Air Pollutant Emission Abatement of the Fossil-Fuel Power Plants by Multiple Control Strategies in Taiwan

Abstract

:1. Introduction

2. Experimental Procedure

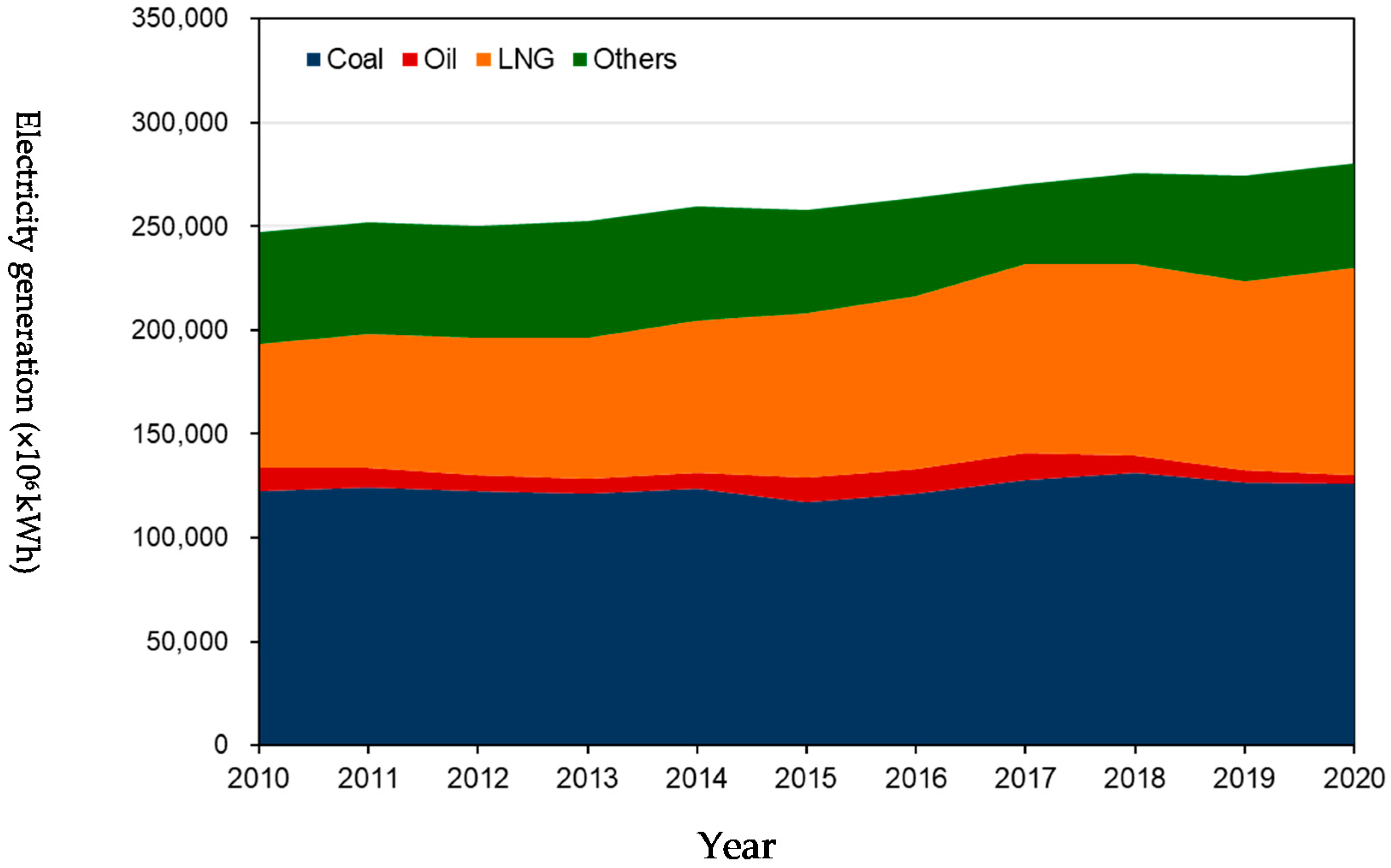

2.1. Power Plant Operating Data

2.2. Air Pollutant Emission Data

2.3. Emissions Factor for Each Power Plant

3. Results and Discussion

3.1. Air Pollutant Emissions from Different Fuel-Based Power Generation Units

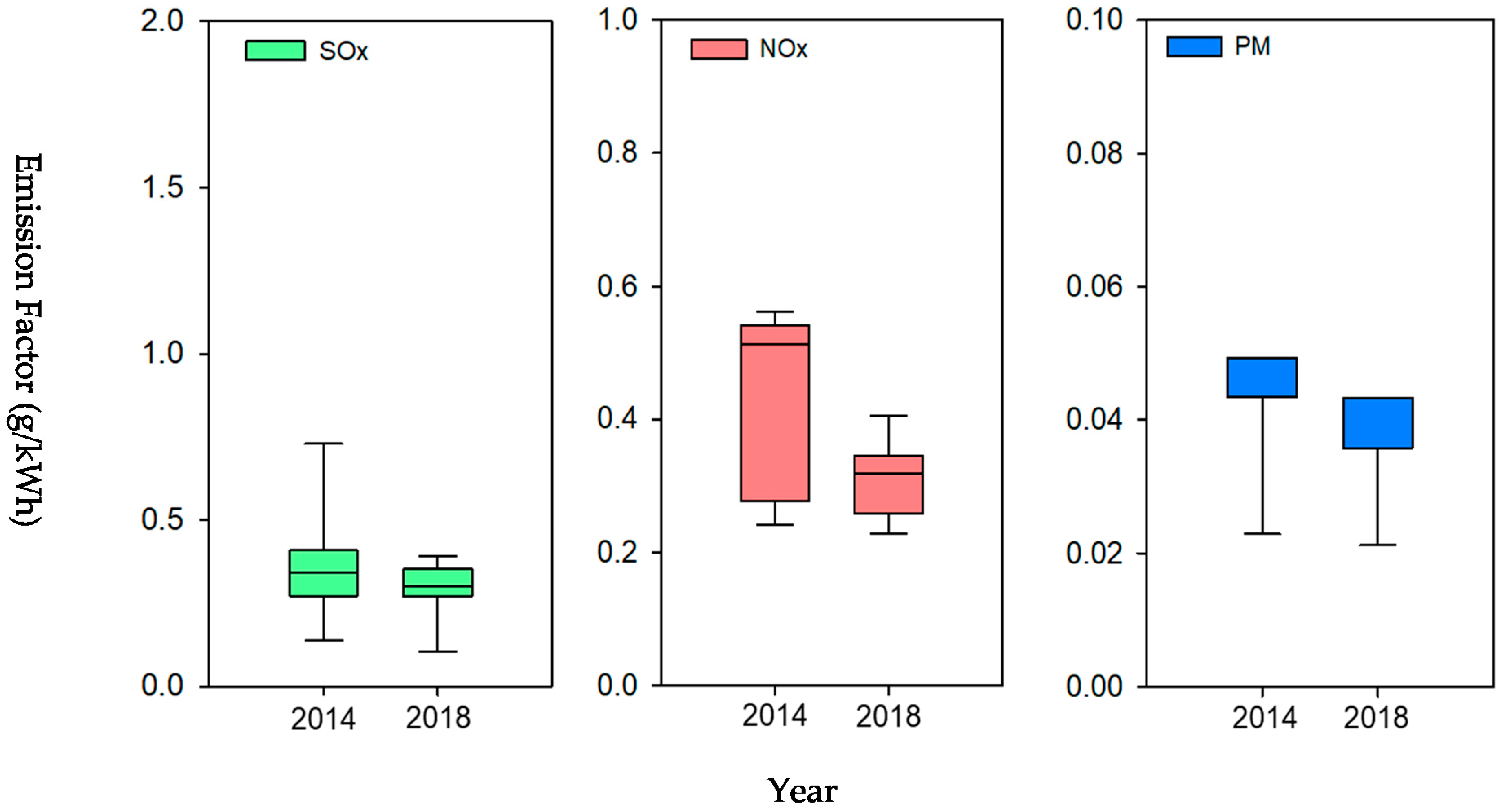

3.2. Air Pollutant Emission Factors from Electricity Generation Units

3.2.1. Coal-Fired Generation Units

3.2.2. LNG-Fueled Generation Units

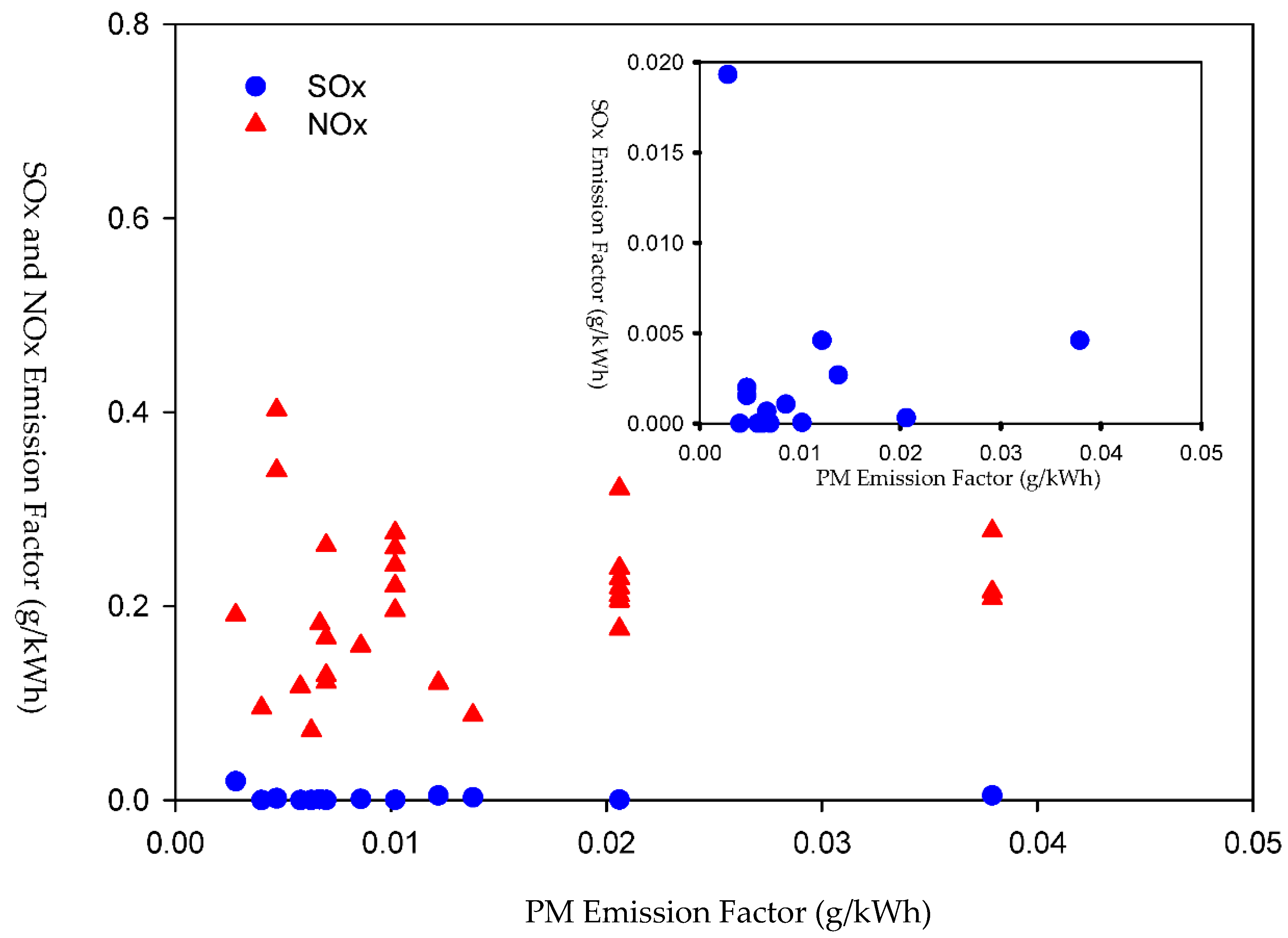

3.3. Emission Characteristics of Different Power Plants

3.4. Air Pollution Emissions and Control Equipment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- BP (British Petroleum). BP Statistical Review of World Energy. 2020. Available online: https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/statistical-review/bpstats-review-2018-coal.pdf (accessed on 5 May 2021).

- International Energy Agency (IEA). Energy and Air Pollution. In World Energy Outlook Special Report 2016; IEA: Paris, France, 2016; Available online: https://www.iea.org/reports/energy-and-air-pollution (accessed on 10 September 2020).

- Bureau of Energy (BOE). Ministry of Economic Affairs. Available online: https://www.moeaboe.gov.tw/ECW/populace/home/Home.aspx (accessed on 29 November 2020).

- Taiwan Environmental Protection Agency (TEPA). Taiwan Air Pollutants Emission Data System. 2021. Available online: https://teds.epa.gov.tw/Introduction.aspx (accessed on 26 May 2021).

- WHO Regional Office for Europe; OECD. Economic Cost of the Health Impact of Air Pollution in Europe: Clean Air, Health and Wealth; WHO Regional Office for Europe: Copenhagen, Denmark, 2015. [Google Scholar]

- European Environment Agency (EEA). Air Quality in Europe–2018 Report; EEA: Copenhagen, Denmark, 2018. [Google Scholar]

- The World Bank. The Cost of Air Pollution: Strengthening the Economic Case for Action; The World Bank: Washington, DC, USA, 2016. [Google Scholar]

- Burt, E.; Orris, P.; Buchanan, S. Scientific Evidence of Health Effects from Coal Use in Energy Generation; University of Illinois at Chicago School of Public Health: Chicago, IL, USA, 2013. [Google Scholar]

- Hendryx, M.; Zullig, K.J.; Luo, J. Impacts of coal use on health. Annu. Rev. Public Health 2020, 41, 397–415. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kravchenko, J.; Lyerly, H.K. The impact of coal-powered electrical plants and coal ash impoundments on the health of residential communities. N. C. Med. J. 2018, 79, 289–300. [Google Scholar] [CrossRef] [PubMed]

- Jing, L. 670,000 Smog-Related Deaths a Year: The Cost of China’s Reliance on Coal. South China Morning Post. 5 November 2014. Available online: https://www.scmp.com/news/china/article/1632163/670000-deaths-year-costchinas-reliance-coal (accessed on 5 October 2020).

- Biswas, T. Study estimates health impact of coal based power plants in India. BMJ 2013, 346, f2187. [Google Scholar] [CrossRef] [PubMed]

- Casey, J.A.; Su, J.G.; Henneman, L.R.F.; Zigler, C.; Neophytou, A.M.; Catalano, R.; Gondalia, R.; Chen, Y.T.; Kaye, L.; Moyer, S.S.; et al. Improved asthma outcomes observed in the vicinity of coal power plant retirement, retrofit and conversion to natural gas. Nat. Energy 2020, 5, 398–408. [Google Scholar] [CrossRef] [PubMed]

- U.S. EIA (Energy Information Adminstration). Changes in Coal Sector Led to Less SO2 and NOx Emissions from Electric Power Industry. 2021. Available online: https://www.eia.gov/todayinenergy (accessed on 20 February 2021).

- USEPA. Energy and the Environment: Reduce the Environmental Impact of Your Energy Use. 2021. Available online: https://www.epa.gov/energy/reduce-environmental-impact-your-energy-use (accessed on 2 July 2021).

- Tang, L.; Qu, J.; Mi, Z.; Bo, X.; Chang, X.; Anadon, L.D.; Wang, S.; Xue, X.; Li, S.; Wang, X.; et al. Substantial emission reductions from Chinese power plants after the introduction of ultra-low emissions standards. Nat. Energy 2019, 4, 929–938. [Google Scholar] [CrossRef]

- Chen, X.; Liu, Q.; Sheng, T.; Li, F.; Xu, Z.; Han, D.; Zhang, X.; Huang, X.; Fu, Q.; Cheng, J. A high temporal-spatial emission inventory and updated emission factors for coal-fired power plants in Shanghai, China. Sci. Total Environ. 2019, 688, 94–102. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Bo, X.; Zhao, Y.; Nielsen, C.P. Benefits of current and future policies on emissions of China’s coal-fired power sector indicated by continuous emission monitoring. Environ. Pollut. 2019, 251, 415–424. [Google Scholar] [CrossRef] [PubMed]

- Ruan, R.; Liu, H.; Tan, H.; Yang, F.; Li, Y.; Duan, Y.; Zhang, S.; Lu, X. Effects of APCDs on PM emission: A case study of a 660MW coal-fired unit with ultralow pollutants emission. Appl. Therm. Eng. 2019, 155, 418–427. [Google Scholar] [CrossRef]

- Shon, Z.H.; Kang, M.; Park, G.; Bae, M. Impact of temporary emission reduction from a large-scale coal-fired power plant on air quality. Atmos. Environ. X 2020, 5, 100056. [Google Scholar] [CrossRef]

- U.S. EIA (Energy Information Administration). Electricity Explained: Electricity and the Environment. 9 December 2020. Available online: https://www.eia.gov/energyexplained/electricity/electricity-and-the-environment.php (accessed on 15 June 2021).

- Marrasso, E.; Roselli, C.; Sasso, M. Electric efficiency indicators and carbon dioxide emission factors for power generation by fossil and renewable energy sources on hourly basis. Energy Convers. Manag. 2019, 196, 1369–1384. [Google Scholar] [CrossRef]

- USEIA. Global Electricity Consumption Continues to Rise Faster than Population. 2020. Available online: https://www.eia.gov/todayinenergy/detail.php?id=44095 (accessed on 1 September 2021).

- International Renewable Energy Agency (IRENA). Renewable Energy Sources. 2021. Available online: https://www.irena.org/ (accessed on 1 September 2021).

- Sher, F.; Yaqoob, A.; Saeed, F.; Zhang, S.; Jahan, Z.; Klemes, J.J. Torrefied biomass fuels as a renewable alternative to coal in co-firing for power generation. Energy 2020, 209, 11844. [Google Scholar] [CrossRef]

- Al-Sharaa, N.K.; Sher, F.; Iqbal, S.Z.; Curnick, O.; Chen, G.Z. Design and optimization of electrochemical cell potential for hydrogen gas production. J. Energy Chem. 2021, 52, 421–427. [Google Scholar] [CrossRef]

- Sher, F.; Al-Sharaa, N.K.; Iqbal, S.Z.; Jahan, Z.; Chen, G.Z. Enhancing hydrogen production from steam electrolysis in molten hydroxides via selection of non-precious metal electrodes. Int. J. Hydrogen Energy 2020, 45, 28260–28271. [Google Scholar] [CrossRef]

- Qureshi, Y.; Ali, U.; Sher, F. Part load operation of natural gas fired power plant with CO2 capture system for selective exhaust gas recirculation. Appl. Therm. Eng. 2021, 190, 116808. [Google Scholar] [CrossRef]

- Al-Juboori, O.; Sher, F.; Rahman, S.; Rasheed, T.; Chen, G.Z. Electrochemical Production of Sustainable Hydrocarbon Fuels from CO2 Co-electrolysis in Eutectic Molten Melts. ACS Sustain. Chem. Eng. 2020, 8, 12877–12890. [Google Scholar] [CrossRef]

- Ishaq, H.; Ali, U.; Sher, F.; Anus, M.; Imran, M. Process analysis of improved process modifications for ammonia-based post-combustion CO2 capture. J. Environ. Chem. Eng. 2021, 9, 104928. [Google Scholar] [CrossRef]

- Taiwan Power Company (TPC). Information Disclosure. 2020. Available online: https://www.taipower.com.tw/TC/pageList.aspx (accessed on 10 December 2020).

- Taiwan Power Company (TPC). History of Net Power Generation and Purchased by TPC. 2021. Available online: https://www.taipower.com.tw/TC/Chart.aspx?mid=194 (accessed on 5 May 2021).

- Taiwan Environmental Protection Agency (TEPA). Taiwan Continuous Emission Monitoring Data System. 2020. Available online: https://cems.epa.gov.tw/home/Downloads (accessed on 20 November 2020).

- USEPA. Current Knowledge of Particulate Matter (PM) Continuous Emission Monitoring; Final Report EPA-454/R-00-039; U.S. Environmental Protection Agency: Research Triangle Park, NC, USA, 2000.

- UK Environment Agency (UKEA). Performance Standards and Test. Procedures for Continuous Emission Monitoring Systems: For. Gaseous, Particulate and Flow-Rate Monitoring Systems; Version 3.5; UKEA: London, UK, 2016. [Google Scholar]

- International Energy Agency (IEA). Technology Roadmap: High.-Efficiency, Low-Emissions Coal-Fired Power Generation; IEA: Paris, France, 2012; Available online: https://iea.blob.core.windows.net/assets/c43bc244-0050-45ec-807c-d870ae9241a7/TechnologyRoadmapHighEfficiencyLowEmissionsCoalFiredPowerGeneration_WEB_Updated_March2013.pdf (accessed on 10 September 2020).

- USEPA. 40 CFR Appendix Table 1 to Subpart UUUUU of Part 63—Emission Limits for New or Reconstructed EGUs; USEPA: Washington, DC, USA, 2015.

- Zhang, X. Emission Standards and Control of PM2.5 from Coal-Fired Power Plant; IEA Clean Coal Centre: London, UK, 2016; Available online: https://www.researchgate.net/profile/Xing-Zhang/publication/337446167_Emission_standards_and_control_of_PM25_from_coal-fired_power_plant/links/5ee23b50299bf1faac4b069a/Emission-standards-and-control-of-PM25-from-coal-fired-power-plant.pdf (accessed on 10 September 2020).

- ERIA (Economic Research Institute for ASEAN and East Asia). Improving Emission Regulations for Coal-Fired Power Plants in ASEAN; ERIA: Jakarta, Indonesia, 2017. [Google Scholar]

- EEA (European Environment Agency). EMEP/EEA Air Pollutant Emission Inventory Guidebook 2019; EEA: Copenhagen, Denmark, 2019; Available online: https://www.eea.europa.eu/publications/emep-eea-guidebook-2019 (accessed on 10 September 2020).

- Bureau of Energy (BOE). Ministry of Economic Affairs. Stable Supply of Natural Gas. 2021. Available online: https://www.moeaboe.gov.tw/ECW/english/content/Content.aspx?menu_id=8677 (accessed on 31 August 2021).

| Year | Items | Oil * | LNG | Coal | Total |

|---|---|---|---|---|---|

| # of generation units | 6 | 32 | 21 | 59 | |

| 2010 | Capacity of unit (MW) | 375–500 | 246.8–755.8 | 251–660 | |

| Installed capacity (MW) | 2750.0 | 15,746.63 | 11,320.3 | 29,816.93 | |

| Electricity generation (109 kWh) | 7.79 | 58.0 | 83.82 | 149.61 | |

| # of generation units | 6 | 32 | 21 | 59 | |

| 2014 | Capacity of unit (MW) | 375–500 | 246.8–755.8 | 300–660 | |

| Installed capacity (MW) | 2750.0 | 15,746.63 | 11,320.3 | 29,816.93 | |

| Electricity generation (109 kWh) | 6.24 | 70.92 | 82.37 | 159.52 | |

| # of generation units | 4 | 31 | 24 | 59 | |

| 2018 | Capacity of unit (MW) | 500 | 251.4–892.6 | 500–800 | |

| Installed capacity (MW) | 2000.0 | 16,475.43 | 13,720.3 | 32,195.73 | |

| Electricity generation (109 kWh) | 6.59 | 90.10 | 90.52 | 187.21 |

| Year | 2010 | 2014 | 2018 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Pollutants | SOx | NOx | TPM | SOx | NOx | PM | SOx | NOx | PM |

| Oil | 9427 | 4217 | 262 | 10,143.1 | 4222.5 | 301.1 | 6736.7 | 4814.4 | 330.6 |

| LNG | 7558 | 15,472 | 733 | 89.3 | 16,374.4 | 1309.7 | 127.2 | 18,370.9 | 1281.8 |

| Coal | 26,678 | 46,977 | 4427 | 30,593.8 | 38,598.9 | 3751.7 | 23,232.7 | 25,344.8 | 2884.0 |

| Sum | 43,663 | 66,656 | 5422 | 40,826.3 | 59,195.8 | 5362.5 | 30,096.6 | 48,530.0 | 4496.4 |

| Emission Factor (g/kWh) | 2014 | 2018 | |||||

|---|---|---|---|---|---|---|---|

| APCD | SOx | NOx | PM | SOx | NOx | PM | |

| Oil | LNB + OFA + EP | 1.6356 ± 0.3367 | 0.6581 ± 0.2018 | 0.0543 ± 0.0055 | 1.1573 ± 0.0913 | 0.8049 ± 0.0891 | 0.0564 |

| LNB | 0.0026 ± 0.0062 | 0.1961 ± 0.1024 | 0.0122 ± 0.0087 | 0.0017 ± 0.0048 | 0.1962 ± 0.0827 | 0.0116 ± 0.0065 | |

| SWI | 0.0007 | 1.0188 ± 0.0942 | 0.0456 ± 0 | - | - | - | |

| LNG | LNB+SWI | 0.0007 | 0.2081 ± 0.0505 | 0.0456 ± 0 | 0.0046 ± 0 | 0.2334 ± 0.0384 | 0.0379 ± 0 |

| LNB+SCR | 0.0003 | 0.1521 | 0.0160 | 0.0027 ± 0.0017 | 0.1514 ± 0.0436 | 0.0095 ± 0.0039 | |

| CS-I | 0.3283 ± 0.0165 | 0.6859 ± 0.4705 | 0.0358 ± 0.0088 | 0.3322 ± 0.0268 | 0.2587 ± 0.0133 | 0.0358 | |

| Coal | CS-II | 0.3660 ± 0.1751 | 0.4452 ± 0.1274 | 0.0440 ± 0.0101 | 0.2855 ± 0.0986 | 0.3145 ± 0.0570 | 0.0379 ± 0.0084 |

| CS-III | - | - | - | 0.0830 ± 0.0026 | 0.1065 ± 0.0096 | 0.0027 ± 0.0007 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsai, J.-H.; Chen, S.-H.; Chen, S.-F.; Chiang, H.-L. Air Pollutant Emission Abatement of the Fossil-Fuel Power Plants by Multiple Control Strategies in Taiwan. Energies 2021, 14, 5716. https://doi.org/10.3390/en14185716

Tsai J-H, Chen S-H, Chen S-F, Chiang H-L. Air Pollutant Emission Abatement of the Fossil-Fuel Power Plants by Multiple Control Strategies in Taiwan. Energies. 2021; 14(18):5716. https://doi.org/10.3390/en14185716

Chicago/Turabian StyleTsai, Jiun-Horng, Shih-Hsien Chen, Shen-Fong Chen, and Hung-Lung Chiang. 2021. "Air Pollutant Emission Abatement of the Fossil-Fuel Power Plants by Multiple Control Strategies in Taiwan" Energies 14, no. 18: 5716. https://doi.org/10.3390/en14185716

APA StyleTsai, J.-H., Chen, S.-H., Chen, S.-F., & Chiang, H.-L. (2021). Air Pollutant Emission Abatement of the Fossil-Fuel Power Plants by Multiple Control Strategies in Taiwan. Energies, 14(18), 5716. https://doi.org/10.3390/en14185716