Research on Fresh and Hardened Sealing Slurries with the Addition of Magnesium Regarding Thermal Conductivity for Energy Piles and Borehole Heat Exchangers

Abstract

1. Introduction

- -

- Physicochemical compatibility with the environment (no negative impact on the natural environment);

- -

- Appropriate rheological properties (the slurry can be pumped);

- -

- Economic factors (minimization of slurry cost);

- -

- Highest possible thermal conductivity.

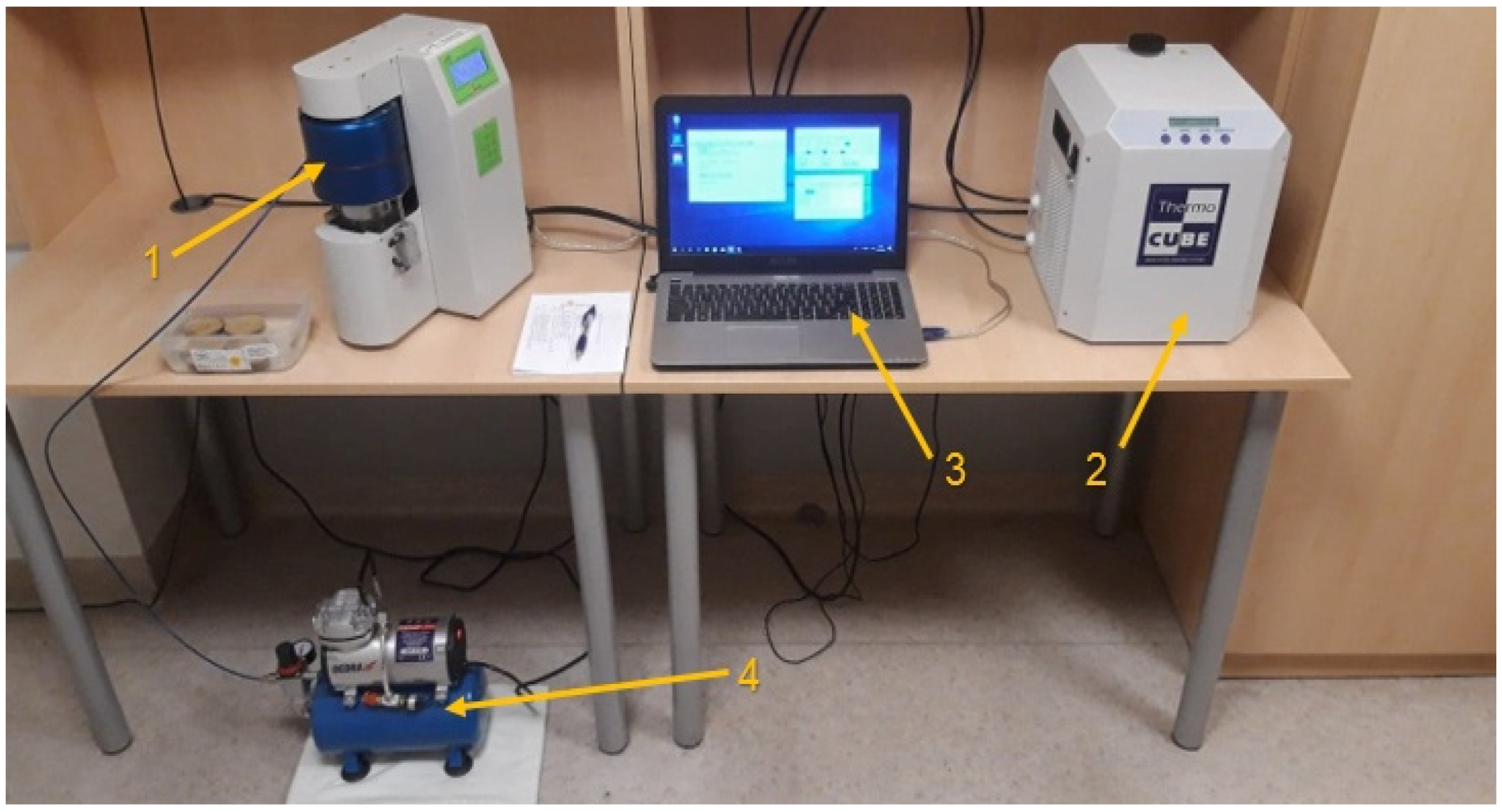

2. Research Methodology

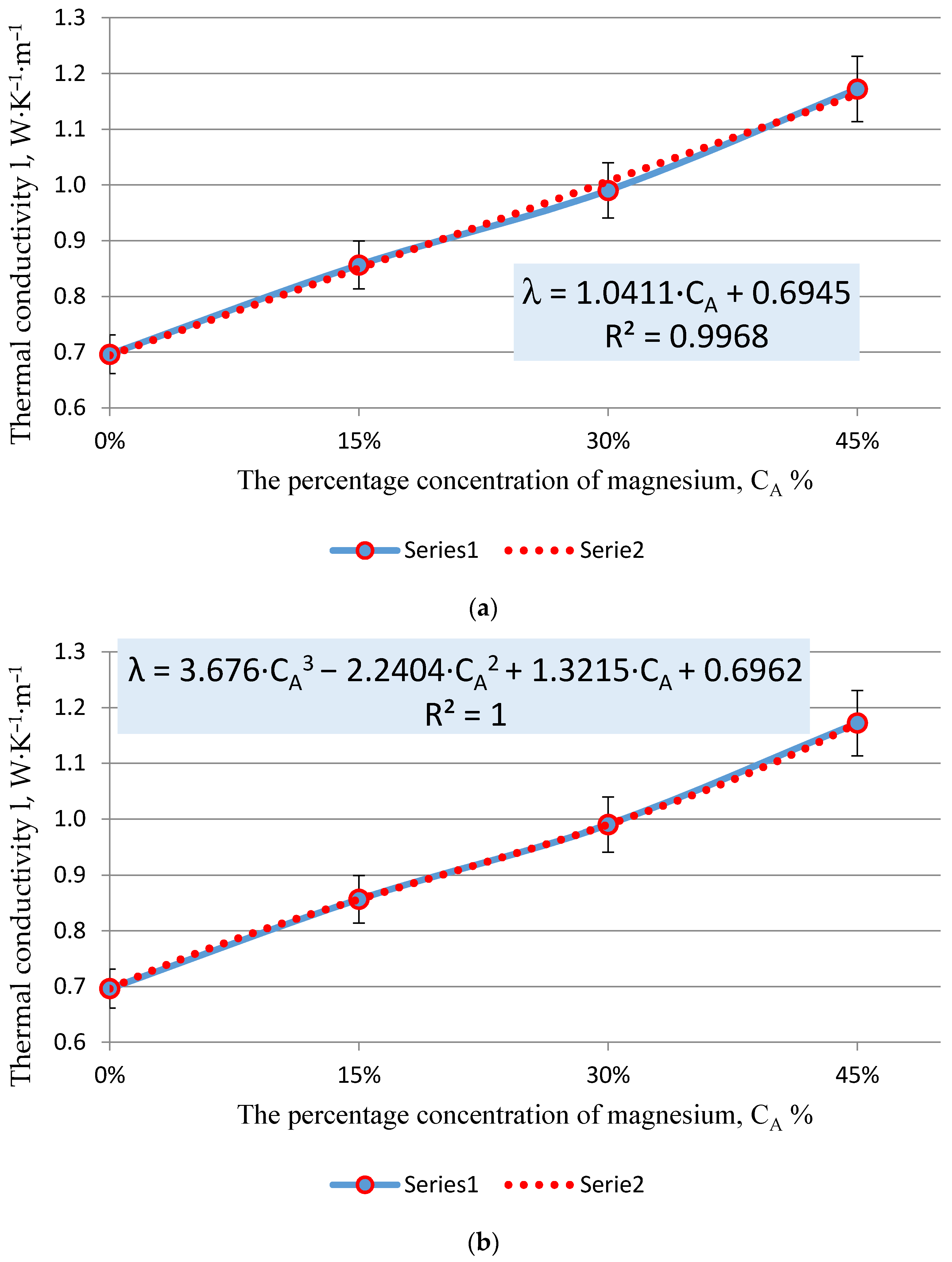

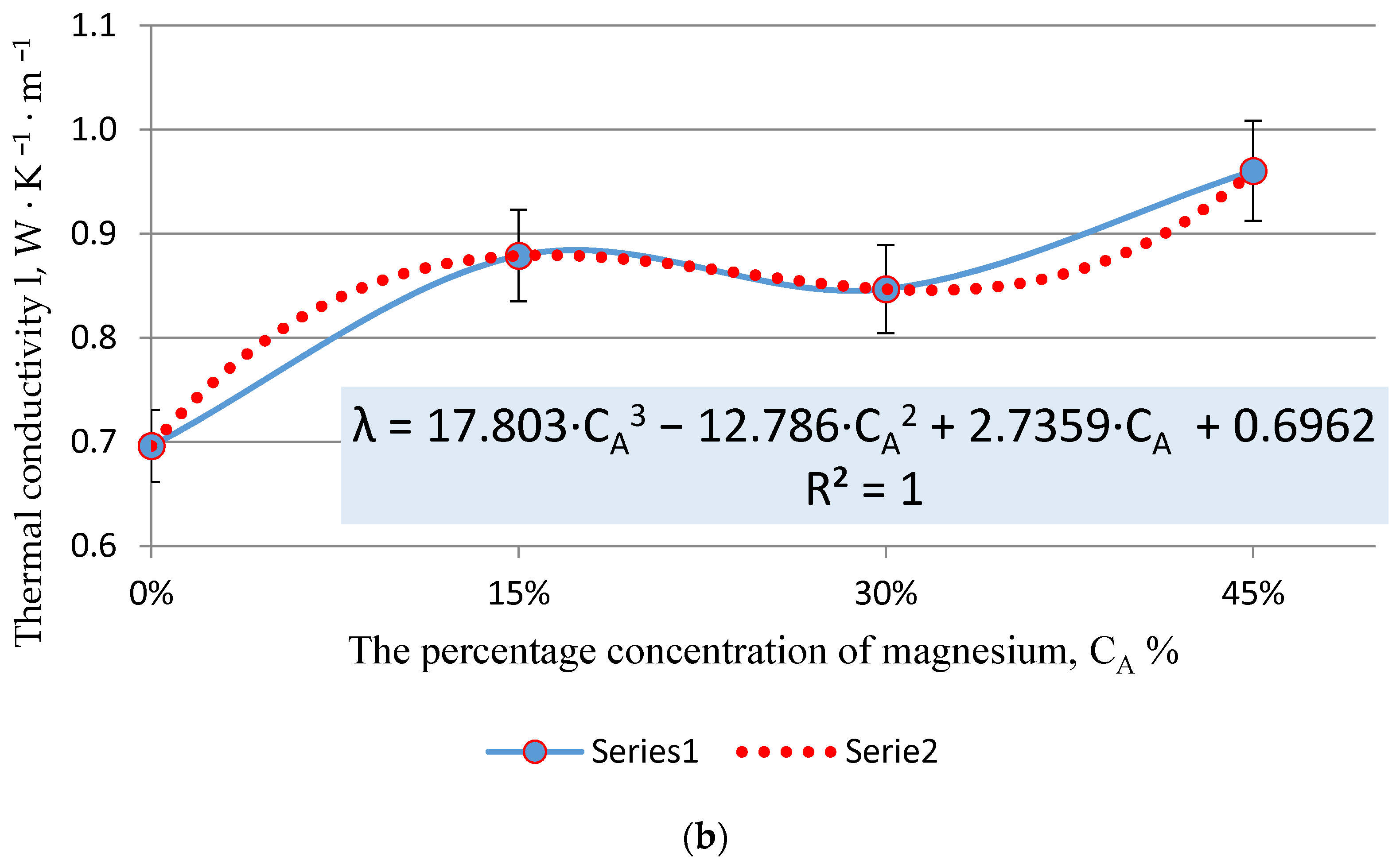

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources. Available online: https://www.legislation.gov.uk/eudr/2018/2001 (accessed on 27 July 2021).

- Polityka Energetyczna Polski do 2040 r.—Załącznik do Uchwały nr 22/2021 Rady Ministrów z dnia 2 lutego 2021 r; Ministry of Climate and Environment: Warsaw, Poland, 2021. (In Polish)

- Sala, K. Przemysłowe wykorzystanie energii geotermalnej w Polsce na przykładzie geotermalnego zakładu ciepłowniczego w Bańskiej Niżnej (Industrial Use of Geothermal Energy in Poland Based on the Example of a Geothermal Heating Plant in Bańska Niżna). Stud. Ind. Geogr. Comm. Pol. Geogr. Soc. 2018, 32, 73–82. [Google Scholar] [CrossRef]

- Sapińska-Śliwa, A.; Wiglusz, T.; Kruszewski, M.; Sliwa, T.; Kowalski, T. Wiercenia Geotermalne. Doświadczenia Techniczne i Technologiczne (Geothermal Drilling: Techniques and Side Aspects); Laboratory of Geoenergetics Book Series Volume 3; Drilling, Oil and Gas Foundation: Krakow, Poland, 2017. (In Polish) [Google Scholar]

- Sowizdzal, A. Geothermal energy resources in Poland—Overview of the current state of knowledge. Renew. Sustain. Energy Rev. 2018, 82, 4020–4027. [Google Scholar] [CrossRef]

- Operacz, A.; Bielec, B.; Tomaszewska, B.; Kaczmarczyk, M. Physicochemical Composition Variability and Hydraulic Conditions in a Geothermal Borehole—The Latest Study in Podhale Basin, Poland. Energies 2020, 13, 3882. [Google Scholar] [CrossRef]

- Bujakowski, W.; Bielec, B.; Miecznik, M.; Pająk, L. Reconstruction of geothermal boreholes in Poland. Geotherm. Energy 2020, 8, 10. [Google Scholar] [CrossRef]

- Mazurkiewicz, J.; Kmiecnik, E.; Tomaszewska, B. Analiza możliwości wykorzystania wód podziemnych z utworów czwartorzędowych w systemach geotermii niskotemperaturowej na obszarze Małopolski. Część I (Analysis of the possibility to use the quaternary groundwater in the low-temperature geothermal systems in Małopolska. Part I). Prz. Geol. 2015, 63, 926–930. (In Polish) [Google Scholar]

- Antelmi, M.; Alberti, L.; Angelotti, A.; Zille, A. Thermal and hydrogeological aquifers characterization by coupling depth-resolved thermal response test with moving line source analysis. Energy Convers. Manag. 2020, 225, 113400. [Google Scholar] [CrossRef]

- Ingersoll, L.R.; Adler, F.T.; Plass, H.J.; Ingersoll, A.C. Theory of earth heat exchangers for the heat pump. ASHVE Trans. 1950, 56, 167–188. [Google Scholar]

- Luo, J.; Rohn, J.; Bayer, M.; Priess, A. Thermal Efficiency Comparison of Borehole Heat Exchangers with Different Drillhole Diameters. Energies 2013, 6, 4187–4206. [Google Scholar] [CrossRef]

- Sliwa, T.; Sapińska-Śliwa, A.; Knez, D.; Bieda, A.; Kowalski, T.; Złotkowski, A. Borehole Heat Exchangers: Production and Storage of Heat in the Rock Mass; Laboratory of Geoenergetics Book Series Volume 2; Drilling, Oil and Gas Foundation: Krakow, Poland, 2016. [Google Scholar]

- Quaggiotto, D.; Zarrella, A.; Emmi, G.; De Carli, M.; Pockelé, L.; Vercruysse, J.; Psyk, M.; Righini, D.; Galgaro, A.; Mendrinos, D.; et al. Simulation-Based Comparison between the Thermal Behavior of Coaxial and Double U-Tube Borehole Heat Exchangers. Energies 2019, 12, 2321. [Google Scholar] [CrossRef]

- Sliwa, T.; Jarosz, K.; Rosen, M.A.; Sojczyńska, A.; Sapińska-Śliwa, A.; Gonet, A.; Fąfera, K.; Kowalski, T.; Ciepielowska, M. Influence of Rotation Speed and Air Pressure on the Down the Hole Drilling Velocity for Borehole Heat Exchanger Installation. Energies 2020, 13, 2716. [Google Scholar] [CrossRef]

- Boban, L.; Miše, D.; Herceg, S.; Soldo, V. Application and Design Aspects of Ground Heat Exchangers. Energies 2021, 14, 2134. [Google Scholar] [CrossRef]

- Koene, F.G.H.; van Helden, W.G.J.; Romer, J.C. Energy piles as cost effective ground heat exchangers. In Proceedings of the TERRASTOCK 2000, Stuttgart, Germany, 28 August–1 September 2000. [Google Scholar]

- Schröder, B.; Hanschke, T. Energiepfhähle—Umweltfreundliches Heizen und Kühlen mit geothermisch aktivierten Stahlbetonfertigpfählen. Bautechnik 2003, 80, 925–927. (In German) [Google Scholar] [CrossRef]

- Brandl, H. Energy foundations and other thermo-active ground structures. Géotechnique 2006, 56, 81–122. [Google Scholar] [CrossRef]

- Mousa, M.M.; Bayomy, A.M.; Saghir, M.Z. Experimental and Numerical Study on Energy Piles with Phase Change Materials. Energies 2020, 13, 4699. [Google Scholar] [CrossRef]

- Sliwa, T.; Sapińska-Śliwa, A.; Wysogląd, T.; Kowalski, T.; Konopka, I. Strength Tests of Hardened Cement Slurries for Energy Piles, with the Addition of Graphite and Graphene, in Terms of Increasing the Heat Transfer Efficiency. Energies 2021, 14, 1190. [Google Scholar] [CrossRef]

- Tester, J.W.; Brown, D.W.; Potter, R.M. Hot Dry Rock Geothermal Energy—A New Energy Agenda for the 21st Century; Los Alamos National Laboratory Report LA-11514-MS; US Department of Energy: Washington, DC, USA, 1989.

- Tenzer, H. Development of hot dry rock technology. GHC Bull. 2001, 12, 14–22. [Google Scholar]

- Wójcicki, A.; Sowiżdżał, A.; Bujakowski, W.; Szewczyk, J. Ocena Potencjału, Bilansu Cieplnego i Perspektywicznych Struktur Geologicznych Dla Potrzeb Zamkniętych Systemów Geotermicznych (Hot Dry Rocks) w Polsce; Ministry of Environment: Kraków, Poland, 2013. (In Polish)

- Sapińska-Śliwa, A.; Kowalski, T.; Knez, D.; Sliwa, T.; Gonet, A.; Bieda, A. Geological and drilling aspects of construction and exploitation geothermal systems HDR/EGS. AGH Drill. Oil Gas 2015, 32, 49–63. [Google Scholar] [CrossRef][Green Version]

- Breede, K.; Dzebisashvili, K.; Liu, X.; Falcone, G. A systematic review of enhanced (or engineered) geothermal systems: Past, present and future. Geotherm. Energy 2013, 1, 4. [Google Scholar] [CrossRef]

- Li, L.; Guo, X.; Zhou, M.; Xiang, G.; Zhang, N.; Wang, Y.; Wang, S.; Pagou, A.L. The Investigation of Fracture Networks on Heat Extraction Performance for an Enhanced Geothermal System. Energies 2021, 14, 1635. [Google Scholar] [CrossRef]

- Kępińska, B. Geothermal Energy Use in Europe. In Proceedings of the GEOTHERMAL TRAINING PROGRAMME 30th Anniversary Workshop Orkustofnun, Reykjavík, Iceland, 26–27 August 2008. [Google Scholar]

- Pająk, L.; Gonet, A.; Śliwa, T.; Knez, D. Analiza możliwości wykorzystania magazynów ciekłego propanu, lokowanych w strefie kawern wysadów solnych, do produkcji energii (Analysis of Energy Production Possibilities from Liquid Propane Storage in Salt Domes Cavities). Wiert. Naft. Gaz 2010, 27, 657–667. (In Polish) [Google Scholar]

- Solik-Heliasz, E.; Małolepszy, Z. Możliwości wykorzystania energii geotermalnej z wód kopalnianych w Górnośląskim Zagłębiu Węglowym (The possibilities of utilisation of geothermal energy from mine waters in the Upper Silesian Coal Basin). In Proceedings of the International Scientific Conference Geothermal Energy in Underground Mines, Ustroń, Polska, 21–23 November 2001. [Google Scholar]

- Solik-Heliasz, E. Ocena możliwości odzysku ciepła z wód pompowanych z kopalń węgla kamiennego (Assessment of possibility of heat recovery from waters pumped from hard coal mines). Pr. Nauk. GIG Górnictwo Sr. 2002, 2, 17–24. (In Polish) [Google Scholar]

- Namysłowska-Wilczyńska, B.; Wilczyński, A.; Wojciechowski, H. Możliwości wykorzystania zasobów wodnych i energetycznych w podziemnych kopalniach surowców mineralnych (Possibilities of the utilization of water and Energy in undeground mineral resources mines). Zesz. Nauk. Inst. Gospod. Surowcami Miner. Energią Pol. Akad. 2016, 95, 47–58. (In Polish) [Google Scholar]

- Małolepszy, Z. Man-made, low-temperature geothermal reservoirs in abandoned workings of underground mines on example of coal mines, Poland. In Proceedings of the IGC2003 Conference Multiple Integrated Uses of Geothermal Resources, Reykjavik, Iceland, 14–17 September 2003. [Google Scholar]

- Warnecki, M. Analiza Możliwości Pozyskiwania Pozabilansowych Zasobów Gazu Ziemnego z Nasyconych Poziomów Solankowych w Procesach Sekwestracji CO2 (Analysis of Additional Gas Production Possibility from Deep Saline Aquifers in the Process of CO2 Sequestration); Instytut Nafty i Gazu—Państwowy Instytut Badawczy: Kraków, Poland, 2016.

- Bertani, R. Geothermal Energy: An Overview on Resources and Potential; Session 1, Geothermal Electricity Production: Possibilities, Technical and Economic Feasibility in Central European Region; International Geothermal Days, Conference & Summer School: Bratislava, Slovakia, 2009. [Google Scholar]

- Vasilescu, A.R. Design and Execution of Energy Piles: Validation by In-Situ and Laboratory Experiments. Doctorate Thesis, L’École Centrale de Nantes, Nantes, France, 2019. Available online: https://tel.archives-ouvertes.fr/tel-02395284/document (accessed on 27 July 2021).

- Lyu, W.; Pu, H.; Chen, J. Thermal Performance of an Energy Pile Group with a Deeply Penetrating U-shaped Heat Exchanger. Energies 2020, 13, 5822. [Google Scholar] [CrossRef]

- Crandall, A.C. House Heating with Earth Heat Pump. Electr. World 1946, 126, 94–95. [Google Scholar]

- Kemler, E.N. Methods of Earth Heat Recovery for the Heat Pump. Heat. Vent. 1947, 9, 69–72. [Google Scholar]

- Sliwa, T. Wybrane systemy geotermalne w skałach suchych (Chosen geothermal systems in dry rocks). In Proceedings of the Conference on Current State and Development Prospects of Mining in the Aspect of Environmental Protection, Proceedings Dniepropietrowsk, Dnipropetrovsk, Ukraine, 13–14 May 1996. [Google Scholar]

- Sliwa, T. Wybrane systemy geotermalne w aspekcie warunków geologicznych (Chosen geotermic systems in aspect of geology). Zesz. Nauk. AGH Wiert. Naft. Gaz 1998, 15, 199–208. [Google Scholar]

- Gonet, A.; Sliwa, T.; Stryczek, S.; Sapińska-Śliwa, A.; Jaszczur, M.; Pająk, L.; Złotkowski, A. Metodyka Identyfikacji Potencjału Cieplnego Górotworu Wraz z Technologią Wykonywania i Eksploatacji Otworowych Wymienników Ciepła (Methodology for the Identification of Potential Heat of the Rock Mass along with Technology Implementation and Operation of the Borehole Heat Exchangers); Wydawnictwa AGH: Kraków, Poland, 2011. (In Polish) [Google Scholar]

- Gehlin, S.; Andersson, O. Geothermal Energy Use, Country Update for Sweden. In Proceedings of the European Geothermal Congress 2016, Strasbourg, France, 19–23 September 2016. [Google Scholar]

- Perego, R.; Pera, S.; Galgaro, A. Techno-Economic Mapping for the Improvement of Shallow Geothermal Management in Southern Switzerland. Energies 2019, 12, 279. [Google Scholar] [CrossRef]

- Gehlin, S.; Andersson, O.; Rosberg, J.E. Country Update for Sweden 2020. In Proceedings of the World Geothermal Congress 2020, Reykjavik, Iceland, 26 April–2 May 2020. [Google Scholar]

- Link, K.; Lupi, N.; Siddiqi, G. Geothermal Energy in Switzerland Country Update 2015–2020. In Proceedings of the World Geothermal Congress 2020, Reykjavik, Iceland, 26 April–2 May 2020. [Google Scholar]

- Lund, J.W.; Toth, A.N. Direct Utilization of Geothermal Energy 2020 Worldwide Review. In Proceedings of the World Geothermal Congress 2020, Reykjavik, Iceland, 26 April–2 May 2020. [Google Scholar]

- Weber, J.; Born, H.; Pester, S.; Moeck, I. Geothermal Energy Use in Germany, Country Update 2015–2019. In Proceedings of the World Geothermal Congress 2020, Reykjavik, Iceland, 26 April–2 May 2020. [Google Scholar]

- Shrestha, G.; Yoshioka, M.; Fujii, H.; Uchida, Y. Evaluation of Suitable Areas to Introduce a Closed-Loop Ground Source Heat Pump System in the Case of a Standard Japanese Detached Residence. Energies 2020, 13, 4294. [Google Scholar] [CrossRef]

- Sliwa, T.; Gonet, A. Analiza efektywności wymiany ciepła w wymiennikach otworowych o różnej konstrukcji (Heat transfer efficiency analysis in different constructions of borehole heat exchangers). Wiert. Naft. Gaz 2011, 28, 555–570. (In Polish) [Google Scholar]

- Kępińska, B. Geothermal Energy Country Update Report from Poland, 2015–2019. In Proceedings of the World Geothermal Congress 2020, Reykjavik, Iceland, 26 April–2 May 2020. [Google Scholar]

- Bae, S.; Nam, Y.; da Cunha, I. Economic Solution of the Tri-Generation System Using Photovoltaic-Thermal and Ground Source Heat Pump for Zero Energy Building (ZEB) Realization. Energies 2019, 12, 3304. [Google Scholar] [CrossRef]

- Hałaj, E.; Kotyza, J.; Hajto, M.; Pełka, G.; Luboń, W.; Jastrzębski, P. Upgrading a District Heating System by Means of the Integration of Modular Heat Pumps, Geothermal Waters, and PVs for Resilient and Sustainable Urban Energy. Energies 2021, 14, 2347. [Google Scholar] [CrossRef]

- Palomba, V.; Bonanno, A.; Brunaccini, G.; Aloisio, D.; Sergi, F.; Dino, G.E.; Varvaggiannis, E.; Karellas, S.; Nitsch, B.; Strehlow, A.; et al. Hybrid Cascade Heat Pump and Thermal-Electric Energy Storage System for Residential Buildings: Experimental Testing and Performance Analysis. Energies 2021, 14, 2580. [Google Scholar] [CrossRef]

- Bieda, A.; Kowalski, T.; Sliwa, T.; Skowroński, D.; Kowalska-Kubsik, I.; Rado, R. Udarowo-obrotowa metoda wiercenia otworowych wymienników ciepła jako alternatywa wiertnicza przyjazna środowisku (Rotary-percussion drilling for borehole heat exchangers as an environmentally friendly drilling alternative). Przemysł Chem. 2018, 97, 864–986. (In German) [Google Scholar] [CrossRef]

- Zhou, A.; Huang, X.; Wang, W.; Jiang, P.; Li, X. Thermo-Hydraulic Performance of U-Tube Borehole Heat Exchanger with Different Cross-Sections. Sustainability 2021, 13, 3255. [Google Scholar] [CrossRef]

- Kovacevic, M.S.; Bacic, M.; Arapov, I. Possibilities of underground engineering for the use of shallow geothermal Energy. Gradevinar 2012, 12, 1019–1028. [Google Scholar]

- Aydin, M.; Sisman, A. Experimental and computational investigation of multi U-tube boreholes. Appl. Energy 2015, 145, 163–171. [Google Scholar] [CrossRef]

- Yoon, S.; Lee, S.R.; Xue, J.; Zosseder, K.; Go, G.H.; Park, H. Evaluation of the Thermal Efficiency and a Costanalysis of Different Types of Ground Heat Exchangers in Energy Piles. Energy Convers. Manag. 2015, 105, 393–402. [Google Scholar] [CrossRef]

- Sliwa, T.; Nowosiad, T.; Vytyaz, O.; Sapińska-Śliwa, A. Study on the efficiency of deep borehole heat exchangers. SOCAR Proc. 2016, 2, 29–42. [Google Scholar] [CrossRef]

- Sliwa, T.; Kruszewski, M.; Zare, A.; Assadi, M.; Sapińska-Śliwa, A. Potential application of vacuum insulated tubing for deep borehole heat exchangers. Geothermics 2018, 75, 58–67. [Google Scholar] [CrossRef]

- Rybach, L. Geothermal Heat Pumps. In Encyclopedia of Solid Earth Geophysic; Gupta, H.K., Ed.; Springer: Dordrecht, The Netherlands, 2011; pp. 411–415. [Google Scholar]

- Lee, S.-R.; Yoon, S.; Go, G.-H.; Kang, H.-B.; Park, D.-W. Evaluation of Heat Exchange Rate for Different Types of Ground Heat Exchangers. In Proceedings of the International Offshore and Polar Engineering Conference, Anchorage, AK, USA, 30 June–5 July 2013. [Google Scholar]

- Fouché, O.; Soussi, C.; Bracq, G.; Minec, S. Seasonal Storage of Sensible Heat in Tunnel-Surrounding Rocks. In Proceedings of the ISRM 1st International Conference on Advances in Rock Mechanics, Hammamet, Tunisia, 29–31 March 2018. [Google Scholar]

- Lund, J.; Sanner, B.; Rybach, L.; Curtis, S.; Hellstrom, G. Ground source heat pumps—A world review. GHC Bull. 2004, 8, 1–10. [Google Scholar]

- Alberti, L.; Angelotti, A.; Antelmi, M.; La Licata, I. A Numerical Study on the Impact of Grouting Material on Borehole Heat Exchangers Performance in Aquifers. Energies 2017, 10, 703. [Google Scholar] [CrossRef]

- Delaleux, F.; Py, X.; Olives, R.; Dominguez, R. Enhancement of geothermal borehole heat exchangers performances by improvement of bentonite grouts conductivity. Appl. Therm. Eng. 2012, 33–34, 92–99. [Google Scholar] [CrossRef]

- Sliwa, T.; Sowa, M.; Stryczek, S.; Gonet, A.; Złotkowski, A.; Sapińska-Śliwa, A.; Knez, D. Badania stwardniałych zaczynów cementowych z dodatkiem grafitu (The study of hardened cement slurries with addition of graphite). Wiert. Naft. Gaz 2011, 28, 571–585. (In Polish) [Google Scholar]

- Berktas, I.; Nejad Ghafar, A.; Fontana, P.; Caputcu, A.; Menceloglu, Y.; Saner Okan, B. Synergistic Effect of Expanded Graphite-Silane Functionalized Silica as a Hybrid Additive in Improving the Thermal Conductivity of Cementitious Grouts with Controllable Water Uptake. Energies 2020, 13, 3561. [Google Scholar] [CrossRef]

- Dziadoń, A. Magnez i Jego Stopy; Monografie, Studia, Rozprawy, M28; Wydawnictwo Politechniki Świętokrzyskiej: Kielce, Poland, 2012. (In Polish) [Google Scholar]

- Tian, H.; Du, L.; Wei, X.; Deng, S.; Wang, W.; Ding, J. Enhanced thermal conductivity of ternary carbonate salt phase change material with Mg particles for solar thermal energy storage. Appl. Energy 2017, 204, 525–530. [Google Scholar] [CrossRef]

- Du, F.P.; Tang, H.; Huang, D.Y. Thermal conductivity of epoxy resin reinforced with magnesium oxide coated multiwalled carbon nanotubes. Int. J. Polym. Sci. 2013, 2013, 541823. [Google Scholar] [CrossRef]

- Sliwa, T.; Sapińska-Śliwa, A.; Gonet, A.; Kowalski, T.; Sojczyńska, A. Geothermal Boreholes in Poland—Overview of the Current State of Knowledge. Energies 2021, 14, 3251. [Google Scholar] [CrossRef]

- Lee, S.-M.; Park, S.-H.; Jang, Y.-S.; Kim, E.-J. Proposition of Design Capacity of Borehole Heat Exchangers for Use in the Schematic-Design Stage. Energies 2021, 14, 822. [Google Scholar] [CrossRef]

- Robert, F.; Gosselin, L. New methodology to design ground coupled heat pump systems based on total cost minimization. Appl. Therm. Eng. 2014, 62, 481–491. [Google Scholar] [CrossRef]

- Li, C.; Mao, J.; Zhang, H.; Li, Y.; Xing, Z.; Zhu, G. Effects of load optimization and geometric arrangement on the thermal performance of borehole heat exchanger fields. Sustain. Cities Soc. 2017, 35, 25–35. [Google Scholar] [CrossRef]

- “Cement, Kruszywa, Beton” w Ofercie Grupy Górażdże, Rodzaje, Właściwości, Zastosowanie; Grupa Górażdże: Chorula, Poland, 2016.

- Karta Charakterystyki Magnezu—Karta Charakterystyki Magnez Wiórki Firmy Carlroth Zgodnie z Rozporządzeniem (WE) nr 1907/2006 (REACH), Zmienionej 2015/830/UE Sporządzona 23.01.2017 r; Carl Roth: Karlsruhe, Germany, 2017.

- FOX 50 110 °C Instrument Manual, LaserComp—TA Instruments 2002–2016; LaserComp–TA Instruments: Wakefield, MA, USA, 2016.

- Tariq, R.; Hussain, Y.; Sheikh, N.A.; Afaq, K.; Ali, H.M. Regression-based empirical modeling of thermal conductivity of CuOwater nanofluid using data-driven techniques. Int. J. Thermophys. 2020, 41, 43. [Google Scholar] [CrossRef]

- Qian, X.; Lee, S.; Soto, A.-M.; Chen, G. Regression Model to Predict the Higher Heating Value of Poultry Waste from Proximate Analysis. Resources 2018, 7, 39. [Google Scholar] [CrossRef]

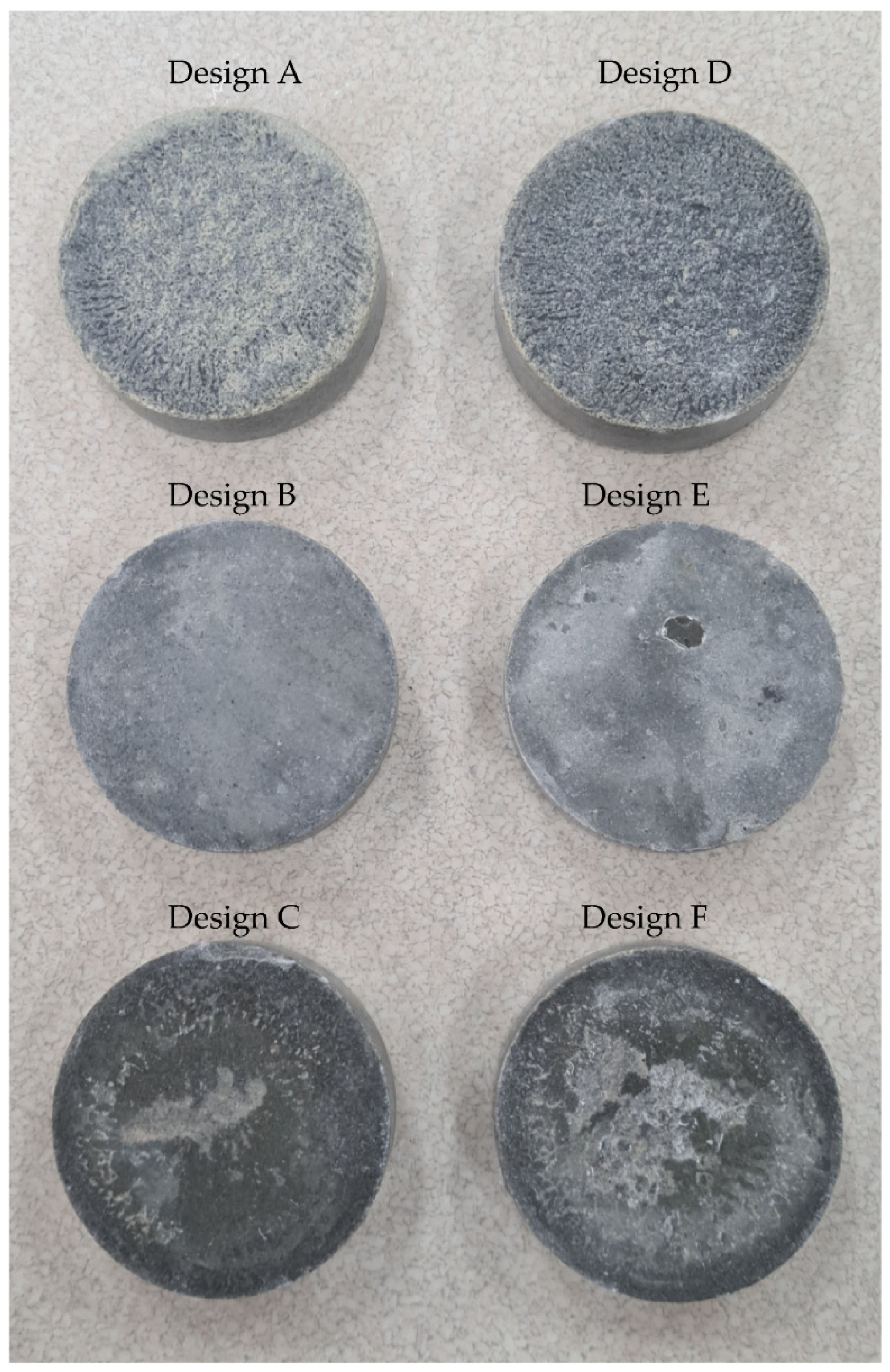

| Design Composition | Magnesium Flakes | Magnesium Shavings | |||||

|---|---|---|---|---|---|---|---|

| Design name | A | B | C | D | E | F | |

| The percentage concentration of the additive | % | 15 | 30 | 45 | 15 | 30 | 45 |

| Cement | g | 400 | 400 | 400 | 400 | 400 | 400 |

| Additive | g | 60 | 120 | 180 | 60 | 120 | 180 |

| Mixing liquid (water) | g | 230 | 260 | 290 | 230 | 260 | 290 |

| W/M | - | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Magnesium Type and Design Name | Magnesium Flakes | Magnesium Shavings | |||||

|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | ||

| Dynamic viscosity | mPas | 55 | 83 | not measurable | 40 | not measurable | not measurable |

| Liquidity | mm | 195 | 195 | 140 | 245 | 235 | 195 |

| Density | g∙cm−3 | 1.77 | 1.75 | 1.64 | 1.79 | 1.71 | 1.63 |

| Conventional viscosity | s | 20 | 25 | not measurable | 11 | not measurable | not measurable |

| Test | Thermal Conductivity | Thickness |

|---|---|---|

| no. | W∙K−1∙m−1 | mm |

| 1 | 0.707 | 18.01 |

| 2 | 0.698 | 18.14 |

| 3 | 0.696 | 18.29 |

| 4 | 0.682 | 18.03 |

| 5 | 0.698 | 18.06 |

| Descriptive statistics | ||

| Average | 0.696 | 18.11 |

| Median | 0.698 | 18.06 |

| Standard deviation | 0.00907 | 0.11 |

| The range of variation | 0.025 | 0.28 |

| Minimum | 0.682 | 18.01 |

| Maximum | 0.707 | 18.29 |

| Test | Thermal Conductivity | Thickness | Thermal Conductivity | Thickness | Thermal Conductivity | Thickness |

|---|---|---|---|---|---|---|

| No. | W∙K−1∙m−1 | mm | W∙K−1∙m−1 | mm | W∙K−1∙m−1 | mm |

| Design A | Design B | Design C | ||||

| 1 | 0.890 | 17.73 | 0.893 | 18.04 | 1.105 | 18.41 |

| 2 | 0.788 | 17.81 | 0.994 | 17.88 | 1.213 | 18.57 |

| 3 | 0.820 | 17.70 | 0.935 | 17.88 | 1.216 | 18.75 |

| 4 | 0.889 | 17.70 | 1.085 | 18.03 | 1.169 | 18.41 |

| 5 | 0.895 | 17.70 | 1.044 | 16.97 | 1.158 | 18.85 |

| Descriptive statistics | ||||||

| Average | 0.856 | 17.73 | 0.990 | 17.76 | 1.172 | 18.60 |

| Median | 0.889 | 17.70 | 0.994 | 17.88 | 1.169 | 18.57 |

| Standard deviation | 0.0493 | 0.048 | 0.0779 | 0.45 | 0.0456 | 0.20 |

| The range of variation | 0.11 | 0.11 | 0.192 | 1.07 | 0.111 | 0.44 |

| Minimum | 0.788 | 17.70 | 0.893 | 16.97 | 1.105 | 18.41 |

| Maximum | 0.895 | 17.81 | 1.085 | 18.04 | 1.216 | 18.85 |

| Test | Thermal Conductivity | Thickness | Thermal Conductivity | Thickness | Thermal Conductivity | Thickness |

|---|---|---|---|---|---|---|

| No. | W∙K−1∙m−1 | mm | W∙K−1∙m−1 | mm | W∙K−1∙m−1 | mm |

| Design D | Design E | Design F | ||||

| 1 | 0.896 | 18.95 | 0.773 | 16.00 | 0.9818 | 19.38 |

| 2 | 0.926 | 18.92 | 0.860 | 16.86 | 1.1640 | 22.15 |

| 3 | 0.827 | 17.32 | 0.892 | 16.94 | 0.8724 | 16.54 |

| 4 | 0.917 | 19.53 | 0.823 | 15.82 | 0.8388 | 16.51 |

| 5 | 0.829 | 18.69 | 0.887 | 16.94 | 0.9456 | 15.72 |

| Descriptive statistics | ||||||

| Average | 0.879 | 18.68 | 0.847 | 16.51 | 0.961 | 18.06 |

| Median | 0.896 | 18.92 | 0.860 | 16.86 | 0.946 | 16.54 |

| Standard deviation | 0.0480 | 0.82 | 0.0495 | 0.55 | 0.127 | 2.68 |

| The range of variation | 0.099 | 2.21 | 0.118 | 1.12 | 0.325 | 6.43 |

| Minimum | 0.827 | 17.32 | 0.773 | 15.82 | 0.839 | 15.72 |

| Maximum | 0.926 | 19.53 | 0.892 | 16.94 | 1.164 | 22.15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sliwa, T.; Kowalski, T.; Cekus, D.; Sapińska-Śliwa, A. Research on Fresh and Hardened Sealing Slurries with the Addition of Magnesium Regarding Thermal Conductivity for Energy Piles and Borehole Heat Exchangers. Energies 2021, 14, 5119. https://doi.org/10.3390/en14165119

Sliwa T, Kowalski T, Cekus D, Sapińska-Śliwa A. Research on Fresh and Hardened Sealing Slurries with the Addition of Magnesium Regarding Thermal Conductivity for Energy Piles and Borehole Heat Exchangers. Energies. 2021; 14(16):5119. https://doi.org/10.3390/en14165119

Chicago/Turabian StyleSliwa, Tomasz, Tomasz Kowalski, Dominik Cekus, and Aneta Sapińska-Śliwa. 2021. "Research on Fresh and Hardened Sealing Slurries with the Addition of Magnesium Regarding Thermal Conductivity for Energy Piles and Borehole Heat Exchangers" Energies 14, no. 16: 5119. https://doi.org/10.3390/en14165119

APA StyleSliwa, T., Kowalski, T., Cekus, D., & Sapińska-Śliwa, A. (2021). Research on Fresh and Hardened Sealing Slurries with the Addition of Magnesium Regarding Thermal Conductivity for Energy Piles and Borehole Heat Exchangers. Energies, 14(16), 5119. https://doi.org/10.3390/en14165119