Single Source Multi-Frequency AC-AC Converter for Induction Cooking Applications

Abstract

:1. Introduction

- ⮚

- The control algorithm feeds power to two loads with a single frequency source.

- ⮚

- ⮚

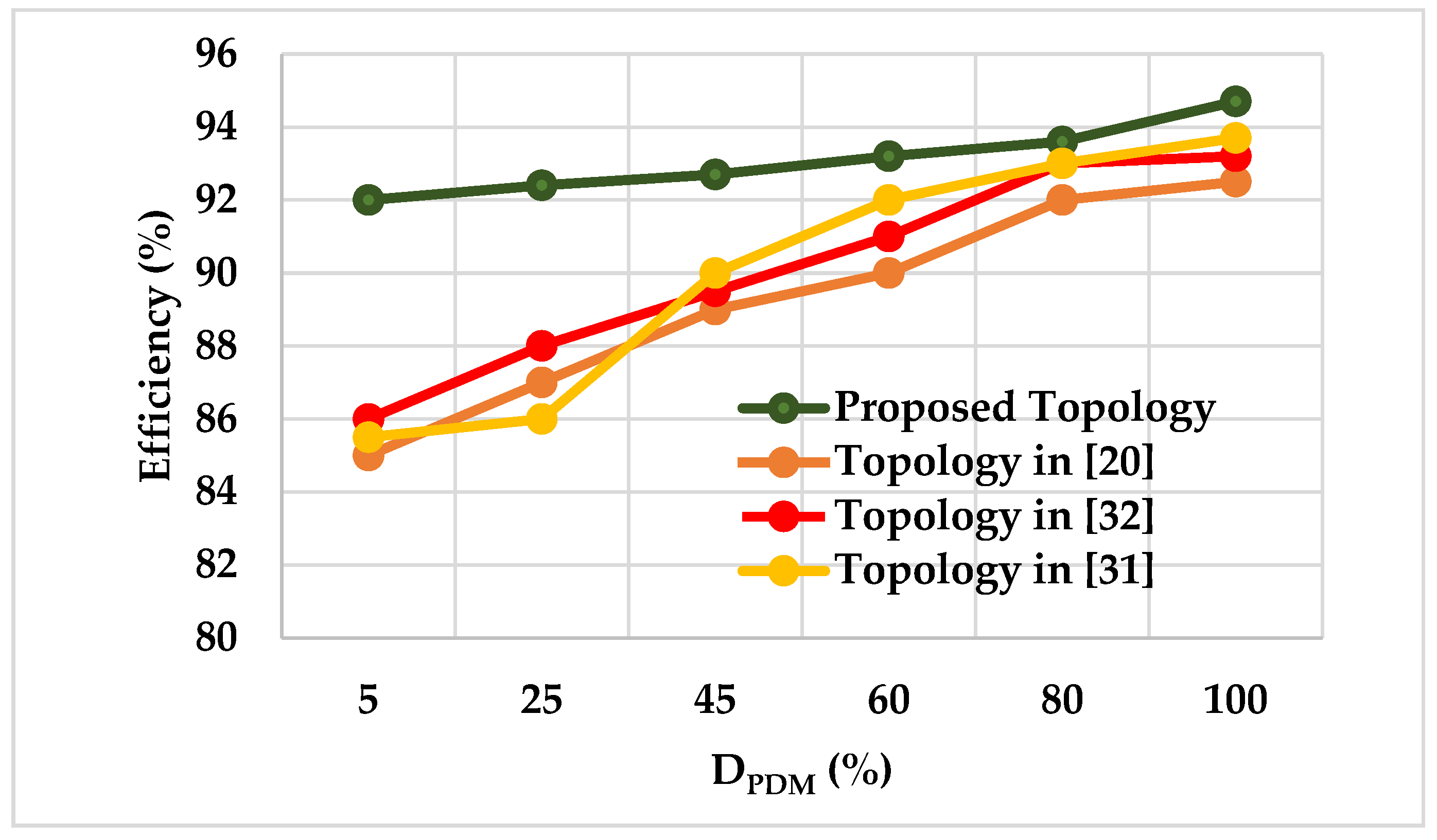

- The efficiency of the system is greater than 92% for 0% to 100% of the rated power.

- ⮚

- As switching frequency is not varied, soft switching is realized for the whole operating range.

2. System Description

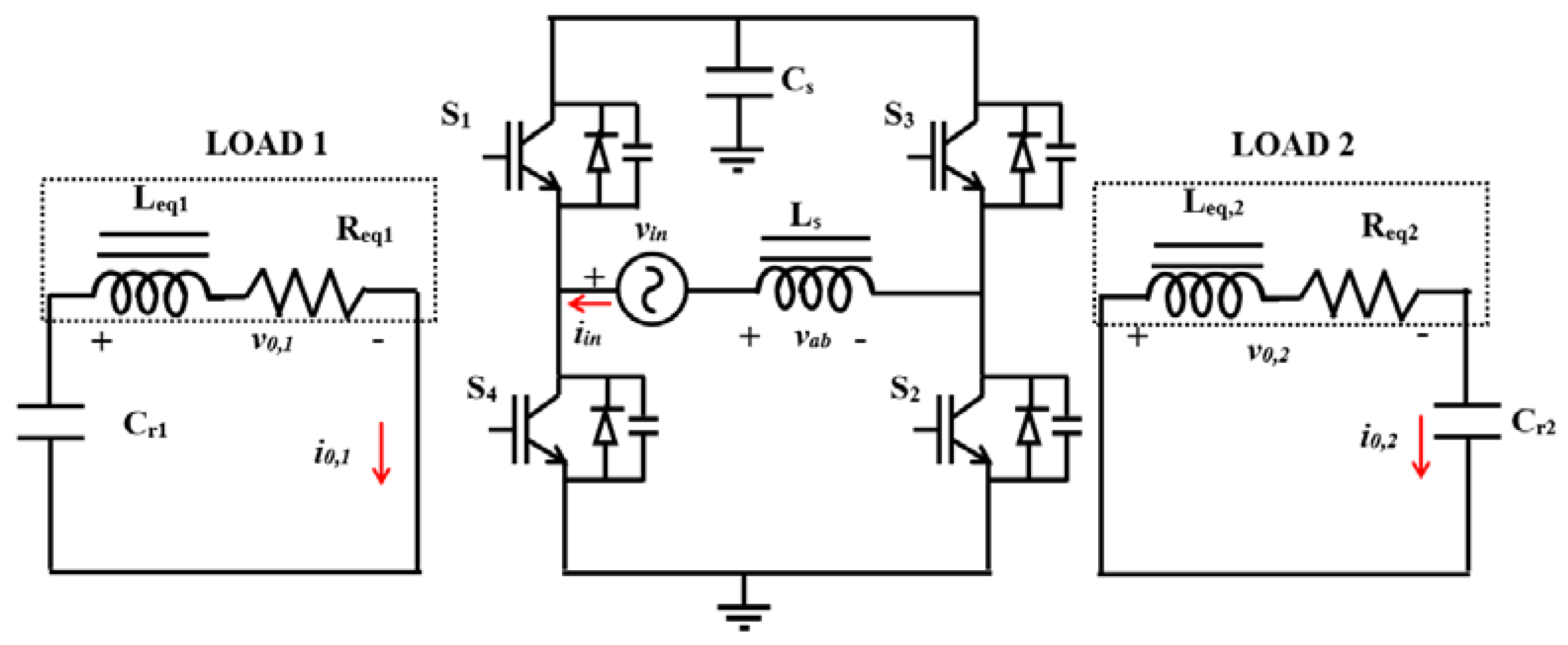

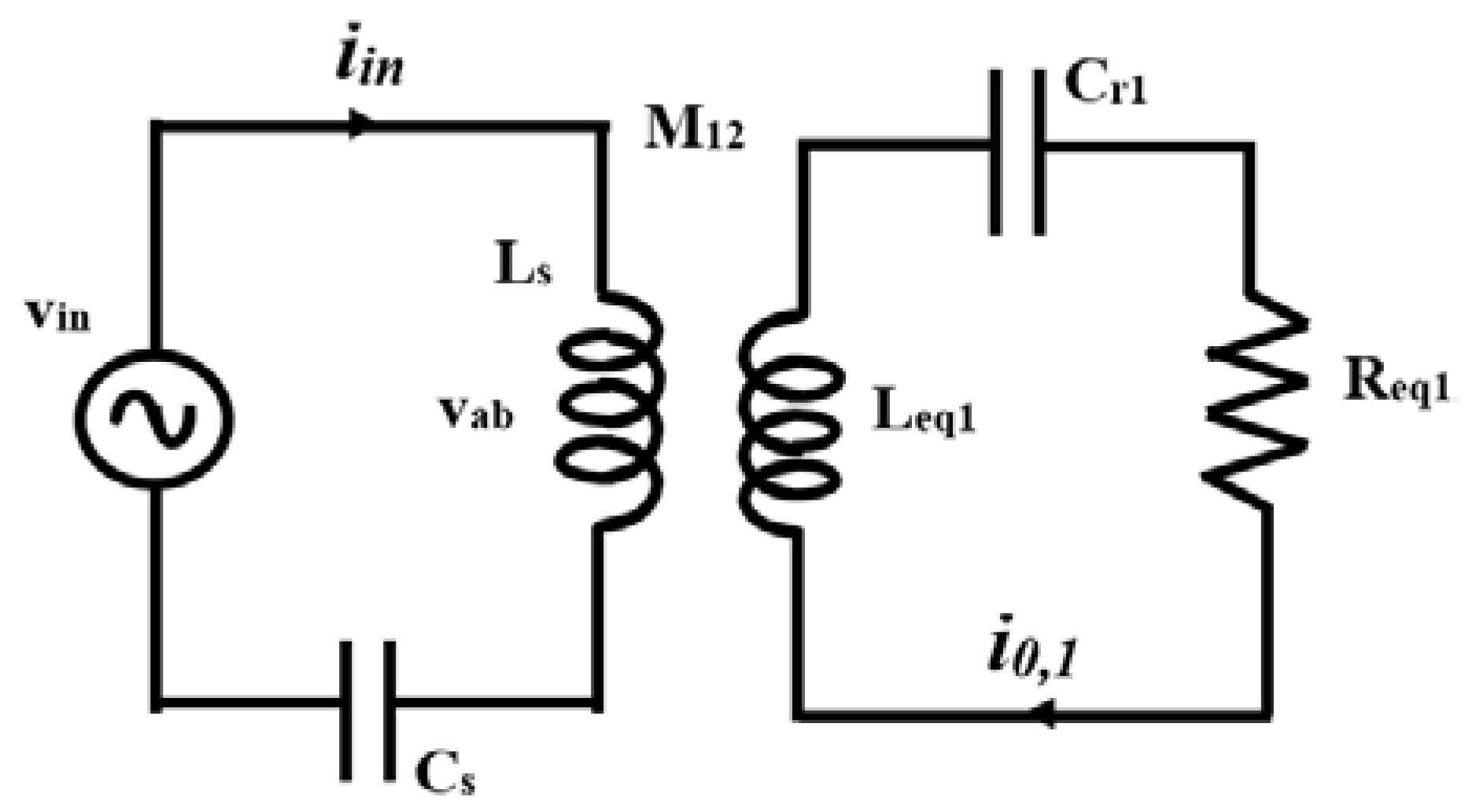

2.1. Circuit Description

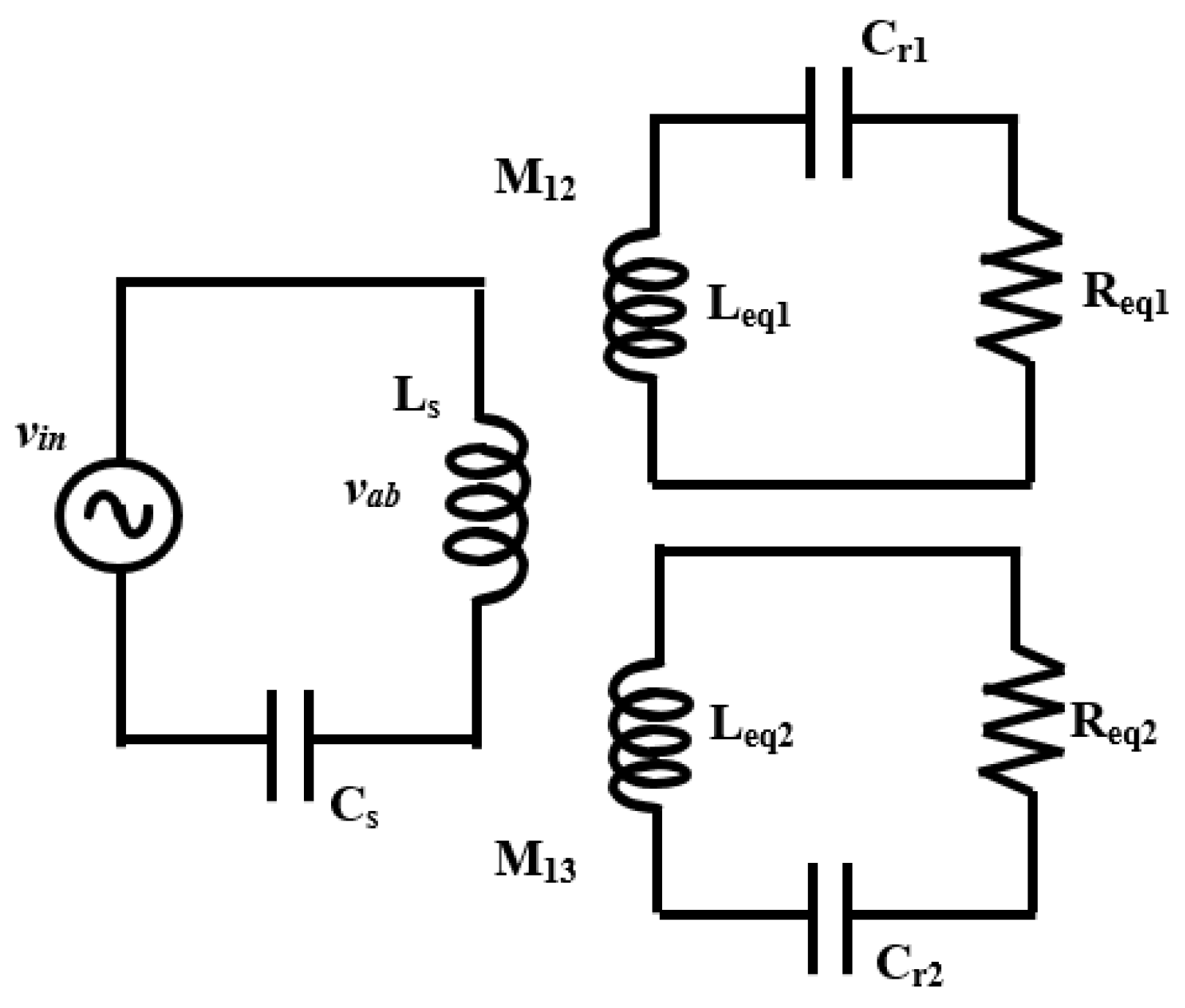

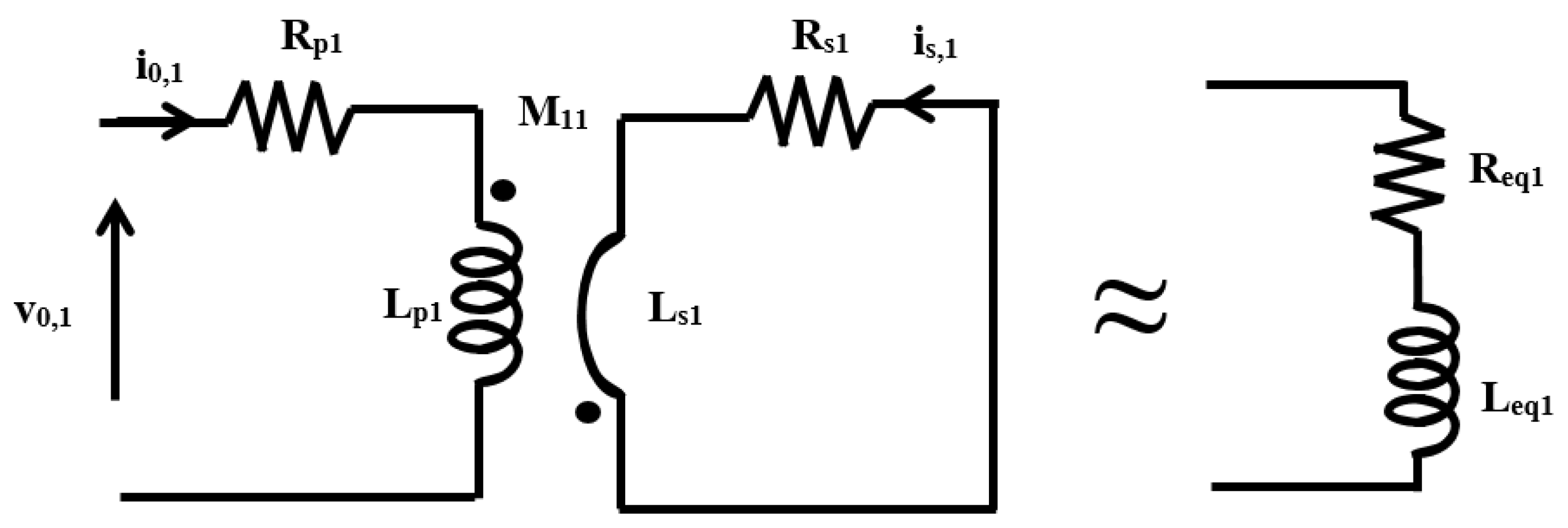

2.2. Induction Heating Modeling

2.3. Frequency Bifurcation of a Two Coil-Based IH System

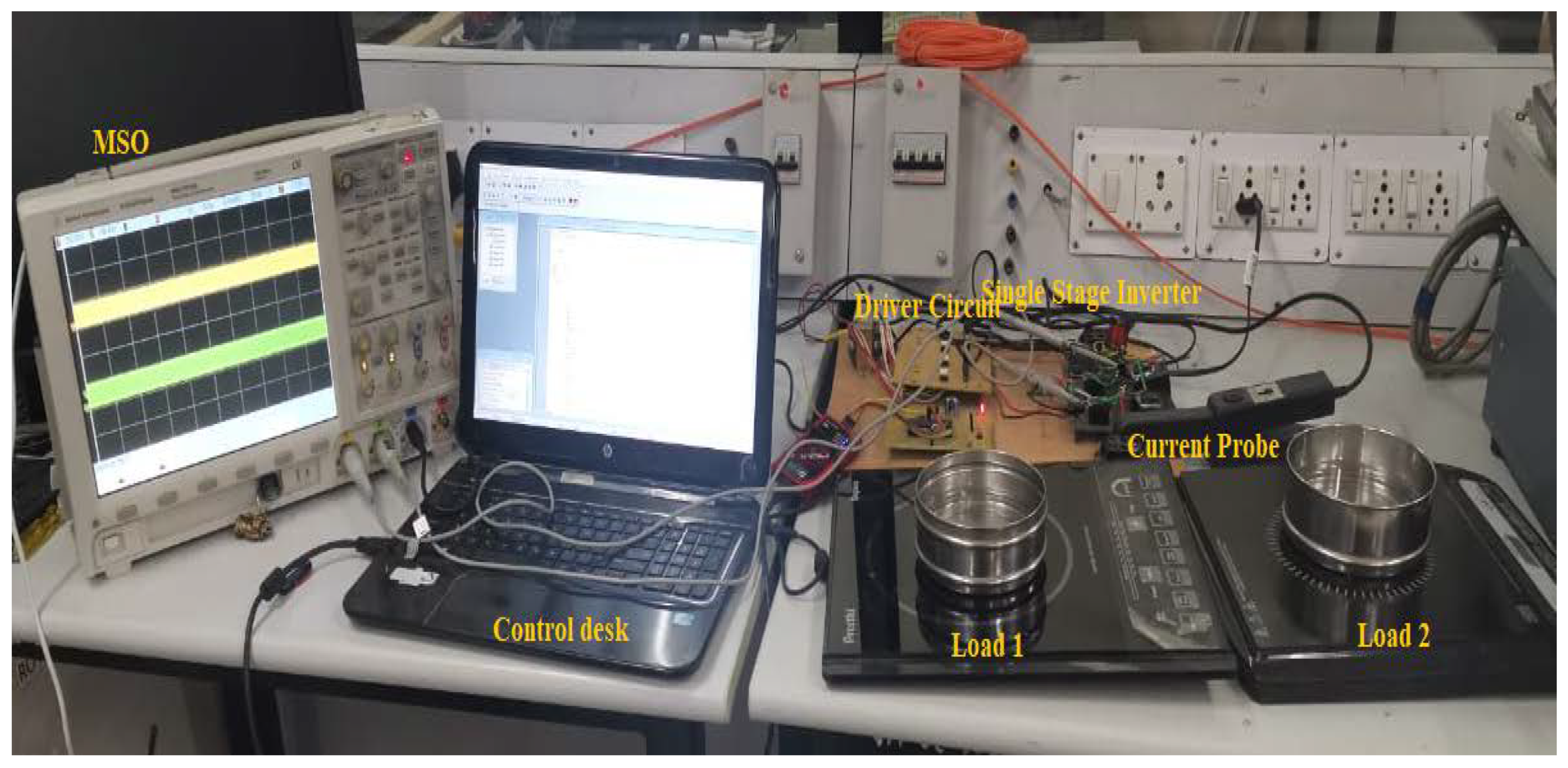

3. Simulation and Experimental Results

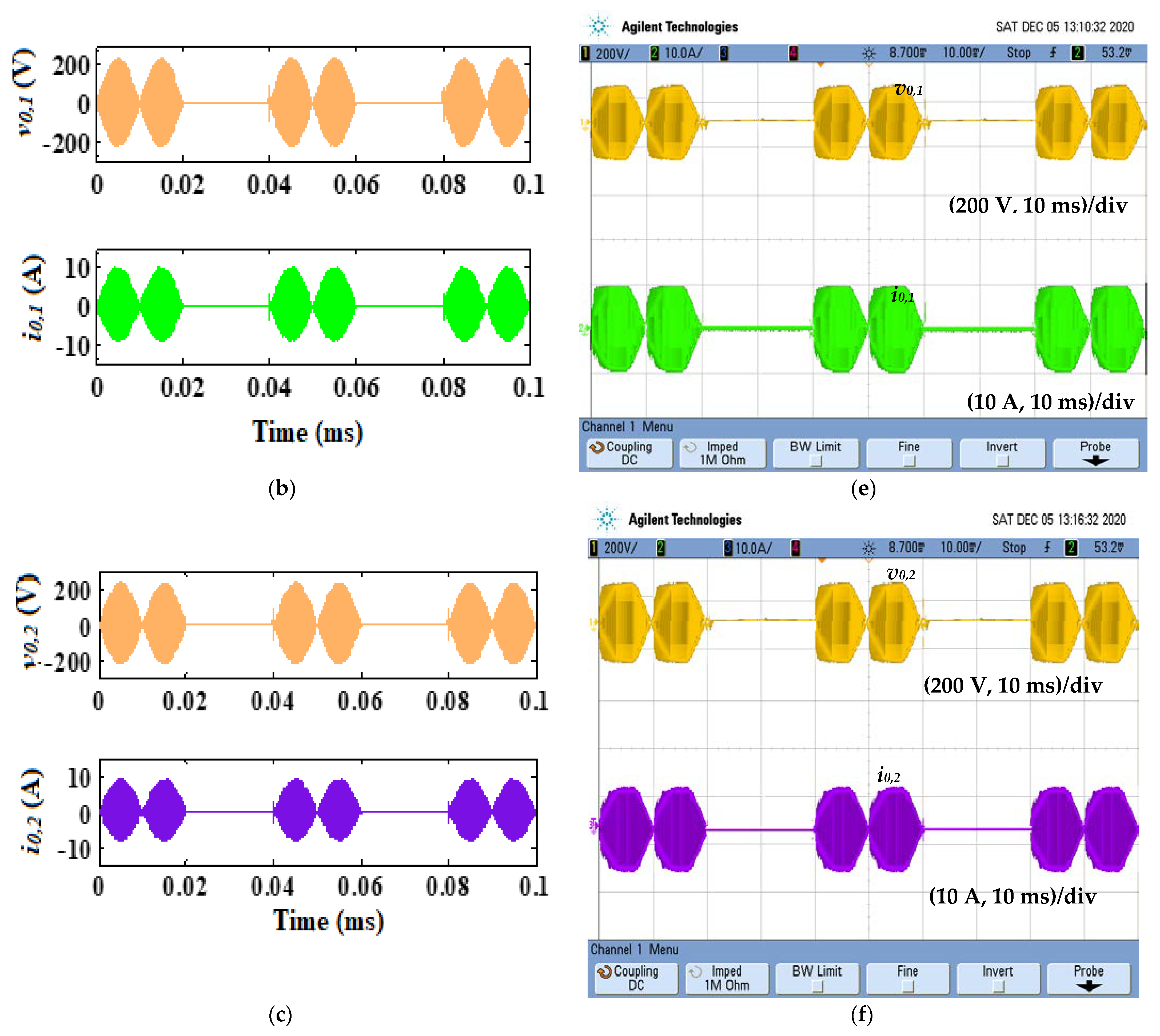

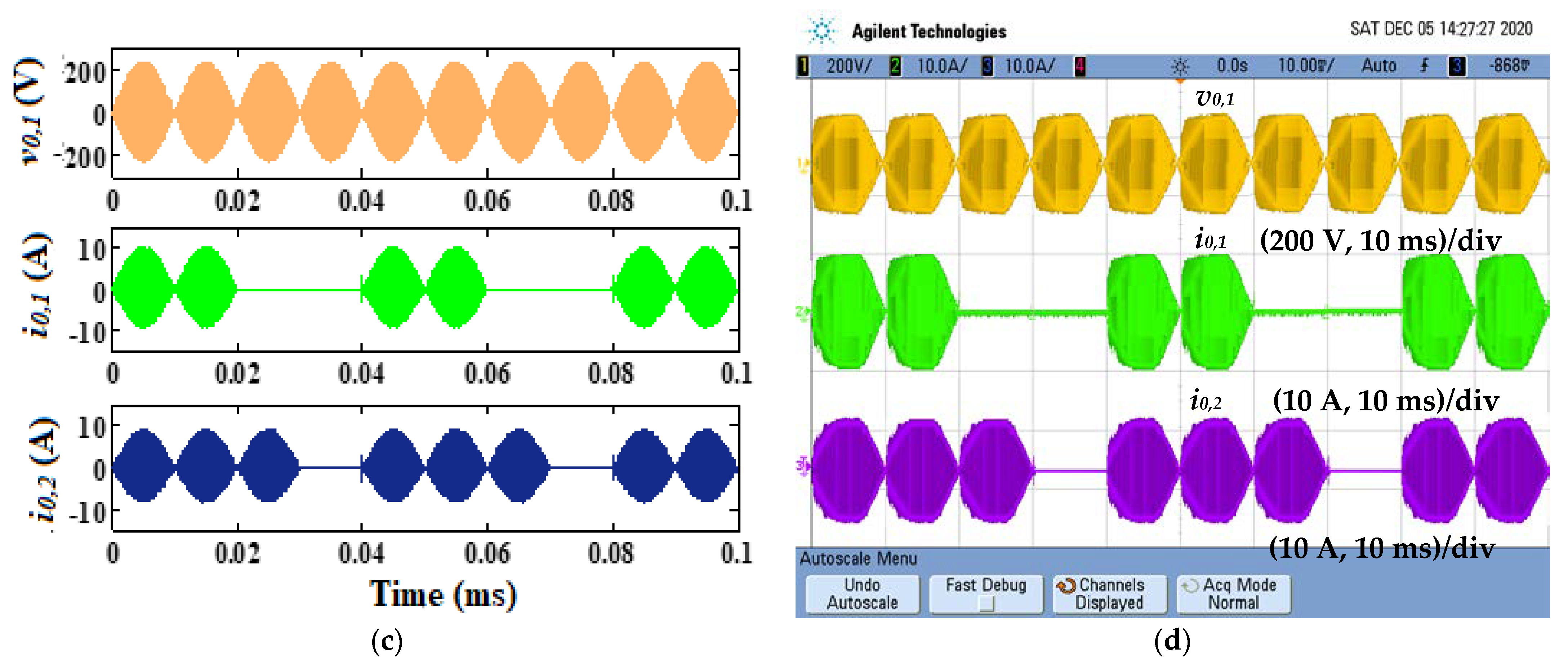

3.1. Dual Load Operation

3.2. PDM Based Dual Output Power Control for Induction Heating Load

3.3. Independent Power Control

- (i)

- Load 1 requires 137.5 W and load 2 requires 445 W. In this case, the PDM control signal is chosen with 25% of DPDM for 20 kHz switching and 100% DPDM for 33 kHz switching frequency.

- (ii)

- Load 1 requires 275 W and load 2 requires 356 W. In this case, the PDM control signal is chosen with 50% of DPDM for 20 kHz switching and 75% DPDM for 33 kHz switching frequency.

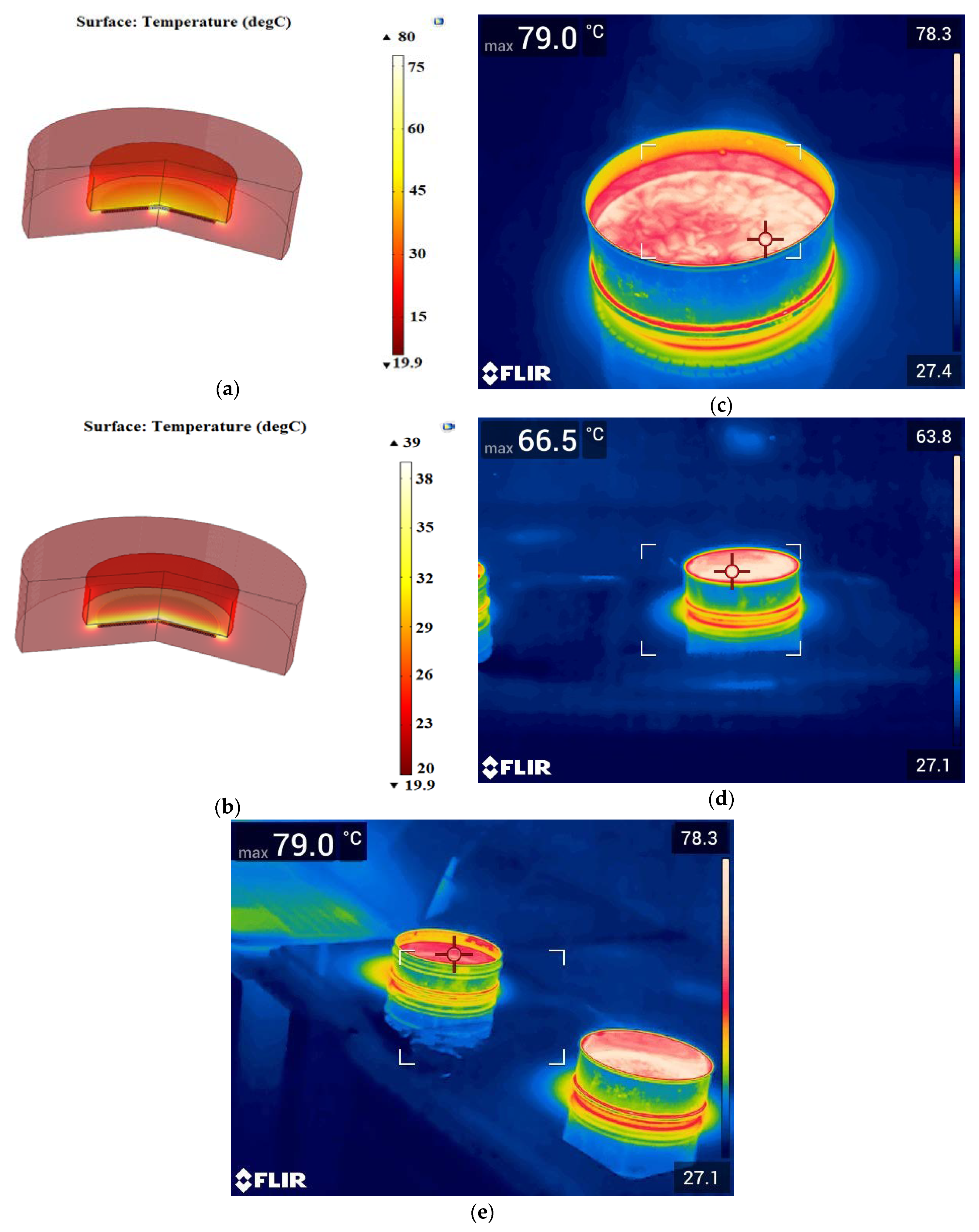

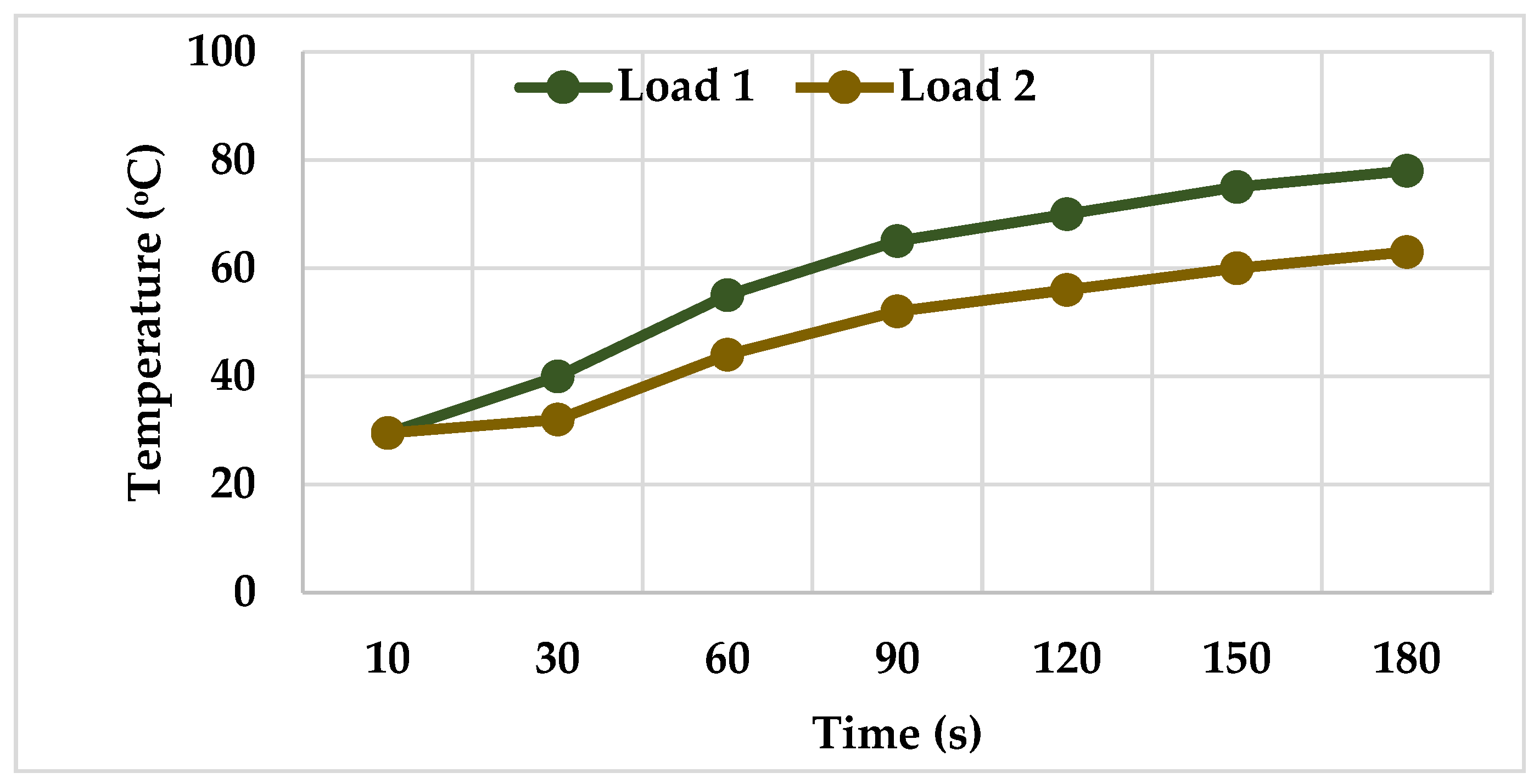

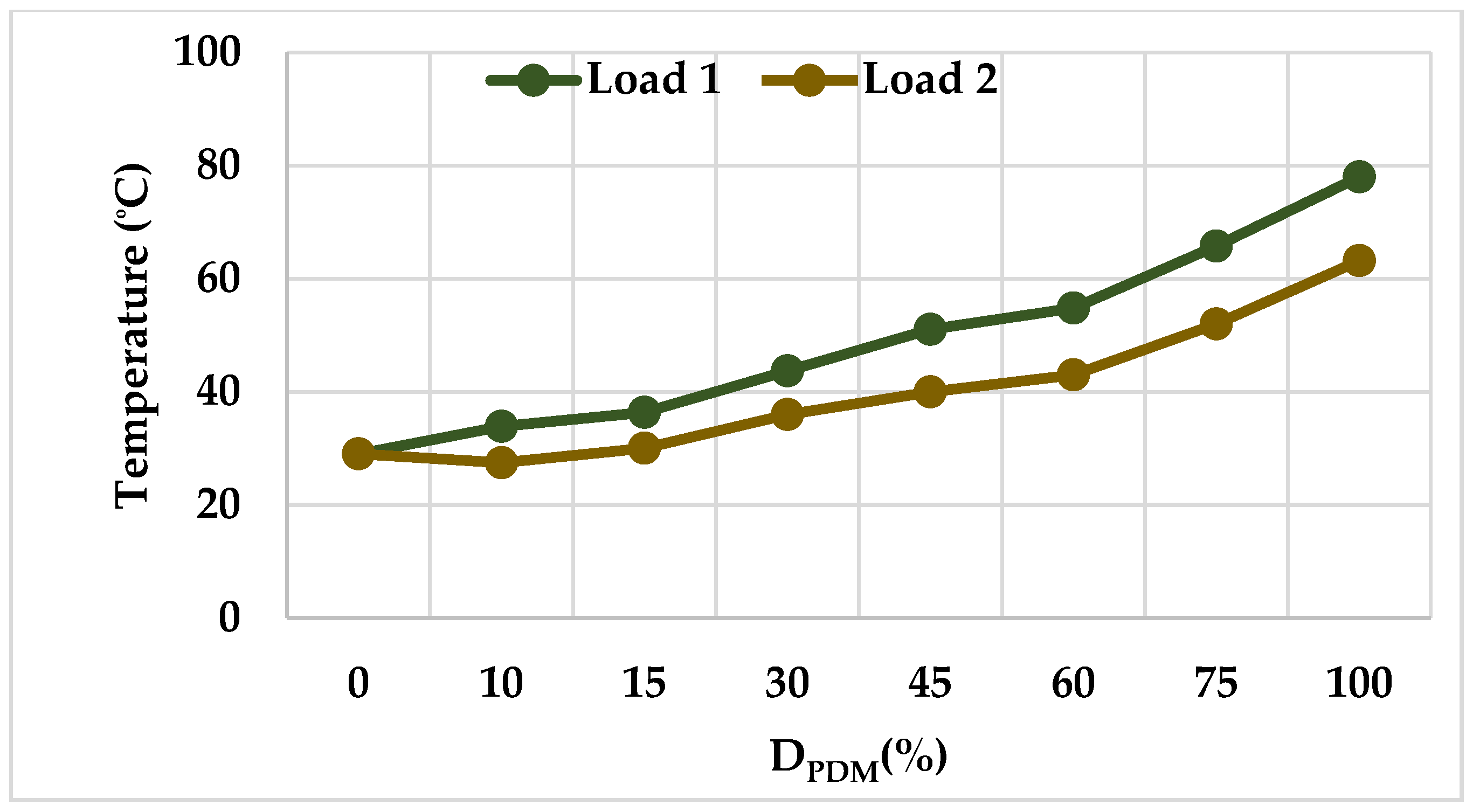

3.4. Thermal Analysis of Load

4. Conclusions

- Output power is controlled from 100% to 0% of the rated power.

- The proposed inverter possesses higher efficiency of about 94.7% at 100% DPDM and is greater than 92% for other values of DPDM.

- Independent power control is achieved.

- The output power can be regulated to any value within the rated power.

- As switching frequency is not varied, soft switching is realized for the whole operating range.

- The PDM frequency is chosen as 25 Hz, which results in no noise.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Req | Equivalent load resistance (Ω) |

| Leq | Equivalent load inductance (H) |

| Vab | Supply voltage (V) |

| Rp1 | Work coil resistance of load 1 (Ω) |

| Rp2 | Work coil resistance of load 2 (Ω) |

| Lp1 | Primary inductance of load 1 (H) |

| Lp2 | Primary inductance of load 2 (H) |

| Ls1 | Secondary inductance of load 1 (H) |

| Ls2 | Secondary inductance of load 2 (H) |

| Vm | Maximum peak value of the input voltage (V) |

| θ | Angle difference between voltage and current (degree) |

| M12 | Mutual inductance of source on load 2 (H) |

| M21 | Mutual inductance of source on load 1 (H) |

| Zeq1 | Equivalent impedance of load 1 (Ω) |

| Zeq2 | Equivalent impedance of load 2 (Ω) |

| η1 | Efficiency of load 1 |

| η2 | Efficiency of load 2 |

| v0,1 | Load 1 voltage (V) |

| v0,2 | Load 2 voltage (V) |

| i0,1 | Load 1 current (A) |

| i0,2 | Load 2 current (A) |

| Req1 | Equivalent load resistance of load 1 (Ω) |

| Req2 | Equivalent load resistance of load 2 (Ω) |

| Leq1 | Equivalent load inductance of load 1 (H) |

| Leq2 | Equivalent load inductance of load 2 (H) |

| Cr1 | Resonant capacitor of load 1 (F) |

| Cr2 | Resonant capacitor of load 2 (F) |

| ωs | Angular switching frequency (rad/sec) |

| Ls | Input inductor (H) |

| Rs | Source coil resistance (Ω) |

| Cs | Source capacitor (F) |

| Prat | Rated output power (W) |

| fPDM | PDM switching frequency (Hz) |

| fr | Resonant frequency (Hz) |

| fr1 | Resonant frequency of load 1 (Hz) |

| fr2 | Resonant frequency of load 2 (Hz) |

| ωr1 | Angular resonant frequency of load 1 (rad/sec) |

| ωr2 | Angular resonant frequency of load 2 (rad/sec) |

| d12 | Distance between source and load 1 (cm) |

| d13 | Distance between source and load 2 (cm) |

References

- Acero, J.A.; Burdio, J.M.; Barragan, L.A.; Navarro, D.; Alonso, R.M.; Garcia, J.R.; Monterde, F.; Hernandez, P.; Llorente, S.; Garde, I. The domestic induction heating appliance: An overview of recent research. In Proceedings of the 2008 Twenty-Third Annual IEEE Applied Power Electronics Conference and Exposition, Austin, TX, USA, 24–28 February 2008; Volume 16, pp. 651–657. [Google Scholar] [CrossRef]

- Park, S.M.; Jang, E.; Joo, D.; Lee, B.K. Power Curve-Fitting Control Method with Temperature Compensation and Fast-Response for All-Metal Domestic Induction Heating Systems. Energies 2019, 12, 2915. [Google Scholar] [CrossRef] [Green Version]

- Yilmaz, I.; Ermis, M.; Cadirci, I.; Yılmaz, I. Medium frequency induction melting furnace as a load on the power system. In Proceedings of the 2011 IEEE Industry Applications Society Annual Meeting, Orlando, FL, USA, 9–13 October 2011; Volume 48, pp. 1–12. [Google Scholar] [CrossRef]

- Egalon, J.; Caux, S.; Maussion, P.; Souley, M.; Pateau, O. Multiphase System for Metal Disc Induction Heating: Modeling and RMS Current Control. IEEE Trans. Ind. Appl. 2012, 48, 1692–1699. [Google Scholar] [CrossRef] [Green Version]

- Millán, I.; Burdío, J.; Acero, J.A.; Lucía, O.; Llorente, S. Series resonant inverter with selective harmonic operation applied to all-metal domestic induction heating. IET Power Electron. 2011, 4, 587. [Google Scholar] [CrossRef]

- Lucía, O.; Burdío, J.M.; Millán, I.; Acero, J.; Barragán, L.A. Efficiency-Oriented Design of ZVS Half-Bridge Series Resonant Inverter With Variable Frequency Duty Cycle Control. IEEE Trans. Power Electron. 2010, 25, 1671–1674. [Google Scholar] [CrossRef]

- Sarnago, H.; Lucía, Ó.; Pérez-Tarragona, M.; Burdío, J.M. Dual-Output Boost Resonant Full-Bridge Topology and its Modu-lation Strategies for High-Performance Induction Heating Applications. IEEE Trans. Ind. Electron. 2016, 63, 3554–3561. [Google Scholar] [CrossRef]

- Park, N.J.; Lee, D.Y.; Hyun, D.S. A power control scheme with constant switching frequency in class-D inverter for induc-tion-heating jar application. IEEE Trans. Ind. Electron. 2007, 54, 1252–1260. [Google Scholar] [CrossRef]

- Vishnuram, P.; Ramasamy, S.; Sureshkumar, A.; Suresh, P. Phase-Locked Loop-Based Asymmetric Voltage Cancellation for the Power Control in Dual Half-Bridge Series Resonant Inverter Sharing Common Capacitor for Induction Heating Applications. J. Control Autom. Electr. Syst. 2019, 30, 1094–1106. [Google Scholar] [CrossRef]

- Trentin, A.; Zanchetta, P.; Clare, J.; Wheeler, P. Automated Optimal Design of Input Filters for Direct AC/AC Matrix Converters. IEEE Trans. Ind. Electron. 2011, 59, 2811–2823. [Google Scholar] [CrossRef]

- Hao, L.L.; Hu, A.P.; Covic, G.A. A direct ac-ac converter for inductive power-transfer systems. IEEE Trans. Power Electron. 2012, 27, 661–668. [Google Scholar]

- Yamamoto, E.; Hara, H.; Uchino, T.; Kawaji, M.; Kume, T.J.; Jun Koo, K.; Krug, H.P. Development of MCs and its applications in industry. IEEE Ind. Electron. Mag. 2011, 5, 4–12. [Google Scholar] [CrossRef]

- Ahmed, N.A.; Nakaoka, M. Boost-half-bridge edge resonant soft switching PWM high-frequency inverter for consumer in-duction heating appliances. Proc. Electr. Power Appl. 2006, 153, 932–938. [Google Scholar] [CrossRef]

- Forest, F.; Faucher, S.; Gaspard, J.; Montloup, D.; Huselstein, J.; Joubert, C. Frequency-Synchronized Resonant Con-verters for the Supply of Multiwinding Coils in Induction Cooking Appliances. IEEE Trans. Ind. Electron. 2007, 54, 441–452. [Google Scholar] [CrossRef]

- Chen, M.-P.; Chen, J.-K.; Murata, K.; Nakahara, M.; Harada, K. Surge analysis of induction heating power supply with PLL. IEEE Trans. Power Electron. 2001, 16, 702–709. [Google Scholar] [CrossRef]

- Sarnago, H.; Óscar, L.; Popa, I.; Burdío, J. Constant-Current Gate Driver for GaN HEMTs Applied to Resonant Power Conversion. Energies 2021, 14, 2377. [Google Scholar] [CrossRef]

- Carretero, C.; Lucia, O.; Acero, J.; Burdio, J.M. Phase-shift modulation in double half-bridge inverter with common resonant capacitor for induction heating appliances. IET Power Electron. 2015, 8, 1128–1136. [Google Scholar] [CrossRef]

- Komeda, S.; Fujita, H. A Phase-Shift-Controlled Direct AC-to-AC Converter for Induction Heaters. IEEE Trans. Power Electron. 2017, 33, 4115–4124. [Google Scholar] [CrossRef]

- Burdio, J.; Barragan, L.; Monterde, F.; Navarro, D.; Acero, J.A. Asymmetrical Voltage-Cancellation Control for Full-Bridge Series Resonant Inverters. IEEE Trans. Power Electron. 2004, 19, 461–469. [Google Scholar] [CrossRef]

- Nagarajan, B.; Rama, R.S. CFAVC scheme for high frequency series resonant inverter-fed domestic induction heating system. Int. J. Electron. 2016, 103, 160–176. [Google Scholar] [CrossRef]

- Ahmed, N.A. High-Frequency Soft-Switching AC Conversion Circuit with Dual-Mode PWM/PDM Control Strategy for High-Power IH Applications. IEEE Trans. Ind. Electron. 2010, 58, 1440–1448. [Google Scholar] [CrossRef]

- Esteve, V.; Kilders, E.S.; Jordan, J.; Dede, E.J.; Cases, C.; Maset, E.; Ejea, J.B.; Ferreres, A. Improving the Efficiency of IGBT Series-Resonant Inverters Using Pulse Density Modulation. IEEE Trans. Ind. Electron. 2011, 58, 979–987. [Google Scholar] [CrossRef]

- Forest, F.; Laboure, E.; Costa, F.; Gaspard, J. Principle of a multi-load/single converter system for low power induction heating. IEEE Trans. Power Electron. 2000, 15, 223–230. [Google Scholar] [CrossRef]

- Burdio, J.M.; Monterde, F.; Garcia, J.R.; Barragan, L.A.; Martinez, A. A two-output series-resonant inverter for induction-heating cooking appliances. IEEE Trans. Power Electron. 2005, 20, 815–822. [Google Scholar] [CrossRef]

- Haerinia, M.; Afjei, E. Investigation of receiving pot core effect on magnetic flux density in inductive coupling-based wireless power transfer. In Proceedings of the 2016 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Institute of Electrical and Electronics Engineers (IEEE), Piscataway, NJ, USA, 24–26 June 2016; pp. 541–545. [Google Scholar]

- Cannon, B.L.; Hoburg, J.F.; Stancil, D.D.; Goldstein, S.C. Magnetic Resonant Coupling As a Potential Means for Wireless Power Transfer to Multiple Small Receivers. IEEE Trans. Power Electron. 2009, 24, 1819–1825. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Lu, T.; Zhao, Z.; He, F.; Chen, K.; Yuan, L. Selective Wireless Power Transfer to Multiple Loads Using Receivers of Different Resonant Frequencies. IEEE Trans. Power Electron. 2015, 30, 6001–6005. [Google Scholar] [CrossRef]

- Lyu, Y.L.; Meng, F.Y.; Yang, G.H.; Che, B.J.; Wu, Q.; Sun, L.; Erni, Q.; Li, J.L.-W. A method of using nonidentical resonant coils for frequency splitting elimination in wireless power transfer. IEEE Trans. Power Electron. 2015, 30, 6097–6107. [Google Scholar] [CrossRef]

- Choi, W.-K.; Park, C.-W.; Lee, K. Circuit Analysis of Achievable Transmission Efficiency in an Overcoupled Region for Wireless Power Transfer Systems. IEEE Syst. J. 2017, 12, 3873–3876. [Google Scholar] [CrossRef]

- Narayanamoorthi, R.; Vimala Juliet, A.; Chokkalingam, B. Cross Interference Minimization and Simultaneous Wireless Power Transfer to Multiple Frequency Loads Using Frequency Bifurcation Approach. IEEE Trans. Power Electron. 2019, 34, 10898–10909. [Google Scholar] [CrossRef]

- Vishnuram, P.; Ramasamy, S.; Pradeep, V. Fuzzy Logic-Based Pulse Density Modulation Scheme for Mitigating Uncertainties in AC–AC Resonant Converter Aided Induction Heating System. J. Circuits Syst. Comput. 2018, 28. [Google Scholar] [CrossRef]

- Vishnuram, P.; Ramachandiran, G.; Ramasamy, S. A novel power control technique for series resonant inverter-fed induc-tion heating system with fuzzy-aided digital pulse density modulation scheme. Int. J. Fuzzy Syst. 2018, 20, 1115–1129. [Google Scholar] [CrossRef]

- Vishnuram, P.; Ramachandiran, G. A simple multi-frequency multiload independent power control using pulse density modulation scheme for cooking applications. Int. Trans. Electr. Energy Syst. 2021, 31, 12771. [Google Scholar] [CrossRef]

| Components | Load 1 | Load 2 |

|---|---|---|

| Equivalent load resistance, Req | 11 Ω | 11 Ω |

| Equivalent load inductance, Leq | 0.12 mH | 0.12 mH |

| Resonant capacitor, Cr | 520 nF | 200 nF |

| Input inductor, Ls | 200 μH | |

| Source capacitor Cs | 200 nF | |

| Parameters | Value |

|---|---|

| Vin | 230 V (RMS), 50 Hz |

| Prat | 1000 W |

| fPDM | 25 Hz |

| fr | 25 kHz |

| fr1 | 20 kHz |

| fr2 | 33 kHz |

| S.No | DPDM (%) | Pin (W) | Load 1 | Load 2 | P0 (W) | Efficiency (%) | |||

|---|---|---|---|---|---|---|---|---|---|

| Load 1 | Load 2 | I01rms (A) | P01 (W) | I02rms (A) | P02 (W) | ||||

| 1 | 100 | 100 | 1050.69 | 7.07 | 550 | 6.36 | 445 | 995 | 94.7 |

| 2 | 80 | 80 | 850.43 | 6.32 | 440 | 5.69 | 356 | 796 | 93.6 |

| 3 | 60 | 60 | 640.56 | 5.48 | 330 | 4.93 | 267 | 597 | 93.2 |

| 4 | 45 | 45 | 483.01 | 4.74 | 247.5 | 4.27 | 200.25 | 447.75 | 92.7 |

| 5 | 25 | 25 | 269.21 | 3.54 | 137.5 | 3.18 | 111.25 | 248.75 | 92.4 |

| 6 | 5 | 5 | 54.08 | 1.58 | 27.5 | 1.42 | 22.25 | 49.75 | 92 |

| S.No | DPDM (%) | Pin (W) | Load 1 | Load 2 | P0 (W) | Efficiency (%) | |||

|---|---|---|---|---|---|---|---|---|---|

| Load 1 | Load 2 | I01rms (A) | P01 (W) | I02rms (A) | P02 (W) | ||||

| 1 | 100 | 80 | 966.92 | 7.07 | 550 | 5.69 | 356 | 906 | 93.7 |

| 2 | 100 | 50 | 825.67 | 7.07 | 550 | 4.50 | 222.5 | 772.5 | 93.56 |

| 3 | 100 | 10 | 637.33 | 7.07 | 550 | 2.01 | 44.5 | 594.5 | 93.28 |

| 4 | 85 | 100 | 974.37 | 6.52 | 467.5 | 6.36 | 445 | 912.5 | 93.65 |

| 5 | 45 | 100 | 741.28 | 4.74 | 247.5 | 6.36 | 445 | 692.5 | 93.42 |

| 6 | 10 | 100 | 539.08 | 2.24 | 55 | 6.36 | 445 | 500 | 92.75 |

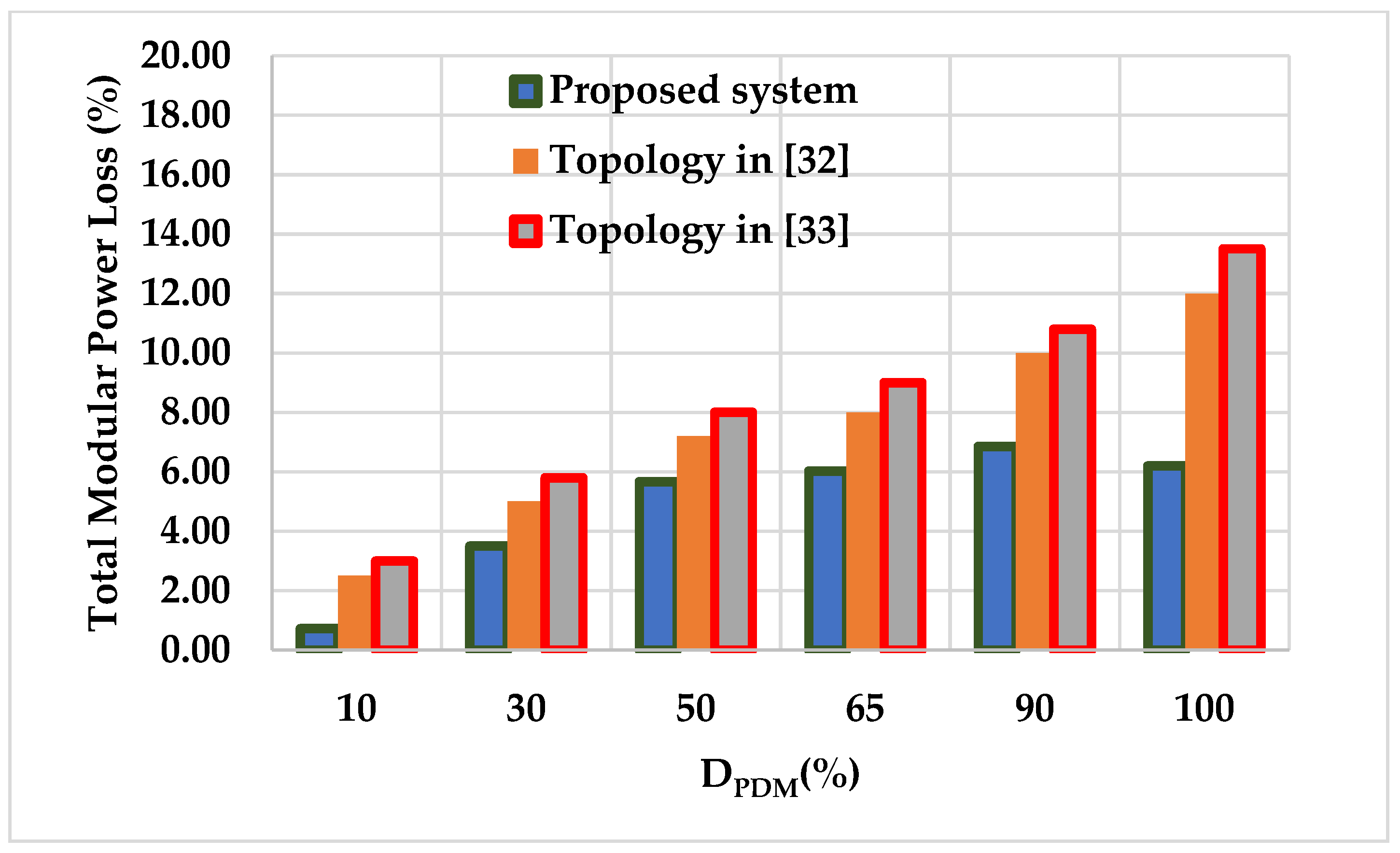

| S. No | Ref. No | Number of Semiconductor Switches | Modulation Technique | Number of Loads | Flicker Issue | Soft Switching | Control Complexity | Maximum Efficiency (%) |

|---|---|---|---|---|---|---|---|---|

| 1 | [20] | 8 | AVC | 1 | No | Partially | Neutral | 92.5 |

| 2 | [32] | 4 | PDM | 2 | Yes | Partially | Neutral | 93.2 |

| 3 | [33] | 4 | PDM | 1 | Yes | Fully | Good | 93.7 |

| 4 | Proposed | 4 | PDM | 2 | No | Fully | Good | 94.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vishnuram, P.; Dayalan, S.; Thanikanti, S.B.; Balasubramanian, K.; Nastasi, B. Single Source Multi-Frequency AC-AC Converter for Induction Cooking Applications. Energies 2021, 14, 4799. https://doi.org/10.3390/en14164799

Vishnuram P, Dayalan S, Thanikanti SB, Balasubramanian K, Nastasi B. Single Source Multi-Frequency AC-AC Converter for Induction Cooking Applications. Energies. 2021; 14(16):4799. https://doi.org/10.3390/en14164799

Chicago/Turabian StyleVishnuram, Pradeep, Suchitra Dayalan, Sudhakar Babu Thanikanti, Karthik Balasubramanian, and Benedetto Nastasi. 2021. "Single Source Multi-Frequency AC-AC Converter for Induction Cooking Applications" Energies 14, no. 16: 4799. https://doi.org/10.3390/en14164799

APA StyleVishnuram, P., Dayalan, S., Thanikanti, S. B., Balasubramanian, K., & Nastasi, B. (2021). Single Source Multi-Frequency AC-AC Converter for Induction Cooking Applications. Energies, 14(16), 4799. https://doi.org/10.3390/en14164799