An Experimental Framework for 5G Wireless System Integration into Industry 4.0 Applications

Abstract

:1. Introduction

2. Learnings from Industry and Related Framework Design Considerations

- The manufacturing industry, and especially the small and medium enterprises, has little or no experience with wireless communications. In general, some experience with Wi-Fi (non-optimized in most cases) was observed, but not with 4G, 5G, and the other wireless technologies. This is mainly due to the fact that, until recently, products and business models for their usage in factory were practically nonexistent. Thus, an initial learning process should be expected when introducing these technologies in manufacturing environments.

- -

- Design consideration: a common language and understanding needs to be established. Each factory and operational teams are different from others so, ideally, this should be done on an individual factory and use case basis. Benchmarking the performance of the wireless solution, not only over 5G, but also over other technologies such as Wi-Fi should help in improving the understanding of the different wireless operational possibilities. In this case, disseminating performance test results to manufacturing experts is an important aspect to consider.

- Deploying a wireless system is typically not considered in the business models, and is generally perceived as a cost and not as benefit. Moreover, due to the lack of experience with wireless communications, in most cases, a large degree of skepticism about the reliability, capabilities and potential of these technologies was detected.

- -

- Design consideration: In order to build trust and convince the manufacturing industry about the suitability and the potential benefits of wireless applied to production, live demonstrations of wireless-operated industrial use cases are encouraged. This could take form of trials in factories or demos in lab environments, where wireless-integrated production concepts are shown to manufacturing experts.

- In general, current wired industrial factory control networks are not optimized for direct integration with wireless technologies. Integration gaps range from a non-optimal topology, to the use of non-IP traffic or transmission modes, such as broadcast, that may not be directly enabled/supported by wireless technologies. To fully exploit the benefits of wireless applied to industrial production, a re-architecture of such control networks will be an essential step.

- -

- Design consideration: hardware and software prototypes should be flexible enough to cope with modern (IP-based) and old (non-IP-based) communication protocols. Furthermore, the prototypes should be flexible enough to support different control architectures and modes of operation such as infrastructure mode (where end-devices communicate to a centralized entity or controller) and device-to-device communication (where the end-devices can communicate directly among themselves).

- There is a huge hype among the manufacturing industry about cloud control and cloud monitoring, which lead to a noticeable tendency of installing such systems within their production equipment without a proper performance impact assessment, as high capacity communication links available from each device to the cloud are taken for granted. However, this might not always be true, especially when operating over wireless, which could lead to some operational problems.

- -

- Design consideration: a proper data traffic analysis should be done before proceeding with the integration of an application with wireless in order to identify all potential communication flows in a given system. Further, a performance evaluation should be done after the wireless solution is deployed, to ensure operational correctness.

- Legacy is extremely important. Not all companies will have the chance to invest in the most advanced solutions, but still introducing a few wireless components for specific communication needs might result in a considerable gain for them.

- -

- Design consideration: hardware and software prototypes should be able to transport over wireless legacy communication protocols that are conceived for industrial wired setups.

3. Experimental Framework for 5G Integration

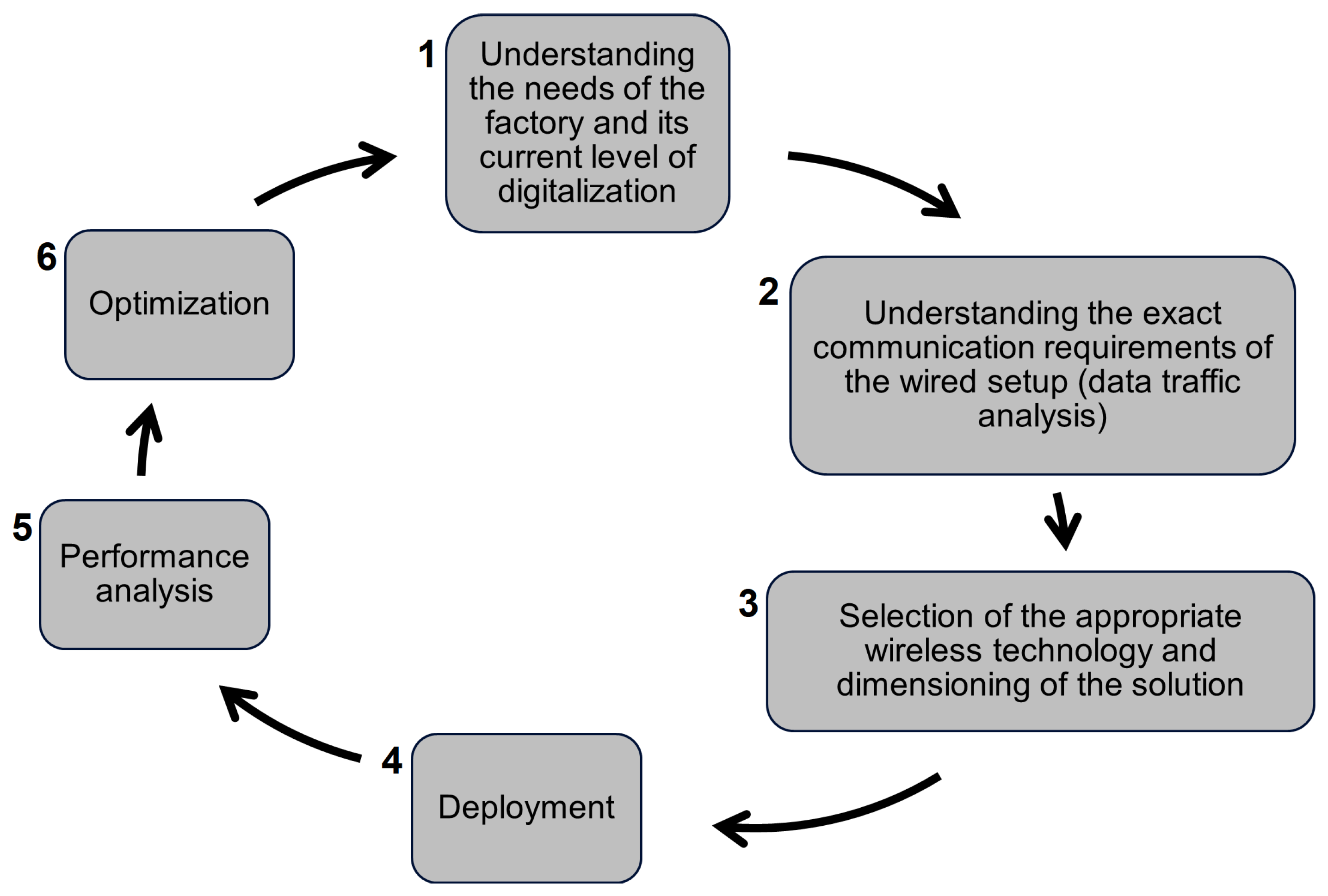

3.1. Industrial Automation Operational Flow

- STEP 1.

- Understanding the needs of the factory and its current level of digitalization: the factory is visited in order to get a good overview of overall operations and digitalization status. It is important, that during a first visit, common ground and common languages are established. Conversations are typically initiated with management, digitalization, research and innovation responsibles to learn about their views on 5G, the specific applications that they envision to run in their factories in the future, but also about those current applications that they would like to operate over wireless for improving the current production systems. Conversations are also held with IT responsibilities in order to understand the current wired and Wi-Fi network architectures, office and production network splits and network performance. With this information, we can feed the following steps of the operational flow with realistic information about the specific operational conditions required.

- STEP 2.

- Understanding the exact communication requirements of the wired setup (data traffic analysis): in this step, that also takes place at the factory, a specific targeted I4.0 application is selected and the production area is visited—ideally, together with someone from both the IT and manufacturing departments, in order to have an overview of the exact machinery setting and its control network architecture. Further, a data traffic analysis is performed over relevant interfaces, candidates to be potentially operated over 5G, to understand and characterize the exact communication flows, protocols used, and the volume of data in different parts of the industrial system. This step is essential, as similar applications in different factories might implement very different control communication systems, and thus the more detailed the information, the better. It is important to check with the IT or production engineers about the control-loop latencies implemented in their systems, as well as survival times (sometimes called control failure times). These two parameters, together with the control architectures and the traffic statistics (throughput, packet sizes and inter-packet times) are essential information for evaluating whether the chosen application would be suitable for operation over 5G.

- STEP 3.

- Selection of the appropriate wireless technology and dimensioning of the solution: based on the information collected in the previous step, we can analyze the suitability of 5G or other wireless technologies for coping with the targeted application and guide the factory about the most appropriate one. These could be done by simple “pen and paper” exercises based on requirements and wireless capabilities or via simulation/emulation. In general, the decision will be made according to capacity and control-loop latency requirements. High throughput time-critical applications could only be supported by 5G, while those applications that are delay-tolerant could be supported by 5G or other alternative technologies such as 4G or Wi-Fi (under very specific and optimized operational conditions) [9]. It should be noted that some of the most demanding applications might still not be supported by 5G, e.g., applications requiring sub-ms latencies, and in that case, legacy wired setups should still be used.

- STEP 4.

- Deployment: once the wireless technology has been selected, i.e., 5G, the practical system integration begins. One or more of the relevant interfaces identified in STEP 2 are selected for integration of a 5G interface into them. This process is normally not straight forward as the IT integration itself, and the debugging of connectivity and 5G-integrated interface routing schemes, turns typically into a quite time-consuming task. Ideally, at the end of this step, the result is a fully functional 5G-integrated I4.0 application, both in terms of hardware and software, ready to be tested in operational conditions.

- STEP 5.

- Performance analysis: the fully functional 5G-integrated industrial application is thoroughly tested. In this step, typically, reliability tests are executed by monitoring the correct operation of the industrial system during a long period of time (could be from several hours to several days). Performance tests are also done, looking at the communication efficiency in terms of, for example, control-loop latency performance. Other parameters such as throughput or time between failures could be monitored, ensuring that the outcome of the testing is well aligned with the methodology defined in [12], guaranteeing that a fair comparison with future results reported by Industry for similar use cases will possible. Further, the industrial production efficiency could be evaluated, by mapping the empirical wireless performance to the operation of the underlying industrial process [13]. Scalability tests could also be performed, in case they are relevant for the targeted use case. Ideally, similar tests should be done over other suitable wireless technologies (i.e., 4G, Wi-Fi), in order to benchmark their performance with the 5G one and estimate the potential gains achieved by operating the application over 5G.

- STEP 6.

- Optimization: this final step deals with the potential enhancements in those areas of the system identified based on the analysis of the outcome of the different performance tests. Depending on the results, optimizations could take place in different domains: at the machinery side, in case it is detected that an optimized performance would be feasible by a slight re-architecture of the industrial control network or by a slight tuning of parameters in the control communication protocols; at the 5G network side, by optimizing the radio interface for the specific targeted application by tuning of 5G configuration parameters; or at the 5G-application integration point, in case it is identified that changes in the integration hardware or software are needed.

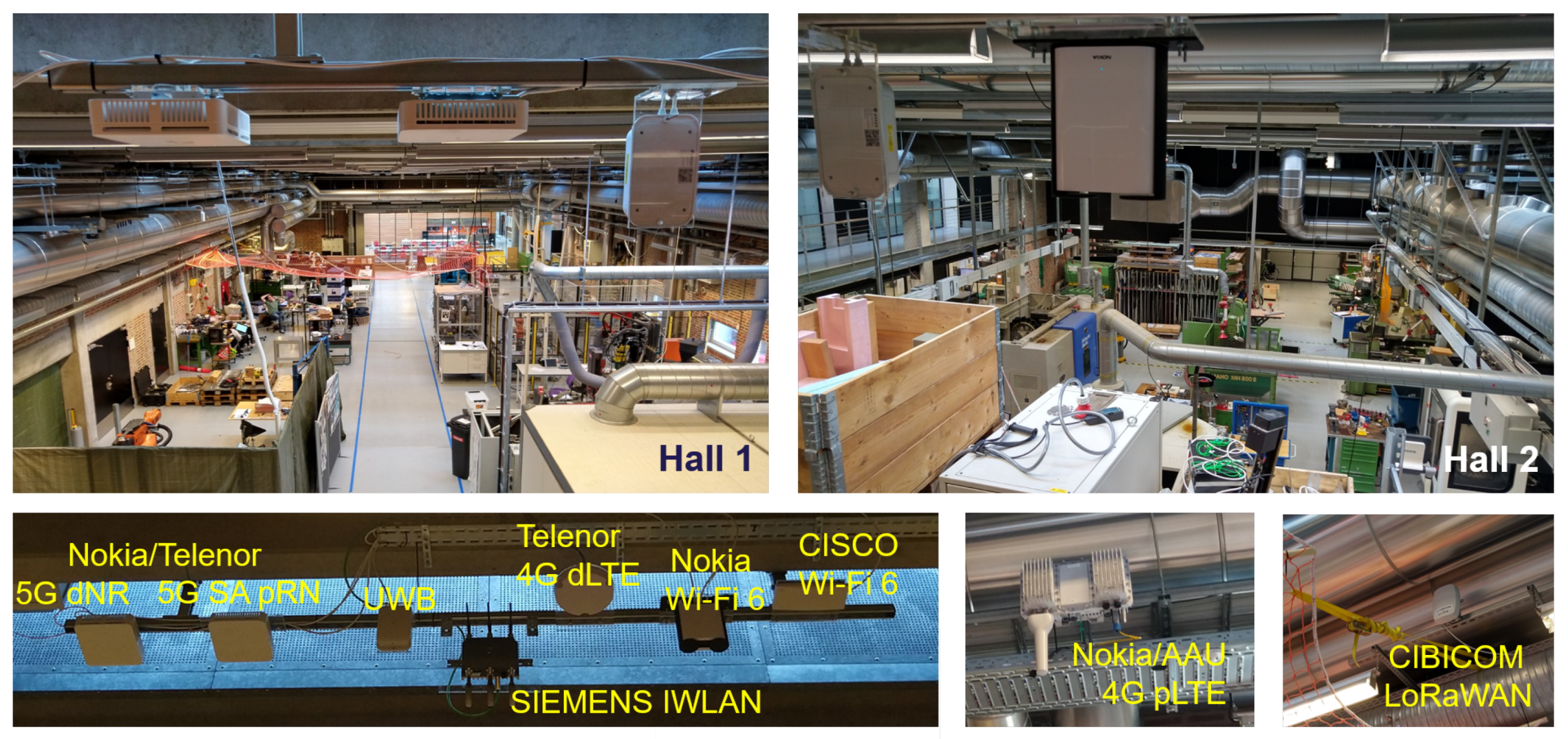

3.2. Industrial Research Lab Facilities

- 1× 5G NR private network (5G pNR), 3 cells.

- 1× 5G NR dedicated operator network slice (5G dNR), 3 cells.

- 2× 4G LTE private networks (4G pLTE), 3 cells each.

- 1× 4G LTE dedicated operator network slice (4G dLTE), 3 cells.

- 2× Wi-Fi 6 networks, 3 cells each.

- 1× industrial wireless LAN network (IWLAN), 3 cells.

- 1× LoRaWAN network, 1 gateway.

- 1× ultra-wideband radio positioning system (UWB), 16 anchors.

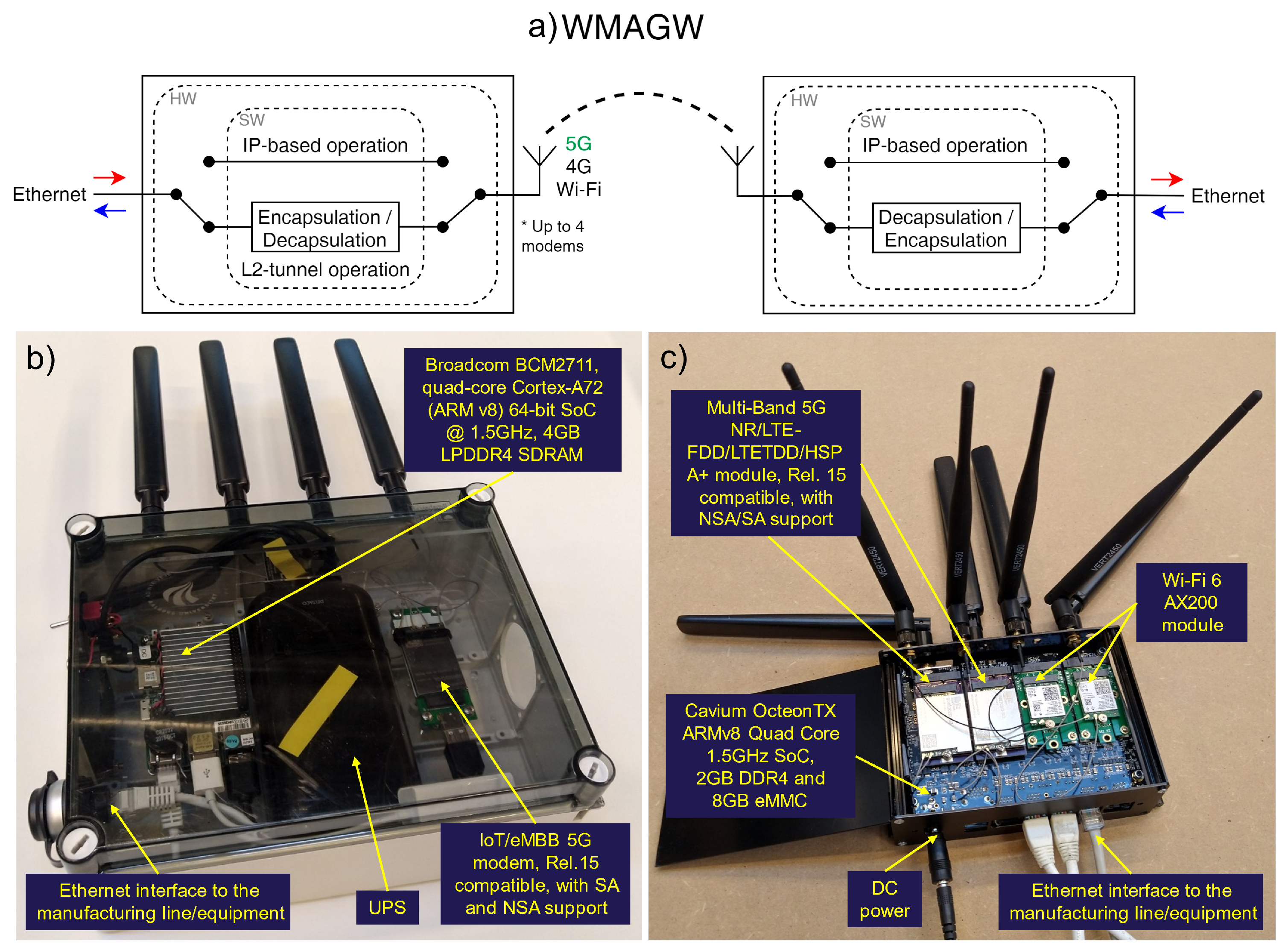

3.3. 5G Hardware and Software Prototyping Tools

- Network traffic sniffer (NTS): intended to log all data passing through an ethernet interface and extract relevant network traffic statistics.

- 5G Emulator (5GE): aimed at introducing controlled delays into an ethernet link to imitate the communication performance of a wireless technology, e.g., 5G.

- Wireless multi-access gateway (WMAGW): designed as the main integration element to enable the wireless transport, e.g., over 5G, of data traffic from a given ethernet-based interface.

| Prototype | Hardware | Software | Other Characteristics |

|---|---|---|---|

| NTS | Raspberry Pi 4 Model B [27] | tcpdump 4.99 [28] | HW TAP functionality |

| (v2) | Broadcom BCM2711, QC@1.5 GHz/4 GB | Network transparent | |

| OS: Raspberry Pi OS Lite | |||

| NIC: Realtec USB3.0/Gbps ethernet adapter | |||

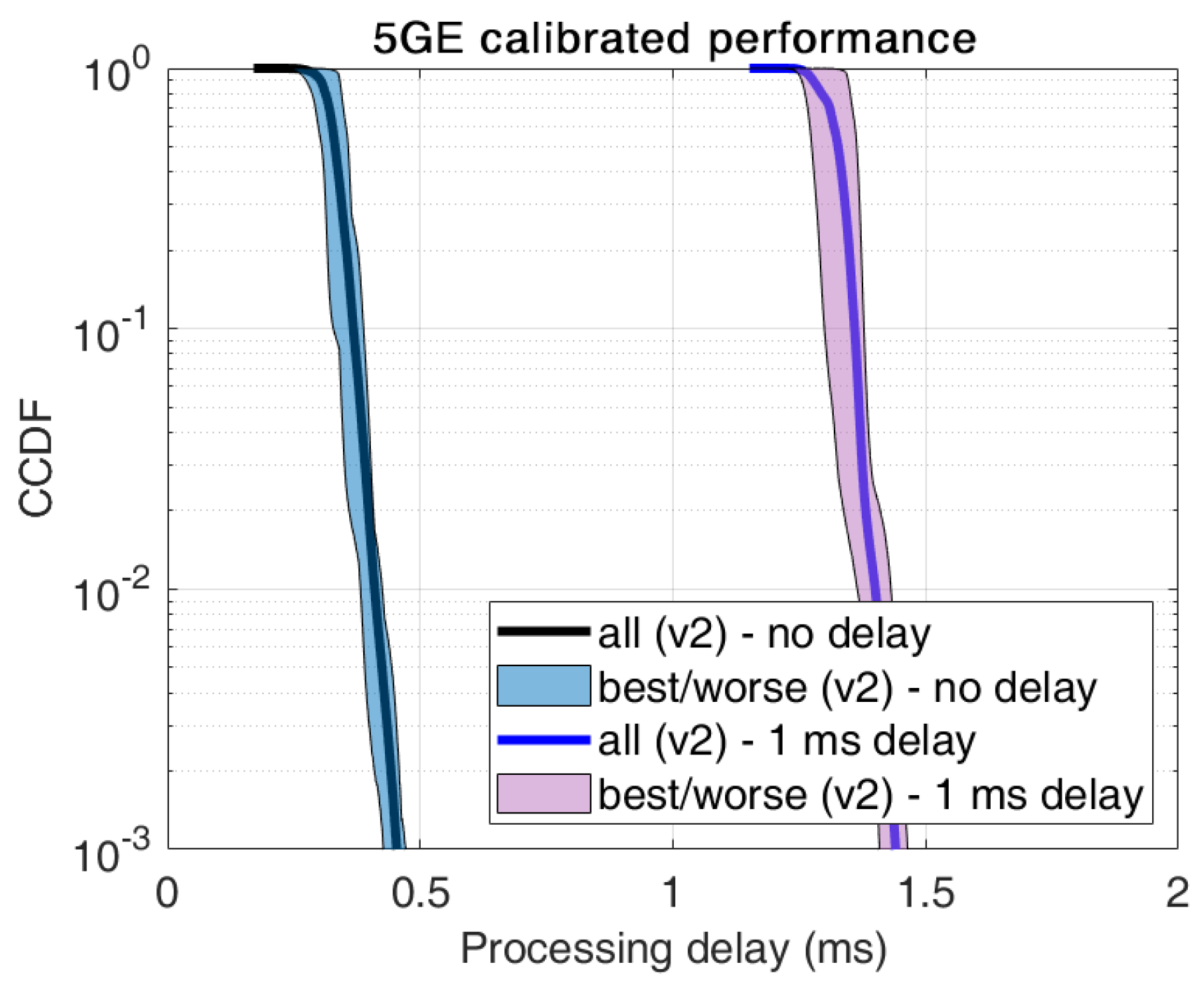

| 5GE | Raspberry Pi 4 Model B [27] | netem 2.6 [29] | Multi-technology support |

| (v2) | Broadcom BCM2711, QC@1.5 GHz/4 GB | Custom delay generation | Network transparent |

| OS: Raspberry Pi OS Lite | |||

| NIC: Realtec USB3.0/Gbps ethernet adapter | |||

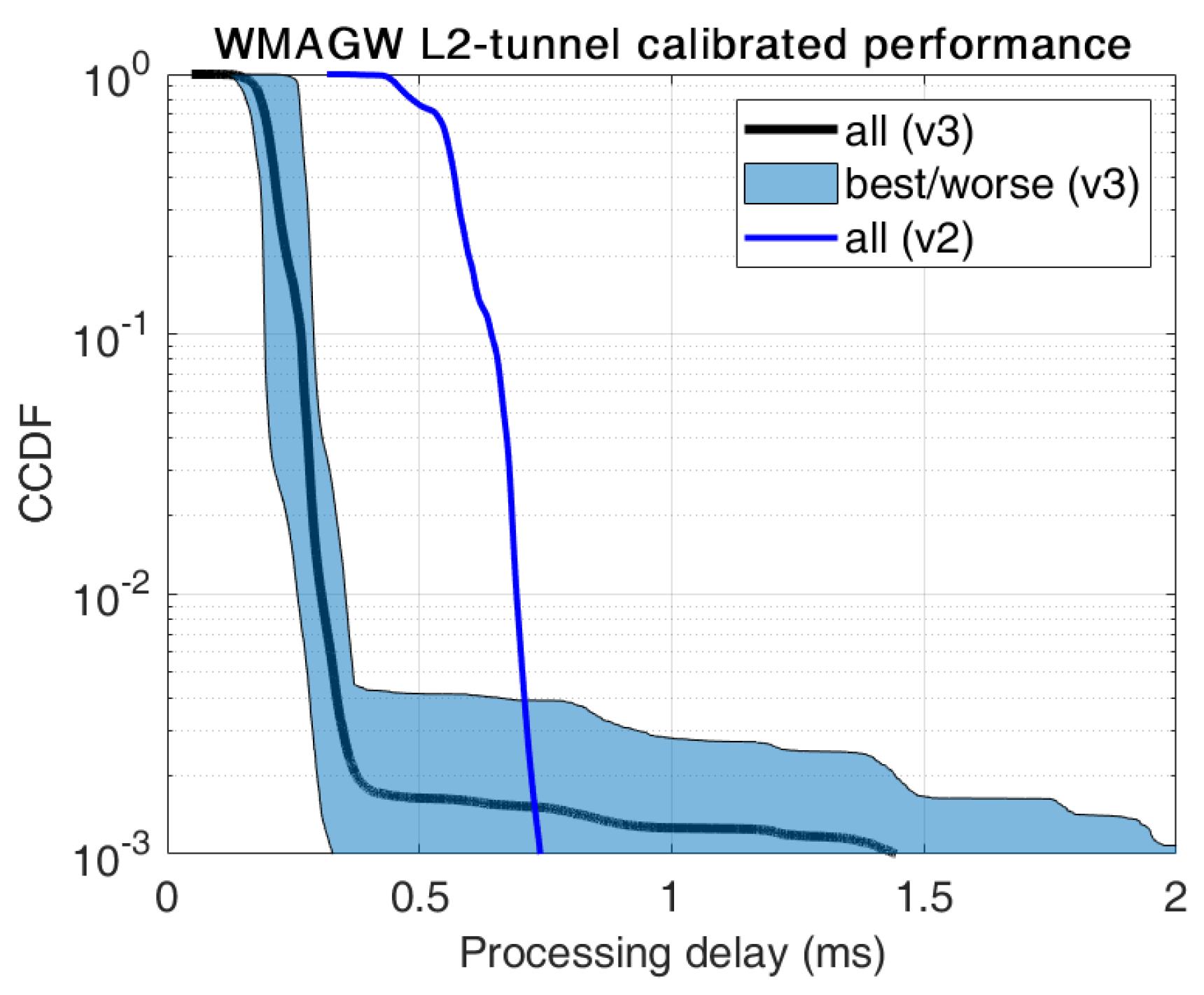

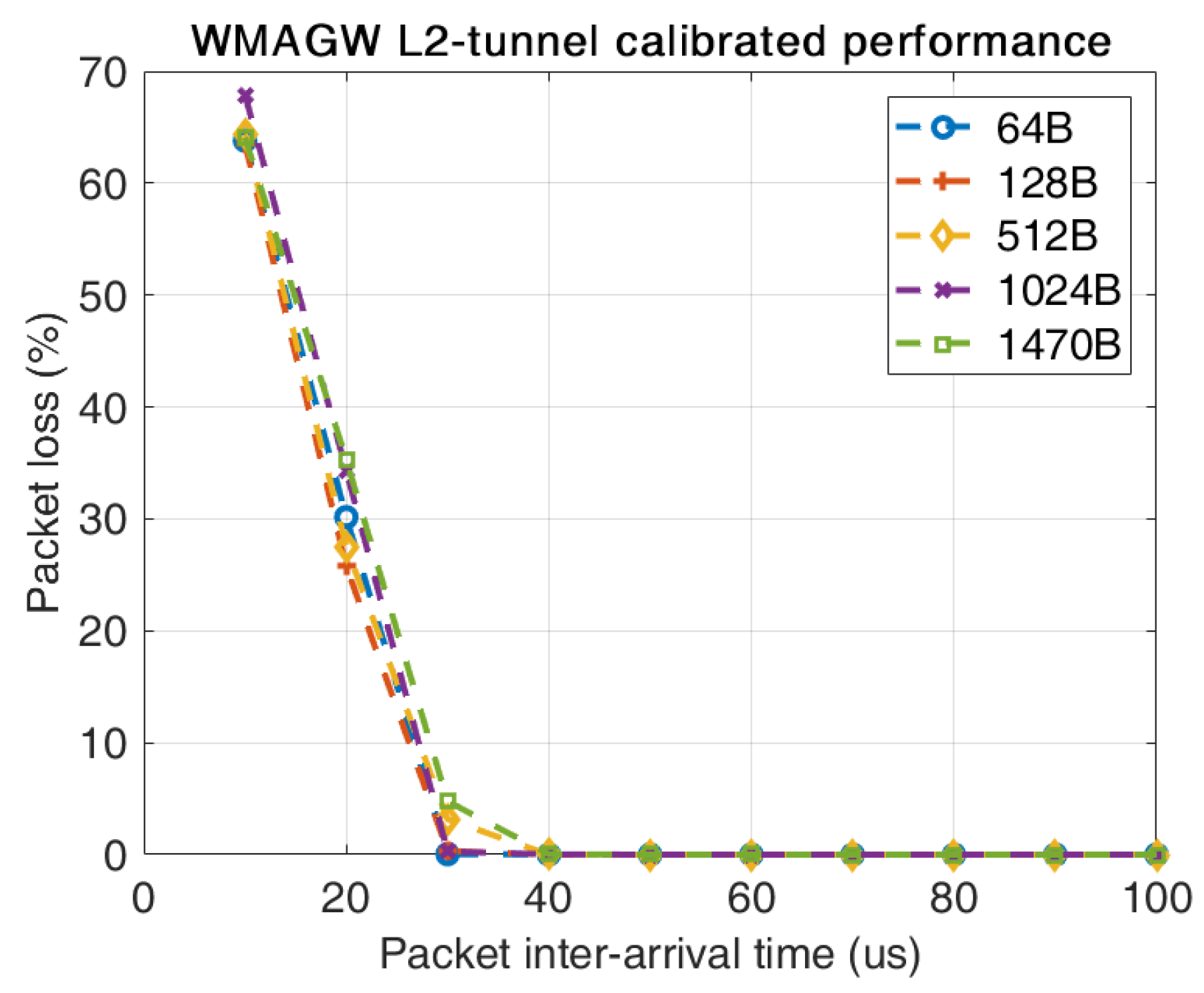

| WMAGW | Gateworks Newport GW6404 [30] | Custom multi-access tunnel | Auto-network discovery |

| (v3) | Cavium OcteonTX8, QC@1.5GHz/2 GB | Custom IP bridge | Multi-connectivity support |

| OS: Ubuntu 20.04.2 | Gbps/USB3.0 support | ||

| NIC: Gbps ethernet port | L2 BC/MC support | ||

| 5G modem: QUECTEL RM500Q [31] | 5G SA/NSA support | ||

| 5G modem: SIMCOM 8200 [32] | |||

| 5G modem: SIMCOM 8300G [33] | |||

| Wi-Fi 6 modem: Intel AX200NGW [34] |

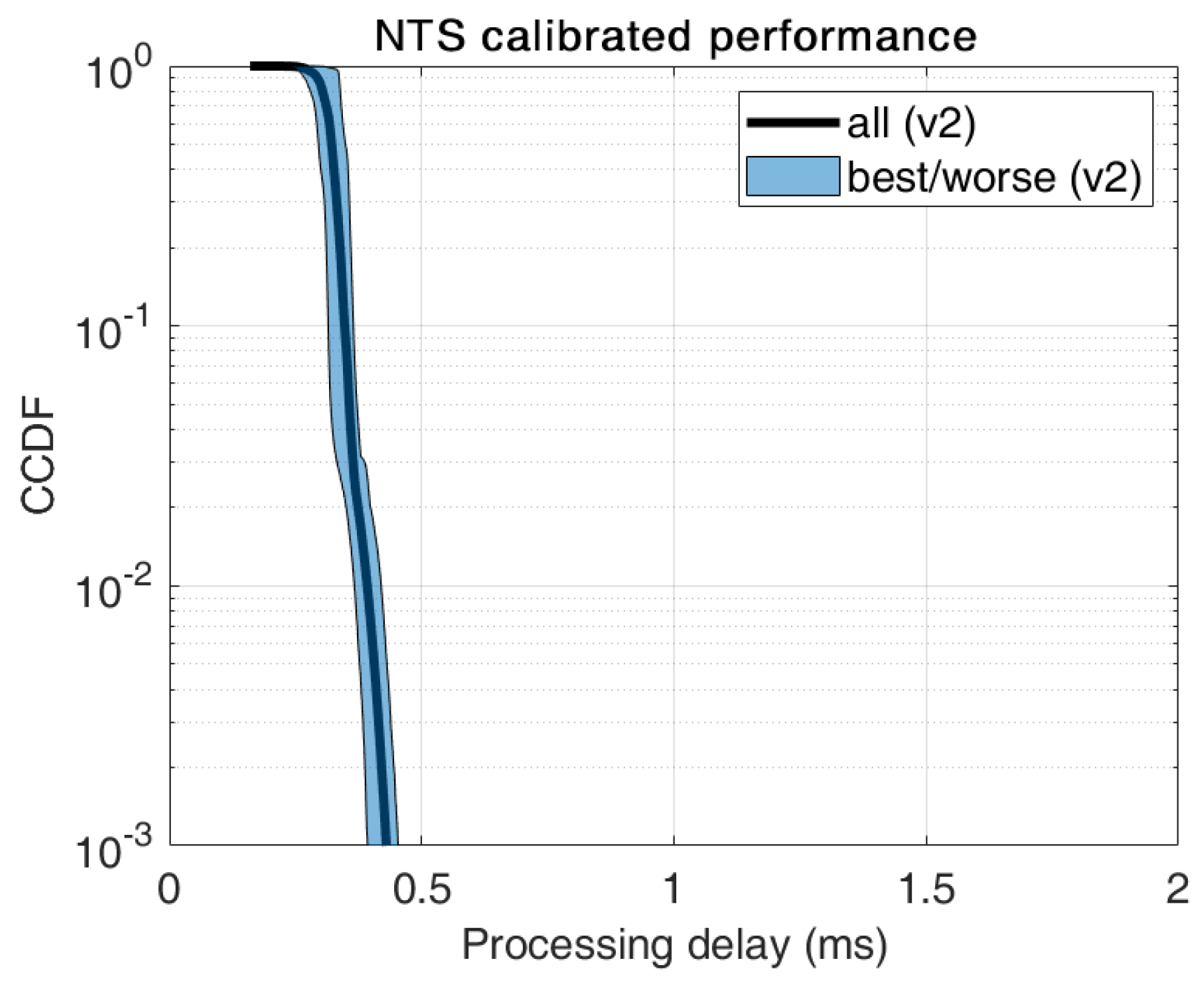

Capabilities and Calibration of the 5G Prototyping Tools

4. Framework Applicability Example: 5G Autonomous Mobile Robots

4.1. 5G-Connected Autonomous Mobile Robots

- STEP 1.

- An AMR manufacturer would like to start exploring the integration of their products with 5G technology. For mobility reasons, autonomous mobile robots are wireless-native elements. However, as current AMR products operate over Wi-Fi, which presents issues in terms of reliability and scalability when applied to mobile applications [42], optimized alternative are to be explored. AMR vendors are, in general, aware of the techniques for optimizing Wi-Fi performance, however, the products that they sell to their customers will operate over the Wi-Fi networks of the customers, which status remains unknown and might be unoptimized in many cases. Apart from the increased reliability, having 5G-compatible versions of their products would create new business opportunities for AMR vendors.

- STEP 2.

- In this case, our industrial partner brought some of their AMR products and related control elements such as the fleet manager (FM) to our lab. The control elements and system architecture were open for us so that we could perform a thorough data traffic analysis of its mode of operation. The targeted AMRs are managed from the centralized FM deployed at infrastructure-side (typically in a server room) and accessible via the Wi-Fi network. From the FM, it is possible to send specific missions with automated paths or set waypoints to navigate to for the AMRs. Although, as wireless-native components, AMRs are based on a wireless-wired hybrid architecture, different from that of the standard static production industrial use cases based only on a wired architecture, the framework can still be applied by identifying the relevant communication interfaces that are subject to be integrated into 5G. In this case, thus interface was the standard AMR communication interface (the same that is used currently in the Wi-Fi version of the product), over which the data traffic flowing was analyzed with the help of the NTS device. We observed that control-loops between the AMR and the FM are executed once per second, and they make use of the TCP protocol with average packets sizes of 4 kB and 100 B, in FM-AMR and AMR-FM communication direction, respectively. The total throughput of the AMR application is, therefore, approximately 32 kbit/s (for a single robot).

- STEP 3.

- Based on the throughput, packet sizes and inter-packet times values, it was clear that the current AMR implementation is suitable for operation over 5G and its better mobility and reliability support should result in an improved performance of the AMRs in standard mobility operation conditions than when operated over Wi-Fi.

- STEP 4.

- To integrate the AMR with 5G, a WMAGW (v3) was used. The prototype device was interfaced to the standard communication interface of the AMR by following the 5G-integrated architecture illustrated in Figure 9a. The WMAGW was configured in IP-mode to operate in infrastructure mode to route the control data traffic between the AMR and the FM. In this case, as the architecture of the use case is quite simple, and there are not many communication flows, the IT integration and debugging of the 5G-integrated solution was quite quick. A picture of the deployed 5G-integrated AMR solution is shown in Figure 9b.

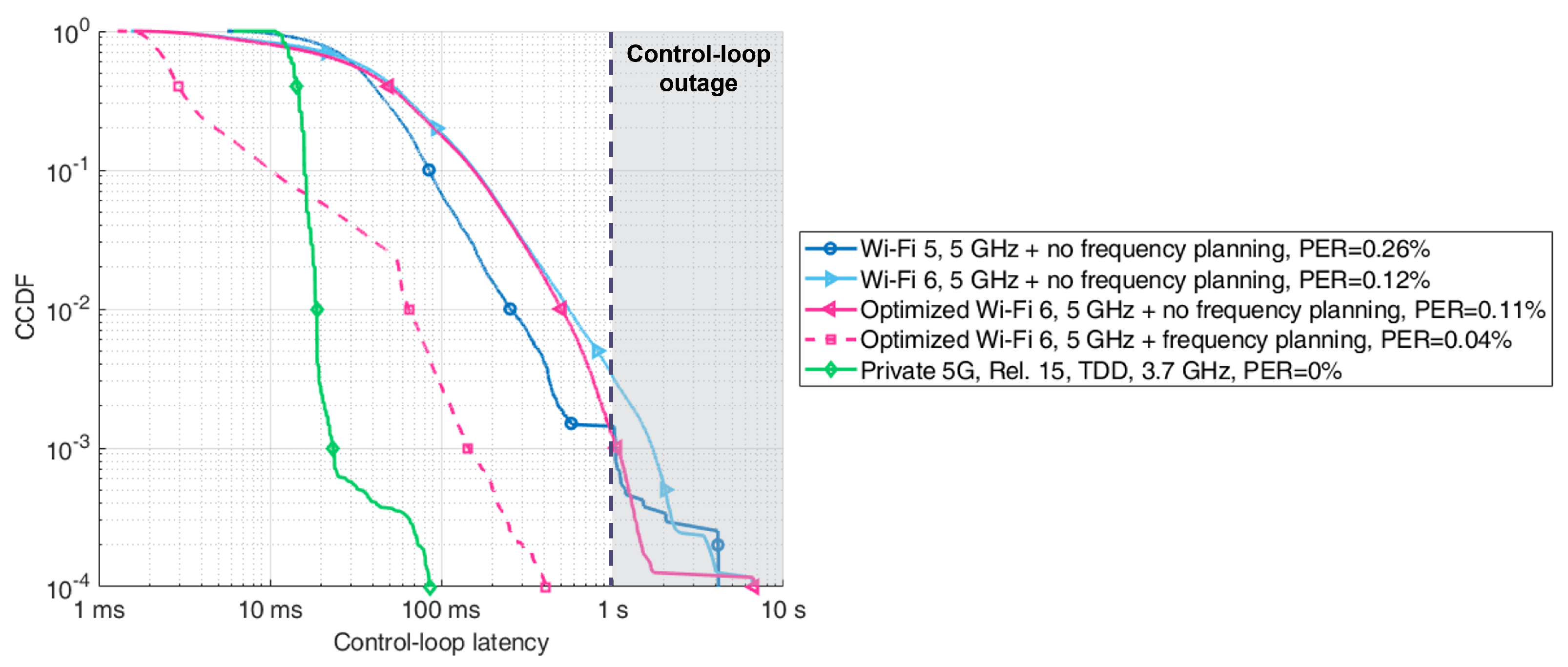

- STEP 5.

- To validate the correct operation of the 5G-integrated application, a performance test was carried out. The test was performed by having the AMR automatically navigating within the lab over the measurement route indicated in Figure 9c. This specific route was chosen to ensure that the AMR was navigating across the multiple 5G cells and guarantee that a proper assessment of the attachment/re-attachment to multiple cells and the connection reliability in mobility conditions was done. The performance of the control of the AMR over 5G was compared to the one over different Wi-Fi configurations. The performance tests focused on two main different domains: control-loop latency performance and packet error rate. The results from the tests are displayed in Figure 10. Given the communication requirements of the AMR, with expected control loops every 1 s, all control-loops with latency higher than that will make the AMR stop and enter in a momentary outage. As indicated in the results, no outage was experienced for the 5G-integrated solution, which exhibited a reliable deterministic performance with median control-loop latency of 11 ms and lower than 25 ms at the 99.9 percentile (10−3). This was, however, not the case for Wi-Fi 5/6, over which control-loop latencies higher than 1 s were experienced during 0.1–0.3% of the time in those cases where no frequency planning was considered (which resembles the typical Wi-Fi deployment situation in operational factories where the AMRs are expected to operate). During these outage occurrences, control-loop latencies close to up to 10 s were observed. These long control-loop latencies will keep the AMR stopped and non-operational for a few seconds every time they happen, which will have an impact of the underlying industrial production process in which AMRs are involved. The performance of the AMR over optimized Wi-Fi 6 and ideal frequency planning (i.e., dedicated spectrum channels per access point) was also observed to fulfill the control-loop requirements for the given use case. However, such performance was less deterministic than the one observed for the 5G-integrated solution. While a median control-loop latency, better than the 5G one, of 5 ms was observed; the value at the 99.9 percentile is increased to over 0.5 s, illustrating the higher reliability of 5G as compared to Wi-Fi. Further, the 5G-integrated solution experienced no packet loss, while in the Wi-Fi case, the PER was 0.4–0.26%.

- STEP 6.

- Once it was verified that it is possible to operate AMRs over 5G, the next step would be to look into potential optimizations. Based on the experimental results and the practical observations done along the different operational steps, the potential areas of optimization for the 5G-integrated solution could be: the parametrization of the 5G network configuration to optimize the control-loop latency and reduce the tails of the distribution, or the re-design of the AMR communication schemes to make them more efficient and scalable when operated over wireless in general, or over 5G in particular.

4.2. 5G Mobile Edge-Cloud Planner for Autonomous Mobile Robots

- STEP 1.

- Once the reliable 5G-control was demonstrated to the AMR manufacturer, they were immediately interested in trying to unleash the full 5G potential by investigating whether other more heavy processes than the FM-based control could be operated over 5G. Moving part of the current on-board intelligence from the AMR to the mobile edge-cloud (MEC) would result in cheaper products and more flexible AMR products as the on-board processing power could be reduced and having a single high-processing power centralized server deployed at infrastructure-side would enable cloud-in-the-loop operation [43] towards all the AMRs, facilitating the exchange of information between AMRs and reducing the burden of having to push SW upgrades to each AMR individually. The specific application selected to be moved to the 5G MEC was the AMR planner. Currently, an AMR navigates by using its on-board planner and does not share any information with other robots. This typically results in sub-optimal navigation routes in the case that the AMR navigates into an obstacle and needs to re-plan its route, even if that same obstacle was previously detected and avoided by another robot. This problem can be mitigated by moving the planner functionalities to the edge-cloud where a centralized virtual shared-world could be built, allowing for the optimization of the navigation for all AMRs at once.

- STEP 2.

- The AMR vendor provided us with an external planner unit and re-architectured the AMR communication (mainly the I/O connections) to make use of the external device instead of its on-board planner. The new architecture is illustrated in Figure 11a, and can be compared for further reference to the standard AMR architecture in Figure 9a. All internal communication within the AMR happens over ethernet, so the NTS device was used to analyze the data traffic in the I/O-planner communication link. TCP traffic was found with average packet sizes of 128 B and average PIAT of 0.5 ms in both the I/O-planner and planner-I/O communication directions. The overall throughput was 1.3–1.9 Mbit/s (for a single robot), which confirms that, as expected, the I/O-planner commutation is more demanding than AMR-FM one.

- STEP 3.

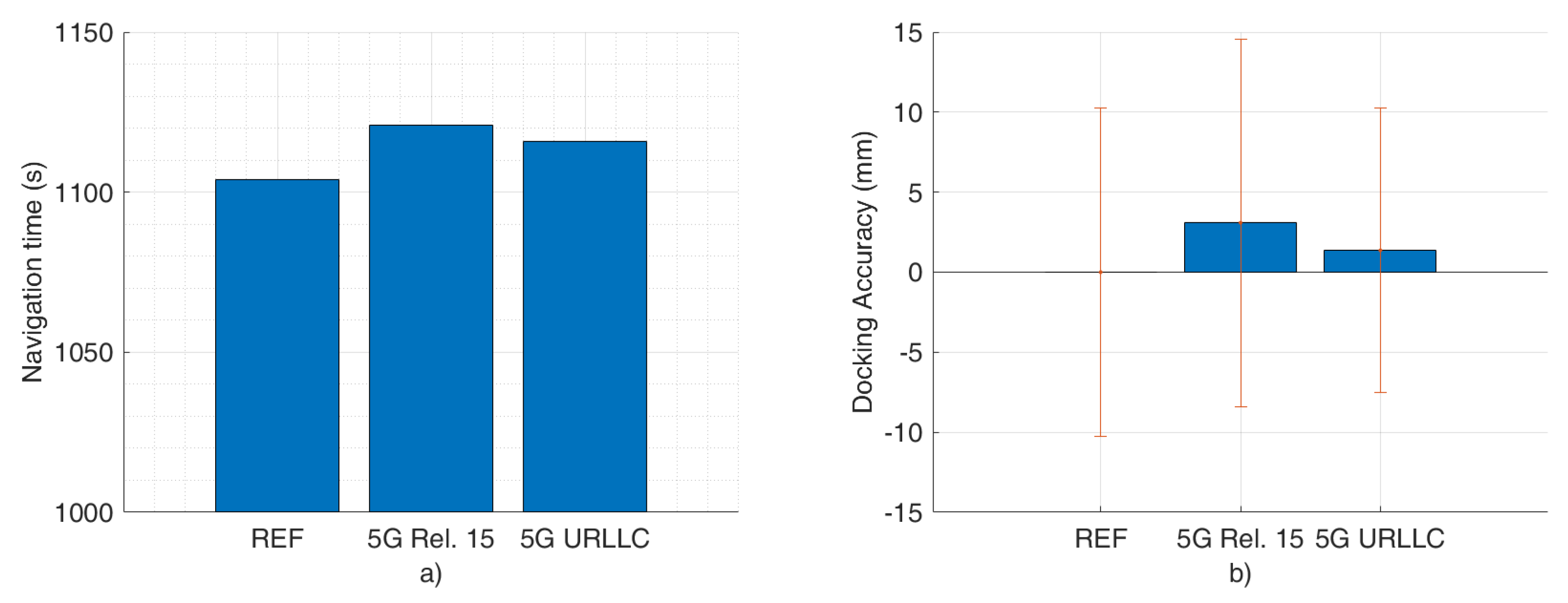

- Although more demanding than in the AMR-FM case, the I/O-planner link is also suitable for 5G operation, at least based on the the throughput, packet sizes and inter-packet times values. However, it was questioned what the impact of the higher 5G delays (compared to the cabled ethernet reference) would be on the performance of the robot. Understanding this is of paramount importance, as the timely and reliable operation of the planner is application-critical, and a excessively long I/O-planner communication delay could result in a sub-optimal navigation performance of the robot. In this case, before proceeding to the deployment step, it was decided to make a 5G-based I/O-planner emulation test to understand the potential impact of 5G delays into the functional operation of the AMR. To do that, the 5GE device was used. As displayed in Figure 11b, the emulator was placed between the I/O of the robot and the external planner device, mirroring the 5G MEC planner configuration illustrated in Figure 11a. A navigation performance and a docking accuracy tests were performed for benchmarking the operation of the reference cabled planner (REF) to the one achieved over 5G. For 5G two different delay distributions were loaded into the 5GE, one with empirical values obtained over 5G Rel. 15 (current 5G commercial version) with an average delay of 4.9 ms, and one with values from a simulation of 5G URLLC [9] with an average delay of 0.75 ms. In the navigation test, a mission was configured to make the AMR navigate over an obstructed route between two selected waypoints within the lab, ensuring that the robot needed to re-plan its path upon detection of the obstacle. The route was covered 40 times in order to ensure that the overall mission times were long enough to observe any potential differences between the reference operation with cabled planner and the 5G-emulated one. For the docking accuracy test, the robot was set to execute a docking maneuver into its charging station from a starting point located at 1 m distance. This test was repeated 15 times in order to obtain an insight into the average experienced accuracy over 5G as compared to the REF. The docking accuracy was evaluated with the assistance of an external optical positioning system with mm-accuracy [44]. The results from the navigation performance tests are presented in Figure 12a, and they indicate that a very small increase in navigation time of 1.5% is expected in the worst case with the 5G MEC planner as compared to its reference operation with the on-board planner. For the docking accuracy test, the results are shown in Figure 12b, and they illustrate that the use of the 5G MEC planner would result in a slight loss of accuracy of maximum 1–3 mm, which would be negligible for reliable operation of the AMRs.

5. Considerations for Future Framework Versions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aceto, G.; Persico, V.; Pescape, A. A Survey on Information and Communication Technologies for Industry 4.0: State-of-the-Art, Taxonomies, Perspectives, and Challenges. IEEE Commun. Surv. Tutor. 2019, 21, 3467–3501. [Google Scholar] [CrossRef]

- Varga, P.; Peto, J.; Franko, A.; Balla, D.; Haja, D.; Janky, F.; Soos, G.; Ficzere, D.; Maliosz, M.; Toka, L. 5G support for Industrial IoT Applications - Challenges, Solutions, and Research gaps. Sensors 2020, 20, 828. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- O’Connell, E.; Moore, D.; Newe, T. Challenges Associated with Implementing 5G in Manufacturing. Telecom 2020, 1, 48–67. [Google Scholar] [CrossRef]

- Sanchez, M.; Exposito, E.; Aguilar, J. Industry 4.0: Survey from a system integration perspective. Int. J. Comput. Integr. Manuf. 2020, 33, 1017–1041. [Google Scholar] [CrossRef]

- The Reference Architectural Model Industrie 4.0 (RAMI 4.0), version 1.0; Zentralverband Elektrotechnik- und Elektronikindustrie (ZVEI): Frankfurt am Main, Germany, 2015.

- Colli, M.; Berger, U.; Bockholta, M.; Madsen, O.; Møller, C.; Wæhrens, B.V. A maturity assessment approach for conceiving context-specific roadmaps in the Industry 4.0 era. Annu. Rev. Control 2019, 48, 165–177. [Google Scholar] [CrossRef]

- Colli, M.; Madsen, O.; Berger, U.; Møller, C.; Wæhrens, B.W.; Bockholt, M. Contextualizing the outcome of a maturity assessment for Industry 4.0. IFAC-PapersOnLine 2018, 51, 1347–1352. [Google Scholar] [CrossRef]

- Seferagic, A.; Famaey, J.; De Poorter, E.; Hoebeke, J. Survey on Wireless Technology Trade-Offs for the Industrial Internet of Things. Sensors 2020, 20, 488. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rodriguez, I.; Mogensen, R.S.; Schjørring, A.; Razzaghpour, M.; Maldonado, R.; Berardinelli, G.; Adeogun, R.; Christensen, P.H.; Mogensen, P.; Madsen, O.; et al. 5G Swarm Production: Advanced Industrial Manufacturing Concepts enabled by Wireless Automation. IEEE Commun. Mag. 2021, 59, 48–54. [Google Scholar] [CrossRef]

- Gidlund, M.; Lennvall, T.; Akerberg, J. Will 5G become yet another wireless technology for industrial automation? In Proceedings of the IEEE International Conference on Industrial Technology (ICIT), Toronto, ON, Canada, 22–25 March 2017; pp. 1319–1324. [Google Scholar]

- Spinelli, F.; Mancuso, V. Toward Enabled Industrial Verticals in 5G: A Survey on MEC-Based Approaches to Provisioning and Flexibility. IEEE Commun. Surv. Tutor. 2021, 23, 596–630. [Google Scholar] [CrossRef]

- 5G Alliance for Connected Industries and Automation (5G-ACIA). White Paper: Performance Testing of 5G Systems for Industrial Automation. Available online: https://5g-acia.org/whitepapers/performance-testing-of-5g-systems-for-industrial-automation-2/ (accessed on 16 July 2021).

- Mogensen, R.S.; Rodriguez, I.; Schou, C.; Mortensen, S.; Sørensen, M.S. Evaluation of the Impact of Wireless Communication in Production via Factory Digital Twins. Manuf. Lett. 2021, 28, 1–5. [Google Scholar] [CrossRef]

- ProfiTAP ProfiShark Network TAPs. Available online: https://www.profitap.com/profishark-network-taps/ (accessed on 16 July 2021).

- CISCO Security Packet Analyzer. Available online: https://www.cisco.com/c/en/us/products/security/security-packet-analyzer/index.html (accessed on 16 July 2021).

- Solarwinds Network Traffic Analyzer. Available online: https://www.solarwinds.com/netflow-traffic-analyzer (accessed on 16 July 2021).

- Keysight 5G Network Emulation. Available online: https://www.keysight.com/es/en/cmp/2020/5g-network-emulation-software.html (accessed on 16 July 2021).

- Spirent Network Emulator. Available online: https://www.spirent.com/products/network-impairment-emulation-testing (accessed on 16 July 2021).

- iTrinegy NE-ONE Professional Network Emulator. Available online: https://itrinegy.com/ne-one-professional-range/ (accessed on 16 July 2021).

- HMS Wireless Router 5G NV1000. Available online: https://www.hms-networks.com/docs/librariesprovider6/labs/router-only.pdf (accessed on 16 July 2021).

- SIEMENS SCALANCE MUM856-1. Available online: https://new.siemens.com/global/en/products/automation/industrial-communication/industrial-5g/5g-router-scalance-mum.html (accessed on 16 July 2021).

- Robustel 5G IoT Router R5020. Available online: https://www.robustel.com/en/product/r5020/ (accessed on 16 July 2021).

- 5G Alliance for Connected Industries and Automation (5G-ACIA). White Paper: Integration of Industrial ethernet Networks with 5G Networks. Available online: https://5g-acia.org/wp-content/uploads/2021/04/5G-ACIA_Integration-of-Industrial-Ethernet-Networks-with-5G-Networks-.pdf (accessed on 16 July 2021).

- Wollschlaeger, M.; Sauter, T.; Jasperneite, J. The Future of Industrial Communication: Automation Networks in the Era of the Internet of Things and Industry 4.0. IEEE Ind. Electron. Mag. 2017, 11, 17–27. [Google Scholar] [CrossRef]

- Baud, M.; Felser, M. Profinet IO-Device Emulator based on the Man-in-the-middle Attack. In Proceedings of the IEEE Conference on Emerging Technologies and Factory Automation (ETFA), Prague, Czech Republic, 20–22 September 2006. [Google Scholar]

- Suer, M.T.; Thein, C.; Tchouankem, H.; Wolf, L. Multi-Connectivity as an Enabler for Reliable Low Latency Communications—An Overview. IEEE Commun. Surv. Tutor. 2020, 22, 156–169. [Google Scholar] [CrossRef]

- Raspberry Pi 4 Model B. Available online: https://www.raspberrypi.org/products/raspberry-pi-4-model-b/specifications/ (accessed on 4 June 2021).

- tcpdump. Public Repository. Available online: https://www.tcpdump.org/ (accessed on 4 June 2021).

- netem. Network Emulator. Linux Traffic Control. Available online: https://wiki.linuxfoundation.org/networking/netem (accessed on 4 June 2021).

- Gateworks Newport GW6404. Available online: https://www.gateworks.com/products/industrial-single-board-computers/octeon-tx-single-board-computers-gateworks-newport/gw6400-single-board-computer/ (accessed on 16 July 2021).

- QUECTEL 5G RM500Q. Available online: https://www.quectel.com/product/5g-rm500q-gl/ (accessed on 4 June 2021).

- SIMCOM 5G SIM8200G. Available online: https://www.simcom.com/product/SIM8200G.html (accessed on 4 June 2021).

- SIMCOM 5G SIM8300G. Available online: https://www.simcom.com/product/SIM8300G_M2.html (accessed on 4 June 2021).

- Intel Wi-Fi 6 AX200. Available online: https://www.intel.com/content/www/us/en/products/docs/wireless/wi-fi-6-ax200-module-brief.html (accessed on 4 June 2021).

- Herlich, M.; Maier, C. Measuring and Monitoring Reliability of Wireless Networks. IEEE Commun. Mag. 2021, 59, 76–81. [Google Scholar] [CrossRef]

- Brown, L.D.; Cai, T.T.; Dasgupta, A. Confidence intervals for a binomial proportion and asymptotic expansions. Annu. Stat. 2002, 30, 160–201. [Google Scholar] [CrossRef]

- Navarro-Ortiz, J.; Romero-Diaz, P.; Sendra, S.; Ameigeiras, P.; Ramos-Munoz, J.J.; Lopez-Soler, J.M. A survey on 5G usage scenarios and traffic models. IEEE Commun. Surv. Tutor. 2020, 22, 905–929. [Google Scholar] [CrossRef]

- Mogensen, R.S.; Rodriguez, I.; Berardinelli, G.; Pocovi, G.; Kolding, T. Empirical IIoT Data Traffic Analysis and Comparison to 3GPP 5G Models. In Proceedings of the IEEE Vehicular Technology Conference (VCT), Online Conference, 27–30 September 2021. [Google Scholar]

- Rodriguez, I.; Mogensen, R.S.; Khatib, E.J.; Berardinelli, G.; Mogensen, P.; Madsen, O.; Møller, C. On the Design of a Wireless MES Solution for the Factories of the Future. In Proceedings of the Global IoT Summit (GIoTS), Aarhus, Denmark, 17–21 June 2019. [Google Scholar]

- Mogensen, R.S.; Rodriguez, I.; Berardinelli, G.; Fink, A.; Marcker, R.; Markussen, S.A.; Raunholt, T.; Kolding, T.E.; Pocovi, G.; Barbera, S. Implementation and Trial Evaluation of a Wireless Manufacturing Execution System for Industry 4.0. In Proceedings of the IEEE Vehicular Technology Conference (VTC), Honolulu, HI, USA, 22–25 September 2019. [Google Scholar]

- Oyekanlu, E.A.; Smith, A.C.; Thomas, W.P.; Mulroy, G.; Hitesh, D.; Ramsey, M.; Kuhn, D.J.; McGhinnis, J.D.; Buonavita, S.C.; Looper, N.A.; et al. A Review of Recent Advances in Automated Guided Vehicle Technologies: Integration Challenges and Research Areas for 5G-Based Smart Manufacturing Applications. IEEE Access 2020, 8, 202312–202353. [Google Scholar] [CrossRef]

- Fink, A.; Mogensen, R.S.; Rodriguez, I.; Kolding, T.; Karstensen, A.; Pocovi, G. Empirical Performance Evaluation of Enterprise Wi-Fi for IIoT Applications Requiring Mobility. In Proceedings of the European Wireless (EW), Verona, Italy, 10–12 November 2021. [Google Scholar]

- Kehl, P.; Lange, D.; Maurer, F.K.; Nemeth, G.; Overbeck, D.; Jung, S.; Konig, N.; Schmitt, R.H. Comparison of 5G Enabled Control Loops for Production. In Proceedings of the IEEE Annual International Symposium on Personal, Indoor and Mobile Radio Communications (PIMRC), Online Conference, 31 August–3 September 2020. [Google Scholar]

- Raunholt, T.; Rodriguez, I.; Mogensen, P.; Larsen, M. Towards a 5G Mobile Edge Cloud Planner for Autonomous Mobile Robots. In Proceedings of the IEEE Vehicular Technology Conference (VTC), Online Conference, 27–30 September 2021. [Google Scholar]

- Pocovi, G.; Shariatmadari, H.; Berardinelli, G.; Pedersen, K.; Steiner, J.; Li, Z. Achieving Ultra-Reliable Low-Latency Communications: Challenges and Envisioned System Enhancements. IEEE Netw. 2018, 32, 8–15. [Google Scholar] [CrossRef]

- Gundall, M.; Huber, C.; Rost, P.; Halfmann, R.; Schotten, H.D. Integration of 5G with TSN as Prerequisite for a Highly Flexible Future Industrial Automation: Time Synchronization based on IEEE 802.1AS. In Proceedings of the Annual Conference of the IEEE Industrial Electronics Society (IECON), Online Conference, 18–21 October 2020. [Google Scholar]

- Lu, T.; Fan, Z.; Lei, Y.; Shang, Y.; Wang, C. The Edge Computing Cloud Architecture Based on 5G Network for Industrial Vision Detection. In Proceedings of the IEEE 6th International Conference on Big Data Analytics (ICBDA), Online Conference, 5–8 March 2021. [Google Scholar]

- 5G Alliance for Connected Industries and Automation (5G-ACIA). White Paper: Security Aspects of 5G for Industrial Networks. Available online: https://5g-acia.org/whitepapers/security-aspects-of-5g-for-industrial-networks/ (accessed on 16 July 2021).

- Tuptuk, N.; Hailes, S. Security of smart manufacturing systems. J. Manuf. Syst. 2018, 47, 93–106. [Google Scholar] [CrossRef]

- Adeogun, R.; Berardinelli, G.; Mogensen, P.; Rodriguez, I.; Razzaghpour, M. Towards 6G in-X subnetworks with sub-millisecond communication cycles and extreme reliability. IEEE Access 2020, 8, 110172–110188. [Google Scholar] [CrossRef]

| Prototype | Processing Delay | Jitter | Max. Supported Throughput |

|---|---|---|---|

| NTS (v2) | 0.45 ms | 33 s | N/A |

| 5GE (v2) | 0.47 ms | 33 s | N/A |

| WMAGW (v3) L2-tunnel | <0.4 ms (99.5%) | 103 s | 294 Mbit/s |

| WMAGW (v3) IP-mode | N/A | N/A | 480 Mbit/s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodriguez, I.; Mogensen, R.S.; Fink, A.; Raunholt, T.; Markussen, S.; Christensen, P.H.; Berardinelli, G.; Mogensen, P.; Schou, C.; Madsen, O. An Experimental Framework for 5G Wireless System Integration into Industry 4.0 Applications. Energies 2021, 14, 4444. https://doi.org/10.3390/en14154444

Rodriguez I, Mogensen RS, Fink A, Raunholt T, Markussen S, Christensen PH, Berardinelli G, Mogensen P, Schou C, Madsen O. An Experimental Framework for 5G Wireless System Integration into Industry 4.0 Applications. Energies. 2021; 14(15):4444. https://doi.org/10.3390/en14154444

Chicago/Turabian StyleRodriguez, Ignacio, Rasmus Suhr Mogensen, Andreas Fink, Taus Raunholt, Søren Markussen, Per Hartmann Christensen, Gilberto Berardinelli, Preben Mogensen, Casper Schou, and Ole Madsen. 2021. "An Experimental Framework for 5G Wireless System Integration into Industry 4.0 Applications" Energies 14, no. 15: 4444. https://doi.org/10.3390/en14154444

APA StyleRodriguez, I., Mogensen, R. S., Fink, A., Raunholt, T., Markussen, S., Christensen, P. H., Berardinelli, G., Mogensen, P., Schou, C., & Madsen, O. (2021). An Experimental Framework for 5G Wireless System Integration into Industry 4.0 Applications. Energies, 14(15), 4444. https://doi.org/10.3390/en14154444