Abstract

Although battery electric vehicles (BEVs) are locally emission-free and assist automakers in reducing their carbon footprint, two major disadvantages are their shorter range and higher production costs compared to combustion engines. These drawbacks are primarily due to the battery, which is generally the heaviest and most expensive component of a BEV. Lightweight measures (strategies to decrease vehicle mass, e.g., by changing materials or downsizing components) lower energy consumption and reduce the amount of battery energy required (and in turn battery costs). Careful selection of lightweight measures can result in their costs being balanced out by a commensurate reduction in battery costs. This leads to a higher efficiency vehicle, but without affecting its production and development costs. In this paper, we estimate the lightweight potential of BEVs, i.e., the cost limit below which a lightweight measure is fully compensated by the cost savings it generates. We implement a parametric energy consumption and mass model and apply it to a set of BEVs. Subsequently, we apply the model to quantify the lightweight potential range (in €/kg) of BEVs. The findings of this paper can be used as a reference for the development of cheaper, lighter, and more energy-efficient BEVs.

1. Introduction

Over the past decade, the emission limits set by the European Union for new passenger cars have become increasingly stringent [1]. One effective way for vehicle manufacturers to lower their fleet emissions and comply with the European regulations is to produce battery electric vehicles (BEVs) [2]. However, a major obstacle for BEVs remains their lower range compared to internal combustion engine vehicles (ICEVs) [3]. For this reason, range is a crucial selling point for BEVs [4,5]. One strategy that can guarantee a certain target range is to reduce the vehicle’s consumption, which depends on external and internal resistances.

External resistances are associated with rolling, aerodynamics, climbing, and acceleration resistance ([6] p. 137) [7]. The former is caused by deformation of the tire during vehicle motion [7] and can be described with the tire rolling coefficient fRR, the mass of the vehicle mveh, the gravitational acceleration g, and the road inclination angle α:

FRolling = mveh × g × fRR × cos(α)

The aerodynamic resistance FAerodynamic is caused by air friction and pressure differences between the front and the rear of the vehicle [8] (p. 14). It depends on the vehicle’s frontal area Af, its drag coefficient cd, its speed vveh, and the air density ρair:

FAerodynamic = cd × Af × ρair × vveh2/2

The acceleration resistance FAcceleration is caused by the inertia of the vehicle and its rotating parts. This resistance is modeled based on the acceleration of the vehicle aveh, its mass, and the rotational mass factor ei [9] (p. 10):

FAcceleration = mveh × ei × aveh

Finally, the slope resistance FSlope is induced by gravity when the vehicle drives on a non-horizontal road. It depends on vehicle mass, gravitational acceleration, and road inclination angle α [8] (p. 16).

FSlope = mveh × g × sin(α)

The total external resistance is obtained by adding up rolling, drag, acceleration, and slope resistance. As shown in Equations (1)–(4), three out of four components of the external resistance are mass-dependent. In order for the vehicle to follow a defined speed profile, it has to overcome these.

Internal resistances describe losses within components caused by friction as well as the energies required for auxiliary units [10] (p. 34). An example are gearbox losses, which are composed by gear, bearing, and load independent losses.

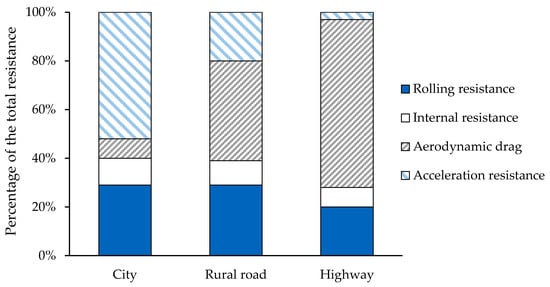

Figure 1 outlines the percentage contributions of internal and external resistances (the slope resistance is excluded) in three different scenarios: city, rural road, and highway. Mass-dependent resistances account for approximately 92% of the losses in the city scenario, 55% in the rural road scenario, and 30% in the highway scenario [10] (p. 35).

Figure 1.

Percentage distribution of the vehicle resistance in different driving scenarios [10] (p. 36).

Figure 1 and Equations (1)–(4) show the strong correlation between mass and energy consumption. Reducing vehicle mass is consequently an effective strategy for decreasing energy consumption and achieving the target range. Furthermore, the lower the vehicle’s consumption, the less battery energy is needed to attain the target range. This is significant for two reasons. First, a lower energy demand means lower battery costs. Since the role of the battery is a key element of the vehicle cost structure [11], reducing its cost will have a significant impact on the total vehicle costs. Second, as the gravimetric energy density of lithium-ion batteries is lower than that of gasoline and diesel fuels [12], a decrease of a few kWh can result in a considerable mass reduction [13], leading to a further drop in energy consumption.

The high cost of lithium-ion batteries combined with their low gravimetric energy density make mass reduction strategies (lightweight measures) particularly attractive for BEVs. However, every lightweight measure also generates costs [14] (p. 49). For example, vehicle mass can be reduced by investing in lighter (but also more expensive) materials for the body in white (BIW). Such a strategy is being pursued with the BMW i3, whose body is largely made of carbon fibers [15].

Lightweight measures are therefore an important strategic choice during the early development of BEVs. In the best-case scenario, the investment required for a lightweight measure can be partially or even fully compensated by the reduction in battery energy (and thus the costs) it generates. To create such a scenario, we must define the circumstances under which a lightweight measure can compensate its costs, by answering the question: What is the lightweight potential of BEVs? The purpose of the present paper is to answer this question. However, before we can investigate the lightweight potential of BEVs, we first have to understand the influence that a lightweight measure has on the vehicle.

The paper is structured as follows: after explaining the importance of lightweight measures (Section 1.1) the state of the art is evaluated (Section 1.2) and the research gap identified (Section 1.3). Based on the research gap, a tool to quantify the mass and lightweight potential of BEVs is presented (Section 2). Section 3 provides a validation of the presented tool using a dataset of existing BEVs. The approach is then applied in Section 4 to quantify the lightweight potential of current BEVs. Section 5 and Section 6 close the paper with a discussion and outlook.

1.1. Primary and Secondary Mass Reduction in the Early Development Phase

To understand the impact of a lightweight measure on a vehicle, we first have to briefly explain the BEV development process. During the early development phase of a BEV, concept engineers compile a detailed portfolio of requirements for the vehicle. This includes design parameters such as acceleration time, maximum speed, and target range [16]. In subsequent development steps, the vehicle components are detailed and sized according to the portfolio target values. This results in an initial dimensioning of the vehicle’s components and an estimation of its mass and costs.

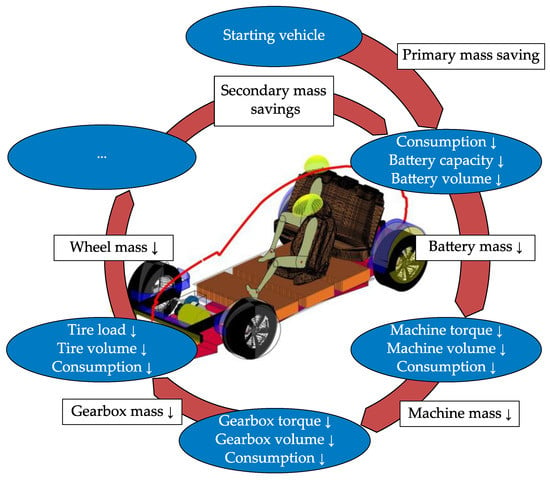

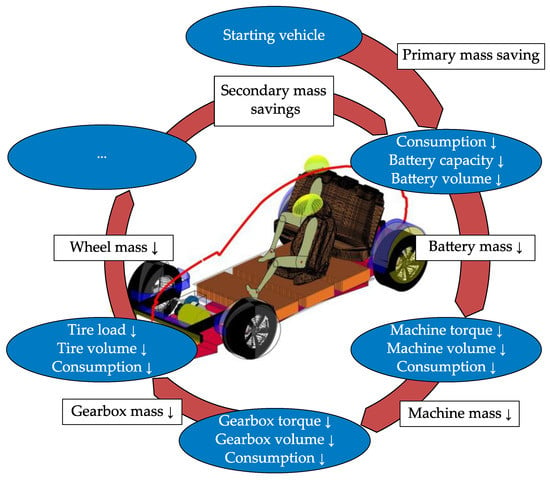

What will happen if a lightweight measure is applied at this stage of development? The lightweight measure will cause a reduction in vehicle mass, which we will define as a primary mass saving (PMS). This will cause consumption to decrease, setting a mass spiral in motion (Figure 2).

Due to the resulting lower energy consumption, a smaller battery pack will now be sufficient to create the target range required in the vehicle portfolio. Electric machines and gearboxes can then also be downsized, as less torque is required to fulfill the required acceleration time and maximum speed. These adjustments are propagated to other mass-dependent components, such as the wheels, suspension system, and BIW. The mass savings induced by the spiral are referred to as secondary mass savings (SMSs). These SMSs can themselves trigger further SMSs (Figure 2).

One way of quantifying the SMSs is with the secondary to primary ratio (SPR), which expresses the relationship between the SMSs and the PMS which induces them [17] (pp. 9–10) according to Equation (5). For example, an SPR of 0.5 means that given a mass reduction of 100 kg, a secondary mass saving of 50 kg is possible.

SPR = SMS/PMS

For vehicles equipped with an electric powertrain, the SMSs induced by a lightweight measure further reduce the battery energy required, thus decreasing the vehicle’s production and development costs. In the case of ICEVs, this reduction is in the required tank capacity, which, however, has little impact on vehicle costs.

Figure 2.

A mass spiral showing the SMSs generated from a lightweight measure. Based on [18].

Therefore, to quantify the lightweight potential of BEVs, it is necessary to model the component masses (for assessing SPR and SMSs) and the correlation between mass and energy consumption (to estimate the savings in battery energy). The following section reviews the work of some authors who have attempted to address this problem.

1.2. Existing Methods of Modeling Lightweight Potential

In the early development phase, several researchers were concerned with the key role of mass reduction. To address the problem, parametric models were developed to simplify the problem of mass estimation (Table 1).

Table 1.

Overview of existing methods of vehicle mass estimation. Based on [13].

Malen et al. [19] divided the vehicle into 13 subsystems and assigned a secondary mass coefficient to each subsystem. These coefficients describe the incremental mass change in the corresponding subsystem for a unit change in gross vehicle mass and are determined by empirical analysis of a dataset of 32 ICEVs. The sum of the subsystem’s secondary mass coefficients yields the SPR. According to the authors, fuel and exhaust systems as well as electrical, cooling, and closure systems have low coefficients and hence experience little mass fluctuation. Malen et al. [19] estimate an SPR of between 0.8 and 1.5 if all subsystems are resized. When the powertrain is not available for resizing, the SPR drops to a range between 0.4 and 0.5.

Gobbels et al. [20] propose a method of quantifying SMSs in passenger cars. The vehicle components are modeled separately and organized into six subsystems (body, engine, transmission, suspensions, interior, and electronics). For the body and suspensions, the mass reduction potential is determined by finite element simulations. The engine and transmission subsystems are described by regression models, while the interior and electronics subsystems are regarded as mass-independent. The modeling is based on two reference vehicles, an Opel Corsa C and a Volkswagen Golf VI. The approach predicts an SPR of 0.30 for the Opel Corsa and 0.46 for the Volkswagen Golf.

Yanni et al. [21] derive a linear regression model to estimate the vehicle mass based on its power and external dimensions. However, the authors did not consider BEVs, and the resulting estimation only includes SMSs that result from a change in the vehicle’s external dimensions.

Alonso et al. [22] follow the same approach defined by Malen et al. [19] and develop an empirical method to determine how the different subsystems are affected by a change in the overall vehicle mass. The modeling follows an empirical approach, based on a dataset of 77 ICEVs. The authors do not consider BEVs, though, and focus exclusively on combustion engines, estimating an SPR of 0.49.

Fuchs et al. [17,23] divide the vehicle into eight subsystems to create a parametric mass model. Each subsystem is further divided into subcomponents, which are modeled with empirical and semi-physical models. A dataset of 24 vehicles (including BEVs and ICEVs) is used to derive the empirical models. The authors couple the parametric mass model with an energy consumption simulation, which is used to size the powertrain and quantify the vehicle consumption. The research done by Fuchs et al. [17] highlights the large impact of target range and battery energy on the mass of BEVs. In a simulation of a two-seater BEV with a range of 150 km, the authors predict an SPR of between 0.32 and 0.45.

Wiedemann [24] develops a parametric model for BEVs which also includes a parametric mass calculation. He estimates a basic vehicle mass using the model of Yanni et al. [21]. The mass of the electric powertrain is modeled by adding the contributions of battery, electric machine, power electronics, and gearbox, which are all estimated using empirical models. As with Fuchs, Wiedemann also implements an energy consumption simulation to model the interdependencies between vehicle mass and consumption. Wiedemann’s model can estimate the SMSs, but only on the powertrain components.

Mau et al. [25] divide the vehicle into seven subsystems, and model each subsystem empirically. For example, powertrain mass is calculated based on engine torque, gearbox type, and drive configuration (front/rear/all-wheel drive). However, the model does not consider BEVs or SMSs.

Finally, Felgenhauer et al. [26] develop an empirical regression model based on the methods of Mau and Yanni [21,25]. The model includes BEVs but can only estimate SMSs resulting from a change in the vehicle’s external dimensions.

1.3. Research Gap

Among the authors listed in Table 1, only Malen et al. [19], Gobbels et al. [20], Fuchs [17], and Alonso et al. [22] consider all mass-dependent vehicle subsystems when modeling the SMSs. Fuchs is the only author to include BEVs in an energy consumption simulation.

Apart from the fact that the empirical data employed by Fuchs is outdated (the database he uses includes vehicles built before 2013), another disadvantage (which is true of all approaches in Table 1) is that the author does not model the vehicle package but focuses on its mass. Transferred to a practical example, Fuchs’ parametric model is able to quantify the number of kWh the battery is required to store to reach a certain range but it cannot estimate whether the simulated vehicle can accommodate this energy. This is particularly critical since the lightweight potential derived might be calculated on the basis of vehicles that are not feasible in the first place.

To address these issues, the parametric mass model presented in this paper estimates the mass of BEVs using an approach similar to that of Fuchs [17] but employing an up-to-date vehicle dataset. Moreover, the model is encapsulated by a vehicle architecture tool that includes an energy consumption simulation and a package model. The former calculates the energy consumption and estimates the battery energy requirements depending on the vehicle mass and target range. The latter sizes and positions the components and checks the feasibility of the vehicle. This ensures that the simulated vehicle is feasible in terms of energy consumption, mass, and package. All the parts of the vehicle architecture tool (energy consumption, parametric mass model, and package model) are implemented in MATLAB.

2. Materials and Methods

The first part of this section briefly discusses the workflow of the vehicle architecture tool. This is followed by detailing of the parametric mass model.

2.1. Vehicle Architecture Tool

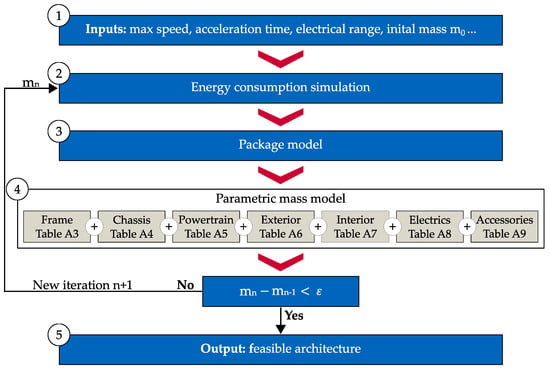

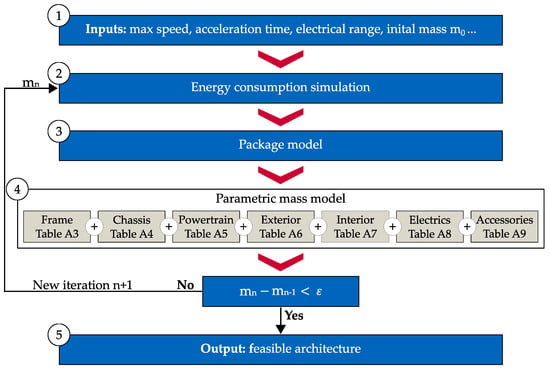

The inputs of the tool correspond to the content of the portfolio defined by the concept engineers (Section 1.1) and include variables such as acceleration time, vehicle speed, electric range, and initial vehicle mass m0 (Step 1, Figure 3). The tool inputs are listed in Table A1.

Based on these inputs, the requirements of the electric powertrain (such as electric machine power and required battery energy) are derived with an energy consumption simulation (Step 2, Figure 3). The consumption simulation is available as an open-source MATLAB code in [27] and documented in [7].

In the third step, the vehicle components are sized and positioned by a package model. Here, the components are modeled using empirical and semi-physical models. The outcome of this step is a rough layout of the vehicle package. Several components of the package model have been discussed in previous publications [5,13,28].

Following the package modeling, the component masses are estimated with the parametric mass model (Step 4, Figure 3). The vehicle components are organized into seven modules and the mass of each module derived empirically. For the modeling, the inputs given in Step 1 are combined with the results of the energy consumption simulation and the package model. The total mass of the vehicle is derived by totaling the contributions of the seven modules. This step yields the new mass estimate m1.

At this point, m1 is compared with the mass m0 assumed in Step 1. If the difference between the two values is above a certain tolerance, a new iteration is required. Then, m1 is reintroduced in the LDS and the new power and energy requirements calculated. Due to the changed requirements, the components are also sized differently, which impacts the vehicle package. The iterative process continues until the difference between the masses of two consecutive iterations n and n − 1 falls below a given tolerance (which is set to a default value of 5 kg). For each iteration, the tool not only tests the feasibility of the target range and power as a function of the mass but also ensures that the vehicle package is feasible.

If the mass does not converge after ten consecutive iterations, the tolerance is stepwise increased. Otherwise the approach outputs the resulting vehicle package. Figure 4 shows a typical output of Step 5.

Figure 3.

Overview of the vehicle architecture tool based on [5,29]. The tool is implemented entirely in MATLAB.

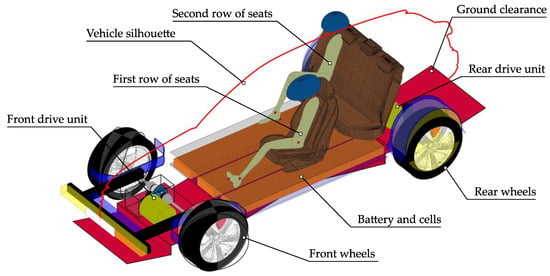

Figure 4.

Typical output of the vehicle architecture tool, showing the calculated package layout and its components.

2.2. Parametric Mass Model

To implement the parametric mass model, we define seven modules: frame, chassis, powertrain, exterior, interior, electrics, and accessories. The modules are divided into subsystems, which are modeled separately using empirical models such as linear regression and constant values (the latter based on normal distributions). The empirical models are derived using the method documented in [30]. In total, more than 100 different subsystems are defined (a complete list is given in Appendix B, Table A2, Table A3, Table A4, Table A5, Table A6, Table A7, Table A8 and Table A9).

To derive the empirical models, a benchmark analysis is performed on a dataset of the benchmarking service provider A2mac1 [31]. The dataset comprises more than 200 vehicles (listed in Appendix C, Table A10, Table A11, Table A12, Table A13, Table A14 and Table A15), most of which were built after 2015. Although this work focuses on BEVs, due to the limited number of BEVs sold today, ICEVs and hybrid electric vehicles (HEVs) are also considered for subsystems where there are only slight changes between BEVs and ICEVs. This is the case for components of the frame, chassis, interior, exterior, and accessories modules. Depending on the considered subsystem, different subsets of vehicles from the list in Appendix C are used for the empirical modeling.

Particular attention is necessary when modeling the chassis and frame since these modules are sized based on the heaviest vehicle model variant. A model series (for example the Audi e-tron) normally contains several model variants (Audi e-tron 50 quattro, Audi e-tron 55 quattro, etc.) with different optional and different empty masses. To avoid errors, when building a correlation between components of the chassis and frame and vehicle mass, we consider the gross mass of the heaviest model variant (see Table A3 and Table A4).

The statistical evaluation shows a strong correlation between the vehicle and module mass for the chassis, powertrain, and frame. On the other hand, an analysis of the interior, exterior, electrics, and accessories subsystems did not show any strong dependency on this variable. Therefore, these modules do not cause any SMSs, since their mass is independent of the vehicle’s mass. The following presents the modeling techniques applied for the parametric mass model, using the BIW component as an example.

The estimation of BIW mass mBIW follows an approach similar to that of Fuchs [17] (pp. 39–41) and is derived from an empirical analysis of the vehicles documented in A2mac1. We only consider vehicles with unibody construction, in which the powertrain and chassis are mounted directly on the BIW [32] (p. 576). The variables employed for the empirical modeling comprise a vehicle substitute volume VS, the vehicle gross mass mveh, gross, and the material composition of the BIW.

The VS is calculated from the exterior dimensions (as defined in the SAE J1100 [33]) of the vehicle and its body style (sedan, hatchback, SUV). Since sedans have a different rear-end in comparison to other body styles, their substitute volume VS, sedans is calculated differently. Given the vehicle’s front and rear overhangs (L104, L105), wheelbase (L101), width (W103), and height (H100), the VS, sedans is derived using Equation (6) [17] (pp. 39–41).

VS, sedans = (0.5 × L104 + L101 + 2/3 × L105) × W103 × H100

For hatchbacks and SUVs, the substitute volume VS, non-sedans is estimated using Equation (7) [17] (pp. 39–41):

VS, non-sedans = (0.5 × L104 + L101 + 3/4 × L105) × W103 × H100

In addition to the vehicle’s crash-safety, aerodynamic, aesthetics, and package requirements, its unibody structure must provide sufficient bending and torsional rigidity to deliver the desired comfort and driving dynamic properties [32] (pp. 576–587). In the event of a collision, the gross mass of the vehicle mveh, gross (i.e., the maximum allowable vehicle mass, including passengers and payload) contributes to the deformation of the BIW. For this reason, mveh, gross is chosen as the second independent variable for calculating the mBIW [34].

Modern stringent safety regulations and high comfort demands require increasingly high BIW masses [32] (p. 585). The use of lightweight materials helps manufacturers comply with the strict emissions regulations by keeping the vehicle’s mass as low as possible. Depending on the vehicle’s price bracket and driving dynamic requirements, the BIW can be partially or entirely made of high-strength steel, aluminum, or carbon fiber [35]. Since carbon fiber monocoques are rare and very expensive in terms of energy and production costs, they are not considered in this paper. The mass percentage of aluminum palu for the documented vehicles is extracted using the A2mac1 database [31]. The remaining material is assumed to be entirely steel.

Once the required modeling variables have been retrieved from A2mac1, the data is evaluated to derive an empirical mass model. Equation (8) shows the resulting empirical correlation between the BIW mass and the modeling variables.

mBIW = 4.57 kg + (5.92 kg/m3) × Vs × palu + (13.20 kg/m3) × Vs × (1 − palu) + 0.079 × mveh, gross

The coefficients shown in Equation (8) are derived from the vehicle data listed in Appendix C using the least squares method. The term multiplying Vs × palu represents an empirical aluminum density of the BIW. The empirical BIW-density of the steel is, with a value of 13.2 kg/m3, twice that of aluminum. Finally, the last term of Equation (8) models the influence of the vehicle gross mass on mBIW. According to its value, a reduction in mveh, gross of 100 kg (for example due to an decrease of the required vehicle payload) induces 7.9 kg of SMSs solely on the BIW.

The remaining components are modeled with regressions (as with the BIW) or, if no dependency is identified between the component mass and the other vehicle dimensions, with constant values. A complete list of derived regressions and constant values for each module is given in Appendix B. The following section now goes on to evaluate parametric mass model precision.

3. Evaluation

This section presents an assessment of the accuracy of the parametric mass model. For this purpose, an evaluation dataset is created from 16 BEVs using A2mac1 (Table 2). To assess parametric mass model accuracy alone, the vehicle package is not simulated and the energy consumption simulation is not applied (Figure 3). Therefore, the mass estimation presented in this section relies solely on the set of empirical models listed in Table A3, Table A4, Table A5, Table A6, Table A7, Table A8 and Table A9. Nevertheless, since the results of package modeling and energy consumption simulation are also required for mass modeling, we must collect further inputs to enable a standalone run of the parametric mass model. For example, the mass of the electric machine (Table A5) is calculated from its maximum torque, which we collect from the ADAC database [36].

Table 2.

Evaluation dataset for the parametric mass model.

A further required input is vehicle gross mass mveh, gross, which is needed to calculate mBIW (Table A3) as well as several subsystems of the chassis (Table A4). The ADAC database [36] also lists the gross mass mveh, gross of every documented vehicle. To do this, we link each of the A2mac1 vehicles listed in Table 2, with the corresponding model series in ADAC and retrieve the gross mass of the heaviest model variant. Some vehicles, such as the Tesla Model 3 Long Range RWD, are not available in Europe and not documented in the ADAC database. In these cases, we retrieve the mveh, gross from the manufacturer sites.

The BMW i3 120 Ah RE is a special case due to its range extender. With this vehicle, it is not possible to estimate the mass of the combustion engine, since internal combustion powertrains are not considered in the parametric mass model. Therefore, we simulate the vehicle as if it was built without the range extender.

Once the required inputs are collected, the vehicles in Table 2 are simulated and the mass of the seven modules estimated. For each simulated vehicle, we can then retrieve the real module masses from the A2mac1 database. Again, in the case of the BMW i3, we subtract the contributions of the combustion powertrain from the real powertrain mass listed in A2mac1, since we cannot simulate this subsystem.

Once the simulated and real module masses are available, we assess the correctness of the model using mean absolute error (MAE) and normalized mean absolute error (nMAE).

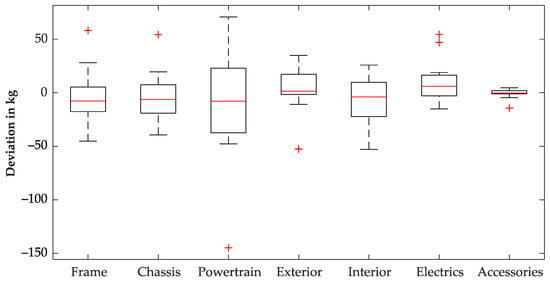

The resulting MAE and nMAE are shown in Table 3 while Figure 5 depicts the deviation (in kg) between calculated and real modules masses. The powertrain module has the highest MAE, and the mean deviation between calculated and real powertrain masses is equal to 37 kg. This is because in most vehicles it is the heaviest module. For example, in BEVs such as the Audi e-tron [37] or the Opel Ampera-e [38], the battery accounts for more than 25% of the empty vehicle mass.

Table 3.

Overview of the MAE and nMAE for the different modules.

Figure 5.

Boxplot showing the difference between calculated and real module masses.

The powertrain of the Mercedes EQC has the highest deviation (red cross at −144 kg, Figure 5). Nevertheless, this deviation is not an error of the model, but is rather caused by the unconventional design of the battery. The EQC has massive battery housing with a series of internal side reinforcements [39], which lead to an above-average battery mass. Further inaccuracies occur with Tesla vehicles, whose electric machines have an above-average torque-to-mass ratio, which results in overestimation of these components.

With the other modules, the nMAE is usually between 5% and 8%. The electrics and accessories modules have higher values (15.9% and 28.4%, respectively). Nevertheless, these modules are lighter than the others, which means that the absolute error is not particularly high (compare the MAEs in Table 3 and the boxplots in Figure 5).

Overall the median of the absolute deviation is always close to 0 kg (Figure 5) which denotes that there is no tendency to over- or underestimate any of the seven modules.

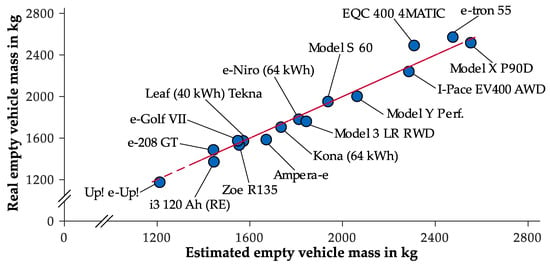

Finally, for each vehicle in Table 2 the calculated empty vehicle mass (derived by totaling the contributions of the calculated modules) is compared with the real mass (Figure 6). The nMAE of the empty vehicle mass estimation shown in Figure 6 is 2.9%. This corresponds to a mean error of 53.1 kg for the evaluation dataset. This evaluation step confirms that, despite the limited amount of inputs, the mass estimation is still precise.

Figure 6.

Comparison of estimated and real empty vehicle mass presented as a whole model plot.

In the following section, the parametric mass model is applied in an assessment of the lightweight potential of current BEVs.

4. Lightweight Potential Assessment

To assess the lightweight potential, we define four reference vehicles (RVs) to be used in a parametric study (Table 4). The RVs come from different segments and have differing cells, topologies, and powertrain requirements.

The RV-A is a hatchback and has the same external dimensions as a BMW i3. It is fitted with a permanent magnet synchronous machine (PMSM) on its rear axle, while its battery (composed of prismatic cells) yields an electric range of 280 km. Like the BMW i3, the RV-A has a light BIW, which is assumed to be made entirely of aluminum (since carbon-fiber BIWs are not considered in the parametric mass model). Due to its aluminum frame and the small external dimensions, the RV-A is the lightest of the reference vehicles.

The RV-B is slightly larger than the RV-A and is derived from the VW ID.3. The battery consists of pouch cells and provides an electric range of 420 km. Machine topology and body type are the same as for the RV-A, but the RV-B has a lower drag coefficient of 0.26, like the VW ID.3 [40].

Table 4.

Selected key characteristics of the RVs’ portfolios.

Table 4.

Selected key characteristics of the RVs’ portfolios.

| RV-A | RV-B | RV-C | RV-D | |

|---|---|---|---|---|

|  |  |  | |

| Similar model | BMW i3 120 Ah | Volkswagen ID.3 | Tesla Model 3 SR | Audi e-tron 55 |

| Wheelbase (L101) | 2570 mm | 2770 mm | 2875 mm | 2928 mm |

| Width (W103) | 1775 mm | 1809 mm | 1850 mm | 1935 mm |

| Height (H100) | 1570 mm | 1568 mm | 1443 mm | 1629 mm |

| Body Type | Hatchback | Hatchback | Sedan | SUV |

| Drag coefficient | 0.29 | 0.26 | 0.23 | 0.29 |

| E-machine front/E-machine rear | –/PMSM | –/PMSM | –/PMSM | PMSM/PMSM |

| Cell type | Prismatic | Pouch | Cylindrical | Pouch |

| Acceleration time (0–100 km/h) | 7.3 s | 7.9 s | 5.6 s | 5.7 s |

| Maximum speed | 150 km/h | 160 km/h | 225 km/h | 200 km/h |

| Target range (in WLTP *) | 280 km | 420 km | 400 km | 400 km |

* For the calculation of the target range we employ the Worldwide harmonized Light vehicles Test Procedure (WLTP). This procedure was developed by the UNECE in substitution of the obsolete New European Driving Cycle (NEDC) [41] and is adopted for type approval of light duty motor vehicles in Europe [42].

The RV-C is a sedan car, similar to the Tesla Model 3 Standard Range. It has a PMSM on the rear axle, and its battery is composed of cylindrical cells. The vehicle has demanding powertrain requirements (low acceleration time and high maximum speed) and a low drag coefficient. Although the RV-C is larger than the RV-B, it has a lower range requirement and lower consumption (also due to its improved aerodynamics). This results in a similar mass to the RV-B, despite the bigger dimensions.

Finally, the RV-D is similar to an Audi e-tron. It has an all-wheel-drive topology with a PMSM on each axle. While all the other vehicles have a rectangular battery installed beneath the passenger compartment, the RV-D has an additional level of cell modules underneath the second row of seats. This solution enables it to attain an electric range of 400 km, despite its large dimensions, high drag resistance, and mass.

The RVs are simulated with the vehicle architecture tool. The tool confirms the feasibility of all the RVs and yields the vehicle empty mass mveh,empty base, which represents the mass of the vehicle when no lightweight measures are applied.

To study the impact of lightweight measures on the RVs, two mass savings (indicated as mLW) of 50 kg and 100 kg are introduced and the RVs simulated again. Since the mLW act like a PMS, they lead to further savings, according to the mass spiral shown in Figure 2. Despite the mass reduction, the RV portfolios (target range, acceleration time, maximum speed, Table 4) remain unchanged.

Table 5 shows the impact of mLW on energy consumption. The value listed at mLW = 0 kg corresponds to the consumption of the vehicle without lightweight measures. The values listed at mLW = 50 kg and mLW = 100 kg represent the resulting energy consumption after the lightweight measure is applied and the SMSs calculated. The lightweight measure and its induced SMSs result in the RVs becoming lighter, which leads to a reduction in their energy consumption. The reduction in energy consumption depends on the selected test procedure for the target range definition. In the scope of this paper, we refer to the WLTP since it is the adopted procedure for type approval of light duty vehicles in Europe.

Table 5.

Influence of different lightweight measures on energy consumption, required battery energy, and module masses.

As the energy consumption decreases, less battery energy is needed to achieve the target range given in Table 4. For a 50 kg mass saving, the battery energy can be reduced by up to 1.84 kWh, while for 100 kg, the figure is between 2.33 kWh and 3.27 kWh. Due to the lower energy requirement, the battery can be downsized, which leads to mass savings in the powertrain and other module. These mass reductions also lower the machine power required, since with a lighter vehicle, less machine torque is needed to achieve the acceleration time.

Table 5 also shows a breakdown of the SMSs for chassis, frame, and powertrain. As it can be seen, the SMS are not continuous. For example, the RV-D has a lower SMS for the chassis than the other vehicles. This is due to the fact that despite the lightweight measure, the RV-D is still too heavy to reduce its wheel size. On the other hand all the other RVs can reduce their tire widths as a consequence of the lightweight measure thus generating higher SMS on the chassis.

The powertrain module always generates the highest SMSs. Finally, by adding the contributions of the three modules, it is possible to derive both the total SMSs induced by the mLW and, in turn, the SPR. The SPR (regardless of the RVs and the mLW) is within the range 0.42 to 0.50. This means that, on average, for each kilogram saved in the vehicle, a further saving of between 0.42 kg and 0.50 kg can be obtained on the basis of the SMSs.

Once the SPR and SMSs have been calculated, the lightweight potential of the RVs can be assessed. To do this, we use the cost data presented by König et al. [43]. First, based on the battery energy saved, we derive the saved battery cost by assuming an average cost at the pack level of 200 €/kWh for the year 2020 [43]. Furthermore, we assume production costs for the frame and chassis (material + labor + depreciation) of 1.3 €/kg for steel and 5.3 €/kg for aluminum. The PMSM costs are estimated at 10 €/kW. The cost savings are shown at the bottom of Table 5. We would like to stress that the values given are production costs, which normally account for 60% of the selling price, excluding taxes [43]. Furthermore, besides the given production cost savings, the customer also benefits from lightweight measures by way of the vehicle’s reduced energy consumption. As electricity prices vary significantly by country, we do not calculate these costs.

An assessment of the lightweight potential yields a range of between 6.9 €/kg and 9.3 €/kg. This means that, regardless of the RVs, if the costs of a lightweight measure are below 6.9 €/kg, they will be compensated by the induced power and energy saving. On the other hand, lightweight measures above 9.3 €/kg are not balanced for any of the RVs. Therefore, although they still result in a reduction in vehicle energy consumption, this will be accompanied by an increase in production costs.

The parametric study highlights that, in the case of BEVs, besides the benefits of reduced energy consumption, lightweight measures can also induce a significant monetary saving. Since the values shown in Table 5 are calculated for a single vehicle, high production volumes can induce effects of scale, thus amplifying the savings in production costs.

5. Discussion

After illustrating the potential of mass savings in the vehicle development process (Section 1), we present a tool and a parametric mass model capable of estimating the lightweight potential of BEVs (Section 2). Section 3 then presents an evaluation of the parametric mass model, which shows a percentual error of 2.9% (corresponding to approximately 53 kg). These deviations are mostly caused by the limited amount of modeling parameters. The choice of the modeling parameter set is the result of a tradeoff between modeling precision and usability of the tool during the early development design. Increasing the number of parameters would lead to higher accuracies, but would also hinder the usage of the tool for the early development design.

Regarding the vehicle interiors and exteriors, inaccuracies are mostly caused by the fact that their masses do not exclusively depend on the vehicle dimensions, but also on the model variant and optional. The available optional features, in turn, vary between manufacturers, which hinders the empirical modeling of this feature.

Inaccuracies are still present in the chassis because the subsystems of this module are sometimes built into different model series. This complicates the modeling since it is not always possible to precisely identify the model (and therefore the gross mass) that has been used for sizing the chassis subsystems. Regarding the powertrain, distinguishing between machine technologies (PMSM and IM) improved the results. Nevertheless, the number of machines available on the market is still low and displays a high variability between manufacturers. For a more precise estimation, it is possible to use sophisticated machine design tools such as [44]. However, such solutions require a higher number of input parameters, which are often not available in the early development phase.

Breaking the battery down into housing, module, and electrics components also improves the model accuracy, although deviations can still be observed, mostly in the battery housing. Finally, inaccuracies in the empty mass estimation are also caused by the fact that some vehicles are simply designed better than others and act therefore as outliners.

Following the mass model evaluation, we assess the lightweight potential of four RVs (Section 4). It is not possible to define an exact SPR but only a range, since there are components in the mass model which cause discontinuities. One example are the tires: as the vehicle mass decreases, the tire load and, in turn, the required tire volume also decreases. However, there are only a finite number of compatible tires, meaning that the SMSs caused by the tires are stepwise and not continuous [13].

6. Conclusions and Outlook

The parametric study yields an SPR between 0.42 and 0.50. Since the RVs cover different vehicle segments and have different portfolios, we assume that the derived SPR range can be generalized onto the majority of BEVs. Furthermore, since the gravimetric and volumetric energy density of lithium-ion batteries is expected to increase constantly in the coming years [43], this will lead to a decrease in SMSs caused by the battery and, in turn, of the SPR. Therefore, when quantifying lightweight potential, it is also necessary to carefully determine the year for which the as yet undeveloped vehicle is planned and choose the energy density accordingly.

A lightweight potential of between 6.9 €/kg and 9.3 €/kg is derived from the calculated SMSs and SPR. Again, it is possible to define a range (and not an exact value) for the lightweight potential. Nevertheless, the range can be applied to quantifying the suitability of lightweight measures during the vehicle development process. In Table 5, we also list the corresponding mass, power, and energy savings. Therefore, if more precise cost data is available, the lightweight potential can be recalculated using the data in Table 5.

The lightweight potential range given in this paper is only valid if every module and component is available for resizing. Since the tool is employable in the early development phase, there is still great design freedom, and resizing and adjustments are not as cost-intensive as in the following development phases. Nevertheless, this design freedom could be limited already in the early development if the vehicle has to be built on a preexisting platform (with an already given set of possible electric machines and cell sizes).

In conclusion, the method presented here is capable of estimating both SMSs and lightweight potential for BEVs. This approach can support manufacturers’ efforts to quantify lightweight measures and assist their decision-making in the early stages of the development process. In future publications, we will apply the presented tool to test the influence of other variables (such as acceleration time, drag coefficient, etc.) on vehicle energy consumption.

Author Contributions

As first author, L.N. defined the approach for the development of the presented model, defined the relevant steps, and detailed the evaluation and the lightweight potential assessment. A.R. provided support in defining the approach, collecting the data, and deriving the mass models. A.K. provided support with cost calculation and proofreading the paper. P.K. provided support with the data collection and in the evaluation of the mass model. M.H. provided support with proofreading the paper. M.L. made an essential contribution to the conception of the research project. He revised the paper critically for important intellectual content. M.L. gave final approval of the version to be published and agrees to all aspects of the work. As guarantor, he accepts responsibility for the overall integrity of the paper. All authors have read and agreed to the published version of the manuscript.

Funding

The research conducted by L.N. was funded by the Technical University of Munich and the AUDI AG. The research conducted by A.K. was performed within the “UNICARagil” project (FKZ 16EMO0288). A.K. acknowledges the financial support of the project by the Federal Ministry of Education and Research of Germany (BMBF).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Acknowledgments

The author L.N. would like to thank the colleagues at AUDI AG in the persons of Maximilian Heinrich and Hendrik Gronau for the support they provided during the concept development phase. L.N. would also like to thank Ferdinand Schockenhoff from the Technical University of Munich, who supported the writing of this publication. Finally, L.N. would like to thank A2Mac1 EURL, in the person of Pir Ivedi, for enabling access to the A2Mac1 automotive benchmarking database.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. Overview Model Inputs

Table A1.

Required Inputs for the vehicle architecture tool.

Table A1.

Required Inputs for the vehicle architecture tool.

| Required Inputs | |

|---|---|

| Parameter | Unit |

| Acceleration time from 0 to 100 km/h | s |

| Air suspension | Yes/No |

| All-wheel steering | Yes/No |

| Aluminum percentage in the frame | % |

| Body style (sedan, hatchback, SUV) | – |

| Cell type (prismatic, pouch, cylindrical) | – |

| Cluster type | Digital/Analog |

| Door material | Steel/Aluminum |

| Driver seating height (H30-1) | mm |

| Driving cycle for vehicle consumption (WLTP, NEDC, etc.) | – |

| Electric Machine number and type (IM, PMSM) | – |

| Electric range | km |

| Fenders material | Steel/Aluminum |

| Gearbox transmission ratio | – |

| Gearbox type (coaxial, parallel axles) | – |

| Gravimetric energy density at the cell level | Wh/kg |

| Hatch material | Steel/Aluminum |

| Head up Display | Yes/No |

| Headlights type | LED/Xenon/Halogen |

| Hood material | Steel/Aluminum |

| Maximum speed | m/s |

| Number of doors | 2/4 |

| Number of seats | – |

| Overhang front and rear (L104, L105) | mm |

| Panorama roof | Yes/No |

| Sliding rear seats | Yes/No |

| Sliding roof | Yes/No |

| Subwoofer | Yes/No |

| Tire diameter | mm |

| Tire type (Extra load, Normal load) | - |

| Vehicle height (H100) | mm |

| Vehicle wheelbase (L101) | mm |

| Vehicle width (W103) | mm |

| Volumetric energy density at the cell level | Wh/l |

Appendix B. Main Components of the Mass Modeling

This appendix documents the set of empirical models which are implemented in the parametric mass model. The models are categorized according to the modules presented in Figure 3. For representation purposes, a set of symbols is introduced (Table A2).

Table A2.

List of symbols employed in Table A3, Table A4, Table A5, Table A6, Table A7, Table A8 and Table A9.

| Symbol | Unit | Description |

|---|---|---|

| Drim, inches | inch | Rim diameter in inches 1 |

| Dtire | mm | Tire diameter 1 |

| Ebatt, kWh | kWh | Installed battery gross energy in kWh 2 |

| Ebatt, Wh | Wh | Installed battery gross energy expressed in Wh 2 |

| Ecell, grav | Wh/kg | Gravimetric energy density at the cell level 1; an overview is available at [43] |

| H100 | mm | Vehicle height 1 |

| L101 | mm | Vehicle wheelbase 1 |

| L103 | mm | Vehicle length 1 |

| L104 | mm | Front overhang 1 |

| L105 | mm | Rear overhang 1 |

| Lf, max | kg | Maximum load at the front axle 3 |

| Lr, max | kg | Maximum load at the rear axle 3 |

| mf, brakes | kg | Mass of the front brakes 3 |

| mveh, gross | kg | Gross vehicle mass (calculated in the iterative process, Figure 3) |

| mwheel | kg | Wheel mass (Table A4), required for the calculation of the spare wheel mass |

| palu | % | Percentage of aluminum in the Body in White1 |

| Pmax | kW | Installed electric machine power (including all machines) 4 |

| Tmax | Nm | Maximum electric machine torque 4 |

| Ubatt | V | Battery nominal voltage 2 |

| Vbatt | l | Battery housing volume (excluding sills and mounts) 2 |

| Vs | m3 | Substitute volume of the vehicle; see Equations (6) and (7) |

| W103 | mm | Vehicle width 1 |

| wtire | mm | Tire width 3 |

If a component is modeled using a constant value (for example the ABS system in Table A4), we only list the mean value (in kg) of the component mass (calculated from the analysis of the vehicles in Appendix C).

If a component is modeled using a regression model (for example the front axle links, Table A4), we document the resulting regression formula. A linear regression to estimate the mass of a random component mcomponent using two generic variables X1 and X2 is presented in Equation (A1).

where a is the intercept of the regression (always in kg) and b and c are the multiplication factors for X1 and X2. The units of the b and c result from the units of X1 and X2 and are not printed in Table A3, Table A4, Table A5, Table A6, Table A7, Table A8 and Table A9. In the following tables, when a regression is listed, we show the empirically derived intercept and multiplication factors.

mcomponent = a + b × X1 + c × X2

The mass of the cell (Table A5) is the only case where the modeling bases on a physical equation. First, the mass of the cell is calculated by dividing the required battery energy Ebatt, Wh for the gravimetric cell energy density as shown in Equation (A2).

mcells = Ebatt, Wh/Ecell, grav

Subsequently, in order to derive the mass of cells including the module housings mmodules we employ the scaling factor Kcell2mod:

mmodules = mcells × Kcell2mod

Kcell2mod considers the increase in cell mass caused by the module housings. From an empirical analysis we derive a value Kcell2mod of 1.23 for pouch cells, 1.14 for cylindrical cells and 1.12 for prismatic cells.

Based on the list of symbols shown in Table A2 and the methods explained in the previous paragraphs, Table A3, Table A4, Table A5, Table A6, Table A7, Table A8 and Table A9 present the empirical models for parametric mass estimation. The tables document for each defined subsystem and module the corresponding constant value or regressions.

Table A3.

Empirical Models for the Frame module.

Table A3.

Empirical Models for the Frame module.

| Module Frame | ||

|---|---|---|

| Component | Regression Model/Constant Value | R2 |

| Body in White | 4.5748 kg + 5.9108 × Vs × palu + 13.2029 × Vs × (1 − palu) + 0.079719 × mveh, gross | 0.86 |

| Other frame components | −18.2704 kg + 4.0904 × Vs | 0.49 |

Table A4.

Empirical models for the Chassis module.

Table A4.

Empirical models for the Chassis module.

| Module Chassis | ||

|---|---|---|

| Component | Regression Model/Constant Value | R2 |

| ABS system | 2.71 kg | – |

| Brake disc covers | 0.81 kg | – |

| Brake fluid | 0.58 kg | – |

| Brake hoses | 0.57 kg | – |

| Brake lines system | 1.41 kg | – |

| Front axle active spring-damper | 16.68 kg | – |

| Mein Standort Front axle links | −83.2618 kg + 0.028098 × Lf, max + 0.05264 × W103 | 0.58 |

| Front axle passive spring-damper | 2.6178 kg + 0.0099122 × Lf, max | 0.48 |

| Front brakes | −4.857 kg + 0.01543 × mveh, gross | 0.68 |

| Further components air springs | 8.97 kg | – |

| Master cylinder | 4.59 kg | – |

| Parking brake actuators | 1.12 kg | – |

| Rear axle links (Multilink axle) | −65.917 kg + 0.0087817 × mveh, gross + 0.053902 × W103 | 0.43 |

| Rear axle links (Torsion beam axle) | −0.7229 kg + 0.021897 × mveh, gross | 0.56 |

| Rear brakes | 2.0549 kg + 0.58549 × mf, brakes | 0.64 |

| Rear axle passive spring-damper | 1.6343 kg + 0.0086881 × Lr, max | 0.53 |

| Rear axle passive spring-damper | 14.55 kg | – |

| Rear axle steering system | 11.46 kg | – |

| Rim weight (only one rim) | −13.0632 kg + 1.4047 × Drim, inches | 0.88 |

| Steering system | −10.8485 kg + 0.0023547 × mveh, gross + 0.0099135 × L101 | 0.79 |

| Tire weight (only one tire) | −16.8902 kg + 0.054111 × wtire + 0.023404 × Dtire | 0.86 |

Table A5.

Empirical models for the Powertrain module. The transmission mass is not calculated empirically but estimated with the semi-physical model described in [5]. The cell mass estimation is semi-physical and bases on the results of the package model.

Table A5.

Empirical models for the Powertrain module. The transmission mass is not calculated empirically but estimated with the semi-physical model described in [5]. The cell mass estimation is semi-physical and bases on the results of the package model.

| Module Powertrain | ||

|---|---|---|

| Component | Regression Model/Constant Value | R2 |

| Battery elec. components * (AWD vehicles) | 23 kg | – |

| Battery elec. components * (RWD/FWD vehicles) | 11 kg | – |

| Battery structural | 16.42 kg + 0.335 × Vbatt | 0.44 |

| Cells with module casing (Kcell2mod is cell dependent) | Kcell2mod × (Ebatt/Ecell, grav) | – |

| Coolant fluid (AWD vehicles) | 10.17 kg | – |

| Coolant fluid (RWD/FWD vehicles) | 7.39 kg | – |

| Electric Machine mounts (for 1 machine) | 11.52 kg | – |

| IM (with housing) | 29.3478 kg + 0.13049 × Tmax | 0.70 |

| Noise insulation (for 1 machine) | 1.42 kg | – |

| PMSM (with housing) | 23.145 kg + 0.088425 × Tmax | 0.34 |

| Powertrain cooling system (without coolant) | 11.1957 kg + 0.04334 × Pmax | 0.39 |

| Transmission fluid (for 1 gearbox) | 1.1 kg | – |

* The battery electrical components include battery management system, electric connections, cables, and battery junction box.

Table A6.

Empirical models for the Exterior module.

Table A6.

Empirical models for the Exterior module.

| Module Exterior | ||

|---|---|---|

| Component | Regression Model/Constant Value | R2 |

| Fenders (material: aluminum) | 5.12 kg | – |

| Fenders (material: steel) | 5.44 kg | – |

| Fog lights | 1.22 kg | – |

| Front bumper | −36.828 kg + 0.030762 × W103 | 0.46 |

| Front doors (material: aluminum) | −41.2364 kg + 0.023812 × H100 + 0.012925 × L101 | 0.69 |

| Front doors (material: steel) | −23.6024 kg + 0.010987 × H100 + 0.014954 × L101 | 0.72 |

| Halogen headlights | −18.2866 kg + 0.013802 × W103 | 0.46 |

| Hood (material: aluminum) | −72.4132 kg + 0.047314 × W103 | 0.52 |

| Hood (material: steel) | −78.9009 kg + 0.053745 × W103 | 0.62 |

| LED headlights | −24.5286 kg + 0.017902 × W103 | 0.41 |

| Rear bumper | −38.4403 kg + 0.028829 × W103 | 0.35 |

| Rear doors (material: aluminum) | −84.4604 kg + 0.022327 × H100 + 0.026756 × L101 | 0.60 |

| Rear doors (material: steel) | −46.0006 kg + 0.015526 × H100 + 0.017865 × L101 | 0.73 |

| Rear quarter glass (for SUV, hatchback) | −2.4013 kg + 0.0051943 × L105 | 0.34 |

| Rear quarter glass (for sedan) | 1.91 kg | – |

| Rear window (only for sedan) | 8.37 kg | – |

| Roof glass (case: glass fixed) | 21.44 kg | – |

| Roof glass (case: sliding glass) | 30.87 kg | – |

| Stoplights | 0.24 kg | – |

| Tailgate (material: aluminum) | −85.0098 kg + 0.053148 × W103 + 0.0090562 × H100 | 0.71 |

| Tailgate (material: steel) | −103.0405 kg + 0.055876 × W103 + 0.019184 × H100 | 0.75 |

| Taillights | −11.7713 kg + 0.0061357 × W103 + 0.002682 × H100 | 0.38 |

| Trunk (material: aluminum) | 19.95 kg | – |

| Trunk (material: aluminum) | 18.16 kg | – |

| Windshield (L101< 2493 mm) | 12.4 kg | – |

| Windshield (2493 mm < L101 ≤ 2640 mm) | 12.51 kg | – |

| Windshield (2640 mm < L101 ≤ 2750 mm) | 13.68 kg | – |

| Windshield (2750 mm < L101 ≤ 2927 mm) | 12.71 kg | – |

| Windshield (L101 > 2927 mm) | 13.66 kg | – |

| Wiper system with reservoir and fluids | 4.86 kg | – |

| Wipers | 3.6 kg | – |

| Xenon headlights | −22.3259 kg + 0.011882 × W103 + 0.005333 × H100 | 0.33 |

Table A7.

Empirical models for the Interior module.

Table A7.

Empirical models for the Interior module.

| Module Interior | ||

|---|---|---|

| Component | Regression Model/Constant Value | R2 |

| A/C refrigerant | 0.53 kg | – |

| A/C system | 16.2 kg | – |

| Airbag sensors and control unit | 0.44 kg | – |

| Brake pedal | 1.58 kg | – |

| Center console | −25.4609 kg + 0.012031 × L101 | 0.50 |

| Cross car beam | 6.25 kg | – |

| Curtain airbag | 2.48 kg | – |

| Dashboard | 7.82 kg | – |

| Drive pedal | 0.38 kg | – |

| Driver airbag | 1.07 kg | – |

| Front passenger airbag | 1.66 kg | – |

| Front seatbelt (one seatbelt) | 2.29 kg | – |

| Front seat (one seat) | −44.0809 kg + 0.025718 × W103 + 0.0072844 × L101 | 0.57 |

| Glovebox | 2.38 kg | – |

| Head up display | 1.49 kg | – |

| Heating system passenger compartment | −19.5455 kg − 0.00029838 × L101 + 0.019574 × W103 | 0.52 |

| Horn system | 0.51 kg | – |

| Infotainment | 1.11 kg | – |

| Instrument cluster (case: analog) | 1.26 kg | – |

| Instrument cluster (case: digital) | 1.66 kg | – |

| Interior trim parts | −261.2804 kg + 0.13939 × W103 + 0.0089323 × L103 | 0.83 |

| Knee airbag | 1.42 kg | – |

| Noise insulation (L101 ≤ 2750 mm) | 6.42 kg | – |

| Noise insulation (L101 > 2750 mm) | 12.76 kg | – |

| Rear passenger airbag | 0.79 kg | – |

| Rear seatbelt (one seatbelt) | 1.73 kg | – |

| Rear seats | −97.1243 kg + 0.09552 × W103 − 0.018138 × L101 | 0.47 |

Table A8.

Empirical models for the Electrics module.

Table A8.

Empirical models for the Electrics module.

| Module Electrics | ||

|---|---|---|

| Component | Regression Model/Constant Value | R2 |

| 12 V battery | 19.96 kg | – |

| 12 V battery cables | 0.33 kg | – |

| AC home charging cable | 2.33 kg | – |

| AC public charging cable | 2.16 kg | – |

| Additional charging plug components | 1.47 kg | – |

| Charging plug | 3.42 kg | – |

| DC-DC converter | 1.8787 kg + 0.0069707 × Ubatt | 0.75 |

| DC-DC converter supports | 0.65 kg | – |

| Fuse box | 1.11 kg | – |

| High voltage cables | −13.6378 kg + 0.0068436 × L101 | 0.33 |

| High voltage charger | 5.3459 kg + 0.10956 × Ebatt | 0.62 |

| Inverter | 9.13 kg | – |

| Inverter supports | 2.74 kg | – |

| Low voltage wiring | −71.1687 kg + 0.034458 × L101 | 0.62 |

| Other low voltage components | 4.22 kg | – |

Table A9.

Empirical models for the Accessories module. All the accessories (except for the pedestrian warning, which is always present for BEVs) are optional and can be activated/deactivated using the set of optional inputs shown in Table A1.

Table A9.

Empirical models for the Accessories module. All the accessories (except for the pedestrian warning, which is always present for BEVs) are optional and can be activated/deactivated using the set of optional inputs shown in Table A1.

| Module Accessories | ||

|---|---|---|

| Component | Regression Model/Constant Value | R2 |

| ADAS control unit (if present) | 1.03 kg | – |

| Adaptive Cruise Control (if present) | 0.37 kg | – |

| Blind Spot Monitoring (if present) | 0.5 kg | – |

| DC-DC converter | −0.075773 kg + 0.66284 × mwheel | 0.78 |

| Keyless entry (if present) | 0.25 kg | – |

| Lane Keeping Support (if present) | 0.18 kg | – |

| Night vision camera (if present) | 1.02 kg | – |

| Park assist (if present) | 0.43 kg | – |

| Pedestrian warning | 0.79 kg | – |

| Phone connectivity (if present) | 0.4 kg | – |

| Toolbox (if spare tire present) | 5.25 kg | – |

| Toolbox (if spare tire not present) | 3.34 kg | – |

| Tow hitch system (if present) | 21.66 kg | – |

| Trunk opening assist (if present) | 0.24 kg | – |

Appendix C. Employed Vehicles for the Parametric Mass Model

Table A10.

Overview of the employed vehicles for the parametric mass model (Part 1/6).

Table A10.

Overview of the employed vehicles for the parametric mass model (Part 1/6).

| Brand | Model Variant | ADAC Model Series |

|---|---|---|

| Acura | MDX 3.5 SOHC Tech | - |

| Alfa Romeo | 147 1.9l JTD Multijet | 147 (937) (January 2005–August 2006) |

| Alfa Romeo | Giulia 2.0 Veloce Q4 | Giulia (952) (from June 2016) |

| Alfa Romeo | Mito 1.4 T Elegante | MiTo (955) (September 2008–October 2013) |

| Alfa Romeo | Stelvio 2.2 JTD Q4 Lusso | Stelvio (949) (from April 2017) |

| Audi | A1 1.4 TFSi S-Tronic Ambition | A1 (8X) (July 2010–November 2014) |

| Audi | A3 1.4 TFSi Attraction | A3 (8P) (July 2008–Mai 2012) |

| Audi | A3 1.4 e-tron | A3 (8V) Sportback e-tron (January 2015–Mai 2016) |

| Audi | A4 1.4 TFSI Base | A4 (B9) limousine (November 2015–August 2018) |

| Audi | A5 3.0 TDi | A5 (8T) Coupé (June 2007–July 2011) |

| Audi | A6 55 TFSi e S-Line | A6 (C8) Limousine (from July 2018) |

| Audi | A7 2.8 FSi quattro | A7 (4G) Sportback (October 2010–Mai 2014) |

| Audi | A7 3.0T quattro | A7 (4G) Sportback (August 2014–December 2017) |

| Audi | A8 4.2 FSi | A8 (D4) (January 2010–October 2013) |

| Audi | A8 3.0 TFSI quattro | A8 (D5) (from November 2017) |

| Audi | e-tron 55 quattro Edition One | e-tron (GE) (from March 2019) |

| Audi | Q2 1.4 TFSI COD Design | Q2 (GA) (from October 2016) |

| Audi | Q3 45 TFSI quattro | Q3 (F3) (from December 2018) |

| Audi | Q5 2.0 TDI quattro | Q5 (FY) (January 2017–August 2020) |

| Audi | Q5 2.0T Quattro S | Q5 (FY) (January 2017–August 2020) |

| Audi | Q7 3.0 TFSI S-Line | Q7 (4M) (June 2015–June 2019) |

| Audi | Q8 quattro Prestige | Q8 (4M) (from August 2018) |

| BAIC BJEV | EU5 Jing Cai R500 ZhiFeng | - |

| BAIC BJEV | EX360 Fashion 2018 | - |

| BMW | 1 Series 118i Advantage | 1er-Reihe (F40) (from September 2019) |

| BMW | 2 Series 225xe | 2er-Reihe Active Tourer (F45) (September 2014–February 2018) |

| BMW | 3 Series 320d | 3er-Reihe (G20) Limousine |

| BMW | 3 Series 330e Business Plus | 3er-Reihe (G20) Limousine |

| BMW | 5 Series 520i | 5er-Reihe (G30) Limousine |

| BMW | 5 Series 530e iPerformance | 5er-Reihe (G30) Limousine |

| BMW | 7 Series 730 i | 7er-Reihe (E65/E66) (April 2005–November 2008) |

| BMW | 7 Series 730d | 7er-Reihe (G11/G12) (October 2015–January 2019) |

| BMW | i3 REx | I3 (from November 2017) |

| BMW | X1 sDrive 18d | X1 (F48) (October 2015–Mai 2019) |

| BMW | BMW X1 xDrive 25Le | - |

| BMW | X3 xDrive 20d | X3 (G01) (from October 2017) |

| BMW | X5 2.0 xDrive40e | X5 (G05) (from November 2018) |

| BMW | X5 xDrive 40i | X5 (G05) (from November 2018) |

| BYD | e5 300 Comfort | - |

| BYD | e6 Jingying Ban | - |

| BYD | Song DM 1.5 comfort | - |

| BYD | Tang 2.0 Ultimate | - |

Table A11.

Overview of the employed vehicles for the parametric mass model (Part 2/6).

Table A11.

Overview of the employed vehicles for the parametric mass model (Part 2/6).

| Brand | Model Variant | ADAC Model Series |

|---|---|---|

| BYD | Tang EV 600D ChuangLing | - |

| Cadillac | CT6 3.0 Platinum | CT6 (November 2016–December 2018) |

| Cadillac | CTS Luxury 3.6 | CTS (II) Limousine (October 2007–November 2013) |

| Chevrolet | Bolt EV Premier | - |

| Chevrolet | Blazer 3.6L Premier AWD | - |

| Chevrolet | Camaro 2SS Coupe | Camaro (VI) Coupé (June 2016–August 2019) |

| Chevrolet | Equinox 3.0 | - |

| Chevrolet | Suburban 5.3 L Premier | - |

| Chevrolet | Tahoe LTZ 5.3 Ecotec 3 | - |

| Chevrolet | Traverse 3.6 High Country AWD | - |

| Chevrolet | Trax LTZ 1.4 | - |

| Chevrolet | Volt 1.5 Premier | - |

| Chrysler | Pacifica Touring L | - |

| Chrysler | Pacifica Hybrid Limited | - |

| Citroën | C3 Aircross 1.6 HDI Feel | C3 Aircross (from October 2017) |

| Citroën | C4 Grand Picasso 2.0 HDI Exclusive | Grand C4 Picasso (I) (October 2006–August 2013) |

| Citroën | DS5 Hybrid4 So Chic | DS 5 (March 2012–Mai 2015) |

| Dacia | Duster 1.2 TCe Essentiel | Duster (II) (from January 2018) |

| Dacia | Lodgy 1.5 dci Laureate | Lodgy (June 2012–March 2017) |

| Denza | EV Executive | - |

| Dodge | Challenger R/T 6.4 | Challenger (from July 2014) |

| DS | 3 Crossback | DS3 (from April 2019) |

| DS | 7 Crossback 1.5 BlueHDI Executive | DS7 (from February 2018) |

| Dodge | Durango Crew 3.6 | - |

| Dodge | Journey 3.6 Crew | - |

| Fiat | 500 0.9 Twin Air Lounge | 500 (312) (from July 2015) |

| Fiat | 500 L Twin Air Lounge | 500L (199) (October 2012–July 2017) |

| Fiat | Grande Punto 1.2 Dynamic | Grande Punto (199) (October 2005–Mai 2010) |

| Fiat | Tipo 1.6 Multijet Lounge | Tipo (356) (Mai 2016–November 2020) |

| Ford | Edge SEL 2.0 Ecoboost | Edge (June 2016–August 2018) |

| Ford | Expedition Limited 4 × 4 | - |

| Ford | Explorer 3.0L Platinum 4WD 2019 | Explorer (VI) (from January 2020) |

| Ford | Explorer 3.5 2011 | - |

| Ford | Ecosport 1.5L (D) Titanium Plus | EcoSport (from December 2017) |

| Ford | Fiesta 1.0 EcoBoost Titanium | Fiesta (VIII) (from June 2017) |

| Ford | Flex 3.5 | - |

| Ford | Focus 1.6 TDCi Titanium | Focus (II) (November 2004–January 2008) |

| Ford | Focus 1.5 EcoBoost Vignale | Focus (IV) (from September 2018) |

| Ford | Galaxy 1.8 TDCi Ghia | Galaxy (II) (July 2006–April 2010) |

| Ford | Grand C-Max 2.0 TDCi Titanium | Grand C-MAX (II) (November 2010–Mai 2015) |

| Ford | Ka+ 1.2 Ti-VCT Essential | Ka+ (October 2016–March 2018) |

| Ford | Mustang I4 Coupe 2.3L | Mustang Fastback (June 2015–February 2018) |

| Geometry | A Standard range power edition | - |

Table A12.

Overview of the employed vehicles for the parametric mass model (Part 3/6).

Table A12.

Overview of the employed vehicles for the parametric mass model (Part 3/6).

| Brand | Model Variant | ADAC Model Series |

|---|---|---|

| GMC | Arcadia 3.6 Denali | - |

| Honda | Civic 1.0 i-VTEC Executive | Civic (X) (from March 2017) |

| Honda | Clarity Plug-In TRG | - |

| Honda | CR-V 2.0 Hybrid Comfort | CR-V (V) (from January 2018) |

| Honda | Mobilio RS | - |

| Honda | Odyssey Elite | - |

| Honda | Pilot EX Sensing 3.5 | - |

| Hyundai | Ioniq 1.6 Plug-in | IONIQ (AE) Hybrid (October 2016–July 2019) |

| Hyundai | JX 35 3.5 | - |

| Hyundai | Kona electric Executive 64 kWh | Kona (OS) Elektro (from August 2018) |

| Hyundai | Nexo Fuel Cell Limited | Nexo (FE) (from August 2018) |

| Hyundai | Santa Fe 2.2 CRDi Pack Premium | Santa Fe (DM) (October 2012–November 2015) |

| Hyundai | Santa Fe Ultimate 2.0T AWD | - |

| Hyundai | Tucson 1.7 CRDi DCT S-Edition | Tucson (TL) (July 2015–July 2018) |

| Jaguar | E-Pace 2.0 SE P300 AWD | E-Pace (X540) (January 2018–October 2020) |

| Jaguar | F-Pace 2.0d AED Prestige | F-Pace (X761) (from January 2016) |

| Jaguar | I-Pace EV 400 First Edition | I-Pace (X590) (from October 2018) |

| Jaguar | XE 2.0 25t Prestige | XE (X760) (June 2015–February 2019) |

| Jaguar | XJ L 3.0D Portfolio | XJ (X351) (Mai2010–September 2015) |

| Jeep | Grand Cherokee 3.6 VVT Overland 4 × 4 | Grand Cherokee (WK) (December 2010–June 2013) |

| Jeep | Grand Cherokee Laredo E 4X4 3.6 | Grand Cherokee (WK) (June 2013–December 2016) |

| Jeep | Renegade Limited 2.4 | Renegade (BU) (October 2014–August 2018) |

| Jeep | Renegade 4 × e | Renegade (BU) (from September 2018) |

| Kia | Carens 1.7 CRDi Active | Carens (RP) (Mai 2013–October 2016) |

| Kia | Niro EV EX Premium | e-Niro (DE) (from December 2018) |

| Kia | Sedona SX 3.3 | - |

| Kia | Sorento LX 3.3 | - |

| Kia | Sorento 3.5 EX | - |

| Kia | Soul! | Soul (PS) (November 2016–March 2019) |

| Kia | Sportage 2.0 CRDi BVA AWD Premium | Sportage (QL) (January 2016–June 2018) |

| Kia | Stinger GT2 AWD | Stinger (CK) (from October 2017) |

| Kia | Telluride SX V6 AWD | - |

| Land Rover | Discovery HSE Si6 | Discovery (V) (March 2017–November 2020) |

| Land Rover | Range Rover Supercharged LWB 5.0 | Range Rover (IV) (January 2013–October 2017) |

| Land Rover | Range Rover Velar First Edition | Range Rover Velar (from July 2017) |

| Lexus | RX 350 3.5 | RX (AL2) (January 2016–August 2019) |

| Lexus | GS 450h F-Sport | GS (L10) (June 2012–September 2015) |

| Lincoln | Aviator 3.0L GR Touring Hybrid | - |

| Maxus | EG10 Luxury | - |

| Mazda | 3 2.0 Skyactiv-G M Hybrid Selection | 3 (BP) (from March 2019) |

| Mazda | CX-3 1.5 SkyActiv-D Dynamique | CX-3 (DK) (June 2015–June 2018) |

| Mazda | CX-30 2.0 Skyactiv-X M Hybrid | CX-30 (from September 2019) |

| Mazda | CX-9 2.5 T Sport | - |

Table A13.

Overview of the employed vehicles for the parametric mass model (Part 4/6).

Table A13.

Overview of the employed vehicles for the parametric mass model (Part 4/6).

| Brand | Model Variant | ADAC Model Series |

|---|---|---|

| Mazda | CX-9 2.5 T Sport | - |

| Mercedes | A-Class 200 AMG Line | A-Klasse (177) (from Mai 2018) |

| Mercedes | A-Class A250e AMG Line | A-Klasse (177) Limousine (from March 2019) |

| Mercedes | C-Class 180 | C-Klasse (205) Limousine (March 2014–April 2018) |

| Mercedes | E-Class 200 | E-Klasse (213) Limousine (April 2016–June 2020) |

| Mercedes | EQC 400 4MATIC 1886 Edition | EQC (293) (from June 2019) |

| Mercedes | GL-Class 450 3.0 4MATIC | GL-Klasse (X166) (July 2012–November 2015) |

| Mercedes | GLC 220d 4MATIC | GLC (253) (June 2015–April 2019) |

| Mercedes | GLE 550e 3.0 4Matic | GLE (166) (August 2015–October 2018) |

| Mercedes | GLE-Class 450 4MATIC AMG Line | GLE (167) (from March 2019) |

| Mercedes | M-Class ML350 3.5 4MATIC | M-Klasse (166) (July 2011–April 2015) |

| Mercedes | S-Class 350d | S-Klasse (222) Limousine (Mai 2013–Mai 2017) |

| Mini | Cooper D 1.5 | MINI (F56) 3-Türer (March 2014–February 2018) |

| Mitsubishi | Outlander PHEV GT S-AWC | Outlander (III) Plug-In Hybrid (October 2015–August 2018) |

| Nio | ES8 Base | - |

| Nissan | Altima 2.5 Platinum AWD | - |

| Nissan | Juke 1.0 DIG-T Tekna | Juke (F16) (from December 2019) |

| Nissan | Leaf Tekna | Leaf (ZE1) (from January 2018) |

| Nissan | Micra 0.9 IG-T Tekna | Micra (K14) (from March 2017) |

| Nissan | Pathfinder S 3.5 4 × 4 | Pathfinder (R51) (April 2010–August 2015) |

| Nissan | Qashqai + 2 2.0 CVT All-Mode | Qashqai + 2 (J10) (March 2010–October 2014) |

| Nissan | Quest 3.5 SV | - |

| Nissan | Rogue SV 2.5 | - |

| Opel | Adam 1.4 EcoFlex Jam | ADAM (January 2013–Mai 2019) |

| Opel | Ampera-e | Ampera-E (July 2017–June 2019) |

| Opel | Astra 1.4T Innovation | Astra (J) (June 2012–June 2015) |

| Opel | Corsa 1.0 Ecotec Innovation | Corsa (E) (December 2014–Mai 2019) |

| Opel | Grandland X 1.6 eCDTi Innovation | Grandland X (ab October 2017) |

| Opel | Insignia 2.0 CDTi Selection | Insignia (A) (November 2008–June 2013) |

| Opel | Zafira Tourer 2.0 CDTi Innovation | Zafira (C) Tourer (January 2012–June 2016) |

| Peugeot | 208 e GT | e-208 (II) (from January 2020) |

| Peugeot | 208 1.2 Puretech GT Line | 208 (II) (from December 2019) |

| Peugeot | 308 1.2 PureTech Allure | 308 (II) (from June 2017) |

| Peugeot | 3008 1.6 GT Hybrid4 300 | 3008 (II) (October 2016–September 2020) |

| Peugeot | 508 1.6 Puretech GT | 508 (II) Limousine (from October 2018) |

| Porsche | 911 3.8 Carrera S | 911 (991) Carrera Coupé (December 2011–October 2015) |

| Porsche | Cayenne Turbo | Cayenne (955) Turbo (September 2002–December 2006) |

| Porsche | Cayenne S Hybrid | Cayenne (958) (October 2014–December 2017) |

| Porsche | Cayenne e-hybrid | Cayenne (9YA) (from November 2017) |

| Porsche | Panamera 4.8 S | Panamera (970) (September 2009–April 2013) |

| Renault | Captur 1.5L (D) k9 kdci Platine | Captur (I) (March 2017–December 2019) |

| Renault | Clio 1.0 TCe Intense | Clio (V) (from September 2019) |

| Renault | Espace 1.6 dCi Intense | Espace (V) (April 2015–February 2020) |

Table A14.

Overview of the employed vehicles for the parametric mass model (Part 5/6).

Table A14.

Overview of the employed vehicles for the parametric mass model (Part 5/6).

| Brand | Model Variant | ADAC Model Series |

|---|---|---|

| Renault | Kadjar 1.2 TCE Intens | Kadjar (Mai 2015–December 2018) |

| Renault | Mégane | Mégane (IV) (March 2016–Mai 2020) |

| Renault | Scenic Grand 1.5 dCi Hybrid | Grand Scénic (IV) (from November 2016) |

| Renault | Talisman 1.6 dCi Initiale Paris | Talisman Limousine (February 2016–June 2020) |

| Renault | Twingo 1.2 GT | Twingo (II) (September 2007–December 2011) |

| Renault | Zoe R135 Edition One | Zoe (from October 2019) |

| Roewe | Marvel X AWD | - |

| Roewe | RX5 EV400 | - |

| Seat | Arona 1.0 TSI Style | Arona (KJ) (from November 2017) |

| Seat | Ateca 2.0 TDI 4Drive Excellence | Ateca (5FP) (from August 2016) |

| Renault | Kadjar 1.2 TCE Intens | Kadjar (Mai 2015–December 2018) |

| Renault | Mégane | Mégane (IV) (March 2016–Mai 2020) |

| Renault | Scenic Grand 1.5 dCi Hybrid | Grand Scénic (IV) (from November 2016) |

| Renault | Talisman 1.6 dCi Initiale Paris | Talisman Limousine (February 2016–June 2020) |

| Renault | Twingo 1.2 GT | Twingo (II) (September 2007–December 2011) |

| Renault | Zoe R135 Edition One | Zoe (from October 2019) |

| Roewe | Marvel X AWD | - |

| Roewe | RX5 EV400 | - |

| Seat | Arona 1.0 TSI Style | Arona (KJ) (from November 2017) |

| Seat | Ateca 2.0 TDI 4Drive Excellence | Ateca (5FP) (from August 2016) |

| Seat | Ibiza 1.0 Eco TSI Xcellence | Ibiza (KJ) (from June 2017) |

| Škoda | Kodiaq 1.4 TSI Style | Kodiaq (from March 2017) |

| Škoda | Octavia Combi 1.6 TDi 4x4 Elegance | Octavia (III) Combi (March 2013–December 2016) |

| Škoda | Yeti 2.0 TDi Experience | Yeti (August 2009–October 2013) |

| Smart | ForTwo 1.0 Prime | fortwo (453) coupé (November 2014–June 2019) |

| Subaru | Ascent 2.4 L Touring | - |

| Suzuki | Ertiga | - |

| Tesla | Model 3 Long Range RWD | Model 3 (from March 2019) |

| Tesla | Model X P90D | Model X (from June 2016) |

| Tesla | Model Y Performance | Model Y (from January 2021) |

| Tesla | Model S 60 | Model S (August 2013–April 2016) |

| Toyota | Auris 126 D4D Linea Terra | Auris (E15) (March 2007–March 2010) |

| Toyota | Camry Hybrid | Camry (XV70) Limousine (from March 2019) |

| Toyota | C-HR 1.2 T Dynamic | C-HR (X10) (October 2016–November 2019) |

| Toyota | C-HR 1.8 Hybrid | C-HR (X10) (October 2016–November 2019) |

| Toyota | C-HR EV Topline | - |

| Toyota | Corolla 2.0 Hybrid Collection | Corolla (E21) (from April 2019) |

| Toyota | Corolla Verso 2.0 D4D Linea Sol | Corolla Verso (R1) (Mai 2004–June 2007) |

| Toyota | Fortuner 2.8 L (D) Sigma-4 6MT | - |

| Toyota | Highlander Hybrid LE-L4 AWD | - |

| Toyota | iQ + 1.0 | iQ (AJ1) (January 2009–Mai 2014) |

| Toyota | Mirai | Mirai (AD1) (from December 2015) |

| Toyota | Prius 1.8 PHV | Prius (XW5) Plug-In (from March 2017) |

Table A15.

Overview of the employed vehicles for the parametric mass model (Part 6/6).

Table A15.

Overview of the employed vehicles for the parametric mass model (Part 6/6).

| Brand | Model Variant | ADAC Model Series |

|---|---|---|

| Toyota | RAV4 Limited AWD | RAV4 (XA4) (January 2016–December 2018) |

| Toyota | RAV4 2.5 Hybrid Lounge | Rav4 (XA5) (from January 2019) |

| Toyota | Sienna LTD | - |

| Volkswagen | Atlas V6 SEL w/4Motion | - |

| Volkswagen | Golf VII e-Golf | Golf (VII) e-Golf (April 2017–Mai 2020) |

| Volkswagen | Golf VII 2.0 TDi DSG Highline | Golf (VII) (November 2012–December 2016) |

| Volkswagen | Golf Alltrack TSI 4Motion | Golf (VII) Alltrack (March 2017–April 2020) |

| Volkswagen | Golf VII GTE | Golf (VII) GTE (December 2014–October 2016) |

| Volkswagen | Golf VIII 1.5 eTSi Style 1st Edition II | Golf (VIII) (from December 2019) |

| Volkswagen | Jetta 1.4 TSI SEL Premium | - |

| Volkswagen | Jetta 2.0 TDi Comfortline | Jetta (IV) (January 2011–August 2014) |

| Volkswagen | Passat 1.9 TDi | Passat (B6) Limousine (March 2005–October 2010) |

| Volkswagen | Passat 1.4 TSi ACT Comfortline | Passat (B8) Limousine (October 2014–March 2019) |

| Volkswagen | Passat Variant 2.0 TDi SCR Highline | Passat (B8) Variant (October 2014–Mai 2019) |

| Volkswagen | Phaeton 3.0 TDi | Phaeton (Mai 2002–Mai 2007) |

| Volkswagen | Polo 1.0 TSi Highline | Polo (VI) (from November 2017) |

| Volkswagen | T-Cross 1.0 TSi Style | T-Cross (from April 2019) |

| Volkswagen | Tiguan 1.4 TSi 4Motion Sport | Tiguan (I) (October 2007–February 2011) |

| Volkswagen | Tiguan 2.0 TDi 4Motion Highline | Tiguan (II) (April 2016–June 2020) |

| Volkswagen | Tiguan SEL TSI | Tiguan (II) (April 2016–June 2020) |

| Volkswagen | Touareg V6 TDI | Touareg (II) (April 2010–August 2014) |

| Volkswagen | Touran 1.6 TDi SCR Comfortline | Touran (II) (from September 2015) |

| Volkswagen | Touran 2.0 TDi Highline | Touran (I) (August 2010–April 2015) |

| Volkswagen | T-Roc 1.5 TSi Sport | T-Roc (from November 2017) |

| Volkswagen | Up! e-Up! | up! e-up! (November 2013–June 2016) |

| Volkswagen | Up! 1.0 Take Up! | up! (December 2011–June 2016) |

| Volvo | S60 2.4 D5 Summum | S60 (F) (September 2010–July 2013) |

| Volvo | S90 2.0 D4 Momentum | S90 (P) (July 2016–March 2020) |

| Volvo | XC40 T3 2WD | XC40 (X) (from February 2018) |

| Volvo | XC60 2.0 T8 Twin Engine AWD | XC60 (U) (from July 2017) |

| Volvo | XC90 T8 Inscription | XC90 (L) (from January 2015) |

| Weltmeister | EX5 | - |

| WEY | P8 2.0 Flagship | - |

| Xpeng | G3 520 ZunXiang | - |

| Zotye | E200 | - |

References

- Setting CO2 Emission Performance Standards for New Passenger Cars and for New Light Commercial Vehicles, and Repealing Regulations (EC) No 443/2009 and (EU) No 510/2011: EC 2019/631. 2019. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32019R0631 (accessed on 13 June 2020).

- ICCT. CO2 Emission Standards for Passenger Cars and Light-Commercial Vehicles in the European Union. 2019. Available online: https://theicct.org/publications/ldv-co2-stds-eu-2030-update-jan2019 (accessed on 12 February 2020).

- Löbberding, H.; Wessel, S.; Offermanns, C.; Kehrer, M.; Rother, J.; Heimes, H.; Kampker, A. From Cell to Battery System in BEVs: Analysis of System Packing Efficiency and Cell Types. World Electr. Veh. J. 2020, 11, 77. [Google Scholar] [CrossRef]