Abstract

This paper covers the hydrogen technologies regarding the role of hydrogen as an energy carrier and the possibilities of its production and use. It is initially presented the modalities and the efficiency of the current technologies of obtaining hydrogen, detailing its obtaining by the electrolysis of the water, the electrochemical efficiency and the specific consumption of electricity as well as the thermodynamics of the electrochemical processes. The following paragraph addresses hydrogen conversion possibilities. This paragraph details the thermodynamic analysis of the fuel cell, the external characteristic of the fuel cell and the types of fuel cell. The last paragraph addresses the possibilities of using the fuel cells for electrical vehicles and cogeneration systems for buildings.In this context, the traditional transport and distribution grid will have to adapt to the new realities as they will need to actively participate in the internal energy market by the transformation of the traditional electricity grid in energy flow, from unidirectional to bidirectional through the production of hydrogen offering the same facilities as the gas grid.

1. Introduction

Hydrogen is the simplest element. A hydrogen atom consists of only one proton and one electron. It is also the most abundant element in the universe. Hydrogen is colorless, odorless, tasteless, non-toxic, and non-poisonous and it is a gas under atmospheric conditions. Despite its simplicity and abundance on Earth it is always combined with other elements. Water, for example, is a combination of hydrogen and oxygen (H2O). Hydrogen is also found in many organic compounds, especially hydrocarbons, which make up many fuels, such as gasoline, natural gas, methanol and propane.

Hydrogen is the lightest element with an atomic mass of 1.0. Liquid hydrogen has a density of 0.07 g per cubic centimeter compared to water having a density of 1.0 g/cc and gasoline approximately 0.75 g/cc. It has the 142 kJ/g being the highest energy content per unit weight of any known fuel. These values of hydrogen and hydrogen technologies have both advantages and disadvantages. The advantage is that it stores about 2.6 times more energy per unit of mass compared to gasoline, and the disadvantage is that it needs about 4 times more volume for the same amount of energy.

Hydrogen is not an energy source but a chemical energy carrier, also known as an energy vector. As a vector, it is used to convert, store, and then release energy. When used, hydrogen does not produce greenhouse gases, particulates, SOx or ground-level ozone.

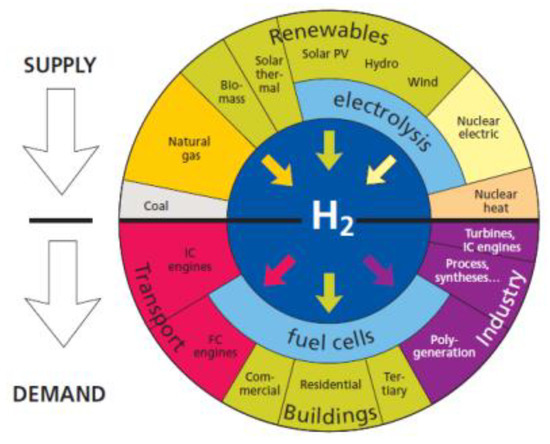

Strategic vision of the U.S. Department of Energy (DOE) in clean energy technologies and advance economic competitiveness and scientific innovation looks like the hydrogen offer a broad range of benefits for the environment, of which I quote “including reduced greenhouse gas emissions, reduced oil consumption, expanded use of renewable power (through use of hydrogen for energy storage and transmission), highly efficient energy conversion, fuel flexibility (use of diverse, domestic fuels, including clean and renewable fuels), reduced air pollution, and highly reliable grid support”. Figure 1 illustrates in the vision of the European Commission through Directorates-General for Energy and Transport [1] the role of hydrogen as an energy carrier between primary energy source, energy conversion and its applications.

Figure 1.

The role of hydrogen [1].

Ambitious renewable energy targets have been agreed in the EU for 2030, with 32% of the entire EU energy demand and more than 50% of the electricity demand to be from renewable energy sources. Developing renewable energy sources to such a level, thus the level of intermittent generation, will require greater level of balancing services. In this context, hydrogen could be vital in order to balance and complement in a flexible way the renewable energy sources. Hydrogen could as well play its role in electricity storage (either long-term or seasonal). With declining costs for renewable electricity, in particular from solar PV and wind, interest is growing in electrolytic hydrogen and there have been several demonstration projects in recent years [2]. The European Commission published its hydrogen strategy for a climate-neutral Europe on the 8 July 2020 in which “it sets strategic objectives to install at least 6 GW of renewable hydrogen electrolysers by 2024 and at least 40 GW of renewable hydrogen electrolysers by 2030 and foresees industrial applications and mobility as the two main lead markets”. In accordance with Directive (EU) 2018/2001 the Member States must to ensure guarantees of origin and traceability of hydrogen, distinguishing renewable hydrogen from low-carbon hydrogen and carbonaceous hydrogen. The Member States can introduce a support framework, targeting the production of renewable or low-carbon hydrogen produced by water electrolysis. This is a stepping stone for the development of a hydrogen branch in EU, which is one of the energy sources the European Commission bets on to achieve net zero emissions by 2050.

A large number of scientific papers address the issue of hydrogen. They are published in journals dedicated to hydrogen, chemistry, energy and the environment and covers the all domain illustrated in Figure 1. This article synthesizes and updates the fundamental concepts in production and conversion of hydrogen being based on previous holistic reviews of hydrogen and fuel cells and addresses the beginners (master and PhD students) in theme approach hydrogen.

2. Hydrogen Production

2.1. Hydrogen Production of Coal and Natural Gas

Initially, hydrogen was produced using existing energy systems based on coal and natural gas.

The gasification of coal is one method that can produce hydrogen under next gasification reaction is:

CH0.8 + O2 + H2O → CO + CO2 + H2 + other species

The site of US energy “Ref. [3] describes the stages of hydrogen production from which I quote” Hydrogen is produced by first reacting coal with oxygen and steam under high pressures and temperatures to form synthesis gas, a mixture consisting primarily of carbon monoxide and hydrogen.

Through steam-methane reforming the natural gas (CH4) can be used to produce hydrogen. Steam-methane reforming reaction is:

CH4 + H2O (+ heat) → CO + 3H2

Steam reforming is endothermic—that is, heat must be supplied to the process for the reaction to proceed. The methane reacts with high-temperature steam (700–1000 °C) under 3–25 bar pressure in the presence of a catalyst to produce hydrogen.

“Subsequently, the carbon monoxide and steam are reacted using a catalyst to produce carbon dioxide and more hydrogen”, process called the “water-gas shift reaction”.

Water-gas shift reaction is:

CO + H2O → CO2 + H2 (small amount of heat)

“The second way to hydrogen production is partial oxidation. In partial oxidation, the methane and other hydrocarbons in natural gas react with a limited amount of oxygen (typically from air) that is not enough to completely oxidize the hydrocarbons to carbon dioxide and water”.

“Partial oxidation is an exothermic process, it gives off heat. The process is, typically, much faster than steam reforming but this process initially produces less hydrogen per unit of the input fuel than is obtained by steam reforming of the same fuel. The chemical reaction of partial oxidation is”:

CH4 + ½O2 → CO + 2H2 (+ heat)

Subsequently, the carbon monoxide and steam are reacted under “water-gas shift reaction”.

2.2. Biological Hydrogen Production

Biological hydrogen production processes offer a technique through which biomass can be utilized for the generation of the cleanest energy carrier for the use of mankind. Maximum H2 yield is found to be 7.1 mol H2/mol glucose.

Biological hydrogen production processes can be classified as follows [4]:

- Direct bio photolysis of water using green algae. The conversion of water to hydrogen by green algae may be represented by the following general reaction:2H2O + light energy → 2H2 + O2

- Indirect bio photolysis of water using blue-green algae (cyanobacteria). The reaction for hydrogen formation from water by cyanobacteria can be represented by following reactions:and12H2O + 6CO2 + light energy → C6H12O6 + 6O2C6H12O6 + 12H2O + lightenergy → 12H2 + 6CO2

- Photodecomposition of organic compounds by photosynthetic of purple non-sulfur bacteria the reaction is as follows:CH3COOH + 2H2O + lightenergy → 4H2 + 2CO2

- The anaerobic fermentation of carbohydrate (or organic wastes) produces intermediates, such as low molecular weight organic acids, which are then converted into hydrogen by photosynthetic bacteria in the second step in a photo-bioreactor. The overall reactions of the process can be represented as:Stage I. Dark fermentation:C6H12O6 + 2H2O → 2CH3COOH + 2CO2 + 4H2Stage II. Photo-fermentation (photosynthetic bacteria):2CH3COOH + 4H2O → 8H2 + 4CO2

2.3. Hydrogen Production by Water Splitting

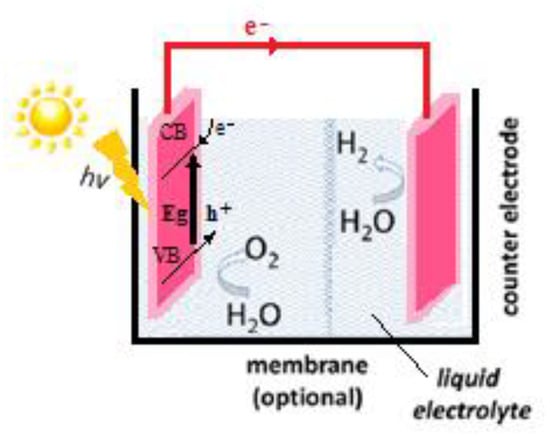

Water splitting by photo electrochemistry is one frontier research based on a photosynthetic cell and is intensively researched to split the water to the constituents by the effective conversion of solar into chemical energy.

Solar water splitting in photo catalytic and photo electrochemical systems use semiconductors, especially common metal oxides such as: titanium oxide-TiO2, tungsten trioxide-WO3, Bismuth vanadate-BiVO4, hematite iron oxide-α-Fe2O3, and cuprous oxide -Cu2O. The steps of a photo catalytic reaction involve the absorption of light by a semiconductor material followed by an electron transfer from the valence band (VB) to the conduction band (CB) creating a hole in the VB. The VB and CB are separated by some energy barrier called the band gap (Eg).

I quote from the paper [5] which showed that the photosynthetic cell contains “two redox systems in the electrolyte and upon light absorption and generation of electron and hole pairs in the semiconductor photo anode (photocathode), One redox system reacts with the photo generated holes (electrons) at the surface of the semiconductor photo anode (photocathode) and the other reacts with the electrons (holes) entering at the counter electrode. A schematic diagram of a water splitting device based on this principle is shown in Figure 2, where an n-type semiconductor electrode is used as the photo anode to generate oxygen and a suitable counter electrode is used to generate hydrogen”.

Figure 2.

Photolysis of water by using an n-type semiconductor electrode.

The overall reaction is the cleavage of water by sunlight [6]:

- Light absorption and generation of electron/hole pairs at the photo anode,

- Light-driven reaction at the photo anode,

- Light-driven reaction at the cathode,

- The overall reaction is:

“A chemically and optically stable semiconductor is preferred to have a band gap of 1.8–2.0 eV, (to overcome the over-potential associated with oxygen evolution), and to have the conduction and valence bands are positioned favorably so that they straddle the hydrogen and oxygen evolution potentials”.

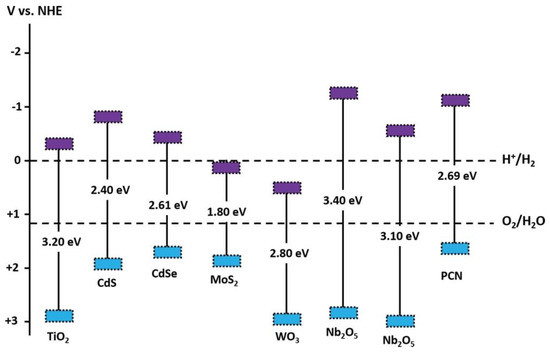

The energy difference between the oxygen evolution potential and the hydrogen evolution potential is 1.229 eV at 25 °C. Figure 3 shows the conduction and valence band positions of several semiconductors in contact with aqueous electrolyte at pH 1.

Figure 3.

CB and VB positions of several semiconductors [6].

2.4. Water Electrolysis

Water can dissociate into molecular hydrogen (H2) and oxygen (O2) by applying an electrical energy in an electrolyte solution of an electrochemical cell. Result of electrolysis of one mole of water produces one mole of hydrogen and 0.5 moles of oxygen. Chemical reactions that occur at the two electrodes are:

Anode (+): 2H2O → O2 + 4H+ + 4e− Uox = 1.23 V

Cathode (−): 4H+ + 4e → 2H2 Ured = 0 V

2H2O → 2H2 + O2 U = −1.23 V

At room temperature the splitting of water is very small, approximately 7–10 moles/L because pure water is a very weak conductor of electricity. An electrolyte in water must therefore be added to provide the ion flow, which can flow through the solution, thus completing the electrical circuit. The electrolyte must be soluble in water. Acid or base are used to improve the conductivity. Within an alkaline electrolyzer, KOH, NaOH and H2SO4 are used with water, splitting into positive and negative ions that conduct electricity.

2.4.1. Thermodynamics of Electrochemical Processes

In the chemical processes the modification of the internal energy represents the variation of energy due to the breaking or forming of the chemical bonds and the formation of new molecules. The enthalpy of the system contains both the component of the internal energy due to the changes of the molecular interaction forces (intramolecular forces) as well as the mechanical work of expansion according to the relation:

Therefore, the enthalpy variation represents the energy required to perform the chemical reaction. In any chemical reaction, reactants are transformed into reaction products. The reaction enthalpy represents the heat of reaction determined at constant pressure (in which the symbol ° shows the standard conditions, 25 °C and 1 atm). Enthalpy (H) is a form of energy stored in the system. This stock cannot be measured. Only the variation of the energy quantity of the system is measured by the heat exchanged with the environment, at constant pressure, .

The variation of enthalpy , in a chemical reaction is equal to the difference between the sum of the enthalpies of the reaction products and the sum of the enthalpies of the reactants:

In which the term -enthalpy, represents the heat released or consumed during the reaction. When the chemical bonds are formed, heat is released, and when the chemical bonds are broken, heat is consumed.

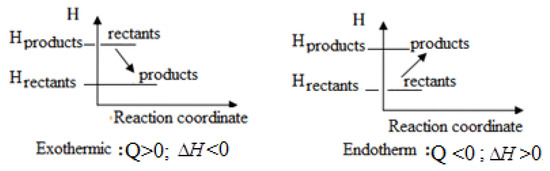

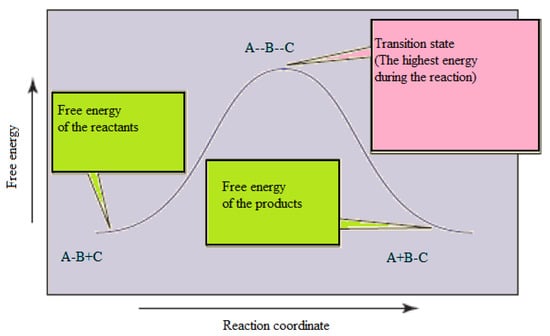

If the bonds formed during the chemical reaction are stronger than those that break, it will be negative, and the reaction is called exothermic (the system gives off the heat of the environment Q > 0). If the bonds that are formed are weaker than those that break, then it will be positive, and the reaction is called the endotherm Q < 0. (The sign convention for the enthalpy variation and the reaction heat is Q = −) The graphical representation of these statements is shown in Figure 4.

Figure 4.

Types of reactions [7].

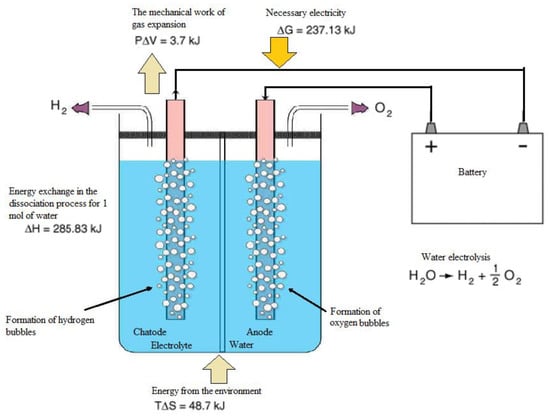

As the reactants are transformed into products, the reaction passes through a state of maximum energy, called the transition state, whose structure is intermediate between that of the reactants and that of the products. To illustrate in Figure 5, a form reaction is considered:

Figure 5.

Energy transition [7].

Reactants Reaction products

Figure 5 and Figure 6 shows a difference between the free energy of the reactants and that of the transition state called free activation energy, ΔG‡ which constitutes the energy barrier of the reaction. The lower the free activation energy, the faster the reaction proceeds. We note that ΔG° is related to the equilibrium constant of the reaction, while ΔG‡ is related to the reaction rate.

Figure 6.

Types of reactions [7].

In the transition state, some bonds are broken, and new ones are formed. Thermodynamics expresses the equilibrium concentrations of the reactants and products by the equilibrium constant . Concentrations are expressed in moles/Liter and are measured at thermodynamic equilibrium. The relative concentrations of reactants and products at equilibrium depend on their stability: the more stable the compounds, the higher their equilibrium concentration. That is, if the products are more stable (have less free energy) than the reactants, they will be in a higher concentration at equilibrium than the reactants and > 1. Conversely, if the reactants are more stable, they will be in higher concentration at equilibrium and will be smaller than 1.

The difference between the free energy of the products and that of the reactants (under standard conditions) is called the Gibbs free energy change called free enthalpy (). In [8] it is shown that if the products are more stable than the reactants it will be negative and the reaction is exergonic, i.e., it releases more energy than it consumes (Figure 6a,b). If the reactants are more stable than the products it will be positive and the reaction is endergonic, i.e., it consumes more energy than it releases (Figure 6c,d). The fact that we know if a reaction is exergonic or endergonic, this does not tell us how quickly the reaction is carried out. This is how chemical kinetics, the branch of chemistry that studies the speeds of chemical reactions, is concerned.

The fact that reactants or products are favored at equilibrium is indicated by and, which are linked by the equation:

where: is the gas constant ( = 8.31 J/mol°K), and —temperature.

The Gibbs free energy change can be expressed by the enthalpy variation given by the relationship:

The term —entropy, represents the degree of disorder of the system (a measure of the freedom of movement of the system). For example, “in a reaction in which two molecules react and form a single molecule, the entropy of the product will be lower than that of the reactants (because two molecules can move in ways that are not possible when they are joined), and will be negative. In a reaction in which one molecule breaks with the formation of two smaller molecules the entropy increases, and will be positive” is shown in [8].

The efficiency in the electrochemical reaction is expressed by the variation of the Gibbs free energy () and the variation of the enthalpy ():

In order to decompose one mole of water into hydrogen and oxygen, the energy that is required corresponds to the formation of one mole of water. The lowest part of reaction that must be applied as electrical energy is the reaction energy, that is free, (change in Gibbs free energy) defined by Equation (8).

2.4.2. Electrolysis Law

The law of electrolysis is stated as follows: The mass of the substance deposited in the time unit at one of the electrolytic bath electrodes passed through the conduction current is equal to the product between the intensity of the electric current I and the electrochemical equivalent A/Fnv.

in which:

dm/dt = I(A/Fnv)

m—is the amount of material deposited at the cathode (in grams),

A—is the atomic mass of the material,

nv—is valence,

F—represents Faraday constant given by the relation , having the value of 96,500 coulombs, (—Avogadro’s number, electron charge C),

t—is the time of electrolysis.

It follows that the ratio of the total electrical charge required for the deposition to the mass of the deposited substance is always constant for an ion of a given valence, regardless of the element

dq/dm = nvF/A

The physical significance of constant F known as Faraday’s constant, or Faraday’s number can be deduced from the relation:

q = I t = m nv F/A

If m = A/nv then Faraday’s constant is numerically equal to the amount of electricity that electrolyte deposits a gram equivalent of any chemical element. Faraday’s constant determined experimentally has the value: F ≈ 96,500 Coulombi/equivalent.gram. So, a Faraday represents the amount of electricity needed to convert to electrolysis a gram-equivalent of a substance.

2.4.3. Thermodynamics of Water Electrolysis

A complete analysis of the electrolysis process can be performed through the use of thermodynamic potentials, as principle I of thermodynamic understands the temperature conditions of 25 °C and pressure of 1 atm. From the thermodynamic tables we have the following properties of the substances (Table 1).

Table 1.

Transformations in the electrolysis process.

Where:

ΔH = HH2 + HO2 − HH2O

ΔS = SH2 + SO2 − SH2O

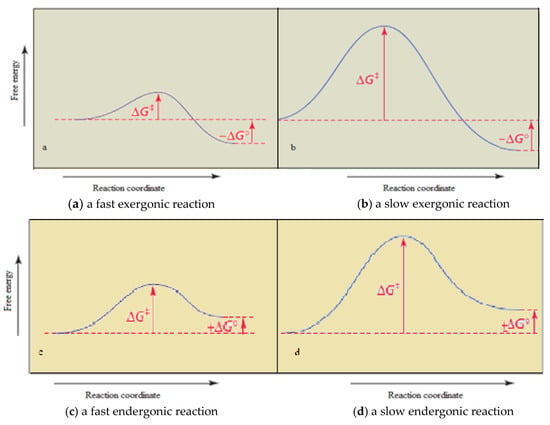

The Figure 7 shows the main principle for electrolysis cell and energy balance. Applying high voltage to an electrochemical cell immersed in water, hydrogen and oxygen gas bubbles develop at cathode (negative electrode) and anode (positive electrode).

Figure 7.

Energy balance in water electrolysis [9].

The enthalpy variation represents the energy requirement to perform the electrolysis of the water. This energy requirement must not be put on account of the electrical energy with which the electrolysis cell must be supplied. In the process of electrolysis, energy is provided by dissociation and mechanical work is performed by expanding the gases produced up to normal pressure

The variation of the internal energy due to the breaking of the chemical bonds of the water is:

The entropy = 48.7 kJ, increases in the electrolysis process and the amount of heat released from the process is released constituting the contribution to the heat from the environment. Gibbs free energy is the one that specifies the amount of energy in other forms that must be introduced into the system in order for electrolysis of the water to take place. This energy is determined by the relation:

If the voltage losses on the conductors are neglected, the supply voltage of the electrolysis cell is determined from the relation:

In the above hypothesis, the supply voltage of the electrolysis cell if it operates adiabatically is determined from the relation:

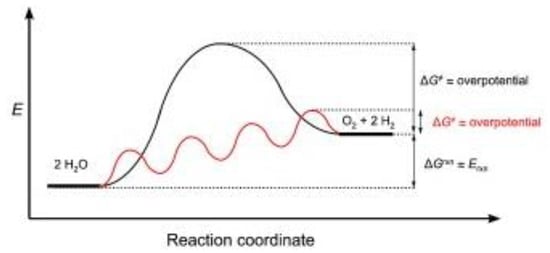

Semi-reactions for water electrolysis and energy diagram for non-catalytic (black) and catalytic water oxidation (red PyR catalyst = pyridine) is shown in Figure 8.

Figure 8.

Diagram for non-catalytic and catalytic water oxidation [7].

2.4.4. Electrochemical Efficiency and Specific Electricity Consumption

The efficiency of an electrochemical process and the final cost of the obtained products are given by the degree of transformation of a reactant into the desired product as well as the amount of energy used in that transformation. From an economic point of view it is necessary to know which electrochemical process is more cost-effective in obtaining the same product from the point of view of mass and energy conversion.

Water is isolated in the electrolyzer to produce hydrogen and oxygen by the use of electrical energy based on Faraday’s electrolysis law. In the instance of electrolysis, in the paper [9] I showed that the voltage efficiency can be defined as the ratio between the minimum voltages at the electrolyzerand the practical voltage applied to the system with the relation:

The efficiency of the current can be defined as the ratio between practical mass and theoretical mass obtained for a useful electrolysis product:

This efficiency is also known as the current efficiency, since the ratio between the used current to obtain the useful product and the total current passing in the circuit. The electrolyzer electrical efficiency is known as the product of the current efficiency and voltage efficiency which is obtained by combining the two relationships:

The global size that characterizes the process is the specific mass consumption of energy CSE defined as the ratio between the electricity used and the mass m obtained from the electrolysis according to the relation:

where m is the practical mass of product obtained.

2.5. Hydrogen Efficiency of Current Technologies Production

The theoretical consumption of energy for producing 1 m3 of H2 is 2.9 kWh/m3 H2. In order for gas to evolve, the voltages need 1.65–1.7 V. As a result, the industry used voltage of about 1.8–2.6 V. Therefore, the practical energy consumption is almost 1.5 to 2.2 bigger than the theoretical energy consumption. Taking into account the density of hydrogen (0.083 kg/m3) and that specific volume of hydrogen gas is 11.9 m3/kg it results that one kg of hydrogen has the equivalent of a 33 kWh of energy. The efficiency of producing one kg of hydrogen by gasification of biomass, coal, and natural gas reforming and water electrolysis is shown in Table 2.

Table 2.

The efficiency of technologies [9].

The efficiency between 1 kg of hydrogen and it’s energy equivalent of 33 kWh is 66.8%, leading to an electricity consumption of 50 kWh. The amount of hydrogen produced (in mol) in electrolyzer with number of cells in 1 h, according to Faraday’s law, can be given by relation:

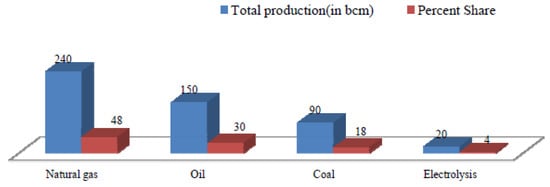

Current world hydrogen production is approximately 500 bcm (billion cubic meters) or 44.5 million tons per annum [10], representing around 2% of primary energy and currently technology conversion is shown in Figure 9.

Figure 9.

Global hydrogen productions in billion cubic meters.

3. Hydrogen Conversion

3.1. Direct Combustion

The portal [11] presents the main uses of hydrogen and its combustion characteristics from which I quote. The auto-ignition temperature of a substance represents the lowest temperature that when reached, it will spontaneously ignite, without needing the presence of a flame or spark. The temperature of auto-ignition for hydrogen is over 540 °C, which is higher than the temperature of auto-ignition for gasoline vapors, which is 232 °C. The flammability of hydrogen ranges from 4% and 75% in air and is comparable to other fuels. A 29% hydrogen-to-air volume ratio is the optimal combustion condition. “Hydrogen burns with a pale blue flame making it nearly invisible in daylight. However at night, it can be seen under impurities, for example sodium from ocean air or other burning materials. Hydrogen flames radiate little infrared (IR) heat, but substantial ultraviolet (UV) radiation. Liquid hydrogen is stored at −253 °C under pressures up to 150 psi and has different characteristics and different potential hazards than gaseous hydrogen. The volume ratio of liquid to gas is approximately 1:850. Hydrogen undergoes a rapid phase change from liquid to gas. If hydrogen is spilt on ambient-temperature surfaces, the liquid hydrogen will rapidly boil with its vapors rapidly expanding by850 times in volume as it heats to room temperature. If large quantities of hydrogen are spilt, they will displace the oxygen in the air as hydrogen will act as an asphyxiator”.

Based on liquid hydrogen from the 1970s, NASA used special engines to propel spacecraft and other rockets into orbit. When hydrogen is burned in the air of the main product it is water. The key advantage of hydrogen burning is that carbon dioxide (CO2) is not produced by the burning of hydrogen. Burning pure hydrogen does not cause pollution, which is why it is used in the energy field. Other combustion applications are under development, including new combustion equipment, specifically designed for hydrogen in turbines and engines. Hydrogen internal combustion vehicles are now in the demonstration phase, and combustion of hydrogen-based mixtures is being tested [12,13,14,15,16].The disadvantage of internal combustion is that the combustion temperature is very high and as a result it will form a large amount of nitrogen oxides (NOx), which is a pollutant but by using about twice as much air (with turbochargers or superchargers) for complete combustion, the formation of NOx is reduced to near zero. Unfortunately, this also reduces the power output to about half that of a similarly sized gasoline engine.

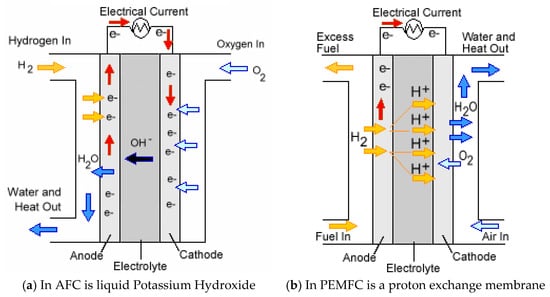

3.2. Fuel Cells

Fuel cells are a promising technology for use as a source of heat and electricity for buildings, and as a source of electricity for vehicles with electric propulsion engines.Into the fuel cell is combines hydrogen and oxygen to produce electricity, heat, and water. Fuel cells are often compared to batteries. Both convert the energy produced by a chemical reaction into usable electricity but compared to the batteries whose load is lost over time (battery discharge), the fuel cell will produce electricity, as long as fuel (hydrogen) is supplied. Schematically, a fuel cell may be represented as a system of two electrodes separated by a liquid or solid electrolyte (Figure 10).

Figure 10.

Electrolytes of an Alkaline and a PEM fuel cell [17].

Fuel cells convert the electrochemical energy of hydrogen and oxygen into electricity and heat, in the presence of a catalyst. Fuel cells are electrochemical generators of electricity that are characterized by continuous supply with reactants to the two electrodes. All fuel cells have a similar structure. They contain two electrodes separated by an electrolyte and which are connected in an external circuit.

The anode is fed with gaseous fuels (H2, CH3OH, N2H4, or hydrocarbons such as methane CH4, butane C4H10, propane C3H8), where their direct oxidation takes place, and the cathode is fed with an oxidant (for example oxygen in the air) being the place where it has instead of reducing oxygen. The electrodes must be permeable, so they have a porous structure.

3.2.1. Thermodynamic Analysis of the Fuel Cell

Electrochemical oxidation of hydrogen is carried out at the anode by a conductive material (e.g., platinum dispersed on activated carbon) constituting the negative pole of the cell so that for an acid electrolyte it resulted:

The electrochemical reduction of oxygen occurs at a catalytic cathode constituting the positive pole of the cell so that, for an acid electrolyte is obtained:

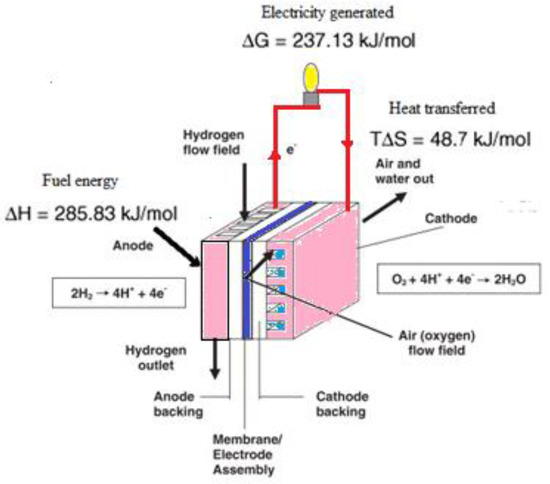

The catalytic functions of the electrodes are of major importance in the operation of the fuel cells because all electrochemical reactions take place on the surface of the catalyst layers as follows: the hydrogen electrode (anode) must ensure the adsorption of the hydrogen molecule, its activation and promote the reaction with the hydroxyl ion, and the oxygen electrode (cathode) should allow molecular oxygen adsorption and promote reaction with water. Basically, in a fuel cell, the chemical energy accumulated in hydrogen will be converted into electricity and thermal energy. At a gas pressure of 1 atm. and a temperature of 298 °K the energy values for the global reaction () are shown in Table 3 and Figure 11.

Table 3.

Transformations in the fuel cell.

Figure 11.

Energy balance of the fuel cell [18].

Where:

ΔH = HH2O − HH2 − HO2

ΔS = SH2O − SH2 − SO2

By combining hydrogen and oxygen atoms a volume contraction occurs and therefore a mechanical thing of compression:

The entropy decreases with = −48.7 kJ in the recombination process because the number of water molecules is smaller than the number of oxygen and hydrogen molecules that combine.

Since entropy decrease the amount of heat must be eliminated to the external environment. The amount of energy per mole of hydrogen that can be supplied as electricity is given by Gibbs free energy:

A negative Gibbs energy reaction has a favorable equilibrium constant greater than 1, which indicates that the products are more stable (have less free energy) than the reactants. The maximum non-expansion work that can be obtained in a process at constant temperature and pressure is given by the value of for the process, according to the relation:

Taking into account the physical significance of Faraday’s constant (), result:

Of this relation is can determine the electrochemical voltage:

where: —number of electrons changes and is Faraday’s constant

The maximum yield is expressed by the variation of the Gibbs free energy () and the variation of the enthalpy () in the electrochemical reaction with value:

This is a much higher efficiency than the thermodynamic efficiency of power plants or photovoltaic systems.

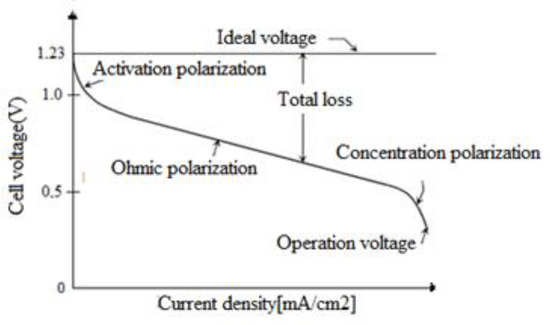

3.2.2. External Characteristics of the Fuel Cell

The external characteristic of any source of electricity is dependent on the voltage at the terminals of the charged current. Electricity is obtained from a fuel cell only when a reasonable current is discharged. As a result of the losses inside the cell, the actual voltage at the terminals is lower than the equilibrium voltage defined by the relation (33). There are three main sources of losses:

- (a)

- Activation polarization. Activation Loss- as I expressed it in the paper [19]-“is directly related to the velocities of the electrochemical reactions at the surface of the electrodes through which the transfer of electrons occurs. Activation loss occurs because the chemical process initially has not begun even when the necessary reversible voltage is supplied; the electrode reactions are at zero or inherently slow. Free energy of activation is an energy barrier to the reaction that has to be overcome by reactive speciesand it depends on the catalytic properties of the electrode materials. The relationship for calculating this loss is given by the Tafel equation”:where: α—is the electron transfer coefficient of the reaction to the electrode approached, —is the density of the transferred current and —is current density related to activation losses.

- (b)

- Ohmic polarization. The Ohmic polarization as I expressed it in the paper [19] “occurs due to the resistance to ion flux in the electrolyte and the electrical resistance of the electrode materials with relation”:Dominants are Ohm losses through electrolyte. For example, the area specific ionic resistance of alkaline fuel cell can be calculated by dividing the thickness of the electrolyte layer by the ionic conductivity of the alkaline solution (ionic conductivity as a function of temperature T and molarity M) or of the PEM fuel cell can be calculated by dividing the membrane thickness by the conductivity of the membrane.

- (c)

- Concentration polarization as I expressed it in the paper [19] “means the loss of voltage due to not being able to maintain the initial concentration of the reactants consumed at the reaction electrode. Concentration polarization can be attributed to some processes, for example slow diffusion of gas into the pores of the electrodes, the diffusion of reactants/products by electrolyte to/from the electrochemical reaction site. At high current densities, the slow transport of either reactants or products to and from the electrochemical reaction site is a pivotal contribution to concentration polarization. The relationship of this loss is given by the equation:where: —is defined as the current at which the fuel is consumed at a rate equal to the maximum supply flow”.

The voltage at the terminals of an electrochemical cell is obtained by subtracting the voltage losses from the ideal voltage of the cell given by the relation:

In these conditions the external characteristic of the fuel cell is shown in the Figure 12.

Figure 12.

V-I characteristic of a single PEM fuel cell [19].

The efficiency of a real fuel cell can be expressed according to the ratio of the operating voltage to the ideal voltage of the cell. The actual cell voltage is lower than the ideal cell voltage due to losses associated with cell polarization and ohmic loss.

From the relation (30) of the fuel cell efficiency can be written as a ratio between electricity and the enthalpy variation as follows:

From this relation it results that a fuel cell can be associated with a voltage efficiency defined by the relation:

A fuel cell can operate at different current densities, expressed in mA/cm2. The voltage corresponding to the cell then determines the efficiency of the fuel cell. As the current density decreases, the cell voltage increases, thus increasing the efficiency of the cell, but in order to obtain the required amount of power, the active area of the cell (electrode surface) must be increased. Thus, the design of the fuel cell for greater efficiency leads to an increase in the cost of capital, but the operating cost decreases. The “ideal efficiency” of a fuel cell defined by the relation (34) in combination with the relation shows that if the entropy is zero = 0, then the efficiency has the value 100% according to the relation:

In order to achieve the most efficient types of cells, the enthalpy, entropy and free energy Gibbs of the main fuels must be analyzed. Table 4 shows their values for the main substances under standard conditions of 1 atm and 25 °C. From this table it follows that any combination (chemical reaction) between the three substances, namely oxygen, hydrogen and carbon must be analyzed to determine the entropy value and implicitly the efficiency of the cell.

Table 4.

Standard values of enthalpy, entropy and free energy [20].

Also, from this table there is positive entropy for carbon monoxide and carbon dioxide which indicates that the term does not produce heat but can contribute to the production of electricity (analogy with heat pumps). The thermodynamic data of the different reactions under standard conditions are shown in Table 5.

Table 5.

Voltage and efficiency of chemical reactions [20].

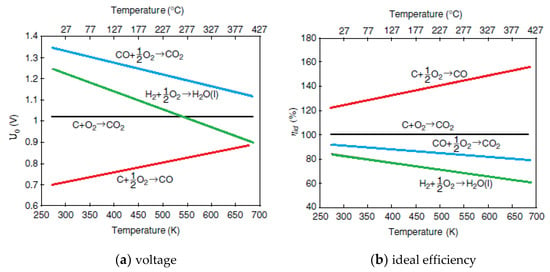

However, the actual voltage of the chemical reactions is influenced by the operating temperature in the sense of decreasing the value with temperature (Figure 13a) except for the carbon monoxide reaction where the voltage increases and implicitly the ideal efficiency (Figure 13b).

Figure 13.

Temperature dependence of voltage and combustion cell efficiency [20].

A brief description of all fuel cell types is given in Table 6, where fuel cells are classified primarily by the operating temperature range and kind of electrolyte they employ.

Table 6.

Fuel cell type’s comparison [9].

This classification determines the kind of electrochemical reactions that take place in the cell, the applications and power range. There are several types of fuel cells currently under development, each with its own advantages, limitations, and potential applications.

A classification can be made according to the operating temperature. There are thus low temperature and high temperature fuel cells, as:

- Low temperature fuel cells are AFC (Alkaline Fuel Cell), PEMFC (Polymer Electrolyte Fuel Cell), DMFC (Direct Methanol Fuel Cell) and PAFC (Phosphoric Acid Fuel Cell).

- High temperature fuel cells operate at 600–1000 ° C. These are of two types: MCFC (Molten Carbnate Fuel Cell) and SOFC (Solid Oxide Fuel Cell).

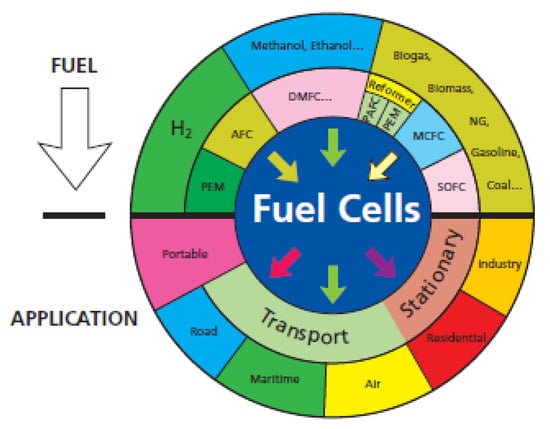

3.2.3. Applications of Fuel Cells

Figure 14 illustrates in the vision of the European Commission through Directorates-General for Energy and Transport [1] the role of fuel cell and its applications.Fuel cells are a promising technology for use as a source of heat and electricity for buildings, and as a source of electricity for vehicles with electric propulsion engines (type PEMFC). The best fuel cells operate on pure hydrogen. But fuels such as natural gas, methanol, or even gasoline can be reformed to produce the hydrogen needed for fuel cells.

Figure 14.

Types and applications of fuel cells [1].

In transport [1] Table 7 illustrates how, in a hydrogen-oriented economy, the introduction of hydrogen-fueled vehicles could reduce the average greenhouse gas emissions of the European car fleet, compared to the average level of 140 g/km of CO2 in 2008. The last column presents the corresponding amounts of CO2 emissions that could be avoided.

Table 7.

Average Greenhouse Gas Emissions [1].

In stationary use of fuel cell to cogeneration has made considerable advances over the last few years, particularly in the area of low-capacity applications [20]. Several nano, micro and mini combined heat and power systems are already available for single family homes and multiplex buildings. These units serve as “electricity producing heaters” and offer a highly efficient alternative to conventional heating systems. Fuel cell based micro-combined heat and power systems are widely known to have the capacity to contribute substantially to improving the overall energy system for residential level [21,22]. Most customers rely on centralized electricity that is traditionally produced and delivered to the grid. Fuel cell based micro-combined heat and power (mCHP) can help develop the traditional system in an innovative way, where customers both produce their own heat and part of their own electricity. For example in the Lower Danube University of Galati, based on a research project was development one micro CHP with fuel cell for boiler supply [23].

4. Conclusions

For the electricity market, reaching the European Unions’ ambitious green policy requires the application of innovative technologies and changes in the current electricity grids. It will also demand the participation of all the market actors. In this context, the traditional transport and distribution grid will have to adapt to the new realities as they will need to actively participate in the internal energy market.

An important point promoting by EU was make the transformation of the traditional electricity grid in energy flow from unidirectional (from the producer to the consumer) to bidirectional (promoting the prosumers in energy flow and smart metering) and bidirectional informational flow by smart grid.

However, the system is upgrade undergoing (through the production of hydrogen) offering the same facilities as the gas grid.

Comparing the traditional gas grid to the traditional electricity grid it will be noticed that the gas system has another component, storage, which allows gas stocks.

By producing and storing hydrogen the two networks become similar and compatible.

Like electricity, hydrogen is a carrier of energy but has the great advantage of storage.

Intermittent electricity generation from renewable sources can be stored seasonally and used when demand is high (for example, summer storage to winter use).

Short-term storage of hydrogen produced from renewable sources can linearize and flatten the peak consumption curve of day (balancing services).

Finally, “Just as energy is the basis of life itself and ideas the source of innovation, so is innovation the vital spark of all human change, improvement and progress”.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- European Commission. Directorate-General for Energy and Transport-Hydrogen Energy and Fuel Cells-A Vision of Our Future; Office for Official Publications of the European Communities: Luxembourg, 2003; ISBN 92-894-5589-6. [Google Scholar]

- The Fuel Cells and Hydrogen Joint Undertaking (FCH JU). Available online: https://www.fch.europa.eu/fchju-projects/h2020 (accessed on 2 August 2021).

- Hydrogen and Fuel Cell Technologies Office. Available online: https://www.energy.gov/eere/fuelcells/hydrogen-production-natural-gas-reforming (accessed on 2 August 2021).

- Das, D.; Veziroglu, T.N. Advances in biological hydrogen production processes. Int. J. Hydrog. Energy 2008, 33, 6046–6057. [Google Scholar] [CrossRef]

- Ampelli, C.; Centi, G.; Passalacqua, R.; Perathoner, S. Electrolyte-less design of PEC cells for solar fuels: Prospects and openissues in the development of cells and related catalytic electrodes. Catal. Today 2016, 259, 246–258. [Google Scholar] [CrossRef]

- Wijayantha, K.G.U.; Auty, D.H. Twin Cell Technology for Hydrogen Generation. In Encyclopedia of Materials: Science and Technology, 2nd ed.; Elsevier: Oxford, UK, 2005; pp. 1–5. [Google Scholar]

- Adriana Urdă- Curs 5. Echilibrul Chimic și Viteza de Reacție în Procesele Chimice- University courses and teaching materials -Procese Catalitice în Protecţia Mediului; Editura Universităţii din Bucureşti: Bucharest, Romania, 2005; 164p. (In Romanian) [Google Scholar]

- Khan Academy. Available online: https://www.khanacademy.org/science/biology/energy-and-enzymes/free-energy-tutorial/a/gibbs-free-energy (accessed on 2 August 2021).

- Badea, N.; Badea, G.V. Surseregenerabile de Energie; Editura Fundaţiei Universitare “Dunărea de Jos” din Galaţi: Galati, Romania, 2017; 360p, ISBN 978-973-627-594-4. [Google Scholar]

- Dupont, V. Steam reforming of sunflower oil for hydrogen gas production/oxidación catalítica del aceite de girasol en la producción del gas hidrógeno/reformage à la vapeur de l’huile de tournesol dans la production de gaz hydrogène. Helia 2007, 30, 103–132. [Google Scholar] [CrossRef]

- Hydrogen Tools. Available online: https://h2tools.org (accessed on 2 August 2021).

- Shivaprasad, K.V.; Rajesh, R.; Wogasso, W.A.; Nigatu, B.; Addisu, F. Usage of hydrogen as a fuel in spark ignition engine. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 376, p. 012037. [Google Scholar]

- Osama, H. Ghazal-A comparative evaluation of the performance of different fuelinduction techniques for blends hydrogene-methane SI engine. Int. J. Hydrog. Energy 2013, 38, 6848–6856. [Google Scholar] [CrossRef]

- Negurescu, N.; Pana, C.; Cernat, A. Aspects of Using Hydrogen in SI Engine. Univ. Politehnica Buchar. Sci. Bull. Ser. D Mech. Eng. 2012, 74, 11–20, ISSN 1454-2358. [Google Scholar]

- Brayek, M.; Jemni, M.A.; Driss, Z.; Kantchev, G.; Abid, M.S. Study of Spark-Ignition Engine Fueled with Hydrogen Produced by the Reaction Between Aluminum and Water in Presence of KOH. Arab. J. Sci. Eng. 2019, 44, 695–705. [Google Scholar] [CrossRef]

- Al-Baghdadi, M.A.S. Hydrogen–ethanol blending as an alternative fuel of spark ignition engines. Renew. Energy 2003, 28, 1471. [Google Scholar] [CrossRef]

- Earth Science Australia. Available online: http://earthsci.org/mineral/energy/fuelcell/fuelcell.html (accessed on 2 August 2021).

- Hermann, A.; Chaudhuri, T.; Spagnol, P. Bipolar plates for PEM fuel cells: A review. Int. J. Hydrog. Energy 2005, 30, 1297–1302. [Google Scholar] [CrossRef]

- Nicolae, B.; Vlad, B.G. Low Emission Infrastructure for Powered EVs. In Proceedings of the 2019 Electric Vehicles International Conference (EV), Icpe Solar Park, Bucharest, Romania, 3–4 October 2019. [Google Scholar]

- Ehsani, M.; Gao, Y.; Longo, S.; Ebrahimi, K.M. Modern Electric, Hybrid Electric, and Fuel Cell Vehicles-Fundamentals, Theory, and Design; CRC Press: Boca Raton, FL, USA, 2005; ISBN 0-8493-3154-4. [Google Scholar]

- Onovwionaa, H.I.; Ugursal, V.I. Residential cogeneration systems: Review of the current technology. Renew Sust. Energy Rev. 2006, 10, 389–431. [Google Scholar] [CrossRef]

- Pade, L.L.; Schröder, S.T. Fuel cell based micro-combined heat and power under different policy frameworks—An economic analysis. Energy Convers. Manag. 2013, 66, 295–303. [Google Scholar] [CrossRef] [Green Version]

- Badea, N.; Paraschiv, I.; Oanca, M. Micro CHP with fuel cell for boiler supply. In Proceedings of the 4th International Symposium on Electrical and Electronics Engineering (ISEEE), Galaţi, Romania, 11–13 October 2013. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).