Thermodynamic Analysis and Systematic Comparison of Solar-Heated Trigeneration Systems Based on ORC and Absorption Heat Pump

Abstract

:1. Introduction

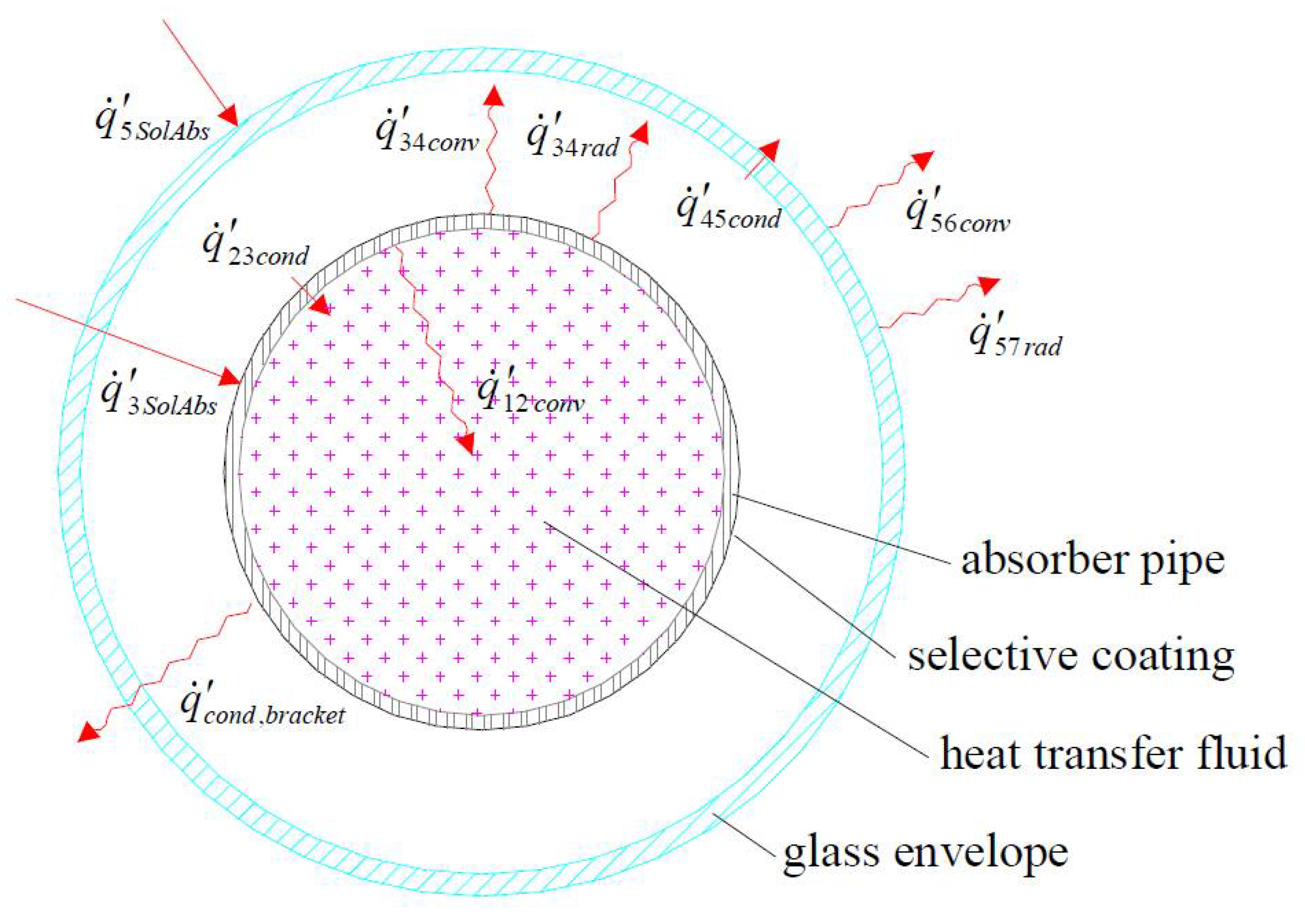

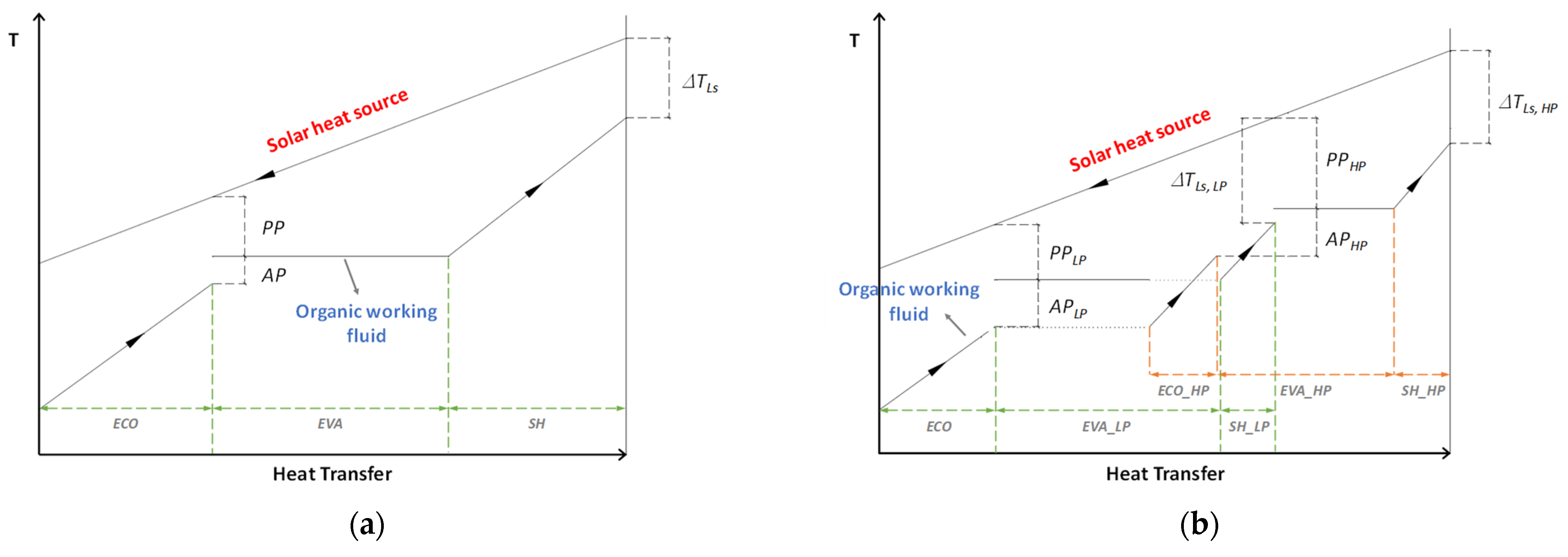

2. Thermodynamic Analysis of CCHP Solutions

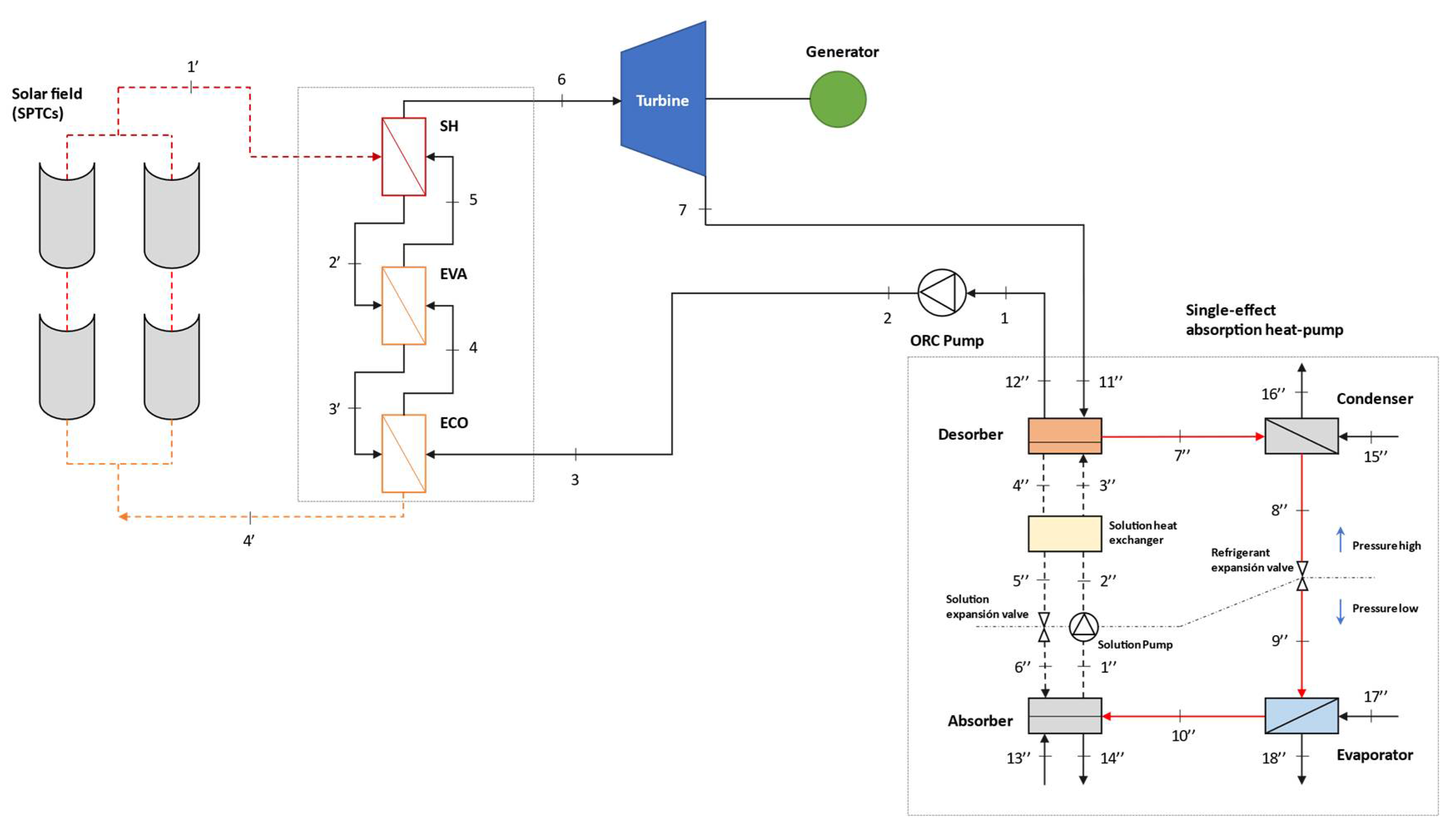

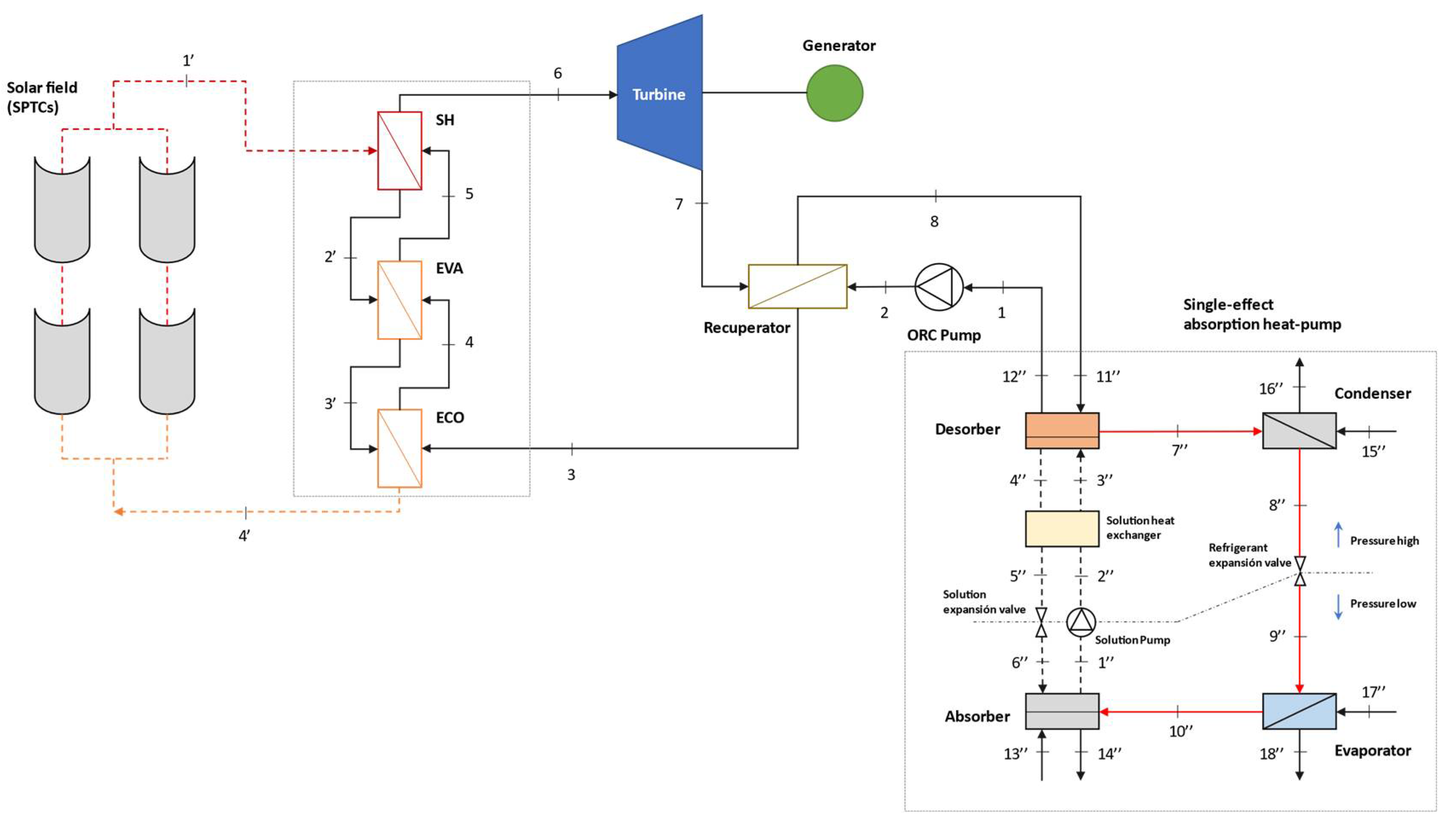

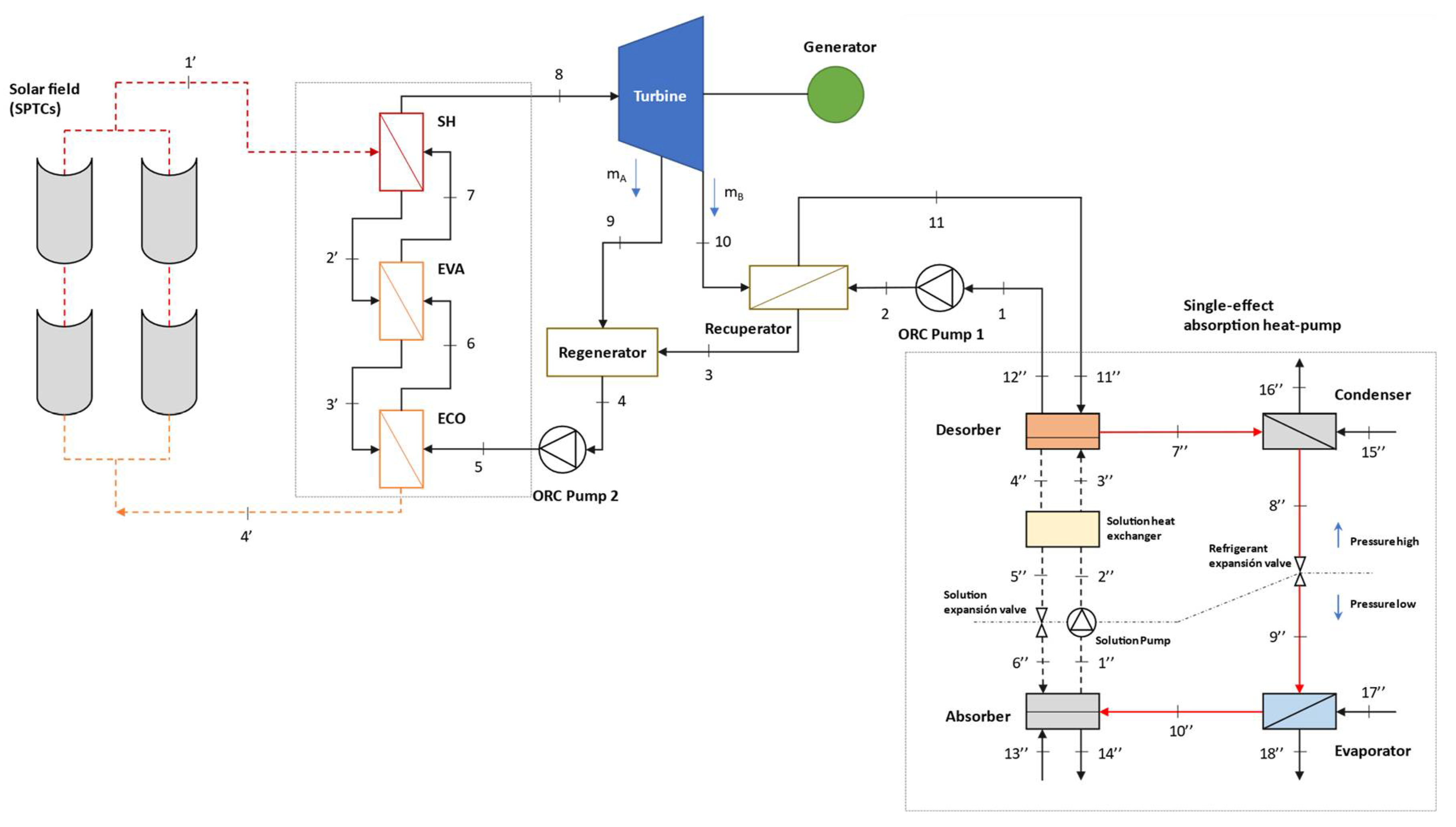

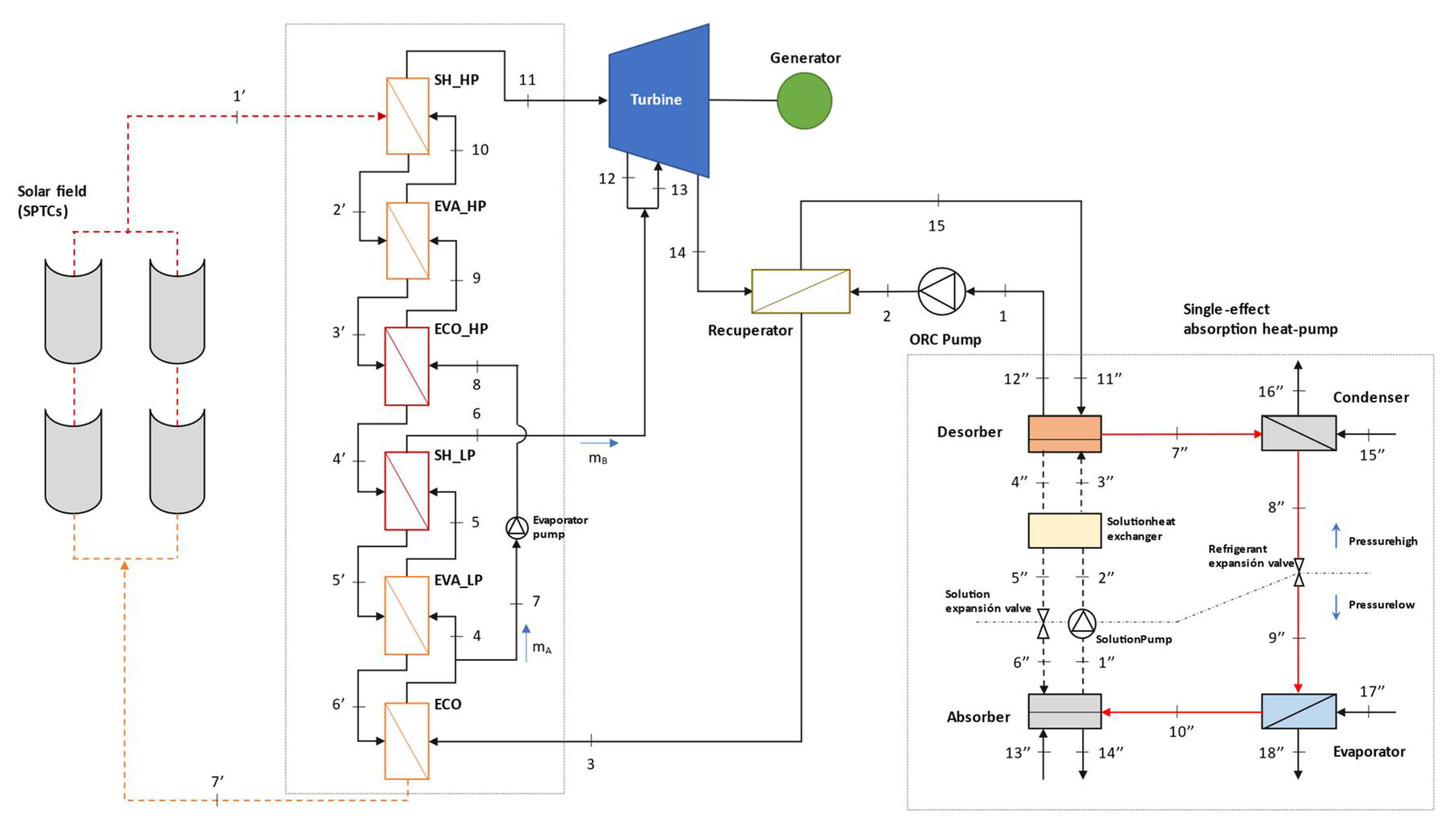

2.1. Investigated Thermodynamic CCHP Configurations

2.2. CCHP Performance Indexes

2.3. CCHP Thermodynamic Calculation Procedure and Numerical Assumptions

- The turbine isentropic efficiency;

- The ORC pump isentropic efficiency;

- For SH cycles, the superheating temperature;

- For REC cycles, the recuperator effectiveness;

- The condensation temperature.

- Saturated liquid solution at states 1 and 4;

- Subcooled liquid solution at states 2, 3 and 5;

- Vapor-liquid mixture solution at state 6;

- Superheated water vapor at state 7;

- Saturated water liquid at high pressure at state 8;

- Vapor-liquid mixture (water) at state 9;

- Saturated water vapor at low pressure at state 10.

3. Results and Discussion

3.1. Analysis of CCHP Variants

3.2. Parametric Analysis

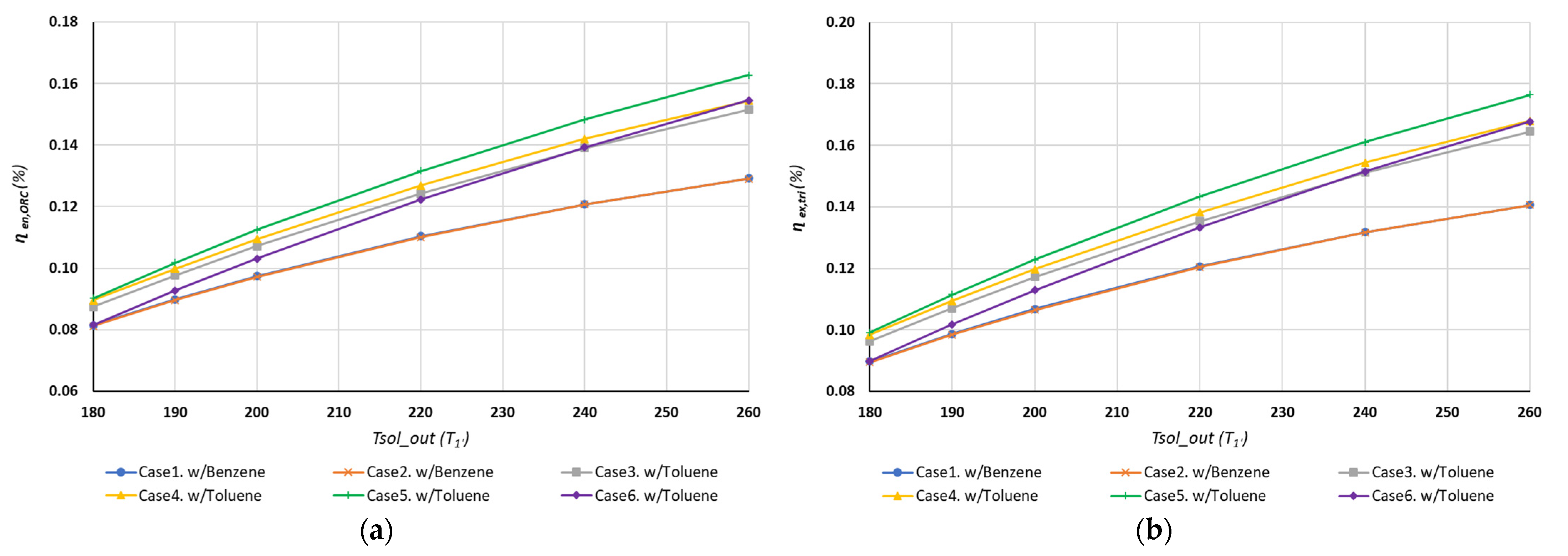

3.2.1. Effect of the Solar Field Outlet Temperature

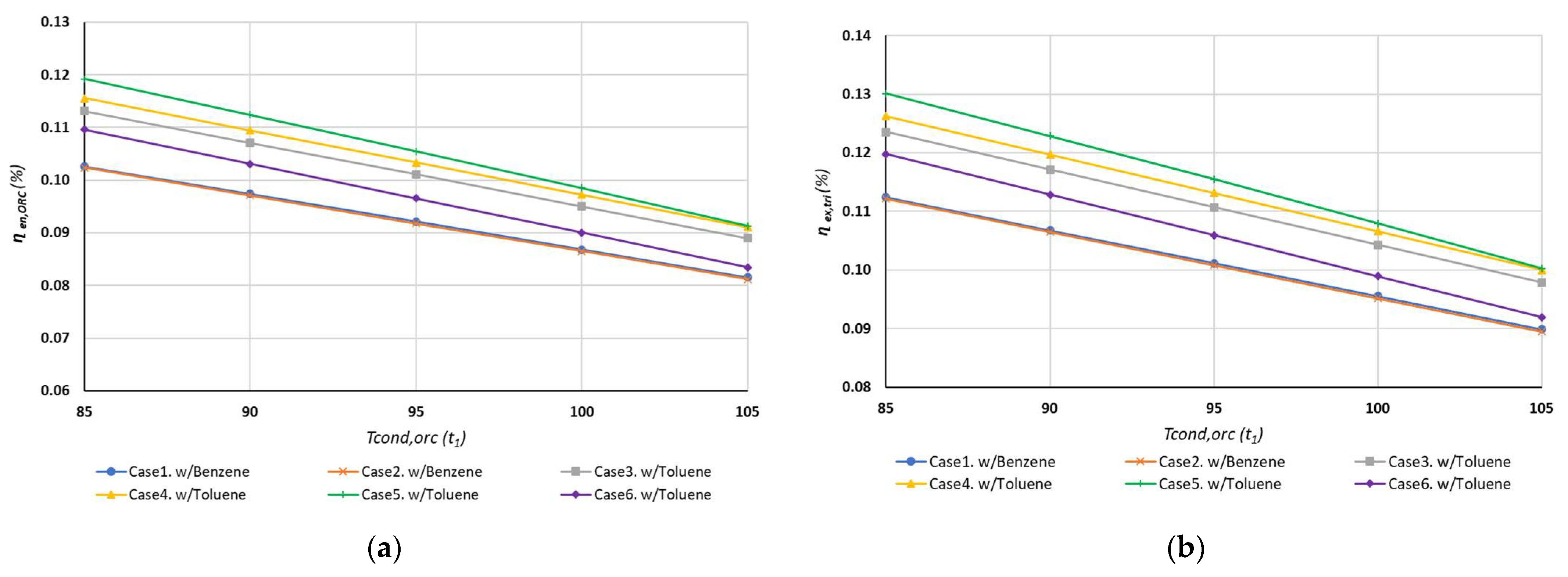

3.2.2. Effect of ORC Condensation Temperature

3.3. Optimisation Analysis

4. Conclusions

- For the six CCHP configurations and the seven organic working fluids analysed, the best performing variant is the CCHP with single-pressure ORC regenerative recuperated superheated cycle (Case 5) with toluene as a working fluid. The achieved energy and exergy efficiency are: 11.24% and 12.04%, respectively, for the ORC, and 163.7% and 12.3%, respectively, for the CCHP. The electricity, cooling and heating productions are 56.2 kW, 222.3 kW and 530.1 kW, respectively.

- For the seven organic working fluids analysed, benzene performs best for Cases 1 and 2, and toluene for Cases 3–6.

- At nominal conditions and on average for the seven working fluids considered, Case 5 is about 25% more efficient than Case 1, and about 8% more efficient than Case 6 in terms of ORC energy efficiency.

- A CCHP with single-pressure ORC superheated cycle (Case 2) only results in an increase in efficiency if a recovery stage is available downstream of the turbine.

- The use of a dual-pressure evaporator (Case 6) does not imply a performance improvement of the CCHP system if the temperature of the heat source at the evaporator outlet is constrained.

- A higher temperature of the solar heat source causes a higher organic fluid evaporation pressure in the ORC, leading to higher heat recovery efficiency in the evaporator and in CCHP efficiency. For Case 5 with toluene, the electricity produced by the turbine presents an increase of 83% as with the increase of the heat source inlet temperature from 180 to 260 °C.

- As the ORC condensation temperature increases, both the ORC energy efficiency and CCHP exergy efficiency decrease. For Case 5 with toluene, the increase in the ORC condensation temperature from 85 to 105 °C represents a decrease of 23% of the electricity produced by the turbine.

- The optimum design conditions for all the analysed cases are produced for the maximum solar field outlet temperature (260 °C) and the minimum ORC condensation temperature (85 °C). For Case 5 with toluene, in comparison with nominal design conditions, the optimum design is 50% more efficient in terms of ORC energy efficiency.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbols | |

| h | heat transfer coefficient, W/(m2 K) |

| mass flow rate, kg/s | |

| T | temperature, °C |

| ΔT | temperature difference, °C |

| η | efficiency |

| W | electric power, kW |

| Q | thermal power, kW |

| heat rate per SPTC unit length, kW/m | |

| aperture width of SPTC, m | |

| L | length of SPTC, m |

| N | number of SPTCs |

| θ | solar incidence angle on the SPTC, º |

| Acronyms | |

| CCHP | combined cooling heating and power |

| ORC | organic Rankine cycle |

| SPTC | solar parabolic trough collector |

| REC | recuperator heat exchanger or recuperated cycle |

| REG | regenerative cycle |

| SC | simple cycle |

| SH | superheater heat exchanger or superheated cycle |

| DNI | direct normal irradiance |

| LS | live steam |

| PP | pinch point |

| AP | approach point |

| COP | coefficient of performance |

| LP | low pressure |

| H | high pressure |

| UA | overall heat transfer coefficient |

| Subscripts | |

| en | energy |

| ex | exergy |

| sol | solar field |

| 0 | atmospheric conditions |

| in | inlet |

| out | inlet |

| turb | turbine |

| cond | heat conduction |

| conv | heat convection |

| rad | heat radiation |

| SolAbs | solar absorption |

| tri | trigeneration |

| d | heat pump desorber |

| a | heat pump absorber |

| s.he | heat pump solution heat exchanger |

| c | heat pump condenser |

| e | heat pump evaporator |

| Evap.pump | evaporator pump |

| s.pump | solution pump |

| cool | heat pump cooling mode |

| heat | heat pump heating mode |

References

- Al-Sulaiman, F.A.; Hamdullahpur, F.; Dincer, I. Trigeneration: A comprehensive review based on prime movers. Int. J. Energy Res. 2011, 35, 233–258. [Google Scholar] [CrossRef]

- Vélez, F.; Segovia, J.J.; Martín, M.C.; Antolín, G.; Chejnec, F.; Quijano, A. A technical, economical and market review of organic Rankine cycles for the conversion of low-grade heat for power generation. Energy Convers. Manag. 2013, 69, 209–216. [Google Scholar] [CrossRef]

- Quoilin, S.; Van Den Broek, M.; Declaye, S.; Dewallef, P.; Lemort, V. Techno-economic survey of Organic Rankine Cycle (ORC) systems. Renew. Sustain. Energy Rev. 2013, 22, 168–186. [Google Scholar] [CrossRef] [Green Version]

- Villarini, M.; Bocci, E.; Moneti, M.; Di Carlo, A.; Micangeli, A. State of art of small scale solar powered ORC systems: A review of the different typologies and technology perspectives. Energy Procedia 2014, 45, 257–267. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Ge, Z.; Duan, Y.; Yang, Z.; Liu, Q. Parametric optimization and thermodynamic performance comparison of single-pressure and dual-pressure evaporation organic Rankine cycles. Appl. Energy 2018, 217, 409–421. [Google Scholar] [CrossRef]

- Fernández-Guillamón, A.; Molina-García, Á.; Vera-García, F.; Almendros-Ibáñez, J.A. Organic Rankine Cycle Optimization Performance Analysis Based on Super-Heater Pressure: Comparison of Working Fluids. Energies 2021, 14, 2548. [Google Scholar] [CrossRef]

- Manente, G.; Lazzaretto, A.; Bonamico, E. Design guidelines for the choice between single and dual pressure layouts in organic Rankine cycle (ORC) systems. Energy 2017, 123, 413–431. [Google Scholar] [CrossRef]

- Branchini, L.; De Pascale, A.; Peretto, A. Systematic comparison of ORC configurations by means of comprehensive performance indexes. Appl. Therm. Eng. 2013, 61, 129–140. [Google Scholar] [CrossRef]

- Delgado-Torres, A.M.; García-Rodríguez, L. Analysis and optimization of the low-temperature solar organic Rankine cycle (ORC). Energy Convers. Manag. 2010, 51, 2846–2856. [Google Scholar] [CrossRef]

- Villarini, M.; Bocci, E.; Di Carlo, A.; Sbordone, D. Technical-Economic Analysis of an Innovative Small Scale Solar Thermal—ORC Cogenerative System. In International Conference on Computational Science and Its Applications Part II LNCS; Springer: Berlin/Heidelberg, Germany, 2013; Volume 7972, pp. 271–287. [Google Scholar]

- Hassoun, A.; Dincer, I. Analysis and performance assessment of a multigenerational system powered by Organic Rankine Cycle for a net zero energy house. Appl. Therm. Eng. 2015, 76, 25–36. [Google Scholar] [CrossRef]

- Khalid, F.; Dincer, I.; Rosen, M.A. Thermoeconomic analysis of a solar-biomass integrated multigeneration system for a community. Appl. Therm. Eng. 2017, 120, 645–653. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Multi-objective optimization of a solar driven trigeneration system. Energy 2018, 149, 47–62. [Google Scholar] [CrossRef]

- Nasir, M.T.; Ekwonu, M.C.; Park, Y.; Esfahani, J.A.; Kim, K.C. Assessment of a District Trigeneration Biomass Powered Double Organic Rankine Cycle as Primed Mover and Supported Cooling. Energies 2021, 14, 1030. [Google Scholar] [CrossRef]

- García-Domínguez, J.; Blanco-Marigorta, A.M.; Marcos, J.D. Thermodynamic analysis and optimization of a combined cooling, heating, and power system using Organic Rankine Cycles (ORC) and solar parabolic trough collectors. In Proceedings of the 33rd International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Osaka, Japan, 29 June–3 July 2020. [Google Scholar]

- Al-Sulaiman, F.A.; Hamdullahpur, F.; Dincer, I. Performance comparison of three trigeneration systems using organic rankine cycles. Energy 2011, 36, 5741–5754. [Google Scholar] [CrossRef]

- Al-Sulaiman, F.A.; Hamdullahpur, F.; Dincer, I. Performance assessment of a novel system using parabolic trough solar collectors for combined cooling, heating, and power production. Renew. Energy 2012, 48, 161–172. [Google Scholar] [CrossRef]

- Suleman, F.; Dincer, I.; Agelin-Chaab, M. Development of an integrated renewable energy system for multigeneration. Energy 2014, 78, 196–204. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Parametric analysis and optimization of a solar driven trigeneration system based on ORC and absorption heat pump. J. Clean. Prod. 2017, 161, 493–509. [Google Scholar] [CrossRef]

- Petela, R. Exergy of undiluted thermal radiation. Sol. Energy 2013, 74, 469–488. [Google Scholar] [CrossRef]

- Forristall, R. Heat Transfer Analysis and Modeling of a Parabolic Trough Solar Receiver Implemented in Engineering Equation Solver NREL/TP-550-34169; National Renewable Energy Laboratory: Golden, CO, USA, 2003.

- Rashid, K. Design, Economics, and Real-Time Optimization of a Solar/Natural Gas Hybrid Power Plant. Ph.D. Thesis, The University of Utah, Salt Lake City, UT, USA, 2019. [Google Scholar]

- Liao, X.; Garland, P.; Radermacher, R. The modeling of air-cooled absorption chiller integration in CHP system. ASME Int. Mech. Eng. Congr. Expo. 2004, 47012, 371–377. [Google Scholar] [CrossRef]

- Bakhtiari, B.; Fradette, L.; Legros, R.; Paris, J. A model for analysis and design of H2O–LiBr absorption heat pumps. Energy Convers. Manag. 2011, 52, 1439–1448. [Google Scholar] [CrossRef]

- Marcos, J.D.; Izquierdo, M.; Palacios, E. New method for COP optimization in water-and air-cooled single and double effect LiBr–water absorption machines. Int. J. Refrig. 2011, 34, 1348–1359. [Google Scholar] [CrossRef]

- Evola, G.; Le Pierre‘s, N.; Boudehenn, F.; Papillon, P. Proposal and validation of a model for the dynamic simulation of a solar-assisted single-stage LiBr/water absorption chiller. Int. J. Refrig. 2013, 36, 1015–1028. [Google Scholar] [CrossRef]

- Rashid, K.; Safdarnejad, S.M.; Powell, K.M. Process intensification of solar thermal power using hybridization, flexible heat integration, and real-time optimization. Chem. Eng. Process. Process Intensif. 2019, 139, 155–171. [Google Scholar] [CrossRef] [Green Version]

- Spelling, J.; Favrat, D.; Martin, A.; Augsburger, G. Thermoeconomic optimization of a combined-cycle solar tower power plant. Energy 2012, 41, 113–120. [Google Scholar] [CrossRef]

- Baghernejad, A.; Yaghoubi, M.; Jafarpur, K. Exergoeconomic optimization and environmental analysis of a novel solar-trigeneration system for heating, cooling and power production purpose. Sol. Energy 2016, 134, 165–179. [Google Scholar] [CrossRef]

- Kim, I.Y.; de Weck, O.L. Adaptive weighted-sum method for bi-objective optimization: Pareto front generation. Struct. Multidiscip. Optim. 2005, 29, 149–158. [Google Scholar] [CrossRef]

- Zare, V.; Mahmoudi, S.M.S.; Yari, M.; Amidpour, M. Thermoeconomic analysis and optimization of an ammonia-water power/cooling cogeneration cycle. Energy 2012, 47, 271–283. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Collector aperture width, –wap | 2.36 m |

| Collector length–LSPTC | 26.16 m |

| Collector nominal mass flow rate | 1 kg/s |

| Absorber outer diameter | 20.5 mm |

| Absorber inner diameter | 22 mm |

| Glass envelope outer diameter | 37.5 mm |

| Glass envelope inner diameter | 40 mm |

| Number of collectors-NSPTC | 10 |

| Solar field outlet temperature–T1′ | 200 °C |

| Ambient temperature | 30 °C |

| Reference temperature | 298.15 K |

| Sun Temperature | 5770 K |

| Direct Normal Irradiance–DNI | 800 W/m2 |

| Solar incident angle | 0° |

| Wind velocity | 3 m/s |

| Parameter | Value |

|---|---|

| Condensation temperature–T1 | 90 °C |

| Turbine efficiency–ηturb | 85% |

| Pump isentropic efficiency-ηORC,pump, ηEvap,pump, | 70% |

| Recuperator efficiency *–ηREC | 70% |

| Superheating **–ΔTSH | 10 °C |

| Live steam outlet temperature ***–TLS | T1′-25 °C |

| Live steam outlet temperature **–TLS | T1′-25 °C-ΔTSH |

| Pinch Point–PP | 8 K |

| Approach Point–AP | 5 K |

| Parameter | Value |

|---|---|

| Maximum solution concentration,–x4″ | 65% |

| Condensation temperature–T13″; T15″ | 20 °C |

| Condensation mass flow rate | 12 kg/s |

| Evaporation temperature–T17″ | 12 °C |

| Evaporation mass flow rate | 15 kg/s |

| Solution heat exchanger efficiency–ηsol.he | 70% |

| UA desorber | 30 kW/K |

| UA condenser | 70 kW/K |

| UA absorber | 20 kW/K |

| UA evaporator | 30 kW/K |

| Fluid | ηen,ORC [%] | ηex,ORC [%] | ղen,tri [%] | ղex,tri [%] | Wturb [kW] | Qe [kW] | Qa [kW] | Qc [kW] |

|---|---|---|---|---|---|---|---|---|

| Toluene | 9.64 | 10.33 | 166.10 | 10.58 | 48.19 | 228.83 | 302.41 | 241.42 |

| Benzene | 9.74 | 10.43 | 165.90 | 10.68 | 49.15 | 228.49 | 301.98 | 241.06 |

| n-heptane | 8.51 | 9.12 | 167.80 | 9.37 | 42.98 | 232.97 | 307.74 | 245.83 |

| n-octane | 8.56 | 9.16 | 167.70 | 9.42 | 42.77 | 232.80 | 307.53 | 245.65 |

| n-nonane | 8.53 | 9.14 | 167.70 | 9.39 | 42.42 | 232.89 | 307.64 | 245.74 |

| n-decane | 8.53 | 9.13 | 167.70 | 9.39 | 42.27 | 232.91 | 307.67 | 245.76 |

| MDM | 7.32 | 7.84 | 169.50 | 8.10 | 36.51 | 237.32 | 313.35 | 250.46 |

| Fluid | ηen,ORC [%] | ηex,ORC [%] | ղen,tri [%] | ղex,tri [%] | Wturb [kW] | Qe [kW] | Qa [kW] | Qc [kW] |

|---|---|---|---|---|---|---|---|---|

| Toluene | 9.58 | 10.26 | 166.20 | 10.51 | 47.85 | 229.06 | 302.71 | 241.67 |

| Benzene | 9.71 | 10.40 | 166.00 | 10.65 | 48.99 | 228.59 | 302.10 | 241.17 |

| n-heptane | 8.36 | 8.95 | 168.00 | 9.21 | 42.19 | 233.52 | 308.45 | 246.42 |

| n-octane | 8.38 | 8.98 | 168.00 | 9.23 | 41.87 | 233.44 | 308.35 | 246.33 |

| n-nonane | 8.36 | 8.95 | 168.00 | 9.21 | 41.55 | 233.52 | 308.45 | 246.41 |

| n-decane | 8.35 | 8.94 | 168.00 | 9.20 | 41.39 | 233.56 | 308.50 | 246.45 |

| MDM | 7.10 | 7.60 | 169.80 | 7.86 | 35.41 | 238.12 | 314.38 | 251.31 |

| Fluid | ηen,ORC [%] | ηex,ORC [%] | ղen,tri [%] | ղex,tri [%] | Wturb [kW] | Qe [kW] | Qa [kW] | Qc [kW] |

|---|---|---|---|---|---|---|---|---|

| Toluene | 10.71 | 11.47 | 164.50 | 11.72 | 53.50 | 224.94 | 297.41 | 237.29 |

| Benzene | 10.53 | 11.28 | 164.80 | 11.53 | 53.18 | 225.58 | 298.23 | 237.97 |

| n-heptane | 10.45 | 11.19 | 164.90 | 11.44 | 52.78 | 225.88 | 298.61 | 238.28 |

| n-octane | 10.57 | 11.32 | 164.70 | 11.57 | 52.83 | 225.44 | 298.05 | 237.82 |

| n-nonane | 10.63 | 11.39 | 164.60 | 11.63 | 52.84 | 225.22 | 297.77 | 237.59 |

| n-decane | 10.66 | 11.41 | 164.60 | 11.66 | 52.81 | 225.14 | 297.66 | 237.50 |

| MDM | 10.20 | 10.92 | 165.30 | 11.17 | 50.87 | 226.80 | 299.80 | 239.27 |

| Fluid | ηen,ORC [%] | ηex,ORC [%] | ղen,tri [%] | ղex,tri [%] | Wturb [kW] | Qe [kW] | Qa [kW] | Qc [kW] |

|---|---|---|---|---|---|---|---|---|

| Toluene | 10.95 | 11.73 | 164.20 | 11.97 | 54.69 | 224.06 | 296.27 | 236.35 |

| Benzene | 10.83 | 11.60 | 164.30 | 11.84 | 54.63 | 224.50 | 296.84 | 236.82 |

| n-heptane | 10.67 | 11.42 | 164.60 | 11.67 | 53.82 | 225.10 | 297.61 | 237.45 |

| n-octane | 10.76 | 11.52 | 164.40 | 11.76 | 53.73 | 224.77 | 297.18 | 237.10 |

| n-nonane | 10.78 | 11.55 | 164.40 | 11.79 | 53.57 | 224.68 | 297.07 | 237.01 |

| n-decane | 10.79 | 11.55 | 164.40 | 11.80 | 53.47 | 224.65 | 297.03 | 236.97 |

| MDM | 10.29 | 11.02 | 165.10 | 11.27 | 51.32 | 226.46 | 299.36 | 238.91 |

| Fluid | ηen,ORC [%] | ηex,ORC [%] | ղen,tri [%] | ղex,tri [%] | Wturb [kW] | Qe [kW] | Qa [kW] | Qc [kW] |

|---|---|---|---|---|---|---|---|---|

| Toluene | 11.24 | 12.04 | 163.70 | 12.29 | 56.19 | 222.98 | 294.89 | 235.21 |

| Benzene | 11.17 | 11.96 | 163.80 | 12.20 | 56.41 | 223.26 | 295.24 | 235.50 |

| n-heptane | 10.77 | 11.53 | 164.40 | 11.78 | 54.42 | 224.71 | 297.11 | 237.04 |

| n-octane | 10.90 | 11.68 | 164.20 | 11.92 | 54.51 | 224.22 | 296.48 | 236.53 |

| n-nonane | 10.96 | 10.55 | 164.10 | 11.98 | 54.49 | 224.02 | 296.22 | 236.31 |

| n-decane | 10.99 | 11.77 | 164.10 | 12.02 | 54.49 | 223.91 | 296.08 | 236.19 |

| MDM | 10.36 | 11.09 | 165.00 | 11.34 | 51.67 | 226.23 | 299.07 | 238.66 |

| Fluid | ηen,ORC [%] | ηex,ORC [%] | ղen,tri [%] | ղex,tri [%] | Wturb [kW] | Qe [kW] | Qa [kW] | Qc [kW] |

|---|---|---|---|---|---|---|---|---|

| Toluene | 10.31 | 11.04 | 165.10 | 11.29 | 51.46 | 226.40 | 299.29 | 238.84 |

| Benzene | 10.18 | 10.90 | 165.30 | 11.15 | 51.30 | 226.89 | 299.91 | 239.36 |

| n-heptane | 10.10 | 10.82 | 165.40 | 11.07 | 50.96 | 227.15 | 300.25 | 239.64 |

| n-octane | 10.09 | 10.81 | 165.40 | 11.06 | 50.39 | 227.20 | 300.31 | 239.69 |

| n-nonane | 10.10 | 10.82 | 165.40 | 11.07 | 50.19 | 227.16 | 300.26 | 239.65 |

| n-decane | 10.11 | 10.83 | 165.40 | 11.08 | 50.11 | 227.12 | 300.21 | 239.61 |

| MDM | 9.67 | 10.36 | 166.00 | 10.61 | 48.21 | 228.72 | 302.28 | 241.31 |

| Pair | T1′ [°C] | ηen,ORC [%] | ηex,ORC [%] | ղen,tri [%] | ղex,tri [%] | Wturb [kW] | Qe [kW] | Qa [kW] | Qc [kW] | COPcool | COPheat |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Case 1. w/Benzene | 180 | 8.14 | 8.72 | 168.70 | 8.98 | 40.92 | 234.87 | 310.19 | 247.85 | 0.7268 | 1.727 |

| 190 | 8.98 | 9.62 | 167.30 | 9.87 | 45.23 | 231.54 | 305.91 | 244.31 | 0.7266 | 1.727 | |

| 200 | 9.74 | 10.43 | 165.90 | 10.68 | 49.15 | 228.49 | 301.98 | 241.06 | 0.7264 | 1.726 | |

| 220 | 11.04 | 11.82 | 163.60 | 12.06 | 56.00 | 223.08 | 295.01 | 235.31 | 0.7261 | 1.726 | |

| 240 | 12.08 | 12.94 | 161.50 | 13.18 | 61.70 | 218.41 | 289.06 | 230.34 | 0.7256 | 1.726 | |

| 260 | 12.92 | 13.83 | 159.60 | 14.07 | 66.43 | 214.41 | 283.92 | 226.09 | 0.7253 | 1.725 | |

| Case 2. w/Benzene | 180 | 8.12 | 8.69 | 168.70 | 8.95 | 40.77 | 234.96 | 310.30 | 247.94 | 0.7268 | 1.727 |

| 190 | 8.96 | 9.59 | 167.30 | 9.84 | 45.07 | 231.64 | 306.03 | 244.41 | 0.7266 | 1.727 | |

| 200 | 9.71 | 10.40 | 166.00 | 10.65 | 48.99 | 228.59 | 302.10 | 241.17 | 0.7264 | 1.726 | |

| 220 | 11.01 | 11.79 | 163.60 | 12.04 | 55.83 | 223.17 | 295.12 | 235.40 | 0.7261 | 1.726 | |

| 240 | 12.07 | 12.92 | 161.50 | 13.16 | 61.54 | 218.47 | 289.14 | 230.41 | 0.7256 | 1.726 | |

| 260 | 12.91 | 13.83 | 159.60 | 14.06 | 66.32 | 214.42 | 283.93 | 226.10 | 0.7253 | 1.725 | |

| Case 3. w/ Toluene | 180 | 8.75 | 9.37 | 167.80 | 9.63 | 43.6 | 232.65 | 307.33 | 245.49 | 0.7266 | 1.727 |

| 190 | 9.76 | 10.45 | 166.10 | 10.71 | 48.71 | 228.69 | 302.23 | 241.27 | 0.7264 | 1.726 | |

| 200 | 10.71 | 11.47 | 164.50 | 11.72 | 53.50 | 224.94 | 297.41 | 237.29 | 0.7262 | 1.726 | |

| 220 | 12.42 | 13.30 | 161.50 | 13.53 | 62.21 | 217.99 | 288.52 | 229.90 | 0.7256 | 1.726 | |

| 240 | 13.90 | 14.88 | 158.80 | 15.12 | 69.89 | 211.76 | 280.52 | 223.28 | 0.7251 | 1.725 | |

| 260 | 15.16 | 16.23 | 156.30 | 16.46 | 76.56 | 206.19 | 273.36 | 217.36 | 0.7247 | 1.725 | |

| Case 4. w/ Toluene | 180 | 8.96 | 9.59 | 167.50 | 9.85 | 44.61 | 231.90 | 306.36 | 244.69 | 0.7266 | 1.727 |

| 190 | 9.99 | 10.70 | 165.80 | 10.95 | 49.81 | 227.86 | 301.17 | 240.40 | 0.7264 | 1.726 | |

| 200 | 10.95 | 11.73 | 164.20 | 11.97 | 54.69 | 224.06 | 296.27 | 236.35 | 0.7261 | 1.726 | |

| 220 | 12.69 | 13.59 | 161.10 | 13.82 | 63.55 | 217.00 | 287.24 | 228.84 | 0.7255 | 1.726 | |

| 240 | 14.20 | 15.20 | 158.30 | 15.43 | 71.36 | 210.67 | 279.11 | 222.11 | 0.725 | 1.725 | |

| 260 | 15.44 | 16.57 | 155.90 | 16.80 | 77.90 | 205.21 | 272.11 | 216.32 | 0.7246 | 1.725 | |

| Case 5. w/ Toluene | 180 | 9.02 | 9.66 | 167.40 | 9.92 | 44.96 | 231.65 | 306.05 | 244.43 | 0.7266 | 1.727 |

| 190 | 10.18 | 10.90 | 165.50 | 11.15 | 50.78 | 227.18 | 300.28 | 239.67 | 0.7263 | 1.726 | |

| 200 | 11.24 | 12.04 | 163.70 | 12.29 | 56.19 | 222.98 | 294.89 | 235.21 | 0.7261 | 1.726 | |

| 220 | 13.16 | 14.09 | 160.40 | 14.33 | 66.01 | 215.26 | 285.01 | 226.99 | 0.7254 | 1.725 | |

| 240 | 14.83 | 15.87 | 157.40 | 16.10 | 74.71 | 208.36 | 276.15 | 219.66 | 0.7249 | 1.725 | |

| 260 | 16.27 | 17.42 | 154.60 | 17.64 | 82.45 | 202.12 | 268.15 | 213.04 | 0.7243 | 1.724 | |

| Case 6. w/ Toluene | 180 | 8.15 | 8.73 | 168.70 | 8.98 | 40.57 | 234.84 | 310.15 | 234.84 | 0.7268 | 1.727 |

| 190 | 9.27 | 9.93 | 166.80 | 10.18 | 46.22 | 230.48 | 304.54 | 230.48 | 0.7265 | 1.727 | |

| 200 | 10.31 | 11.04 | 165.10 | 11.29 | 51.46 | 226.40 | 299.29 | 226.40 | 0.7263 | 1.726 | |

| 220 | 12.23 | 13.10 | 161.80 | 13.33 | 61.24 | 218.67 | 289.34 | 218.67 | 0.7256 | 1.726 | |

| 240 | 13.93 | 14.91 | 158.70 | 15.14 | 70.02 | 211.65 | 280.38 | 211.65 | 0.7251 | 1.725 | |

| 260 | 15.45 | 16.54 | 155.80 | 16.77 | 78.07 | 205.11 | 271.98 | 205.11 | 0.7246 | 1.725 |

| Pair | T1 [°C] | ηen,ORC [%] | ηex,ORC [%] | ղen,tri [%] | ղex,tri [%] | Wturb [kW] | Qe [kW] | Qa [kW] | Qc [kW] | COPcool | COPheat |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Case 1. w/Benzene | 85 | 10.26 | 10.99 | 165.20 | 11.24 | 51.75 | 226.57 | 299.50 | 239.02 | 0.7263 | 1.726 |

| 90 | 9.74 | 10.43 | 165.90 | 10.68 | 49.15 | 228.49 | 301.98 | 241.06 | 0.7264 | 1.726 | |

| 95 | 9.21 | 9.87 | 166.70 | 10.12 | 46.55 | 230.42 | 304.45 | 243.11 | 0.7265 | 1.727 | |

| 100 | 8.68 | 9.30 | 167.50 | 9.55 | 43.94 | 232.34 | 306.94 | 245.16 | 0.7266 | 1.727 | |

| 105 | 8.15 | 8.73 | 168.30 | 8.99 | 41.32 | 234.28 | 309.43 | 247.23 | 0.7267 | 1.727 | |

| Case 2. w/Benzene | 85 | 10.24 | 10.97 | 165.20 | 11.22 | 51.60 | 226.65 | 299.61 | 239.11 | 0.7263 | 1.726 |

| 90 | 9.71 | 10.40 | 166.00 | 10.65 | 48.99 | 228.59 | 302.10 | 241.17 | 0.7264 | 1.726 | |

| 95 | 9.18 | 9.83 | 166.80 | 10.08 | 46.37 | 230.52 | 304.59 | 243.23 | 0.7265 | 1.727 | |

| 100 | 8.65 | 9.26 | 167.60 | 9.52 | 43.74 | 232.46 | 307.09 | 245.29 | 0.7266 | 1.727 | |

| 105 | 8.12 | 8.69 | 168.30 | 8.95 | 41.11 | 234.41 | 309.60 | 247.36 | 0.7267 | 1.727 | |

| Case 3. w/ Toluene | 85 | 11.31 | 12.11 | 163.60 | 12.35 | 56.45 | 222.71 | 294.59 | 234.92 | 0.7259 | 1.726 |

| 90 | 10.71 | 11.47 | 164.50 | 11.72 | 53.50 | 224.94 | 297.41 | 237.29 | 0.7262 | 1.726 | |

| 95 | 10.11 | 10.82 | 165.40 | 11.07 | 50.53 | 227.14 | 300.23 | 239.62 | 0.7263 | 1.726 | |

| 100 | 9.51 | 10.18 | 166.30 | 10.43 | 47.55 | 229.34 | 303.07 | 241.97 | 0.7265 | 1.726 | |

| 105 | 8.90 | 9.53 | 167.20 | 9.79 | 44.56 | 231.55 | 305.92 | 244.32 | 0.7266 | 1.727 | |

| Case 4. w/ Toluene | 85 | 11.56 | 12.38 | 163.20 | 12.62 | 57.70 | 221.78 | 293.40 | 233.93 | 0.7259 | 1.726 |

| 90 | 10.95 | 11.73 | 164.20 | 11.97 | 54.69 | 224.06 | 296.27 | 236.35 | 0.7261 | 1.726 | |

| 95 | 10.34 | 11.07 | 165.10 | 11.32 | 51.66 | 226.30 | 299.15 | 238.73 | 0.7263 | 1.726 | |

| 100 | 9.72 | 10.41 | 166.00 | 10.66 | 48.62 | 228.54 | 302.04 | 241.12 | 0.7264 | 1.726 | |

| 105 | 9.11 | 9.75 | 166.90 | 10.00 | 45.57 | 230.80 | 304.95 | 243.52 | 0.7265 | 1.727 | |

| Case 5. w/ Toluene | 85 | 11.92 | 12.77 | 162.70 | 13.01 | 59.55 | 220.46 | 291.69 | 232.52 | 0.7258 | 1.726 |

| 90 | 11.24 | 12.04 | 163.70 | 12.29 | 56.19 | 222.98 | 294.89 | 235.21 | 0.7261 | 1.726 | |

| 95 | 10.55 | 11.30 | 164.70 | 11.55 | 52.77 | 225.51 | 298.14 | 237.89 | 0.7262 | 1.726 | |

| 100 | 9.85 | 10.55 | 165.80 | 10.80 | 49.28 | 228.09 | 301.45 | 240.63 | 0.7264 | 1.726 | |

| 105 | 9.13 | 9.77 | 166.90 | 10.03 | 45.70 | 230.72 | 304.85 | 243.44 | 0.7265 | 1.727 | |

| Case 6. w/ Toluene | 85 | 10.96 | 11.73 | 164.10 | 11.98 | 54.65 | 224.04 | 296.24 | 236.33 | 0.7261 | 1.726 |

| 90 | 10.31 | 11.04 | 165.10 | 11.29 | 51.46 | 226.40 | 299.29 | 238.84 | 0.7263 | 1.726 | |

| 95 | 9.66 | 10.34 | 166.10 | 10.59 | 48.24 | 228.78 | 302.35 | 241.37 | 0.7264 | 1.726 | |

| 100 | 9.00 | 9.64 | 167.00 | 9.90 | 45.00 | 231.17 | 305.43 | 243.92 | 0.7266 | 1.727 | |

| 105 | 8.35 | 8.94 | 168.00 | 9.20 | 41.74 | 233.57 | 308.52 | 246.47 | 0.7267 | 1.727 |

| Parameter | Default Value | Examined Range |

|---|---|---|

| Solar field outlet temperature—T1′ | 200 °C | [180–260] °C |

| ORC Condensation temperature–T1 | 90 °C | [85–105] °C |

| Pair | Opt. Variables | Objectives | Performance Indexes | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T1′ [°C] | T1 [°C] | ηen,ORC [%] | ղex,tri [%] | ղex,ORC [%] | ղen,tri [%] | Wturb [kW] | Qe [kW] | Qa [kW] | Qc [kW] | COPcool | COPheat | |

| Case 1. w/Benzene | 260 | 85 | 13.33 | 14.53 | 14.30 | 158.90 | 68.56 | 218.80 | 281.85 | 224.38 | 0.7252 | 1.725 |

| Case 2. w/Benzene | 260 | 85 | 13.36 | 14.54 | 14.30 | 158.90 | 68.47 | 212.79 | 281.84 | 224.74 | 0.7252 | 1.725 |

| Case 3. w/Toluene | 260 | 85 | 15.67 | 17.01 | 16.78 | 155.50 | 79.08 | 204.30 | 270.94 | 215.35 | 0.7245 | 1.725 |

| Case 4. w/Toluene | 260 | 85 | 16.02 | 17.38 | 17.16 | 155.00 | 80.78 | 203.02 | 269.30 | 213.99 | 0.7244 | 1.724 |

| Case 5. w/Toluene | 260 | 85 | 16.82 | 18.23 | 18.02 | 153.80 | 85.20 | 200.07 | 265.51 | 210.86 | 0.7241 | 1.724 |

| Case 6. w/Toluene | 260 | 85 | 16.00 | 17.36 | 17.14 | 155.00 | 80.78 | 203.10 | 269.39 | 214.07 | 0.7244 | 1.724 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-Domínguez, J.; Marcos, J.D. Thermodynamic Analysis and Systematic Comparison of Solar-Heated Trigeneration Systems Based on ORC and Absorption Heat Pump. Energies 2021, 14, 4770. https://doi.org/10.3390/en14164770

García-Domínguez J, Marcos JD. Thermodynamic Analysis and Systematic Comparison of Solar-Heated Trigeneration Systems Based on ORC and Absorption Heat Pump. Energies. 2021; 14(16):4770. https://doi.org/10.3390/en14164770

Chicago/Turabian StyleGarcía-Domínguez, Jesús, and J. Daniel Marcos. 2021. "Thermodynamic Analysis and Systematic Comparison of Solar-Heated Trigeneration Systems Based on ORC and Absorption Heat Pump" Energies 14, no. 16: 4770. https://doi.org/10.3390/en14164770

APA StyleGarcía-Domínguez, J., & Marcos, J. D. (2021). Thermodynamic Analysis and Systematic Comparison of Solar-Heated Trigeneration Systems Based on ORC and Absorption Heat Pump. Energies, 14(16), 4770. https://doi.org/10.3390/en14164770