Analysis of an IPMSM Hybrid Magnetic Equivalent Circuit

Abstract

:1. Introduction

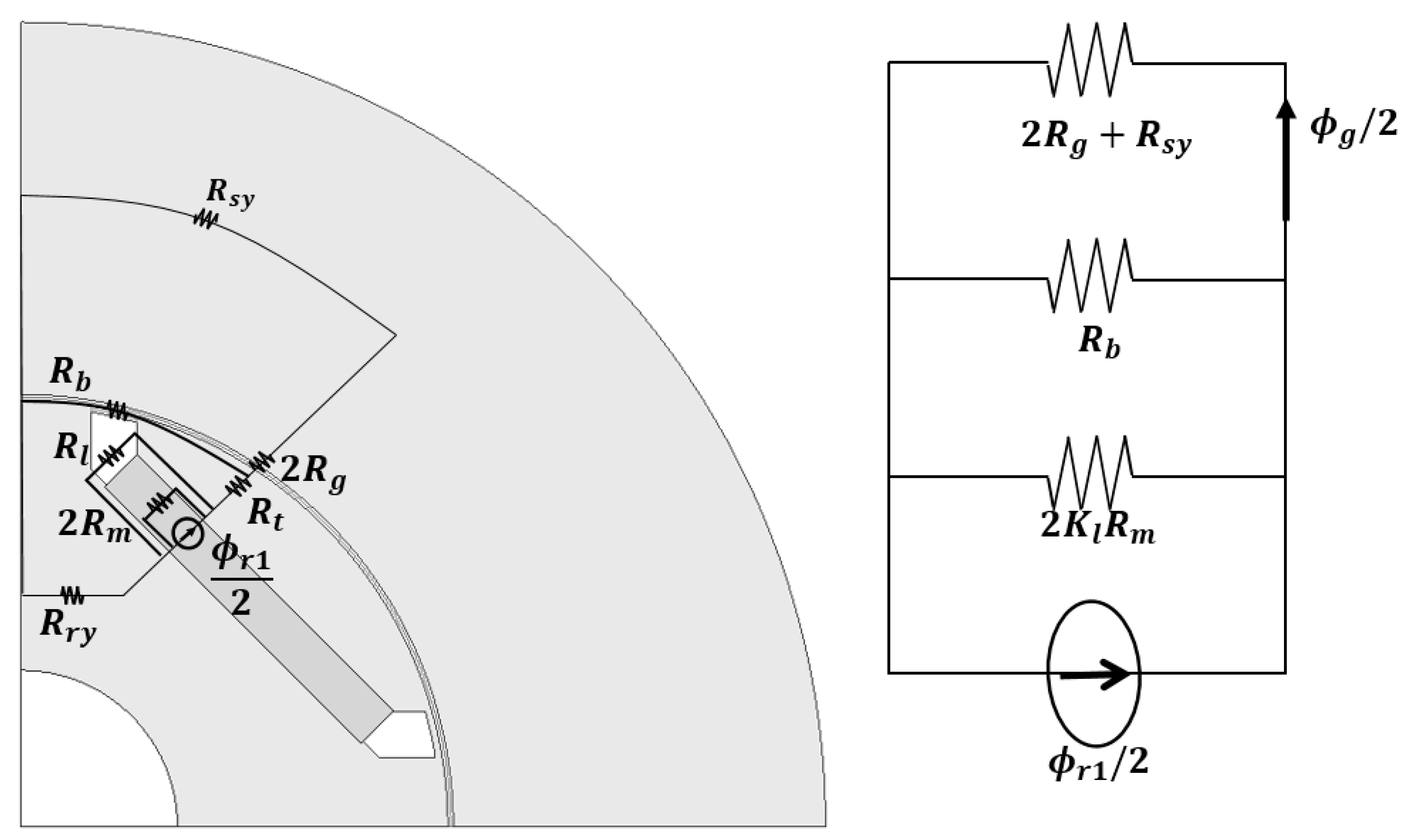

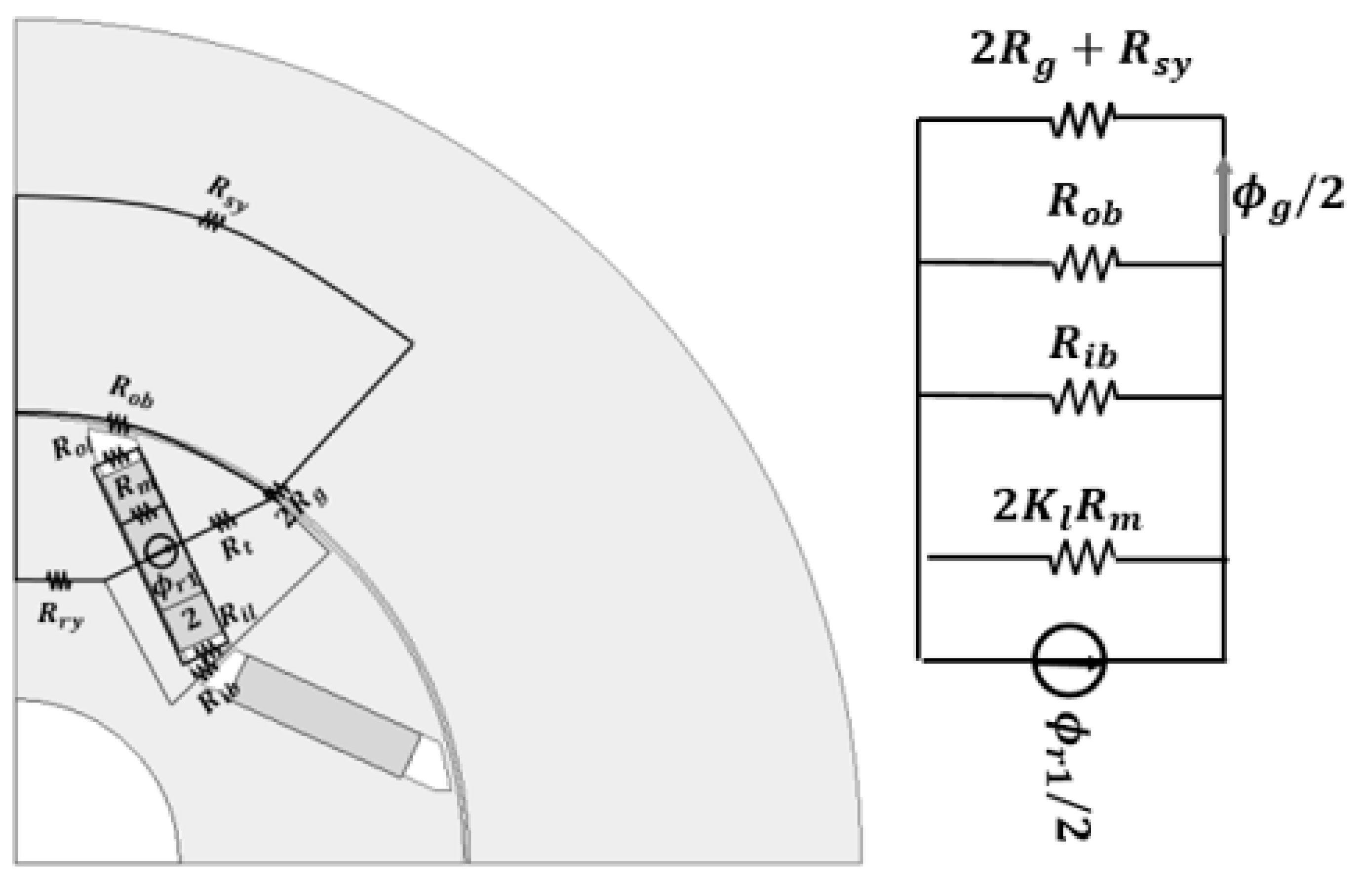

2. Proposed Magnetic Equivalent Circuit

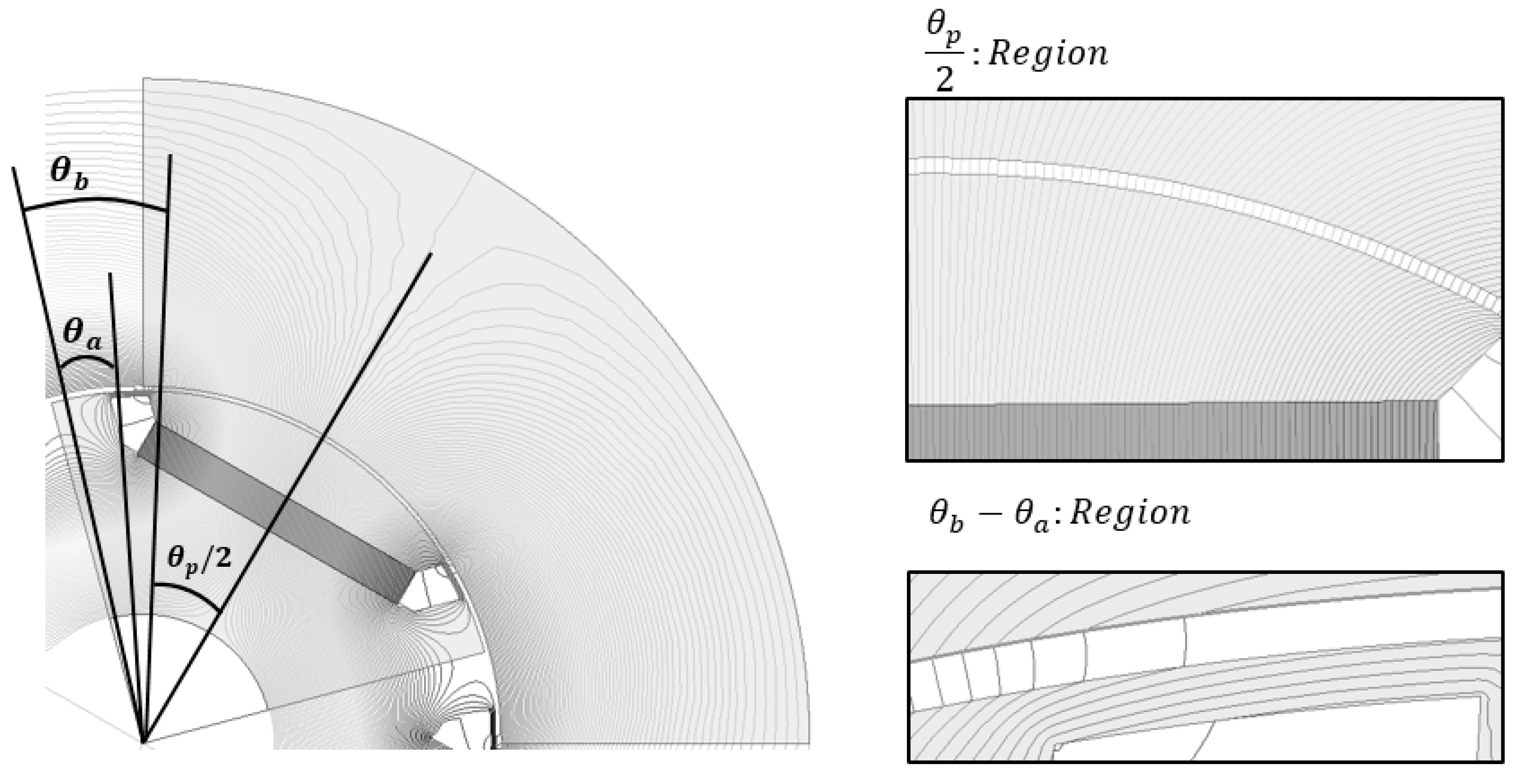

2.1. Calculation of the Slotless Air Gap Flux Density Distribution by Permanent Magnet

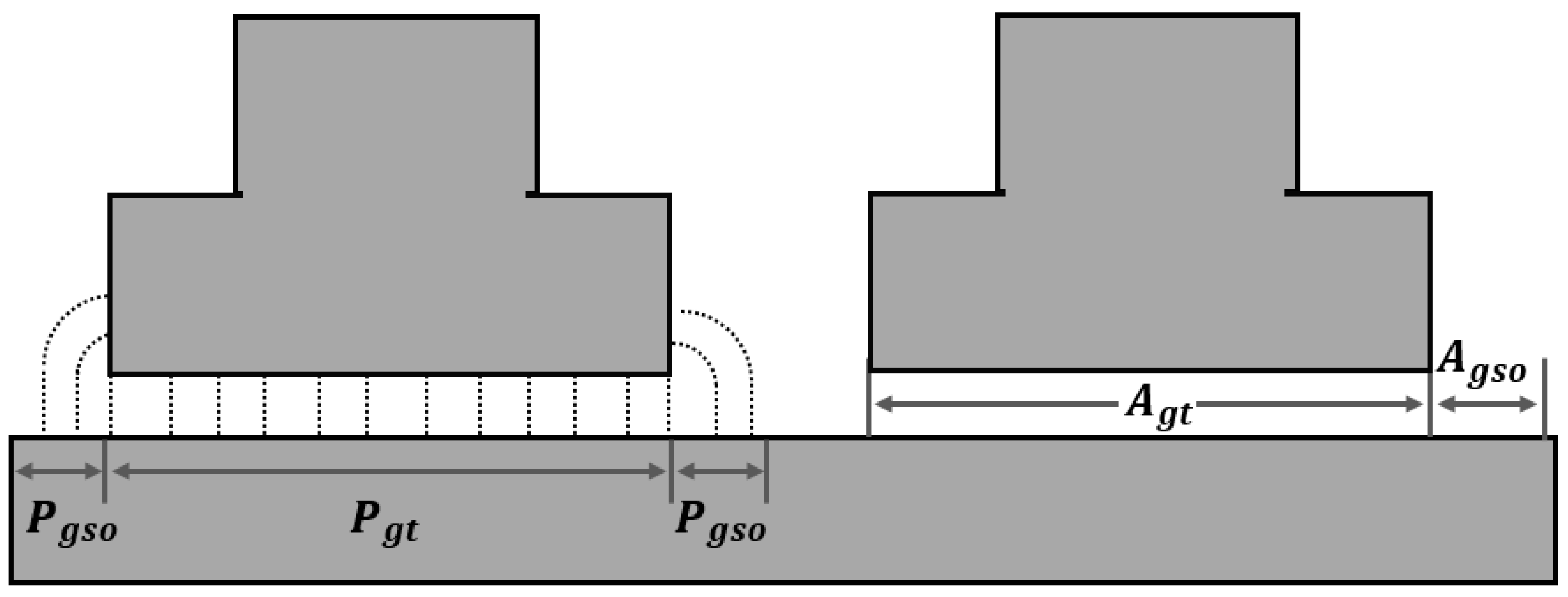

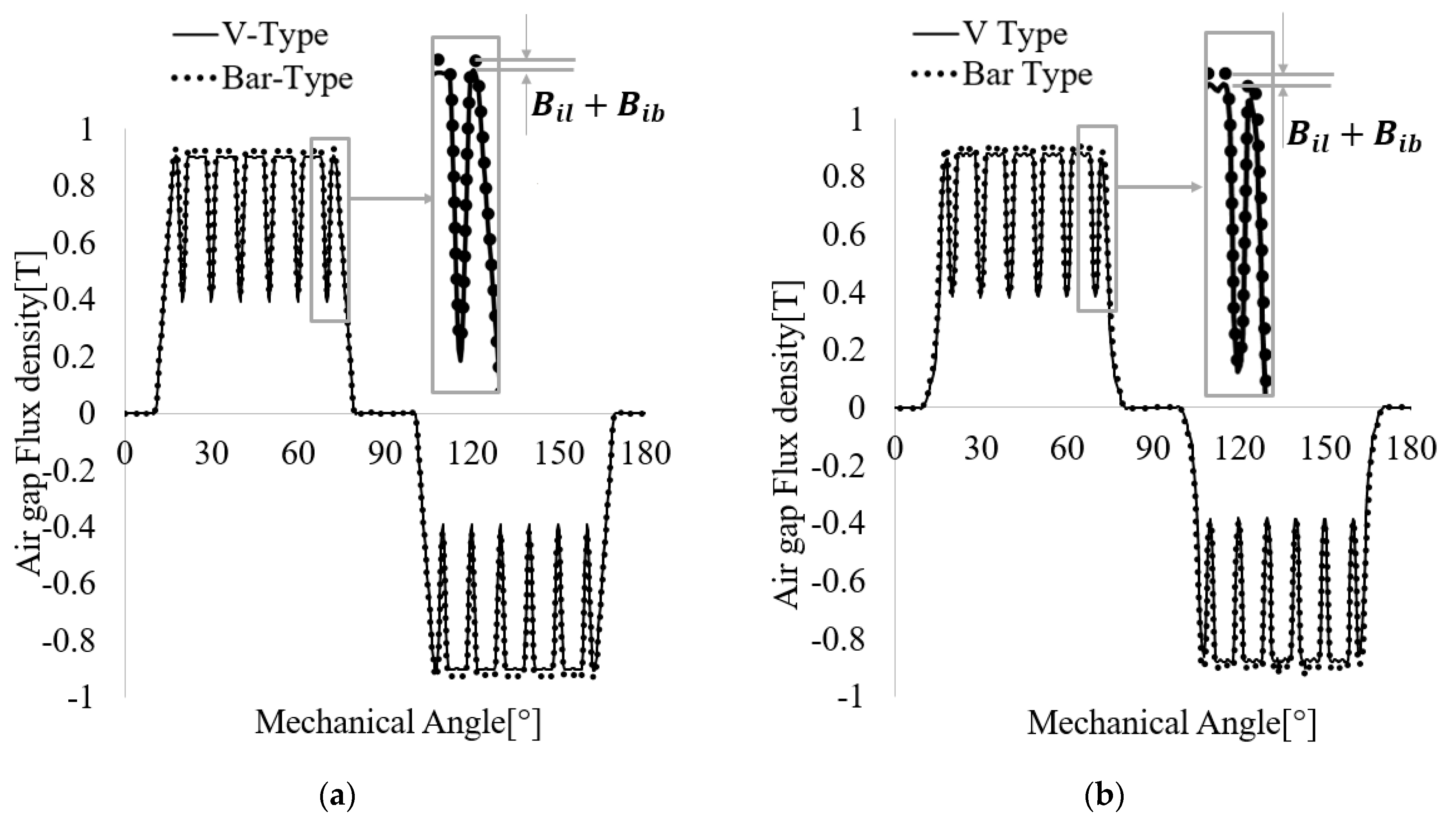

2.2. Calculation of the Air Gap Flux Density Distribution by Permanent Magnet with Slot

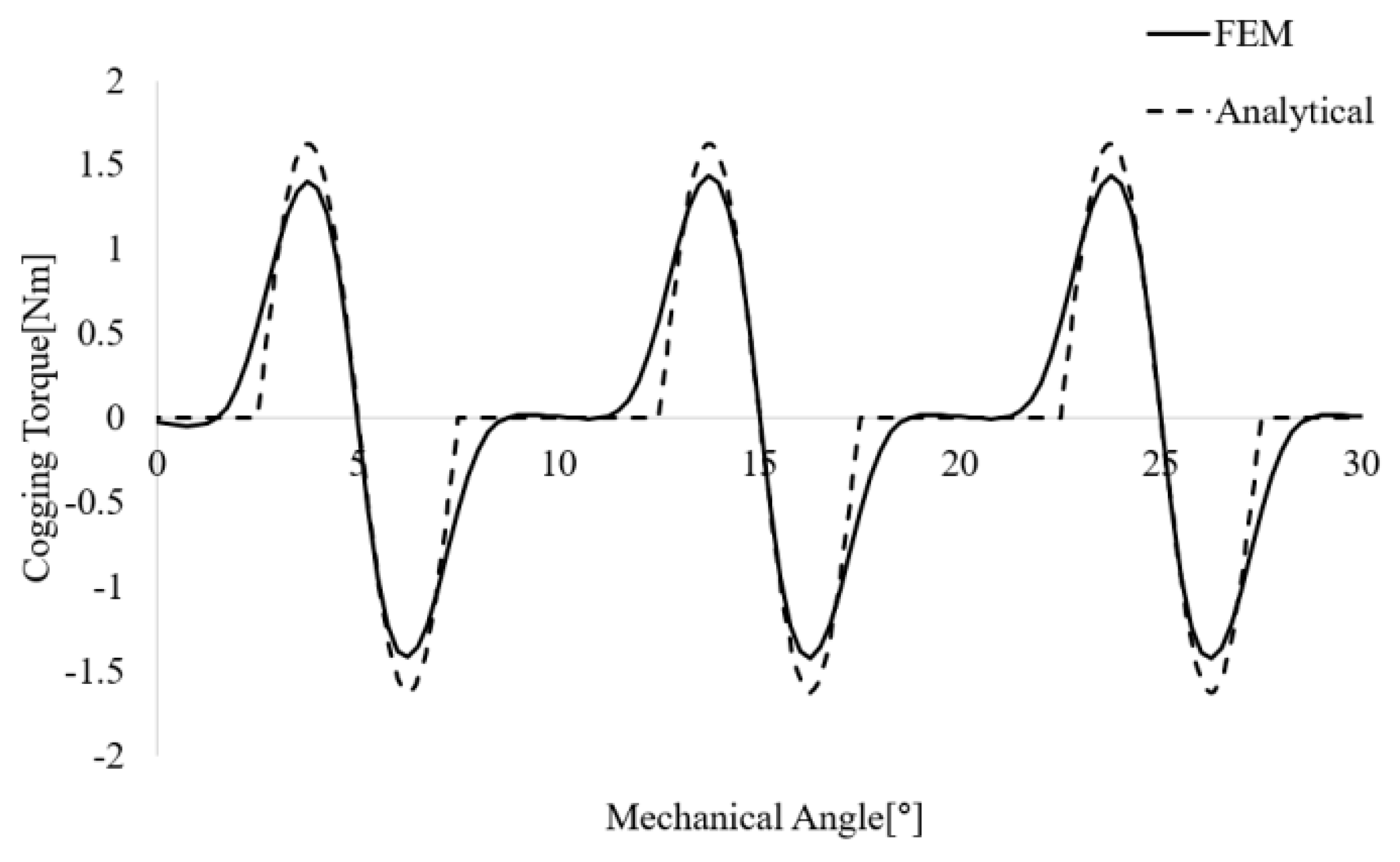

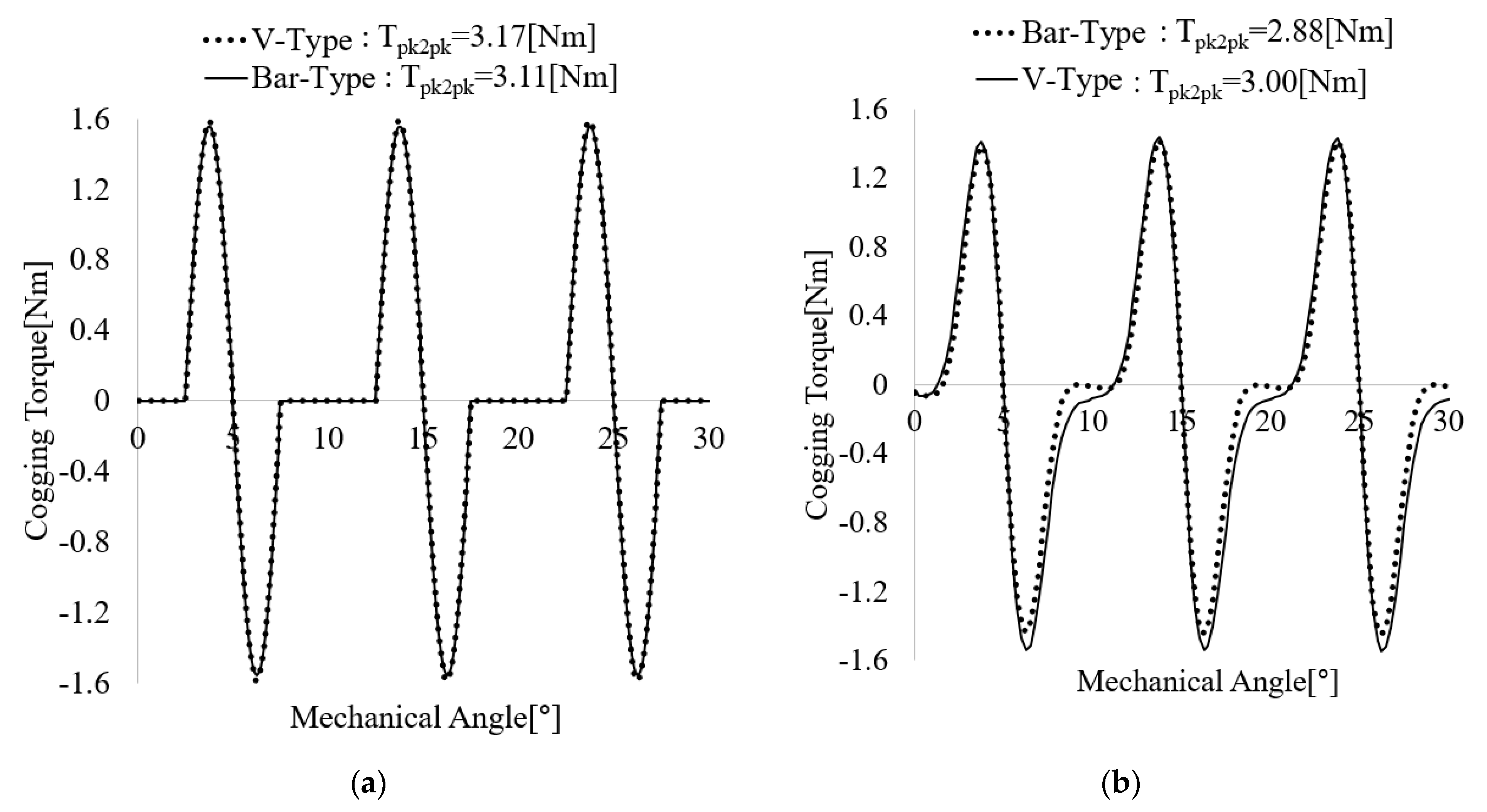

2.3. Calculation Process of Flux Linkage, No-Load-Induced Voltage, and Cogging Torque

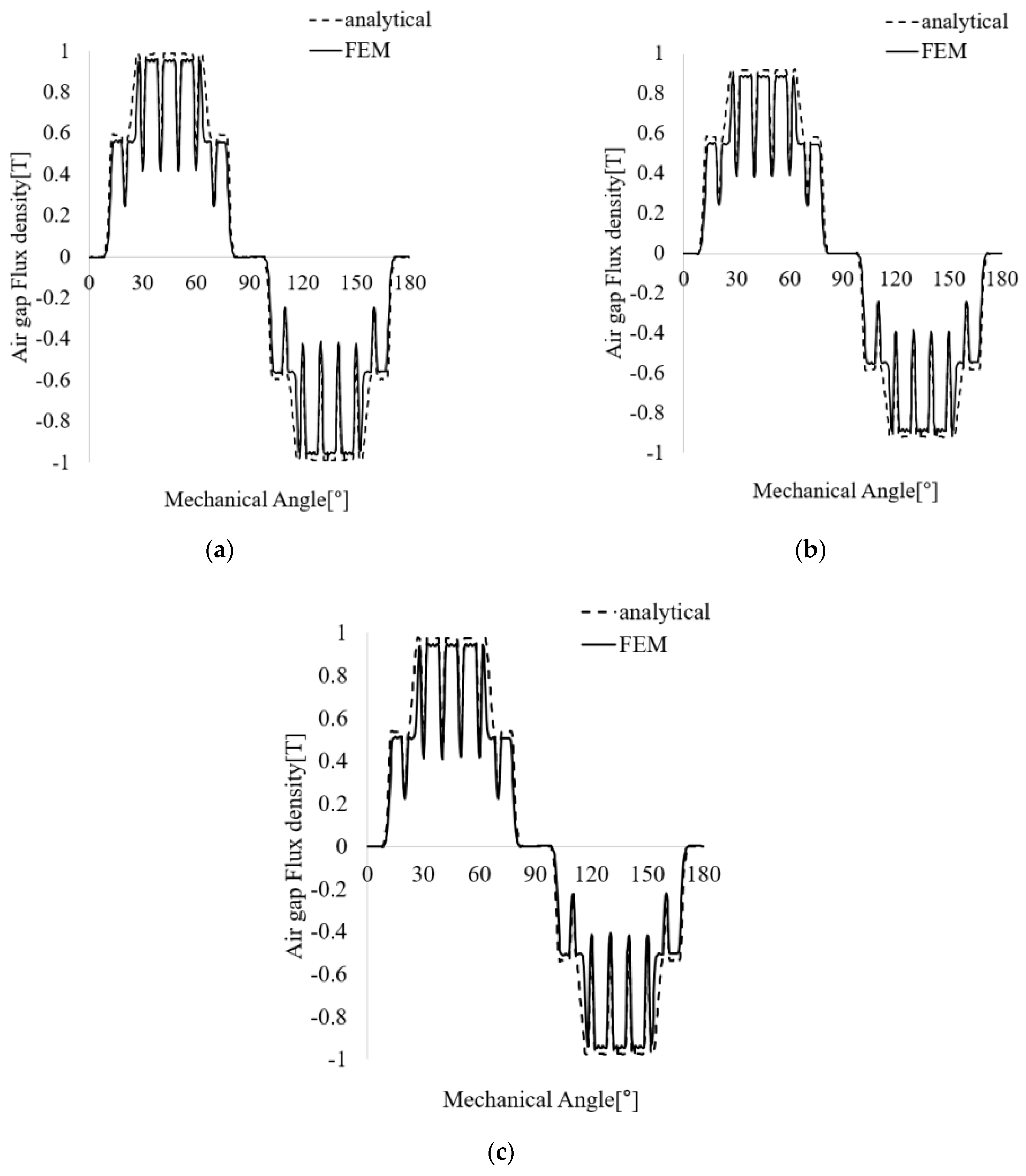

3. Proposed Calculation Method of Air Gap Flux Density Distribution

3.1. Calculation of Air Gap Flux Density Distribution by Permanent Magnet V-Type Rotor

3.2. Calculation of Flux Density Distribution of the Air Gap by Permanent Magnet Double-Layer Type Rotor

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chen, L.; Hopkinson, D.; Wang, J.; Cockburn, A.; Sparkes, M.; O’Neill, W. Reduced Dysprosium Permanent Magnets and Their Application in Electric Vehicle Traction Motors. IEEE Trans. Magn. 2015, 51, 8109004. [Google Scholar] [CrossRef]

- Kim, M.J.; Cho, S.Y.; Lee, K.D.; Lee, J.J.; Han, J.H.; Jeong, T.C.; Kim, W.-H.; Koo, D.-H.; Lee, J. Torque Density Elevation in Concentrated Winding Interior PM Synchronous Motor With Minimized Magnet Volume. IEEE Trans. Magn. 2013, 49, 3334–3337. [Google Scholar] [CrossRef]

- Akaki, R.; Takahashi, Y.; Fujiwara, K.; Matsushita, M.; Takahashi, N.; Morita, M. Effect of Magnetic Property in Bridge Area of IPM Motors on Torque Characteristics. IEEE Trans. Magn. 2013, 49, 2335–2338. [Google Scholar] [CrossRef]

- Jung, H.-C.; Park, G.-J.; Kim, D.-J.; Jung, S.-Y. Optimal Design and Validation of IPMSM for Maximum Efficiency Distribution Compatible to Energy Consumption Areas of HD-EV, 2016 IEEE Conference on Electromagnetic Field Computation (CEFC). IEEE Trans. Magn. 2017, 53, 8201904. [Google Scholar]

- Kang, G.-H.; Son, Y.-D.; Hur, J. A Novel Cogging Reduction Method for Interior-Type Permanent-Magnet Motor. IEEE Trans. Ind. Appl. 2009, 45, 161–167. [Google Scholar] [CrossRef]

- Hur, J.; Reu, J.-W.; Kim, B.-W.; Kang, G.-H. Vibration Reduction of IPM-Type BLDC Motor Using Negative Thrid Harmonic Elimination Method of Air-Gap Flux Density. IEEE Trans. Ind. Appl. 2011, 47, 1300–1309. [Google Scholar]

- Yu, H.-C.; Yu, B.-S.; Yu, J.-T.; Lin, C.-K. A Dual Notched Design of Radial-Flux Permanent Magnet Motors with Low Cogging Torque and Rare Earth Material. IEEE Trans. Magn. 2014, 50, 8203104. [Google Scholar] [CrossRef]

- Bonthu, S.S.R.; Bin Tarek, T.; Choi, S. Optimal Torque Ripple Reduction Technique for Outer Rotor Permanent Magnet Synchronous Reluctance Motors. IEEE Trans. Energy Convers. 2018, 33, 1184–1192. [Google Scholar] [CrossRef]

- Mun, J.-M.; Park, G.-J.; Seo, S.-H.; Kim, D.-W.; Kim, Y.-J.; Jung, S.-Y. Design Characteristics of IPMSM with Wide Constant Power Speed Range For EV Traction. IEEE Trans. Magn. 2017, 53, 8105104. [Google Scholar] [CrossRef]

- Kim, W.-H.; Kim, K.-S.; Kim, S.-J.; Kang, D.-W.; Go, S.-C.; Chun, Y.-D.; Lee, J. Optimal PM Design of PMA-SynRM for Wide Constant-Power Operation and Torque Ripple Reduction. IEEE Trans. Magn. 2009, 45, 4660–4663. [Google Scholar] [CrossRef]

- Kim, K.-C. A Novel Calculation Method on the Current Information of Vector Inverter for Interior Permanent Magnet Synchronous Motor for Electric Vehicle. IEEE Trans. Magn. 2014, 50, 829–832. [Google Scholar] [CrossRef]

- Ma, C.; Zhang, J.; Wang, J.; Yang, N.; Liu, O.; Zuo, S.; Wu, X.; Wang, P.; Li, J.; Fang, J. Analytical Model of Open-Circuit Air-Gap Field distribution in Interior Permanent Magnet Machines Based on Magnetic Equivalent Circuit Method and Boundary Condistions of Macroscopic Equations. IEEE Trans. Magn. 2021, 57, 8104209. [Google Scholar] [CrossRef]

- Chen, Y.; Zhu, Z.Q.; Howe, D. 3-D lumped parameter magnetic circuit analysis of single-phase flux-switching permanent magnet motor. IEEE Trans. Magn. Ind. Appl. 2008, 44, 1701–1710. [Google Scholar] [CrossRef]

- Wang, J.; Lieu, D.; Lorimer, W.; Hartman, A. Comparison of lumped parameter and finite element magnetic modeling in a brushless DC motor. IEEE Trans. Magn. 1997, 33, 4092–4094. [Google Scholar] [CrossRef]

- Sheikh-Ghalavand, B.; Vaez-Zadeh, S.; Isfahani, A.H. An Improved Magnetic Equivalent Circuit Model for Iron-Core Linear Permanent-Magnet Synchronous Motors. IEEE Trans. Magn. 2009, 46, 112–120. [Google Scholar] [CrossRef]

- Moallem, M.; Dawson, G.E. An improved magnetic equivalent circuit method for predicting the characteristics of highly saturated electromagnetic devices. IEEE Trans. Magn. 1998, 34, 3632–3635. [Google Scholar] [CrossRef]

- Mi, C.; Filippa, M.; Liu, W.; Ma, R.Q. Analytical method for predicting the air-gap flux of interior-type permanent-magnet machines. IEEE Trans. Magn. 2004, 40, 50–58. [Google Scholar] [CrossRef]

- Chen, H.; Li, D.; Qu, R.; Zhu, Z.; Li, J. An Improved Analytical Model for Inductance Calculation of Interior Permanent Magnet Machines. IEEE Trans. Magn. 2014, 50, 7027108. [Google Scholar]

- Hwang, C.-C.; Cho, Y.H. Effects of Leakage Flux on Magnetic Fields of Interior Permanent Magnet Synchronous Motors. IEEE Trans. Magn. 2001, 37, 3021–3024. [Google Scholar] [CrossRef]

- Rahaman, M.A.; Slemon, G.R. Analytical models for interior-type permanent magnet synchronous motors. IEEE Trans. Magn. 1985, 21, 1741–1743. [Google Scholar] [CrossRef]

- Radun, A.V. Development of Dynamic Magnetic Circuit Models Including Iron Saturation and Losses. IEEE Trans. Magn. 2013, 50, 7027010. [Google Scholar] [CrossRef]

- Liu, G.; Liu, L.; Chen, Q.; Zhao, W. Torque Calculation of Five-Phase Interior Permanent Magnet Machine Using Improved Analytical Method. IEEE Trans. Energy Convers. 2019, 34, 1023–1032. [Google Scholar] [CrossRef]

- Zhu, L.; Jiang, S.Z.; Zhu, Z.Q.; Chan, C.C. Analytical Modeling of Multi-segment and Multilayer Interior Permanet Magnet Machines. In Proceedings of the 17th International Conference on Electrical Machines and Systems (ICEMS), Hangzhou, China, 22–25 October 2014; pp. 28–33. [Google Scholar]

- Hanselman, D. Brushless Motors: Magnetic Design, Performance, and Control; E-Man Press LLC: Ballston Spa, NY, USA, 2012; p. 656. [Google Scholar]

- Hendershot, J.R.; Miller, T.J.E. Design of Brushless Permanent-Magnet Machines; Motor Design Books LLC: Venice, FL, USA, 2015; p. 798. [Google Scholar]

| Type | Bar | V | Unit |

|---|---|---|---|

| 0.9898 | 0.9891 | [-] | |

| 1,051,237 | 831,420 | [AT/Wb] | |

| 922 | 904.22 | [mT] | |

| 0.447 | 0.438 | [-] |

| Equation | |

|---|---|

| Air Gap Flux | |

| Air Gap Flux Density | |

| Slot Factor | |

| DB | |

| DV | |

| Delta |

| HMEC | FEM | ||||||

|---|---|---|---|---|---|---|---|

| Type | DB | DV | Delta | DB | DV | Delta | Unit |

| Ct1 | 1.16 | [-] | |||||

| Ct2 | 1.17 | ||||||

| Gmin | 0.454 | 0.445 | 0.443 | 0.436 | 0.436 | 0.437 | |

| Bgt1 | 594 | 582 | 536 | 562 | 545 | 508 | [mT] |

| Bgt2 | 987 | 918 | 975 | 960 | 890 | 947 | |

| HMEC | FEM | ||||||

|---|---|---|---|---|---|---|---|

| Type | DB | DV | Delta | DB | DV | Delta | Unit |

| Calculating Time (Bgt1, Bgt2) | 0.103622 | 389.00 | [sec] | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, I.-S.; Jo, B.-W.; Kim, K.-C. Analysis of an IPMSM Hybrid Magnetic Equivalent Circuit. Energies 2021, 14, 5011. https://doi.org/10.3390/en14165011

Song I-S, Jo B-W, Kim K-C. Analysis of an IPMSM Hybrid Magnetic Equivalent Circuit. Energies. 2021; 14(16):5011. https://doi.org/10.3390/en14165011

Chicago/Turabian StyleSong, In-Soo, Byoung-Wook Jo, and Ki-Chan Kim. 2021. "Analysis of an IPMSM Hybrid Magnetic Equivalent Circuit" Energies 14, no. 16: 5011. https://doi.org/10.3390/en14165011

APA StyleSong, I.-S., Jo, B.-W., & Kim, K.-C. (2021). Analysis of an IPMSM Hybrid Magnetic Equivalent Circuit. Energies, 14(16), 5011. https://doi.org/10.3390/en14165011