Effect of Producer Gas from Redgram Stalk and Combustion Chamber Types on the Emission and Performance Characteristics of Diesel Engine

Abstract

:1. Introduction

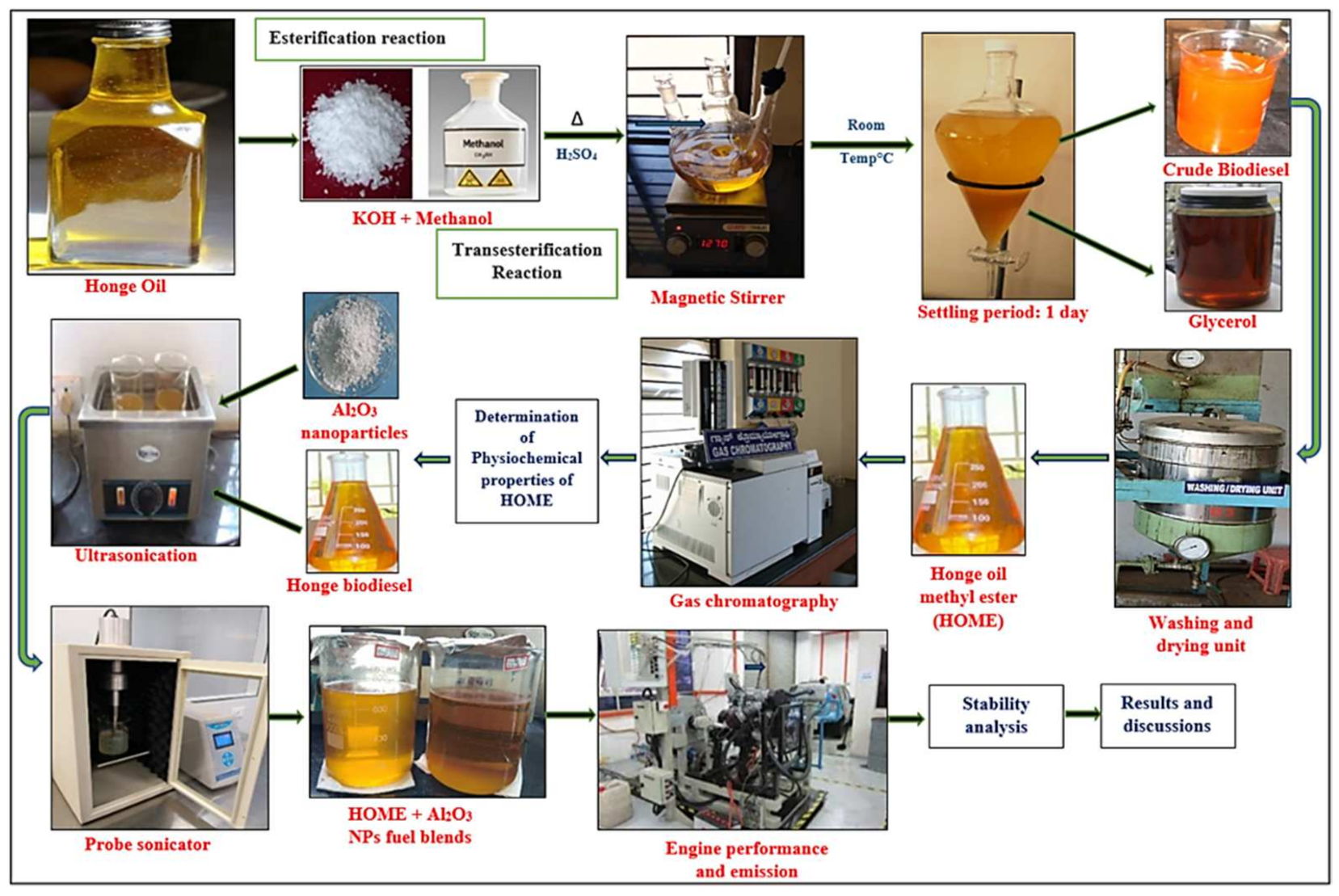

2. Materials and Methodology

2.1. Fuel Characteristics

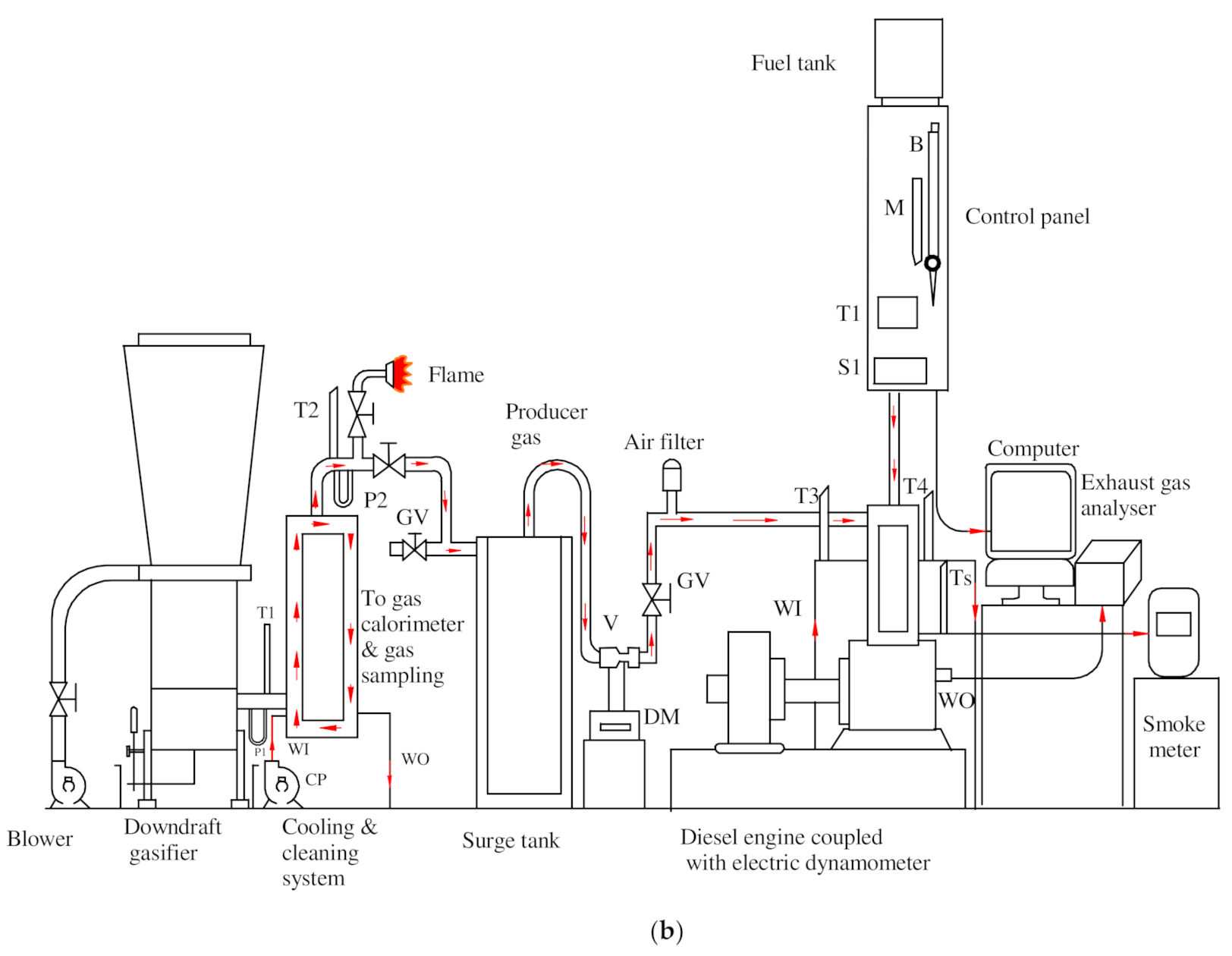

2.2. Experimental Setup

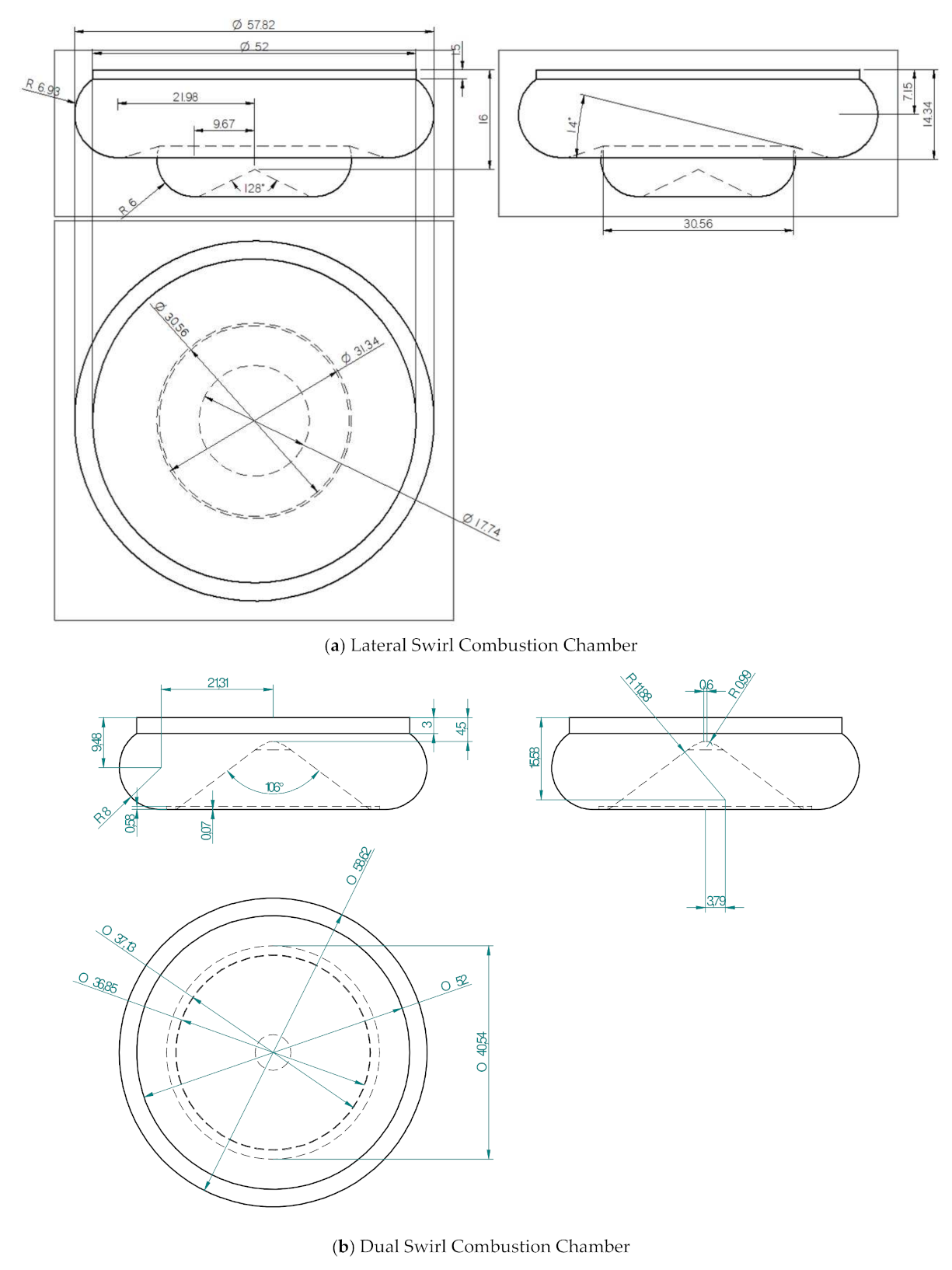

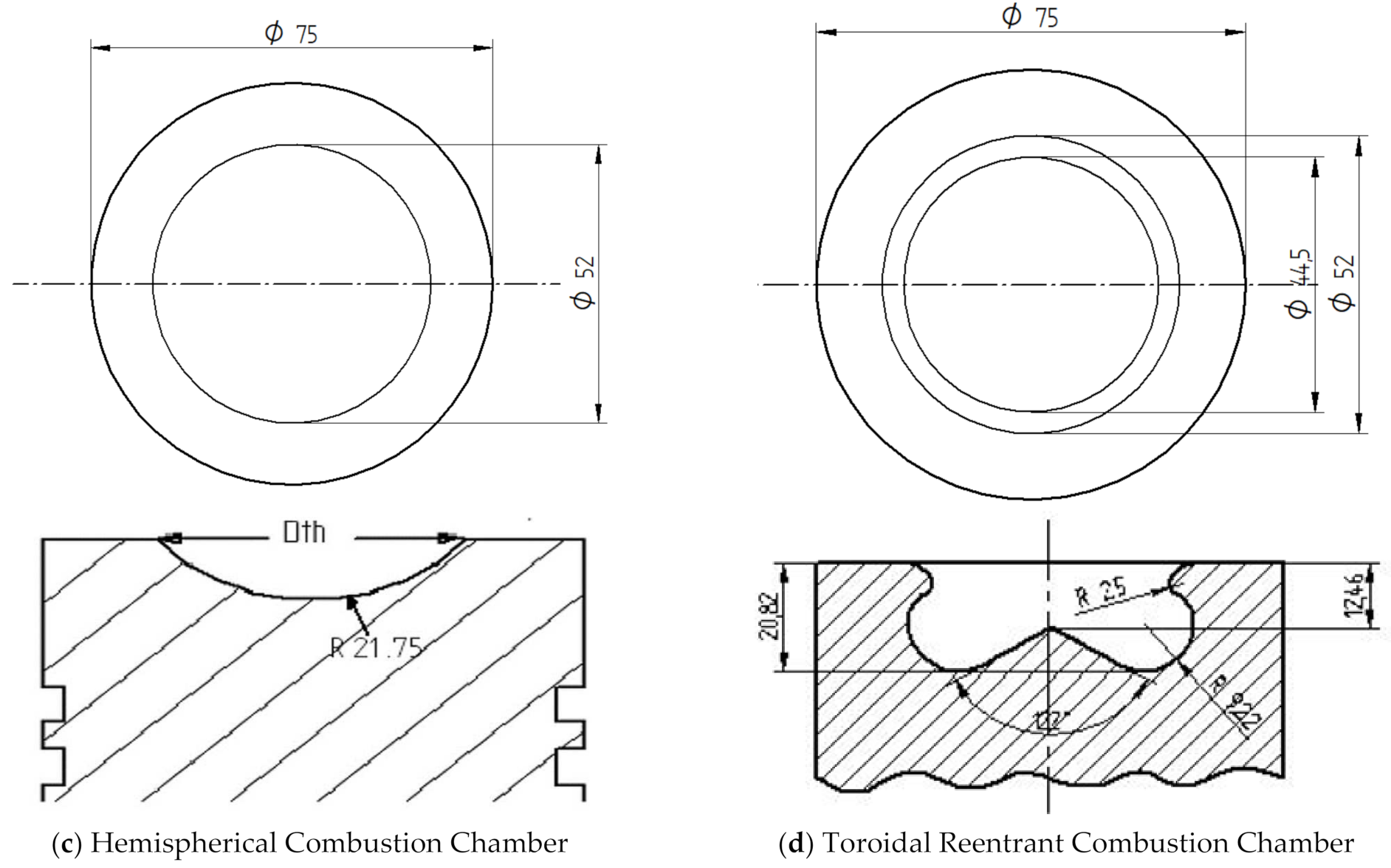

2.3. Methodology

2.4. Analysis of Uncertainty

- y—specific factor which depends on the parameter xi;

- Uy—level of uncertainties or variation in y;

3. Results and Discussion

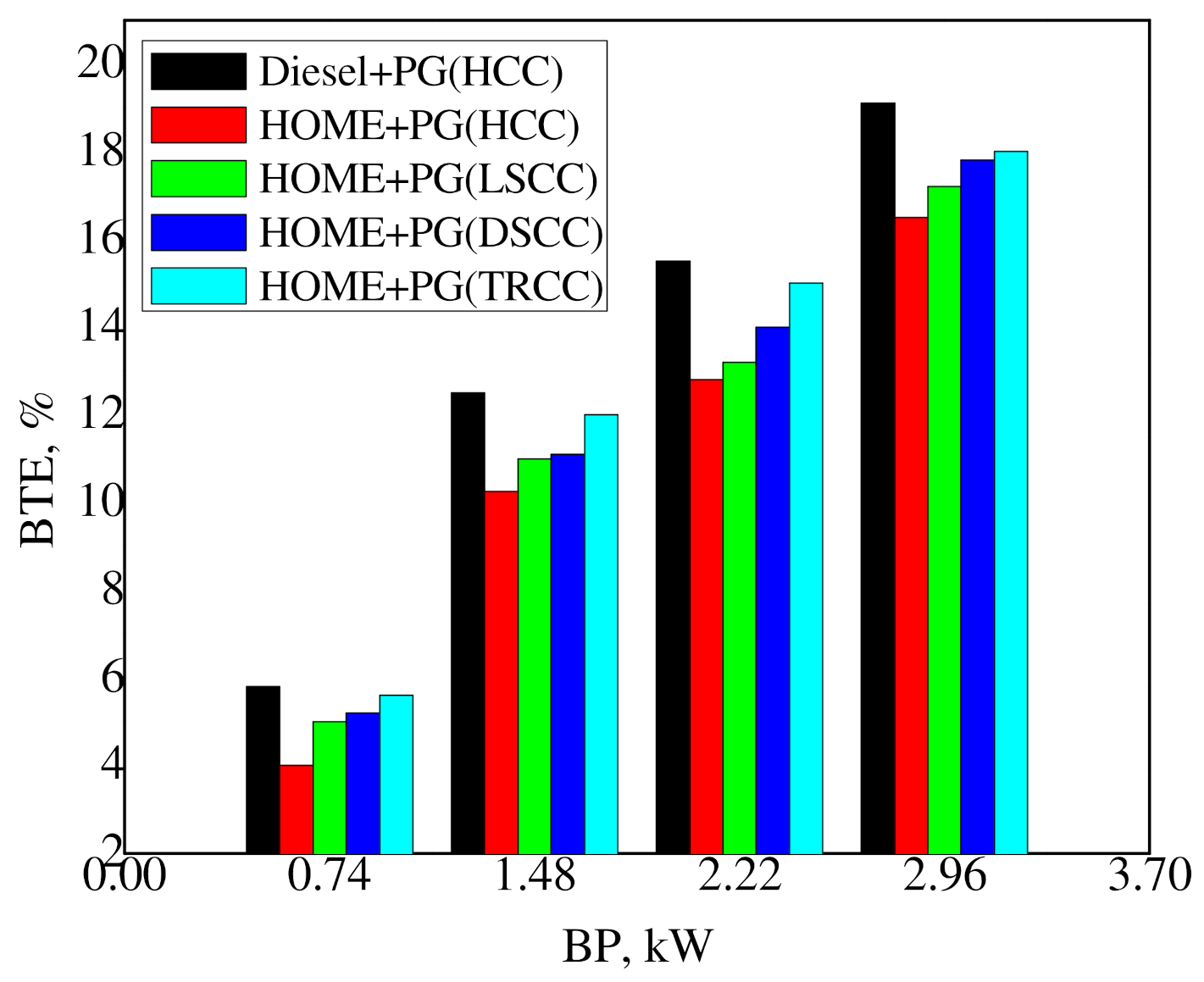

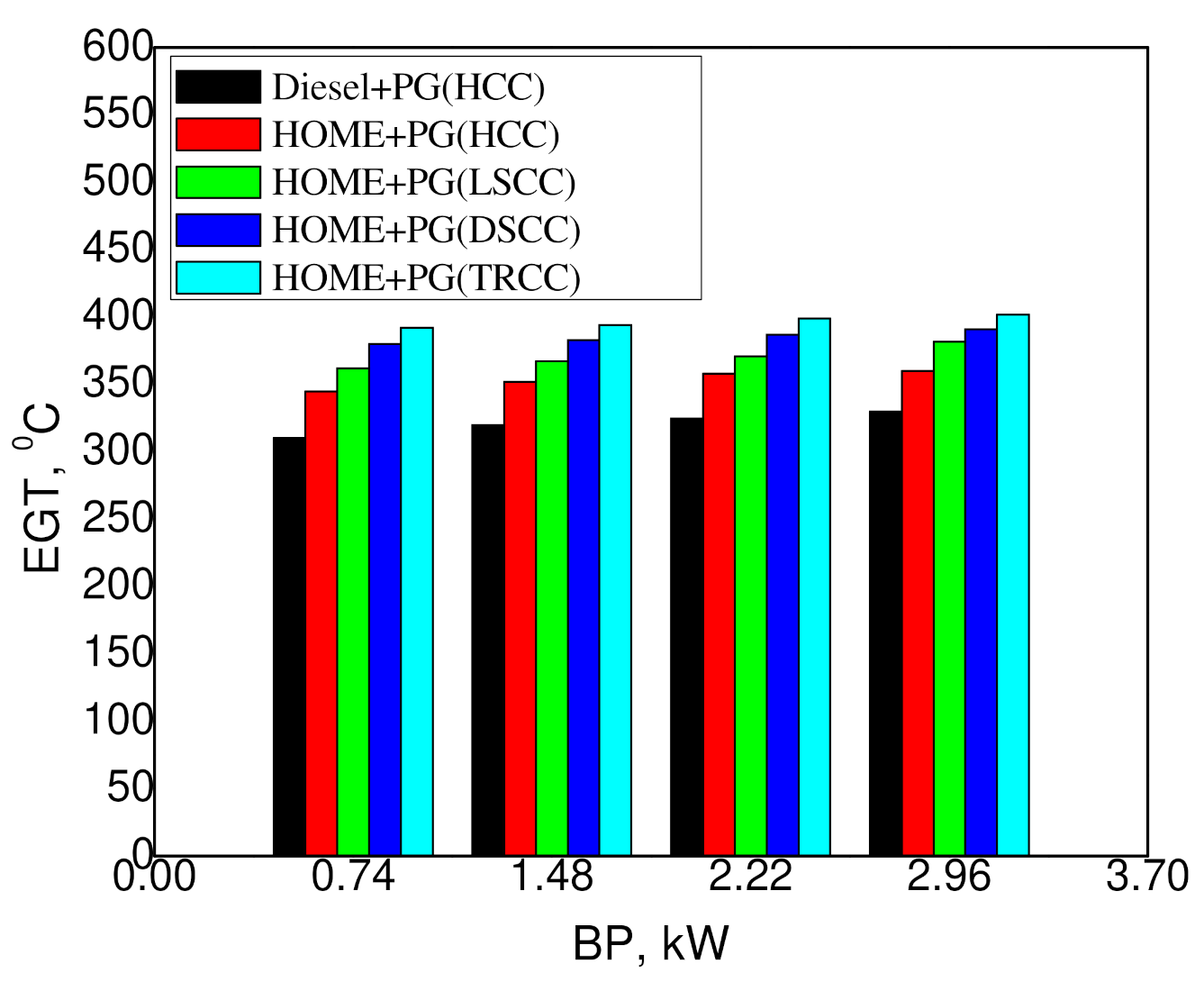

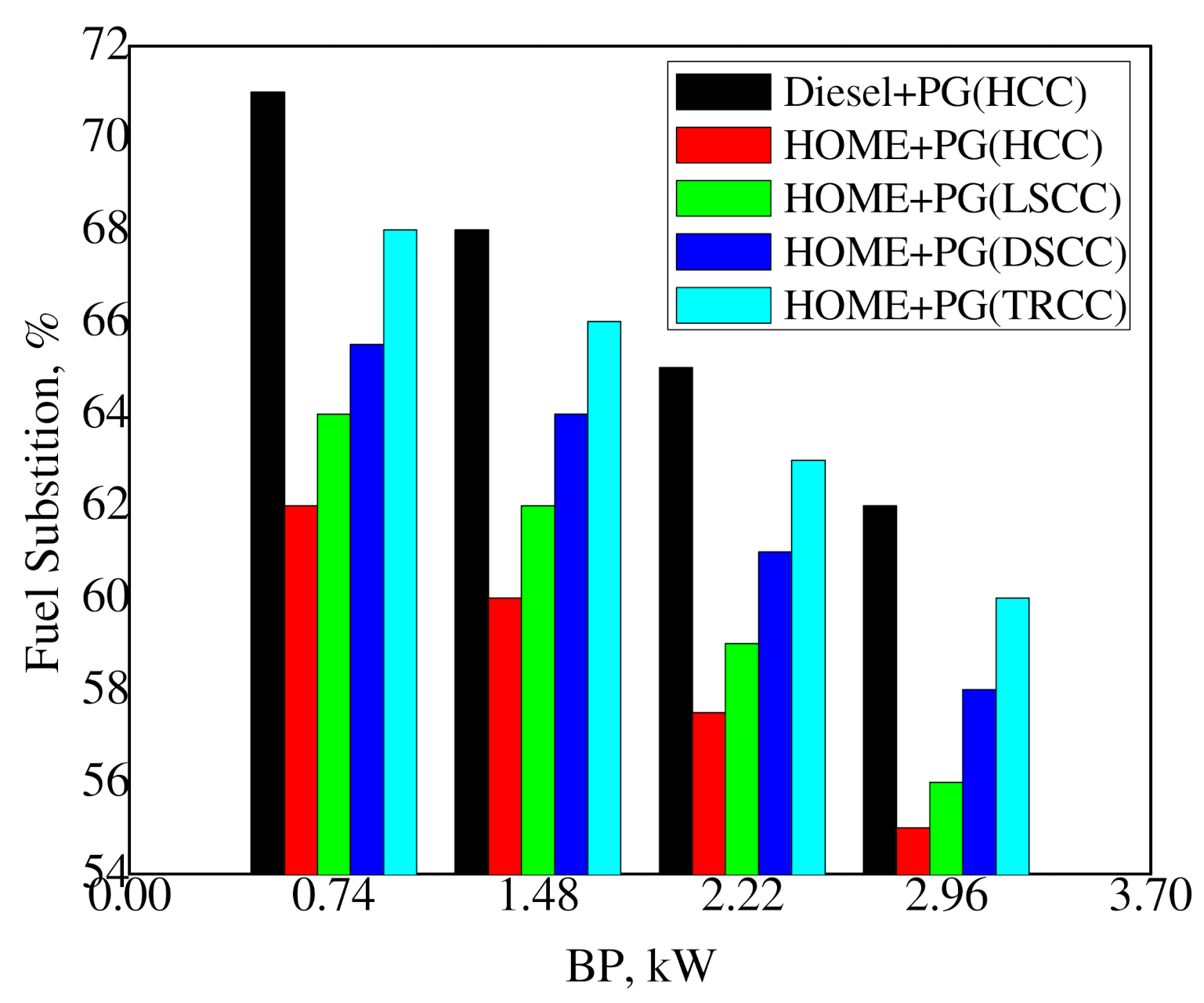

3.1. Performance Parameters

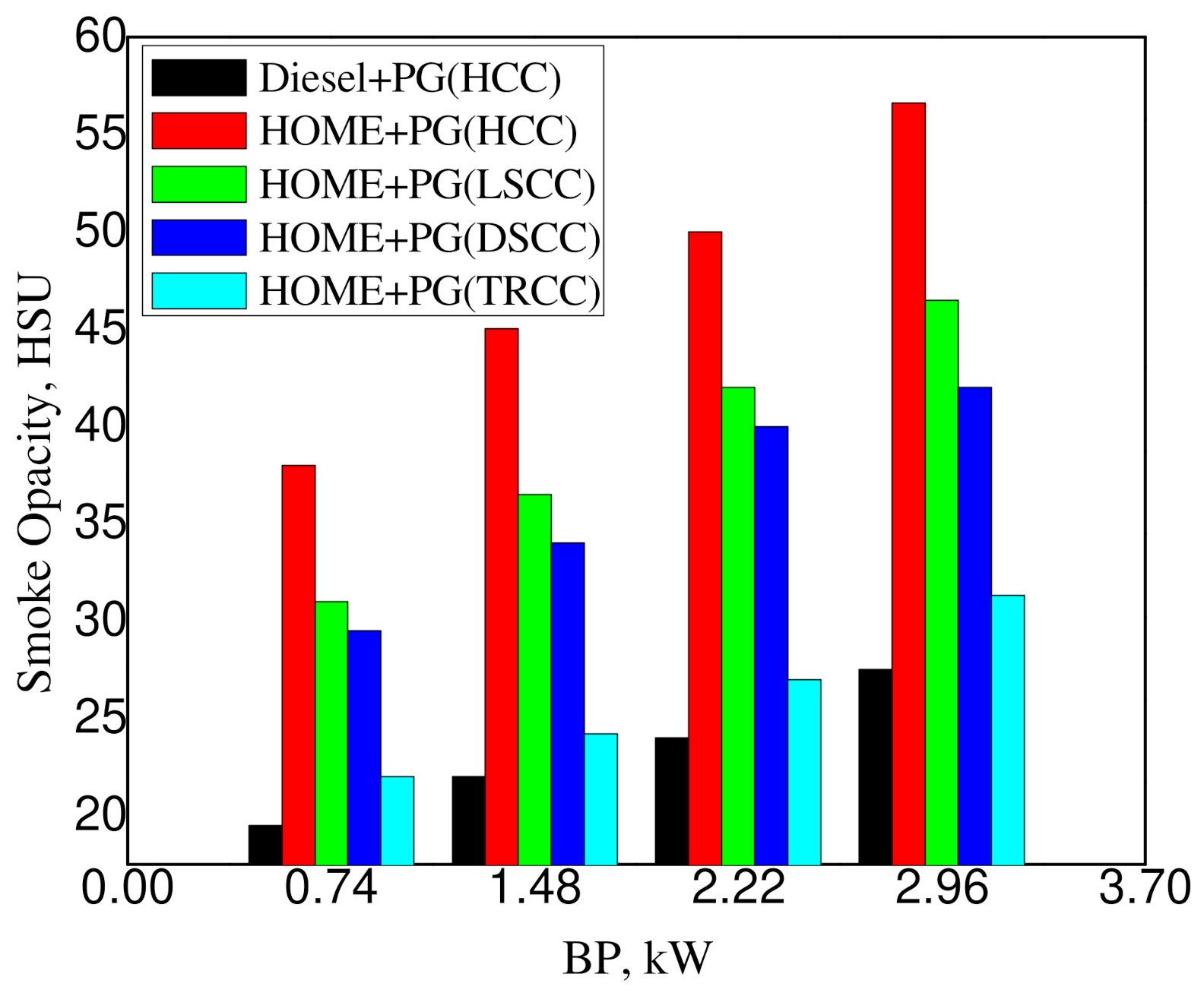

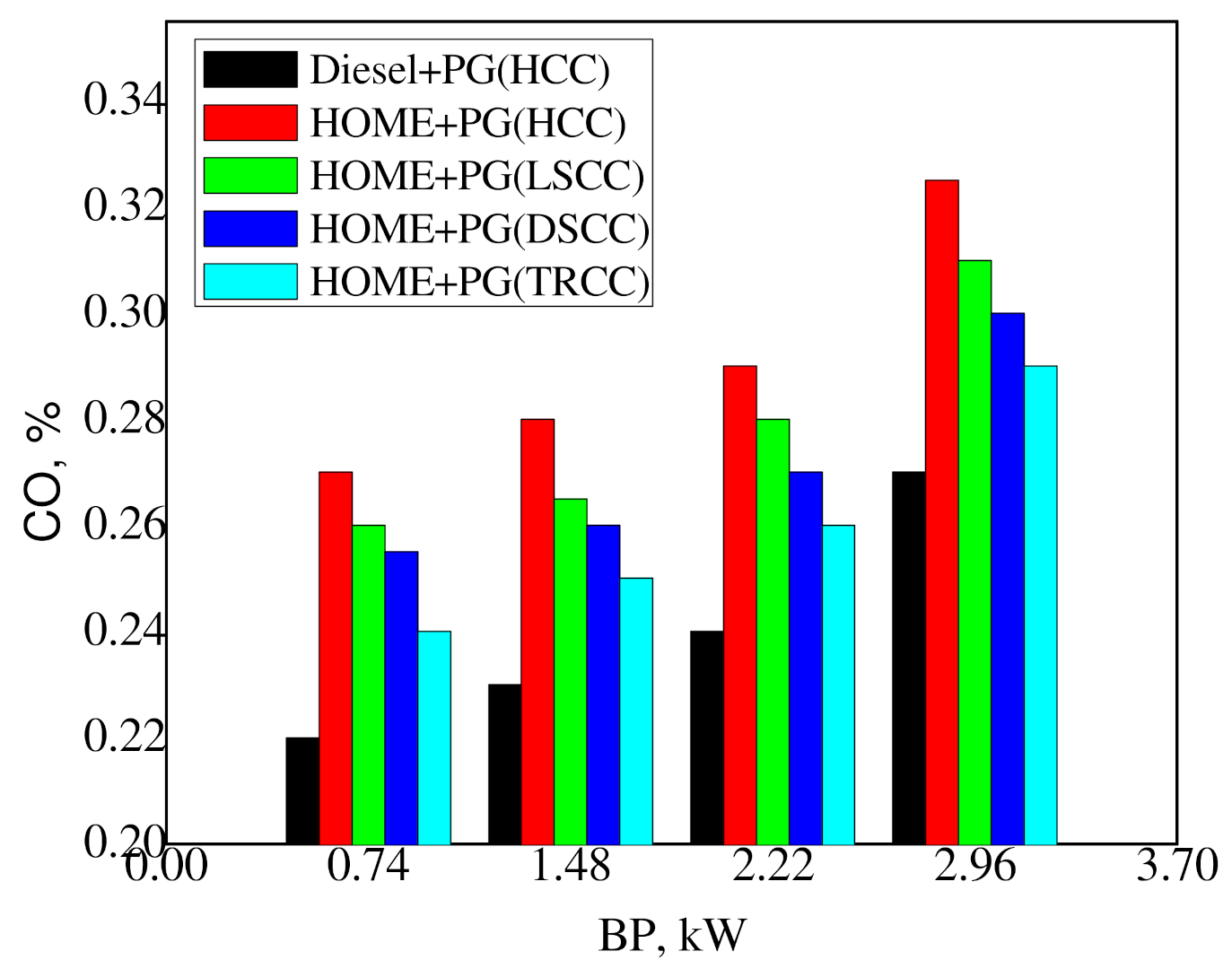

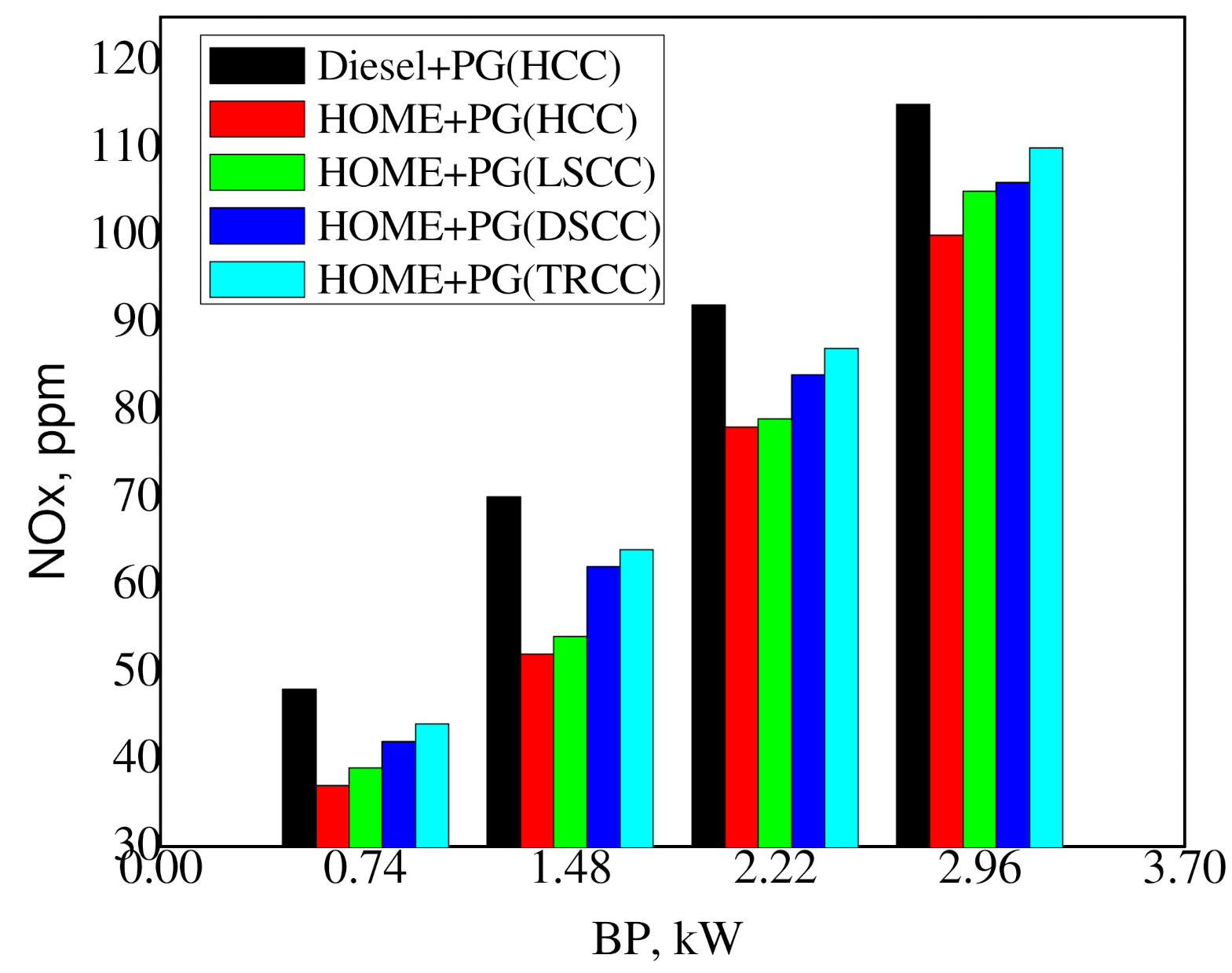

3.2. Emission Characteristics

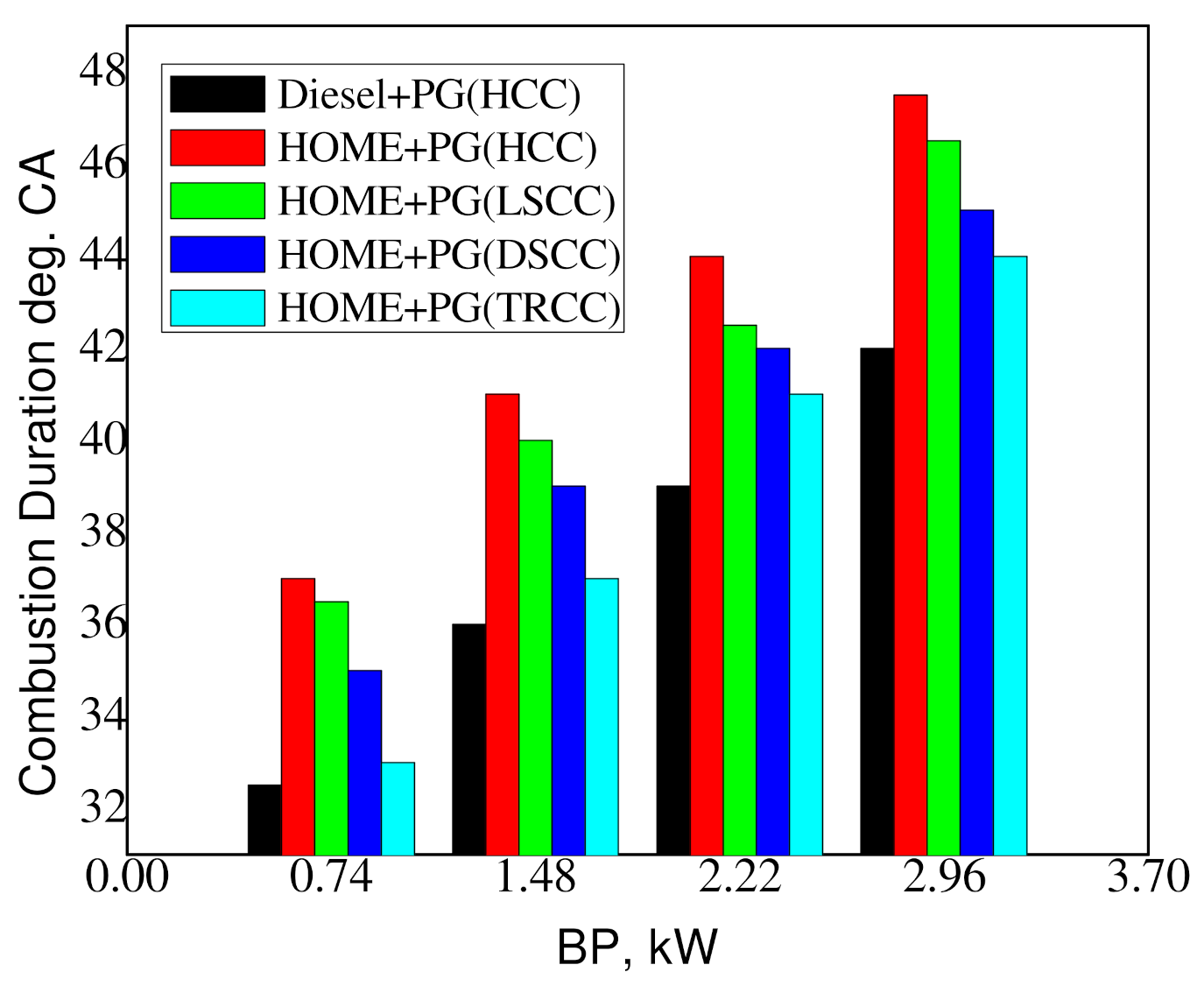

3.3. Combustion Parameters

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| BTE | Brake thermal efficiency |

| CO | Carbon monoxide |

| CO2 | Carbon dioxide |

| CH4 | Methane |

| CA | Crank angle |

| HOME | Honge oil methyl ester |

| HV | Heating value |

| DI | Direct injection |

| DSCC | Dual swirl combustion chamber |

| GHG | Greenhouse gas |

| HCC | Hemispherical combustion chamber |

| HSU | Hartridge smoke unit |

| IOP | Injection opening pressure |

| ID | Ignition delay |

| LSCC | Low swirl combustion chamber |

| PG | Producer gas |

| RGS | Redgram stalk |

| TDC | Top dead center |

| TRCC | Toroidal Rre-entrant combustion chamber |

| VCR | Variable compression ratio |

| UBHC | Unburnt hydrocarbon |

References

- Yaliwal, V.; Banapurmath, N.; Gireesh, N.; Tewari, P. Production and utilization of renewable and sustainable gaseous fuel for power generation applications: A review of literature. Renew. Sustain. Energy Rev. 2014, 34, 608–627. [Google Scholar] [CrossRef]

- Sateesh, K.A.; Yaliwal, V.S.; Soudagar, M.E.M.; Banapurmath, N.R.; Fayaz, H.; Safaei, M.R.; Elfasakhany, A.; El-Seesy, A.I. Utilization of biodiesel/Al2O3 nanoparticles for combustion behavior enhancement of a diesel engine operated on dual fuel mode. J. Therm. Anal. Calorim. 2021. Available online: https://link.springer.com/article/10.1007/s10973-021-10928-7 (accessed on 10 August 2021).

- Soudagar, M.E.M.; Khan, H.M.; Khan, T.; Razzaq, L.; Asif, T.; Mujtaba, M.; Hussain, A.; Farooq, M.; Ahmed, W.; Shahapurkar, K. Experimental Analysis of Engine Performance and Exhaust Pollutant on a Single-Cylinder Diesel Engine Operated Using Moringa Oleifera Biodiesel. Appl. Sci. 2021, 11, 7071. [Google Scholar] [CrossRef]

- Funke, A.; Niebel, A.; Richter, D.; Abbas, M.M.; Müller, A.K.; Radloff, S.; Paneru, M.; Maier, J.; Dahmen, N.; Sauer, J. Fast pyrolysis char—Assessment of alternative uses within the bioliq® concept. Bioresour. Technol. 2016, 200, 905–913. [Google Scholar] [CrossRef]

- Annual Report 2016-17. Central Electricity, Authority (CEA): India, New Delhi. Available online: https://irade.org/Inside_Annual%20Report-2016-17_04-11-2017_LR.pdf (accessed on 26 January 2020).

- The Energy and Resources Institute. Study on the Sustainability of Biomass Based Power Generation in Karnataka Bangalore. TERI, 2013; p. 46. Available online: https://www.researchgate.net/publication/283335779_Study_on_the_sustainability_of_Biomass_based_power_generation_in_Karnataka (accessed on 15 September 2021).

- Harari, P.; Banapurmath, N.; Yaliwal, V.; Soudagar, M.E.M.; Khan, T.Y.; Mujtaba, M.; Safaei, M.R.; Akram, N.; Goodarzi, M.; Elfasakhany, A. Experimental investigation on compression ignition engine powered with pentanol and thevetia peruviana methyl ester under reactivity controlled compression ignition mode of operation. Case Stud. Therm. Eng. 2021, 25, 100921. [Google Scholar] [CrossRef]

- Keerthi Kumar, N.; Banapurmath, N.; Chandrashekar, T.; Jatadhara, G.; Soudagar, M.E.M.; Anqi, A.E.; Mujtaba, M.; Goodarzi, M.; Elfasakhany, A.; Siddiqui, M.I.H. Effect of Parameters Behavior of Simarouba Methyl Ester Operated Diesel Engine. Energies 2021, 14, 4973. [Google Scholar]

- Soudagar, M.E.M.; Mujtaba, M.; Safaei, M.R.; Afzal, A.; Ahmed, W.; Banapurmath, N.; Hossain, N.; Bashir, S.; Badruddin, I.A.; Goodarzi, M. Effect of Sr@ ZnO nanoparticles and Ricinus communis biodiesel-diesel fuel blends on modified CRDI diesel engine characteristics. Energy 2021, 215, 119094. [Google Scholar] [CrossRef]

- Bala Prasad, K.; Dhana Raju, V.; Ahamad Shaik, A.; Gopidesi, R.K.; Sreekara Reddy, M.B.S.; Soudagar, M.E.M.; Mujtaba, M.A. Impact of injection timings and exhaust gas recirculation rates on the characteristics of diesel engine operated with neat tamarind biodiesel. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–19. [Google Scholar] [CrossRef]

- Bala Prasad, K.; Meduri, O.; Dhana Raju, V.; Azmeera, A.K.; Venu, H.; Subramani, L.; Soudagar, M.E.M. Effect of split fuel injection strategies on the diverse characteristics of CRDI diesel engine operated with tamarind biodiesel. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–19. [Google Scholar] [CrossRef]

- Fayaz, H.; Mujtaba, M.; Soudagar, M.E.M.; Razzaq, L.; Nawaz, S.; Nawaz, M.A.; Farooq, M.; Afzal, A.; Ahmed, W.; Khan, T.Y. Collective effect of ternary nano fuel blends on the diesel engine performance and emissions characteristics. Fuel 2021, 293, 120420. [Google Scholar] [CrossRef]

- Mujtaba, M.A.; Muk Cho, H.; Masjuki, H.H.; Kalam, M.A.; Farooq, M.; Soudagar, M.E.M.; Gul, M.; Afzal, A.; Ahmed, W.; Raza, A.; et al. Effect of primary and secondary alcohols as oxygenated additives on the performance and emission characteristics of diesel engine. Energy Rep. 2021, 7, 1116–1124. [Google Scholar] [CrossRef]

- Mujtaba, M.; Kalam, M.; Masjuki, H.; Gul, M.; Soudagar, M.E.M.; Ong, H.C.; Ahmed, W.; Atabani, A.; Razzaq, L.; Yusoff, M. Comparative study of nanoparticles and alcoholic fuel additives-biodiesel-diesel blend for performance and emission improvements. Fuel 2020, 279, 118434. [Google Scholar] [CrossRef]

- Parikh, P.; Bhave, A.; Kapse, D. Study of thermal and emission performance of small gasifier-dual-fuel engine systems. Biomass 1989, 19, 75–97. [Google Scholar] [CrossRef]

- Banapurmath, N.; Yaliwal, V.; Kambalimath, S.; Hunashyal, A.; Tewari, P. Effect of wood type and carburetor on the performance of producer gas-biodiesel operated dual fuel engines. Waste Biomass Valorization 2011, 2, 403–413. [Google Scholar] [CrossRef]

- Barua, P.; Hossain, N.; Chowdhury, T.; Chowdhury, H. Commercial diesel application scenario and potential of alternative biodiesel from waste chicken skin in Bangladesh. Environ. Technol. Innov. 2020, 20, 101139. [Google Scholar] [CrossRef]

- Lata, D.B.; Misra, A. Experimental investigations on the performance of a dual fuel diesel engine with hydrogen and LPG as secondary fuels. In Advances in Computer Science and Engineering; Springer: Berlin/Heidelberg, Germany, 2012; pp. 119–128. [Google Scholar]

- Karabektas, M.; Ergen, G.; Hosoz, M. The effects of using diethylether as additive on the performance and emissions of a diesel engine fuelled with CNG. Fuel 2014, 115, 855–860. [Google Scholar] [CrossRef]

- Yaliwal, V.; Banapurmath, N.; Hosmath, R.; Khandal, S.; Budzianowski, W.M. Utilization of hydrogen in low calorific value producer gas derived from municipal solid waste and biodiesel for diesel engine power generation application. Renew. Energy 2016, 99, 1253–1261. [Google Scholar] [CrossRef]

- Liu, J.; Yang, F.; Wang, H.; Ouyang, M.; Hao, S. Effects of pilot fuel quantity on the emissions characteristics of a CNG/diesel dual fuel engine with optimized pilot injection timing. Appl. Energy 2013, 110, 201–206. [Google Scholar] [CrossRef]

- Razzaq, L.; Imran, S.; Anwar, Z.; Farooq, M.; Abbas, M.M.; Mehmood Khan, H.; Asif, T.; Amjad, M.; Soudagar, M.E.M.; Shaukat, N.J.E. Maximising Yield and Engine Efficiency Using Optimised Waste Cooking Oil Biodiesel. Energies 2020, 13, 5941. [Google Scholar] [CrossRef]

- Banapurmath, N.; Tewari, P. Comparative performance studies of a 4-stroke CI engine operated on dual fuel mode with producer gas and Honge oil and its methyl ester (HOME) with and without carburetor. Renew. Energy 2009, 34, 1009–1015. [Google Scholar] [CrossRef]

- Banapurmath, N.; Yaliwal, V.; Hosmath, R.; Indudhar, M.; Guluwadi, S.; Bidari, S. Dual fuel engines fueled with three gaseous and biodiesel fuel combinations. Biofuels 2018, 9, 75–87. [Google Scholar] [CrossRef]

- Sombatwong, P.; Thaiyasuit, P.; Pianthong, K. Effect of pilot fuel quantity on the performance and emission of a dual producer gas–diesel engine. Energy Procedia 2013, 34, 218–227. [Google Scholar] [CrossRef] [Green Version]

- Elnajjar, E.; Hamdan, M.O.; Selim, M.Y. Experimental investigation of dual engine performance using variable LPG composition fuel. Renew. Energy 2013, 56, 110–116. [Google Scholar] [CrossRef]

- Hossain, N.; Hasan, M.H.; Mahlia, T.M.I.; Shamsuddin, A.H.; Silitonga, A.S. Feasibility of microalgae as feedstock for alternative fuel in Malaysia: A review. Energy Strategy Rev. 2020, 32, 100536. [Google Scholar] [CrossRef]

- Sahoo, B.B.; Sahoo, N.; Saha, U.K. Effect of H2: CO ratio in syngas on the performance of a dual fuel diesel engine operation. Appl. Therm. Eng. 2012, 49, 139–146. [Google Scholar] [CrossRef]

- Köse, H.; Ciniviz, M. An experimental investigation of effect on diesel engine performance and exhaust emissions of addition at dual fuel mode of hydrogen. Fuel Process. Technol. 2013, 114, 26–34. [Google Scholar] [CrossRef]

- Lata, D.; Misra, A.; Medhekar, S. Effect of hydrogen and LPG addition on the efficiency and emissions of a dual fuel diesel engine. Int. J. Hydrogen Energy 2012, 37, 6084–6096. [Google Scholar] [CrossRef]

- Lal, S.; Mohapatra, S. The effect of compression ratio on the performance and emission characteristics of a dual fuel diesel engine using biomass derived producer gas. Appl. Therm. Eng. 2017, 119, 63–72. [Google Scholar] [CrossRef]

- Zhou, J.; Cheung, C.S.; Leung, C.W. Combustion, performance and emissions of a diesel engine with H2, CH4 and H2–CH4 addition. Int. J. Hydrogen Energy 2014, 39, 4611–4621. [Google Scholar] [CrossRef]

- Roy, M.M.; Tomita, E.; Kawahara, N.; Harada, Y.; Sakane, A. Performance and emissions of a supercharged dual-fuel engine fueled by hydrogen-rich coke oven gas. Int. J. Hydrogen Energy 2009, 34, 9628–9638. [Google Scholar] [CrossRef]

- Yoon, S.H.; Lee, C.S. Experimental investigation on the combustion and exhaust emission characteristics of biogas–biodiesel dual-fuel combustion in a CI engine. Fuel Process. Technol. 2011, 92, 992–1000. [Google Scholar] [CrossRef]

- Ramadhas, A.; Jayaraj, S.; Muraleedharan, C. Dual fuel mode operation in diesel engines using renewable fuels: Rubber seed oil and coir-pith producer gas. Renew. Energy 2008, 33, 2077–2083. [Google Scholar] [CrossRef]

- Wategave, S.; Banapurmath, N.; Sawant, M.; Soudagar, M.E.M.; Mujtaba, M.; Afzal, A.; Basha, J.S.; Alazwari, M.A.; Safaei, M.R.; Elfasakhany, A. Clean combustion and emissions strategy using reactivity controlled compression ignition (RCCI) mode engine powered with CNG-Karanja biodiesel. J. Taiwan Inst. Chem. Eng. 2021, 124, 116–131. [Google Scholar] [CrossRef]

- El-Seesy, A.I.; Hassan, H.; Ibraheem, L.; He, Z.; Soudagar, M.E.M. Combustion, emission, and phase stability features of a diesel engine fueled by Jatropha/ethanol blends and n-butanol as co-solvent. Int. J. Green Energy 2020, 17, 793–804. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Afzal, A.; Safaei, M.R.; Manokar, A.M.; EL-Seesy, A.I.; Mujtaba, M.; Samuel, O.D.; Badruddin, I.A.; Ahmed, W.; Shahapurkar, K. Investigation on the effect of cottonseed oil blended with different percentages of octanol and suspended MWCNT nanoparticles on diesel engine characteristics. J. Therm. Anal. Calorim. 2020, 1–18. [Google Scholar] [CrossRef]

- Mujtaba, M.; Masjuki, H.; Kalam, M.; Noor, F.; Farooq, M.; Ong, H.C.; Gul, M.; Soudagar, M.E.M.; Bashir, S.; Rizwanul Fattah, I. Effect of Additivized Biodiesel Blends on Diesel Engine Performance, Emission, Tribological Characteristics, and Lubricant Tribology. Energies 2020, 13, 3375. [Google Scholar] [CrossRef]

- Usman, M.; Hussain, H.; Riaz, F.; Irshad, M.; Bashir, R.; Haris Shah, M.; Ahmad Zafar, A.; Bashir, U.; Kalam, M.A.; Mujtaba, M.A.; et al. Artificial Neural Network Led Optimization of Oxyhydrogen Hybridized Diesel Operated Engine. Sustainability 2021, 13, 9373. [Google Scholar] [CrossRef]

- Malik, A.; Mohapatra, S. Biomass-based gasifiers for internal combustion (IC) engines—A review. Sadhana 2013, 38, 461–476. [Google Scholar] [CrossRef] [Green Version]

- Das, D.; Dash, S.; Ghosal, M. Performance evaluation of a diesel engine by using producer gas from some under-utilized biomass on dual-fuel mode of diesel cum producer gas. J. Cent. South Univ. 2012, 19, 1583–1589. [Google Scholar] [CrossRef]

- Nataraj, K.; Banapurmath, N.; Manavendra, G.; Yaliwal, V. Development of cooling and cleaning systems for enhanced gas quality for 3.7 kW gasifier-engine integrated system. Int. J. Eng. Sci. Technol. 2016, 8, 43–56. [Google Scholar] [CrossRef] [Green Version]

- Asadullah, M. Barriers of commercial power generation using biomass gasification gas: A review. Renew. Sustain. Energy Rev. 2014, 29, 201–215. [Google Scholar] [CrossRef]

- Shelke, G.N.; Mahanta, P. Feasibility study on utilization of biomass briquette in a conventional downdraft gasifier. Int. Energy J. 2016, 15, 157–166. [Google Scholar]

- Yaliwal, V.; Banapurmath, N.; Tewari, P. Performance, combustion and emission characteristics of a single-cylinder, four-stroke, direct injection diesel engine operated on a dual-fuel mode using Honge oil methyl ester and producer gas derived from biomass feedstock of different origin. Int. J. Sustain. Eng. 2014, 7, 253–268. [Google Scholar] [CrossRef]

- Akkoli, K.; Gangavati, P.; Banapurmath, N.; Yaliwal, V. Comparative study of various biofuel combinations derived from agricultural residues on the performance and emissions of CI engine. Int. J. Sustain. Eng. 2020, 13, 140–150. [Google Scholar] [CrossRef]

- Akkoli, K.; Banapurmath, N.; Shivashimpi, M.; Soudagar, M.E.M.; Badruddin, I.A.; Alazwari, M.A.; Yaliwal, V.; Mujtaba, M.; Akram, N.; Goodarzi, M. Effect of injection parameters and producer gas derived from redgram stalk on the performance and emission characteristics of a diesel engine. Alex. Eng. J. 2021, 60, 3133–3142. [Google Scholar] [CrossRef]

- Akkoli, K.; Gangavati, P.; Banapurmath, N. Effect of Cooling Cleaning System on the Performance and Emission Characteristics of Producer Gas Operated Dual-Fuel CI Engine. Int. J. Appl. Eng. Res. 2019, 14, 687–693. [Google Scholar]

- Soudagar, M.E.M.; Nik-Ghazali, N.-N.; Kalam, M.; Badruddin, I.A.; Banapurmath, N.; Ali, M.A.B.; Kamangar, S.; Cho, H.M.; Akram, N. An investigation on the influence of aluminium oxide nano-additive and honge oil methyl ester on engine performance, combustion and emission characteristics. Renew. Energy 2020, 146, 2291–2307. [Google Scholar] [CrossRef]

- Afzal, A.; Soudagar, M.E.M.; Belhocine, A.; Kareemullah, M.; Hossain, N.; Alshahrani, S.; Saleel, C.; Subbiah, R.; Qureshi, F.; Mujtaba, M. Thermal Performance of Compression Ignition Engine Using High Content Biodiesels: A Comparative Study with Diesel Fuel. Sustainability 2021, 13, 7688. [Google Scholar] [CrossRef]

- Aneeque, M.; Alshahrani, S.; Kareemullah, M.; Afzal, A.; Saleel, C.A.; Soudagar, M.E.M.; Hossain, N.; Subbiah, R.; Ahmed, M.H. The Combined Effect of Alcohols and Calophyllum inophyllum Biodiesel Using Response Surface Methodology Optimization. Sustainability 2021, 13, 7345. [Google Scholar] [CrossRef]

- Teja, K.M.V.R.; Prasad, P.I.; Reddy, K.V.K.; Banapurmath, N.R.; Soudagar, M.E.M.; Khan, T.M.Y.; Badruddin, I.A. Influence of Combustion Chamber Shapes and Nozzle Geometry on Performance, Emission, and Combustion Characteristics of CRDI Engine Powered with Biodiesel Blends. Sustainability 2021, 13, 9613. [Google Scholar] [CrossRef]

- Khan, H.; Soudagar, M.E.M.; Kumar, R.H.; Safaei, M.R.; Farooq, M.; Khidmatgar, A.; Banapurmath, N.R.; Farade, R.A.; Abbas, M.M.; Afzal, A. Effect of nano-graphene oxide and n-butanol fuel additives blended with diesel—Nigella sativa biodiesel fuel emulsion on diesel engine characteristics. Symmetry 2020, 12, 961. [Google Scholar] [CrossRef]

- Barreta, L.G.; Lacava, P.T.; Carinhana, D. Study of the influence of biodiesel in soot emissions of diesel laminar diffusion flames. J. Braz. Chem. Soc. 2017, 28, 1384–1388. [Google Scholar]

- Banapurmath, N.R.; Soudagar, M.E.; Ganachari, S.V.; Kulkarni, P.S.; Kumar, N.K.; Yaliwal, V. An exhaustive study on the use of Jatropha based biodiesel for modern diesel engine applications. In Biodiesel Fuels Based on Edible and Nonedible Feedstocks, Wastes, and Algae; CRC Press: Boca Raton, FL, USA, 2021; pp. 541–559. [Google Scholar]

- Krishnakumar, S.; Khan, T.M.Y.; Rajashekhar, C.R.; Soudagar, M.E.; Afzal, A.; Elfasakhany, A. Influence of Graphene Nano Particles and Antioxidants with Waste Cooking Oil Biodiesel and Diesel Blends on Engine Performance and Emissions. Energies 2021, 14, 4306. [Google Scholar] [CrossRef]

- Venu, H.; Raju, V.D.; Lingesan, S.; Soudagar, M.E.M. Influence of Al2O3nano additives in ternary fuel (diesel-biodiesel-ethanol) blends operated in a single cylinder diesel engine: Performance, Combustion and Emission Characteristics. Energy 2021, 215, 119091. [Google Scholar] [CrossRef]

- Mujtaba, M.; Cho, H.M.; Masjuki, H.; Kalam, M.; Farooq, M.; Soudagar, M.E.M.; Gul, M.; Ahmed, W.; Afzal, A.; Bashir, S. Effect of alcoholic and nano-particles additives on tribological properties of diesel–palm–sesame–biodiesel blends. Energy Rep. 2021, 7, 1162–1171. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Banapurmath, N.R.; Afzal, A.; Hossain, N.; Abbas, M.M.; Haniffa, M.A.C.M.; Naik, B.; Ahmed, W.; Nizamuddin, S.; Mubarak, N.M. Study of diesel engine characteristics by adding nanosized zinc oxide and diethyl ether additives in Mahua biodiesel–diesel fuel blend. Sci. Rep. 2020, 10, 15326. [Google Scholar] [CrossRef] [PubMed]

- Jeshvaghani, H.S.; Fallahipanah, M.; Gahruei, M.H.; Chen, L. Performance analysis of Diesel engines fueled by biodiesel blends via thermodynamic simulation of an air-standard Diesel cycle. Int. J. Environ. Sci. Technol. 2014, 11, 139–148. [Google Scholar] [CrossRef] [Green Version]

- Patil, S. Thermodynamic modelling for performance analysis of compression ignition engine fuelled with biodiesel and its blends with diesel. Int. J. Recent Technol. Eng. 2013, 1, 134–138. [Google Scholar]

- Žvar Baškovič, U.; Vihar, R.; Seljak, T.; Katrašnik, T. Feasibility analysis of 100% tire pyrolysis oil in a common rail Diesel engine. Energy 2017, 137, 980–990. [Google Scholar] [CrossRef] [Green Version]

- Vélez Godiño, J.A.; Torres García, M.; Jiménez-Espadafor Aguilar, F.J. Experimental analysis of late direct injection combustion mode in a compression-ignition engine fuelled with biodiesel/diesel blends. Energy 2021, 239, 121895. [Google Scholar] [CrossRef]

- Pastor, J.V.; Olmeda, P.; Martín, J.; Lewiski, F. Methodology for Optical Engine Characterization by Means of the Combination of Experimental and Modeling Techniques. Appl. Sci. 2018, 8, 2571. [Google Scholar] [CrossRef] [Green Version]

| Sl. No. | Properties | Conventional Fossil Fuel | HOME Biodiesel |

|---|---|---|---|

| 1 | Viscosity at 40 °C | 4.6 (Low) (cst) | 5.59 (cst) |

| 2 | Flash point | 56 °C | 162 °C |

| 3 | HV (higher) | 44.5 MJ/kg | 35.5 MJ/kg |

| 4 | Specific gravity | 0.829 | 0.869 |

| 5 | Density | 829 kg/m3 | 869 kg/m3 |

| 6 | Type | Fuel | Biodiesel |

| Parameters | Composition Value |

|---|---|

| Moisture | 4.22% wt. |

| Volatile matter | 82.82% wt. |

| Fixed carbon | 8.92% wt. |

| Ash | 4.036% wt. |

| C | 49.24% mass |

| H | 5.93% mass |

| N | 3.779% mass |

| O | 30.13% mass |

| HV (higher) | 16.75 MJ/kg |

| Density | 502.0 kg/m3 |

| Sl. No. | Engine | Gasifier | ||

|---|---|---|---|---|

| Parameters | Specifications | Parameters | Specifications | |

| 1 | Engine type | Kirloskar DI, single-cylinder, 4-stroke, diesel engine | Supplier | Harith Avani Technologies Pvt. Ltd. Bengaluru |

| 2 | IOP | 205–240 bar | Power and gas flow | 62,735 kJ/h and 15 Nm3/h |

| 3 | Power | 3.7 kW | Mean gas HV | 19 MJ/kg |

| 4 | Bore | 87.5 mm | Biomass consumption | 10 kg/h |

| 5 | Stroke | 110 mm | Hopper capacity | 40 kg |

| 6 | CR | 17.5:1 | Efficiency | 75–80% |

| Carbon Content (C) | Honge Oilwt. (%) |

|---|---|

| 16:0 | 11.65 |

| 18:0 | 7.50 |

| 18:1 | 43.79 |

| 18:2 | 14.64 |

| 20:0 | 1.35 |

| 20:1 | 9.88 |

| 22:0 | 4.45 |

| 24:0 | 2.21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akkoli, K.M.; Banapurmath, N.R.; G, S.; Soudagar, M.E.M.; Khan, T.M.Y.; Baig, M.A.A.; Mujtaba, M.A.; Hossain, N.; Shahapurkar, K.; Elfasakhany, A.; et al. Effect of Producer Gas from Redgram Stalk and Combustion Chamber Types on the Emission and Performance Characteristics of Diesel Engine. Energies 2021, 14, 5879. https://doi.org/10.3390/en14185879

Akkoli KM, Banapurmath NR, G S, Soudagar MEM, Khan TMY, Baig MAA, Mujtaba MA, Hossain N, Shahapurkar K, Elfasakhany A, et al. Effect of Producer Gas from Redgram Stalk and Combustion Chamber Types on the Emission and Performance Characteristics of Diesel Engine. Energies. 2021; 14(18):5879. https://doi.org/10.3390/en14185879

Chicago/Turabian StyleAkkoli, K. M., N. R. Banapurmath, Suresh G, Manzoore Elahi M. Soudagar, T. M. Yunus Khan, Maughal Ahmed Ali Baig, M. A. Mujtaba, Nazia Hossain, Kiran Shahapurkar, Ashraf Elfasakhany, and et al. 2021. "Effect of Producer Gas from Redgram Stalk and Combustion Chamber Types on the Emission and Performance Characteristics of Diesel Engine" Energies 14, no. 18: 5879. https://doi.org/10.3390/en14185879

APA StyleAkkoli, K. M., Banapurmath, N. R., G, S., Soudagar, M. E. M., Khan, T. M. Y., Baig, M. A. A., Mujtaba, M. A., Hossain, N., Shahapurkar, K., Elfasakhany, A., Alsehli, M., Yaliwal, V. S., & Goudadi, S. A. (2021). Effect of Producer Gas from Redgram Stalk and Combustion Chamber Types on the Emission and Performance Characteristics of Diesel Engine. Energies, 14(18), 5879. https://doi.org/10.3390/en14185879