Effects of Pro-Ecological Investments on an Example of the Heating Industry—Case Study

Abstract

:1. Introduction

- What pro-ecological investments have been implemented by MEC Koszalin between 2016 and 2020?

- What was the impact of these investments on the emission of harmful substances into the atmosphere by the analyzed organization?

- Did the implementation of new technological solutions also result in positive economic effects?

2. Literature Review

- Building pro-ecological awareness;

- Reducing exhaust emissions (greenhouse gases);

- The effective use of alternative methods of heat extraction.

3. Materials and Methods

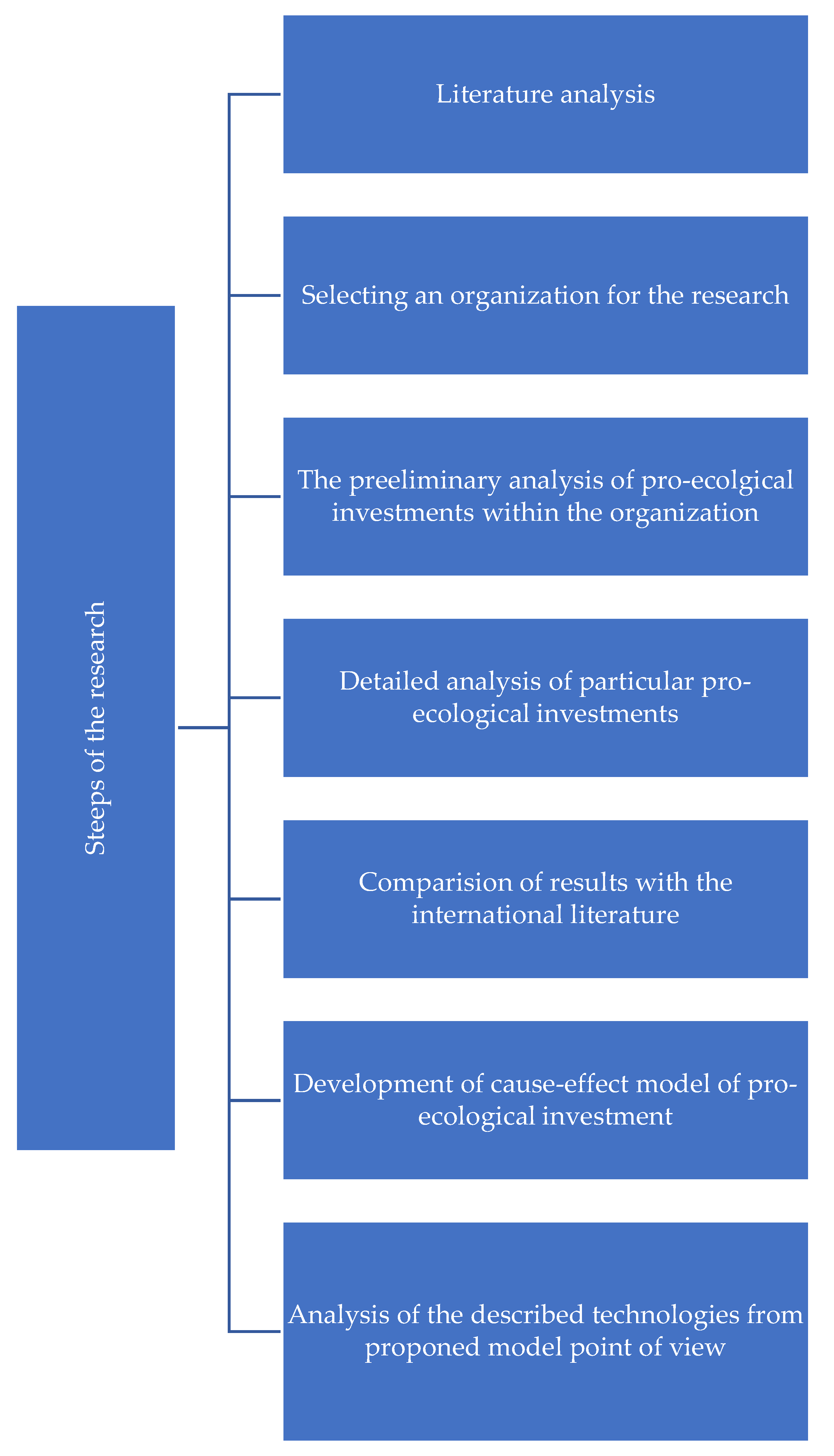

3.1. The Research Conception and Research Plan

3.2. Information about Analyzed Organization

4. Results

4.1. Basic Description of Pro-Ecological Investments in MEC Koszalin

4.2. First Pro-Ecological Investment—Modernization of Boiler WR 25 No. 6

- Development of project documentation for the planned boiler modernization scope.

- Boiler modernization in the scope of: replacement of the whole boiler piping with the application of sheet piling screening of the combustion chamber in the first line, installation of two convective banks in the second line, and an economizer in the third line, with the application of a solution reducing outlet loss (reduction in flue gas temperature); dismantling of the existing mechanical grate and installation of a belt grate with reversible carriage type RTP 2570; the speed of the grate feed is regulated by the rotational speed of the drive motor using a frequency converter; modernization of blowing air and secondary air installation, together with the replacement of blowing air box and fans, as well as application of control valves, separately, in each of the seven grate zones; primary air fan type WWOax63 +K, secondary air fan type WP25/0.75, and fans will be equipped with frequency converters with manual and automatic air volume control; supply and installation of a mechanical system for cleaning the convective bank with the use of electromechanical beaters type OP–2; building of a refractory of the front and back parts of the boiler, together with an ignition vault made of wedge-shaped pieces of andalusite type material; a refractory of the back part of the boiler made of chamotte mortars and perlite; execution of thermal insulation and armoring of the boiler body from steel sheets; renovation of ash and slag hoppers with lining made of chamotte bricks; replacement of the coal hopper equipped with an arc gate valve and automatic and manual control stratifier; replacement of stop valves and boiler protection fittings; installation of platforms for service personnel and connections to passageways to other boilers; testing, pressure tests, and acceptance of pressure part by UDT.

- Execution of electrical works and control and measurement instruments and automation: preparation of design documentation for electrical and control and measurement instruments and automation branch; assembly of a new RK switchboard for boiler WR 25 No. 6; assembling of power supply systems for flue gas exhaust fan, blowing air, and secondary air, as well as grate drive, slag trap, and water heater pump behind the boiler; assembly of the systems for fluent rotation regulation on the frequency converters of the flue gas exhaust fan, air blast, and secondary air fan, as well as grate drive; installation of basic and emergency lighting for the boiler; carrying out tests and checking measurements of all machines, devices, and measurement lines included in the modernization process.

4.3. Second Pro-Ecological Investment—Modernization of Boiler WR 25 No. 5

4.4. Third Pro-Ecological Investment—The Construction of a Video Control System of Waste Storage

4.5. Forth Pro-Ecological Investment—Installation of a New Flue Gas Cleaning System

4.6. Fifth Pro-Ecological Investment—Modernization of Boiler WR 25 No. 7

- Disassembly: disassembly of the existing boiler flue gas dedusting system together with the flue gas exhaust fans; disassembly of the existing installation for transportation of smoke floor dusts of the boiler (tubular chain conveyor fulmar) and dust sprinkler foka; disassembly of the boiler fuel hopper, grate deck, blower air system, and parts of the boiler elements, systems, and equipment; disassembly of the boiler electrical system.

- Assembly work: rebuilding of boiler WR 25 No. 7 from coal fuel to gas fuel; construction of a gas connection from the gas reduction and measurement station to the boiler house building; execution of an internal gas installation from the gas connection’s entrance to the boiler house to the boiler’s gas burners, according to a description of the subject of the contract and the elaborated project documentation; execution of an independent system for flue gas discharge from the boiler together with construction of a new chimney; execution of control and measurement instruments and automation, power supply, control, and visualization installations necessary for proper and failure-free boiler operation; execution of construction works in the FUB boiler house facility in the scope of fire protection of the facility connected with the adaptation of the boiler house facility to the fire protection requirements; execution of fire protection monitoring installation in the FUB boiler house facility related to the adaptation of the boiler house facility to fire safety requirements.

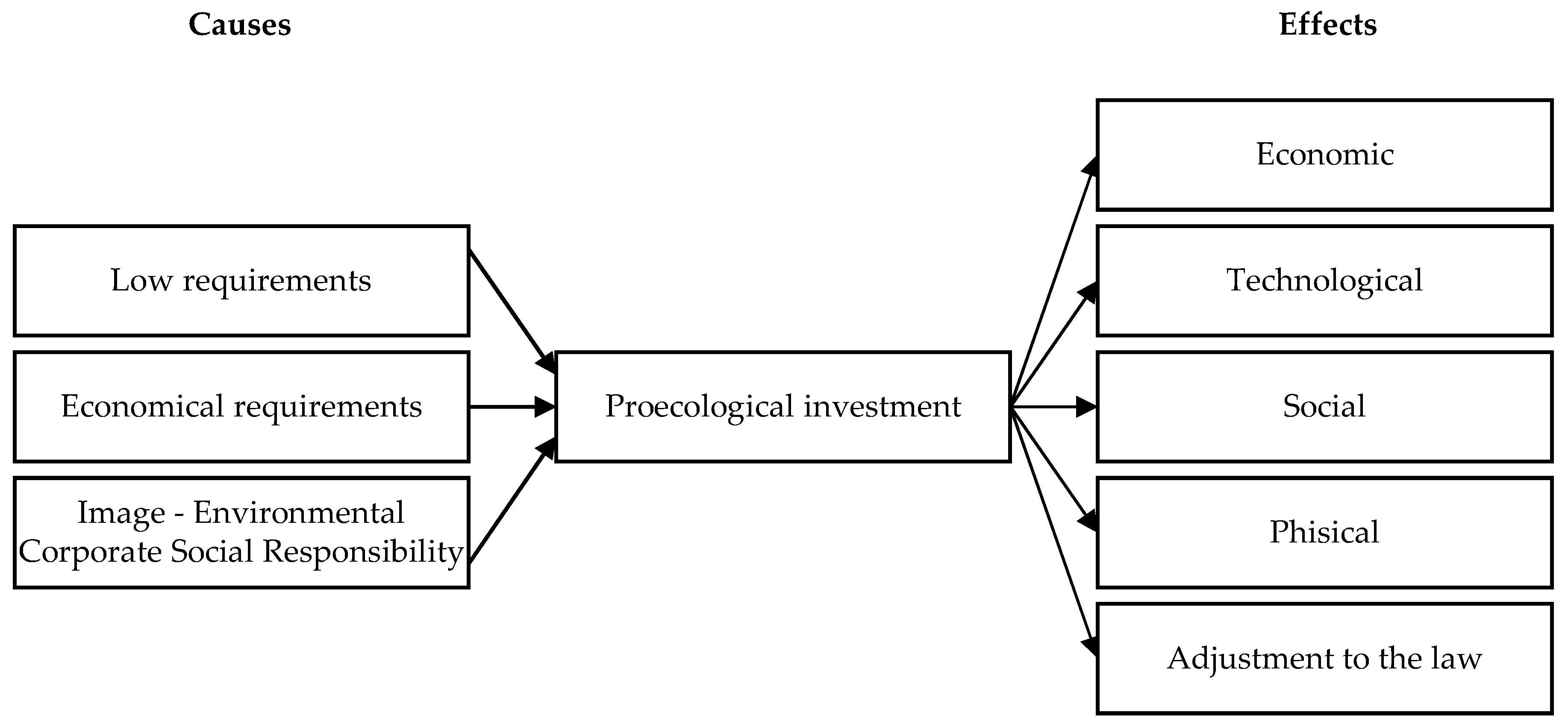

5. Discussion

- low requirements;

- economical requirements;

- image requirements—implementation of environmental corporate social responsibility.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Redukcja Emisji Gazów Cieplarnianych: Cele I Działania unii Europejskiej, Parlament Europejski. Available online: https://www.europarl.europa.eu/pdfs/news/expert/2018/3/story/20180305STO99003/20180305STO99003_pl.pdf (accessed on 22 April 2021).

- Bothner, F. Personal Carbon Trading—Lost in the Policy Primeval Soup? Sustainability 2021, 13, 4592. [Google Scholar] [CrossRef]

- Olivier, J.G.J.; Peters, J.A.H.W. Trends in Global CO2 and Total Greenhouse Gas. In Emissions: 2019 Report, 2020; PBL Netherlands Environmental Assessment Agency: The Hague, The Netherlands, 2020. [Google Scholar]

- Höhne, N.; Elzen, M.D.; Rogelj, J.; Metz, B.; Fransen, T.; Kuramochi, T.; Olhoff, A.; Alcamo, J.; Winkler, H.; Fu, S.; et al. Emissions: World has four times the work or one-third of the time. Nat. Cell Biol. 2020, 579, 25–28. [Google Scholar] [CrossRef] [Green Version]

- Thisted, E.V.; Thisted, R.V. The diffusion of carbon taxes and emission trading schemes: The emerging norm of carbon pricing. Environ. Politics 2019, 29, 804–824. [Google Scholar] [CrossRef]

- Cramton, P.C.; Kerr, S. Tradeable carbon permit auctions: How and why to auction not grandfather. Energy Policy 2002, 30, 333–345. [Google Scholar] [CrossRef]

- Ramseur, J.L.; Parker, L. Carbon Tax and Greenhouse Gas Control: Options and Considerations for Congress. In Carbon Tax and Cap-and-Trade Tools: Market-Based Approaches for Controlling Greenhouse Gases; Burney, N.E., Ed.; Nova Science Publishers: New York, NY, USA, 2010; pp. 1–62. [Google Scholar]

- Parag, Y.; Strickland, D. Personal Carbon Trading: A Radical Policy Option for Reducing Emissions from the Domestic Sector. Environ. Sci. Policy Sustain. Dev. 2010, 53, 29–37. [Google Scholar] [CrossRef]

- Mandaroux, R.; Dong, C.; Li, G. A European Emissions Trading System Powered by Distributed Ledger Technology: An Evaluation Framework. Sustainability 2021, 13, 2106. [Google Scholar] [CrossRef]

- Kannengießer, N.; Lins, S.; Dehling, T.; Sunyaev, A. Trade-offs between Distributed Ledger Technology Characteristics. ACM Comput. Surv. 2020, 53, 1–37. [Google Scholar] [CrossRef]

- Ciesielska-Maciągowska, D.; Klimczak, D.; Skrzek-Lubasińska, M. Central and Eastern European CO2 Market—Challenges of Emissions Trading for Energy Companies. Energies 2021, 14, 1051. [Google Scholar] [CrossRef]

- Christiansen, A.; Arvanitakis, A.; Tangen, K.; Hasselknippe, H. Price determinants in the EU emissions trading scheme. Clim. Policy 2019, 5, 15–30. [Google Scholar] [CrossRef]

- Zaporowski, B. Technologie wytwarzania energii elektrycznej dla polskiej elektroenergetyki. Energy Policy J. 2015, 18, 29–44. [Google Scholar]

- Zaporowski, B. Nowoczesne technologie skojarzonego wytwarzania energii elektrycznej i ciepła. Energy Policy J. 2017, 20, 41–54. [Google Scholar]

- Hu, S.; Wang, X. The origin of proactive environmental corporate social responsibility (ECSR) of large irms: Institutional embeddedness-driven, family involvement-promoted, or resource-dependent? Sustainability 2021, 13, 1197. [Google Scholar] [CrossRef]

- Olkiewicz, M.; Bober, B. Zarządzanie energią determinantą ochrony środowiska. Sci. Pap. Sil. Univ. Technol. 2017, 100, 365–382. [Google Scholar]

- Forcadell, F.J.; Úbeda, F.; Aracil, E. Effects of environmental corporate social responsibility on innovativeness of spanish industrial SMEs. Technol. Forecast. Soc. Chang. 2021, 162, 120355. [Google Scholar] [CrossRef]

- Kong, X.; Pan, Y.; Sun, H.; Taghizadeh-Hesary, F. Can Environmental Corporate Social Responsibility Reduce Firms’ Idiosyncratic Risk? Evidence from China. Front. Environ. Sci. 2020, 8, 608115. [Google Scholar] [CrossRef]

- Chang, T.-W.; Yeh, Y.-L.; Li, H.-X. How to shape an organization’s sustainable green management performance: The mediation effect of environmental corporate social responsibility, 2020. Sustainability 2020, 12, 9198. [Google Scholar] [CrossRef]

- Wang, S.; Wei, Z.; Song, X.; Na, S.; Ye, J. When does environmental corporate social responsibility promote managerial ties in China? The moderating role of industrial power and market hierarchy. Asia Pac. Bus. Rev. 2020, 26, 642–662. [Google Scholar] [CrossRef]

- Wyszomirski, A.; Olkiewicz, M. Environmental corporate social responsibility as a tool for creating the future of environmental protection. Rocz. Ochr. Srodowiska 2020, 22, 1145–1161. [Google Scholar]

- Xu, J.; Wei, J.; Lu, L. Strategic stakeholder management, environmental corporate social responsibility engagement, and financial performance of stigmatized firms derived from Chinese special environmental policy. Bus. Strategy Environ. 2019, 28, 1027–1044. [Google Scholar] [CrossRef]

- Hąbek, P.; Wolniak, R. Assessing the quality of corporate social responsibility reports: The case of reporting practices in selected European Union member states. Qual. Quant. 2016, 50, 339–420. [Google Scholar] [CrossRef] [Green Version]

- Ponomarenko, T.V.; Wolniak, R.; Marinina, O.A. Corporate Social responsibility in coal industry (Practices of russian and european companies). J. Min. Inst. 2016, 222, 882–891. [Google Scholar]

- Wolniak, R. The corporate social responsibility practices in mining sector in Spain and in Poland–similarities and differences, Zeszyty Naukowe Politechniki Śląskiej. Seria Organizacji i Zarządzanie 2017, 111, 111–120. [Google Scholar]

- Hąbek, P.; Wolniak, R. Factors influencing the development of CSR reporting practices: Experts’ versus preparers’ points of view. Engineering Economy 2016, 26, 2016. [Google Scholar] [CrossRef] [Green Version]

- Wei, Z.; Song, X.; Makhdoom, Z.H.; Xie, P. Paradox strategic cognition and ECSR in China: A three-tripod perspective. Asia Pac. Bus. Rev. 2019, 25, 392–412. [Google Scholar] [CrossRef]

- Rela, I.Z.; Awang, A.H.; Ramli, Z.; Md Sum, S.; Meisanti, M. Effects of environmental corporate social responsibility on environmental well-being perception and the mediation role of community resilience. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 2176–2187. [Google Scholar] [CrossRef]

- Pacana, A.; Andrzej Gazda, A.; Bednárová, L. The impact of quality information on innovatory environment of the public administration. Int. J. Interdiscip. Theory Pract. ITPB 2014, 4, 25–26. [Google Scholar]

- Pacana, A.; Ulewicz, R. Analysis of causes and effects of implementation of the quality management system complaint with ISO 9001. Pol. J. Manag. Stud. 2020, 21, 283–296. [Google Scholar]

- Saniuk, S.; Grabowska, S.; Gajdzik, B. Social Expectations and Market Changes in the Context of Developing the Industry 4.0 Concept. Sustainability 2020, 12, 1362. [Google Scholar] [CrossRef] [Green Version]

- Heating Device Market in Poland in 2019; SPIGU, Association of Heating Device Manufacturers and Importers, Warsaw. Available online: https://instalacje.com/media/ai1ibc1x/heating-device-market-in-poland-in-2019.pdf (accessed on 24 August 2021).

- Rosicki, R. Poland’s energy policy: Main problems and forecast. Cent. Eur. Political Stud. 2017, 2, 59–87. [Google Scholar]

- Tomaszewski, K. The Polish road to the new European Green Deal–Challenges and threats to the national energy policy. Energy Policy J. 2020, 2, 5–18. [Google Scholar] [CrossRef]

- Hasterok, D.; Castro, R.; Landrat, M.; Pikoń, K.; Doepfert, M.; Morais, H. Polish Energy Transition 2040: Energy Mix Optimization Using Grey Wolf Optimizer. Energies 2021, 14, 501. [Google Scholar] [CrossRef]

- Kochanek, E. The Energy Transition in the Visegrad Group Countries. Energies 2021, 14, 2212. [Google Scholar] [CrossRef]

- Sobczyk, W.; Sobczyk, E.J. Varying the Energy Mix in the EU-28 and in Poland as a Step towards Sustainable Development. Energies 2021, 14, 1502. [Google Scholar] [CrossRef]

- Wójcik-Jurkiewicz, M.; Czarnecka, M.; Kinelski, G.; Sadowska, B.; Bilińska-Reformat, K. Determinants of Decarbonisation in the Transformation of the Energy Sector: The Case of Poland. Energies 2021, 14, 1217. [Google Scholar] [CrossRef]

- Pakulska, T. Green Energy in Central and Eastern European (CEE) Countries: New Challenges on the Path to Sustainable Development. Energies 2021, 14, 884. [Google Scholar] [CrossRef]

- Zalega, T. Housing conditions and the use of alternative energy sources in households of senior citizens in Poland. J. Econ. Manag. 2017, 29, 139–160. [Google Scholar] [CrossRef]

- Gajdzik, B.; Wolniak, R. Influence of the COVID-19 Crisis on Steel Production in Poland Compared to the Financial Crisis of 2009 and to Boom Periods in the Market. Resources 2021, 10, 4. [Google Scholar] [CrossRef]

- Drozd, R.; Wolniak, R. Metrisable assessment of the course of stream-systemic processes in vector form in industry 4.0. Qual. Quant. 2021, 1–16. [Google Scholar] [CrossRef]

- Wolniak, R.; Saniuk, S.; Grabowska, S.; Gajdzik, B. Identification of energy efficiency trends in the context of the development of industry 4.0 using the Polish steel sector as an example. Energies 2020, 13, 2867. [Google Scholar] [CrossRef]

- Amosov, N.; Andrushin, A.; Arakelyan, E.; Kosoy, A. Industry 4.0 and basic principles of a new architecture for control of power plants processes. In Proceedings of the SHS Web of Conferences, St. Petersburg, Russia, 5 June 2018; p. 8. [Google Scholar]

- Saqib, S.; Shuang, C.; Hongnian, Y.; Yun, L. Management Approaches for Industry 4.0 A human resource management perspective. In Proceedings of the 2016 IEEE Congress on Evolutionary Computation (CEC), IEEE, Vancouver, BC, Canada, 24–29 July 2016; pp. 5308–5316. Available online: https://ieeexplore-1ieee-1org-1gui8jpmm029a.han.polsl.pl/stamp/stamp.jsp?tp=&arnumber=7748365 (accessed on 8 January 2021).

- Sivathanu, B.; Pillai, R. Smart HR 4.0–how industry 4.0 is disrupting HR. Hum. Resour. Manag. Int. Dig. 2018, 26, 7–11. [Google Scholar] [CrossRef]

- Di Nardo, M. Developing a Conceptual Framework Model of Industry 4.0 for Industrial Management. Ind. Eng. Manag. Syst. 2020, 19, 551–560. [Google Scholar] [CrossRef]

- Jonek-Kowalska, I. Consolidation as a risk management method in the lifecycle of a mining company: A novel methodological approach and evidence from the coal industry in Poland. Resour. Policy 2019, 60, 169–177. [Google Scholar] [CrossRef]

- Hahn, H.; Meyer-Nieberg, S.; Pickl, S. Electric load forecasting methods: Tools for decision making. Eur. J. Oper. Res. 2009, 199, 902–907. [Google Scholar] [CrossRef]

- FS-UNEP/BNEF, Global Trends in Renewable Energy Investment, Bloomberg NEF. 2020. Available online: https://www.fs-unep-centre.org/wp-content/uploads/2020/06/GTR_2020.pdf (accessed on 25 April 2021).

- Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.L_.2018.328.01.0082.01.ENG (accessed on 25 April 2021).

- Butnaru, G.; Haller, A.-P.; Clipa, R.; Ștefănică, M.; Ifrim, M. The Nexus between Convergence of Conventional and Renewable Energy Consumption in the Present European Union States. Explorative Study on Parametric and Semi-Parametric Methods. Energies 2020, 13, 5272. [Google Scholar] [CrossRef]

- Badora, A.; Kud, K.; Woźniak, M. Nuclear Energy, Perception and Ecological Attitudes. Energies 2021, 14, 4322. [Google Scholar] [CrossRef]

- Legal Sources on Renewable Energy. Available online: http://www.res-legal.eu/ (accessed on 7 June 2021).

- Brodny, J.; Tutak, M.; Bindzár, P. Assessing the Level of Renewable Energy Development in the European Union Member States: A 10-Year Perspective. Energies 2021, 14, 3765. [Google Scholar] [CrossRef]

- Energy, Transport, Sustainability–10 Predictions for 2021. Available online: https://about.bnef.com/blog/energy-transport-sustainability-10-predictions-for-2021/ (accessed on 25 April 2021).

- Zahoor, A.; Ali, S.; Saud, S.; Shahzad, S.J.H. Transport CO2 emissions, drivers, and mitigation: An empirical investigation in India. Air Qual. Atmos. Health 2020, 13, 1367–1374. [Google Scholar]

- Wimbadi, R.W.; Djalante, R.; Mori, A. Urban experiments with public transport for low carbon mobility transitions in cities: A systematic literature review (1990–2020). Sustain. Cities Soc. 2021, 72, 103023. [Google Scholar] [CrossRef]

- LGfS, 2018, Sustainable City, Local Governments for Sustainability. Available online: http://www.iclei.org/activities/agendas/sustainable-city.html (accessed on 25 April 2021).

- Rodríguez-García, M.; Guijarro-García, M.; Carrilero-Castillo, A. An Overview of Ecopreneurship, Eco-Innovation, and the Ecological Sector. Sustainability 2019, 11, 2909. [Google Scholar] [CrossRef] [Green Version]

- Chandramowli, S.N.; Felder, F.A. Impact of climate change on electricity systems and markets–A review of models and forecasts. Sustain. Energy Technol. Assess. 2014, 5, 62–74. [Google Scholar] [CrossRef]

- Fong, H.G. The World of Risk Management. J. Invest. Manag. 2005, 3, 6–28. [Google Scholar]

- Paige, F.; Agee, P.; Jazizadeh, F. flEECe, an energy use and occupant behavior dataset for net-zero energy affordable senior residential buildings. Sci. Data 2019, 6, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Fischer, C. Feedback on household electricity consumption: A tool for saving energy? Energy Effic. 2008, 1, 79–104. [Google Scholar] [CrossRef]

- Nair, G.; Gustavsson, L.; Mahapatra, K. Factorsinfuencingenergyefciencyinvestments in existing Swedish residential buildings. Energy Policy 2010, 38, 2956–2963. [Google Scholar] [CrossRef]

- Zografakis, N.; Menegaki, A.N.; Tsagarakis, K.P. Efectiveeducation for energy efficiency. Energy Policy 2008, 36, 3226–3232. [Google Scholar] [CrossRef]

- Farrell, K.N.; Beer, D.L. Producing the ecological economy: A study in developing fiduciary principles supporting the application of flow-fund consistent investment criteria for sovereign wealth funds. Ecol. Econ. 2019, 165, 106391. [Google Scholar] [CrossRef]

- Berger, S.K. William Kapp’s theory of social costs and environmental policy: Towards political ecological economics. Ecol. Econ. 2008, 67, 244–252. [Google Scholar] [CrossRef]

- Directive 2012/27/eu of the European Parliament and of the Council of 25 October 2012 on Energy Efficiency. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32012L0027, (accessed on 22 April 2021).

- Nik, N.R.; Rashid, A.; Khalid, A.; Rahman, N.I.A. Environmental Corporate Social Responsibility (ECSR): Exploring its Influence on Customer Loyalty. Procedia Econ. Financ. 2015, 31, 705–713. [Google Scholar]

- Sompolska-Rzechuła, A.; Kurdy´s-Kujawska, A. Towards Understanding Interactions between Sustainable Development Goals: The Role of Climate-Well-Being Linkages. Experiences of EU Countries. Energies 2021, 14, 2025. [Google Scholar] [CrossRef]

- Xiong, X.; Xu, Z.; Yuan, Y. Grey correlation-oriented random forest and particle swarm optimization algorithm for power load forecasting. J. Appl. Sci. Eng. 2021, 25, 19–30. [Google Scholar]

- Bye, B.; Fæhn, T.; Rosnes, O. Residental Energy Efficiency and European Carbon Policies A CGE-Analysis with Bottom-Up Information on Energy Efficiency Technologies; Statistics Norway: Oslo, Norway, 2015. [Google Scholar]

- Dryzek, J.S.; Downes, D.; Hunold, C.; Scholsberg, D.; Hernes, H.K. Ecologicalmodernization, risk society, and the greenstate. In The EcologicalModernization Reader: Environmental Reform in Theory and Practice; Mol, A.P.J., das Spaargaren, G., Eds.; Routledge: London, UK, 2009; pp. 226–253. [Google Scholar]

- Banerjee, S.B. Corporate environmental strategies and actions. Manag. Decis. 2001, 39, 633. [Google Scholar] [CrossRef]

- Wolniak, R.; Gajdzik, B. Digitalisation and innovation in the steel industry in Poland—Selected tools of ICT in an analysis of statistical data and a case study. Energies 2021, 14, 3034. [Google Scholar]

- Davis, L.W. Evaluating the slow adoption of energy efficient investments: Are renters less likely to have energy efficient appliances? In The Design and Implementation of US Climate Policy; University of Chicago Press: Chicago, IL, USA, 2011. [Google Scholar]

- Olkiewicz, M. Quality improvement through foresight methodology as a direction to increase the effectiveness of an organization. Contemp. Econ. 2018, 12, 69–80. [Google Scholar] [CrossRef]

- Hampton, J.J. Fundamentals of Enterprise Risk Management: How Top Companies Assess Risk, Manage Exposures, and Seize Opportunities; American Management Association: New York, NY, USA, 2009. [Google Scholar]

- Pichler, P.P.; Zwickel, T.; Chavez, A.; Kretschmer, T.; Seddon, J.; Weisz, H. Reducing Urban Greenhouse Gas Footprints. Sci. Rep. 2017, 7, 14659. [Google Scholar] [CrossRef] [Green Version]

- Manzardo, A.; Marson, A.; Zuliani, F.; Bacenetti, J.; Scipioni, A. Combination of product environmental footprint method and eco-design process according to ISO 14006: The case of an Italian vinery. Sci. Total. Environ. 2021, 799, 149507. [Google Scholar] [CrossRef] [PubMed]

- Ceryová, D.; Bullová, T.; Turceková, N.; Adamicková, I.; Moravcíková, D.; Bielik, P. Assessment of the Renewable Energy Sector Performance Using Selected Indicators in European Union Countries. Resources 2020, 9, 102. [Google Scholar] [CrossRef]

- Cetković, J.; Lakić, S.; Živković, A.; Žarković, M.; Vujadinović, R. Economic analysis of measures for GHG emission reduction. Sustainability 2021, 13, 1712. [Google Scholar] [CrossRef]

- Palcic, I.; Prester, J. Impact of Advanced Manufacturing Technologies on Green Innovation. Sustainability 2020, 12, 3499. [Google Scholar] [CrossRef] [Green Version]

- British Standards Institution. PAS 2070: 2013 + A1:2014-Specifcation for the Assessment of Greenhouse Gas Emissions of a City; British Standards Institution: London, UK, 2014. [Google Scholar]

- Olkiewicz, M.; Wolniak, R. Responsible pro-environmental management in an organization: A case study. Rocz. Ochr. Sr. 2020, 22, 763–780. [Google Scholar]

- Olkiewicz, M. Management systems as a guarantee of quality assurance. Scientific Papers of Silesian University of Technology. Organ. Manag. Ser. 2018, 128, 317–332. [Google Scholar]

- Meyer, D.F.; Meyer, N. The relationships between entrepreneurial factors and economic growth and development: The case of selected European countries. Polish J. Manag. Stud. 2020, 21, 268–284. [Google Scholar] [CrossRef]

- Appenzeller, H. Risk Management, 2nd ed.; Durham, N.C., Ed.; Carolina Academic Press: Durham, CA, USA, 2005. [Google Scholar]

- Olkiewicz, M. Quality of life and measurement methods. Manag. Qual. Zarządzanie i Jakość 2020, 2, 14–25. [Google Scholar]

- Klimek, P.; Obersteiner, M.; Turner, S. Systemic trade risk of critical resources. Sci. Adv. 2005, 1, e1500522. [Google Scholar] [CrossRef] [Green Version]

- Duan, H.; Mo, J.; Fan, Y.; Wang, S. Achieving China’s energy and climate policy targets in 2030 under multipleun certainties. Energy Econ. 2018, 70, 45–60. [Google Scholar] [CrossRef]

- Vashakmadze, E.; Kambou, G.; Chen, D.H.C.; Nandwa, B.; Okawa, Y.; Vorisek, D. Regionaldimensions of recentweakness in investment: Drivers, investment needs and policy responses. In World Bank Policy Research Working Paper; Bank, T.W., Ed.; World Bank Group: Washington, DC, USA, 2017; p. 7991. [Google Scholar]

- Pretorius, M. Defining business decline, failure and turnaround: A content analysis. S. Afr. J. Entrep. Small Bus. Manag. 2009, 2, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Johansson, M. Improved energy efficiency within the Swedish steel industry—The importance of energy management andnetworking. Energy Effic. 2015, 8, 713–744. [Google Scholar] [CrossRef] [Green Version]

- ISO 31000:2018. Risk management–Principles and guidelines; International Standard Organization: Geneva, Switzerland.

- Czosnyka, M.; Wnukowska, B.; Karbowa, K. Energy efficiency as a base of the energy economy in a modern industrial plants. In Proceedings of the 2018 Progress in Applied Electrical Engineering (PAEE), IEEE, Koscielisko, Poland, 18–22 June 2018; pp. 1–6. [Google Scholar]

- Bober, B.; Olkiewicz, M.; Wolniak, R. Analiza procesów zarządzania ryzykiem jakości w przemyśle farmaceutycznym. Przemysł Chem. 2017, 96, 1818–1819. [Google Scholar] [CrossRef]

- Pachauri, S. An Energy Analysis of Household Consumption: Changing Patterns of Direct and Indirect Use in India. Springer Sci. Bus. Media 2007. [Google Scholar]

- Huculak, M.; Jarczewski, W.; Dej, M. Economicl aspects of the use of deep geothermal heat in district heatingin Poland. Renew. Sustain. Energy Rev. 2015, 49, 29–40. [Google Scholar] [CrossRef]

- Olkiewicz, M.; Wolniak, R.; Skotnicka-Zasadzień, B. Implementation of ISO 14001 Standard In The European Union Countries. Rocz. Ochr. Sr. 2019, 21, 868–880. [Google Scholar]

- Yang, T.; Chen, H.; Zhang, Y.; Zhang, S.; Feng, F. Towards Low-Carbon Urban Forms: A Comparative Study on Energy Efficiencies of Residential Neighborhoods in Chongming Eco-Island. Energy Procedia 2016, 88, 321–324. [Google Scholar] [CrossRef] [Green Version]

- Magazyn Ciepła Systemowego, 2018. Available online: https://cieplosystemowe.biz/wp-content/uploads/2019/08/MCS_40_wiz.pdf (accessed on 22 April 2021).

- Sowiżdżał, A.B.; Chmielowska, A. Development of the Polish geothermal sector in the light of current possibilities of financial support for a geothermal investment. In Proceedings of the E3S Web of Conferences, Kraków, Poland, 22 February 2019. [Google Scholar]

- The Environmental Implementation Review 2019, Country Report Poland, European Commission, Brussels 2019. Available online: https://ec.europa.eu/environment/eir/pdf/report_pl_en.pdf (accessed on 24 August 2021).

- Zaleski, P.; Chawla, Y. Circular Economy in Poland: Profitability Analysis for Two Methods of Waste Processing in Small Municipalities. Energies 2020, 13, 5166. [Google Scholar] [CrossRef]

- Dzikć, M.; Łasiński, K. Technical and economic aspects of biomass co-firing in coal-fired boilers. Int. J. Appl. Mech. Eng. 2014, 19, 849–855. [Google Scholar] [CrossRef] [Green Version]

- Xu, Y.; Yang, K.; Zhou, J.; Zhao, G. Coal-Biomass Co-Firing Power Generation Technology: Current Status, Challenges and Policy Implications. Sustainability 2020, 12, 3692. [Google Scholar] [CrossRef]

- Lalak, J.; Martyniak, D.; Kasprzycka, A.; Żurek, G.; Moroń, W.; Chmielewska, M.; Wiącek, D.; Tys, J. Comparison of selected parameters of biomass and coal. Int. Agrophysics 2016, 30, 475–482. [Google Scholar] [CrossRef] [Green Version]

- Himbane, P.B.; Ndiaye, L.G.; Napoli, A.; Kobor, D. Physicochemical and mechanical properties of biomass coal briquettes produced by artisanal method. Afr. J. Environ. Sci. Technol. 2018, 12, 480–486. [Google Scholar]

- Wysocki, J. Innovative Green Initiatives in the Manufacturing SME Sector in Poland. Sustainability 2021, 13, 2386. [Google Scholar] [CrossRef]

- Buryn, Z. Hnydiuk-Stefan, Analiza Kosztów Emisji CO2 w Ciepłownictwie, 2015. Available online: http://www.ptzp.org.pl/files/konferencje/kzz/artyk_pdf_2015/T1/t1_0393.pdf (accessed on 22 April 2021).

- Włoch, M.; Brzeziński, P. Warszawski System Ciepłowniczy a Wybrane Systemy Europejskie, Warszawa, 2010. Available online: https://www.cire.pl/pliki/2/war_ciep_a_euro.pdf (accessed on 22 April 2021).

- Lin, J.; Lin, B. How Much CO2 Emissions Can Be Reduced in China’s Heating Industry. Sustainability 2016, 8, 642. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Wang, L.; Tong, L.; Sun, S.; Yue, X.; Yin, S.; Zheng, L. Mode selection of China’s urban heating and its potential for reducing energy consumption and CO2 emission. Energy Policy 2014, 67, 756–764. [Google Scholar] [CrossRef]

- Niu, S.W.; Li, Y.X.; Ding, Y.X.; Qin, J. Energy demand for rural household heating to suitable levels in the Loess Hilly region, Gansu province, China. Gen. Inf. 2010, 35, 2070–2078. [Google Scholar] [CrossRef]

- Chang, K.-C.; Lin, W.-M.; Chung, K.-M. Sustainable development for solar heating systems in Taiwan. Sustainability 2015, 7, 1970–1984. [Google Scholar] [CrossRef] [Green Version]

- Xue, B.; Geng, Y.; Müller, K.; Lu, C.; Ren, W. Understanding the causality between carbon dioxide emission, fossil energy consumption and economic growth in developed countries: An empirical study. Sustainability 2014, 6, 1037–1045. [Google Scholar] [CrossRef] [Green Version]

- Xiang, N.; Xu, F.; Sha, J. Simulation analysis of China’s energy and industrial structure adjustment potential to achieve a low-carbon economy by 2020. Sustainability 2013, 5, 5081–5099. [Google Scholar] [CrossRef] [Green Version]

- Lin, B.; Moubarak, M. Mitigation potential of carbon dioxide emissions in the Chinese textile industry. Appl. Energy 2014, 113, 781–787. [Google Scholar] [CrossRef]

- Lin, B.; Liu, H. CO2 emissions of China’s commercial and residential buildings: Evidence and reduction policy. Build. Environ. 2015, 92, 418–431. [Google Scholar] [CrossRef]

- Hao, H.; Liu, Z.; Zhao, F.; Li, W.; Hang, W.; Lund, H.; Kaiser, M.J. Scenario analysis of energy consumption and greenhouse gas emissions from China’s passenger vehicles. Energy 2015, 91, 151–159. [Google Scholar] [CrossRef]

- Höller, S.; Viebahn, P. Facing the uncertainty of CO2 storage capacity in China by developing different storage scenarios. Energy Policy 2016, 89, 64–73. [Google Scholar] [CrossRef] [Green Version]

- Guenther, E.; Hoppe, H.; Poser, C. Environmental corporate social responsibility of firms in the mining and oil and gas industries: Current status quo of reporting following GRI guidelines. Greener Manag. Int. 2007, 53, 7–25. [Google Scholar]

- Leon, P.; Moon, S.G. Contexts and corporate voluntary environmental behaviors: Examining the EPA’s green lights voluntary program. Organ. Environ. 2007, 20, 480–496. [Google Scholar]

- Farrell, K.N.; Mayumi, K. Time horizons and electricity futures: An application of Nicholas Georgescu-Roegen’s general theory of economic production. Energy 2009, 34, 301–307. [Google Scholar] [CrossRef]

- Jose, A.; Lee, S.M. Environmental reporting of global corporations: A content analysis based on website disclosures. J. Bus. Ethics 2007, 72, 307–321. [Google Scholar] [CrossRef]

- Bansal, P.; Roth, K. Why Companies Go Green: A Model of Ecological Responsiveness. Acad. Manag. J. 2000, 43, 717–736. [Google Scholar]

- Punte, S.; Repinski, P.; Gabrielsson, S. Improving energy efficiency in Asia’s industry. Greener Manag. Int. 2006, 50, 41–51. [Google Scholar] [CrossRef]

- Christmann, P. Multinational companies and the natural environment: Determinants of global environment policy standardization. Acad. Manag. J. 2004, 47, 747–760. [Google Scholar] [CrossRef] [Green Version]

- An EU Strategy on Heating and Cooling, European Commission, Brussels, 2016. Available online: https://ec.europa.eu/energy/sites/ener/files/documents/1_EN_ACT_part1_v14.pdf (accessed on 22 April 2021).

- Peattie, K. Environmental Marketing Management: Meeting the Green Challenge; Pitman Publishing: London, UK, 1995. [Google Scholar]

- Carroll, A.B. The Pyramid of Corporate Social Resposibility: Toward the Moral Management of Organizational Stakeholders. Bus. Horiz. 1991, 34, 39–48. [Google Scholar] [CrossRef]

- Baliński, A. Recycling of waste fly ash formed during combustion of hard coal for use in moulding mixtures manufacture. Pr. Inst. Odlew. 2008, 3, 5–30. [Google Scholar]

- Czajkowska, A.; Bożejewicz, D. Review of recovery methods of waste from industry and power plant service. Energy Mark. 2019, 6, 67–76. [Google Scholar]

- Joseph, A.M.; Snellings, R.; Heede, P.V.; Matthys, S. The Use of Municipal Solid Waste Incineration Ash in Various Building Materials: A Belgian Point of View. Materials 2018, 11, 141. [Google Scholar] [CrossRef] [Green Version]

- Lee, T.; Wang, W.; Shih, P.; Lin, K. Enhancement in early strengths of slag-cement mortars by adjusting basicity of the slag prepared from fly-ash of MSWI. Cem. Concr. Res. 2009, 39, 651–658. [Google Scholar] [CrossRef]

- Wang, K.; Lin, K.; Huang, Z. Hydraulic activity of municipal solid waste incinerator fly-ash-slag-blended eco-cement. Cem. Concr. Res. 2001, 31, 97–103. [Google Scholar] [CrossRef]

- Boccaccini, A.R.; Kopf, M.; Stumpfe, W. Glass-ceramics from filter dusts from waste incinerators. Ceram. Int. 1995, 21, 231–235. [Google Scholar] [CrossRef]

- Czas na Ciepłownictwo, Polski Instytut Ekonomiczny, Policy Paper, 2019. Available online: https://pie.net.pl/wp-content/uploads/2020/02/PIE-Ciep%C5%82ownictwo.pdf (accessed on 22 April 2021).

- Możliwości Inwestycyjne w Energetyce Odnawialnej w Ramach Zgodnych z Europejskim Zielonym Ładem, Instytut Energetyki Odnawialnej, Warszawa 2020. Available online: http://konfederacjalewiatan.pl/aktualnosci/2020/1/_files/2020_09/ieo_final_1_.pdf (accessed on 22 April 2021).

- El Ghorab, H.K.; Shalaby, H.A. Eco and Green cities as new approaches for planning and developing cities in Egypt. Alex. Eng. J. 2016, 55, 495–503. [Google Scholar] [CrossRef]

- Merna, T.M.; Al-Thani, F.F. Corrporate Risk Management; Wiley: New York, NY, USA, 2008. [Google Scholar]

| No. | Year | Investment | Costs without VAT (PLN) | Effects |

|---|---|---|---|---|

| 1 | 2016/2017 | Modernization of the boiler type WR 25 No. 6 with heavy refractory, installed in FUB boiler house at in Koszalin for a boiler with sheet piling technology. | 3,715,400.00 |

|

| 2 | 2018 | Modernization of the boiler type WR 25 No. 5 with heavy refractory, installed in the DPM boiler house in Koszalin into a boiler with sheet piling technology with nominal capacity of 11.63 MW. | 2,900,000.00 |

|

| 3 | 2019 | The construction of a video control system of the waste storage site produced within the activities of the company MEC boiler house FUB in Koszalin. | 104,099.59 |

|

| 4 | 2019/2020 | New flue gas cleaning system. | 13,400,000.00 |

|

| 5 | 2020 | Modernization of the boiler WR 25 no. 7 installed in FUB boiler house to a boiler fired by natural gas GZ 5. | 5,200,000.00 |

|

| Suma | 25,319,500.00 | − | ||

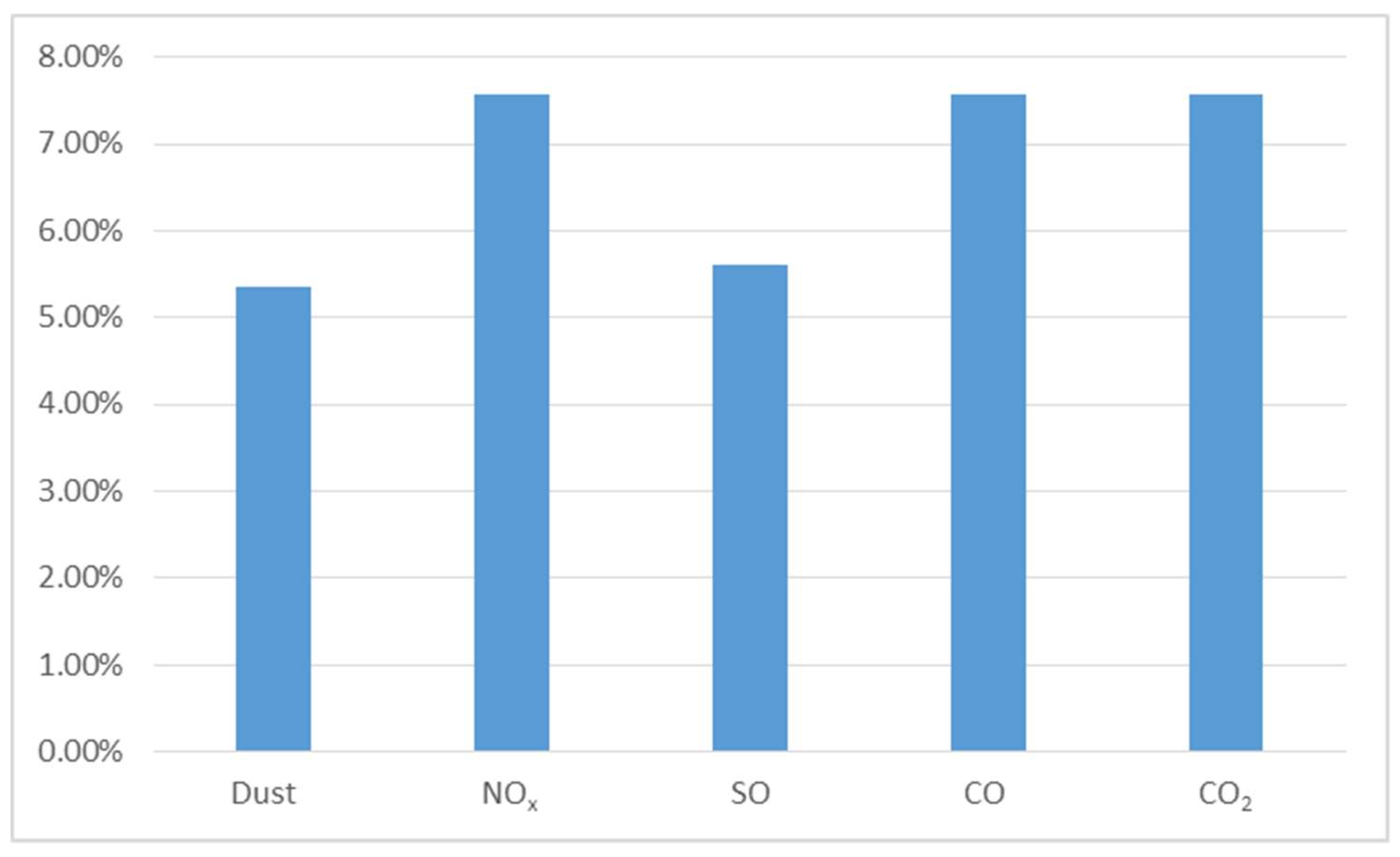

| Type of Pollutants | Dust (Mg) | NOx (Mg) | SO2 (Mg) | CO(Mg) | CO2 (Mg) |

|---|---|---|---|---|---|

| Condition before modernization | 67.370 | 119.768 | 305.408 | 149.710 | 65,872.400 |

| Condition after modernization | 63.754 | 110.684 | 288.276 | 138.355 | 60,876.200 |

| Achieved pollution reduction (Mg/year) | 3.616 | 9.084 | 17.132 | 11.355 | 4996.200 |

| Reduction of pollutants planned in the funding agreement | 1.849 | 3.288 | 8.384 | 4.11 | 1808.4 |

| Achieved pollution reduction in (%) | 5.37% | 7.58% | 5.61% | 7.58% | 7.58% |

| Pro-Ecological Investment | Cause | Effects |

|---|---|---|

| First investment | Economical requirements Image | Economical Technological Social Physical |

| Second investment | Economical requirements Image | Economical Technological Social Physical |

| Third investment | Low | Technological Adjustment to low |

| Fourth investment | Low Economical requirements Image | Economical Technological Social Physical |

| Fifth investment | Economical requirements Image | Economical Technological Social Physical |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olkiewicz, M.; Olkiewicz, A.; Wolniak, R.; Wyszomirski, A. Effects of Pro-Ecological Investments on an Example of the Heating Industry—Case Study. Energies 2021, 14, 5959. https://doi.org/10.3390/en14185959

Olkiewicz M, Olkiewicz A, Wolniak R, Wyszomirski A. Effects of Pro-Ecological Investments on an Example of the Heating Industry—Case Study. Energies. 2021; 14(18):5959. https://doi.org/10.3390/en14185959

Chicago/Turabian StyleOlkiewicz, Marcin, Anna Olkiewicz, Radosław Wolniak, and Adam Wyszomirski. 2021. "Effects of Pro-Ecological Investments on an Example of the Heating Industry—Case Study" Energies 14, no. 18: 5959. https://doi.org/10.3390/en14185959

APA StyleOlkiewicz, M., Olkiewicz, A., Wolniak, R., & Wyszomirski, A. (2021). Effects of Pro-Ecological Investments on an Example of the Heating Industry—Case Study. Energies, 14(18), 5959. https://doi.org/10.3390/en14185959