 141, 19–23. [Google Scholar] [CrossRef]

- Akerman, N.H.; Butterfield, D.A.; Huber, J.A. Phylogenetic diversity and functional gene patterns of sulfur-oxidizing subseafloor Epsilonproteobacteria in diffuse hydrothermal vent fluids. Front. Microbiol. 2013, 4, 185. [Google Scholar] [CrossRef] [Green Version]

- Kucharska, K.; Cieśliński, H.; Rybarczyk, P.; Słupek, E.; Łukajtis, R.; Wychodnik, K.; Kamiński, M. Fermentative conversion of two-step pre-treated lignocellulosic biomass to hydrogen. Catalysts 2019, 9, 858. [Google Scholar] [CrossRef] [Green Version]

- Akobi, C.; Hafez, H.; Nakhla, G. The impact of furfural concentrations and substrate-to-biomass ratios on biological hydrogen production from synthetic lignocellulosic hydrolysate using mesophilic anaerobic digester sludge Furfural:sugars exerted a greater effect on H 2 inhibition than f. Bioresour. Technol. 2016, 221, 598–606. [Google Scholar] [CrossRef]

- Hames, B.; Scarlata, C.; Sluiter, A. Determination of Protein Content in Biomass; National Renewable Energy Laboratory: Golden, CO, USA, 2008. [Google Scholar]

- Tani, K.; Kanno, R.; Ji, X.; Hall, M.; Yu, L.; Kimura, Y.; Madigan, M.T.; Humbel, B.M. Cryo-EM Structure of the Photosynthetic LH1-RC Complex from Rhodospirillum rubrum. BioRxiv 2021, 1–10. [Google Scholar] [CrossRef]

- Kuever, J.; Rainey, F.A.; Widdel, F. Desulfuromonas. Bergey Man. Syst. Archaea Bact. 2015, 1–7. [Google Scholar] [CrossRef]

- Sorokin, C.; Krauss, R.W. The Effects of Light Intensity on the Growth Rates of Green Algae. Plant Physiol. 1958, 33, 109–113. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, K.J.; Chang, J.S. Batch and continuous fermentative production of hydrogen with anaerobic sludge entrapped in a composite polymeric matrix. Process Biochem. 2007, 42, 279–284. [Google Scholar] [CrossRef]

- Scholz, M.; Frank, B.; Stockmeier, F.; Falß, S.; Wessling, M. Techno-economic analysis of hybrid processes for biogas upgrading. Ind. Eng. Chem. Res. 2013, 52, 16929–16938. [Google Scholar] [CrossRef]

- Zhang, Q.; De Oliveira Vigier, K.; Royer, S.; Jérôme, F. Deep eutectic solvents: Syntheses, properties and applications. Chem. Soc. Rev. 2012, 41, 7108–7146. [Google Scholar] [CrossRef]

- Słupek, E.; Makoś-Chełstowska, P.; Gębicki, J. Removal of siloxanes from model biogas by means of deep eutectic solvents in absorption process. Materials 2021, 14, 241. [Google Scholar] [CrossRef] [PubMed]

- Makoś, P.; Słupek, E.; Gębicki, J. Hydrophobic deep eutectic solvents in microextraction techniques—A review. Microchem. J. 2020, 152, 104384. [Google Scholar] [CrossRef]

- Makoś, P.; Słupek, E.; Gębicki, J. Extractive detoxification of feedstocks for the production of biofuels using new hydrophobic deep eutectic solvents–Experimental and theoretical studies. J. Mol. Liq. 2020, 308, 113101–113112. [Google Scholar] [CrossRef]

- Li, K.; Jin, Y.; Jung, D.; Park, K.; Kim, H.; Lee, J. In situ formation of thymol-based hydrophobic deep eutectic solvents: Application to antibiotics analysis in surface water based on liquid-liquid microextraction followed by liquid chromatography. J. Chromatogr. A 2020, 1614, 460730. [Google Scholar] [CrossRef]

- Ghimire, A. Dark fermentative biohydrogen production from organic waste and application of by-products in a biorefinery Anish Ghimire To cite this version: HAL Id : Tel-01404689 Biofuels Waste Treatment Waste Biomass based Biore fi nery Energy and Sustainability Bio. PhD Thesis, Université Paris-Est, Paris, France, 2016. [Google Scholar]

- Kapdan, I.K.; Kargi, F. Bio-hydrogen production from waste materials. Enzyme Microb. Technol. 2006, 38, 569–582. [Google Scholar] [CrossRef]

- Buchanan, B.B. 6 Ferredoxin-Linked Carboxylation Reactions. Enzymes 1972, 6, 193–216. [Google Scholar]

| Raw Material | Microorganism | Liquid Products | References |

|---|---|---|---|

| Cattle wastewater 1.3 g COD/dm3 | Sewage sludge | butyric acid, acetic acid, ethanol, propionic acid | [3] |

| Dairy manures 70 g/dm3 | Clostridium sp. | butyric acid, acetic acid, ethanol, propionic acid, butanol | [15] |

| Jatropha curcas–biodiesel industry residue | Mixed cultures (activated sludge) | butyric acid, ethanol, acetic acid, propionic acid, valeric acid | [16] |

| Delignified wood fibers 0.1 g/dm3 | Clostridium thermocellum ATCC 27405 | acetic acid, ethanol, formic acid | [17] |

| Delignified hydrolysate of lignocellulosic biomass | Anaerobic bacteria | lactic acid, citric acid, acetic acid | [18] |

| Variable | Unit | Symbol | Coding Level | ||

|---|---|---|---|---|---|

| −1 | 0 | 1 | |||

| temperature | °C | X1 | 60 | 75 | 90 |

| time | h | X2 | 2 | 24 | 46 |

| acetic acid concentration | % | X3 | 10 | 35 | 60 |

| Exp. No. | X1 | X2 | X3 | Feed Residues | DES Precursors Concentration | ||||

|---|---|---|---|---|---|---|---|---|---|

| Glu, Xyl | AA | FA | LA | HMF | FF | ||||

| g/L | g/L | g/L | g/L | g/L | g/L | ||||

| 1. | 60 | 2 | 35 | 41.17 | 271.210 | 11.210 | n.d | 0.001 | 0.001 |

| 2. | 90 | 2 | 35 | 21.97 | 330.730 | 112.260 | n.d | 0.001 | 0.015 |

| 3. | 60 | 46 | 35 | 42.85 | 281.230 | 41.360 | n.d | n.d. | 0.005 |

| 4. | 90 | 46 | 35 | 17.54 | 330.730 | 19.590 | 0.428 | 0.102 | 0.690 |

| 5. | 60 | 24 | 10 | 24.96 | 306.880 | 0.066 | n.d. | 0.000 | 0.001 |

| 6. | 90 | 24 | 10 | 19.41 | 117.850 | 4.880 | 0.561 | 0.029 | 0.229 |

| 7. | 60 | 24 | 60 | 18.15 | 536.720 | 280.680 | n.d. | 0.001 | 0.002 |

| 8. | 90 | 24 | 60 | 11.91 | 271.210 | 11.210 | 1.553 | 0.031 | n.d. |

| 9. | 75 | 2 | 10 | 10.13 | 102.630 | 117.030 | n.d. | 0.001 | 0.001 |

| 10. | 75 | 46 | 10 | 11.44 | 115.650 | 1.610 | 0.112 | 0.003 | 0.032 |

| 11. | 75 | 2 | 60 | 11.52 | 420.097 | 137.290 | n.d. | n.d. | n.d. |

| 12. | 75 | 46 | 60 | 11.97 | 394.860 | 153.420 | n.d. | 0.004 | 0.035 |

| 13. | 75 | 24 | 35 | 41.17 | 323.630 | 105.350 | n.d. | 0.001 | 0.017 |

| 14. | 75 | 24 | 35 | 21.97 | 340.570 | 114.380 | n.d. | 0.001 | 0.018 |

| 15. | 75 | 24 | 35 | 42.85 | 332.580 | 83.380 | n.d. | 0.001 | 0.018 |

| Modeled Substance | Regression Equation | Determination Coefficient | Optimal Values |

|---|---|---|---|

| LA | CLA = 8.26 − 0.212 X1 − 0.0691 X3 + 0.001349 X1∗X1 − 0.000406 X2∗X2+ 0.000359 X3∗X3 + 0.000324 X1∗X2 + 0.000661 X1∗X3 | 0.781 | X1 = 90 °C X2 = 32.2 h X3 = 60% |

| HMF | CHMF = 0.498 − 0.01320 X1 − 0.00576 X2 + 0.00053 X3 + 0.000084 X1∗X1 + 0.000012 X2∗X2 | 0.864 | X1 = 90 °C X2 = 46 h X3 = 37.2% |

| FF | CFF = 2.36 − 0.0663 X1 − 0.0399 X2 + 0.0171 X3 + 0.000448 X1∗X1 + 0.000123 X2∗X2 + 0.000509 X1∗X2 | 0.821 | X1 = 90 °C X2 = 46 h X3 = 17.57% |

| FA | CFA = −1464 + 34.8 X1 + 5.30 X2 + 12.93 X3 − 0.185 X1∗X1 − 0.0277 X2∗X2 + 0.0235 X3*X3 − 0.0930 X1∗X2 − 0.1829 X1∗X3 + 0.0598 X2∗X3 | 0.801 | X1 = 60 °C X2 = 46 h X3 = 60% |

| Broth Type | Pre-Treatment Parameters | Gas Amount, L/L medium | Hydrogen Concentration (L H2/L medium/7 d) | Final Protein Concentration, mg/L |

|---|---|---|---|---|

| FA | X1 = 60 °C X2 = 46 h X3 = 60% | 2.048 ± 0.050 | 0.819 ± 0.002 | 0.008 ± 0.003 |

| LA | X1 = 90 °C X2 = 32.2 h X3 = 60% | 0.115 ± 0.015 | n.d. | 0.011 ± 0.002 |

| HMF | X1 = 90 °C X2 = 46 h X3 = 37.2% | 1.847 ± 0.120 | 0.702 ± 0.010 | 0.007 ± 0.001 |

| FF | X1 = 90 °C X2 = 46 h X3 = 17.57% | 1.789 ± 0.111 | 0.612 ± 0.002 | 0.012 ± 0.003 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kucharska, K.; Makoś-Chełstowska, P.; Słupek, E.; Gębicki, J. Management of Dark Fermentation Broth via Bio Refining and Photo Fermentation. Energies 2021, 14, 6268. https://doi.org/10.3390/en14196268

Kucharska K, Makoś-Chełstowska P, Słupek E, Gębicki J. Management of Dark Fermentation Broth via Bio Refining and Photo Fermentation. Energies. 2021; 14(19):6268. https://doi.org/10.3390/en14196268

Chicago/Turabian StyleKucharska, Karolina, Patrycja Makoś-Chełstowska, Edyta Słupek, and Jacek Gębicki. 2021. "Management of Dark Fermentation Broth via Bio Refining and Photo Fermentation" Energies 14, no. 19: 6268. https://doi.org/10.3390/en14196268

APA StyleKucharska, K., Makoś-Chełstowska, P., Słupek, E., & Gębicki, J. (2021). Management of Dark Fermentation Broth via Bio Refining and Photo Fermentation. Energies, 14(19), 6268. https://doi.org/10.3390/en14196268