Influence of Swirl Clocking on the Performance of Turbine Stage with Three-Dimensional Nozzle Guide Vane

Abstract

:1. Introduction

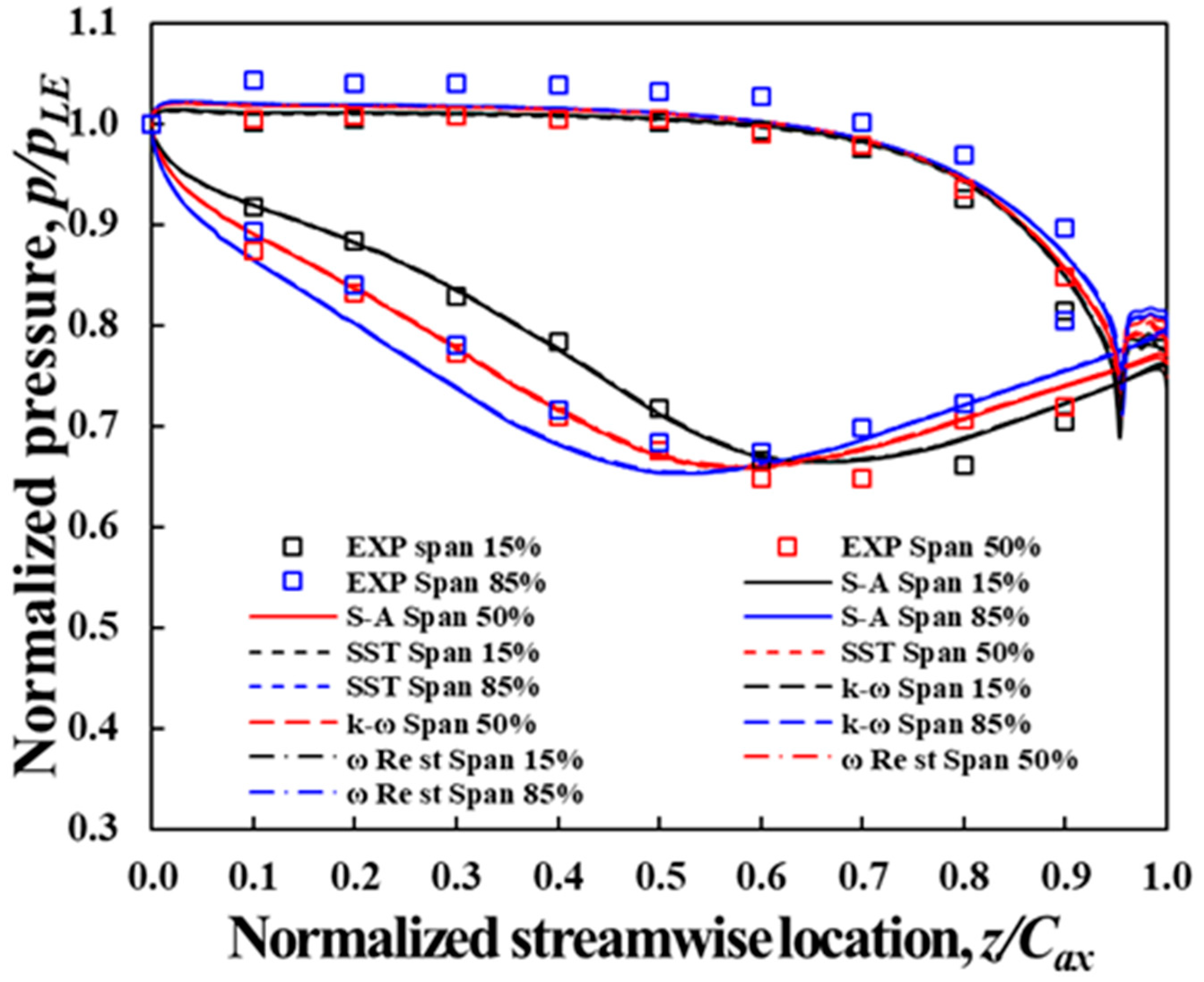

2. Computational Model and Approach

3. Results

3.1. Stage Performance with and without Swirl Clocking

3.2. Effect of Straight Lean, Compound Lean and Sweep

3.3. Combined Effect of Lean with Sweep

3.4. Effect of Swirl Clocking

3.5. Downstream of NGV Passages and Mixing Plane

3.6. Stage Performance with Swirl Clocking

3.7. Straight Lean (SL+12 SP0, SL-12 SP0 and SL-12 SP10) with Swirl Clocking

3.8. Compound Lean with Swirl Clocking

4. Conclusions

- The influence of combined angles of lean and sweep inherits their individual effects.

- Positive lean and sweep (SL12 SP10 model) shows improved stage performance of +0.208%p with no swirl and +0.101%p with swirl clocking positioned at passage center against the baseline configurations.

- Negative lean with sweep (SL-12 SP10 model) shows the enhanced stage efficiency of +0.277%p with swirl clocking positioned at the leading edge compared to the baseline model.

- Compound lean is less sensitive to the swirl clocking while straight lean is strongly influenced.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Adams, M.G.; Beard, P.F.; Stokes, M.R.; Wallin, F.; Chana, K.S.; Povey, T. Effect of a Combined Hot-Streak and Swirl Profile on Cooled 1.5-Stage Turbine Aerodynamics: An Experimental and Computational Study. J. Turbomach. 2021, 143, 021011. [Google Scholar] [CrossRef]

- Semlitsch, B.; Hynes, T.; Langella, I.; Swaminathan, N.; Dowling, A.P. Entropy and Vorticity Wave Generation in Realistic Gas Turbine Combustors. J. Propuls. Power 2019, 35, 839–849. [Google Scholar] [CrossRef]

- Zhong-Qi, W.; Wan-Jin, H.; Wen-Yuan, X. An Experimental Investigation into the Influence of Diameter-Blade Height Ratios on Secondary Flow Losses in Annular Cascades with Leaned Blades. In Volume 1: Turbomachinery; American Society of Mechanical Engineers: Anaheim, CA, USA, 1987; p. V001T01A035. [Google Scholar] [CrossRef] [Green Version]

- Bagshaw, D.A.; Ingram, G.L.; Gregory-Smith, D.G.; Stokes, M.R. An Experimental Study of Reverse Compound Lean in a Linear Turbine Cascade. Proc. Inst. Mech. Eng. Part A J. Power Energy 2005, 219, 443–449. [Google Scholar] [CrossRef] [Green Version]

- Shi, J.; Han, J.; Zhou, S.; Zhu, M.; Zhang, Y.; She, M. An Investigation of a Highly Loaded Transonic Turbine Stage With Compound Leaned Vanes. J. Eng. Gas Turbines Power 1986, 108, 265–269. [Google Scholar] [CrossRef]

- Rosic, B.; Xu, L. Blade Lean and Shroud Leakage Flows in Low Aspect Ratio Turbines. J. Turbomach. 2012, 134, 031003. [Google Scholar] [CrossRef]

- Liu, J.; Qiao, W.; Duan, W. Effect of Bowed/Leaned Vane on the Unsteady Aerodynamic Excitation in Transonic Turbine. J. Therm. Sci. 2019, 28, 133–144. [Google Scholar] [CrossRef]

- Beard, P.F.; Smith, A.D.; Povey, T. Effect of Combustor Swirl on Transonic High Pressure Turbine Efficiency. J. Turbomach. 2014, 136, 011002. [Google Scholar] [CrossRef]

- Johansson, M.; Povey, T.; Chana, K.; Abrahamsson, H. Effect of Low-NOx Combustor Swirl Clocking on Intermediate Turbine Duct Vane Aerodynamics with an Upstream High Pressure Turbine Stage—An Experimental and Computational Study. J. Turbomach. 2017, 139, 011006. [Google Scholar] [CrossRef]

- Wang, Z.; Han, W.; Xu, W. The Effect of Blade Curving on Flow Characteristics in Rectangular Turbine Stator Cascades with Different Incidences. In GT1991; Volume 1: Turbomachinery; Orlando, FL, USA, 1991; Available online: https://asmedigitalcollection.asme.org/GT/proceedings/GT1991/78989/V001T01A021/239047 (accessed on 27 August 2021). [CrossRef] [Green Version]

- Zhang, Z.-G.; Zhou, D.-M.; Li, Y.-S. A Calculation Model of the Secondary Flow Loss for Leaned Stator Cascade. In GT1991; Volume 1: Turbomachinery; Orlando, FL, USA, 1991; Available online: https://asmedigitalcollection.asme.org/GT/proceedings/GT1991/78989/V001T01A067/239110 (accessed on 27 August 2021). [CrossRef]

- Rahim, A.; Khanal, B.; He, L.; Romero, E. Effect of NGV Lean under Influence of Inlet Temperature Traverse. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: San Antonio, TX, USA, 2013; Volume 55225, p. V06AT36A017. [Google Scholar]

- Qureshi, I.; Smith, A.D.; Povey, T. Hp Vane Aerodynamics and Heat Transfer in the Presence of Aggressive Inlet Swirl. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: San Antonio, TX, USA, 2011; Volume 54655, pp. 1925–1942. [Google Scholar]

- Jacobi, S.; Rosic, B. Influence of Combustor Flow With Swirl on Integrated Combustor Vane Concept Full-Stage Performance. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: San Antonio, TX, USA, 2017; Volume 50787, p. V02AT40A016. [Google Scholar]

- Pullan, G.; Harvey, N.W. Influence of Sweep on Axial Flow Turbine Aerodynamics at Midspan. ASME Trans. J. Turbomach. 2007, 129, 591–598. [Google Scholar] [CrossRef]

- Zhao, Z.; Du, X.; Wen, F.; Wang, Z. Investigation of 3D Blade Design on Flow Field and Performance of a Low Pressure Turbine Stage. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: San Antonio, TX, USA, 2017; Volume 50787, p. V02AT40A015. [Google Scholar]

- Jacobi, S.; Mazzoni, C.; Rosic, B.; Chana, K. Investigation of Unsteady Flow Phenomena in First Vane Caused by Combustor Flow with Swirl. J. Turbomach. 2017, 139, 041006. [Google Scholar] [CrossRef]

- Meng, F.; Gao, J.; Fu, W.; Liu, X.; Zheng, Q. Numerical Investigation on a High Endwall Angle Turbine With Swept-Curved Vanes. Heat Transf. 2018, 5C. [Google Scholar] [CrossRef]

- Zhang, S.; MacManus, D.G.; Luo, J. Parametric Study of Turbine NGV Blade Lean and Vortex Design. Chin. J. Aeronaut. 2016, 29, 104–116. [Google Scholar] [CrossRef] [Green Version]

- Lampart, P.; Gardziewicz, A.; Rusanov, A.; Yershov, S. The Effect of Stator Blade Compound Lean and Compound Twist on Flow Characteristics of a Turbine Stage: Numerical Study Based on 3D NS Simulations. ASME-Publ. PVP 2000, 397, 195–204. [Google Scholar]

- Hourmouziadis, J.; Hübner, N. 3-D Design of Turbine Airfoils. In Volume 1: Aircraft Engine; Marine; Turbomachinery; Microturbines and Small Turbomachinery; American Society of Mechanical Engineers: Houston, TX, USA, 1985; p. V001T03A045. [Google Scholar] [CrossRef]

- Denton, J.D.; Xu, L. The Exploitation of Three-Dimensional Flow in Turbomachinery Design. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 1998, 213, 125–137. [Google Scholar] [CrossRef]

- Tan, C.; Yamamoto, A.; Mizuki, S.; Asaga, Y. Influences of Blade Curving on Flow Fields of Turbine Stator Cascades. In 40th AIAA Aerospace Sciences Meeting & Exhibit; American Institute of Aeronautics and Astronautics: Reno, NV, USA, 2002. [Google Scholar] [CrossRef]

- Wang, Z.; Han, W. The Chordwise Lean of Highly Loaded Turbine Blades. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: Birmingham, UK, 1996; Volume 78729, p. V001T01A030. [Google Scholar]

- D’Ippolito, G.; Dossena, V.; Mora, A. The Influence of Blade Lean on Straight and Annular Turbine Cascade Flow Field. J. Turbomach. 2010, 133. [Google Scholar] [CrossRef]

- Harrison, S. The Influence of Blade Lean on Turbine Losses. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: San Antonio, TX, USA, 1990; Volume 79047, p. V001T01A019. [Google Scholar]

- Wang, Z.; Han, W. The Influence of Blade Negative Curving on the Endwall and Blade Surface Flows. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: San Antonio, TX, USA, 1995; Volume 78781, p. V001T01A106. [Google Scholar]

- Spataro, R.; D’Ippolito, G.; Dossena, V. The Influence of Blade Sweep Technique in Linear Cascade Configuration. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: San Antonio, TX, USA, 2011; Volume 54679, pp. 731–740. [Google Scholar]

- Pullan, G.; Harvey, N.W. The Influence of Sweep on Axial Flow Turbine Aerodynamics in the Endwall Region. J. Turbomach. 2008, 130, 041011. [Google Scholar] [CrossRef]

- Havakechian, S.; Greim, R. Aerodynamic Design of 50 per Cent Reaction Steam Turbines. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 1999, 213, 1–25. [Google Scholar] [CrossRef]

- Pritchard, L.J. An Eleven Parameter Axial Turbine Airfoil Geometry Model. In Volume 1: Aircraft Engine; Marine; Turbomachinery, Microturbines and Small Turbomachinery; American Society of Mechanical Engineers: Houston, TX, USA, 1985; p. V001T03A058. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.; Yang, V. Dynamics and Stability of Lean-Premixed Swirl-Stabilized Combustion. Prog. Energy Combust. Sci. 2009, 35, 293–364. [Google Scholar] [CrossRef]

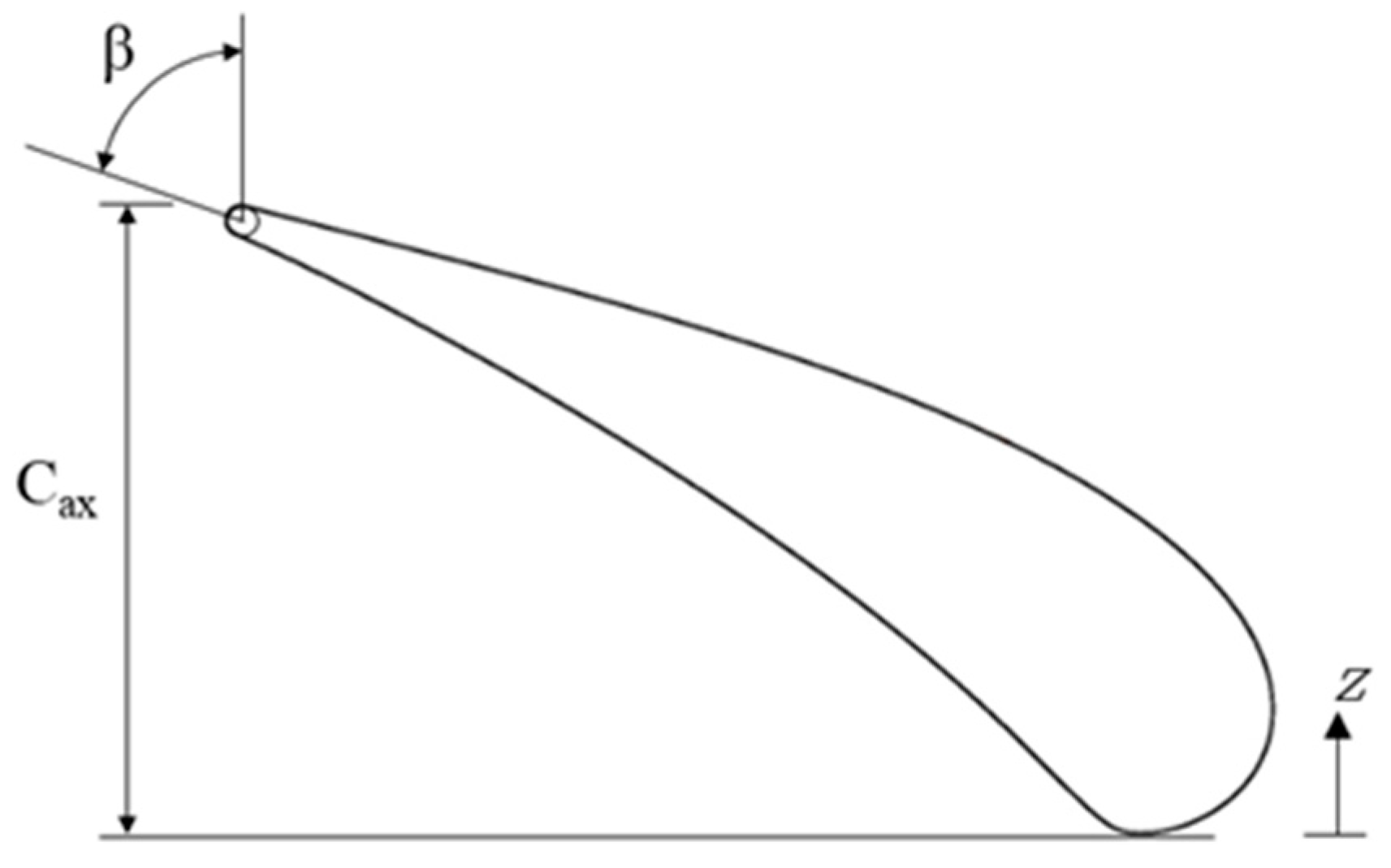

| Parameters | Unit | NGV | Blade |

|---|---|---|---|

| Airfoil count | - | 36 | 71 |

| Axial chord, Cax | mm | 123.6 | 113.2 |

| Exit metal angle, β | ° | 71.2 | 56.5 |

| Tip clearance | mm | - | 2.2 |

| Inlet total pressure | Bar | 22 | - |

| Inlet total temperature | K | 1873 | - |

| Stage pressure ratio, p01/p02 | - | 1.86 | - |

| Exit Mach number, M2 | - | 0.77 | - |

| Inlet Reynolds number, ReCax | - | 1.32 106 | - |

| Span height to axial chord, Hspan/Cax | - | 1.43 | 2.69 |

| Parameter | Abbreviation | Angle Range |

|---|---|---|

| Straight lean angle (εs) | SL | −12°, −6°, 0°, +6°, +12° |

| Compound lean angle (εc) | CL | −12°, −6°, 0°, +6°, +12° |

| Sweep angle (γ) | SP | −5°, 0°, +5°, +10° |

| Straight Lean (°) | Sweep (°) | Swirl |

|---|---|---|

| −12, −6, 0, 6, 12 | −5,0,5,10 | No swirl, swirl at LE, swirl at passage center |

| Compound Lean (°) | Sweep (°) | Swirl |

| −12, −6, 0, 6, 12 | −5,0,5,10 | No swirl, swirl at LE, swirl at passage center |

| Swirl Clocking | |||

|---|---|---|---|

| Type of Model | No Swirl | Swirl @LE | Swirl @Passage Center |

| Straight Lean with Sweep | SL12 SP10 | SP-12 SP10 | SL12SP10 |

| Compound Lean with Sweep | CL12 SP10 | CL12 SP10 | CL12 SP10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeon, S.; Son, C.; Kim, J. Influence of Swirl Clocking on the Performance of Turbine Stage with Three-Dimensional Nozzle Guide Vane. Energies 2021, 14, 5503. https://doi.org/10.3390/en14175503

Jeon S, Son C, Kim J. Influence of Swirl Clocking on the Performance of Turbine Stage with Three-Dimensional Nozzle Guide Vane. Energies. 2021; 14(17):5503. https://doi.org/10.3390/en14175503

Chicago/Turabian StyleJeon, Shinyoung, Changmin Son, and Jinuk Kim. 2021. "Influence of Swirl Clocking on the Performance of Turbine Stage with Three-Dimensional Nozzle Guide Vane" Energies 14, no. 17: 5503. https://doi.org/10.3390/en14175503

APA StyleJeon, S., Son, C., & Kim, J. (2021). Influence of Swirl Clocking on the Performance of Turbine Stage with Three-Dimensional Nozzle Guide Vane. Energies, 14(17), 5503. https://doi.org/10.3390/en14175503