Model-Based Energy Path Analysis of Tip-In Event in a 2WD Vehicle with Range-Extender Electric Powertrain Architecture

Abstract

:1. Introduction

2. System Model and Methodology for Vehicle Driveability Study

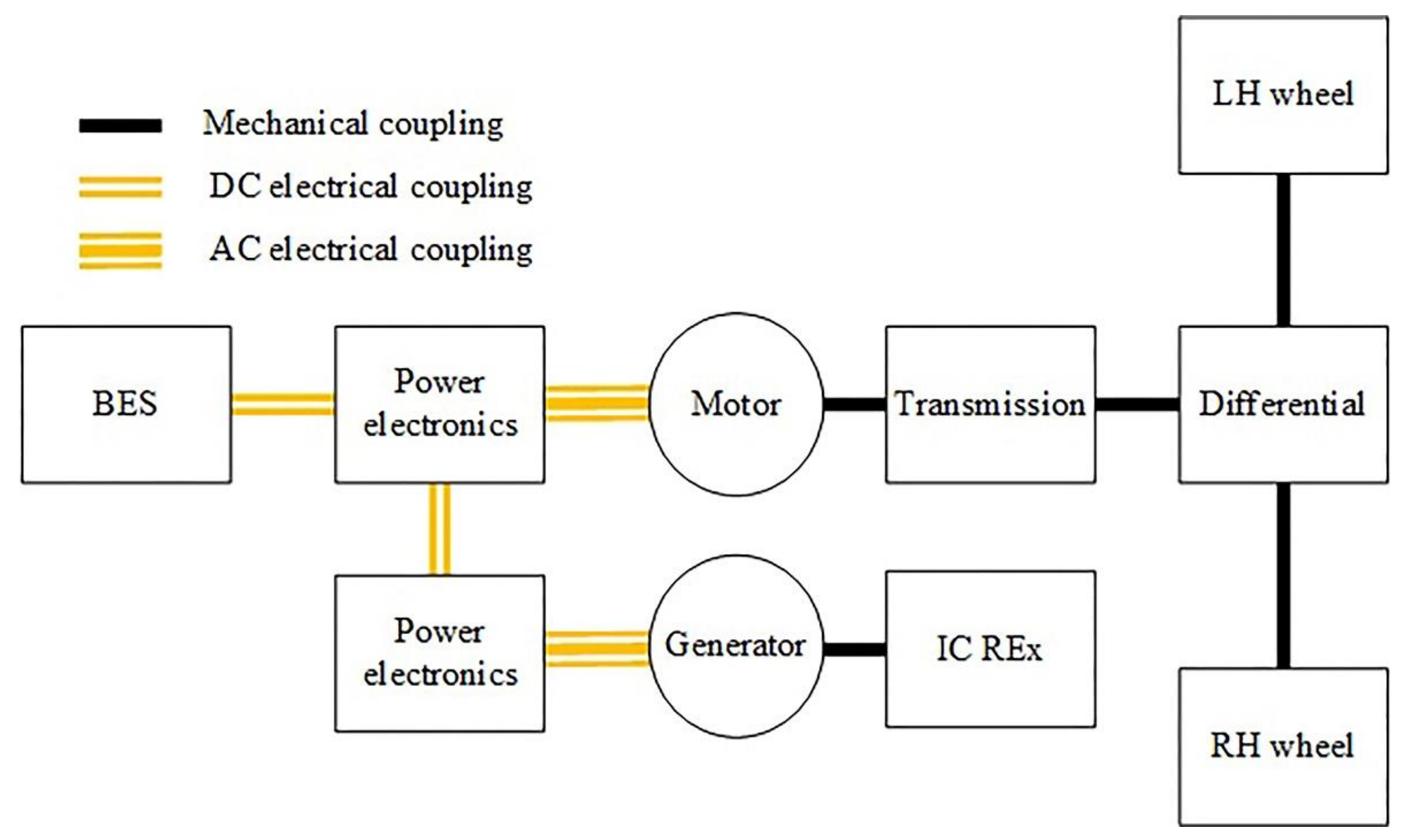

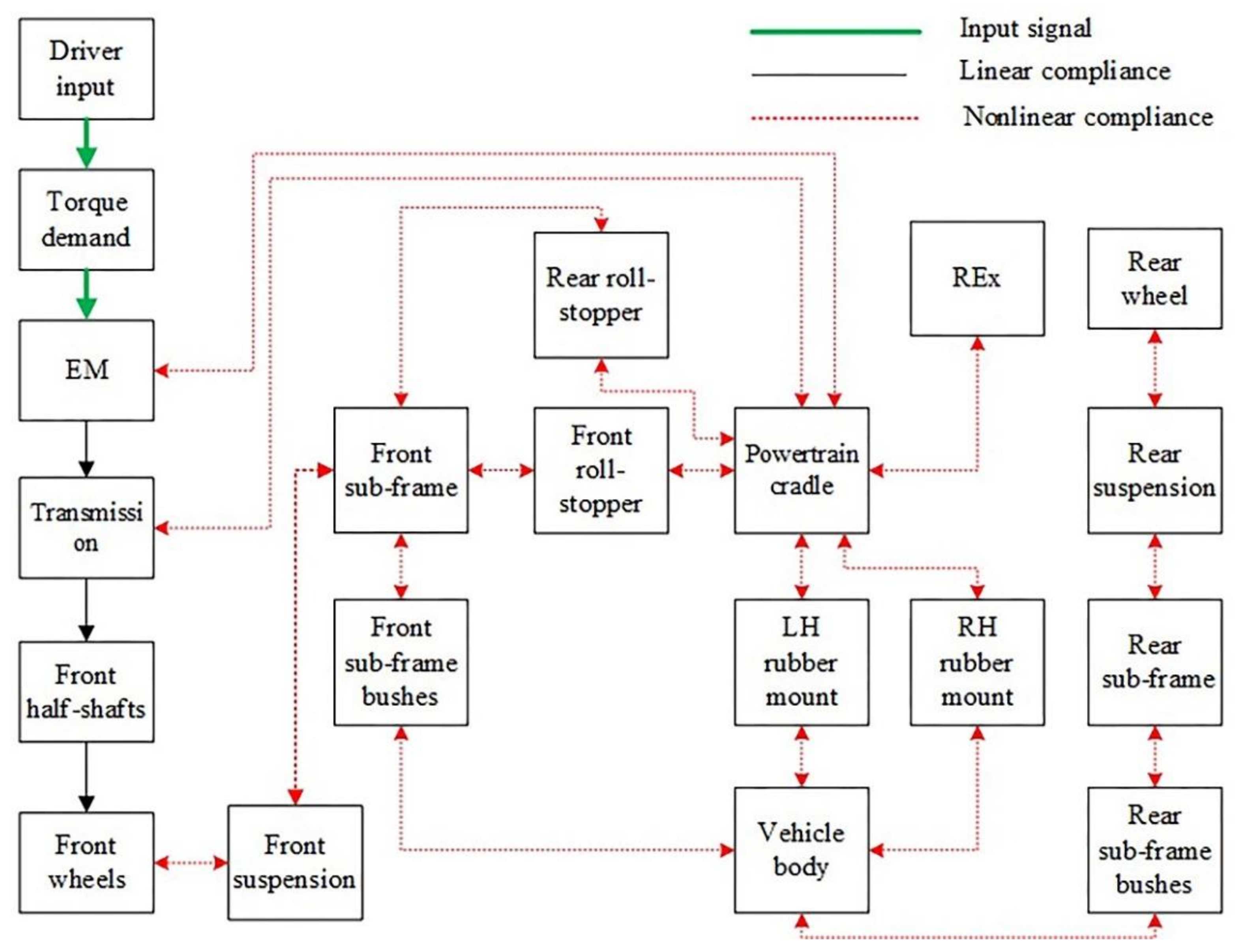

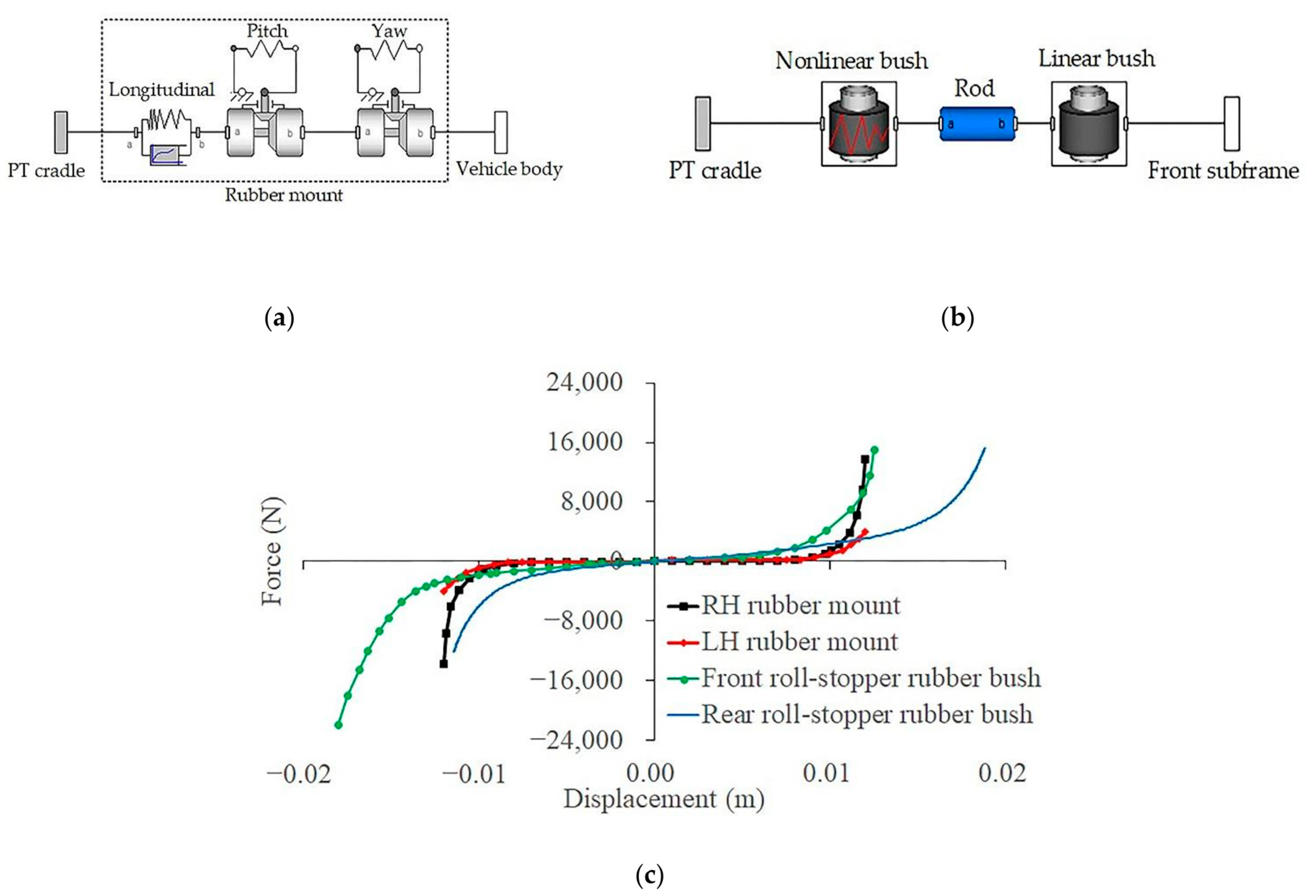

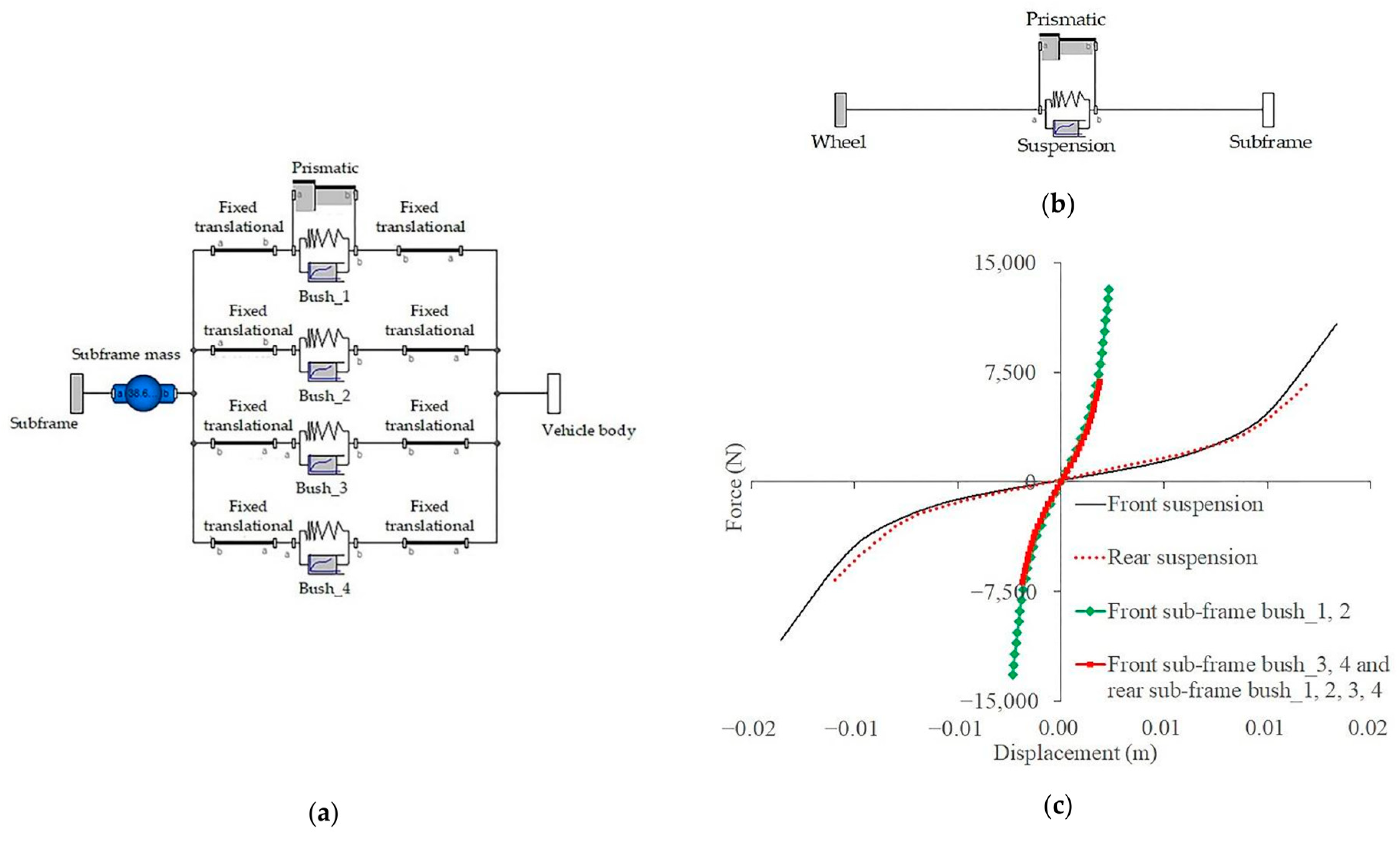

2.1. REEV Model Architecture

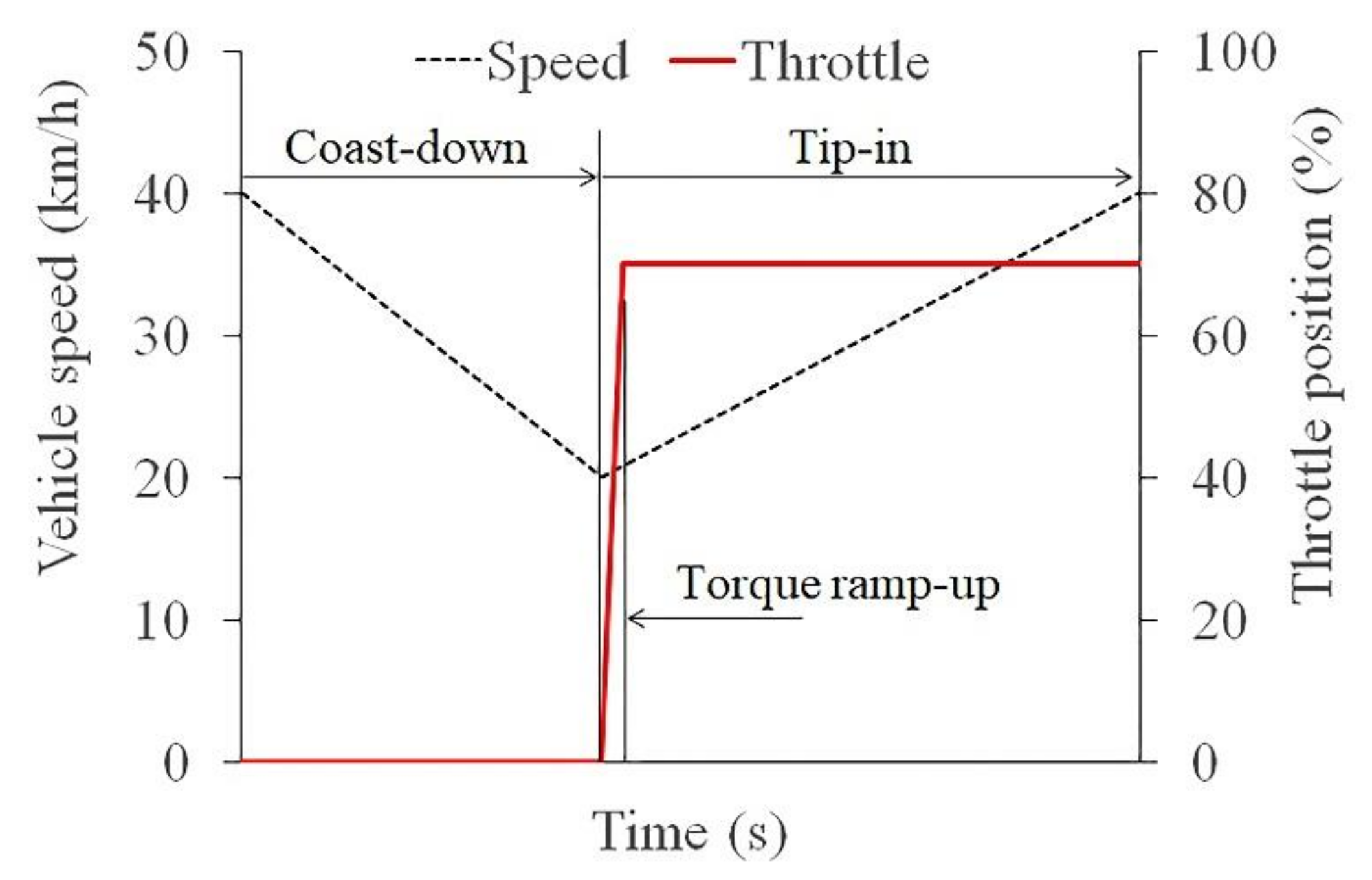

2.2. Throttle Pedal Excitation

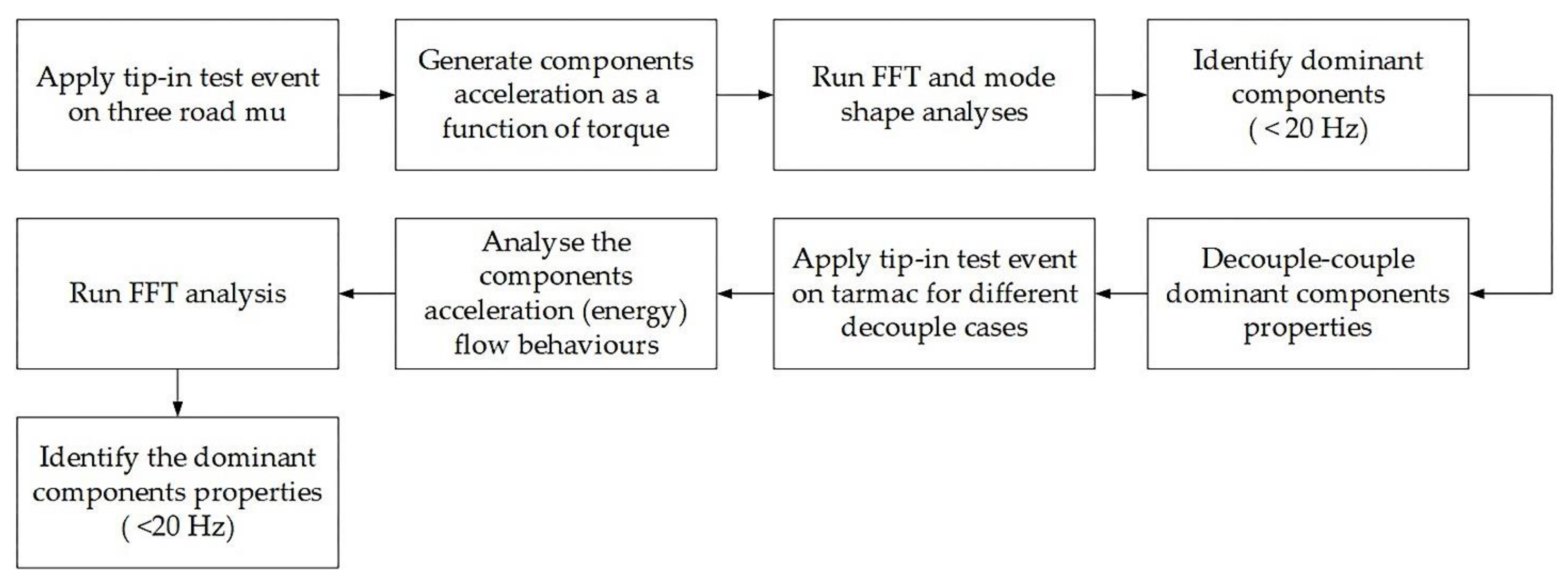

2.3. EPA Method

3. Results

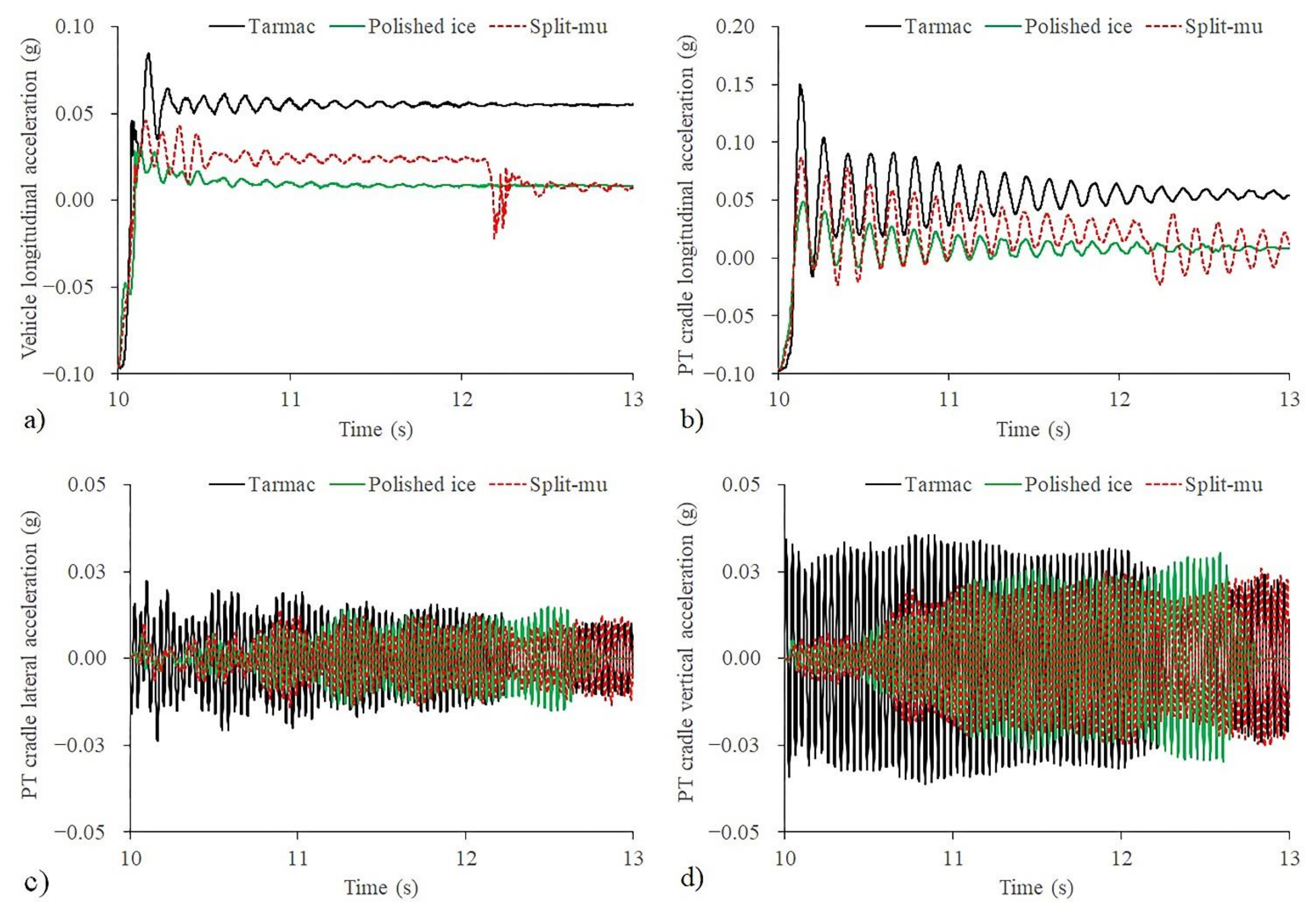

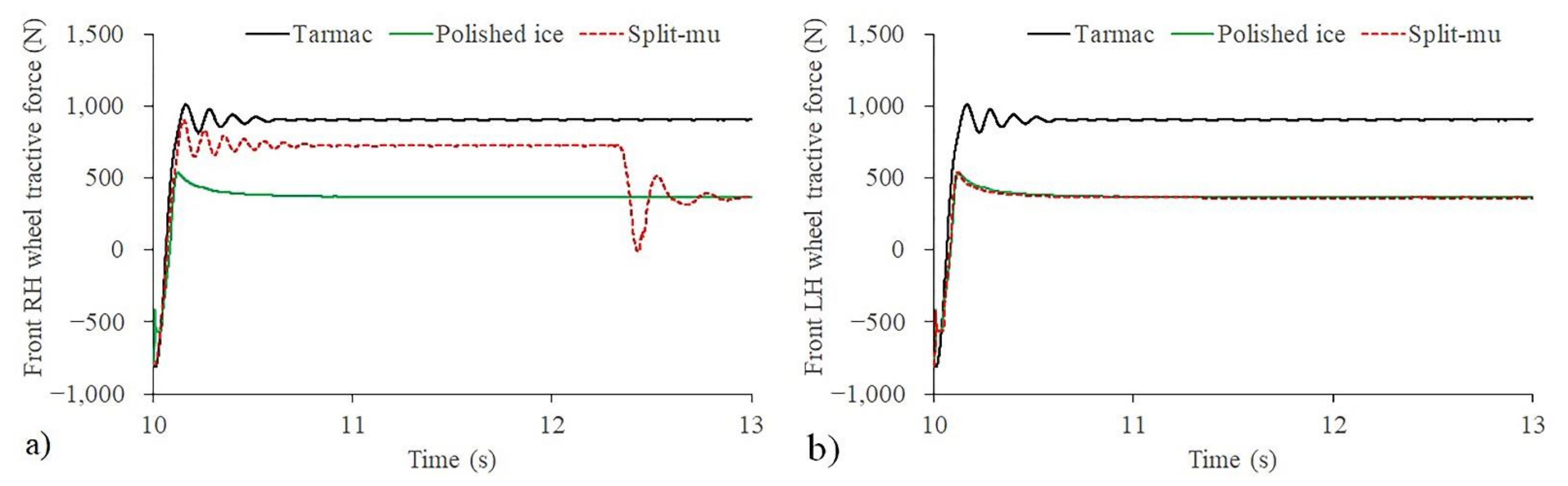

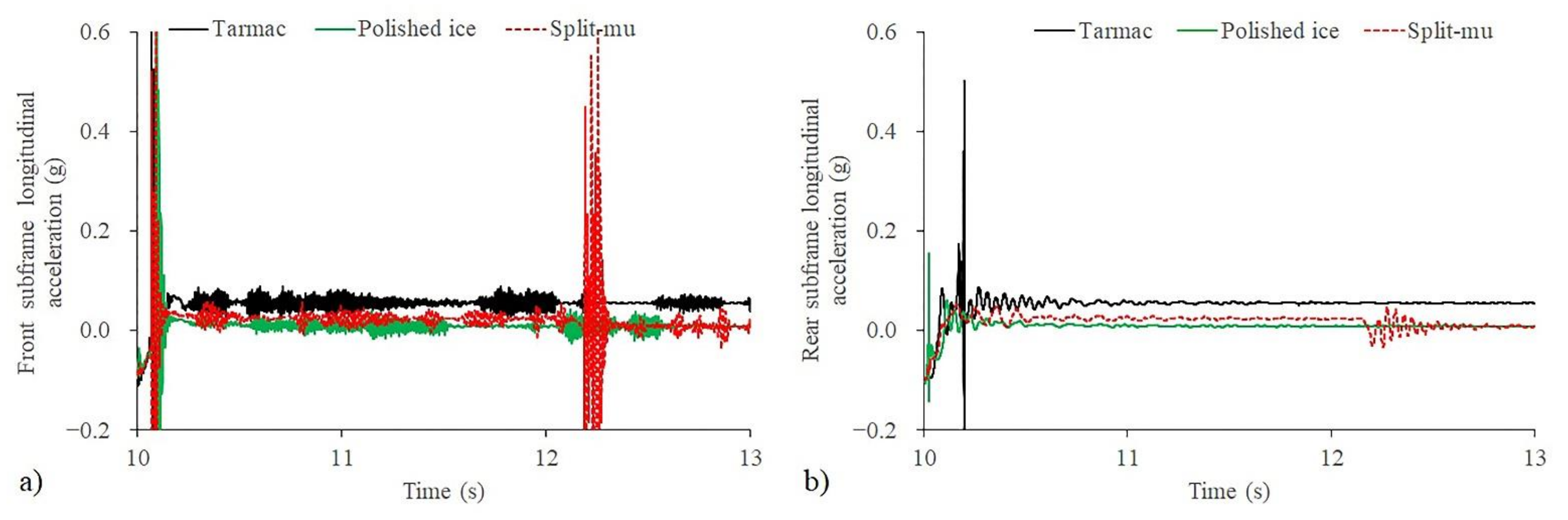

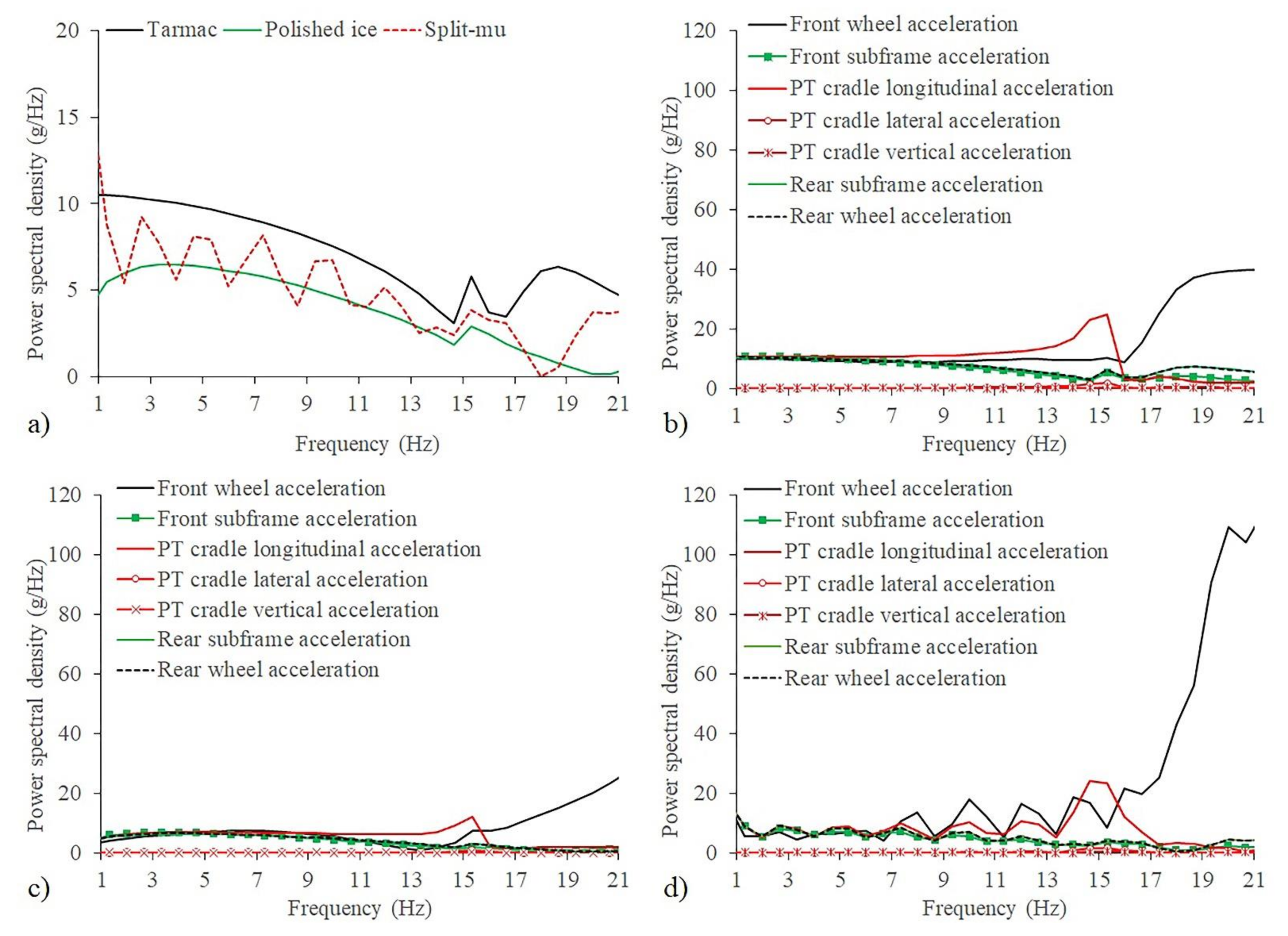

3.1. REEV Model on Three Road Mu

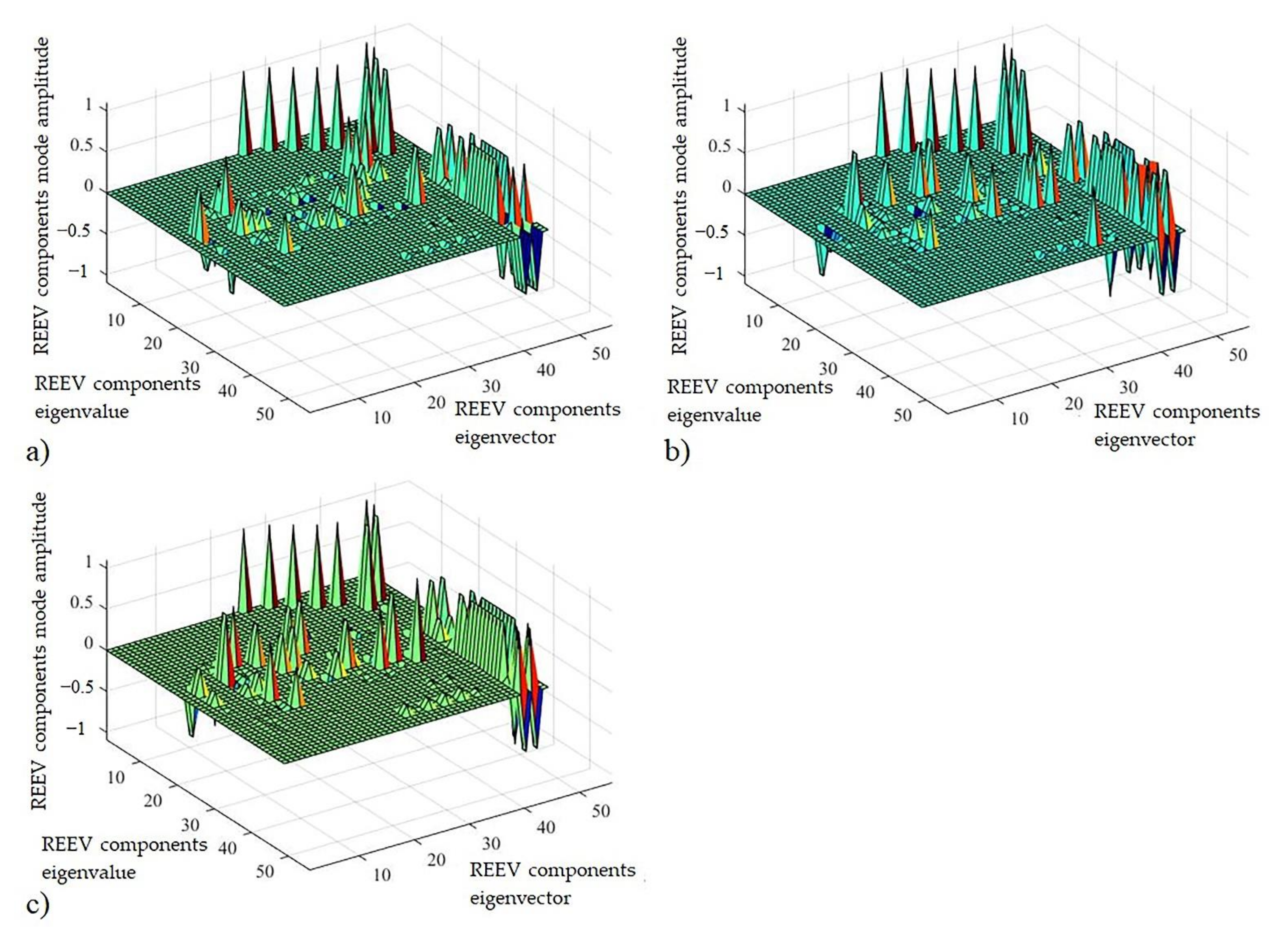

3.2. EPA on Decoupled Dominant Components

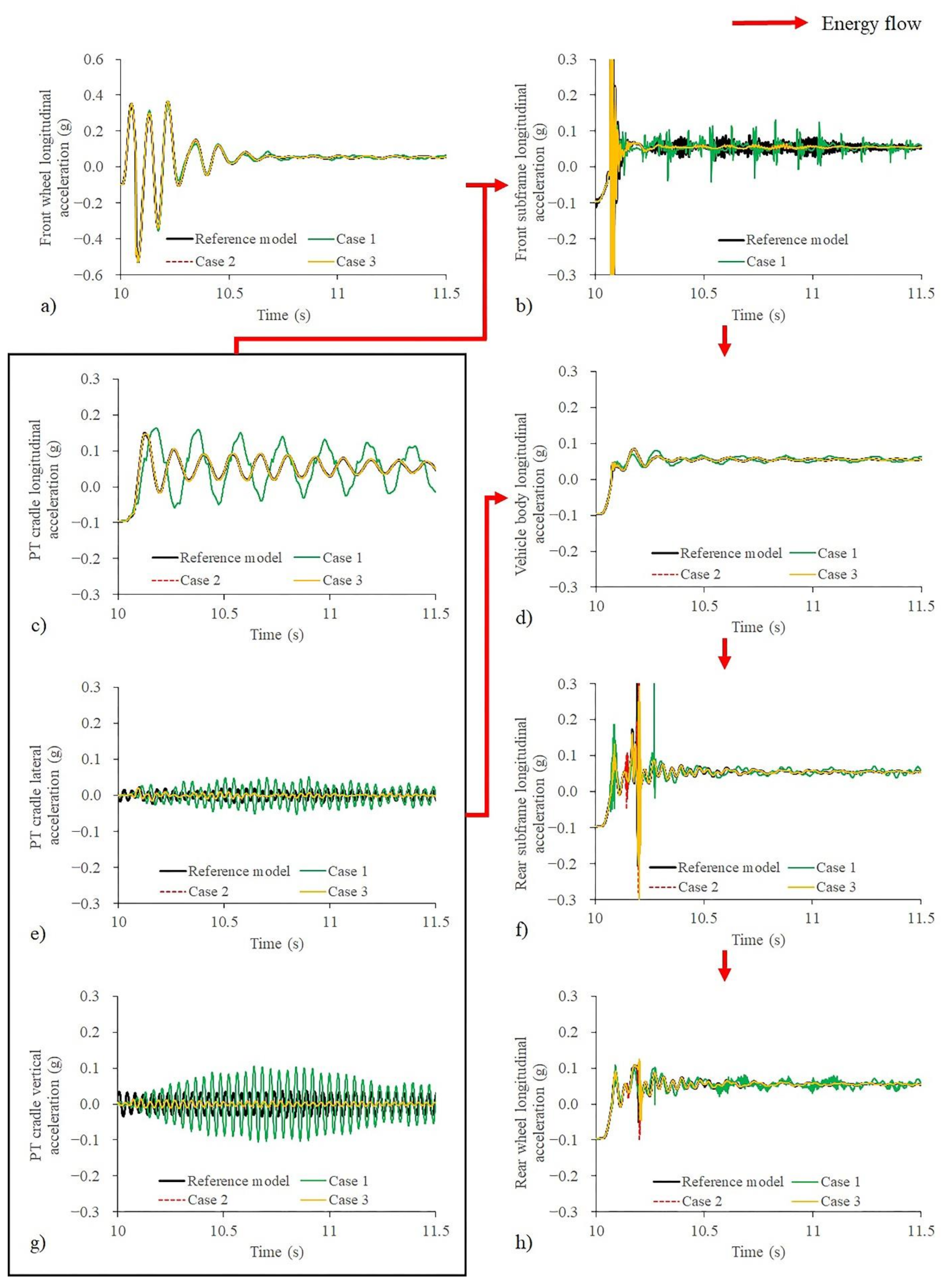

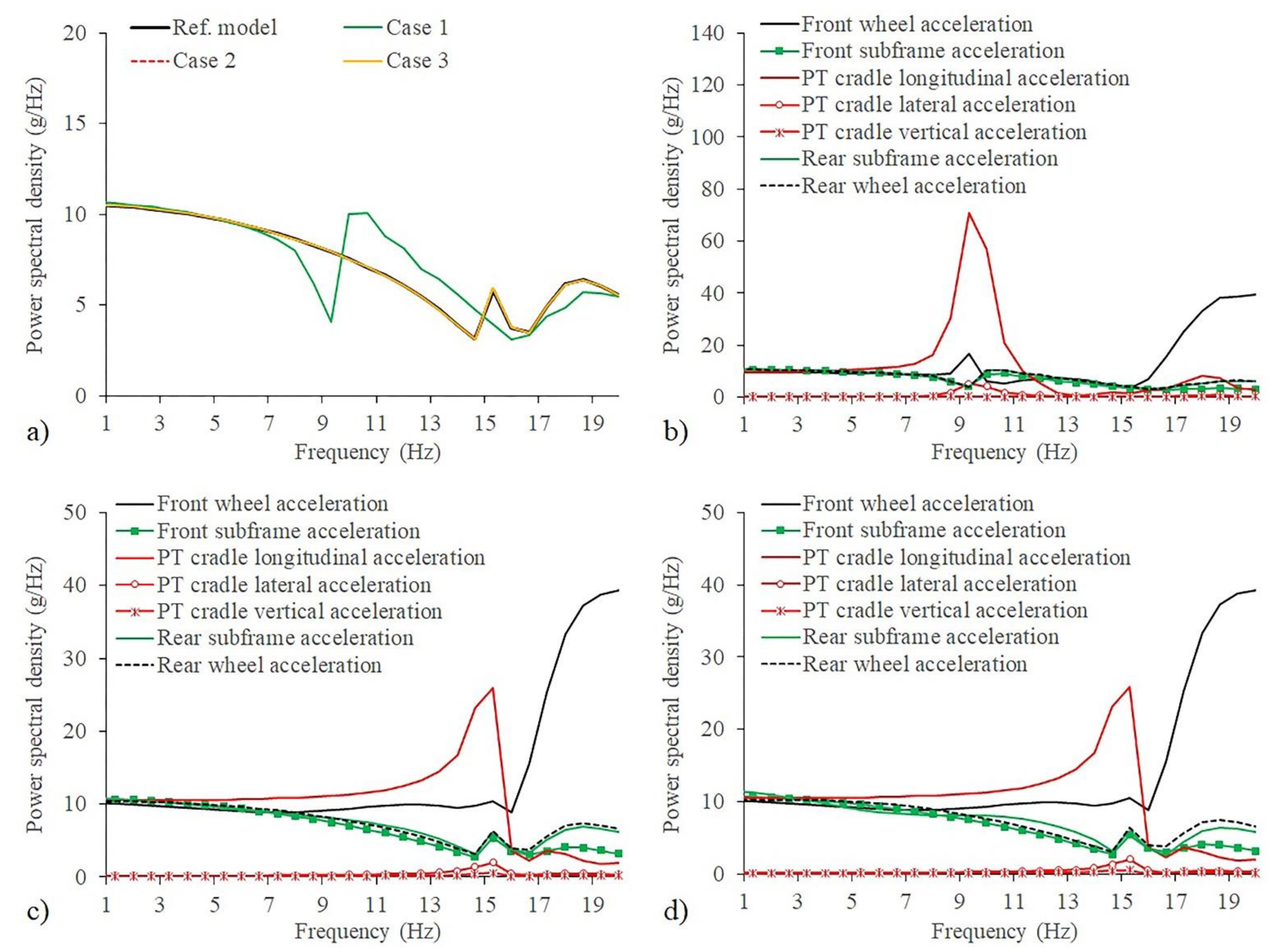

- RH and LH Rubber Mounts Properties (Case 1–3)

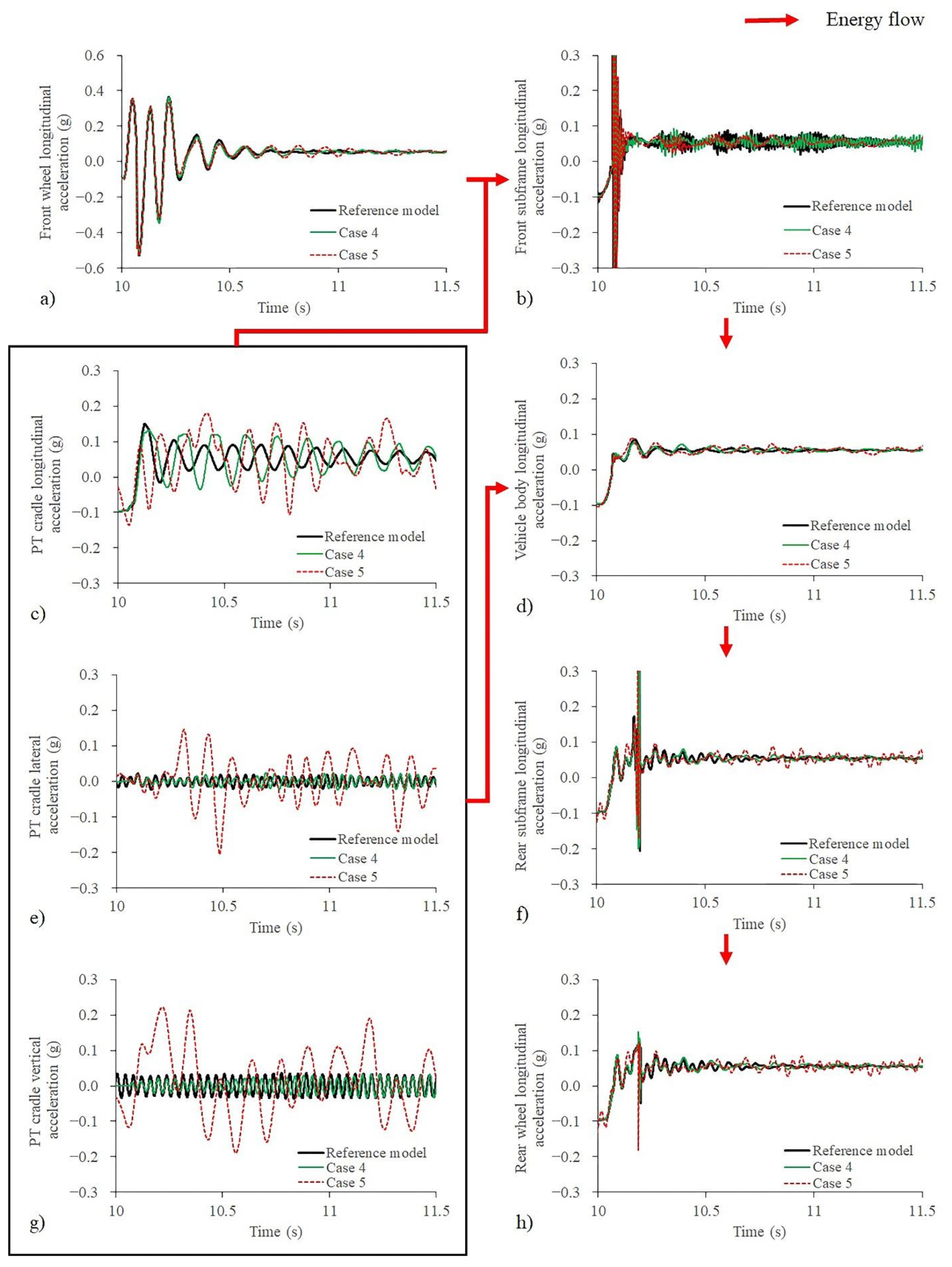

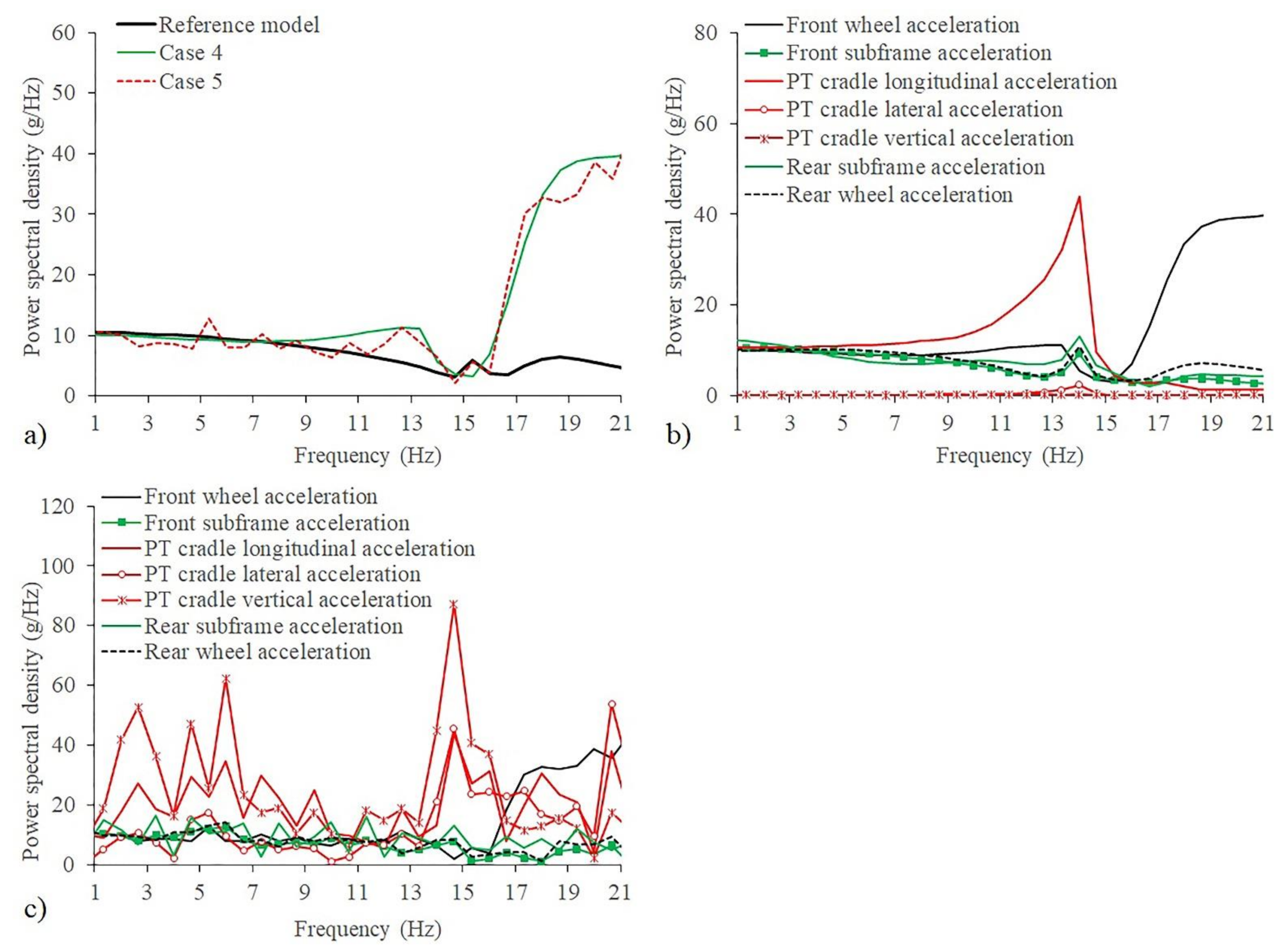

3.3. Front and Rear Roll-Stoppers (Case 4–5)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Parameters | X | Y | Z |

|---|---|---|---|

| Front RH wheel (datum) | 0.0 | 0.0 | 0.0 |

| Front LH wheel | 0.0 | 1596.0 | 0.0 |

| Vehicle body | 1000.0 | 798.0 | −500.0 |

| Front subframe | 1000.0 | 798.0 | 0.0 |

| Front subframe bush 1 | 630.2 | 253.7 | 222.7 |

| Front subframe bush 2 | 630.2 | 1349.7 | 222.7 |

| Front subframe bush 3 | 1510.2 | 440.7 | −14.3 |

| Front subframe bush 4 | 1510.2 | 1162.7 | −14.3 |

| Powertrain cradle | 877.6 | 766.5 | 255.3 |

| Front roll stopper rod | 853.6 | 287.7 | 661.6 |

| Front roll-stopper bush to powertrain cradle | 756.1 | 287.7 | 648.8 |

| Front roll-stopper bush to vehicle body | 950.9 | 287.7 | 674.7 |

| Rear roll stopper rod | 1082.7 | 498.1 | 20.6 |

| Rear roll-stopper bush to powertrain cradle | 1024.2 | 498.1 | 11.7 |

| Rear roll-stopper bush to front subframe | 1141.7 | 498.1 | 29.5 |

| RH rubber mount | 862.2 | 266.2 | 542.2 |

| LH rubber mount | 923.2 | 1259.7 | 470.5 |

| Rear subframe | 2000.0 | 798.0 | −500.0 |

| Rear subframe bush 1 | 1800.0 | 498.0 | −200.0 |

| Rear subframe bush 2 | 1800.0 | 1098.0 | −200.0 |

| Rear subframe bush 3 | 2200.0 | 1098.0 | −200.0 |

| Rear subframe bush 4 | 2200.0 | 498.0 | −200.0 |

| Rear RH wheel | 3000.0 | 1.3 | −500.0 |

| Rear LH wheel | 3000.0 | 1594.7 | −500.0 |

References

- International Energy Agency. Global EV Outlook 2020; International Energy Agency: Paris, France, 2020. [Google Scholar]

- Electric Vehicle Range Extender Market Size, Share & Trends Analysis Report by Product, by Vehicle (Passenger, Commercial), by Component (Battery Pack, Power Converter), And Segment Forecasts, 2018–2025. Available online: https://www.grandviewresearch.com/industry-analysis/electric-vehicle-ev-range-extender-market (accessed on 10 July 2021).

- Shah, R.M.R.A.; McGordon, A.; Rahman, M.; Amor-Segan, M.; Jennings, P. Characterisation of micro turbine generator as a range extender using an automotive drive cycle for series hybrid electric vehicle application. Appl. Therm. Eng. 2021, 184, 116302. [Google Scholar] [CrossRef]

- Crolla, D.A.; Cao, D. The impact of hybrid and electric powertrains on vehicle dynamics, control systems and energy regeneration. Veh. Syst. Dyn 2012, 50, 95–109. [Google Scholar] [CrossRef] [Green Version]

- Milliken, W.F.; Milliken, D.L. Race Car Vehicle Dynamic; Society of Automotive Engineers: Warrendale, PA, USA, 1995. [Google Scholar]

- Loprencipe, G.; Zoccali, P. Ride Quality Due to Road Surface Irregularities: Comparison of Different Methods Applied on a Set of Real Road Profiles. Coatings 2017, 7, 59. [Google Scholar] [CrossRef] [Green Version]

- Kim, D.; Min, K.; Kim, H.; Huh, K. Vehicle sideslip angle estimation using deep ensemble-based adaptive Kalman filter. Mech. Syst. Signal Process. 2020, 144, 106862. [Google Scholar] [CrossRef]

- Liu, C.; Zhou, J.; Gerhard, A.; Kubenz, J.; Prokop, G. Characterization of the Vehicle Roll Movement with the Dynamic Chassis Simulator. In Vehicle and Automotive Engineering 2; Springer Science and Business Media LLC: Berlin, Germany, 2018; pp. 129–141. [Google Scholar]

- Gao, B.; Liang, Q.; Xiang, Y.; Guo, L.; Chen, H. Gear ratio optimization and shift control of 2-speed I-AMT in electric vehicle. Mech. Syst. Signal Process. 2015, 50, 615–631. [Google Scholar] [CrossRef]

- Li, G.; Görges, D. Optimal control of the gear shifting process for shift smoothness in dual-clutch transmissions. Mech. Syst. Signal Process. 2018, 103, 23–38. [Google Scholar] [CrossRef]

- Atabay, O.; Ötkür, M.; Ereke, I.M. Model based predictive engine torque control for improved drivability. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2018, 232, 1654–1666. [Google Scholar] [CrossRef]

- Dorey, R.E.; Holmes, C.B. Vehicle Driveability—Its Characterisation and Measurement. In International Congress & Exposition; Detroit SAE International: Detroit, MI, USA, 1999; p. 8. [Google Scholar]

- Wang, W.; Cao, L.; Qu, F. Driving Performance Test of Plug-in Hybrid Electric Vehicle Based on AVL-DRIVE. In Proceedings of the 2019 5th International Conference on Control, Automation and Robotics (ICCAR), Beijing, China, 19–22 April 2019; pp. 771–775. [Google Scholar]

- Ciceo, S.; Mollet, Y.; Sarrazin, M.; Gyselinck, J.; Auweraer, H.V.d.; Martiş, C. Model-based design and testing for electric vehicle driveability analysis. In Proceedings of the 2016 IEEE 16th International Conference on Environment and Electrical Engineering (EEEIC), Florence, Italy, 7–10 June 2016; pp. 1–4. [Google Scholar]

- Pawar, J. Low Frequency Powertrain and Vehicle System Dynamics; University of Warwick: Coventry, UK, 2009. [Google Scholar]

- Wang, D.; Jiang, M.; He, K.; Li, X.; Li, F. Study on vibration suppression method of vehicle with engine start-stop and automatic start-stop. Mech. Syst. Signal Process. 2020, 142, 106783. [Google Scholar] [CrossRef]

- Shah, R.M.B.R.A.; Jones, R.P.; Pawar, J. System modelling and analysis of the driveability response of 4WD vehicle. Int. Rev. Mech. Eng. 2012, 6, 595–601. [Google Scholar]

- Ehsani, M.; Gao, Y.; Longo, S.; Ebrahimi, K. Modern Electric, Hybrid Electric, and Fuel Cell Vehicles, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Hao, D.; Zhao, C.; Huang, Y. A Reduced-Order Model for Active Suppression Control of Vehicle Longitudinal Low-Frequency Vibration. Shock Vib. 2018, 2018, 1–22. [Google Scholar] [CrossRef]

- Scamarcio, A.; Gruber, P.; de Pinto, S.; Sorniotti, A. Anti-jerk controllers for automotive applications: A review. Annu. Rev. Control 2020, 50, 174–189. [Google Scholar] [CrossRef]

- Johnson, S.R.; Subhedar, J.W. Computer Optimization of Engine Mounting Systems, 3rd ed. In International Conference on Vehicle Structural Mechanics Michigan; USA SAE International: Warrendale, PA, USA, 1979; p. 8. [Google Scholar]

- Road and Pavement Maintenance, Road Safety, Mobility and Transport, European Commission. Available online: https://ec.europa.eu/transport/road_safety/specialist/knowledge/road/managing_safety_of_roads_through_their_whole_life/road_and_pavement_maintenance_en (accessed on 29 July 2021).

- Ivanov, V.; Savitski, D.; Shyrokau, B. A Survey of Traction Control and Antilock Braking Systems of Full Electric Vehicles with Individually Controlled Electric Motors. IEEE Trans. Veh. Technol. 2015, 64, 3878–3896. [Google Scholar] [CrossRef]

- Zhang, J.L.; Yin, C.L.; Zhang, J.W. Improvement of drivability and fuel economy with a hybrid antiskid braking system in hybrid electric vehicles. Int. J. Automot. Technol. 2010, 11, 205–213. [Google Scholar] [CrossRef]

- Oleksowicz, S.; Burnham, K.; Phillip, N.; Barber, P.; Curry, E.; Grzegozek, W. Regenerative Braking Control for High Level Deceleration on Low Mu Surface. SAE Int. J. Altern. Powertrains 2015, 4, 209–224. [Google Scholar] [CrossRef]

- Van der Seijs, M.V.; de Klerk, D.; Rixen, D. General framework for transfer path analysis: History, theory and classification of techniques. Mech. Syst. Signal Process. 2016, 68, 217–244. [Google Scholar] [CrossRef]

- Acri, A.; Nijman, E.; Offner, G. Influences of system uncertainties on the numerical transfer path analysis of engine systems. Mech. Syst. Signal Process. 2017, 95, 106–121. [Google Scholar] [CrossRef]

- Diez-Ibarbia, A.; Battarra, M.; Palenzuela, J.; Cervantes-Madrid, G.; Walsh, S.; De-La-Cruz, M.; Theodossiades, S.; Gagliardini, L. Comparison between transfer path analysis methods on an electric vehicle. Appl. Acoust. 2017, 118, 83–101. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Huang, X.; Zhao, Q. Sensitivity analysis for vibration transfer path systems with non-viscous damping. J. Vib. Control 2010, 17, 1042–1048. [Google Scholar] [CrossRef]

- Haeussler, M.; Kobus, D.; Rixen, D. Parametric design optimization of e-compressor NVH using blocked forces and substructuring. Mech. Syst. Signal Process. 2021, 150, 107217. [Google Scholar] [CrossRef]

- Jimbo, T.; Hibino, R.; Yamaguchi, H.; Matsunaga, H.; Otsubo, H. Multiway analysis of vehicle acceleration behavior. In Proceedings of the ISMA, Leuven, Belgium, 15–17 September 2014; p. 2014. [Google Scholar]

- Hibino, R.; Jimbo, T.; Yamaguchi, H.; Tsurumi, Y.; Otsubo, H.; Kato, S. Clarification of Transient Characteristics by Coupled Analysis of Powertrains and Vehicles. SAE Int. J. Passeng. Cars-Mech. Syst. 2016, 9, 216–226. [Google Scholar] [CrossRef]

- Zhang, N.; Chen, T.; Zheng, M.; Luo, L.; Liu, P. Real-time identification of vehicle body motion-modes based on motion-mode energy method. Mech. Syst. Signal Process. 2020, 143, 106843. [Google Scholar] [CrossRef]

- Shah, R.M.B.R.A.; Cheng, C.; Jones, R.P.; Pawar, J. Modelling of 4WD vehicle driveability during tip-in/tip-out events. In Proceedings of the 22nd International Symposium on Dynamics of Vehicle on Road and Tracks, Manchester, UK, 14–19 August 2011; p. 85. [Google Scholar]

- Yoon, H.-W.; Bang, J.-H.; Park, J.-H. Development of Engine Mount System for Low Frequency Vibration Improvement. In SAE World Congress & Exhibition; Detroit SAE International: Detroit, MI, USA, 2008; p. 10. [Google Scholar]

- Sun, J.; Xue, X.; Cheng, K.W.E. Fuzzy Sliding Mode Wheel Slip Ratio Control for Smart Vehicle Anti-Lock Braking System. Energies 2019, 12, 2501. [Google Scholar] [CrossRef] [Green Version]

- List, H.O.; Schoeggl, P. Objective Evaluation of Vehicle Driveability. In International Congress & Exposition; Detroit SAE International: Detroit, MI, USA, 1998; p. 9. [Google Scholar]

- Krenz, R.A. Vehicle Response to Throttle Tip-In/Tip-Out. In Proceedings of the SAE Surface Vehicle Noise and Vibration Conference, Dearborn, MI, USA, 15 May 1985; pp. 793–800. [Google Scholar]

- Pazooki, A.; Rakheja, S.; Cao, D. Modeling and validation of off-road vehicle ride dynamics. Mech. Syst. Signal Process. 2012, 28, 679–695. [Google Scholar] [CrossRef] [Green Version]

| Components | Mass (kg) | Properties | Values | Units |

|---|---|---|---|---|

| RH rubber mount | Damping | 190 | N·s/m | |

| 0.1 | Pitch stiffness | 1.528 × 10−2 | N·m/° | |

| Yaw stiffness | 3.898 × 10−1 | N·s/m | ||

| LH rubber mount | Damping | 100 | N·s/m | |

| 0.1 | Pitch stiffness | 1.528 × 10−2 | N·m/° | |

| Yaw stiffness | 3.898 × 10−1 | N·m/° | ||

| Front roll-stopper rubber bush | 0.13 | Stiffness | 1 × 108 | N/m |

| Damping | 60 | N·s/m | ||

| Rear roll-stopper rubber bush | Stiffness | 1 × 108 | N/m | |

| 0.13 | Damping | 130 | N·s/m |

| Components | Values | Units |

|---|---|---|

| Front subframe bush_1–2 | 1.81 × 103 | N·s/m |

| Front subframe bush_3–4 | 1.01 × 103 | N·s/m |

| Rear subframe bush_1–4 | 5.5 × 102 | N·s/m |

| Front RH and LH suspensions | 3.5 × 102 | N·s/m |

| Rear RH and LH suspensions | 2.5 × 102 | N·s/m |

| Parameters | Symbols | Values | Units |

|---|---|---|---|

| Frontal area | A | 2.5 | m2 |

| Coefficient of drag | Cd | 0.3 | |

| Vehicle body (including BES) mass | ms | 1670.5 | kg |

| PT mass | mpt | 251.3 | kg |

| Front subframe mass | mfsf | 38.7 | kg |

| Rear subframe mass | mrsf | 15.6 | kg |

| Front tyre mass | mfw | 41.6 | kg |

| Rear tyre mass | mrw | 38.2 | kg |

| Static weight distribution | 57:43 | ||

| Maximum EM torque | τem | 320 | N·m |

| Transmission | 7.139 | Total ratio | |

| Differential type | 50:50 | Open | |

| Tyre rolling resistance | Crr | 0.018 | |

| Effective tyre rolling radius | rew | 0.3415 | m |

| Road Surfaces | Right Wheels | Left Wheels |

|---|---|---|

| Tarmac | 0.85 | 0.85 |

| Polished ice | 0.10 | 0.10 |

| Split-mu | 0.85 | 0.10 |

| Case Studies | RH/LH Rubber Mount Properties | Front Roll-Stopper Properties | Rear Roll-Stopper Properties | ||

|---|---|---|---|---|---|

| Longitudinal | Yaw | Pitch | Longitudinal | Longitudinal | |

| Case 1 | decoupled | ✓ | ✓ | ✓ | ✓ |

| Case 2 | ✓ | decoupled | ✓ | ✓ | ✓ |

| Case 3 | ✓ | ✓ | decoupled | ✓ | ✓ |

| Case 4 | ✓ | ✓ | ✓ | decoupled | ✓ |

| Case 5 | ✓ | ✓ | ✓ | ✓ | decoupled |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raja Ahsan Shah, R.M.; Jones, R.P.; Cheng, C.; Picarelli, A.; Abd Aziz, A.R.; Al Qubeissi, M. Model-Based Energy Path Analysis of Tip-In Event in a 2WD Vehicle with Range-Extender Electric Powertrain Architecture. Energies 2021, 14, 5696. https://doi.org/10.3390/en14185696

Raja Ahsan Shah RM, Jones RP, Cheng C, Picarelli A, Abd Aziz AR, Al Qubeissi M. Model-Based Energy Path Analysis of Tip-In Event in a 2WD Vehicle with Range-Extender Electric Powertrain Architecture. Energies. 2021; 14(18):5696. https://doi.org/10.3390/en14185696

Chicago/Turabian StyleRaja Ahsan Shah, Raja Mazuir, Richard Peter Jones, Caizhen Cheng, Alessandro Picarelli, Abd Rashid Abd Aziz, and Mansour Al Qubeissi. 2021. "Model-Based Energy Path Analysis of Tip-In Event in a 2WD Vehicle with Range-Extender Electric Powertrain Architecture" Energies 14, no. 18: 5696. https://doi.org/10.3390/en14185696

APA StyleRaja Ahsan Shah, R. M., Jones, R. P., Cheng, C., Picarelli, A., Abd Aziz, A. R., & Al Qubeissi, M. (2021). Model-Based Energy Path Analysis of Tip-In Event in a 2WD Vehicle with Range-Extender Electric Powertrain Architecture. Energies, 14(18), 5696. https://doi.org/10.3390/en14185696