In this section, we present how we use the developed fault taxonomy to map results generated from two FDD tools. Results for detecting and diagnosing RTU faults from two commercial FDD tools are employed. We firstly extracted critical information which illustrate fault properties from the FDD reports. Then, we mapped fault names according to the developed fault taxonomy. From this process, we successfully reduced the number of fault names, and hence, redundant information in the FDD tool reports could be dropped. New fault IDs were assigned when the mapped fault names were generated. Lastly, we employed one processed FDD report to calculate fault occurrence at different granular levels to demonstrate efficient analyses and evaluation of the commercial FDD tools can be achieved, and the HVAC system fault prevalence research can be accomplished.

4.1. Description of Data Set

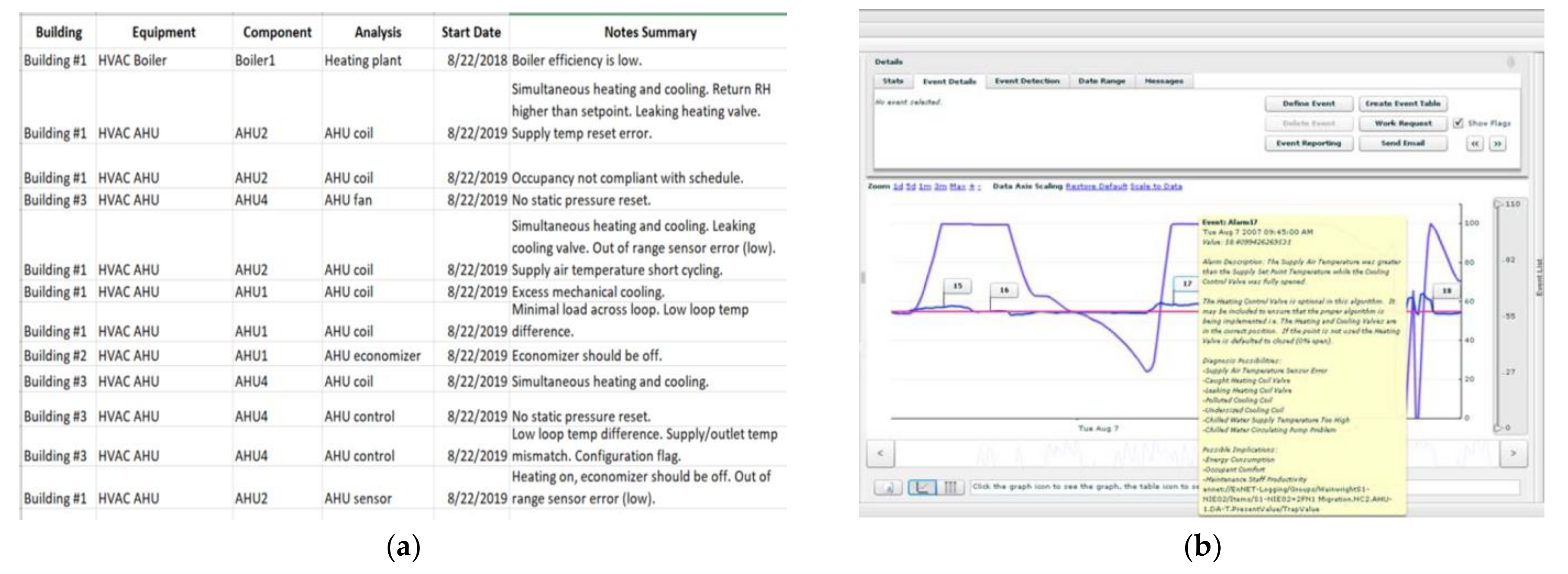

In this study, fault reports from two commercial FDD software tools which listed the identified RTU faults, are used.

The first report (referred to as no. 1 FDD report) generated from the commercial FDD tool A, includes two-year (Year 2018–2019) FDD results of a total of over 2000 RTUs from 131 buildings in the U.S. After converting the raw fault message into a binary daily fault (BDF) format in which multiple fault logs for the same piece of component of an equipment in the same day are removed, and only one unique fault message for the same piece of component of an equipment within one day is kept. The number of BDF messages in the data set reaches 2,865,786 rows.

The second report (referred to as no. 2 FDD report) generated from commercial FDD tool B covers one-year (Year 2018) FDD results of over 5000 RTUs from 808 buildings including office buildings, mercantile buildings, and education buildings, in the U.S. The number of BDF messages in the data set reaches 348,911 rows.

The BDF messages are the fundamental elements and will be used to calculate the HVAC fault prevalence according to different drivers.

4.3. Fault Mapping Results

Table 7 and

Table 8 present the unique fault names according to the taxonomy library.

In the no. 1 FDD tool, a total of 167 raw fault names are reported from a two-year FDD report. Among those 167 faults, 102 faults can be mapped to condition-based faults and 45 faults can be mapped to behavior-based faults according to the taxonomy respectively. After mapping fault names according to the taxonomy, 39 unique faults in the no. 1 FDD report were assigned as given in

Table 7.

In the no. 2 FDD tool, a total of 17 raw fault names are extracted from a one-year FDD report. Among those 17 faults, 6 faults can be mapped to condition-based faults and no fault can be mapped to behavior-based faults. After mapping fault names according to the taxonomy, 6 unique faults in the no. 2 FDD tool were assigned as given in

Table 8.

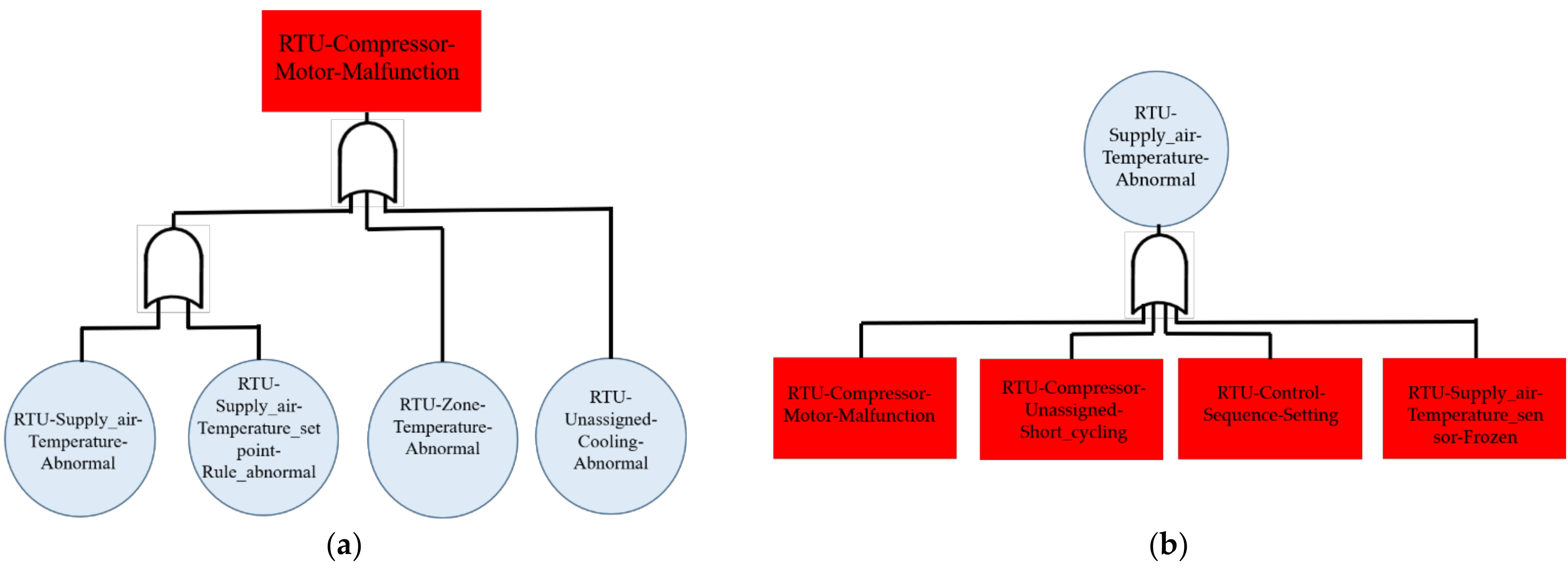

The number of unique faults after mapping is much less than the number of raw fault names in no. 1 FDD report because multiple fault names in the FDD reports can be mapped to the same fault according to the fault taxonomy as can be seen in

Table 9. For instance, the ‘RTU-Zone-Temperature_sensor-Unspecified’ condition-based fault in the taxonomy was used to map 14 raw fault names in the FDD report including: ‘ZAT Sensor Failure: Reading less than 45’, ‘ZAT Failure: Reading greater than 95’, ‘ZAT Circuit open’, ‘ZAT Sensor Circuit is Open’, ‘ZAT Sensor Excessively Fluctuating’, ‘ZAT Circuit is Shorted’, and so on. For these fault names, the fault’s component location and component type, i.e., the zone temperature sensor can be identified. Besides, some fault symptoms (e.g., Reading less than 45 and greater than 95) are given in fault names based on internal rules used by the FDD tool developers. However, the fault name is not well described to reveal the fault nature. Therefore, we mapped this fault to the ‘RTU-Zone-Temperature_sensor-Unspecified’. Another example is in the no. 1 FDD report, the ‘RTU-Supply_air-Temperature_setpoint-Rule_abnormal’ behavior-based fault in the taxonomy was used to map 2 raw fault names in the FDD report including: ‘Free Cooling Setpoint Not Met-SAT Too Warm’ and ‘Free Cooling Setpoint Not Met-SAT Too Cool’. In this case, the supply air temperature abnormal fault was reported by providing both the setpoint information and supply air temperature information. The relation between these two measures is broken to illustrate this behavior-based fault can be either caused by the setpoint setting error or other faults. Therefore, we used the ‘RTU-Supply_air-Temperature_setpoint-Rule_abnormal’ to map both faults.

After mapping fault names according to the taxonomy, 39 unique faults in the no. 1 FDD report, and 6 unique faults in the no. 2 FDD tool were assigned. Both FDD tools have ‘RTU-Supply_air-Temperature_sensor-Unspecified’ fault reported. In the no. 1 FDD report, four fault names including ‘SAT Sensor Failure: Reading less than 35 F’, ‘SAT Sensor Failure: Reading greater than 150 F’, ‘SAT Sensor Failure: Reading greater than 150’ and ‘SAT Circuit Shorted’ are mapped to this fault. In the no. 2 FDD report, one fault name (e.g., ‘HealthSATSensor’) is mapped to this fault. Both FDD tools have faults related to outside temperature sensor, but in the no. 1 FDD report, the fault name can be mapped to ‘RTU-Outside_air-Temperature_sensor-Frozen’ as the raw fault name is ‘Stuck Outside Air Temperature Sensor’. However, in the no. 2 FDD report, the fault name can only be mapped to ‘RTU-Outside_air-Temperature_sensor-Unspecified’ because no detailed information on the fault nature is given in the raw fault name (i.e., ‘HealthOSASensor’). The FDD tool vendor cannot give the detailed information on this fault either.

Table 9 and

Table 10 list the quantitative mapping analyses for no. 1 and no. 2 FDD tool reports respectively.

In order to evaluate the redundant information (i.e., multiple fault names represent one type of fault), the fault name reduction rate is proposed. The fault name reduction rate can represent what the percentage of raw fault names in the FDD tool can be reduced as a result that those raw fault names can be mapped to one fault name in the taxonomy. The higher fault name reduction rate means that a higher amount of fault names represents the same information, and hence has a higher duplicated information in the FDD reports. The calculation of the fault name reduction rate is given below:

Consequently, in the no. 1 FDD report, the total fault name reduction rate is 73.4% because 39 unique fault names were mapped from 147 fault names which can be mapped in the FDD report (71.6% for the condition-based faults, and 77.8% fault the behavior-based faults respectively) as shown in

Table 9. In the no. 2 FDD report, the total fault name reduction rate is 0% because 6 unique fault names were mapped from 6 fault names which can be mapped in the FDD tool (0% for the condition-based faults), as given in

Table 10. A 0% fault name reduction rate illustrates that the FDD tool vendor does not use similar fault names to represent the same fault according to fault name.

However, the mapping result shows that the mapping percentage did not reach 100%, i.e., some faults in the FDD reports were not successfully mapped. As can be seen, for the no. 1 FDD tool, the total successful mapping fault name is 88%. For the no. 2 FDD tool, the total successful mapping fault name is 35.29%

The reasons for unsuccessfully-mapped fault names come from the following aspects:

1. The faults for specific components are not developed in the current version of taxonomy. For example, faults related to a heating recovery wheel are detected by the no. 1 FDD tool. As the heating recovery wheel was not considered in the RTU configuration in the current version taxonomy library, four faults related to the recovery wheel (e.g., ‘ERV Wheel Low Outside Airflow’, ‘ERV Wheel Inefficiency Duration’, ‘ERV Wheel Inefficiency Demand’, ‘ERV Wheel Inefficiency’) were not mapped. In the no. 1 FDD report and in the no. 2 FDD report, 21 raw fault names and two raw fault names are not mapped because of this reason.

2. The faults described by the FDD tool reports cannot be identified. For example, in one FDD tool, a ‘No Communication’ fault is reported. This fault does not provide any details regarding fault location and component type. In the no. 1 FDD report and no. 2 FDD report, two raw fault names and eight raw fault names are not mapped because of this reason.

3. Multiple fault natures are presented in the semantic description of a fault. For instance, in the no. 2 FDD tool, a ‘HealthMultipleFaults’ fault name is used but no specific fault nature and diagnosis information is provided. In this case, the fault name cannot be mapped to the taxonomy. In the no. 2 FDD report, one raw fault name is not mapped because of this reason.

Generally speaking, two objectives are achieved through mapping the FDD results via the developed fault taxonomy. First, the fault name space is decreased after mapping the fault names to the names in the fault library of the taxonomy. Therefore, automated analysis and evaluation on FDD results can be more efficient. Secondly, with the unifying fault taxonomy, the exact names were mapped to the fault messages from different FDD tools. Therefore, the FDD results from different FDD tools can be easily compared.

4.4. Calculation of Fault Prevalence

Initial fault prevalence research has been conducted by employing the fault taxonomy mapping results. The fault prevalence research is based on data collected from various commercialized FDD tools across the U.S. The objective of the research is to understand the fault occurrence for a specific fault or for a specific component. We designed various metrics to assess the fault occurrence and prevalence.

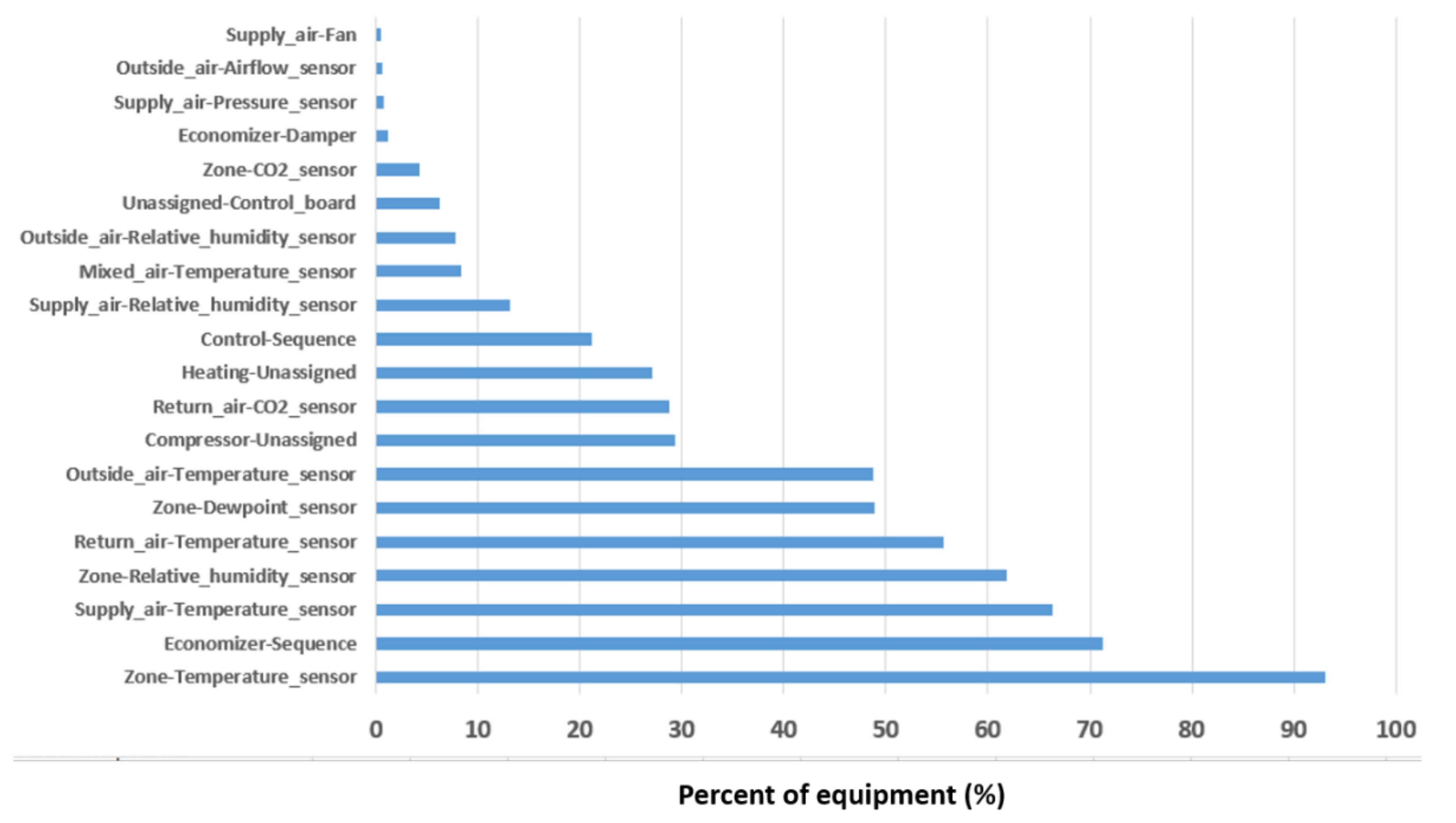

For example, we designed a metric which is the average monthly fault presence. In this metric, we measure what percentage of equipment experiences the presence of fault type ‘x’ on one or more days in a month, averaged across all months (expressed as a percentage of all equipment that could experience that fault). Using no. 1 FDD report as an example, the average monthly fault presence for the 39 mapped faults is from 0.02 to 65.8% as given in

Figure 6. It can be seen that the sensor related faults demonstrate a higher fault presence value compared with faults in other types of components. For instances, zone temperature sensor frozen fault (RTU-Zone-Temperature_sensor-Frozen), zone relative humidity sensor frozen (RTU-Zone-Relative_humidity_sensor-Frozen) fault, and outside air temperature sensor frozen (RTU-Outside_air-Temperature_sensor-Frozen) fault reach to 65.8%, 51.7%, and 44.3% respectively.

The format of fault name convention also enables the efficient data query to explore more detailed fault occurrence or evaluate equipment operation at different granular levels. Using the same data set from no. 1 FDD report, 20 different physical components (components associated with condition-based faults) are reported to experience a type of fault. 0.1% to 93.2% equipment report faults related to those 20 components as shown in

Figure 7. The top five components that a high percentage of equipment may report the faults are zone temperature sensor, economizer sequence, supply air temperature sensor, zone relative humidity sensor, and return air temperature sensor related. It can be seen that, through the clear definition of fault names and a well-designed format in the fault name conventions, it will be much easier to calculate and assess the fault occurrence at various components across the population of equipment.