1. Introduction

Urban planners, engineers and decision makers who influence the built environment are increasingly asked to simultaneously develop policies aimed at enhancing sustainability and resilience—including climate change mitigation and adaptation. Even if social dimensions or economic and environmental considerations are really relevant, in a rather limited view of sustainability, two dominant measures of sustainable construction can be evinced: energy consumption and carbon emission reduction [

1].

More than 40% of the total final energy consumption and about 30% of greenhouse gas (GHG) emissions are in connection with the civil and residential sector. Relevant possibilities of reducing the energy consumption lies in non-residential buildings, for public use, which are characterized by a higher energy intensity (EI) if compared to residential ones [

2] and relevant emissions, 5% of the total share [

3].

Considering the European countries, at least 15% of the final energy today is used in the commercial sectors; in this field, for example food stores and supermarkets are considered quite “high energy intensive” due to their relevant need for thermal comfort, refrigeration at various temperature levels from −18 to + 14 °C and lighting systems, with a relevant amount of electricity used [

4,

5]. The wholesale and retail trade segment represents the highest share of the final energy demand in the tertiary sector, with space conditioning and process cooling for food freezing leading the consumption; even alongside the food supply chain, the preparation and retail steps account for a high share of the energy consumption, between 30–40% [

6].

The common energy saving techniques, related to the various systems installed, the building envelope and demand management represent the opportunity for this specific building category to increase the overall sustainability, in terms of both energy supply and GHG emissions. Moreover, these measures proved to have a beneficial impact on the community awareness about sustainability and eco-friendly technologies [

7]: a corporate social responsibility strategy that enhances the brand value. Energy efficiency is, therefore, considered a strategic priority [

5]. Recent data on energy consumption in the food stores monitored and collected under specific structures and climatic conditions show that the energy use intensity, expressed as energy used over floor or sales area for a whole year and acknowledged as a proper measurement parameter, even if still quite high, has been largely reduced in the last ten years. This is mainly verified in the quite large structures with a floor area higher than 700 m

2, mainly in combination with energy-efficient technologies installed in all subsystems, including refrigeration systems, Heating Ventilation and Air Conditioning (HVAC) for thermal control and lighting systems [

8,

9,

10].

The integration of renewable energy systems (RES) as active measures for energy production appears a reasonable step in conjunction with the aforementioned strategies. The relevant amount of electricity used in supermarkets, focused in daytime, makes it easier to move towards a net Zero Energy Building (nZEB) configuration and to pursue objectives of intelligent use of sustainable resources [

11,

12].

Moreover, energy system integration grows in importance requiring the services of technologies such as storage as a key enabler, both at a central level and distributed for flexible consumers. In particular, as the use of energy is in phase with the solar energy availability, the stores for the sale of food become the most interesting candidates for the installation of photovoltaic (PV) power plants, aimed at self-production of energy among the tertiary sector buildings, making it possible to avoid the problem of placing the surplus of energy produced into the electrical grid. The sector of food stores in general, including supermarkets and superstores, due to the quite high energy load and the quite large availability of surfaces, appears to be strategic in order to promote a further increase of the diffusion of Building Integrated PV (BIPV) plants.

The installation PV plants has been grown in Europe mainly in independent applications at all levels and complexities: on roofs or facades of buildings for domestic and commercial use of various size and typology. Non-programmable RES will surely become the reference source and a strategic innovative element before 2030, mainly thanks to the wider and strategic diffusion of Photovoltaic (PV) plants. In this perspective, the useful integration of these vital contributors within the buildings for the future energy transition strategy is worth investigating; the added advantage of this technology is the opportunity to site the plants everywhere, most importantly on buildings, right where the actual load is, directly contributing to the optimal use of resources.

Today, more than 600 GW of solar PV power plants have already been installed worldwide, making solar PV the second renewable electricity source. A substantial portion of the PV installations until now have been related to the randomness of feed-in tariffs established by local governments and this caused problems to the energy systems, as evidenced by one of the authors of the present paper in [

13,

14].

The spread of Building-integrated PV (BiPV) can represent a new stable driving force for the diffusion of PV systems: they consist of PV modules that function as part of the building envelope (curtain walls, roof panels or shingles, shading devices, skylights). BiPV systems are sometimes installed in new “showcase” buildings even before the systems are generally cost-effective.

Food stores and supermarkets represent a strategic sector in this perspective. In this case, as observed in the previous section, direct use of the energy generated is an obvious choice, hence avoiding costly conversions and energy dispatch. The investigation of proper size and design of PV systems for supermarkets proceeds to be an interesting and innovative topic, as most research focuses on the effect of envelope and system energy-efficient solutions [

15].

The high standardization of envelope and constructions behind stores structures mainly in the medium to high size, that include typical prefabricated materials, gives value to the use of benchmark indicators, derived from measured data in a bottom-up approach, as they can be properly scaled and adapted for future design. Through these indexes, a sizing analysis can take into account different strategies and configurations to maximize the share of self-consumed energy, including proper system and storage sizing, demand-side management and forecast.

The present work aims to determine possible benchmark values and related key performance indicators based on the analysis of the energy use in food retail structures, to try defining possible reference values according to the climate conditions and the size of the store for the sizing of PV systems. The investigation examines the annual energy consumption and cooling and heating demand of typical supermarket structures. Monitored data of some specific cases are then shown; case studies represent the common Italian supermarkets. After an analysis of the energy consumption parameters in the typical seasonal operating conditions, results are compared with the data of similar structures located in different countries; criteria and guidelines for the design of PV systems are developed based on different purposes on balancing energy production and use. The purpose is to validate the efficacy of reference values, based on real data, to determine the correct size of different PV system configurations and evaluating the impact of the integration of the renewable source. Considering the aforementioned aspects, the paper analyzes the perspective of active methods for energy production, consisting of the development of PV plants for reducing the carbon footprint of food retail structures and supermarkets. Starting from the extensive analysis of the energy consumption of two case studies referring to two food stores typical of Italian territory (although similar structures are largely diffused in various European countries and in the world), the paper proposes a possible sizing methodology for PV plants that have as an objective the maximization of the share of self-consumption of the energy produced. Various articles discussed the increase in self-consumption of PV plants. However, almost all the researchers have been focused on the residential sector. Considering the growing interest in reducing the energy use and carbon footprint of the commercial sector, the topic of designing solar PV plants for self-consumption in commercial buildings has been reported only in some recent papers. Allouhi in [

16] have studied the optimal PV size in commercial buildings, in a high self-consumption configuration, for the hot dry climate of Morocco through a life-cycle economic/environmental evaluation, for a gross an annual electricity demand of 2.932 GWh; the optimal size found was 847 kW of peak power. The potential and practicability of self-consumption for an easy integration of PV in buildings, especially without other policies and benefits, is stated even in the supermarket sectors: an analysis carried out on a store in Germany with a yearly electricity consumption of 238 MW h/year showed that systems with PV peak power up to twice the peak load are economically advantageous with an optimal degree of self-consumption and self-sufficiency [

17]. The present work can be inserted within this short set of research, with the specific constraint to pursue the objective of PV integration under the zero grid-injection restriction: unlike cited work, the aim is to provide general and practical guidelines for PV sizing with different configurations, directly derivable from the analysis of the consumption profile.

2. Correlation among Energy Consumption and Size of Store in the Food Retail Sector: Energy Use Intensity

The high repercussion of tertiary sectors on energy consumption depends on the type of building and the operation inside, that are quite different according to the category the building belongs to: office, shopping and commercial, sports, educational buildings, medical treatment and others. The market segment of the food supermarket is the most intensive in terms of energy consumption per square meter, within the buildings for commercial use [

5].

Food stores and supermarket are in general rectangular base buildings, with one floor in which six different zones can be identified: in general sales, produce, dry storage, bakery, delivery area and offices. In some cases, in particular in some high size stores, each different zone is served by a specific HVAC system, while in other cases, mainly for structures with reduced floor area, one or two chillers with multiple air handling units (AHU) are used. In the literature different classifications can be identified, but in general it is clearly evidenced the difference in terms of sales floor area, as reported in

Table 1, in which, according to the classification proposed in [

5] and rearranged by the authors of the present paper, four different typologies of structure can be identified, referring to the sales floor area.

The energy consumption of a supermarket, distributed among the different areas of the structure, is represented in major part by electricity. The composition of the pattern of distribution of the electric energy consumed by the different areas is associated with the following services: lighting, air conditioning and ventilation, cooling system, refrigeration units and miscellaneous consumption. A statistical analysis of electricity consumption permits obtaining of average values, well represented by the energy intensity. Such a value can be expressed in kWh/m2 for the year and can be referred to the total area of the store or only to the sales area.

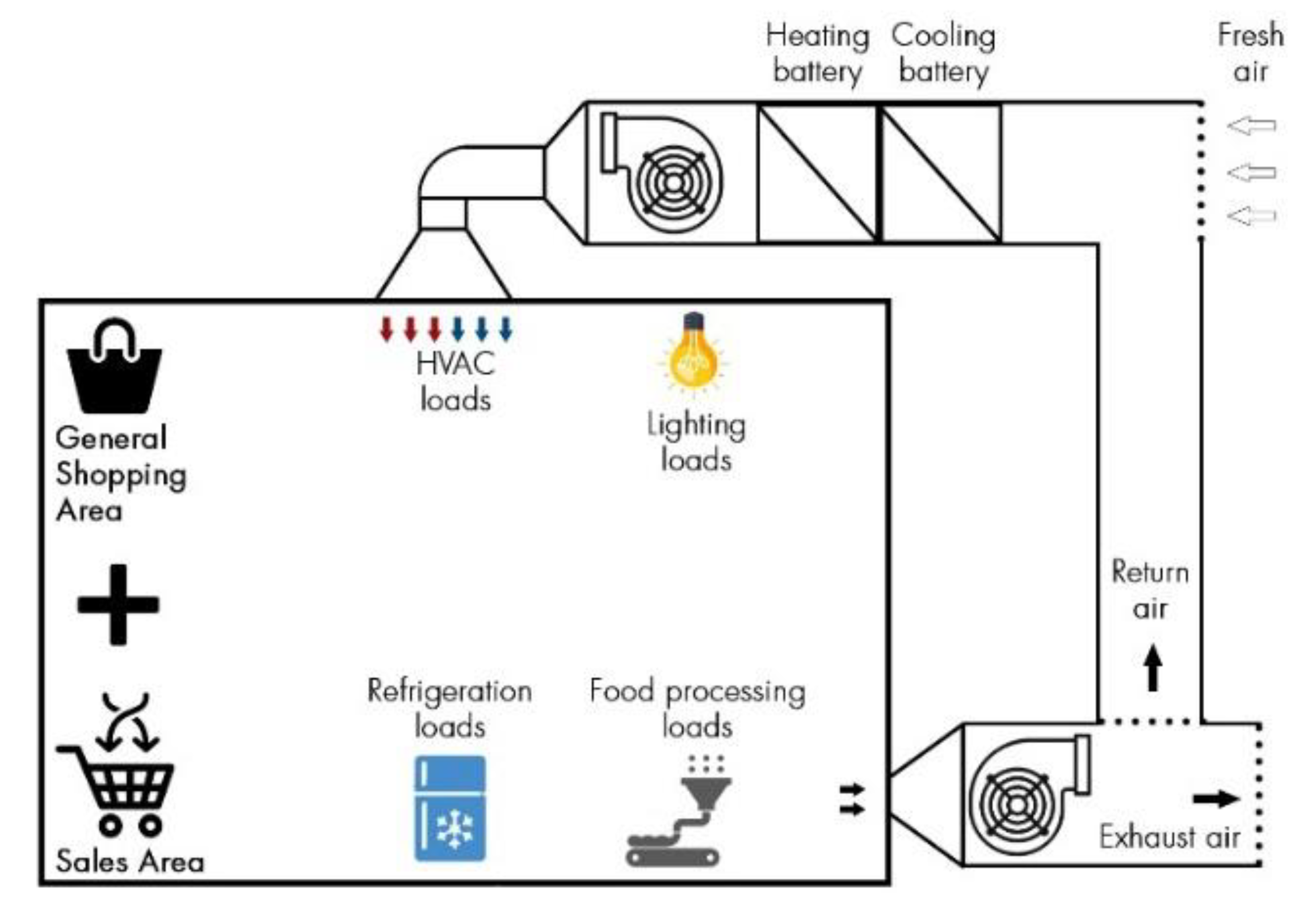

Food stores and supermarkets present a unique space conditioning challenge because of the interaction between the HVAC system and the refrigerated display cabinets: the first has to keep both high thermal comfort levels for the customers shopping experience and guarantee the necessary conditions for non-refrigerated products. In particular, the HVAC system is responsible for the highest share of the total consumption after refrigeration, based on the system configuration, the geographical location and the management. HVAC systems vary among different supermarkets [

18], each one involving different layouts and components that can be arranged in several ways in various configurations. Regardless, five different processes can be considered to achieve all the air-conditioning services, namely heating, cooling, humidifying, dehumidifying and ventilation [

19].

Figure 1 provides a typical layout configuration for a food store considering the HVAC system too.

The total energy used in the food store depends on business practices, store format and size, product food ratio, equipment use for in-store preservation and display, management of HVAC and lighting systems installed. Small supermarkets or convenience stores (<400–500 m

2), mainly diffused in the urban area, show a higher energy intensity than larger superstores due to the high ratio of food against non-food products. In this scenario the energy consumption related to refrigeration can increase up to 50–60%, as shown in a recent paper [

10], while only 30% is correlated with HVAC operation. About 15–20% of final energy consumption is correlated with the lighting systems and miscellaneous electricity loads. Other relevant differences can be reconnected to climatic elements. The smaller the store the highest the energy use due to the higher refrigeration equipment used [

20]: the ratio of food and non-food products becomes less crucial as the total sales area increases, while the lighting share becomes more significant. The EI (Energy intensity) index or normalized EI index, in which the energy intensity is referred to a single day or to a single month, is generally adopted to measure the overall energy use of buildings of public use.

The relevance of the energy consumption of shopping malls and supermarkets among the various tertiary activities has been determined by several studies; as already mentioned, the energy intensity of the food stores or supermarkets is in general quite high with respect to different commercial stores. According to the work of Wu et al. in [

4], that presented a method to evaluate the building energy consumption through specific indexes for different functional sectors in China, the food retail sector is characterized by EI values in the range between 150 kWh/m

2·per year and 450 kWh/m

2 per year. Sales and total floor area and supermarket energy consumption showed a good correlation: the main uncertainties of the estimation are due to the different design of structures and, mainly, by the different references for energy intensity computation. In fact, data reference difference depended on both energy stream, either based on the total energy consumption or limited to the electrical consumption, ignoring the use of gas, and the surface, being either the total floor area or the net sales floor area. Once the influence of the incidence of these uncertainties has been evaluated, a wide range of variability is perceivable in the data. Ríos Fernández and Roqueñí in a recent paper have correlated the energy intensity of the Spanish supermarkets to the floor area: the results, which represent a valid reference element for this paper, are summarized in

Table 2 [

8]. Those values can be considered representative of the case of Italian supermarkets too, due to close climatic conditions between the two countries, mainly considering central and southern Italy.

Different authors from the UK, considering the specific problem of energy consumption of food stores and supermarkets [

21,

22] show an electrical energy consumption over sales floor area that is quite higher. The authors in particular identify very high values, ranging from 770 up to 1480 kWh/m

2 per year, moving from hypermarket to convenience-size stores. Analyzing the energy use by subsystems, the authors assign 30–35% to refrigeration, 20–25% to HVAC and about 15–20% to the lighting system [

22]. Van der Sluis et al. in a similar paper [

23] shows that specific energy consumption (SEC) values, in particular total energy referred to gross floor area, analyzed in different countries, in particular Germany and Canada, show energy intensity values in the range between 400 and 800 kWh/m

2 per year (lowest from a Dutch supermarket chain and highest in Canadian stores). Even if the difference in calculation of energy intensity is taken into account, the electrical energy intensity in UK supermarkets appears to be 2.5 times as high as the value in Dutch supermarkets. As refrigeration is responsible for a large part of the energy used by stores, refrigeration capacity was considered to assess whether it correlated well with energy intensity [

24,

25]. The energy efficiency issue in commercial structures has been largely investigated in recent scientific and technical literature. Enhanced utilization of daylight, or a combination of natural and mechanical ventilation with improved control, improved refrigeration cabinets, with doors on frozen food cabinets or an acceptance of a wider range of internal temperatures as efficiency measures proved to have a wide impact on the final energy use of such structures [

26]. The various efficiency measures mentioned, including HVAC system management, renovation of the lighting system with LED technology and the use of more efficient refrigeration units, as for example the systematic use of cabinet with automatic closing doors, can be important in order to determine a reduction of the EI [

11,

12].

The relevance of such efficiency measures is higher in smaller stores, where there is a high refrigerated food on goods ratio, typically greater than in larger stores that merchandise more non-grocery products. In general, commercial structures such as supermarkets and superstores are among the most energy-consuming subsector of the civil segment, despite the differences in the data analyzed. For this kind of structure, not only the implementation of saving measures but also the integration of active measures with the relevant introduction of energy production from renewable sources becomes particularly interesting. Some studies focused on the economy behind the installation of PV systems [

27]. A study on the profitability of commercial self-consumption solar installations in the supermarkets sector led in three German supermarkets showed the profitability of these kind of systems if the costs of the PV systems decrease between EUR 200/kWh and EUR 600/kWh. Nevertheless, this study does not consider battery storage applications [

28]. Other studies focused more on the environmental consequences [

29]: the common conclusion is the relevance of the integration of PV systems, the particular suitability of stores, for both the magnitude and trend of the demand profile and the available surface and the profitability of high self-consumption schemes.

3. Energy Consumption Profile, Efficiency Measure and Use of Renewable Energies

The framework described in the previous section has focused on general, peculiar, elements of food stores and related typical consumption data for food sales with reference to the average annual data and to reference values of the average EI. The design of a PV plant, however, planned for the energy production, needs the support of the variations of the energy consumption over time. The trend is influenced by several factors: the calendar day, the number of opening hours, the customer’s presence, external temperature, humidity and daylight. Following this purpose, we have monitored the consumption of two food stores. One is the typical supermarket, meant for food sale (case B), while the second is a typical hypermarket (case A), where the food store, which takes up most of the sales area, is mixed with different, smaller stores. The two stores are located in two different towns of Tuscany (central Italy). The climatic data of the coastal region of Tuscany are reported in

Table 3, in which is the average value of external temperature, the typical average solar irradiation, the relative humidity (RH) and the wind velocity.

The specific data of the two structures are reported in

Table 4. The two structures used as test cases are modern structures, equipped with all the main energy efficiency measures, both concerning the building and the various systems (HVAC, lighting and refrigeration units) and are representative of two typical modern food stores available in Italy.

Analyzing the energy consumption data measured in real operating conditions, it can be observed that in this case there is a significant variation both within the single day and in the different seasons. Since energy consumption is largely due to refrigeration, energy uses are more relevant during the summer season.

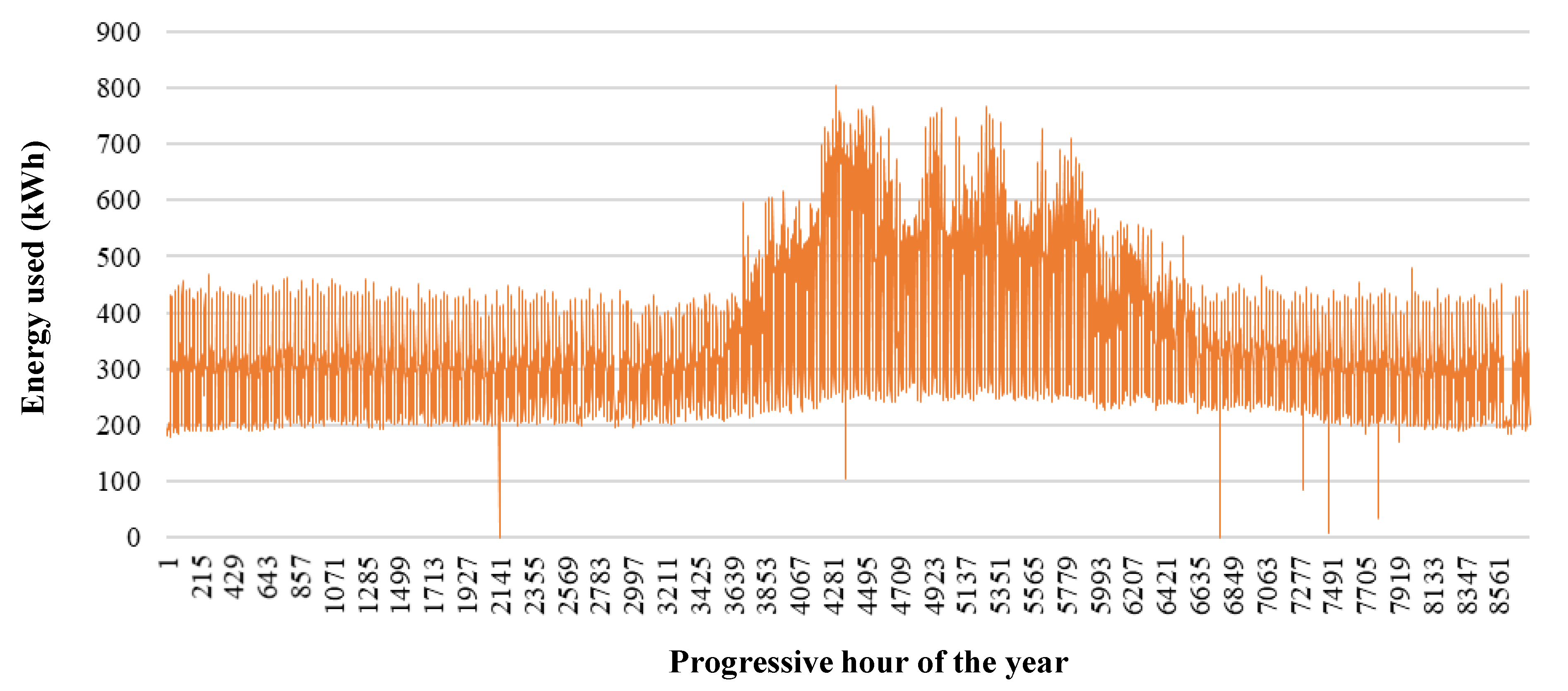

Figure 2 and

Figure 3 provide the hourly trend of energy consumption for the two stores under analysis, measured in real operating conditions. As it is simple to observe, there exists a minimum level of energy consumption for maintaining lighting, security systems and food refrigeration during the night-time and, only in some special cases, the energy consumption drops to zero, even if the supermarket is closed, and even if such cases can be considered as outliers. In particular, in

Figure 2 and

Figure 3, on the ordinate axis the total energy consumption of the store is provided during the different hours of one year (a total of 8760), provided on the abscissa axis and corresponding to the period from 1 January to 31 December.

The analysis of these rough data highlights the overall range of variation but is not useful to understand the actual behavior of the supermarket and identify reference values for system sizing. The maximum hourly energy consumptions for both the stores was during summertime and it corresponded to about 800 kWh for Store A and 100 kWh for Store B, while the minimum values were approximately 200 kWh for Store A and 30 kWh for Store B (the minimum values were obviously observed during the night and in the cold season).

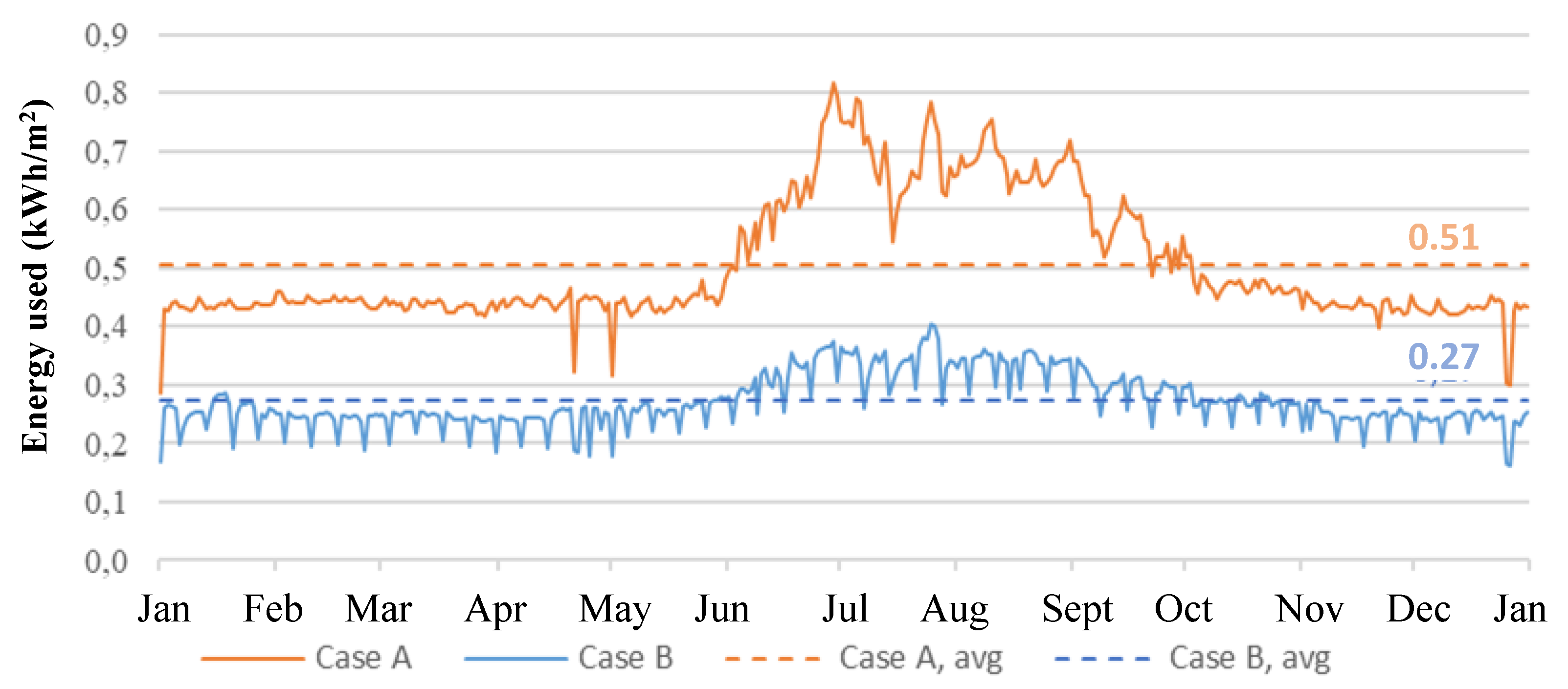

To compare the structures under investigation with the benchmarks defined in the previous section, in

Figure 4 the hourly and average values of energy intensity, referred to the store surface, are provided for both the cases. Some useful data can be extracted from the daily trend; in particular, the base load, occurring during the night, when the supermarkets was closed and the value and the time of the peak of electrical demand, occurring from the late morning and the evening, depending on the different seasons: those data are of fundamental importance for the accurate design of a PV plant for energy production.

In both the cases, Store A and Store B, a base load that is active for the 24 h for all the days of the year (typical days of the week, pre-holidays and holidays) can be detected: a minimum value of the hourly electrical demand of about 200–260 kWh in the first case (store A) and of 30–45 kWh in the latter one (store B) can be considered.

Those minimum values are obviously connected to refrigeration loads that keep working when the store is closed. The consistent and quite constant electricity baseload guarantees a reference value for the sizing of PV systems in a full self-consumption configuration. Considering working days, the daily trend starts ranging between night-time and daytime, with a slightly higher mean value of 264 and 47 kWh for Store A and B, respectively. Concerning the two stores, referring to the average value of the specific energy intensity, were values of 0.51 kWh/m2 d for Store A (186.1 kWh/m2y) and 0.27 kWh/m2 day for Store B (98.55 kWh/m2 y). The values are sensibly lower than those available in the literature.

Some general data that can be obtained from the energy consumption profiles of the two stores are summarized in

Table 5.

4. The n-ZEB Food Store with a PV Plants for Energy Production

The energy demand of the buildings of residential and public use is a problem widely considered in all the countries. Considering the Italian case, interesting recent studies consider this problem with specific reference to food stores and supermarkets. The energy consumption can be reduced through the optimization of the structure (employing effective use of materials), or using efficient technologies and management strategies for acclimatization, as in [

30], or by increasing the use of passive solar design strategies; the building design and architectural features play a relevant role too, defining the passive contribution to heating and cooling, the shading capacity of the building and the amount of natural lighting [

31]. Different studies, such as [

32], propose the use of advanced poly-generation systems.

The systematic installation of RES on public buildings as commercial ones, will permit us to reduce the use of fossil sources and transmission and distribution losses along the main power grid and contribute to electric peak shaving and partial-loads losses reduction. As a direct consequence, this will lead to a new role for such structures, shifting from a passive energy consumer to active prosumers able to produce energy and distribute energy [

33].

In particular, the energy production in buildings of public use and with a relatively high share of electricity consumption can be mainly obtained with the use of solar-based systems, such as PV, for electricity production or solar thermal collectors for hot water production; this process is strictly related to the kind of HVAC system used in the building.

Regardless, the integration of RES, as in particular of the PV plants, though if in general is considered always positive, today has some relevant technical constraints that limit the diffusion of such a practice. PV plants are vital contributors for the future energy transition to a de-carbonized energy system due to the growing role of electricity, both in the supply of alternative fuels and in the final uses. The added advantage of PV lies in its installation flexibility as it can be sited everywhere and, most importantly, on the buildings and developed areas where the actual load is, hence directly contributing to the optimal use of resources. Energy system integration will grow in importance, requiring the services of technologies, such as storage, as key enablers, both at a central and distributed level for flexible consumers. Flexibility at all levels has an increasing relevance: transforming the demand into a provider for optimal use of resources by turning the end users into prime providers of flexibility is a possible answer.

Considering the two different structures analyzed in

Section 3, the profitability and size of the PV power systems can be studied with various different objectives and with different constraints; it could be relevant to understand whether it could be possible to use the electrical grid as a buffer or not. On the basis of these parameters, deduced through the analysis and clustering of electrical consumption trends, different sizing strategies have been developed, according to different goals.

The size of the PV plant can be defined with different objectives and methodologies. Some relevant data concerning the operation of the PV system can be defined, according to the description available in [

34] for residential buildings.

The total energy used in the store in a reference period considered (for example one year) can be defined as, ETOT. The energy imported from the grid, EIMP, is the energy corresponding to the periods during which no production of the PV plant is available or if the production is lower than the request. The energy exported to the power grid, EEXP, reflects periods of excess energy production or waste if it is not possible to store energy or to sell the excess energy.

The energy produced can be easily compared with the value that was estimated as the product of the annual solar irradiation typical for the specific place at a given exposure,

HSN, of a balance of system efficiency,

ηBOS, taking into account the various electrical losses in the system, and the peak power of the PV plant,

PPV.

The maximum production of a PV system expressed in kWh/kW in the specific place and the annual solar irradiation is a consequence of the fact that the nominal power of the PV plant is calculated considering a specific solar irradiation of 1000 W/m2, and an operating temperature of the modules of 25 °C, values referred as Standard Test Conditions (STC).

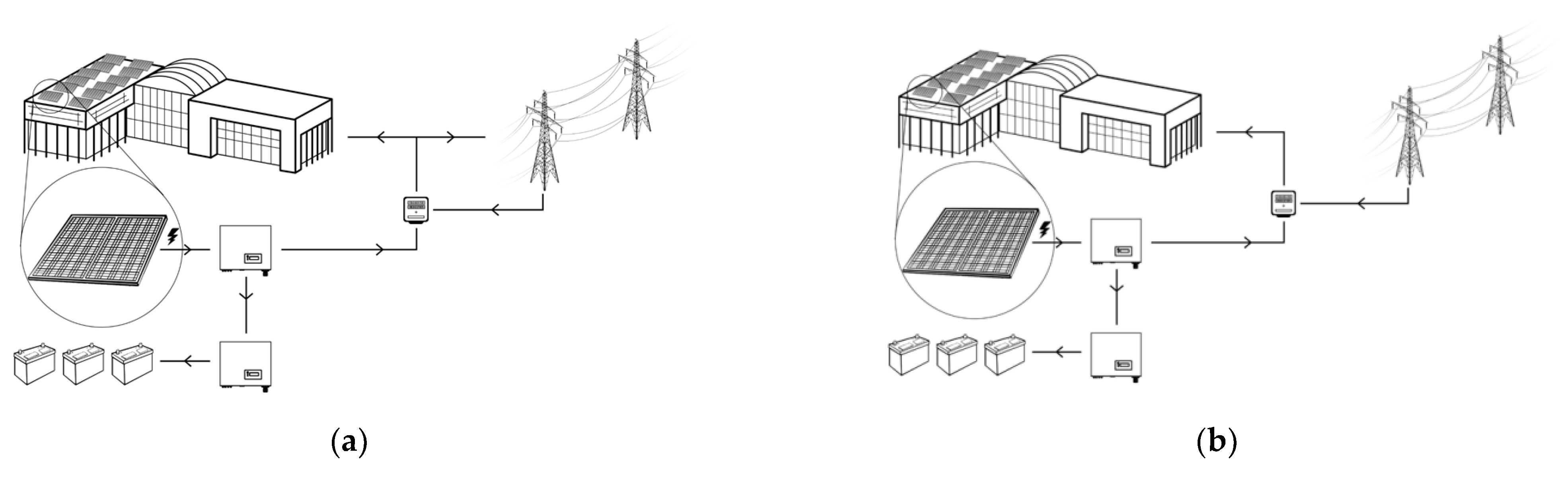

Considering a PV plant on a building, self-consumption can be defined as the percentage of PV electricity that is consumed locally vs. the overall electricity generated by the particular PV generator. If there is an exceeding amount of electricity produced, there can be three possibilities. It is exported to the grid, if this is permitted by the contract; it can be stored in a battery to be used at later times when the solar electricity is not covering the load demand or finally, wasted, if grid-injection restriction is imposed (for example zero injection restriction).

Figure 5 provides the system topology in the two main different cases, when energy export to the grid is possible and when zero-injection restriction are imposed.

For each day and each period of the year, using the results of the measurement exposed in the previous sections, it was possible to evaluate the energy exchanged with the power grid to understand how close the system is to the model of a nearly zero-energy building (nZEB) and the amount of energy in excess, that needs to be exported to the grid if possible

EEXP, (if it is not possible to export energy this amount will be wasted) or imported from the power grid,

EIMP, can be defined as:

The energy produced with the PV plant and directly used,

ED, can be calculated by

To quantify the success of the self-consumption strategy, the energy flows directly used and that are imported from or exported to the grid must be exactly defined. To measure the energy produced and directly used in the structure, two specific indicators can be defined. In particular, the self-consumption index,

ITOT, based on the total energy demand of the building,

ETOT, and the auto-production index,

IPV, defined as ratio of the energy directly used and the overall PV production,

EPV, have been determined and evaluated with the following equation, according to the definition explained in [

31]:

The analysis above considered can be referred to the single day, to the different months of operation or to the whole year.

Concerning the size of the PV plant, different strategies can be identified in order to define it, according to the different objectives as:

- -

producing the total amount of energy consumed in the summer period (when the PV plant production is sized at maximum level);

- -

maximizing the IPV index in the perspective of a full self-consumption strategy (PV plant with minimum size);

- -

obtaining average production level imposing a well-defined amount of energy produced by PV plant (from 40 to 60%) with respect to the total energy required (plant of medium to high size);

- -

maximizing the ITOT index, so obtaining maximum production and minimum energy losses (in this case the use of a storage system is necessary).

In general, in order to pursue a complete self-consumption strategy, the holidays average hourly base load, the annual hourly base load or the minimum daily consumption can be used: in the latter, considering the maximum value of summer daily solar irradiation for the specific zone of interest (7.8 kWh/m2 corresponding to a PV production of 6.3–6.4 kWh for each kW installed during the summer period). The maximization of the IPV indicator can be obtained with a value of the PV plant power installed of 560 kW (for Store A) and of 100 kW (for Store B), respectively.

Considering a sizing strategy based on the whole year, considering average values of production on a yearly basis, the weekdays average hourly base load or the annual average hourly consumption can be considered as reference levels for mean consumption during the year; in the first case, this time compared to the local average solar irradiation (a value of daily solar irradiation of about 4 kWh/m2 can be assumed as an input parameter, corresponding to a PV production of 3.2–3.3 kWh for each kW installed), a PV plant of about 1650 kW (for Store A) and a PV plant of peak power about 280 kW (for Store B) are required.

The corresponding required surface for installing the PV plant can be estimated in dependence of the typical PV technology used: approximately 5.5 m2 for each kW installed in case of PV plant that uses monocrystalline modules, while the value of 7 m2 for each kW installed can be considered in case of polycrystalline PV modules.

The gross annual consumption represents another useful benchmark: an average sizing can be based on a share of about 70% of the total annual energy demand, leading to a PV power installed for case A and B of 1474 and 226 kW, respectively.

In both cases the self-consumption index (IPV) share of the energy directly used decreases by about 20–30%, but the self-sufficiency index (ITOT), based on the share of energy demand covered by on-site production, highly increases, almost doubled.

Table 6 shows the benchmarks used for the system sizing, along with energy produced by PV plant (

EPV) and flows from (

EIMP) and to the grid (

EEXP).

To further optimize the sizing process, the hourly trend of the energy demand of the whole food store needs to be considered. Moreover, in case of impossibility of exporting energy to the grid, the integration of a storage system of appropriate dimensions is necessary. The storage system adds flexibility to the plant and help offset the time gap between production and consumption, in particular, shifting the energy produced from midday hours to the night.

Table 7 summarizes the values achieved in terms of both PV size and ideal size of the storage system, including the total energy stored along the year (

ES). The storage is set at a mean daily PV potential production level, 4 kWh/kW. As it can be seen, starting from complete self-consumption without storage, in both cases the introduction of a battery system allows the PV size to increase by 2.7 times. Even an optimal size, based on a global balance between the two indexes, returns identical values, 91% of

IPV and 72% of

ITOT.

This again highlights how the standardization of these kind of structures and their management is a useful point for a general discussion and approach for the integration of RES, with appropriate scaling based on climatic factors and building dimensions.

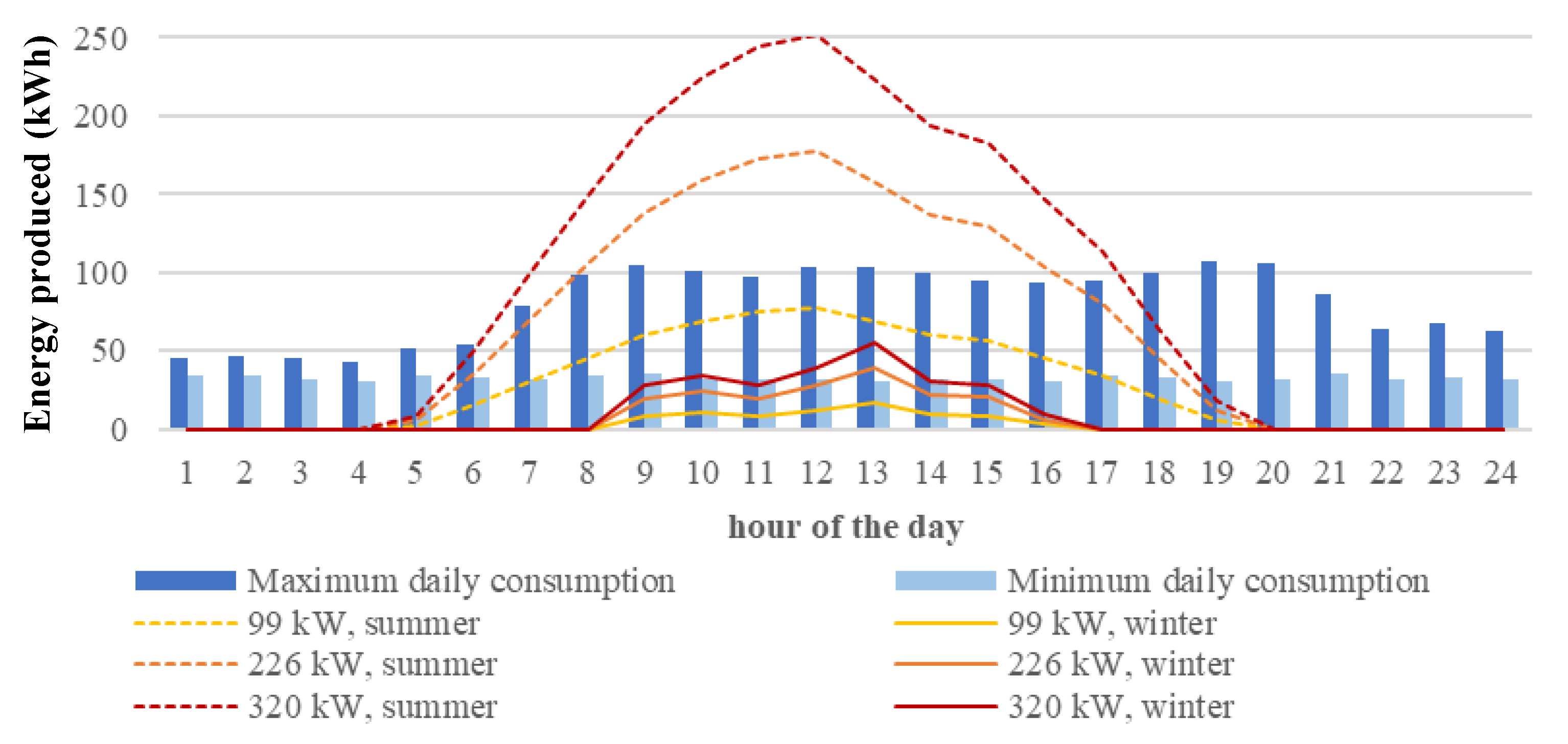

The graph of

Figure 6 shows the daily energy production of three different PV plants disposed on the roof of Store B. The first one is the basic PV plant of peak power 99 kW without storage, while the second and the third are the plants with peak power of 226 and 320 kW, both equipped with a storage system, as reported in

Table 7. In particular, in the figure typical values of energy production profiles of the three plants during summertime (dotted lines) and during winter season are reported, while the bars provided for each hour of the year represent minimum and maximum value of the energy required in the specific hour defined along the whole year.

It is interesting to remark that in all the cases under consideration, the available roof surface of the building is sufficient to contain the modules (the plant of 320 kW of peak power could require approximately 2300 m2 of surface). Indeed, in the last two cases, some problems can be correlated with the quite high size of the electrochemical storage system, 880 and 1280 kWh capacity, that surely contribute to increase the cost of the plants. The authors have clear in mind that PV plant sizing should be based on economic optimization and different considerations have to be introduced, considering the cost of investment, dependent on the specific cost of PV modules and components and the economic savings returned, but the technical validity of the solution proposed in the present paper and the problems involved can be appreciated based only on energy analysis, considering this the first step of a more complete analysis.