Capillary Desaturation Tendency of Hybrid Engineered Water-Based Chemical Enhanced Oil Recovery Methods

Abstract

:1. Introduction

2. Methodology

2.1. Chemicals

2.2. Coreflooding

2.3. Interfacial Tension Estimation

2.4. Capillary Numbers

2.5. Conventional Capillary Desaturation Curves

3. Results and Discussion

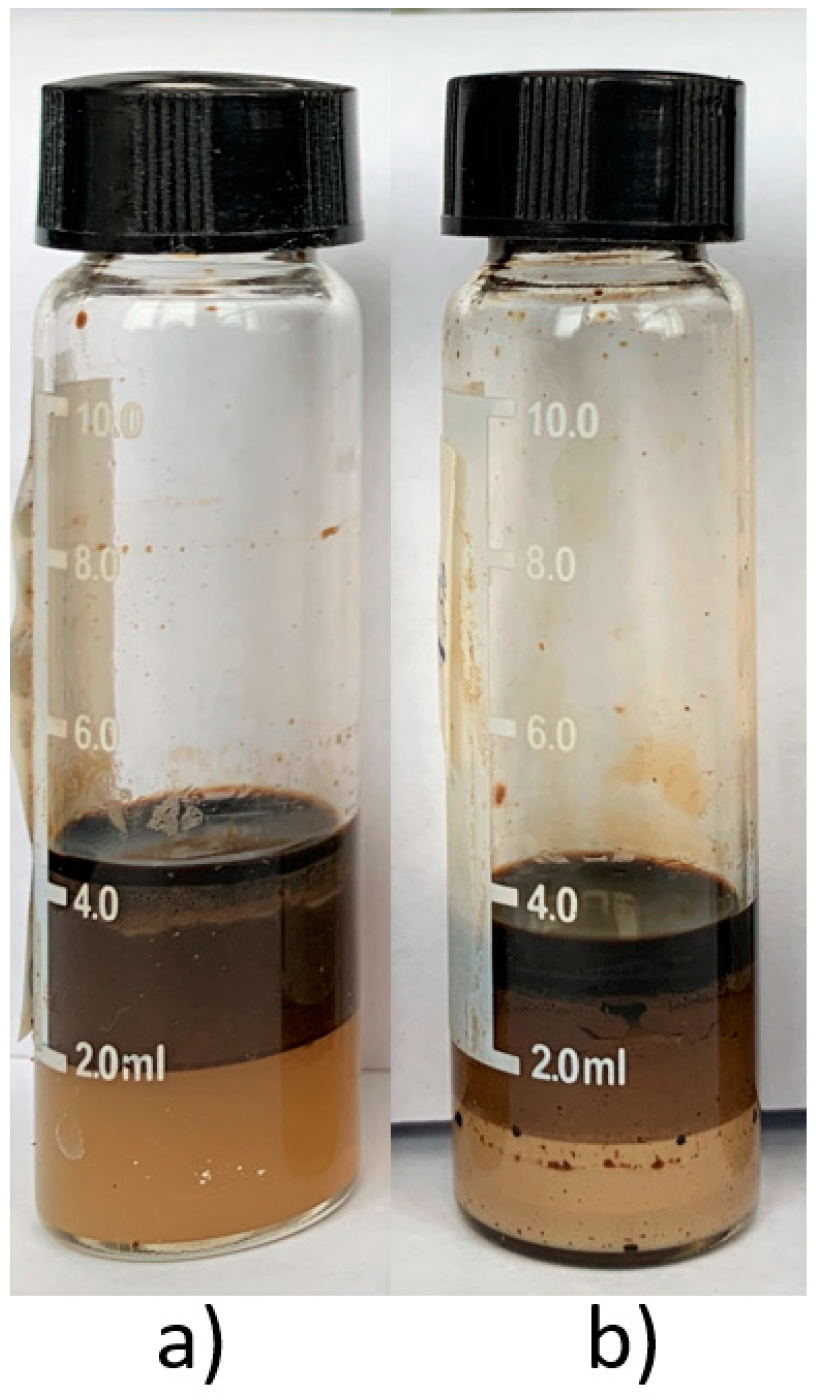

3.1. IFT Results

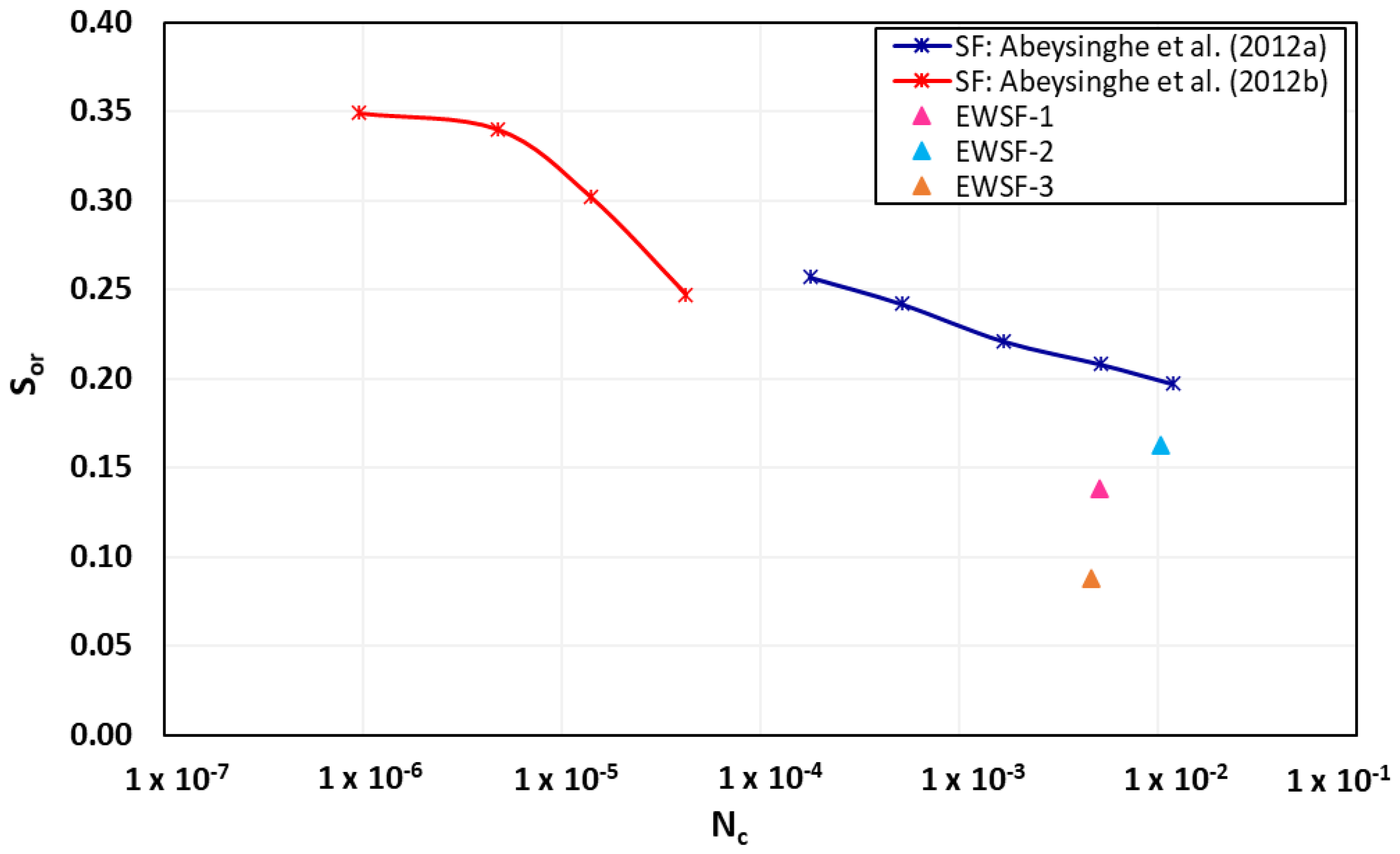

3.2. Hybrid EW-Surfactant Flooding

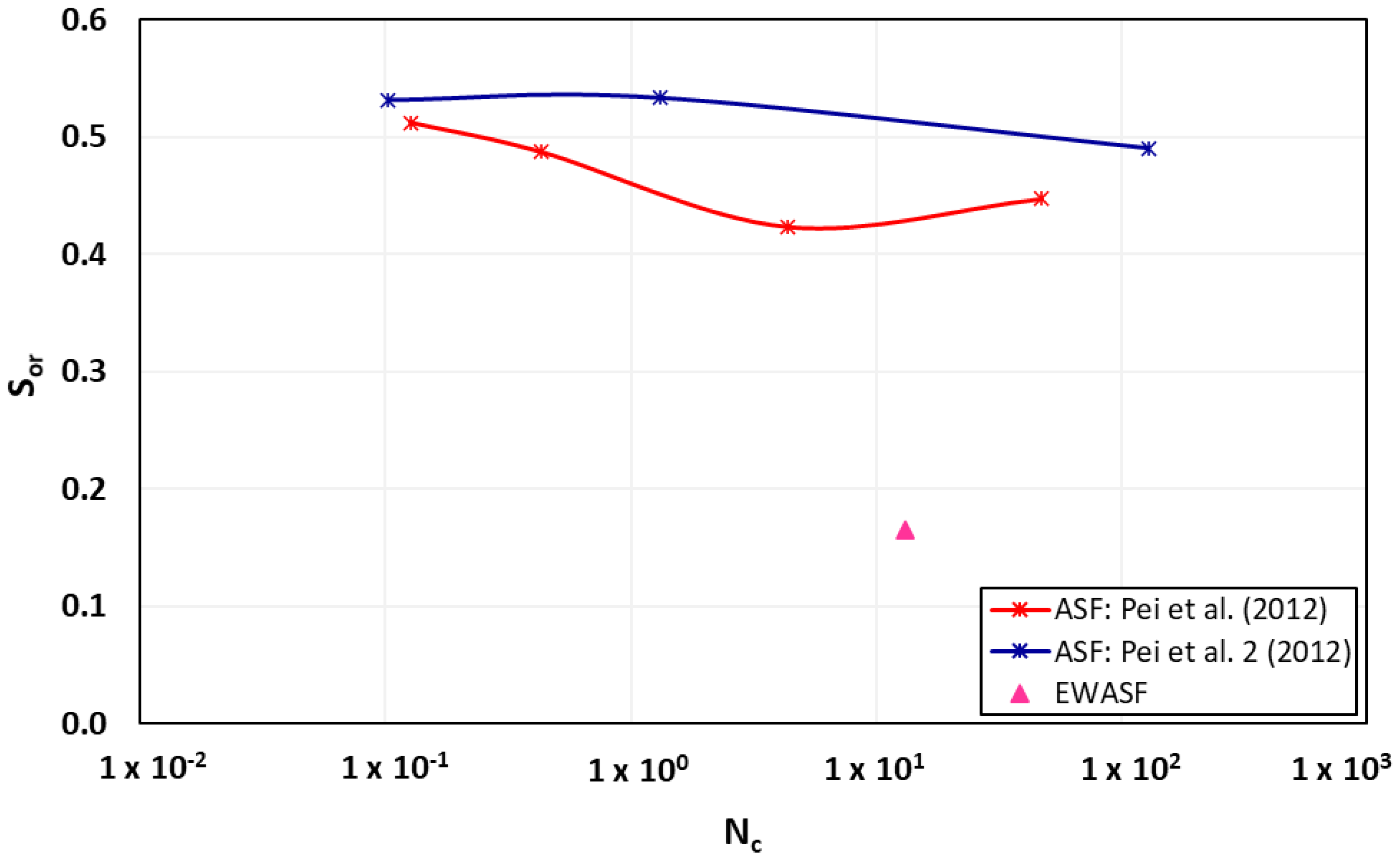

3.3. Hybrid EW-Alkali-Surfactant Flooding

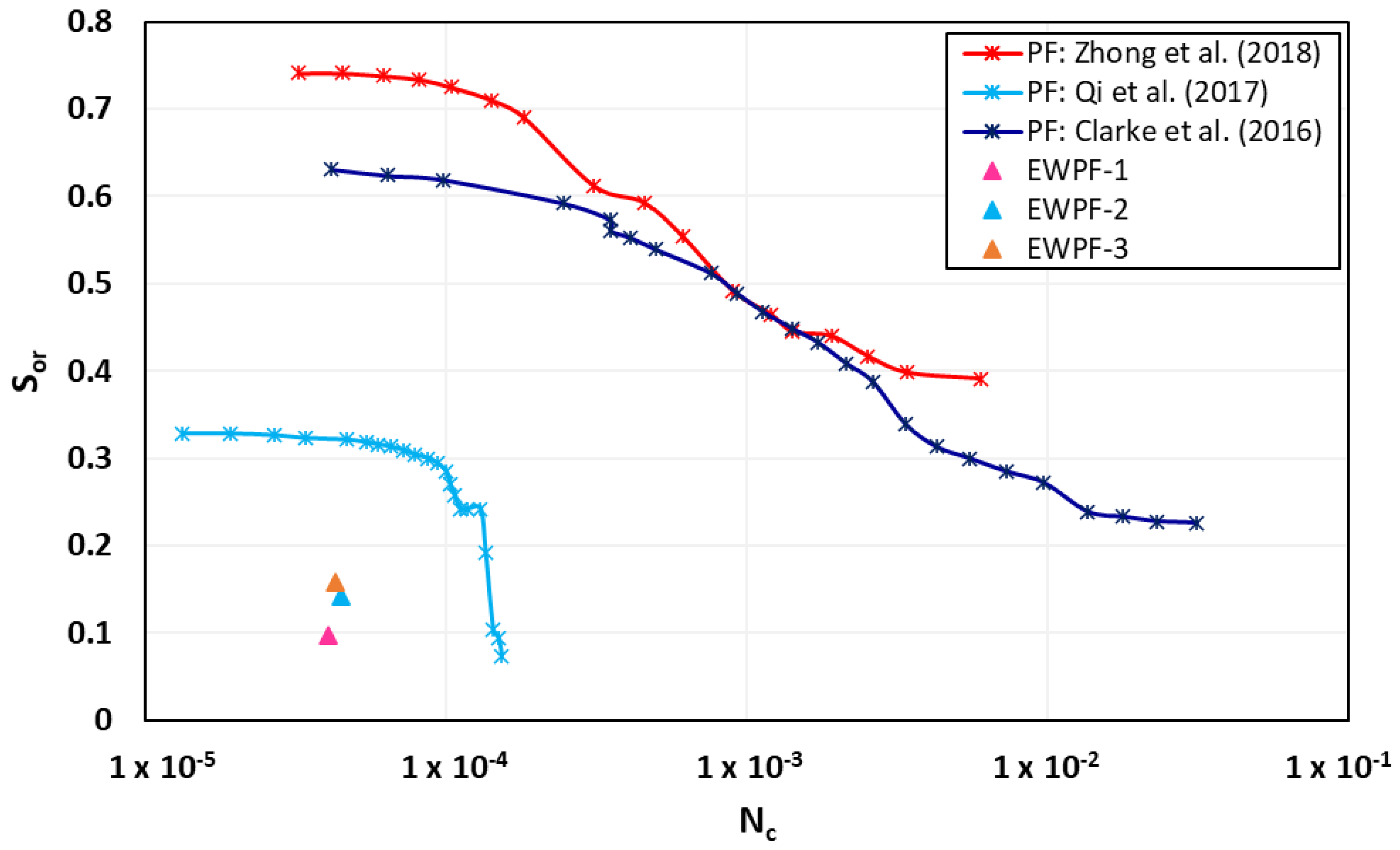

3.4. Hybrid EW-Polymer Flooding

3.5. Hybrid EW-Surfactant-Polymer Flooding

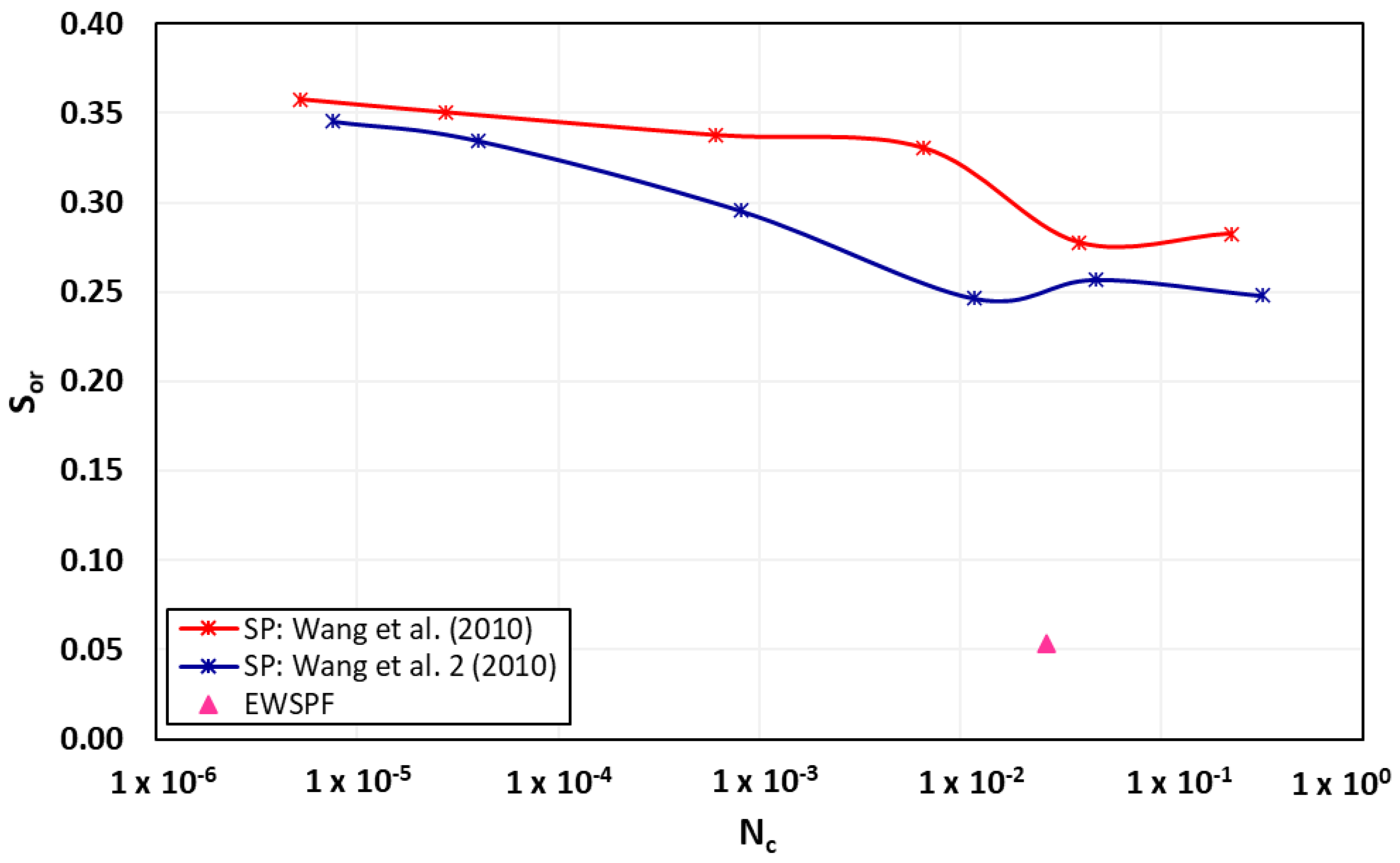

3.6. Hybrid EW-Alkali-Surfactant-Polymer Flooding

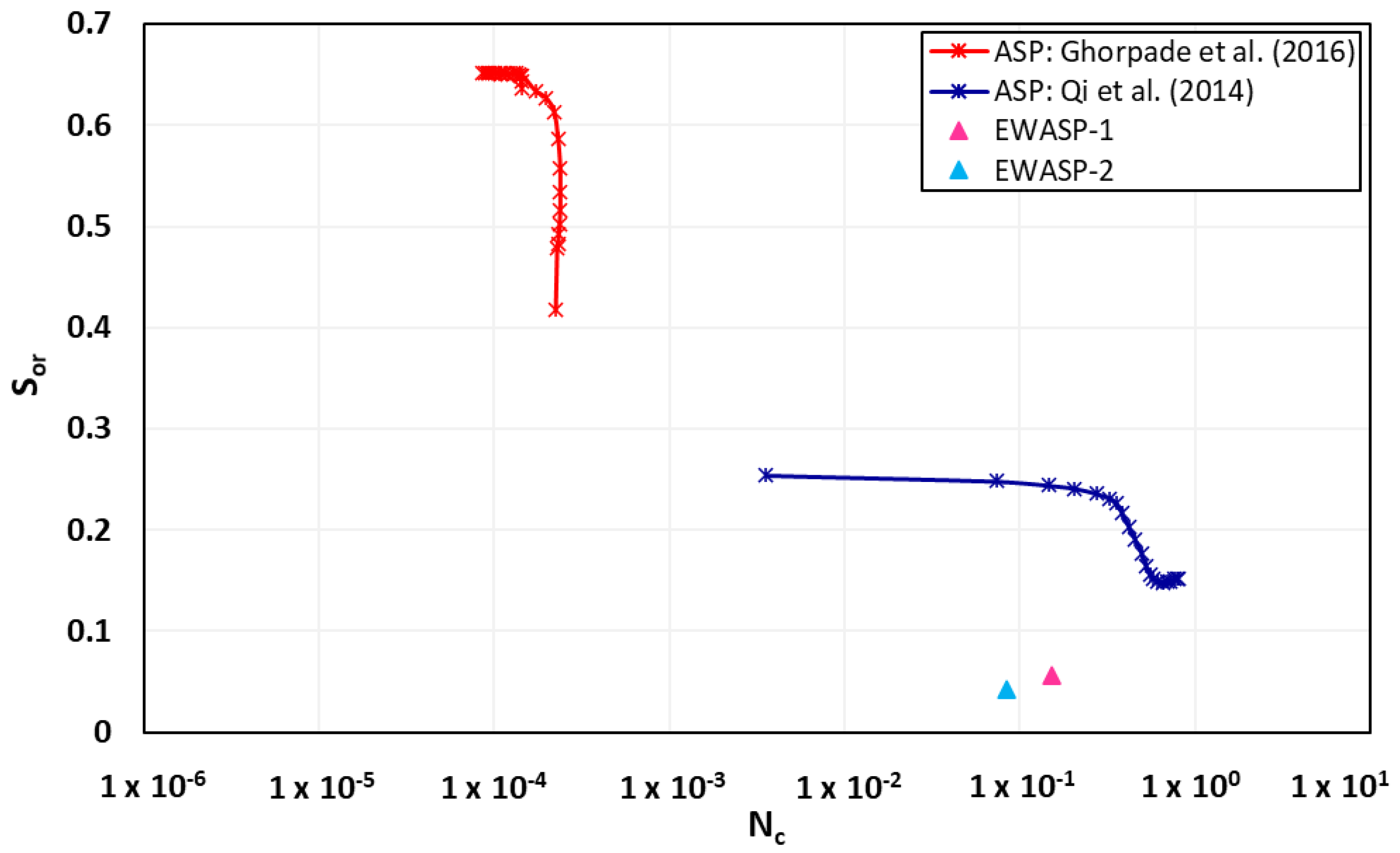

3.7. Comparison of Threshold Capillary Number

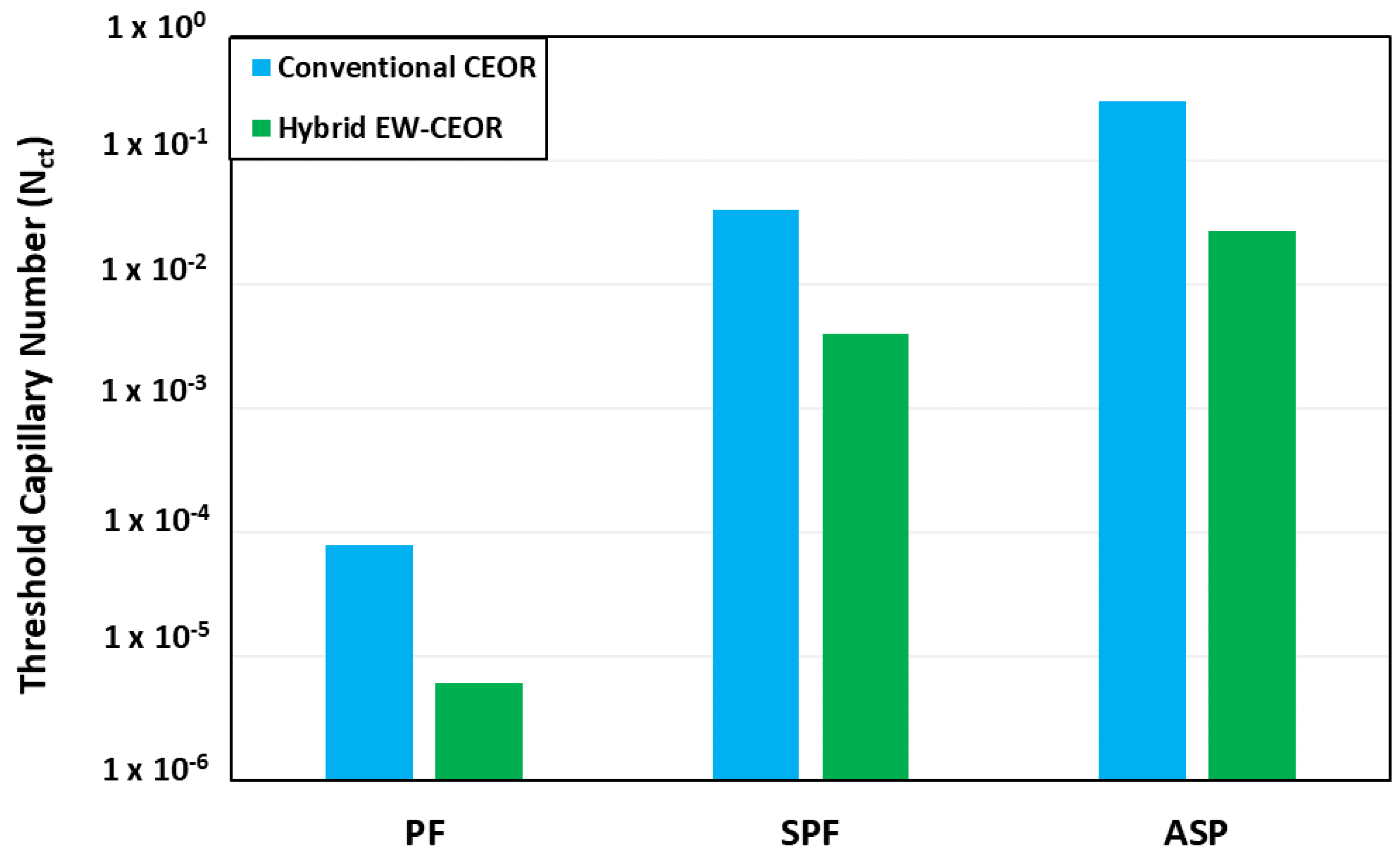

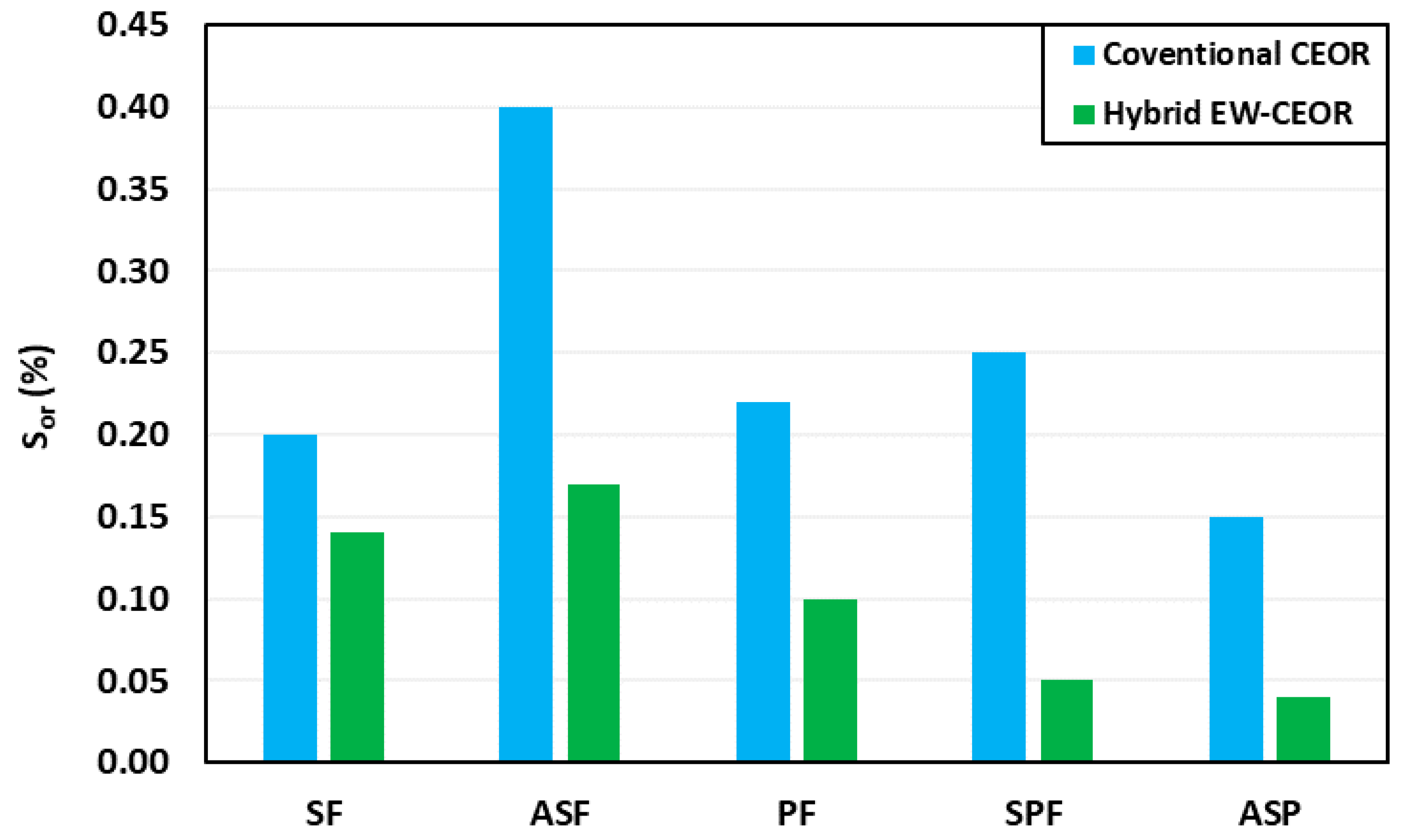

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Δπ | Pressure drop, psi |

| L | Length of core sample, cm |

| μ | Viscosity of displacing fluid, Pa.s |

| Nc | Capillary number |

| Nct | Threshold capillary number |

| σ | Interfacial tension, dynes/cm (mN/m) |

| σμο,μω | Microemulsion/oil or microemulsion/water IFT, dynes/cm (mN/m) |

| Sor | Residual oil saturation |

| ν | Superficial velocity, m/s |

| Vme | Volume of microemulsion |

| Vo,w | Oil or water volume in microemulsion, ml |

| Vs | Surfactant volume in microemulsion |

| ASP | Alkali-surfactant polymer flooding |

| EWSF | Engineered water surfactant flooding |

| PF | Polymer flooding |

| SF | Surfactant flooding |

| SPF | Surfactant polymer flooding |

References

- Mwangi, P.; Brady, P.V.; Radonjic, M.; Thyne, G. The effect of organic acids on wettability of sandstone and carbonate rocks. J. Pet. Sci. Eng. 2018, 165, 428–435. [Google Scholar] [CrossRef]

- Brady, P.V.; Thyne, G. Functional wettability in carbonate reservoirs. Energy Fuels 2016, 30, 9217–9225. [Google Scholar] [CrossRef]

- Xie, Q.; He, S.; Pu, W. The effects of temperature and acid number of crude oil on the wettability of acid volcanic reservoir rock from the Hailar Oilfield. Pet. Sci. 2010, 7, 93–99. [Google Scholar] [CrossRef] [Green Version]

- Chang, H.; Zhang, Z.; Wang, Q.; Xu, Z.; Guo, Z.; Sun, H.; Cao, X.; Qiao, Q. Advances in polymer flooding and alkaline/surfactant/polymer processes as developed and applied in the People’s Republic of China. J. Pet. Technol. 2006, 58, 84–89. [Google Scholar] [CrossRef]

- Saleh, L.D.; Wei, M.; Bai, B. Data analysis and updated screening criteria for polymer flooding based on oilfield data. SPE Reserv. Eval. Eng. 2014, 17, 15–25. [Google Scholar] [CrossRef]

- Sheng, J.J.; Leonhardt, B.; Azri, N. Status of polymer-flooding technology. J. Can. Pet. Technol. 2015, 54, 116–126. [Google Scholar] [CrossRef]

- Standnes, D.C.; Skjevrak, I. Literature review of implemented polymer field projects. J. Pet. Sci. Eng. 2014, 122, 761–775. [Google Scholar] [CrossRef]

- Andersen, P.Ø.; Evje, S.; Kleppe, H.; Skjaeveland, S.M. A model for wettability alteration in fractured reservoirs. SPE J. 2015, 20, 1261–1275. [Google Scholar] [CrossRef] [Green Version]

- Lashkarbolooki, M.; Riazi, M.; Hajibagheri, F.; Ayatollahi, S. Low salinity injection into asphaltenic-carbonate oil reservoir, mechanistical study. J. Mol. Liq. 2016, 216, 377–386. [Google Scholar] [CrossRef]

- Elakneswaran, Y.; Takeya, M.; Ubaidah, A.; Shimokawara, M.; Okano, H.; Nawa, T. Integrated geochemical modelling of low salinity waterflooding for enhanced oil recovery in carbonate reservoir. In Proceedings of the International Petroleum Technology Conference, Dhahran, Saudi Arabia, 13–15 January 2020. [Google Scholar]

- Sarvestani, A.D.; Ayatollahi, S.; Moghaddam, M.B. Smart water flooding performance in carbonate reservoirs: An experimental approach for tertiary oil recovery. J. Pet. Explor. Prod. Technol. 2019, 9, 2643–2657. [Google Scholar] [CrossRef] [Green Version]

- Lager, A.; Webb, K.J.; Black, C.; Singleton, M.; Sorbie, K.S. Low salinity oil recovery-an experimental investigation1. Petrophysics 2008, 49, SPWLA-2008-v49n1a2. [Google Scholar]

- Martin, J.C. The effects of clay on the displacement of heavy oil by water. In Proceedings of the Venezuelan annual meeting, Caracas, Venezuela, 14–16 October 1959. [Google Scholar]

- Bernard, G.G. Effect of floodwater salinity on recovery of oil from cores containing clays. In Proceedings of the SPE California Regional Meeting, Los Angeles, CA, USA, 26–27 October 1967. [Google Scholar]

- Hallenbeck, L.; Sylte, J.; Ebbs, D.; Thomas, L. Implementation of the Ekofisk field waterflood. SPE Form. Eval. 1991, 6, 284–290. [Google Scholar] [CrossRef]

- Austad, T.; Shariatpanahi, S.; Strand, S.; Black, C.; Webb, K. Conditions for a low-salinity enhanced oil recovery (EOR) effect in carbonate oil reservoirs. Energy Fuels 2012, 26, 569–575. [Google Scholar] [CrossRef]

- Mahani, H.; Menezes, R.; Berg, S.; Fadili, A.; Nasralla, R.; Voskov, D.; Joekar-Niasar, V. Insights into the impact of temperature on the wettability alteration by low salinity in carbonate rocks. Energy Fuels 2017, 31, 7839–7853. [Google Scholar] [CrossRef]

- Ligthelm, D.J.; Gronsveld, J.; Hofman, J.; Brussee, N.; Marcelis, F.; van der Linde, H. Novel waterflooding strategy by manipulation of injection brine composition. In Proceedings of the EUROPEC/EAGE conference and exhibition, Amsterdam, The Netherlands, 8–11 June 2009. [Google Scholar]

- Strand, S.; Høgnesen, E.J.; Austad, T. Wettability alteration of carbonates—Effects of potential determining ions (Ca2+ and SO42−) and temperature. Colloids Surf. Physicochem. Eng. Asp. 2006, 275, 1–10. [Google Scholar] [CrossRef]

- Altahir, M.; Yu, M.; Hussain, F. Low salinity water flooding in carbonate rocks—Dissolution effect. In Proceedings of the International Symposium of the Society of Core Analysts, Vienna, Austria, 27 August–1 September 2017. SCA2017-070. [Google Scholar]

- Hiorth, A.; Cathles, L.; Madland, M. The impact of pore water chemistry on carbonate surface charge and oil wettability. Transp. Porous Media 2010, 85, 1–21. [Google Scholar] [CrossRef]

- Hadi, Y.; Hussain, F.; Othman, F. Low salinity water flooding in carbonate reservoirs—Dissolution effect. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Baghdad, Iraq, 10–11 April 2019; p. 012029. [Google Scholar]

- Mokhtari, R.; Ayatollahi, S.; Fatemi, M. Experimental investigation of the influence of fluid-fluid interactions on oil recovery during low salinity water flooding. J. Pet. Sci. Eng. 2019, 182, 106194. [Google Scholar] [CrossRef]

- Zahid, A.; Shapiro, A.; Skauge, A.; Stenby, E. Smart waterflooding (high sal/low sal) in carbonate reservoirs ). In Proceedings of the 74th EAGE Conference and Exhibition incorporating EUROPEC 2012, Copenhagen, Denmark, 4–7 June 2012. SPE-154508-MS. [Google Scholar]

- Masalmeh, S.; Al-Hammadi, M.; Farzaneh, A.; Sohrabi, M. Low salinity water flooding in carbonate: Screening, laboratory quantification and field implementation. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 11–14 November 2019. [Google Scholar]

- Mahani, H.; Keya, A.L.; Berg, S.; Nasralla, R. Electrokinetics of carbonate/brine interface in low-salinity waterflooding: Effect of brine salinity, composition, rock type, and pH on?—Potential and a surface-complexation model. SPE J. 2018, 22, 53–68. [Google Scholar] [CrossRef]

- Karoussi, O.; Hamouda, A.A. Imbibition of sulfate and magnesium ions into carbonate rocks at elevated temperatures and their influence on wettability alteration and oil recovery. Energy Fuels 2007, 21, 2138–2146. [Google Scholar] [CrossRef]

- Shakeel, M.; Pourafshary, P.; Rehan Hashmet, M. Hybrid engineered water—Polymer flooding in carbonates: A review of mechanisms and case studies. Appl. Sci. 2020, 10, 6087. [Google Scholar] [CrossRef]

- Hirasaki, G.J.; Miller, C.A.; Puerto, M. Recent advances in surfactant EOR. SPE J. 2011, 16, 889–907. [Google Scholar] [CrossRef]

- Farrell, H.; Gregory, M.; Borah, M. Progress report: Big muddy field low-tension flood demonstration project with emphasis on injectivity and mobility. In Proceedings of the SPE Enhanced Oil Recovery Symposium, Tulsa, OK, USA, 15–18 April 1984. [Google Scholar]

- Reppert, T.; Bragg, J.; Wilkinson, J.; Snow, T.; Maer, N., Jr.; Gale, W. Second Ripley surfactant flood pilot test. In Proceedings of the SPE/DOE Enhanced Oil Recovery Symposium, Tulsa, OK, USA, 22–25 April 1990. [Google Scholar]

- Maerker, J.; Gale, W. Surfactant flood process design for Loudon. SPE Reserv. Eng. 1992, 7, 36–44. [Google Scholar] [CrossRef]

- Iglauer, S.; Wu, Y.; Shuler, P.; Tang, Y.; Goddard, W.A., III. New surfactant classes for enhanced oil recovery and their tertiary oil recovery potential. J. Pet. Sci. Eng. 2010, 71, 23–29. [Google Scholar] [CrossRef]

- Sheng, J.J. Status of surfactant EOR technology. Petroleum 2015, 1, 97–105. [Google Scholar] [CrossRef] [Green Version]

- Larson, R.; Davis, H.; Scriven, L. Elementary mechanisms of oil recovery by chemical methods. J. Pet. Technol. 1982, 34, 243–258. [Google Scholar] [CrossRef]

- Pashley, R.; Karaman, M. Applied Colloid and Surface Chemistry; Wiley: Hoboken, NJ, USA, 2004; pp. 61–67. [Google Scholar]

- Negin, C.; Ali, S.; Xie, Q. Most common surfactants employed in chemical enhanced oil recovery. Petroleum 2017, 3, 197–211. [Google Scholar] [CrossRef]

- Paul, G.; Froning, H. Salinity effects of micellar flooding. J. Pet. Technol. 1973, 25, 957–958. [Google Scholar] [CrossRef]

- Trushenski, S.P.; Dauben, D.L.; Parrish, D.R. Micellar flooding-fluid propagation, interaction, and mobility. Soc. Pet. Eng. J. 1974, 14, 633–645. [Google Scholar] [CrossRef]

- Puerto, M.; Hirasaki, G.J.; Miller, C.A.; Barnes, J.R. Surfactant systems for EOR in high-temperature, high-salinity environments. SPE J. 2012, 17, 11–19. [Google Scholar] [CrossRef]

- Kamal, M.S.; Hussein, I.A.; Sultan, A.S. Review on surfactant flooding: Phase behavior, retention, IFT, and field applications. Energy Fuels 2017, 31, 7701–7720. [Google Scholar] [CrossRef]

- Adibhatla, B.; Mohanty, K. Parametric analysis of surfactant-aided imbibition in fractured carbonates. J. Colloid Interface Sci. 2008, 317, 513–522. [Google Scholar] [CrossRef]

- Sheng, J.J. Comparison of the effects of wettability alteration and IFT reduction on oil recovery in carbonate reservoirs. Asia-Pac. J. Chem. Eng. 2013, 8, 154–161. [Google Scholar] [CrossRef]

- Teklu, T.W.; Alameri, W.; Kazemi, H.; Graves, R.M.; AlSumaiti, A.M. Low salinity water-surfactant-CO2 EOR. Petroleum 2017, 3, 309–320. [Google Scholar] [CrossRef]

- Glover, C.; Puerto, M.; Maerker, J.; Sandvik, E. Surfactant phase behavior and retention in porous media. Soc. Pet. Eng. J. 1979, 19, 183–193. [Google Scholar] [CrossRef]

- Johannessen, A.M.; Spildo, K. Enhanced oil recovery (EOR) by combining surfactant with low salinity injection. Energy Fuels 2013, 27, 5738–5749. [Google Scholar] [CrossRef]

- Alagic, E.; Skauge, A. Combined low salinity brine injection and surfactant flooding in mixed-wet sandstone cores. Energy Fuels 2010, 24, 3551–3559. [Google Scholar] [CrossRef]

- Alameri, W.; Teklu, T.; Graves, R.; Kazemi, H.; AlSumaiti, A. Low-salinity water-alternate-surfactant in low-permeability carbonate reservoirs. In Proceedings of the IOR 18th European Symposium on Improved Oil Recovery, Berlin, Germany, 14–16 April 2015. [Google Scholar]

- Sekerbayeva, A.; Pourafshary, P.; Hashmet, M.R. Application of anionic surfactant\engineered water hybrid EOR in carbonate formations: An experimental analysis. Petroleum 2020. [Google Scholar] [CrossRef]

- Thomas, A. Polymer Flooding. In Chemical Enhanced Oil Recovery (cEOR)-A Practical Overview; Romero-Zeron, L., Ed.; InTech: Rijeka, Croatia, 2016; pp. 55–99. ISBN 978-953-51-2701-7. [Google Scholar]

- Borthakur, A.; Rahman, M.; Sarmah, A.; Subrahmanyam, B. Partially Hydrolyzed Polyacrylamide For Enhanced oil-recovery. Res. Ind. 1995, 40, 90–94. [Google Scholar]

- Saboorian-Jooybari, H.; Dejam, M.; Chen, Z. Heavy oil polymer flooding from laboratory core floods to pilot tests and field applications: Half-Century studies. J. Pet. Sci. Eng. 2016, 142, 85–100. [Google Scholar] [CrossRef]

- Kaminsky, R.D.; Wattenbarger, R.C.; Szafranski, R.C.; Coutee, A. Guidelines for polymer flooding evaluation and development. In Proceedings of the International Petroleum Technology Conference, Dubai, United Arab Emirates, 4–6 December 2007. [Google Scholar]

- Zhao, F.-l.; Wang, Y.-f.; Dai, C.-L.; Ren, S.; Jiao, C. Techniques of enhanced oil recovery after polymer flooding. Zhongguo Shi You Daxue Xuebao J. China Univ. Pet. 2006, 30, 86–89. [Google Scholar]

- Sheng, J.J. Modern Chemical Enhanced Oil Recovery: Theory and Practice; Gulf Professional Publishing: Burlington, MA, USA, 2010. [Google Scholar]

- Pye, D.J. Improved secondary recovery by control of water mobility. J. Pet. Technol. 1964, 16, 911–916. [Google Scholar] [CrossRef]

- Sandiford, B. Laboratory and field studies of water floods using polymer solutions to increase oil recoveries. J. Pet. Technol. 1964, 16, 917–922. [Google Scholar] [CrossRef]

- Mungan, N. Rheology and adsorption of aqueous polymer solutions. J. Can. Pet. Technol. 1969, 8, 45–50. [Google Scholar] [CrossRef]

- Gogarty, W. Mobility control with polymer solutions. Soc. Pet. Eng. J. 1967, 7, 161–173. [Google Scholar] [CrossRef]

- Du, Y.; Guan, L. Field-Scale polymer flooding: Lessons learnt and experiences gained during past 40 years. In Proceedings of the SPE International Petroleum Conference in Mexico, Puebla Pue, Mexico, 7–9 November 2004. [Google Scholar]

- Lee, Y.; Lee, W.; Jang, Y.; Sung, W. Oil recovery by low-salinity polymer flooding in carbonate oil reservoirs. J. Pet. Sci. Eng. 2019, 181, 106211. [Google Scholar] [CrossRef]

- Al-Murayri, M.T.; Kamal, D.S.; Al-Sabah, H.M.; AbdulSalam, T.; Al-Shamali, A.; Quttainah, R.; Glushko, D.; Britton, C.; Delshad, M.; Liyanage, J. Low-Salinity polymer flooding in a high-temperature low-permeability carbonate reservoir in West Kuwait. In Proceedings of the SPE Kuwait Oil and Gas Show and Conference, Mishref, Kuwait, 13–16 October 2019. [Google Scholar]

- Vermolen, E.C.; Pingo-Almada, M.; Wassing, B.M.; Ligthelm, D.J.; Masalmeh, S.K. Low-salinity polymer flooding: Improving polymer flooding technical feasibility and economics by using low-salinity make-up brine. In Proceedings of the IPTC 2014: International Petroleum Technology Conference, Doha, Qatar, 19–22 January 2014. [Google Scholar]

- Alfazazi, U.; AlAmeri, W.; Hashmet, M.R. Experimental investigation of polymer flooding with low-salinity preconditioning of high temperature-high-salinity carbonate reservoir. J. Pet. Explor. Prod. Technol. 2019, 9, 1517–11530. [Google Scholar] [CrossRef] [Green Version]

- AlSofi, A.M.; Wang, J.; AlBoqmi, A.M.; AlOtaibi, M.B.; Ayirala, S.C.; AlYousef, A.A. Smartwater synergy with chemical enhanced oil recovery: Polymer effects on smartwater. SPE Reserv. Eval. Eng. 2019, 22, 61–77. [Google Scholar] [CrossRef]

- Mohammadi, H.; Jerauld, G. Mechanistic modeling of the benefit of combining polymer with low salinity water for enhanced oil recovery. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 14–18 April 2012. [Google Scholar]

- Alzayer, H.; Sohrabi, M. Numerical Simulation of improved heavy oil recovery by low-salinity water injection and polymer flooding. In Proceedings of the SPE Saudi Arabia Section Technical Symposium and Exhibition, Al-Khobar, Saudi Arabia, 19–22 May 2013. [Google Scholar]

- Borazjani, S.; Bedrikovetsky, P.; Farajzadeh, R. Analytical solutions of oil displacement by a polymer slug with varying salinity. J. Pet. Sci. Eng. 2016, 140, 28–40. [Google Scholar] [CrossRef]

- Santo, A.; Muggeridge, A. An investigation into the benefits of combined polymer-low salinity waterflooding. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Brisbane, Australia, 23–25 October 2018. [Google Scholar]

- AlSofi, A.M.; Wang, J.; AlBoqmi, A.M.; AlOtaibi, M.B.; Ayirala, S.C.; AlYousef, A.A. Smart water synergy with chemical EOR for a slightly viscous Arabian heavy reservoir. In Proceedings of the SPE Heavy Oil Conference and Exhibition, Kuwait City, Kuwait, 6–8 December 2016. [Google Scholar]

- Khaledialidusti, R.; Kleppe, J. Significance of geochemistry in single-well chemical-tracer tests by coupling a multiphase-flow simulator to the geochemical package. SPE J. 2018, 23, 1126–1144. [Google Scholar] [CrossRef]

- Khaledialidusti, R.; Kleppe, J. Surface-charge alteration at the carbonate/brine interface during single-well chemical-tracer tests: Surface-Complexation model. SPE J. 2018, 23, 2302–2315. [Google Scholar] [CrossRef]

- Chang, H.L. Polymer flooding technology yesterday, today, and tomorrow. J. Pet. Technol. 1978, 30, 1113–1128. [Google Scholar] [CrossRef]

- Silveira, B.M.; Lopes, L.F.; Moreno, R.B. Rheological approach of HPAM solutions under harsh conditions for EOR applications. Int. J. Eng. Technol. 2016, 16, 1–8. [Google Scholar]

- Jennings, H.Y., Jr.; Johnson, C., Jr.; McAuliffe, C. A caustic waterflooding process for heavy oils. J. Pet. Technol. 1974, 26, 1344–1352. [Google Scholar] [CrossRef]

- Cooke, C., Jr.; Williams, R.; Kolodzie, P. Oil recovery by alkaline waterflooding. J. Pet. Technol. 1974, 26, 1365–1374. [Google Scholar] [CrossRef]

- Johnson, C., Jr. Status of caustic and emulsion methods. J. Pet. Technol. 1976, 28, 85–92. [Google Scholar] [CrossRef]

- Mayer, E.; Berg, R.; Carmichael, J.; Weinbrandt, R. Alkaline injection for enhanced oil recovery—A status report. J. Pet. Technol. 1983, 35, 209–221. [Google Scholar] [CrossRef]

- Katsanis, E.; Krumrine, P.; Falcone, J., Jr. Chemistry of precipitation and scale formation in geological systems. In Proceedings of the SPE Oilfield and Geothermal Chemistry Symposium, Denver, CO, USA, 1–3 June 1983. [Google Scholar]

- Feng, R.-S.; Guo, Y.-J.; Zhang, X.-M.; Hu, J.; Li, H.-B. Alkali/surfactant/polymer flooding in the Daqing oilfield class II reservoirs using associating polymer. J. Chem. 2013, 2013, 275943. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nelson, R.; Lawson, J.; Thigpen, D.; Stegemeier, G. Cosurfactant-enhanced alkaline flooding. In Proceedings of the SPE Enhanced Oil Recovery Symposium, Tulsa, OK, USA, 15–18 April 1984. [Google Scholar]

- Gao, S.; Li, H.; Li, H. Laboratory investigation of combination of alkaline-surfactant-polymer for Daqing EOR. SPE Reserv. Eng. 1995, 10, 194–197. [Google Scholar] [CrossRef]

- Tong, Z.; Yang, C.; Wu, G.; Yuan, H.; Yu, L.; Tian, G. A study of microscopic flooding mechanism of surfactant/alkali/polymer. In Proceedings of the SPE/DOE Improved Oil Recovery Symposium, Tulsa, OK, USA, 19–22 April 1998. [Google Scholar]

- Hernandez, C.; Chacon, L.J.; Anselmi, L.; Baldonedo, A.; Qi, J.; Dowling, P.C.; Pitts, M.J. ASP system design for an offshore application in La Salina Field, Lake Maracaibo. SPE Reserv. Eval. Eng. 2003, 6, 147–156. [Google Scholar] [CrossRef]

- Mohan, K. Alkaline surfactant flooding for tight carbonate reservoirs. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 4–7 October 2009. [Google Scholar]

- Shaddel, S.; Tabatabae-Nejad, S. Alkali/surfactant improved low-salinity waterflooding. Transp. Porous Media 2015, 106, 621–642. [Google Scholar] [CrossRef]

- Bhicajee, P.; Romero-Zerón, L. Effect of different low salinity flooding schemes and the addition of alkali on the performance of low-salinity waterflooding during the recovery of heavy oil from unconsolidated sandstone. Fuel 2021, 289, 119981. [Google Scholar] [CrossRef]

- Fu, J.; Gao, Y.-l.; Wu, W.-g.; Li, H.; Wu, X. Analysis of scale forming mechanism in alkali-surfactant-polymer (ASP) flooding in Gudao Oilfield and scale preventing techniques. J. Xian Pet. Inst. 2004, 19, 55–58. [Google Scholar]

- Yang, Z.; Chen, G. Current status and prospect of combination flooding at home and abroad. Pet. Geol. Oilfield Dev. Daqing 2004, 23, 94–96. [Google Scholar]

- Wang, Y.; Zhao, F.; Bai, B.; Zhang, J.; Xiang, W.; Li, X.; Zhou, W. Optimized surfactant IFT and polymer viscosity for surfactant-polymer flooding in heterogeneous formations. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 24–28 April 2010. [Google Scholar]

- Bataweel, M.A.; Nasr-El-Din, H.A. ASP vs. SP flooding in high salinity/hardness and temperature in sandstone cores. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 16–18 April 2012. [Google Scholar]

- Dang, C.; Nghiem, L.; Nguyen, N.; Yang, C.; Chen, Z.; Bae, W. Modeling and optimization of alkaline-surfactant-polymer flooding and hybrid enhanced oil recovery processes. J. Pet. Sci. Eng. 2018, 169, 578–601. [Google Scholar] [CrossRef]

- Al-Ajmi, A.I.A. Low Salinity Waterflood in Combination with Surfactant/Polymer; Effect of Surfactant Slug Size. Master’s Thesis, The University of Bergen, Bergen, Norway, 2014. [Google Scholar]

- Xia, H.; Wang, D.; Wu, W.; Jiang, H. Effect of the visco-elasticity of displacing fluids on the relationship of capillary number and displacement efficiency in weak oil-wet cores. In Proceedings of the Asia Pacific Oil and Gas Conference and Exhibition, Jakarta, Indonesia, 30 October–1 November 2007. [Google Scholar]

- Tavassoli, S.; Pope, G.A.; Sepehrnoori, K. Frontal-stability analysis of surfactant floods. SPE J. 2015, 20, 471–482. [Google Scholar] [CrossRef]

- Bethel, F.; Calhoun, J.C. Capillary desaturation in unconsolidated beads. J. Pet. Technol. 1953, 5, 197–202. [Google Scholar] [CrossRef]

- Morrow, N.; Chatzis, I.; Taber, J. Entrapment and mobilization of residual oil in bead packs. SPE Reserv. Eng. 1988, 3, 927–934. [Google Scholar] [CrossRef]

- Tang, J.S. Interwell Tracer tests to determine residual oil saturation to waterflood at Judy Creek Bhl’a’pool. J. Can. Pet. Technol. 1992, 31, PETSOC-92-08-06. [Google Scholar] [CrossRef]

- Abrams, A. The influence of fluid viscosity, interfacial tension, and flow velocity on residual oil saturation left by waterflood. Soc. Pet. Eng. J. 1975, 15, 437–447. [Google Scholar] [CrossRef]

- Chatzis, I.; Morrow, N.R. Correlation of capillary number relationships for sandstone. Soc. Pet. Eng. J. 1984, 24, 555–562. [Google Scholar] [CrossRef]

- Fulcher, R., Jr.; Ertekin, T.; Stahl, C. Effect of capillary number and its constituents on two-phase relative permeability curves. J. Pet. Technol. 1985, 37, 249–260. [Google Scholar] [CrossRef]

- Guo, H.; Dou, M.; Hanqing, W.; Wang, F.; Yuanyuan, G.; Yu, Z.; Yansheng, W.; Li, Y. Proper use of capillary number in chemical flooding. J. Chem. 2017, 2017, 4307368. [Google Scholar] [CrossRef]

- Hilfer, R.; Armstrong, R.; Berg, S.; Georgiadis, A.; Ott, H. Capillary saturation and desaturation. Phys. Rev. E 2015, 92, 063023. [Google Scholar] [CrossRef] [PubMed]

- Morrow, N.R. Interplay of capillary, viscous and buoyancy forces in the mobilization of residual oil. J. Can. Pet. Technol. 1979, 18, PETSOC-79-03-03. [Google Scholar] [CrossRef]

- Garnes, J.; Mathisen, A.; Scheie, A.; Skauge, A. Capillary number relations for some North, Sea reservoir sandstones. In Proceedings of the SPE/DOE Enhanced Oil Recovery Symposium, Tulsa, OK, USA, 22–25 April 1990. [Google Scholar]

- Humphry, K.; Suijkerbuijk, B.; Van Der Linde, H.; Pieterse, S.; Masalmeh, S. Impact of wettability on residual oil saturation and capillary desaturation curves. Petrophysics 2014, 55, 313–318. [Google Scholar]

- Donaldson, E.C.; Chilingarian, G.V.; Yen, T.F. Enhanced Oil Recovery, II: Processes and Operations; Elsevier: Amsterdam, The Netherlands, 1989. [Google Scholar]

- Zivar, D.; Pourafshary, P.; Moradpour, N. Capillary desaturation curve: Does low salinity surfactant flooding significantly reduce the residual oil saturation? J. Pet. Explor. Prod. Technol. 2021, 11, 783–794. [Google Scholar]

- Sorbie, K. Polymer-Improved Oil Recovery; Blackie and Son: Glasgow, UK, 1991; pp. 126–163. [Google Scholar]

- Taber, J. Dynamic and static forces required to remove a discontinuous oil phase from porous media containing both oil and water. Soc. Pet. Eng. J. 1969, 9, 3–12. [Google Scholar] [CrossRef]

- Pusch, G.; Lotsch, T.; Muller, T. Investigation of the Oil Displacing Efficiency of Suitable Polymer Products in Porous Media, Aspects of Recovery Mechanisms during Polymer Flooding. German Soc. Petrol. Sci. Coal Chem. 1987, 6, 295–296. [Google Scholar]

- Delshad, M.; Kim, D.H.; Magbagbeola, O.A.; Huh, C.; Pope, G.A.; Tarahhom, F. Mechanistic interpretation and utilization of viscoelastic behavior of polymer solutions for improved polymer-flood efficiency. In Proceedings of the SPE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 20–23 April 2008. [Google Scholar]

- Zhang, R.; Somasundaran, P. Advances in adsorption of surfactants and their mixtures at solid/solution interfaces. Adv. Colloid Interface Sci. 2006, 123, 213–229. [Google Scholar] [CrossRef]

- Karimov, D.; Hashmet, M.R.; Pourafshary, P. A Laboratory study to optimize Ion composition for the hybrid low salinity water/polymer flooding. In Proceedings of the Offshore Technology Conference Asia, Kuala Lumpur, Malaysia, 2–6 November 2020. [Google Scholar]

- Samanova, A. Surfactant/LSW Flooding in Carbonates: An Investigation of Hybrid EOR Design to Improve Oil Displacement. Master’s Thesis, Nazarbayev University, Astana, Kazakhstan, 2021. [Google Scholar]

- Nelson, R.C. The salinity-requirement diagram—A useful tool in chemical flooding research and development. Soc. Pet. Eng. J. 1982, 22, 259–270. [Google Scholar] [CrossRef]

- Qi, P.; Ehrenfried, D.H.; Koh, H.; Balhoff, M.T. Reduction of residual oil saturation in sandstone cores by use of viscoelastic polymers. SPE J. 2017, 22, 447–458. [Google Scholar] [CrossRef]

- Zhong, H.; Zang, Q.; Yin, H.; Xia, H. Experimental study on medium viscosity oil displacement using viscoelastic polymer. Geofluids 2018, 2018, 4321380. [Google Scholar] [CrossRef] [Green Version]

- Clarke, A.; Howe, A.M.; Mitchell, J.; Staniland, J.; Hawkes, L.A. How viscoelastic-polymer flooding enhances displacement efficiency. SPE J. 2016, 21, 675–687. [Google Scholar] [CrossRef]

- Abeysinghe, K.P.; Fjelde, I.; Lohne, A. Displacement of oil by surfactant flooding in mixed-wet condition. In Proceedings of the International Symposium of the Society of core Analysts, Aberdeen, UK, 27–30 August 2012; pp. 1–12. [Google Scholar]

- Abeysinghe, K.P.; Fjelde, I.; Lohne, A. Dependency of remaining oil saturation on wettability and capillary number. In Proceedings of the SPE Saudi Arabia Section Technical Symposium and Exhibition, Al-Khobar, Saudi Arabia, 8–11 April 2012. [Google Scholar]

- Pei, H.; Zhang, G.; Ge, J.; Tang, M.; Zheng, Y. Comparative effectiveness of alkaline flooding and alkaline-surfactant flooding for improved heavy-oil recovery. Energy Fuels 2012, 26, 2911–2919. [Google Scholar] [CrossRef]

- Ghorpade, T.; Patil, S.; Dandekar, A.; Khataniar, S. Application of alkali-surfactant-polymer ASP flooding for improving viscous oil recovery from Alaskan North Slope Reservoir. In Proceedings of the SPE Western Regional Meeting, Anchorage, AK, USA, 23–26 May 2016. [Google Scholar]

- Qi, L.; Liu, Z.; Yang, C.; Yin, Y.; Hou, J.; Zhang, J.; Huang, B.; Shi, F. Supplement and optimization of classical capillary number experimental curve for enhanced oil recovery by combination flooding. Sci. China Technol. Sci. 2014, 57, 2190–2203. [Google Scholar] [CrossRef]

- Wang, F. Effects of reservoir anaerobic, reducing conditions on surfactant retention in chemical flooding. SPE Reserv. Eng. 1993, 8, 108–116. [Google Scholar] [CrossRef]

- Moore, T.; Slobod, R. The effect of viscosity and capillarity on the displacement of oil by water. Prod. Mon. 1956, 20, 20–30. [Google Scholar]

- Lake, L.W. Enhanced Oil Recovery; Prentice Hall: Englewood Cliffs, NJ, USA, 1989. [Google Scholar]

- Schneider, F.; Owens, W. Steady-state measurements of relative permeability for polymer/oil systems. Soc. Pet. Eng. J. 1982, 22, 79–86. [Google Scholar] [CrossRef]

- Wei, B.; Romero-Zerón, L.; Rodrigue, D. Oil displacement mechanisms of viscoelastic polymers in enhanced oil recovery (EOR): A review. J. Pet. Explor. Prod. Technol. 2014, 4, 113–121. [Google Scholar] [CrossRef] [Green Version]

- Vermolen, E.; Van Haasterecht, M.; Masalmeh, S. A systematic study of the polymer visco-elastic effect on residual oil saturation by core flooding. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 31 March–2 April 2014. [Google Scholar]

- El-Hoshoudy, A.; Desouky, S.; Elkady, M.; Al-Sabagh, A.; Betiha, M.; Mahmoud, S. Hydrophobically associated polymers for wettability alteration and enhanced oil recovery—Article review. Egypt. J. Pet. 2017, 26, 757–762. [Google Scholar] [CrossRef] [Green Version]

- Janiga, D.; Czarnota, R.; Stopa, J.; Wojnarowski, P.; Kosowski, P. Performance of nature inspired optimization algorithms for polymer enhanced oil recovery process. J. Pet. Sci. Eng. 2017, 154, 354–366. [Google Scholar] [CrossRef]

- Sandengen, K.; Melhuus, K.; Kristoffersen, A. Polymer “viscoelastic effect”; does it reduce residual oil saturation. J. Pet. Sci. Eng. 2017, 153, 355–363. [Google Scholar] [CrossRef]

- Wang, D.; Xia, H.; Liu, Z.; Yang, Q. Study of the mechanism of polymer solution with visco-elastic behavior increasing microscopic oil displacement efficiency and the forming of steady “oil thread” flow channels. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Jakarta, Indonesia, 17–19 April 2001. [Google Scholar]

- Wang, J.; Dong, M. A laboratory study of polymer flooding for improving heavy oil recovery. In Proceedings of the Canadian International Petroleum Conference, Calgary, AB, Canada, 12–14 June 2007. [Google Scholar]

- Xia, H.; Wang, D.; Wang, G.; Ma, W.-g.; Deng, H.W.; Liu, J. Mechanism of the effect of micro-forces on residual oil in chemical flooding. In Proceedings of the SPE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 20–23 April 2008. [Google Scholar]

- Urbissinova, T.; Trivedi, J.J.; Kuru, E. Effect of elasticity during viscoelastic polymer flooding—A possible mechanism of increasing the sweep efficiency. In Proceedings of the SPE Western Regional Meeting, Anaheim, CA, USA, 27–29 May 2010. [Google Scholar]

| Case | Number of Data Sets | Injection Sequence |

|---|---|---|

| EWSF | 3 | WF, EWF, EWSF |

| EWPF | 3 | WF, EWF, EWPF |

| EWSPF | 1 | WF, EWF, EWSF, EWPF |

| EWASF | 1 | WF, EWF, EWASF |

| EWASP | 2 | WF, EWF, EWAS/EWASP-Slug, EWPF |

| Author | Chemical Agents | Reservoir | Injection Design | Results |

|---|---|---|---|---|

| Surfactant flooding | ||||

| Abeysinghe et al. [120] | Surfactant: sodium C6–10 alcohol ether sulfate (anionic) | Sandstone | Steady and unsteady state experiments: Waterflooding was followed by surfactant flooding | The reduction in Sor is due to an increase in oil-relative permeability with increasing capillary number during SF. |

| Abeysinghe et al. [121] | Surfactant: sodium C6–10 alcohol ether sulfate (anionic) | Mixed-wet Berea sandstone | Waterflooding followed by surfactant flooding | Sor vs. Nc plot does not characterize the true CDC behavior. In the mixed-wet case, the most important effect of surfactants can be the acceleration of oil; not necessarily thereduction of Sor. |

| Alkali surfactant flooding | ||||

| Pei et al. [122] | Alkali: Sodium hydroxide (NaOH)Surfactant: SLPS (with a purity of 33.3%) and surfactant ORS (with a purity of 33.5%) | Sandpack | Sandpack flooding test: Waterflooding followed by slug-wise and continuous injection of alkali and alkali-surfactant solution. | The tertiary oil recovery of AS flooding is lower compared with the only alkaline flooding, and results in a significant reduction in residual oil saturation. |

| Polymer flooding | ||||

| Qi et al. [117] | Polymer: HPAM 3630s | Bentheimer sandstones | Waterflood was followed by glycerin and polymer floods at a constant pressure gradient. | Increasing polymer elasticity results in decreasing residual oil saturation. |

| Zhong et al. [118] | Polymer: AP-P4 hydrophobically associated polymer | Daqing oilfield sandstone | Waterflooding followed by viscous glycerin flood and viscoelastic polymer flood of same viscosity | A higher reduction in Sor is observed for the polymer flooding at the same capillary number compared to glycerin flooding, showing the contribution of polymer viscoelastic behavior in reducing Sor. |

| Clarke et al. [119] | Polymer: HPAM 3630S | Bentheimer sandstone | Waterflooding followed by polymer flooding | HPAM polymer has caused rapid capillary desaturation at relatively lower capillary numbers, indicating some other mechanisms e.g., viscoelasticity in addition to mobility control. |

| Surfactant polymer flooding | ||||

| Wang et al. [90] | Surfactant: Cocamide Diethanolamine (nonionic) and Petroleum sulfonate (anionic)Polymer: HPAM polymer | Sandstone | Waterflooding followed by 0.3 PV slug of surfactant-polymer solution, chased by waterflooding | An SP formulation with optimum IFT and viscosity can provide higher incremental oil recovery compared to formulation with lowest IFT, largely because of improvement in the sweep efficiency. |

| Alkali surfactant polymer flooding | ||||

| Ghorpade et al. [123] | Alkali: 0.1 wt% NaOHSurfactant: 0.11 wt%Polymer: 1500 ppm | Sandstone simulation model | Waterflooding followed by ASP flooding | An ASP formulation with small concentration of polymer can work better in homogeneous reservoirs containing low-viscosity crude oil. |

| Qi et al. [124] | - | Sandstone | Waterflooding followed by combination flooding | Classic CDC does not explain the relationship between capillary number and Sor for high capillary number conditions and must be corrected before applying desaturation theory to combination flooding. |

| Case | Vo | Vw | Vme | ME Ratio | IFT |

|---|---|---|---|---|---|

| mL | dynes/cm | ||||

| Surfactant | 1.94 | 1.94 | 0.12 | 0.03 | 0.02 |

| Alkali + Surfactant | 0.80 | 1.00 | 2.20 | 0.55 | 0.000018 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shakeel, M.; Samanova, A.; Pourafshary, P.; Hashmet, M.R. Capillary Desaturation Tendency of Hybrid Engineered Water-Based Chemical Enhanced Oil Recovery Methods. Energies 2021, 14, 4368. https://doi.org/10.3390/en14144368

Shakeel M, Samanova A, Pourafshary P, Hashmet MR. Capillary Desaturation Tendency of Hybrid Engineered Water-Based Chemical Enhanced Oil Recovery Methods. Energies. 2021; 14(14):4368. https://doi.org/10.3390/en14144368

Chicago/Turabian StyleShakeel, Mariam, Aida Samanova, Peyman Pourafshary, and Muhammad Rehan Hashmet. 2021. "Capillary Desaturation Tendency of Hybrid Engineered Water-Based Chemical Enhanced Oil Recovery Methods" Energies 14, no. 14: 4368. https://doi.org/10.3390/en14144368

APA StyleShakeel, M., Samanova, A., Pourafshary, P., & Hashmet, M. R. (2021). Capillary Desaturation Tendency of Hybrid Engineered Water-Based Chemical Enhanced Oil Recovery Methods. Energies, 14(14), 4368. https://doi.org/10.3390/en14144368