A Synergetic Sliding Mode Controller Applied to Direct Field-Oriented Control of Induction Generator-Based Variable Speed Dual-Rotor Wind Turbines

Abstract

1. Introduction

- 1.

- This work designed a robust direct FOC method of induction generator-based DRWP systems;

- 2.

- A new robust control to reactive and active power ripples minimization for direct FOC method is designed;

- 3.

- Synergetic sliding mode controllers to minimize error tracking reactive and active power references of induction generator-based DRWP systems;

- 4.

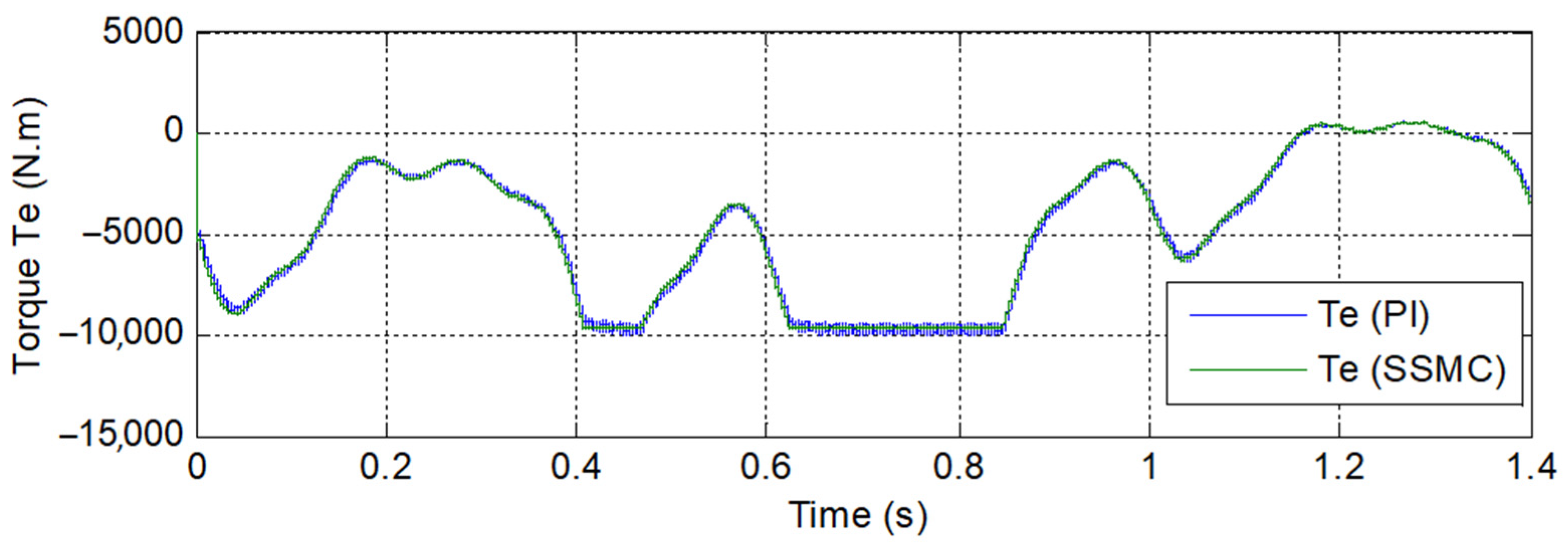

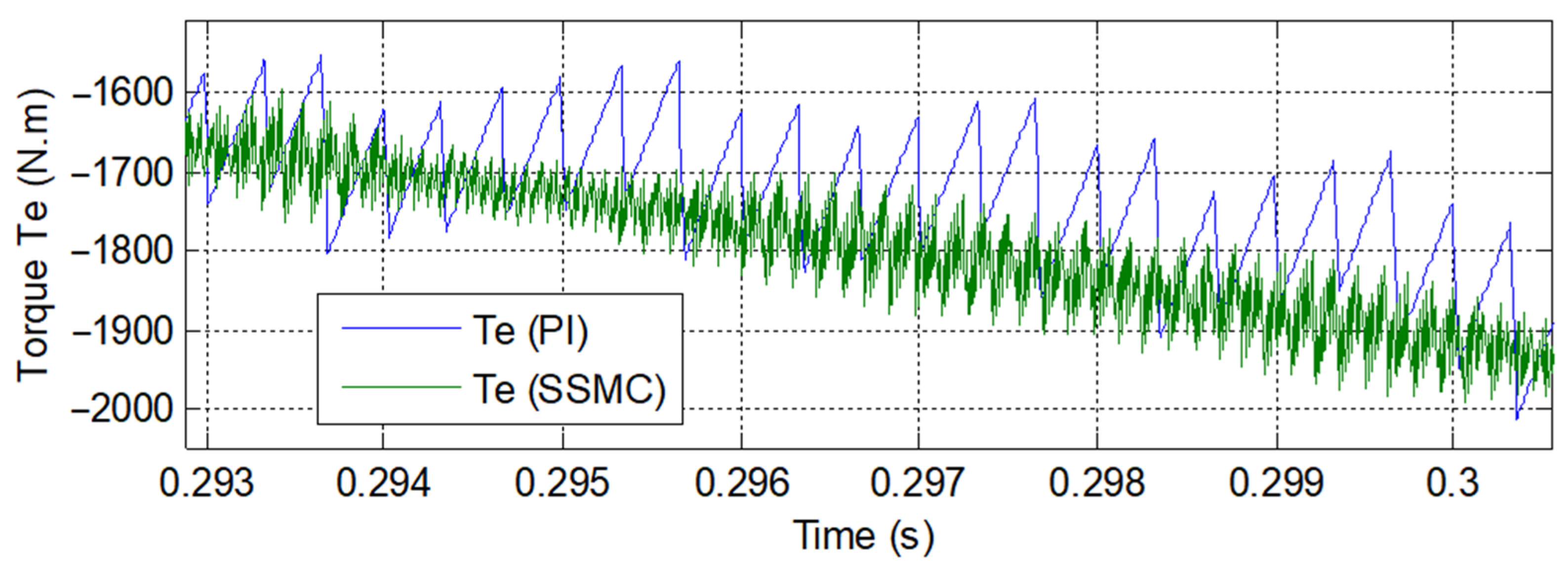

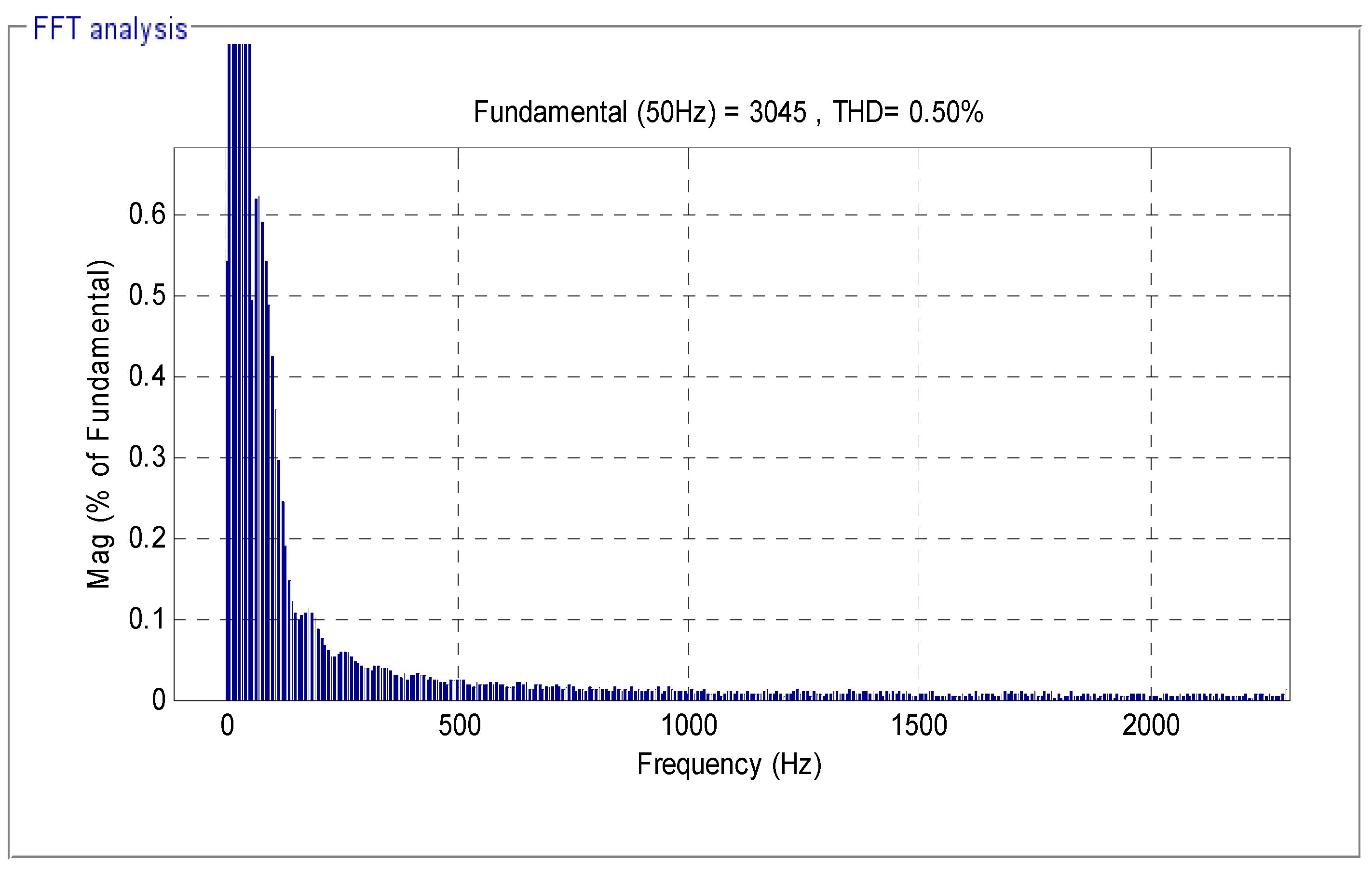

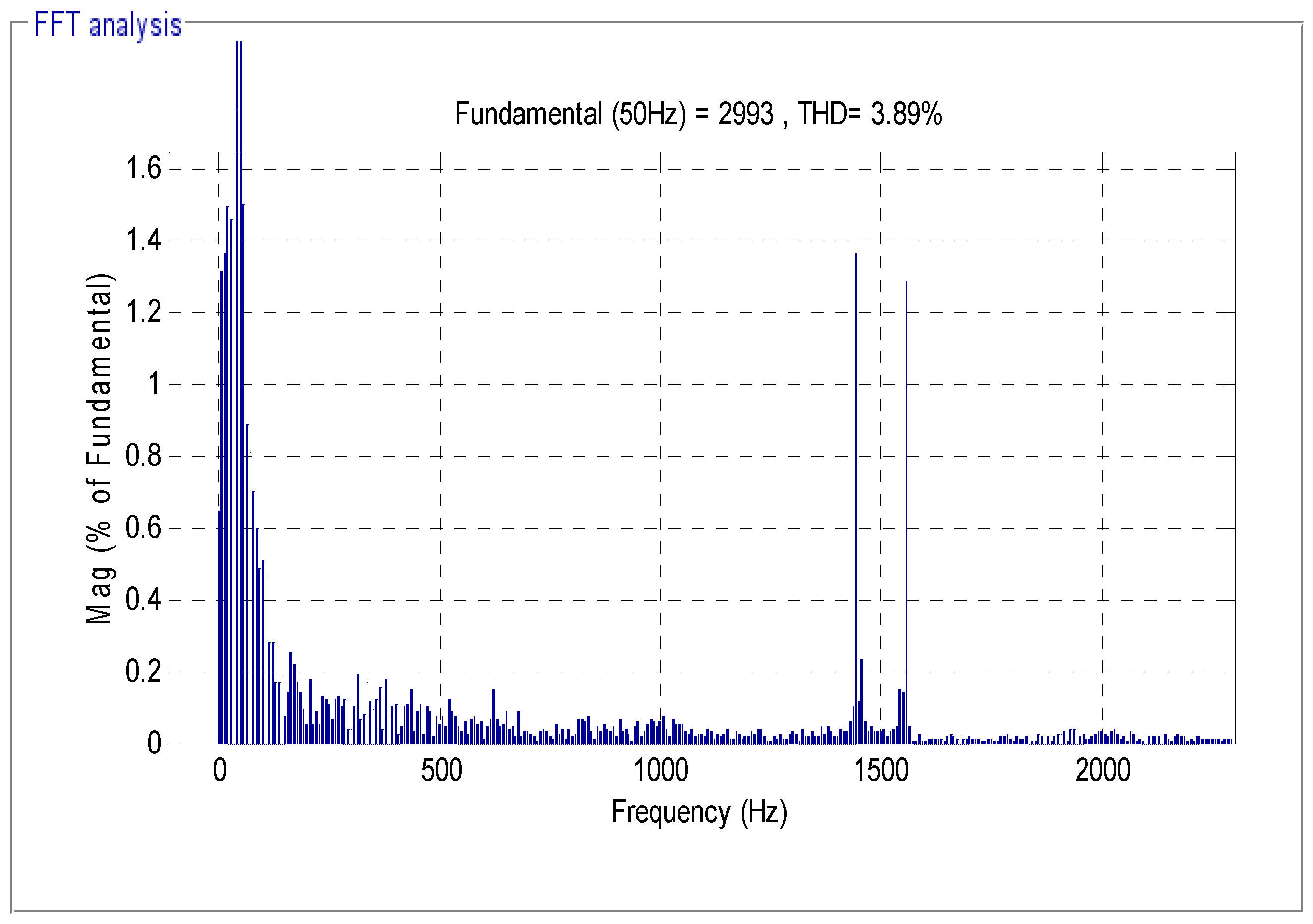

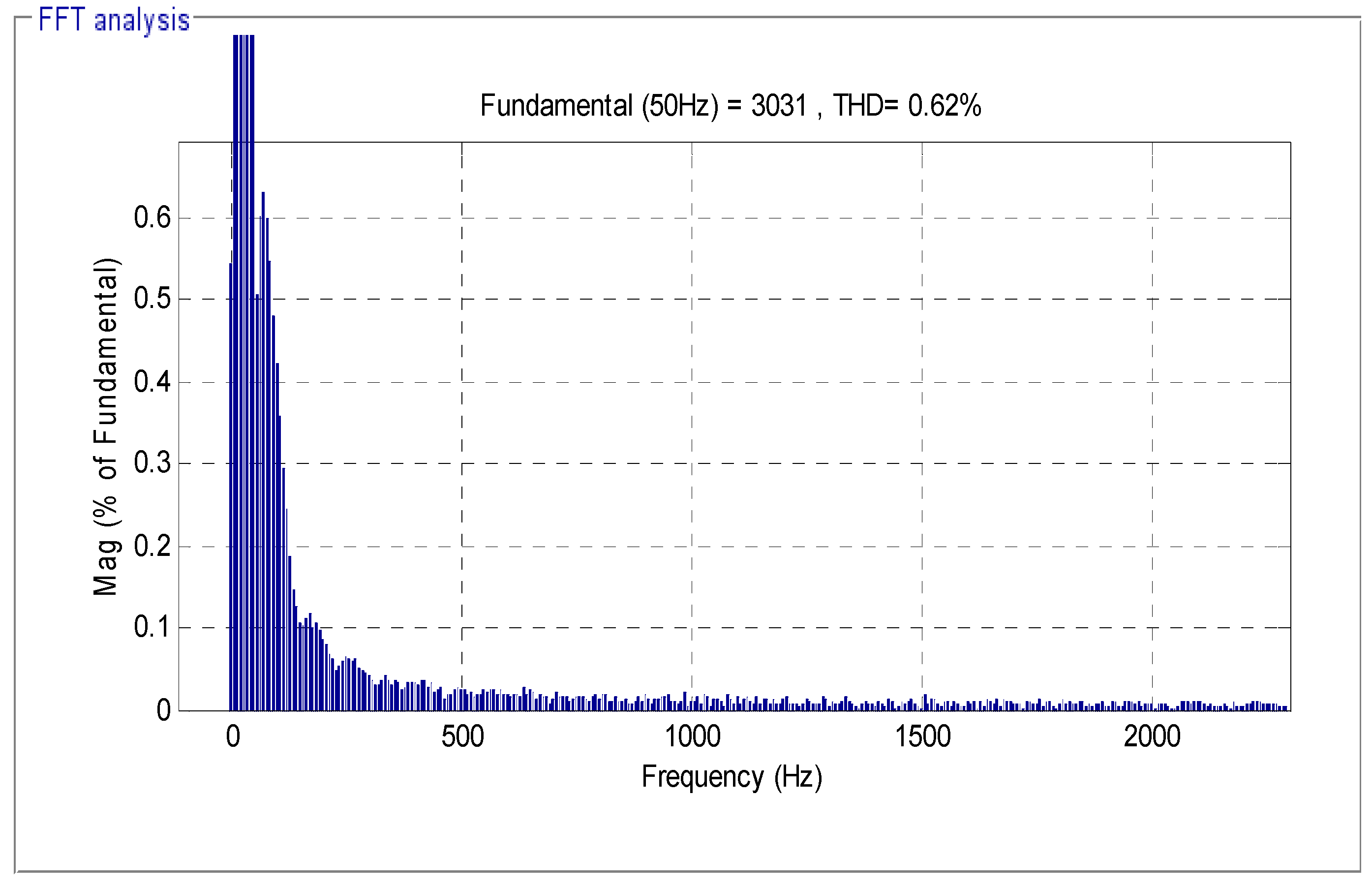

- Using the proposed technique and modified SVM technique minimizes the THD of voltage and torque ripple of the induction generator-based DRWP systems.

2. DRWP Model

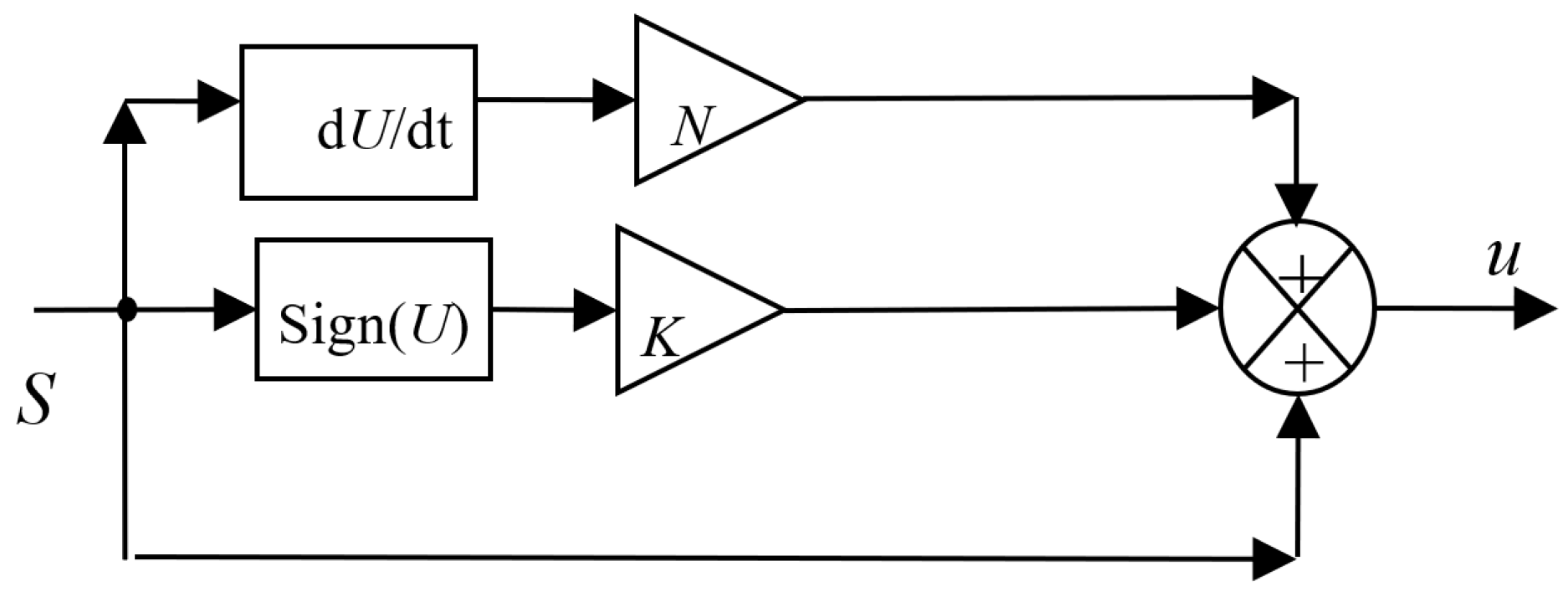

3. Synergetic Sliding Mode Control Theory

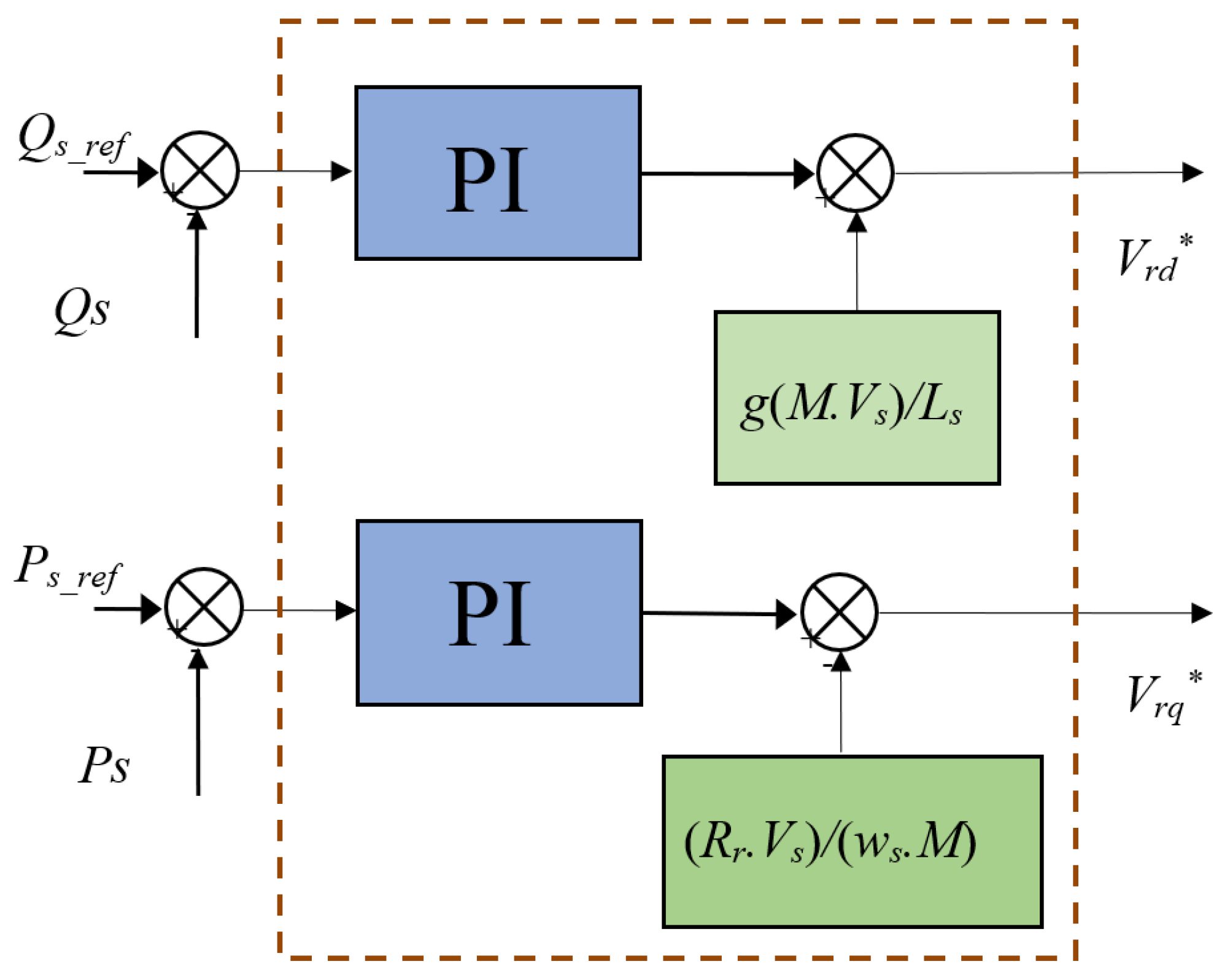

4. Direct FOC Method with SSMC Controllers

5. Numerical Simulation

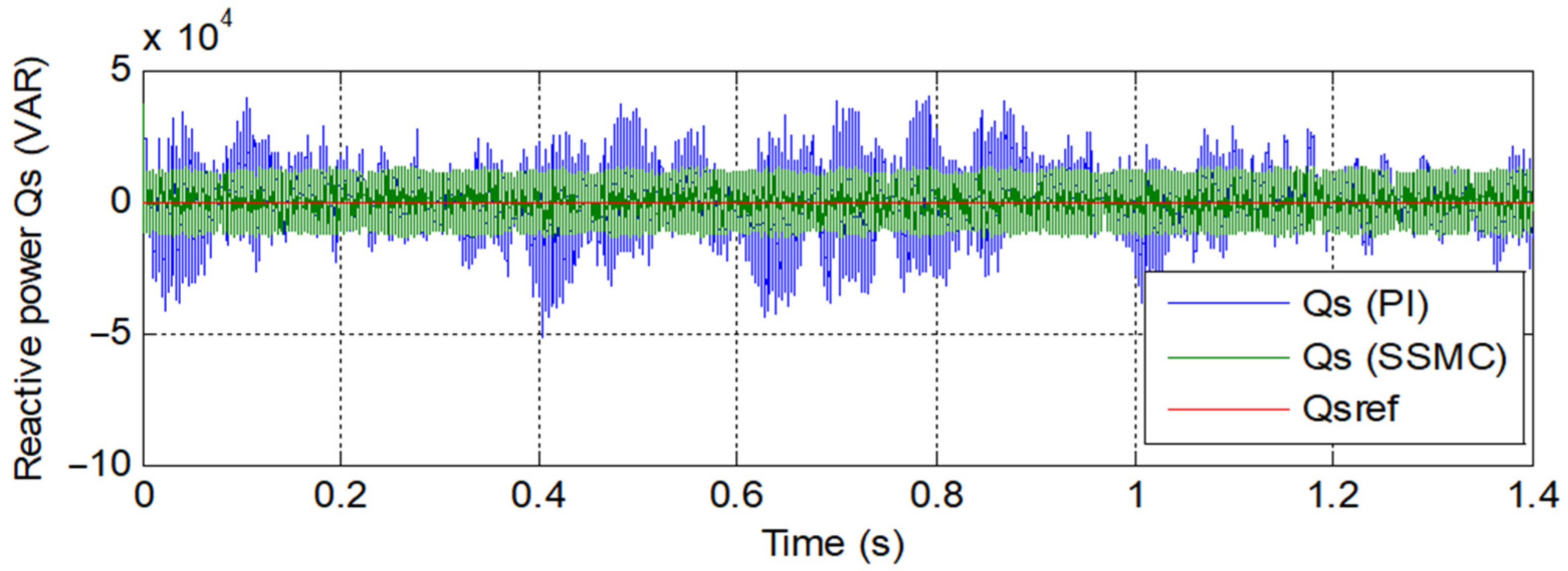

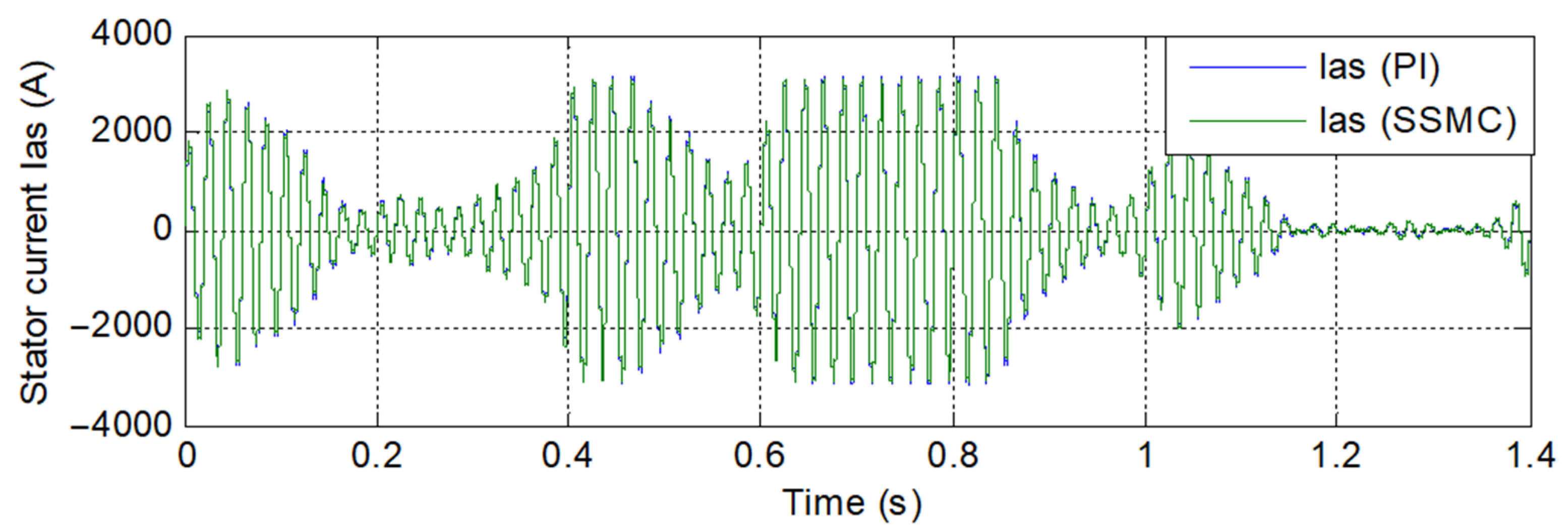

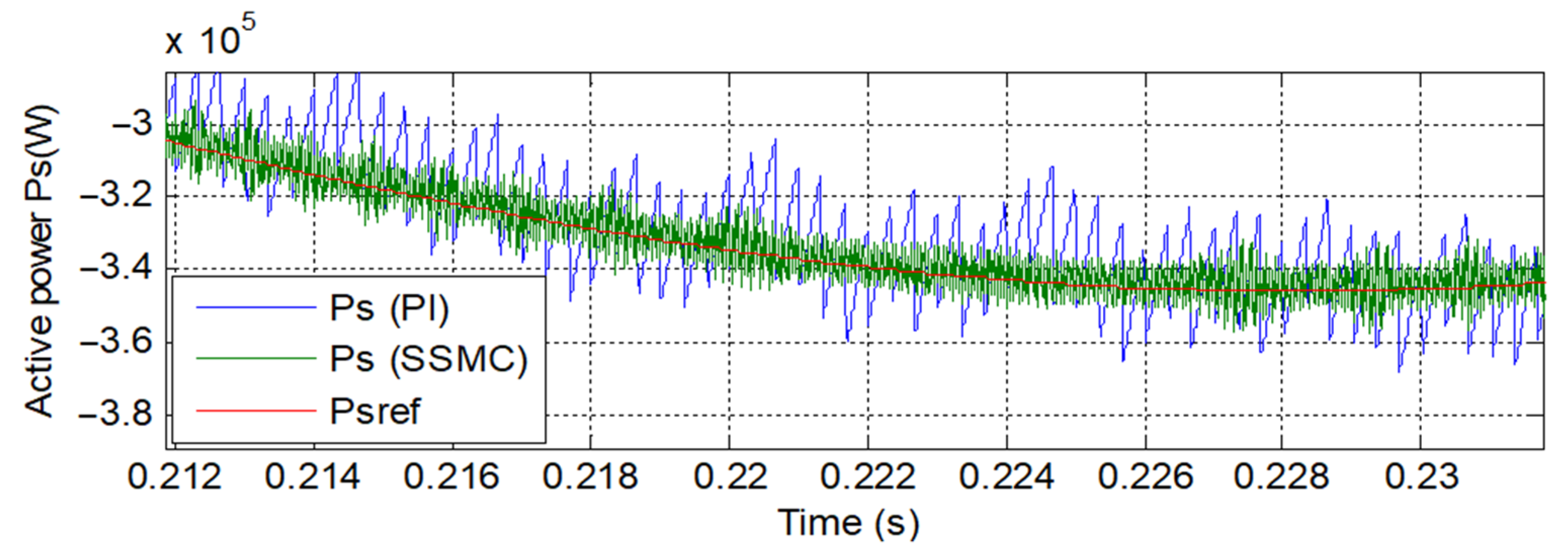

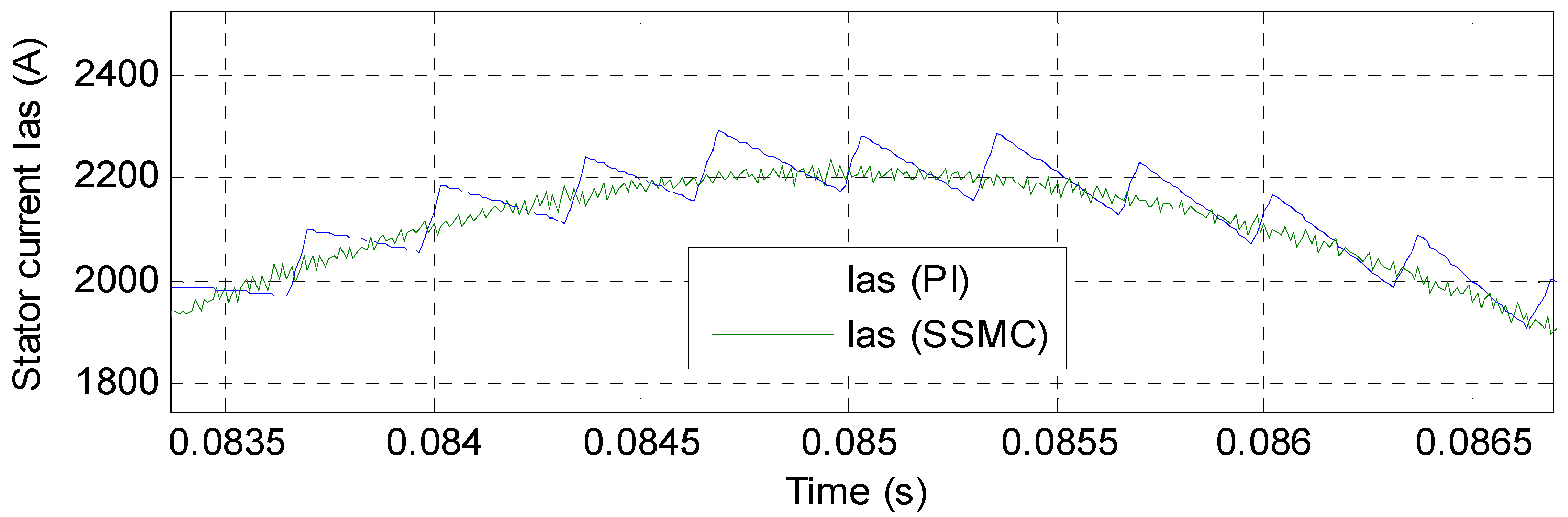

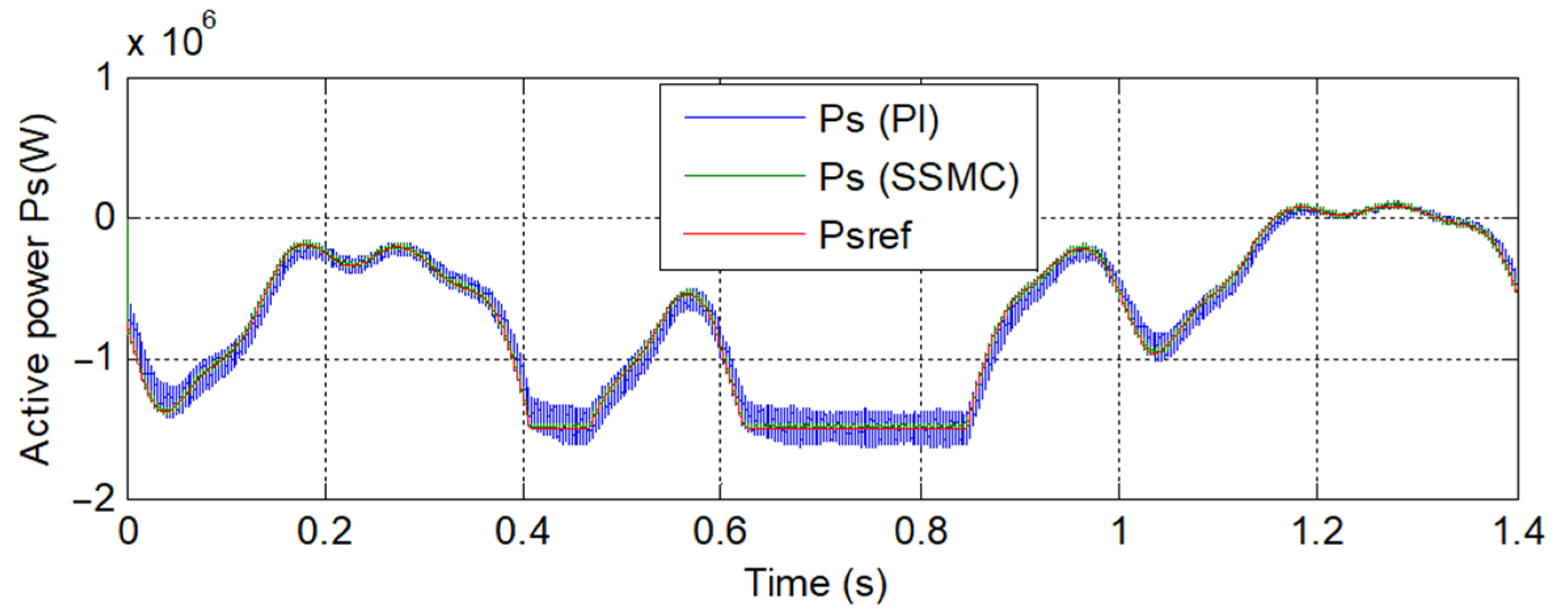

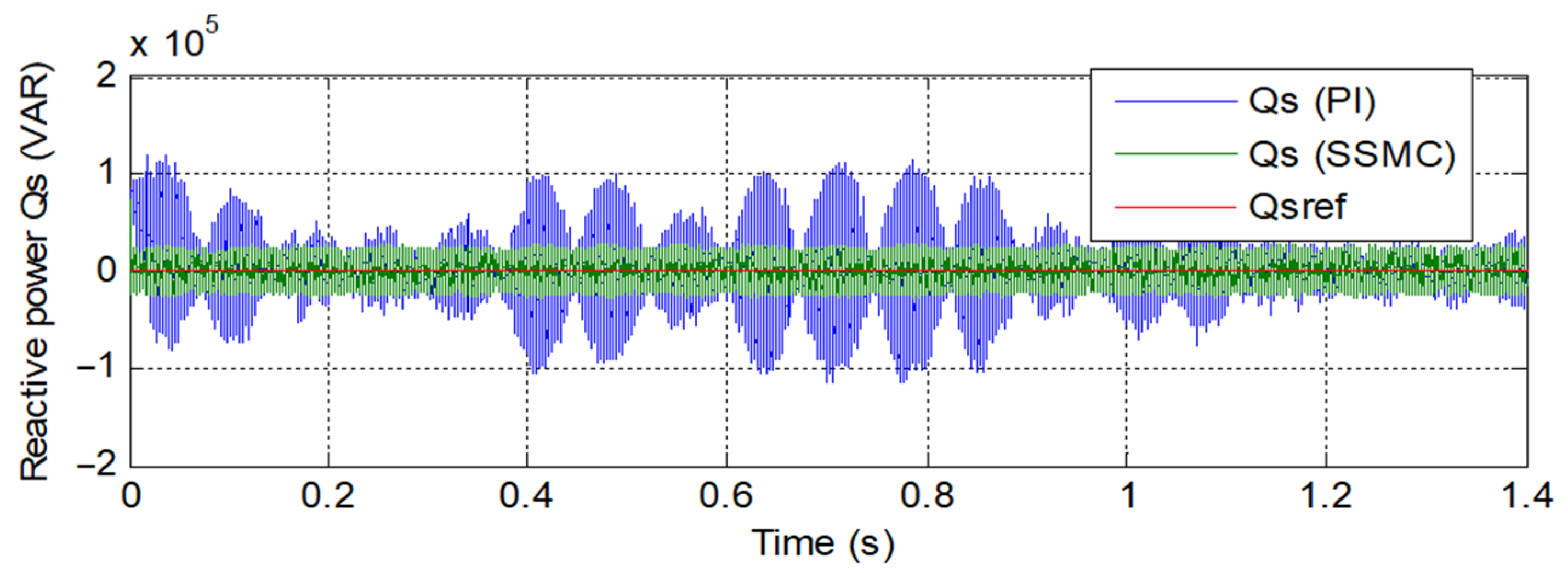

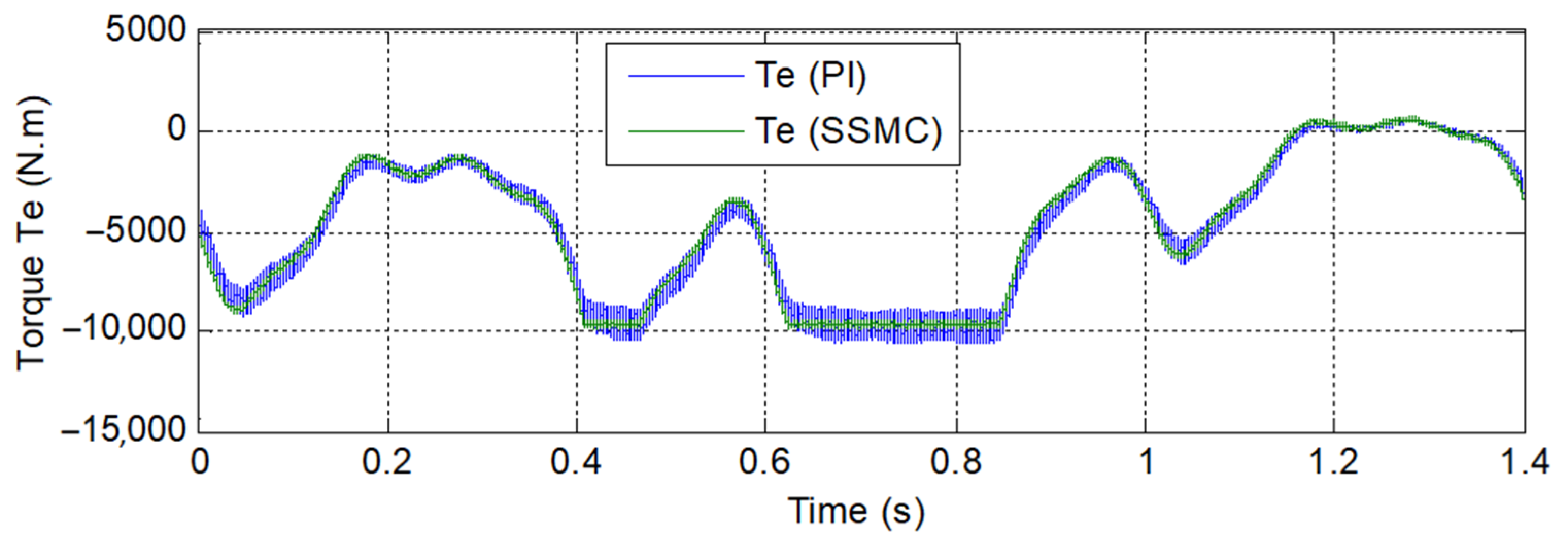

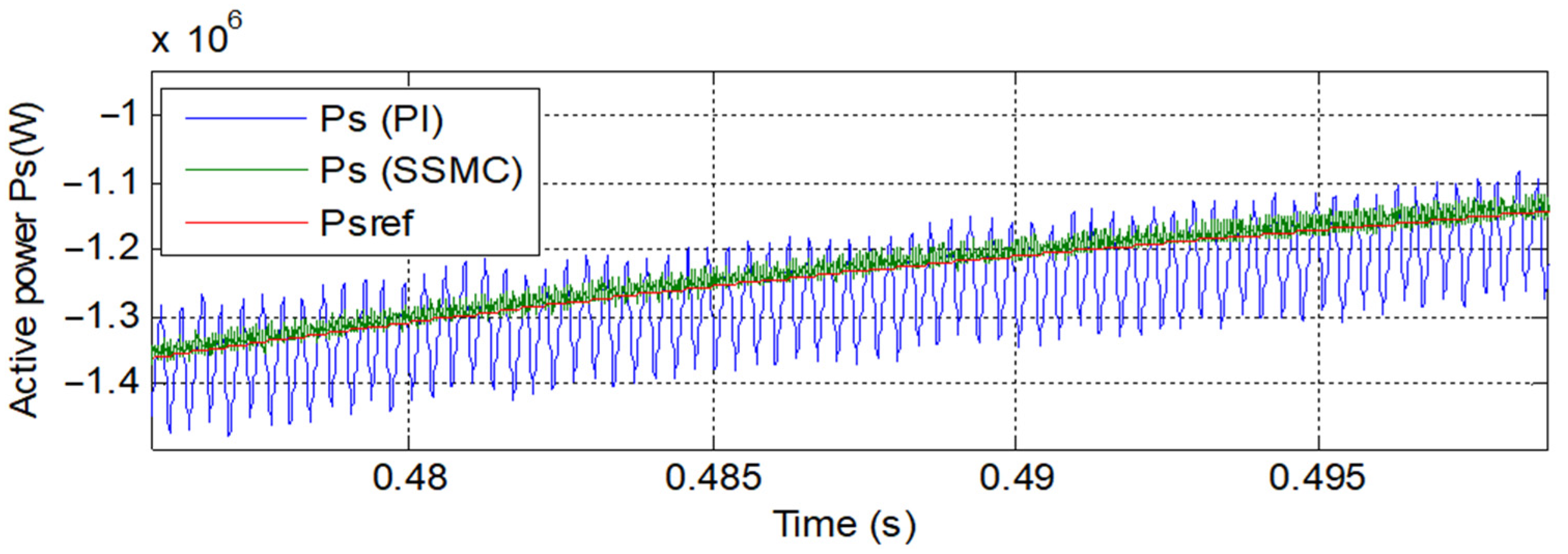

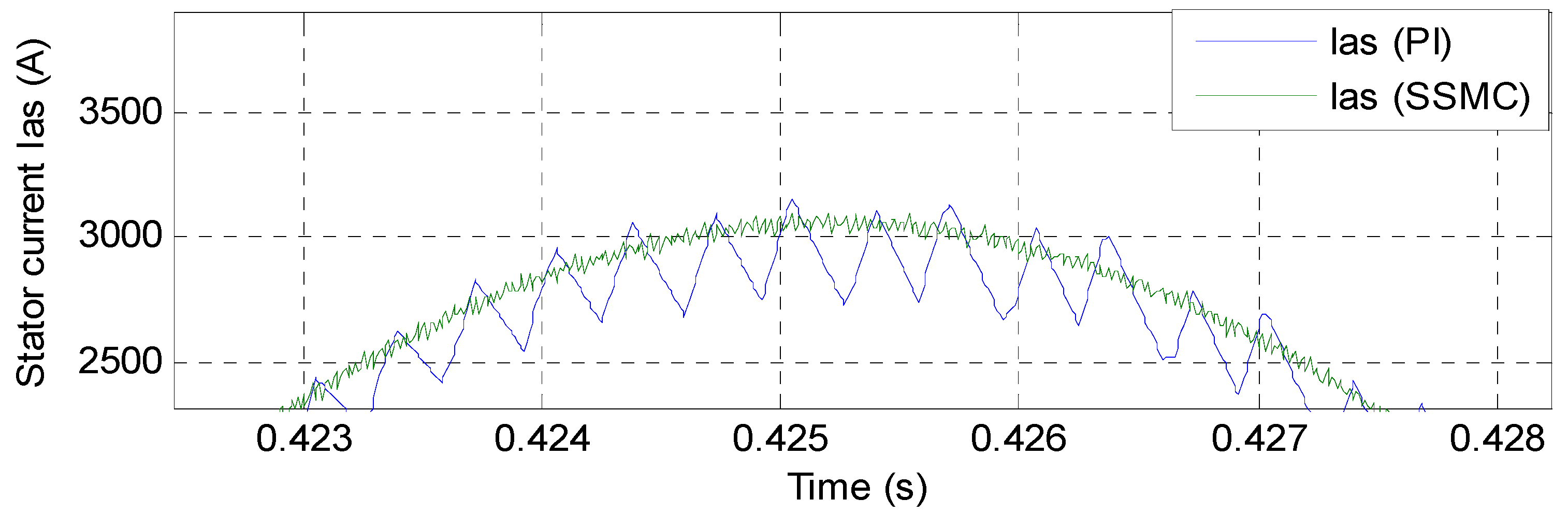

5.1. First Test

5.2. Second Test

6. Conclusions

- (1)

- As in the direct FOC-SSMC method, active and reactive power should not be estimated; the direct FOC-SSMC method causes filter design and converter simplicity. It also improves the transient effectiveness of the controller.

- (2)

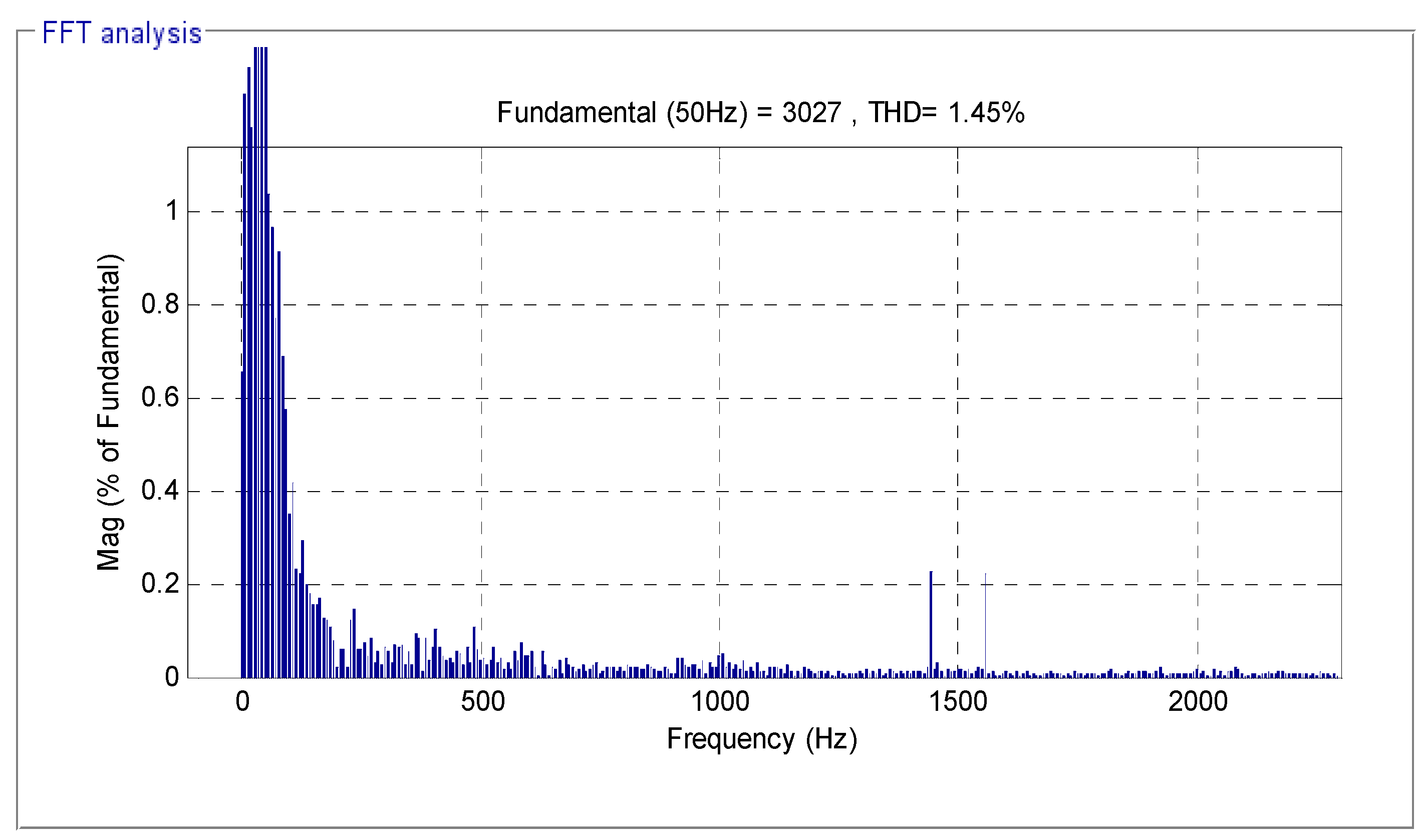

- Direct FOC method gives more THD value and power ripple. There is no improved system effectiveness in comparison with the direct FOC-SSMC method.

- (3)

- Although the robustness of the designed method causes the use of the proposed nonlinear controllers, its characteristics, as stated in part six, such as improved dynamic and transient performance, make it a suitable controller for variable speed dual-rotor wind power production.

Author Contributions

Funding

Conflicts of Interest

References

- Marques, G.; Iacchetti, M.F. Sensorless Frequency and Voltage Control in the Stand-Alone DFIG-DC System. IEEE Trans. Ind. Electron. 2016, 64, 1949–1957. [Google Scholar] [CrossRef]

- Iacchetti, M.F.; Marques, G.; Perini, R. Torque Ripple Reduction in a DFIG-DC System by Resonant Current Controllers. IEEE Trans. Power Electron. 2014, 30, 4244–4254. [Google Scholar] [CrossRef]

- Kaloi, G.S.; Baloch, M.H.; Kumar, M.; Soomro, D.M.; Chauhdary, S.T.; Memon, A.A.; Ishak, D. An LVRT Scheme for Grid Connected DFIG Based WECS Using State Feedback Linearization Control Technique. Electronics 2019, 8, 777. [Google Scholar] [CrossRef]

- Worku, M.Y.; Hassan, M.; Abido, M.A. Real Time-Based under Frequency Control and Energy Management of Microgrids. Electronics 2020, 9, 1487. [Google Scholar] [CrossRef]

- Tian, P.; Hao, Z.; Li, Z. Doubly-Fed Induction Generator Coordination Control Strategy Compatible with Feeder Automation. Electronics 2019, 9, 18. [Google Scholar] [CrossRef]

- Hu, J.; Huang, Y.; Wang, D.; Yuan, H.; Yuan, X. Modeling of Grid-Connected DFIG-Based Wind Turbines for DC-Link Voltage Stability Analysis. IEEE Trans. Sustain. Energy 2015, 6, 1325–1336. [Google Scholar] [CrossRef]

- Kroplewski, P.; Morawiec, M.; Jąderko, A.; Odeh, C. Simulation Studies of Control Systems for Doubly Fed Induction Generator Supplied by the Current Source Converter. Energies 2021, 14, 1511. [Google Scholar] [CrossRef]

- Mondal, S.; Kastha, D. Improved Direct Torque and Reactive Power Control of a Matrix-Converter-Fed Grid-Connected Doubly Fed Induction Generator. IEEE Trans. Ind. Electron. 2015, 62, 7590–7598. [Google Scholar] [CrossRef]

- Mossa, M.A.; Echeikh, H.; Diab, A.A.Z.; Quynh, N.V. Effective Direct Power Control for a Sensor-Less Doubly Fed Induction Generator with a Losses Minimization Criterion. Electronics 2020, 9, 1269. [Google Scholar] [CrossRef]

- Benbouhenni, H. Twelve Sectors DPC Control Based on Neural Hysteresis Comparators of the DFIG Integrated to Wind Power. Tec. Ital.-Ital. J. Eng. Sci. 2020, 64, 347–353. [Google Scholar] [CrossRef]

- Prasad, R.M.; Mulla, M.A. A Novel Position-Sensorless Algorithm for Field-Oriented Control of DFIG with Reduced Current Sensors. IEEE Trans. Sustain. Energy 2018, 10, 1098–1108. [Google Scholar] [CrossRef]

- Benbouhenni, H. Reducing current and torque ripples in DVC control of DFIG operation at constant switching frequency for wind generation application. Majlesi J. Energy Manag. 2019, 8, 47–55. [Google Scholar]

- Benbouhenni, H. Intelligence indirect vector control of a DFIG based wind turbines. Majlesi J. Electr. Eng. 2019, 13, 27–35. [Google Scholar]

- Benbouhenni, H. Comparative study between different vector control methods applied to DFIG wind turbines. Majlesi J. Mechatron. Syst. 2018, 7, 15–23. [Google Scholar]

- Prasad, R.M.; Mulla, M.A. Mathematical Modeling and Position-Sensorless Algorithm for Stator-Side Field-Oriented Control of Rotor-Tied DFIG in Rotor Flux Reference Frame. IEEE Trans. Energy Convers. 2019, 35, 631–639. [Google Scholar] [CrossRef]

- Dahri, N.; Ouassaid, M.; Yousfi, D.A. FOC based robust fuzzy logic controller for a wind energy conversion system to overcome mechanical parameter uncertainties. In Proceedings of the 2020 IEEE International Autumn Meeting on Power, Electronics and Computing (ROPEC), Ixtapa, Mexico, 4–6 November 2020; pp. 1–7. [Google Scholar] [CrossRef]

- Ba-Razzouk, A.; Cheriti, A.; Olivier, G.; Sicard, P. Field-oriented control of induction motors using neural-network decouplers. IEEE Trans. Power Electron. 1997, 12, 752–763. [Google Scholar] [CrossRef]

- Malinowski, M.; Jasinski, M.T.; Kazmierkowski, M.P. Simple Direct Power Control of Three-Phase PWM Rectifier Using Space-Vector Modulation (DPC-SVM). IEEE Trans. Ind. Electron. 2004, 51, 447–454. [Google Scholar] [CrossRef]

- Hea-Gwang, J.; Won-Sang, K.; Kyo-Beum, L.; Byung-Chang, J.; Seung-Ho, S. A sliding-mode approach to control the active and reactive powers for A DFIG in wind turbines. In Proceedings of the 2008 IEEE Power Electronics Specialists Conference, Rhodes, Greece, 15–19 June 2008; pp. 120–125. [Google Scholar] [CrossRef]

- Amrane, F.; Chaiba, A. A novel direct power control for grid-connected doubly fed induction generator based on hybrid artificial intelligent control with space vector modulation. Rev. Sci. Techni. Electrotechn. Energ. 2016, 61, 263–268. [Google Scholar]

- Bizon, N.; Bizon, N. Optimal operation of fuel cell/wind turbine hybrid power system under turbulent wind and variable load. Appl. Energy 2018, 212, 196–209. [Google Scholar] [CrossRef]

- Farahani, E.M.; Hossein Zadeh, N.; Mehran, M.E. Comparison of dynamic responses of dual and single rotor wind turbines under transient conditions. In Proceedings of the 2010 IEEE International Conference on Sustainable Energy Technologies (ICSET), Kandy, Sri Lanka, 6–9 December 2010; pp. 1–8. [Google Scholar] [CrossRef]

- Benbouhenni, H. Application of STA methods and modified SVM strategy in direct vector control system of ASG integrated to dual-rotor wind power: Simulation studies. Int. J. Smart Grid 2021, 5, 62–72. [Google Scholar]

- Yahdou, A.; Djilali, A.B.; Boudjema, Z.; Mehedi, F. Improved Vector Control of a Counter-Rotating Wind Turbine System Using Adaptive Backstepping Sliding Mode. J. Eur. Systèmes Autom. 2020, 53, 645–651. [Google Scholar] [CrossRef]

- Bizon, N. Optimization of the Fuel Cell Renewable Hybrid Power Systems, 1st ed.; Springer: Berlin, Germany, 2020. [Google Scholar] [CrossRef]

- Habib, B. Synergetic control theory scheme for asynchronous generator based dual-rotor wind power. J. Electr. Eng. Electron. Control Comput. Sci. 2021, 7, 19–28. [Google Scholar]

- Huynh, V.; Minh, B.; Amaefule, E.; Tran, A.-T.; Tran, P. Highly Robust Observer Sliding Mode Based Frequency Control for Multi Area Power Systems with Renewable Power Plants. Electronics 2021, 10, 274. [Google Scholar] [CrossRef]

- Resa, J.; Cortes, D.; Marquez-Rubio, J.F.; Navarro, D. Reduction of Induction Motor Energy Consumption via Variable Velocity and Flux References. Electronics 2019, 8, 740. [Google Scholar] [CrossRef]

- Nicola, M.; Nicola, C.-I. Sensorless Fractional Order Control of PMSM Based on Synergetic and Sliding Mode Controllers. Electronics 2020, 9, 1494. [Google Scholar] [CrossRef]

- Roshan, K.P.; Veeranna, K.; Antony, S.; Kumaravel, S.; Ramchand, R. A Low Cost Development Tool for Educating Electric Machines. In Proceedings of the IECON 2019—45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; pp. 6305–6310. [Google Scholar] [CrossRef]

- Ihedrane, Y.; El Bekkali, C.; Bossoufi, B. Direct and indirect field oriented control of DFIG-generators for wind turbines variable-speed. In Proceedings of the 2017 14th International Multi-Conference on Systems, Signals & Devices (SSD), Marrakech, Morocco, 28–31 March 2017; pp. 27–32. [Google Scholar] [CrossRef]

- Touaiti, B.; Ben Azza, H.; Jemli, M. Direct voltage control of stand-alone DFIG in wind energy applications. In Proceedings of the 2015 16th International Conference on Sciences and Techniques of Automatic Control and Computer Engineering (STA), Monastir, Tunisia, 21–23 December 2015; pp. 672–677. [Google Scholar] [CrossRef]

- Djilali, L.; Sanchez, E.N.; Belkheiri, M. Neural sliding mode field oriented control for DFIG based wind turbine. In Proceedings of the 2017 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Banff, Canada, 5–8 October 2017; pp. 2087–2092. [Google Scholar] [CrossRef]

- Samir, A.; Ahmad, T.A.; Djalel, D. A Novel Actuator Fault-tolerant Control Strategy of DFIG-based Wind Turbines Using Takagi-Sugeno Multiple Models. Int. J. Control. Autom. Syst. 2018, 16, 1415–1424. [Google Scholar]

- Dekali, Z.; Baghli, L.; Boumediene, A. Indirect power control for a grid connected double fed induction generator based wind turbine emulator. In Proceedings of the 2019 International Conference on Advanced Electrical Engineering (ICAEE), Dhaka, Bangladesh, 26–28 September 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Listwan, J. Application of Super-Twisting Sliding Mode Controllers in Direct Field-Oriented Control System of Six-Phase Induction Motor: Experimental Studies. Power Electron. Drives 2018, 3, 23–34. [Google Scholar] [CrossRef][Green Version]

- Benbouhenni, H.; Boudjema, Z.; Belaidi, A. Using four-level NSVM technique to improve DVC control of a DFIG based wind turbine systems. Period. Polytech. Electr. Eng. Comput. Sci. 2019, 63, 144–150. [Google Scholar] [CrossRef]

- Sriprang, S.; Nahid-Mobarakeh, B.; Takorabet, N.; Pierfederici, S.; Kumam, P.; Bizon, N.; Taghavi, N.; Vahedi, A.; Mungporn, P.; Thounthong, P. Design and control of permanent magnet assisted synchronous reluctance motor with copper loss minimization using MTPA. J. Electr. Eng. 2020, 71, 11–19. [Google Scholar] [CrossRef]

- Hounthong, P.; Sikkabut, S.; Poonnoy, N.; Mungporn, P.; Yodwong, B.; Kumam, P.; Bizon, N.; Pierfederici, S.; Poonnoi, N.; Nahidmobarakeh, B. Nonlinear Differential Flatness-Based Speed/Torque Control with State-Observers of Permanent Magnet Synchronous Motor Drives. IEEE Trans. Ind. Appl. 2018, 54, 2874–2884. [Google Scholar] [CrossRef]

- Yusoff, N.A.M.; Razali, A.M.; Karim, K.A.; Sutikno, T.; Jidin, A. A Concept of Virtual-Flux Direct Power Control of Three-Phase AC-DC Converter. Int. J. Power Electron. Drive Syst. (IJPEDS) 2017, 8, 1776–1784. [Google Scholar] [CrossRef]

- Amrane, F.; Chaiba, A.; Babes, B.E.; Mekhilef, S. Design and implementation of high performance field oriented control for grid-connected doubly fed induction generator via hysteresis rotor current controller. Rev. Roum. Sci. Tech. Electrotechn. Energ. 2016, 61, 319–324. [Google Scholar]

- Boudjema, Z.; Meroufel, A.; Djerriri, Y.; Bounadja, E. Fuzzy sliding mode control of a doubly fed induction generator for energy conversion. Carpathian J. Electron. Comput. Eng. 2013, 6, 7–14. [Google Scholar]

- Boudjema, Z.; Taleb, R.; Djerriri, Y.; Yahdou, A. A novel direct torque control using second order continuous sliding mode of a doubly fed induction generator for a wind energy conversion system. Turk. J. Electr. Eng. Comput. Sci. 2017, 25, 965–975. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Pn | 1.5 MW |

| Vn | 380 V |

| p | 2 |

| Rs | 0.012 Ω |

| Rr | 0.021 Ω |

| Ls | 0.0137 H |

| Lr | 0.0136 H |

| Lm | 0.0135 H |

| J | 1000 Kg.m2 |

| fr | 0.0024 Nm.s/rad |

| f | 50 Hz |

| Reference | Technique | THD (%) |

|---|---|---|

| Ref. [40] | VFDPC | 4.19 |

| DPC | 4.88 | |

| Ref. [41] | FOC | 3.7 |

| Ref. [42] | SMC | 3.05 |

| Ref. [43] | Robust DTC control | 0.98 |

| Proposed techniques | DFOC | 1.45 |

| DFOC-SSMC | 0.50 |

| Performance Criteria | Classical Technique | Proposed Technique |

|---|---|---|

| Simplicity of calculations | + | + |

| Improvement of transient performance | - | + |

| Improvement of dynamic response | - | + |

| Simplicity of converter and filter design | + | + |

| Negligible parameter effects on system performance | - | + |

| Robustness | - | + |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benbouhenni, H.; Bizon, N. A Synergetic Sliding Mode Controller Applied to Direct Field-Oriented Control of Induction Generator-Based Variable Speed Dual-Rotor Wind Turbines. Energies 2021, 14, 4437. https://doi.org/10.3390/en14154437

Benbouhenni H, Bizon N. A Synergetic Sliding Mode Controller Applied to Direct Field-Oriented Control of Induction Generator-Based Variable Speed Dual-Rotor Wind Turbines. Energies. 2021; 14(15):4437. https://doi.org/10.3390/en14154437

Chicago/Turabian StyleBenbouhenni, Habib, and Nicu Bizon. 2021. "A Synergetic Sliding Mode Controller Applied to Direct Field-Oriented Control of Induction Generator-Based Variable Speed Dual-Rotor Wind Turbines" Energies 14, no. 15: 4437. https://doi.org/10.3390/en14154437

APA StyleBenbouhenni, H., & Bizon, N. (2021). A Synergetic Sliding Mode Controller Applied to Direct Field-Oriented Control of Induction Generator-Based Variable Speed Dual-Rotor Wind Turbines. Energies, 14(15), 4437. https://doi.org/10.3390/en14154437