Abstract

The article presents an analysis of the influence of selected operating environment parameters on the operation of a technological system in a mine and examines the profitability of exploiting a deposit of low quality. A model based on a cyclical transportation system in a surface limestone mine, developed in the Haulsim software, served to evaluate—from an economic perspective—several material transportation scenarios depending on the quality of the deposit. A discrete simulation of machine operation allowed a detailed analysis of the technological, operating and economic parameters for selected solutions. The results may be the basis for a decision to begin or to resign from mineral extraction. The simulation results demonstrate that maintaining the operating environment in good technical condition positively influences machine operating cycle times, the required total time of the transportation task and the operating costs. The analysis was performed for the production period of one full year, allowing for the effective work and technological downtimes. This approach allowed the usefulness of the model to be demonstrated in evaluating not only the effectiveness of individual technological procedures but also its economic aspect, related to a decision on the exploitation of “difficult” deposits.

1. Introduction

In rock raw material mining, the extraction methods and the mining and geological conditions necessitate the use of technological (machine) systems predominantly based on road vehicle transportation with adequately selected loading machines and processing devices. A rational selection of the elements of a technological system employing technological haul trucks and loading machines should be based on a detailed analysis of technical and economic aspects, allow for the deposit conditions, and most importantly reflect the influence of the operating environment on the use of a machine system [1,2].

An analysis of the profitability of deposit extraction and the included evaluation of the effectiveness of the transport system may be viewed in relation to the planned (in the case of the designed mines) or to the incurred (in the case of the already existing mines) expenditures on machine operation (both the use and the ownership), depending on the varied conditions of machine operating environments. This issue is of particular importance in the period of a positive economic situation and constantly growing demand for raw materials in construction. An increase in the price of raw materials allows deposits previously considered low quality to be profitably mined. This issue is a classic problem of natural resource economics and has been researched also for natural resources extracted with the use of mining methods, for example for crude oil [3] and metals [4,5] with the primary aim to identify an optimal production level and extraction cost or to decide on leaving an unmined fragment of the deposit.

A decision to mine new fragments of deposits, e.g., those of low quality, requires an in-depth economic analysis, as it necessitates, prior to such an activity, a reconfiguration of transport routes and a modification of the number of machines involved in the production process, in order to allow the mined material to be transported from new mining faces. An increase in the volume of the transported materials results in lowered unit costs, and thus the extraction of raw materials previously considered unprofitable may prove economical, for example by changing the streams of the mined material within the system (e.g., the limiting of waste transported to the waste heap). This article analyzes the influence of the content of the intermediate product (having a potential for further use) on the efficiency and other operating and economic parameters of the transport system, while placing an emphasis on the correlation with the operating environment, primarily in the context of the energy consumption of a transport system.

The purpose of this research was to offer a reliable simulation model of the actual machine operating conditions and to investigate the influence of selected parameters on the efficiency and cost of transporting intermediate products. The analysis also included the aspect of the reliability of a machine system and its influence on the technological parameters of road transport. The constructed models of actual operating environment and its modifications served to compare variants of the functioning of a machine system in relationship to the operating conditions. Such simulations may inform operational decisions in existing mining plants and aid the design process in the case of their expansion.

Extraction of raw materials is related to numerous technological processes, and therefore the influence of individual factors on these processes and the search of optimal solutions have been the object of interest for a number of authors and have revolved around various aspects of mining operations. The operating effectiveness of a mine is mostly influenced by the transportation costs, which account for 50–60% of the total mining costs [6]. The most frequently analyzed problems are related to the interaction between machines as part of performing a sequence of operations in the technological cycle or of selecting an appropriate type of technical equipment. Trivedi et al. [7] discussed the problem of interaction between machines as a problem typical of operations research, by analyzing the waiting time for the loading/unloading of haul trucks. The arrival and service times for successive machines define in such case a waiting line system, which can be optimized by selecting appropriate machines in order to achieve a measurable economic effect.

Technological systems in mining industry are optimized by implementing various methods based on operations research [8]. The Dijkstra algorithm for defining transportation routes in a mine was used in [9] to demonstrate the influence of selecting roads having particular parameters, e.g., inclination, on the transport cycle times. A waiting line system consisting of machines operated in a technological system of a mine was analyzed by Krause et al. [10], who suggested the application of a model based on a waiting line analysis (Finite Source Model) in designing the size of the machinery fleet in a mine. Differences in the approach to short and long-term modeling have been explored using mixed integer linear goal programming for optimal shovel and truck application in an oil sand deposit case [11].

Transportation processes may be optimized in order to meet instantaneously defined needs of a mining plant [12] or to aid short-term planning of operations. The authors of [13] demonstrated that a combination of discrete simulations of operating mining objects and process optimization models, which allow for, e.g., the limitations due to long-term planning, enables analyses of the influence of any selected factors on, e.g., the global costs, the process efficiency or the output of a mine.

Issues related to the selection of mining machines for the mining plant analyzed in this work were already discussed in [14]. The publication presents a method of multi-criteria decision support allowing for eight criteria divided into the areas of technology, environment and economy. A mixed model proposed by [15] for optimizing machinery selection involves the economic and technological factors and demonstrates the potential for reducing costs and increasing the net present value (NPV) of the project while also reducing greenhouse gas (GHG) emissions.

In the case of mining transportation systems, the problem of energy efficiency is of key importance for evaluating the effectiveness and cost-efficiency of transport. From the perspective of a global optimization of a mining plant, it will relate to the selection of the fleet of machines and their further operation [8,16]. In the case of transport systems using belt conveyors, the issue of energy-efficiency revolves around the application of certain technical solutions, such as belt management based on diagnostic systems [17], energy-efficient idler sets [18], or energy recovery by implementing inverters on conveyors transporting material in a downward direction [19].

The selection of machinery for the transportation system may be also analyzed from the perspective of the quality of the transported material [20]. A search for optimal technological solutions may result in the replacement of machines, a change of the location in the mine or a modification of a technological system. An example of such decisions is the replacement of stationary crushers with a combination of smaller mobile crushers which can be operated more elastically [21].

The failure rate of machines in the technological systems is one of the elements influencing the correct long-term simulation of the operations of the mine analyzed in this article. For one of the copper mines [22], machine failure rate was analyzed with the use of the Monte Carlo simulation, in which failure processes were modeled in order to demonstrate the key factors influencing long-term operational availability of the machines. In turn, preventive maintenance of mining equipment was described by Angeles et al. [23]. Topal et al. drew attention to the high operating costs associated with the use of wheeled transport and pointed out that production planning is very important considering the age of the machines and their availability [24].

Transportation roads were simulated and analyzed in [25], where geotechnical tests served to provide a mine with an optimal solution which allowed for the size of the employed haul trucks.

Saderowa et al. [26] developed simulated transport models, that they compared with analytical solutions and demonstrated the potential of such an approach in analyzing classic transportation systems in an aggregate mine employing haul trucks and loaders. The analysis was performed for various transport distances and operating periods, in dedicated software. Simulation models were also applied in the calculations of railway-based material transportation, and they allowed the authors to confirm the results obtained with the help of classic mathematical calculations [27]. Straka et al. [28] performed a long-term analysis of transport for an operating period of half a year in a mine, together with a description of the principles to be followed when constructing objects and their relationships, as well as when calculating the demand for railway transport. Amin et al. [29] used the Simio software to simulate transport in a limestone mine, searching for an optimal solution to minimize the number of machines. The Monte Carlo simulation was also used in an analysis of a tar sand mine, in which the machinery fleet was modeled on the basis of both the variability of the time for performing technological procedures and the production plan and the transport road network [30].

In conclusion: research into the broadly understood operational effectiveness of mining plants has been a popular area for the implementation of process modeling due to the complex character of the technological processes, variable operating conditions and the number of factors influencing the final economic effect. The authors of this article focus on yet another issue, which involves a complex evaluation of the influence of the production environment on mining operations in a low-quality deposit. Depending on the content of the valuable component, such a deposit necessitates the transportation of different material volumes, and in addition, variable factors significantly influence the profitability of the mining operations.

2. Materials and Methods

The analysis of the mining process and of the operation of the machine system was performed for a limestone deposit owned by a surface mine located in northwest Poland. The deposit has karst interlayers, and thus an average 20% of the mined rock is classified as non-technological material (NTM), which cannot be processed and which is treated as waste in the deposit. This material still needs to be transported to the waste heap, which increases the mining costs.

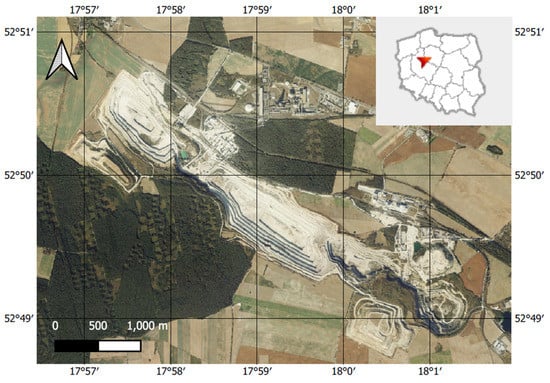

Figure 1 shows the actual view of the Kujawy mining plant. The central part of the figure presents the main excavation of the mine, with the successive transport ramps leading to it. The overburden and the NTM from the production processes is stored in the “Bielawy” waste heap located in the southeast.

Figure 1.

Limestone exploitation area and processing plant in the Kujawy mine and its location in Poland. Available online: https://www.geoportal.gov.pl/ (accessed on 7 September 2021) source: geoportal.com.

The simulation experiment was based on an assumption that depending on the price of the final product, the extraction of the deposit may be economically viable for the content of interlayers between 10% and 40%, which corresponds to the content of intermediate product in the deposit at 60–90%. An assumption was also made that the material extracted from the face should be subjected to preliminary crushing in order to remove grains containing karst 0–40 mm in size, as the fraction suitable for further use in the technological process (the intermediate product) has a grain size greater than 40 mm.

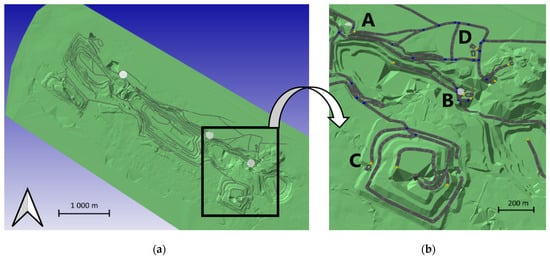

Based on the obtained ground surface model (triangle mesh) and transport road network (additional layer), the Haulsim software was used to build a spatial model comprising separately defined sections forming a network of technological roads (Figure 2). The problem was analyzed with the use of an academic license granted by RPM Software. The modeled transport road system is a coherent entity in which each end point of a road section is simultaneously a start point for another section. The geometry of the characteristic sections is constant (a straight section, a curve, an inclined plane), and the accuracy of the model ensures an increased number of marked sections. This fact allows a precise reconstruction of the road geometry, including its actual longitudinal profile. In such an approach the actual vertical curve of the section is not significantly different than the curve defined in the model. It is thus possible to discretize the model of the extraction environment corresponding to the conditions in the actual mining plant, which is of importance for the actual modeling of the movement components of the haul trucks.

Figure 2.

Spatial model of mine: top view (a) and simulated mine fragment with indicated transport roads and locations of basic technological procedures (b).

The model is additionally provided with the defined loading and unloading points, the waste heap, the crushing and storage locations of the material ready for sale, and the facilities important for the functioning of the machinery fleet, i.e., the repair station, the fuel station, etc.

The transport process was analyzed for the part of the deposit (bold selected: Figure 2a) designated with letter A (Figure 2b), in which the material is mined with the blasting technique and transported to the processing plant (B). In the processing plant, the material transported on haul trucks is fed to the Powerscreen Premiertrak 1100 × 800 crusher, where it is separated into two fractions:

- >40 mm—the product for sale—after processing it is transported via a belt conveyor to the storage site (D)

- Non-technological material (0–40 mm), which is transported on haul trucks to the external “Bielawy” waste heap (C).

The total length of the technological transport road in the analyzed part of the mine site is approximately 5000 m. All of the sections inside and outside the production excavations comprise different types of surface, its condition depending inter alia on the season of the year and atmospheric precipitation. It is maintained in good condition with the use of a subgrader machine and by filling the irregularities with the aggregate available on site.

In order to demonstrate what influence the mining environment, i.e., the type of the surface and the inclination of the road sections for the assumed deposit conditions, has on the efficiency and on the profitability of the transportation process, four simulation models were defined: a base model and two scenarios—with a road surface characterized by higher and lower rolling resistance. In the additional road network model (variant 4), the rolling resistance and inclinations of individual sections were defined as optimal for technological roads in the mine—the rolling resistance was assumed equal to that of improved roads (the rolling resistance of 2.5%), and the inclination of the transport ramps is constant along the road section. The model allows the identification of the limit for the influence of the possible changes in the road quality on the technological procedure times and as a result on the transportation costs and efficiencies.

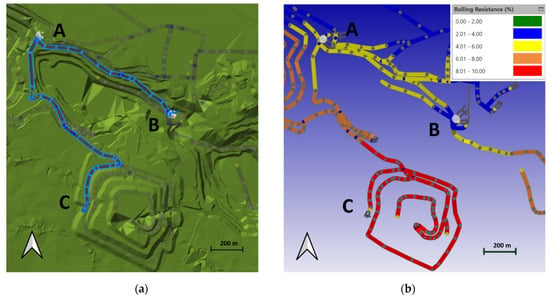

Models of the transport processes involved two transport roads. The first haulage road extends between the face designated as Face/Hauler Loading and the mobile crusher located at a belt conveyor transporting the intermediate product (the valuable material) to the processing plant designated as ZPK Low Crusher. The road is 1089 m long and the elevation difference is 29.5 m. The second road (2542 m in length) comprises the NTM haulage cycle from the site at the mobile crusher to the “Bielawy” heap. Rolling resistances for the transport roads were identified on the basis of an in situ analysis of individual road sections. The parameters of the technological road and of the individual sections are shown in Figure 3.

Figure 3.

Identified model transport roads (a) and rolling resistances (b) for individual road sections of the mine in the base scenario.

The technological system was modeled with the actual machines used in the mine, i.e., with bucket wheel loaders Komatsu WA 600. The fleet of the machines used in transporting the run-of-mine (ROM) material to the preliminary crushing, the NTM to the waste heap and the intermediate product to the processing plant consisted of Komatsu Rigid Dump Trucks HD465-7 having a capacity of 55 Mg. The data for the machines used in the model were supplemented with the actual parameters from the operating and maintenance manuals provided by the mine.

In the Haulsim models, the analyzed movement of the technological vehicles was expressed as the energy consumption required to overcome main motion resistances of a loaded and unloaded vehicle on the road according to a certain configuration. Depending on the method for forcing the motion, the following components were identified:

- motion due to the driving force, which involves acceleration, motion at a constant speed and deceleration,

- cornering and motion on an inclined road due to the component of the gravity force.

Consideration was also paid to important aspects related to other energy-consumption components in technological road vehicle transportation, such as idling of the machine in the loading and unloading points, as well as in the waiting line. The analysis did not include the energy-consumption related to the operation of the engine needed to lift the dump body filled with ROM material during unloading, because this was considered as a constant energy output independent of the configuration of the operating environment.

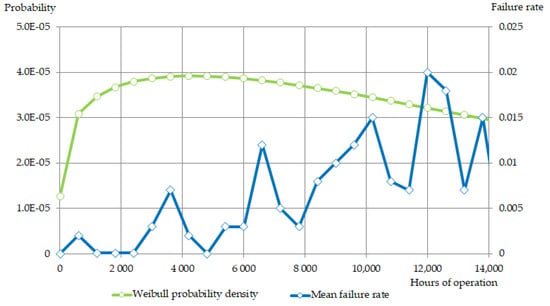

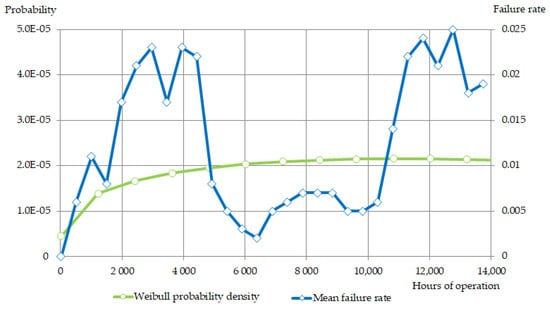

In order to reconstruct real operating conditions of machines over a long period of operation, the operating times allowed for the failure process of the elements of the machine system, separately for the loaders and for the haul trucks. The reliability of the machinery fleet for the time period equal to one year (a total of 4000 operating hours was assumed) was evaluated on the basis of an analysis of the full operation period equal to 14,000 operating hours for wheel loaders (Figure 4) and haul trucks (Figure 5). The analysis included the failure intensity rate of the machinery fleet with allowance for the operation to date (6–10 thousand operating hours). The failure process of the machines in the simulation model was generated with the use of a distribution which best fitted the data from the reliability analysis, i.e., with the use of the Weibull distribution [31,32,33,34].

Figure 4.

The failure intensity parameter for wheel loaders, for a total observation period of 14,000 h of operation [33].

Figure 5.

The failure intensity parameter for haul trucks, for the total observation period of 14,000 h of operation [33].

The distribution of failure intensity was determined for all machines based on service requests submitted to the restoration system. These requests included serious failures as well as minor defects indicated and detected by the telemetry system or the operators.

The Weibull distribution was also used to model unplanned maintenance downtime. When defining the failure intensity distribution, the mean number of events per unit of time was assumed to change with time, and in such case the number of defective objects is defined and the time to failure is random.

The study was supplemented with an additional classification and analysis of the costs representing the main components of the use and ownership of a machinery fleet, i.e.,

- costs of fuel,

- costs of lease,

- costs of the Total Maintenance and Repair (TMNR),

- costs of tires (for haul trucks),

- costs of labor—salaries.

For each configuration of the technological system, the analysis was based on an assumed extraction level of 500 Mg per hour. The machines were also assumed to be in lease and maintained by an external service partner of the manufacturer which leased the machines. The investment costs related to the machines were assigned to the category of owning costs and included as leasing costs, because the majority of machines operated in mining industry is purchased with the use of this financing method. All of the machines were operated in two working shifts, with the effective time Te = 7 h. The analyzed machines were assumed to operate for 25 days per month, resulting in 350 working hours per month.

The simulations were performed in four variants of the intermediate product content, in the range 60–90% at 10% intervals. The content of the intermediate product translates directly into the volume of the transported material, as all of the NTM must be transported to the waste heap after the preliminary crushing process.

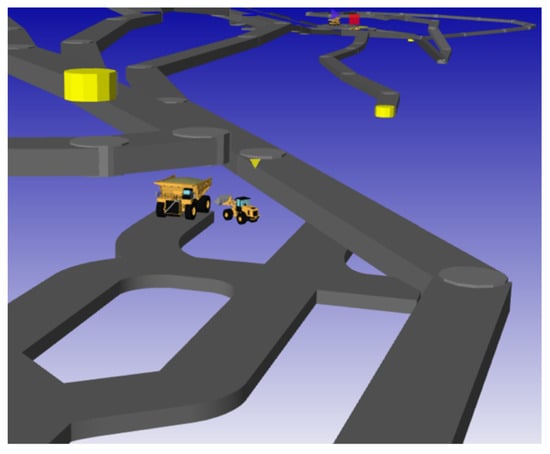

The model was validated in several stages, as the operating time of the machines required adjustment due to the duration of individual technological procedures in relation to the calendar time, which was de facto reconstructed in the simulated model. An example of visualization of simulated processes is shown in Figure 6. The validation of the model involved the following tasks:

Figure 6.

The process of loading the material on the haul truck visualized against the network of mine roads (removed layer in the terrain model) in the simulated model.

- 1.

- Simulation of one transportation cycle, with allowance for:

- The loading time due to the number of loading cycles,

- The transport time involving:

- the time of maneuvering the haul truck at the loading site;

- the time of transporting the material to the unloading point;

- the time of maneuvering at the unloading point;

- the unloading time.

- 2.

- Simulation of the efficiency of the daily output, which allows for:

- Real working hours at the mining plant;

- Downtimes due to the cycle of production changes.

- 3.

- Simulation of the efficiency of the weekly and monthly outputs, which allows for:

- Weekend-related downtime and average number of days in a month.

- The need to control the process of transporting NTM from the crusher to the waste heap in order to avoid the accumulation of excess stock.

- 4.

- Simulation for the annual output allowed for:

- Failure intensity of mining machines;

- Necessary downtime and time out of service due to planned and unplanned maintenance.

The four variants of the product-NTM ratios were provided with additional three models allowing for different configurations of road qualities in the mine. In the base scenario, the roads were assumed to be identical to the direct in situ observation in the mining plant. In the modeled variants, the analysis of the operational environment took into account variation in the rolling resistance due to the effect of precipitation, as well as seasonal variation. The rolling resistance values for the individual road sections were given as average results from in situ mine road surveys. The quality of the road was not analyzed in terms of the type of material used for its construction because the input parameter in the model was the rolling resistance (which is directly influenced by the road construction material).

In a scenario referred to as weak, all of the roads were assumed to have a quality worse than in the base scenario, showing increased rolling resistance due to, e.g., transverse and longitudinal irregularities and low wheel load capacity. In the optimistic scenario, the roads were assumed to have a higher standard. In the additional scenario, the roads were assumed to have the lowest rolling resistance available for technological roads and the transport ramps—to have a constant inclination. A constantly inclined transport road minimizes the number of changes of the operating modes of the drive systems in the haul trucks, improving the transport economy. Table 1 summarizes the information on the quality of the transport roads. In the simulations, the road quality was described with the use of a basic parameter influencing transport effectiveness, i.e., with the rolling resistance of wheels on various surfaces.

Table 1.

Basic parameters of the haulage roads for ROM and NTM.

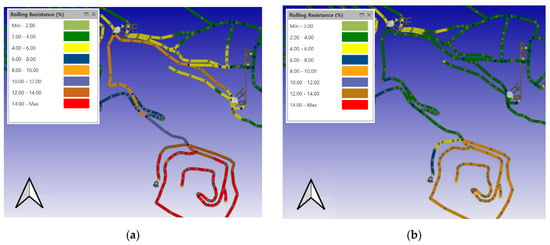

For comparison, Figure 7 shows a view of the model of the transport routes divided into individual sections for the variants with low and high road surface quality. They demonstrate that the difference in the level of average rolling resistances between the “good” and the “weak” surface remains within the range of 3.0–8.6% (Table 2). The road sections having the highest surface quality in the “good” variant show a rolling resistance of 2.5%, and the sections having the lowest quality in the “weak” (degraded) variant show 9% rolling resistance for the haulage of ROM material from the face to the crusher. Mean rolling resistance along the route from the crusher to the waste heap remains within the range from 4.0% in the “good” variant to 10.5% in the “weak” variant. When considering individual sections, the differences between the rolling resistances are even greater, within a range from 2.5% to 16% (Table 3).

Figure 7.

Modeled variants of rolling resistances in the scenario for low quality roads (a) and good quality roads (b).

Table 2.

Rolling resistances of road sections in different modeled transport scenarios—road 1.

Table 3.

Rolling resistances of road sections in different modeled transport scenarios—road 2.

The estimation of the economic aspect of the modeling was possible by classifying and analyzing the costs representing the main components of the use and ownership of the machinery fleet (Table 4). The number of modeled machines was selected in accordance with the assumed parameters of the mining operations. The loading process was performed by two loaders (one at the face and one on the site at the crusher) and by two haul trucks. The costs of the loader at the crusher were assigned to the mining costs of the analyzed fragment of the deposit only to an extent to which it performed works related to the deposit (only direct loading tasks). The remaining machines performed the entire technological process, and thus 100% of their operating costs were assigned to the mining costs.

Table 4.

Costs of machinery fleet (in EUR).

3. Results

A total number of 16 simulation models were constructed. They allowed a multi-aspect and reliable evaluation of the product-NTM ratios, and most importantly an analysis of the influence of the mining environment on the effectiveness of the processes measured with efficiency, as well as with the total and unit cost.

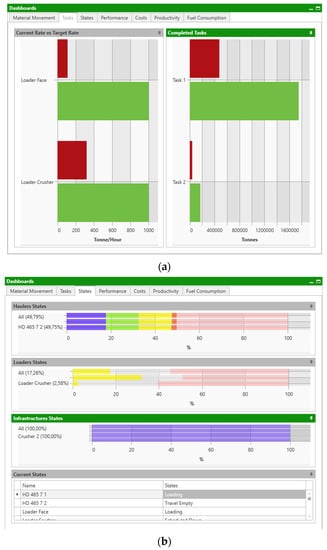

The model validation process consisted of adjusting the operational availability time of the machines to the observations in the simulation, i.e., to the advancement degree of the technological process. This was performed in the dialog window of the software (see Figure 8). The base model prepared in the first stage served to construct successive variants of the models of the technological process, changing the content of the intermediate product in the mined deposit. The manipulation of the quantity of ROM material in the transported stream resulted in the change of the number of cycles along the haulage road to the waste heap and consequently in the time of the entire transport task.

Figure 8.

Source of information about the implementation of the processes in the model: (a) task advancement; (b) machine regimes.

As in the case of the base model, with an increased number of transport cycles to the waste heap, the successive model variants required independent (for each individual model) regulation of the ratio between the output and the NTM in order to avoid the overstock at the crusher.

The product-NTM ratio has a direct influence on the total operating costs, as it defined the volume of the processed rock mass. For example, in the case of the 90% deposit quality, 10% of NTM is transported to the waste heap, while in the first place all of the ROM material (100%) is transported from the face to the crusher by the haul trucks. Subsequently, after crushing, 90% of the material is transported to the ZPK processing plant via the belt conveyor, while the 10% of the material is transported to the waste heap with the use of wheel transportation. Thus, the total transported masses are 110%. The necessity to transport larger masses resulted in a greater number of transport cycles, which in consequence increased the duration time of both the process and its simulation. In addition, the configuration and the quality of the transport roads was demonstrated to have an influence not only on fuel consumption but also on the reduction of the cycle time and on the increase of the transport efficiency.

The total simulation time shown in Table 5 should be interpreted in relation to 10 months (300 calendar days, 250 working days) of the effective operating time of the mine per one year. This fact indicates that at 20% NTM content the target transport system (2 haul trucks + 2 loaders) is capable of performing the annual output plan only in the variant in which the transport roads are of optimal quality. Depending on the quality of the road, a greater percentage share of NTM will require a greater number of haul trucks. The simulation also demonstrated that the base (actual) road quality does not ensure the expected haulage over the planned time.

Table 5.

Operating time of the model in days (target time of 300 days).

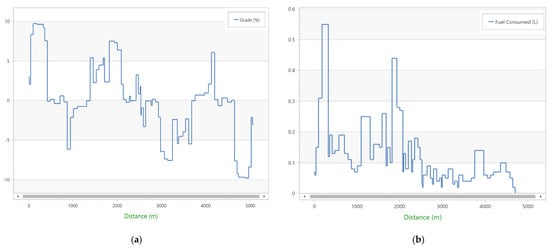

The discrete simulation provided partial production costs—assigned to the unit of time and to the operated object (machine)—which were then aggregated to the total costs of the transport cycle and the time of the transportation task. Figure 9 below shows a representative model of the consumed fuel and its cost in relation to individual sections of the road in the base (actual) variant and in the optimal scenario. An analogical model was constructed for the two remaining simulation variants.

Figure 9.

Longitudinal profile of the transport road (a) versus fuel consumption (b) for individual road sections modeled in the base scenario over one cycle of transporting NTM to the waste heap.

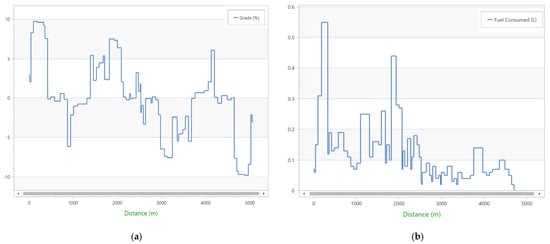

In the optimal scenario, the road inclination was defined as constant and therefore the graph in Figure 10a is a straight line. Constant road inclination is one of the factors influencing the regime of the haul trucks. The variability range of the fuel consumption is nearly two-fold lower than in the case of the base scenario (Figure 9b vs. Figure 10b), and the total fuel consumption by the haul truck per one transport cycle was 5.44 L, while in the base scenario it was 7.71 L.

Figure 10.

Longitudinal profile of the transport road (a) versus fuel consumption (b) for individual road sections modeled in the optimal scenario over one cycle of transporting NTM to the waste heap.

The costs of the transport cycle were summed for the production shift and for the total planned production volume. The results represent a complex analysis of the operational costs depending on the operating environment (see Table 6). Such calculations may become a basis for a decision to start or resign from extracting minerals from a low-quality deposit, and in combination with the sale price it may provide a reliable estimation of the future profit.

Table 6.

Operational costs of transportation in the analyzed variants.

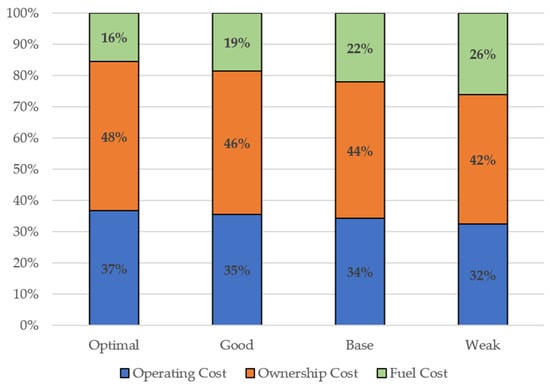

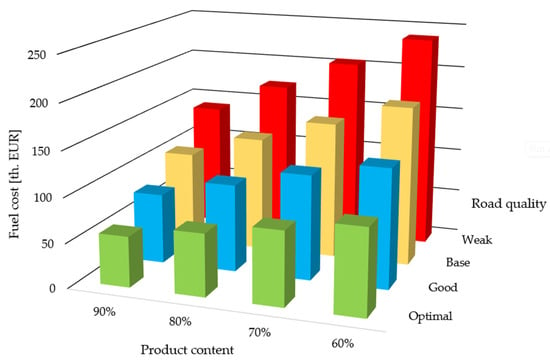

The unit costs summary below (Table 7) was calculated on the basis of the components shown in Table 4. In the simulation model, the production costs were calculated on the basis of the simulated values in relation to the unit of time, and subsequently aggregated to total costs. The cost structure resulting from individual models is variable and strongly correlated with the quality of the technological roads. For example, Figure 11 shows the cost structure for the variant in which NTM accounts for 10% of the ROM material. A decrease in the road quality causes an increase in the fuel consumption, as a share both in the total transportation cost and in the absolute values. The results obtained for the presented model allow an approximation that an increase in the rolling resistances by 1% results in an increase of the share of fuel costs by around 1.25%. When quantified, the fuel cost for the haul trucks changes from 56.4 thousand EUR for optimal quality roads to 139.8 thousand EUR for roads showing high rolling resistances, in the case when NTM accounted for 10% of the mined material. In the case with high NTM content (40%), the fuel cost varied in the range from 95.2 to 238.5 thousand EUR. The fluctuation range indicates the scale of the possible savings resulting from improving the road quality.

Table 7.

Unit costs of transportation in the analyzed scenarios, in relation to 1 Mg of the final product.

Figure 11.

Cost structure for haul trucks depending on the assumed road quality scenario, for the 10% NTM content.

In the analysis, the transportation costs remain within a range from 422 thousand EUR in the case of the variant with good quality roads to 537 thousand EUR in the case of the variant with weak quality roads. In the base variant, the sum total of the transport costs was 468 thousand EUR. The simulations did not reveal any significant changes of the cost structure in the case of changing the product-NTM ratio.

Quantitatively, the greatest cost changes were observed for the fuel used by the haul trucks, which phenomenon is related to the energy output required to overcome the motion resistances depending on the quality of the operating conditions (the transport roads and the maneuvering locations at the loading and unloading points). The range of changes in fuel costs depending on the product content and road quality is shown in Figure 12.

Figure 12.

Fuel consumption costs for haul trucks in the 16 analyzed models of the technological system.

A decision to invest in improving the quality of the transport roads has a measurable influence on the effectiveness of the system and reduces the transport costs according to a scale presented in Table 8.

Table 8.

Annual profit/loss in transport costs in the case of changing the parameters of the technological roads with respect to the base scenario.

In addition to the above calculations, an observation should be made that the cost of a set of tires for the analyzed type of mining machines oscillates between 40 and 50 thousand EUR and accounts for approx. 30% of the costs associated with operating haul trucks [1]. By modifying the operating environment, it is possible not only to lower fuel consumption, but also to prolong the life of the tires, as well as of the machines. Further analyses should focus on the economic balance of investments on improving the quality of technological roads with respect to the lower costs of operating the machine system. Such an analysis may allow economically justified decisions in the perspective of the planned lifetime of both the mine and the machinery fleet. Improved road quality in a mining plant has another, unquantified effect in the form of increased work safety.

4. Discussion

The results of research related to the modeling of technological processes in surface mining, as published to date and known to the authors, focus mainly on the modeling of the stream of the ROM material, on the general representation of the technological diagrams, or on short-term analyses of individual work cycles of machines.

This work offers a novel approach to the problem of long-term modeling of the operation of mining machines in a surface mine, with allowance for the aspects of energy-consumption and failure intensity of the technological system. Such a task entailed a number of difficulties related to properly defining all of the input parameters and the multi-object simulation model.

The results of the simulation experiments clearly indicate the reliability of the selected and analyzed operating and technological parameters, primarily for the estimation of the profitability of mining a low-quality deposit. It is particularly important to compare the results of the base model, which reproduces the current state, with the actual times of the production task. The difference is less than 6% (317 days in the model vs. 300 days of actual work). This fact indicates high consistency, especially if account is made of the time range of the model operation and of the projected randomness of phenomena during the operation. The running time of the model determines the costs and efficiency of the haulage process, and therefore estimating the time of individual technological operations is crucial for the credibility of the obtained results.

The discrete simulation enabled an almost costless analysis (except for the cost of work of the analyst and for the cost of the software) aiding investment decisions and allowing for a number of parameters, which are excluded in analytical models, or which are not included in short-term predictions due to the limited probability of the occurrence of particular circumstances (e.g., random events such as failures). The comparison involved total system production values obtained when considering the equipment reliability, availability and maintainability (RAM) characteristics. It is demonstrated that by considering the RAM aspects in the context of truck and wheel loaders, the total production of the system can be maximized and specific information on the production availability and productivity of its components can be obtained.

5. Conclusions

The methodology presented in this article illustrates a practical application of modeling transportation processes in surface mining, which allow haul trucks and loading machines to be evaluated in particular operating conditions of a quarry, especially in the context of low-quality deposits.

The implemented modeling allowed a systematic arrangement of alternative variants of the operating environment by both unit and total costs of machine operation, as well as by other directly influencing parameters. Specifying a universal set of reliable parameters in the modeling of the transportation and loading processes allowed a complex and long-term analysis of the functioning of a technological plant and an evaluation from the operational and economic perspective.

Such analyses enable the identification of the production potential understood as the ability of the entire system or each of its elements to perform technological processes. It is additionally possible to indicate an object characterized by the highest and the lowest failure intensity, and similar operating characteristics may serve as a basis to develop optimized operating systems, e.g., the method for performing planned maintenance and for scheduling their frequency for different time periods of the functioning of a mining plant.

As demonstrated in the analysis, in mining plants in which wheel transportation dominates, technological roads should be maintained in the best possible quality. The sole costs of fuel may increase more than two-fold in the case when the roads are not maintained properly (the decrease from the good to the weak quality).

The analyses show the structure and the influence of the technological and operating parameters, and primarily of the operating costs of a varied machinery fleet in rock raw material mining industry, relative to low-quality deposits. Further research should be performed in order to identify the profitability limit of investments on the modification of the operating environment of a machine system with respect to the potentially lower component operating costs of machines and also to their increased durability, reliability and operating life.

The proposed methodology has a universal character and therefore may be implemented in similar conditions in which vehicles and other transport machines operate subjected to a relationship of resistance resulting from the operating environment—transport roads—and overcoming these resistances in vehicle transport. The maximum service speed, the traction force profile and the rolling resistance are the unit contributions necessary to define the running frequencies in order to allow a vehicle to slot into the overall traffic pattern on a particular transport line. Collaborative analyses can be performed not only in quarrying, but in the case of any similar relationships, for example mining of metal ores and environmental engineering.

It should be noted that the analyzed model concerned several technological activities and did not simulate the operation of the entire mine. It is not yet clear at this stage whether simulations of complex systems will also provide unambiguous results, showing savings from better road quality or other investments in the mine. The reason is the difficulty in simultaneously observing the modeled simulation of discrete events produced by many objects (faces, dumps, machines) and interdependent processes (queues, blocked roads, breakdowns, etc.). In the case of a mine with several independent production processes, the analysis of complex transport systems can be divided into basic technological lines where the presented method allows the assessment of the impact of changes in the transport system/network on the haulage efficiency.

Author Contributions

Conceptualization, Z.K. and P.B.; methodology, Z.K. and P.B.; software, Z.K.; validation, M.P. and P.B.; formal analysis, M.P. and P.B.; investigation, Z.K.; resources, M.P.; data curation, M.P.; writing—original draft preparation, Z.K. and P.B.; writing—review and editing, Z.K., P.B.; visualization, Z.K.; supervision, Z.K., P.B. and M.P.; project administration, Z.K.; funding acquisition, Z.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded with the research subsidy from the Polish Ministry of Science and Higher Education granted for 2021.

Data Availability Statement

The detailed results of simulation tests for all presented variants are available on request from the corresponding author.

Acknowledgments

The authors thank RPM Software Pty Ltd. for granting the Haulsim license to the Wrocław University of Technology.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Czaplicki, J.M. Shovel-Truck Systems. Modelling, Analysis and Calculation; Taylor & Francis Group: London, UK, 2008; ISBN 978-042-920-696-2. [Google Scholar]

- Koptev, V.; Kopteva, A.; Ivanova, T. Directions for the development of transport machines for open-pit mining. J. Appl. Eng. Sci. 2021, 19, 137–141. [Google Scholar]

- Stiglitz, J. Monopoly and the Rate of Extraction of Exhaustible Resources. Am. Econ. Rev. 1976, 66, 655–661. [Google Scholar]

- Chermak, J.M.; Patrick, R.H. Comparing tests of the theory of exhaustible resources. Resour. Energy Econ. 2002, 24, 301–325. [Google Scholar] [CrossRef]

- Halvorsen, R.; Smith, T. A Test of the theory of exhaustible resources. Q. J. Econ. 1991, 106, 123–140. [Google Scholar] [CrossRef]

- Nel, S.; Kizil, M.; Knights, P. Improving truck-shovel matching. In Proceedings of the 35th APCOM Symposium—Application of Computers and Operations Research in the Minerals Industry, Wollongong, Australia, 24–30 September 2011; pp. 381–391. [Google Scholar]

- Trivedi, R.; Rai, P.; Nath, R. Shovel-truck optimization study in an opencast mine—A queueing approach. Indian J. Eng. Mater. Sci. 1999, 6, 153–157. [Google Scholar]

- Shah, K.; Rehman, S. Modeling and Optimization of Truck-Shovel Allocation to Mining Faces in Cement Quarry. J. Min. Environ. 2020, 11, 21–30. [Google Scholar] [CrossRef]

- Souza, F.; Câmara, T.; Torres, V.; Nader, B.; Galery, R. Mine fleet cost evaluation-dijkstra’s optimized path. REM-Int. Eng. J. 2019, 72, 321–328. [Google Scholar] [CrossRef] [Green Version]

- Krause, A.; Musingwini, C. Modelling open pit shovel-truck systems using the Machine Repair Model. J. S. Afr. Inst. Min. Metall. 2007, 107, 469–476. [Google Scholar]

- Upadhyay, S.P.; Askari-Nasab, H.; Tabesh, M.; Badiozamani, M.M. Simulation and optimization in open pit mining. In Application of Computers and Operations Research in the Mineral Industry, Proceedings of the 37th International Symposium, Florence, Italy, 16–24 May 2015; Society for Mining Metallurgy & Exploration Inc. (SME): Englewood, CO, USA, 2015; pp. 532–543. [Google Scholar]

- Sofranko, M.; Wittenberger, G.; Skvarekova, E. Optimisation of technological transport in quarries using application software. Int. J. Min. Miner. Eng. 2015, 6, 1–13. [Google Scholar] [CrossRef]

- Upadhyay, S.P.; Askari-Nasab, H. Simulation and optimization approach for uncertainty-based short-term planning in open pit mines. Int. J. Min. Sci. Technol. 2018, 28, 153–166. [Google Scholar] [CrossRef]

- Patyk, M.; Bodziony, P.; Krysa, Z. A Multiple Criteria Decision Making Method to Weight the Sustainability Criteria of Equipment Selection for Surface Mining. Energies 2021, 14, 3066. [Google Scholar] [CrossRef]

- Nakousi, C.; Pascual, R.; Anani, A.; Kristjanpoller, F.; Lillo, P. An asset-management oriented methodology for mine haul-fleet usage scheduling. Reliab. Eng. Syst. Saf. 2018, 180, 336–344. [Google Scholar] [CrossRef]

- Matsimbe, J. Optimization of Shovel-Truck Productivity in Quarries. Int. J. Res. Advent Technol. 2020, 8, 1–9. [Google Scholar]

- Błażej, R.; Jurdziak, L.; Kawalec, W. Condition Monitoring of Conveyor Belts as a Tool for Proper Selection of Their Replacement Time. In Advances in Condition Monitoring of Machinery in Non-Stationary Operations; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Król, R.; Kawalec, W.; Gładysiewicz, L. An Effective Belt Conveyor for Underground Ore Transportation Systems. IOP Conf. Ser. Earth Environ. Sci. 2017, 95, 042047. [Google Scholar] [CrossRef]

- Kawalec, W.; Król, R. Generating of Electric Energy by a Declined Overburden Conveyors in a Continous Surface Mine. Energies 2021, 14, 4030. [Google Scholar] [CrossRef]

- Šofranko, M.; Lištiaková, V.; Žilák, M. Optimizing transport in surface mines, taking into account the quality of extracted raw ore. Acta Montan. Slovaca 2012, 17, 103–110. [Google Scholar]

- Teplická, K.; Straka, M. Sustainability of extraction of raw material by a combination of mobile and stationary mining machines and optimization of machine life cycle. Sustainability 2020, 12, 10454. [Google Scholar] [CrossRef]

- Morad, A.M.; Pourgol-Mohammad, M.; Sattarvand, J. Application of reliability-centered maintenance for productivity improvement of open pit mining equipment: Case study of Sungun Copper Mine. J. Cent. South Univ. 2014, 21, 2372–2382. [Google Scholar] [CrossRef]

- Angeles, E.; Kumral, M. Optimal Inspection and Preventive Maintenance Scheduling of Mining Equipment. J. Fail. Anal. Prev. 2020, 20, 1408–1416. [Google Scholar] [CrossRef]

- Topal, E.; Ramazan, S. A new MIP model for mine equipment scheduling by minimizing maintenance cost. Eur. J. Oper. Res. 2010, 207, 1065–1071. [Google Scholar] [CrossRef]

- Nurić, A.; Nurić, S. Numerical modeling of transport roads in open pit mines. J. Sustain. Min. 2019, 18, 25–30. [Google Scholar] [CrossRef]

- Saderova, J.; Rosova, A.; Kacmary, P.; Sofranko, M.; Bindzar, P.; Malkus, T. Modelling as a tool for the planning of the transport system performance in the conditions of a raw material mining. Sustainability 2020, 12, 8051. [Google Scholar] [CrossRef]

- Saderova, J.; Marasova, D.; Gallikova, J. Determining of mining transport capacity by simulation. In Proceedings of the 19th International Multidisciplinary Scientific GeoConference-SGEM, Albena, Bulgaria, 28 June–6 July 2019; Volume 19, pp. 217–224. [Google Scholar]

- Straka, M.; Rosová, A.; Lenort, R.; Besta, P.; Šaderová, J. Principles of computer simulation design for the needs of improvement of the raw materials combined transport system. Acta Montan. Slovaca 2018, 23, 163–174. [Google Scholar]

- Amin, I.; Adil, M.; Rehman, S.U.; Ahmad, I. Simulation of Truck-Shovel Operations Using Simio. Int. J. Econ. Environ. Geol. 2017, 8, 55–58. [Google Scholar]

- Upadhyay, S.; Tabesh, M.; Badiozamani, M.; Askari-Nasab, H. A Simulation Model for Estimation of Mine Haulage Fleet Productivity. In Springer Series in Geomechanics and Geoengineering, Proceedings of the 28th International Symposium on Mine Planning and Equipment Selection; Springer: Berlin/Heidelberg, Germany, 2020; pp. 42–50. [Google Scholar]

- Barabady, J.; Kumar, U. Reliability analysis of mining equipment: A case study of a crushing plant at Jajarm Bauxite Mine in Iran. Reliab. Eng. Syst. Saf. 2008, 93, 341–361. [Google Scholar] [CrossRef]

- Bebbington, M.; Lai, C.D.; Zitikis, R. A flexible Weibull extension. Reliab. Eng. Syst. Saf. 2007, 92, 719–726. [Google Scholar] [CrossRef]

- Bodziony, P.; Patyk, M. Analysis of Utilisation States and Reliability Parameters of Process-Line Configuration for Low-Quality Rock Deposits. Adv. Sci. Technol. Res. J. 2021, 15, 126–133. [Google Scholar] [CrossRef]

- Sinha, R.S.; Mukhopadhyay, A.K. Failure rate analysis of jaw crusher using Weibull model. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2017, 231, 760–772. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).