The Energetic Aspect of Organic Wastes Addition on Sewage Sludge Anaerobic Digestion: A Laboratory Investigation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Selection of Substrates and Its Characteristics

2.2. Preparation of Substrates

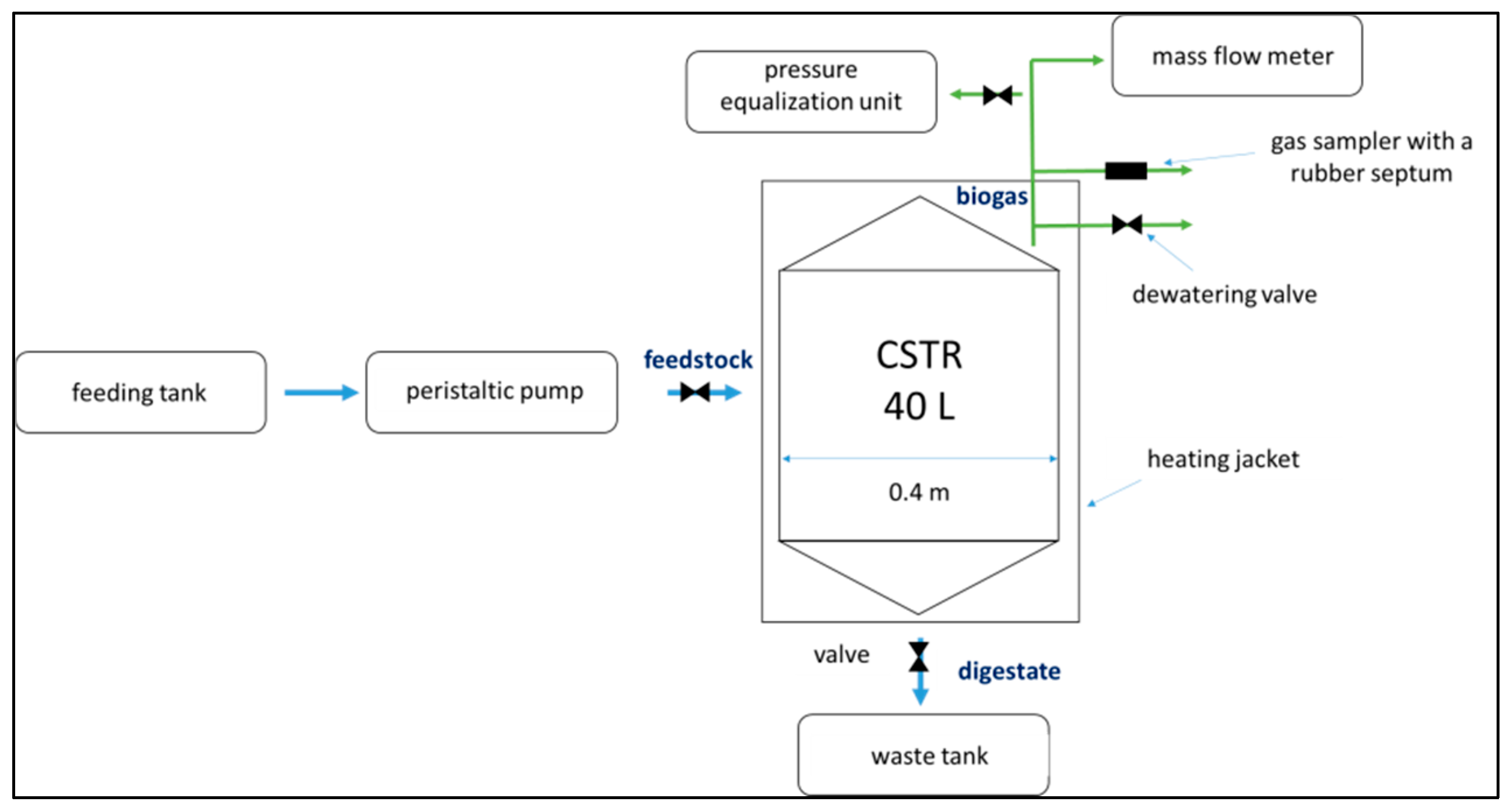

2.3. Operational Conditions and Laboratory Installation

2.4. Energy Balance Evaluation

2.5. Analytical Methods and Statistical Analysis

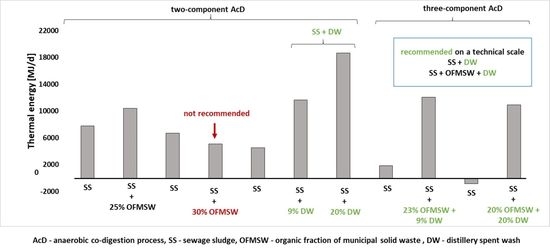

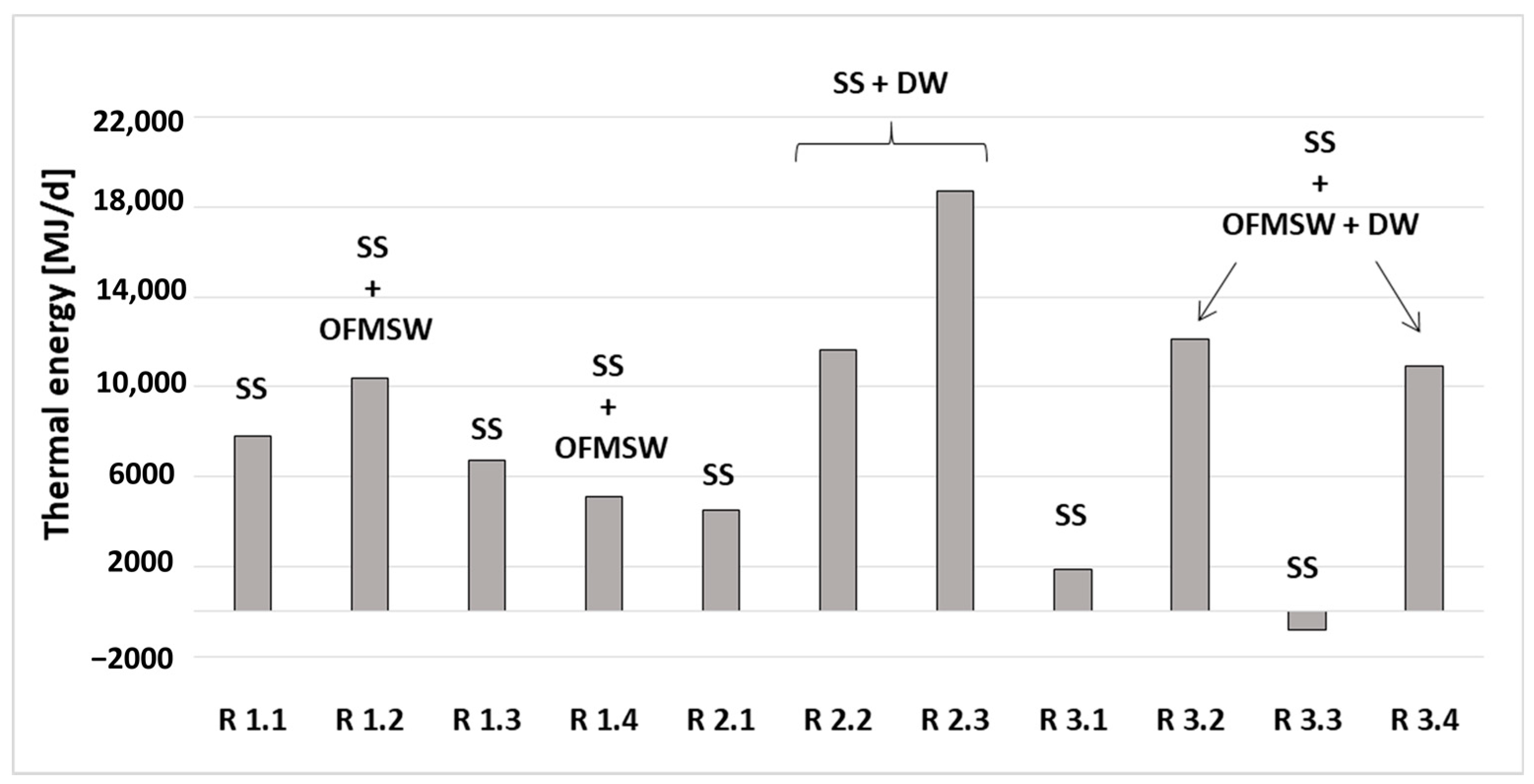

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kainthola, J.; Kalamdhad, S.A.; Goud, V.V. A review on enhanced biogas production from anaerobic digestion of lignocellulosic biomass by different enhancement techniques. Process. Biochem. 2019, 84, 81–90. [Google Scholar] [CrossRef]

- Campana, P.-E.; Mainardis, M.; Moretti, A.; Cottes, M. 100% renewable wastewater treatment plants: Techno-economic assessment using a modelling and optimization approach. Energy Convers. Manag. 2021, 239, 114214. [Google Scholar] [CrossRef]

- Panepinto, D.; Fiore, S.; Zappone, M.; Genon, G.; Meucci, L. Evaluation of the energy efficiency of a large wastewater treatment plant in Italy. Appl. Energy 2016, 161, 404–411. [Google Scholar] [CrossRef]

- Gu, Y.; Li, Y.; Li, X.; Luo, P.; Wang, H.; Wang, X.; Wu, J.; Li, F. Energy Self-sufficient Wastewater Treatment Plants: Feasibilities and Challenges. Energy Procedia 2017, 105, 3741–3751. [Google Scholar] [CrossRef]

- Wójtowicz, A.; Jędrzejewski, C.; Bieniowski, M.; Darul, H. Modelowe Rozwiązania w Gospodarce Osadowej; Izba Gospodarcza Wodociągi Polskie: Bydgoszcz, Poland, 2013. [Google Scholar]

- Hao, X.; Liu, R.; Huang, X. Evaluation of the potential for operating carbon neutral WWTPs in China. Water Res. 2015, 87, 424–431. [Google Scholar] [CrossRef]

- Christoforidou, P.; Bariamis, G.; Iosifidou, M.; Nikolaidou, E.; Samaras, P. Energy Benchmarking and Optimization of Wastewater Treatment Plants in Greece. Environ. Sci. Proc. 2020, 2, 36. [Google Scholar] [CrossRef]

- Masłoń, A.; Czarnota, J.; Szaja, A.; Szulżyk-Cieplak, J.; Łagód, G. The Enhancement of Energy Efficiency in a Wastewater Treatment Plant through Sustainable Biogas Use: Case Study from Poland. Energies 2020, 13, 6056. [Google Scholar] [CrossRef]

- Mainardis, M.; Magnolo, F.; Ferrara, C.; Vance, C.; Misson, G.; De Feo, G.; Speelman, S.; Murphy, F.; Goi, D. Alternative seagrass wrack management practices in the circular bioeconomy framework: A life cycle assessment approach. Sci. Total Environ. 2021, 798, 149283. [Google Scholar] [CrossRef] [PubMed]

- Paul, S.; Dutta, A. Challenges and opportunities of lignocellulosic biomass for anaerobic digestion. Resour. Conserv. Recycl. 2018, 130, 164–174. [Google Scholar] [CrossRef]

- Shen, Y.; Linville, J.; Leigh, U.; Demirtas, M.; Mintz, M.M.; Snyder, S.W. An Overview of Biogas Production and Utilization at Full-scale Wastewater Treatment Plants (WWTPs) in the United States: Challenges and Opportunities towards Energy-neutral WWTPs. United States. Renew. Sust. Energ. Rev. 2015, 50, 346–362. [Google Scholar] [CrossRef] [Green Version]

- Hu, Y.; Bassi, A.; Xu, C. Energy from Biomass. In Future Energy: Improved, Sustainable and CleanOptions for our Planet, 3rd ed.; Letcher, T., Ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 154–196. [Google Scholar] [CrossRef]

- Appels, L.; Baeyens, J.; Degrève, J.; Dewil, R. Principles and potential of the anaerobic digestion of waste-activated sludge. Prog. Energy Combust. Sci. 2008, 34, 755–781. [Google Scholar] [CrossRef]

- Iglesias, R.; Muñoz, R.; Polanco, M.; Díaz, I.; Susmozas, A.; Moreno, A.D.; Guirado, M.; Carreras, N.; Ballesteros, M. Biogas from Anaerobic Digestion as an Energy Vector: Current Upgrading Development. Energies 2021, 14, 2742. [Google Scholar] [CrossRef]

- Siddique, M.N.; Wahid, Z.A. Achievements and perspectives of anaerobic co-digestion: A review. J. Clean. Prod. 2018, 194, 359–371. [Google Scholar] [CrossRef]

- Mata-Alvarez, J.; Dosta, J.; Romero-Güiza, M.S.; Fonoll, X.; Peces, M.; Astals, S. A critical review on anaerobic co-digestion achievements between 2010 and 2013. Renew. Sustain. Energy Rev. 2014, 36, 412–427. [Google Scholar] [CrossRef]

- Karki, R.; Chuenchart, W.; Surendra, K.C.; Shrestha, S.; Raskin, L.; Sung, S.; Hashimoto, A.; Kumar Khanal, S. Anaerobic co-digestion: Current status and perspectives. Bioresour. Technol. 2021, 330, 125001. [Google Scholar] [CrossRef] [PubMed]

- Rabii, A.; Aldin, S.; Dahman, Y.; Elbeshbishy, E. A Review on Anaerobic Co-Digestion with a Focus on the Microbial Populations and the Effect of Multi-Stage Digester Configuration. Energies 2019, 12, 1106. [Google Scholar] [CrossRef] [Green Version]

- El Ibrahimi, M.; Khay, I.; El Maakoul, A.; Bakhouya, M. Techno-economic and environmental assessment of anaerobic co-digestion plants under different energy scenarios: A case study in Morocco. Energy Convers. Manag. 2021, 245, 114553. [Google Scholar] [CrossRef]

- Fernando-Foncillas, C.; Estevez, M.M.; Uellendahl, H.; Varrone, C. Co-Management of Sewage Sludge and Other Organic Wastes: A Scandinavian Case Study. Energies 2021, 14, 3411. [Google Scholar] [CrossRef]

- Braun, R.; Wellinger, A. Potential of Co-Digestion; IEA: Paris, France, 2002. [Google Scholar]

- Chow, W.L.; Chong, S.; Lim, J.W.; Chan, Y.J.; Chong, M.F.; Tiong, T.J.; Chin, J.K.; Pan, G.-T. Anaerobic Co-Digestion of Wastewater Sludge: A Review of Potential Co-Substrates and Operating Factors for Improved Methane Yield. Processes 2020, 8, 39. [Google Scholar] [CrossRef] [Green Version]

- Atelge, M.R.; Atabani, A.E.; Banu, J.R.; Krisa, D.; Kaya, M.; Eskicioglu, C.; Kumar, G.; Lee, C.; Yildiz, Y.S.; Unalan, S.; et al. A critical review of pretreatment technologies to enhance anaerobic digestion and energy recovery. Fuel 2020, 270, 117494. [Google Scholar] [CrossRef]

- Montusiewicz, A. Współfermentacja Osadów Ściekowych i Wybranych Kosubstratów Jako Metoda Efektywnej Biometanizacji; Politechnika Lubelska: Lublin, Poland, 2012. [Google Scholar]

- Zaborowska, E.; Majtacz, J.; Drewnowski, J.; Sobotka, D.; Al-Hazmi, H.; Kowal, P.; Mąkinia, J. Improving the energy balance in wastewater treatment plants by optimization of aeration control and application of new technologies. In Water Supply and Wastewater Disposal; Sobczuk, H., Kowalska, B., Eds.; LUT: Lublin, Poland, 2018; pp. 317–328. [Google Scholar]

- Asteriadis, I.; Azis, K.; Ntougias, S.; Melidis, P. A control strategy for an intermittently aerated and fed bioreactor to reduce aeration costs: A simulation study. Biochem. Eng. J. 2021, 173. [Google Scholar] [CrossRef]

- Izadi, P.; Eldyasti, A. Enhancement of simultaneous nitrogen and phosphorus removal using intermittent aeration mechanism. J. Environ. Sci. 2021, 109, 1–14. [Google Scholar] [CrossRef]

- Chen, Y.; Cheng, J.J.; Creamer, K.S. Inhibition of anaerobic digestion process: A review. Bioresour. Technol. 2008, 99, 4044–4064. [Google Scholar] [CrossRef] [PubMed]

- Sankaran, K.; Premalatha, M.; Vijayasekaran, M.; Somasundaram, V.T. DEPHY project: Distillery wastewater treatment through anaerobic digestion and phycoremediation—A green industrial approach. Renew. Sustain. Energy Rev. 2014, 17, 634–643. [Google Scholar] [CrossRef]

- Chowdhary, P.; Raj, A.; Bharagava, R.N. Environmental pollution and health hazards from distillery wastewater and treatment approaches to combat the environmental threats: A review. Chemosphere 2018, 194, 229–246. [Google Scholar] [CrossRef]

- Mohana, S.; Acharya, B.K.; Madamwar, D. Distillery spent wash: Treatment technologies and potential applications. J. Hazard. Mater. 2009, 163, 12–25. [Google Scholar] [CrossRef] [PubMed]

- Gunes, B.; Stokes, J.; Davis, P.; Connolly, C.; Lawler, J. Pre-treatments to enhance biogas yield and quality from anaerobic digestion of whiskey distillery and brewery wastes: A review. Renew. Sustain. Energy Rev. 2019, 113, 109281. [Google Scholar] [CrossRef]

- Bala, R.; Gupta, G.K.; Dasgupta, B.V.; Mondal, M.K. Pretreatment optimisation and kinetics of batch anaerobic digestion of liquidised OFMSW treated with NaOH: Models verification with experimental data. J. Environ. Manag. 2019, 237, 313–321. [Google Scholar] [CrossRef]

- American Public Health Association (APHA). Standard Methods for the Examination of Water and Wastewater, 22nd ed.; APHA: Washington, DC, USA, 2012. [Google Scholar]

- Tyagi, V.; Fdez-Güelfo, L.A.; Zhou, Y.; Álvarez-Gallego, C.; García, L.I.; Ng, W. Anaerobic co-digestion of organic fraction of municipal solid waste (OFMSW): Progress and challenges. Renew. Sustain. Energy Rev. 2018, 93, 380–399. [Google Scholar] [CrossRef]

- Jain, S.; Jain, S.; Wolf, I.T.; Lee, J.; Tong, Y.W. A comprehensive review on operating parameters and different pretreatment methodologies for anaerobic digestion of municipal solid waste. Renew. Sustain. Energy Rev. 2015, 52, 142–154. [Google Scholar] [CrossRef]

- Zhang, J.; Lv, C.; Tong, J.; Liu, J.; Liu, J.; Yu, D.; Wang, Y.; Chen, M.; Wei, Y. Optimization and microbial community analysis of anaerobic co-digestion of food waste and sewage sludge based on microwave pretreatment. Bioresour. Technol. 2016, 200, 253–261. [Google Scholar] [CrossRef]

- Ahmed, B.; Tyagi, V.K.; Aboudi, K.; Naseem, A.; Alvarez-Gallego, C.J.; Fernandez-Guelfo, L.A.; Kazmi, A.A.; Romero-Garcia, L.I. Thermally enhanced solubilization and anaerobic digestion of organic fraction of municipal solid waste. Chemosphere 2021, 282, 131136. [Google Scholar] [CrossRef]

- Ripoll, V.; Agabo-García, C.; Perez, M.; Solera, R. Improvement of biomethane potential of sewage sludge anaerobic co-digestion by addition of “sherry-wine” distillery wastewater. J. Clean. Prod. 2020, 251, 119667. [Google Scholar] [CrossRef]

- Ansari, F.A.; Singh, D.P.; Khan, A.H.; Kisku, G.C.; Ashquin, M.; Ahmad; Yunus, G.M.; Rahman, Q. Physico-chemical characteristics of spentwash of distillery industry. Pollut. Res. 2008, 27, 125–127. [Google Scholar]

- Nagao, N.; Tajima, N.; Kawai, M.; Niwa, C.; Kurosawa, N.; Matsuyama, T.; Yusoff, F.M.; Toda, T. Maximum organic loading rate for the single-stage wet anaerobicdigestion of food waste. Bioresour. Technol. 2012, 118, 210–218. [Google Scholar] [CrossRef]

- Di Maria, F.; Sordi, A.; Cirulli, G.; Micale, C. Amount of energy recoverable from anexisting sludge digester with the co-digestion with fruit and vegetable waste at reduced retention time. Appl. Energ. 2015, 150, 9–14. [Google Scholar] [CrossRef]

- Dareioti, M.A.; Kornaros, M. Anaerobic mesophilic co-digestion of ensiled sorghum, cheese whey and liquid cow manure in a two-stage CSTR system: Effect of hydraulic retention time. Bioresour. Technol. 2015, 175, 553–556. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; He, Q.; Ma, Y.; Wang, X.; Peng, X. Dynamics of microbial community in a mesophilic anaerobic digester treating food waste: Relationship between community structure and processs tability. Bioresour. Technol. 2015, 189, 113–120. [Google Scholar] [CrossRef] [PubMed]

- Madsen, M.; Holm-Nielsen, J.B.; Esbensen, K.H. Monitoring of anaerobic digestion processes: A review perspective. Renew. Sustain. Energy Rev. 2011, 15, 3141–3155. [Google Scholar] [CrossRef] [Green Version]

- Khakbaz, A.; De Nobili, M.; Mainardis, M.; Contin, M.; Aneggi, E.; Mattiussi, M.; Cabras, I.; Busut, M.; Goi, D. Monitoring of heavy metals, EOX and LAS in sewage sludge for agricultural use: A case study. Detritus 2020, 12, 160–168. [Google Scholar] [CrossRef]

- Grosser, A. Determination of methane potential of mixtures composed of sewage sludge, organic fraction of municipal waste and grease trap sludge using biochemical methane potential assays. A comparison of BMP tests and semi-continuous trial results. Energy 2018, 143, 488–499. [Google Scholar] [CrossRef]

- Szaja, A.; Montusiewicz, A. Enhancing the co-digestion efficiency of sewage sludge and cheese whey using brewery spent grain as an additional substrate. Bioresour. Technol. 2019, 291, 1–9. [Google Scholar] [CrossRef]

| Parameter | Unit | SS | OFMSW | DW |

|---|---|---|---|---|

| Average Value ± Standard Deviation | ||||

| COD | mg L−1 | 43,528 ± | 33,745 ± 1709 | 72,870 ± 470 |

| sCOD | mg L−1 | 2083 | 9672 ± 1812 | 38,886 ± 175 |

| VFA | mg L−1 | 1486 ± | 6695 ± 1200 | 1449 ± 261 |

| pH | 6.05 ± | 6.7 ± 0.5 | 3.45 ± 0.2 | |

| ALK | mg L−1 | 840 ± | 3175 ± 85 | - |

| TS | g kg−1 | 37.3 ± | 33.8 ± 2.3 | 50.4 ± 4.1 |

| VS | g kg−1 | 28 ± | 22.2 ± 1.9 | 46.3 ± 3.7 |

| Nog | mg L−1 | 864 ± | 1392.7 ± 53 | 2275 ± 78 |

| N-NH4+ | mg L−1 | 68.9 ± | 305 ± 5.2 | 7.75 ± 3.5 |

| P-PO43− | mg L−1 | 112.8 ± | 21.1 ± 1.9 | 316.5 ± 33 |

| Run | Feedstock Composition | Component Volume | Volumetric Ratio | HRT | OLR | |||

|---|---|---|---|---|---|---|---|---|

| SS | OFMSW | DW | SS:OFMSW:DW | Avg *. | Upp./low. 95% Mean ** | |||

| L | L | L | d | kg vs. m−3d−1 | ||||

| Experiment 1 | ||||||||

| R 1.1 | SS (control) | 2.0 | − | 100:0:0 | 20 | 1.37 | 1.23/1.51 | |

| R 1.2 | SS + OFMSW | 1.5 | 0.5 | − | 75:25:0 | 1.17 | 1.07/1.27 | |

| R 1.3 | SS (control) | 2.0 | − | 100:0:0 | 1.37 | 1.3/1.44 | ||

| R 1.4 | SS + OFMSW | 1.4 | 0.6 | − | 70:30:0 | 1.08 | 1.03/1.13 | |

| Experiment 2 | ||||||||

| R 2.1 | SS (control) | 2.0 | − | 100:0:0 | 20 | 1.43 | 1.42/1.44 | |

| R 2.2 | SS + DW | 2.0 | − | 0.2 | 91:0:9 | 18 | 1.78 | 1.75/1.81 |

| R 2.3 | SS + DW | 2.0 | − | 0.5 | 80:0:20 | 16 | 2.23 | 2.18/2.28 |

| Experiment 3 | ||||||||

| R 3.1 | SS (control) | 2.0 | − | 100:0:0 | 20 | 1.44 | 1.36/1,52 | |

| R 3.2 | SS + OFMSW + DW | 1.5 | 0.5 | 0.2 | 68:23:9 | 18 | 1.58 | 1.52/1.64 |

| R 3.3 | SS (control) | 2.0 | − | 100:0:0 | 20 | 1.42 | 1.31/1.53 | |

| R 3.4 | SS + OFMSW+ DW | 1.5 | 0.5 | 0.5 | 60:20:20 | 16 | 1.79 | 1.68/1.9 |

| Parameter | Unit | R 1.1 | R 1.2 | R 1.3 | R 1.4 | R 2.1 | R 2.2 | R 2.3 | R 3.1 | R 3.2 | R 3.3 | R 3.4 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| VS | g kg−1 | 27.4 | 23.3 | 27.5 | 21.5 | 28.5 | 32.3 | 35.7 | 28.7 | 28.8 | 28.4 | 28.7 |

| Feedstock density | kg m–3 | 976 | 996.6 | 977 | 993.6 | 1001.5 | 995.9 | 993.4 | 989.8 | 985.1 | 991.4 | 983.4 |

| LVS | kg d−1 | 3342.8 | 2902.6 | 3358.4 | 2670.3 | 3567.8 | 4423.0 | 5319.7 | 3550.9 | 3901 | 3519.5 | 4233.5 |

| Ym * | m3CH4 kg−1 VSadd | 0.23 ± 0.03 | 0.29 ± 0.087 | 0.22 ± 0.04 | 0.26 ± 0.061 | 0.19 ± 0.030 | 0.2 ± 0.018 | 0.2 ± 0.031 | 0.17 ± 0.024 | 0.23 ± 0.032 | 0.15 ± 0.018 | 0.2 ± 0.031 |

| Daily methane production | m3 CH4 d−1 | 768.8 | 841.8 | 738.8 | 694.3 | 677.9 | 884.6 | 1063.9 | 603.7 | 897.2 | 527.9 | 846.7 |

| Tfeed | °C | 8 | 8 | 8 | 8 | 8 | 10 | 13 | 8 | 10 | 8 | 13 |

| Vos | m3 d−1 | 125 | 125 | 125 | 125 | 125 | 137.5 | 150 | 125 | 138.5 | 125 | 150 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szaja, A.; Montusiewicz, A.; Lebiocka, M. The Energetic Aspect of Organic Wastes Addition on Sewage Sludge Anaerobic Digestion: A Laboratory Investigation. Energies 2021, 14, 6113. https://doi.org/10.3390/en14196113

Szaja A, Montusiewicz A, Lebiocka M. The Energetic Aspect of Organic Wastes Addition on Sewage Sludge Anaerobic Digestion: A Laboratory Investigation. Energies. 2021; 14(19):6113. https://doi.org/10.3390/en14196113

Chicago/Turabian StyleSzaja, Aleksandra, Agnieszka Montusiewicz, and Magdalena Lebiocka. 2021. "The Energetic Aspect of Organic Wastes Addition on Sewage Sludge Anaerobic Digestion: A Laboratory Investigation" Energies 14, no. 19: 6113. https://doi.org/10.3390/en14196113

APA StyleSzaja, A., Montusiewicz, A., & Lebiocka, M. (2021). The Energetic Aspect of Organic Wastes Addition on Sewage Sludge Anaerobic Digestion: A Laboratory Investigation. Energies, 14(19), 6113. https://doi.org/10.3390/en14196113