A Study on Performance and Emission Characteristics of Diesel Engine Using Ricinus Communis (Castor Oil) Ethyl Esters

Abstract

:1. Introduction

2. Materials and Procedure

2.1. Yielding of Castor Ethyl Ester

2.2. Determining the Physical and Chemical Properties of Biodiesel

2.3. Engine Test

3. Biodiesel Properties

4. Result and Discussions

4.1. Engine Performance

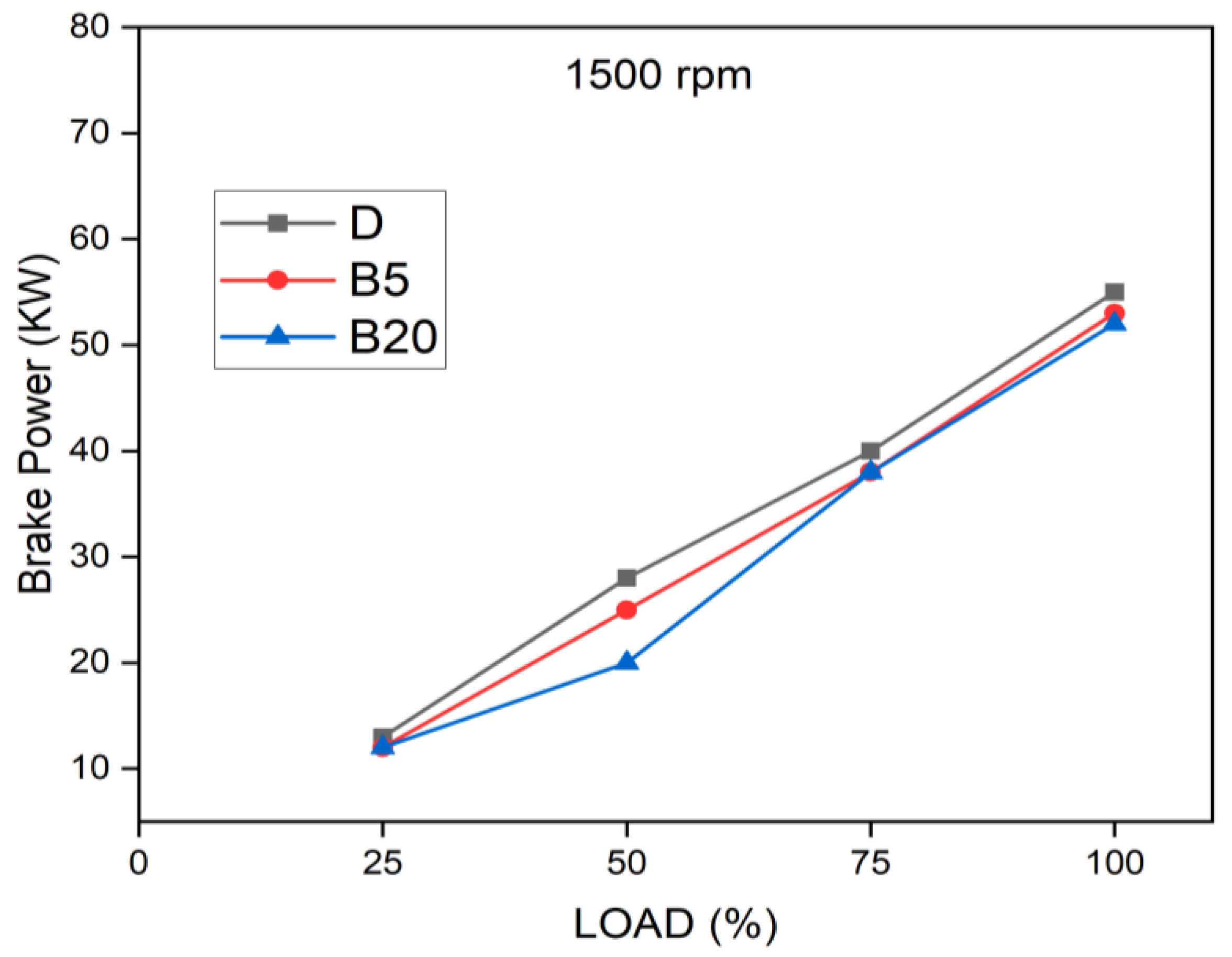

4.2. Brake Power of Biodiesel Blends with Diesel

4.3. Brake Specific Fuel Consumption (BSFC)

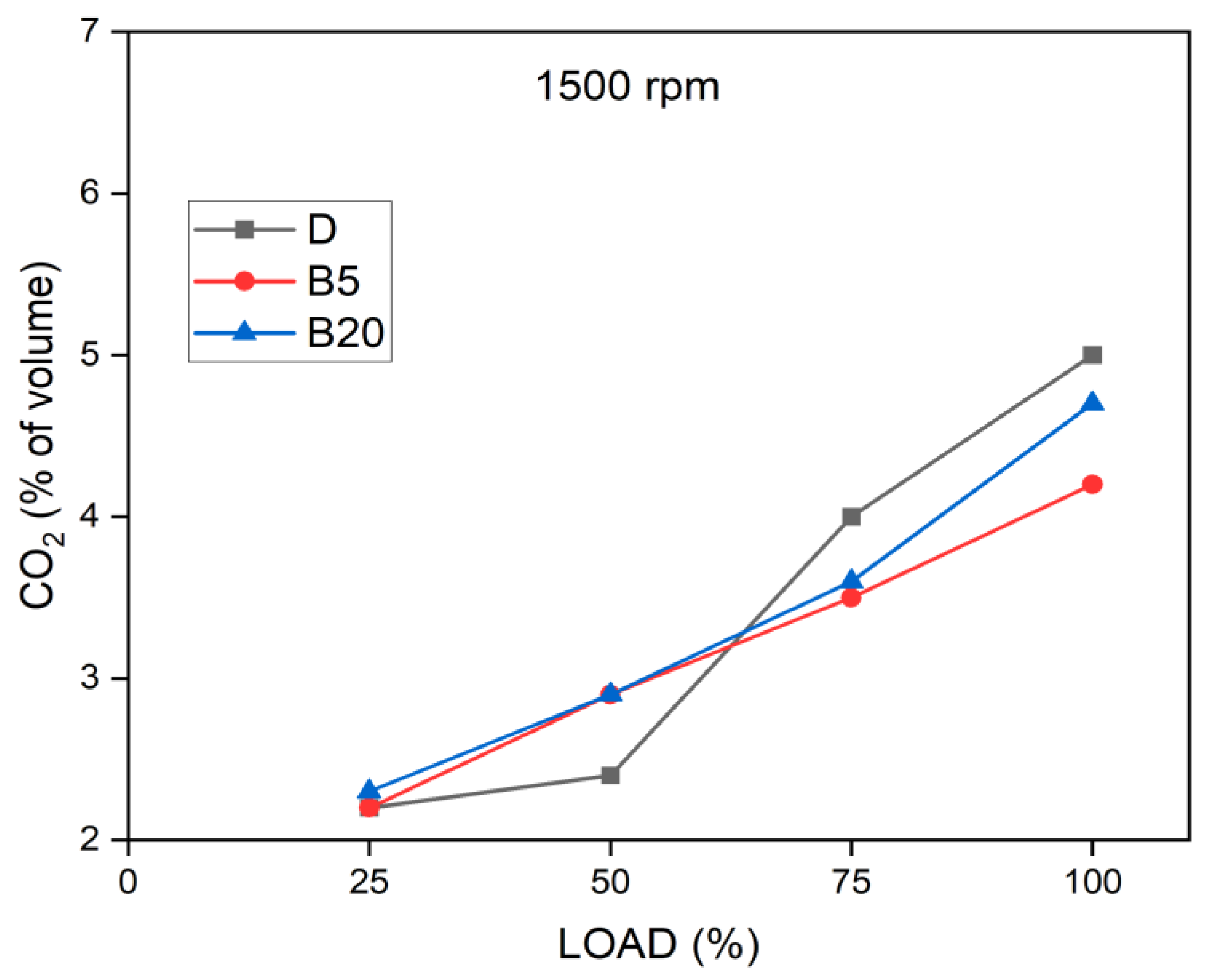

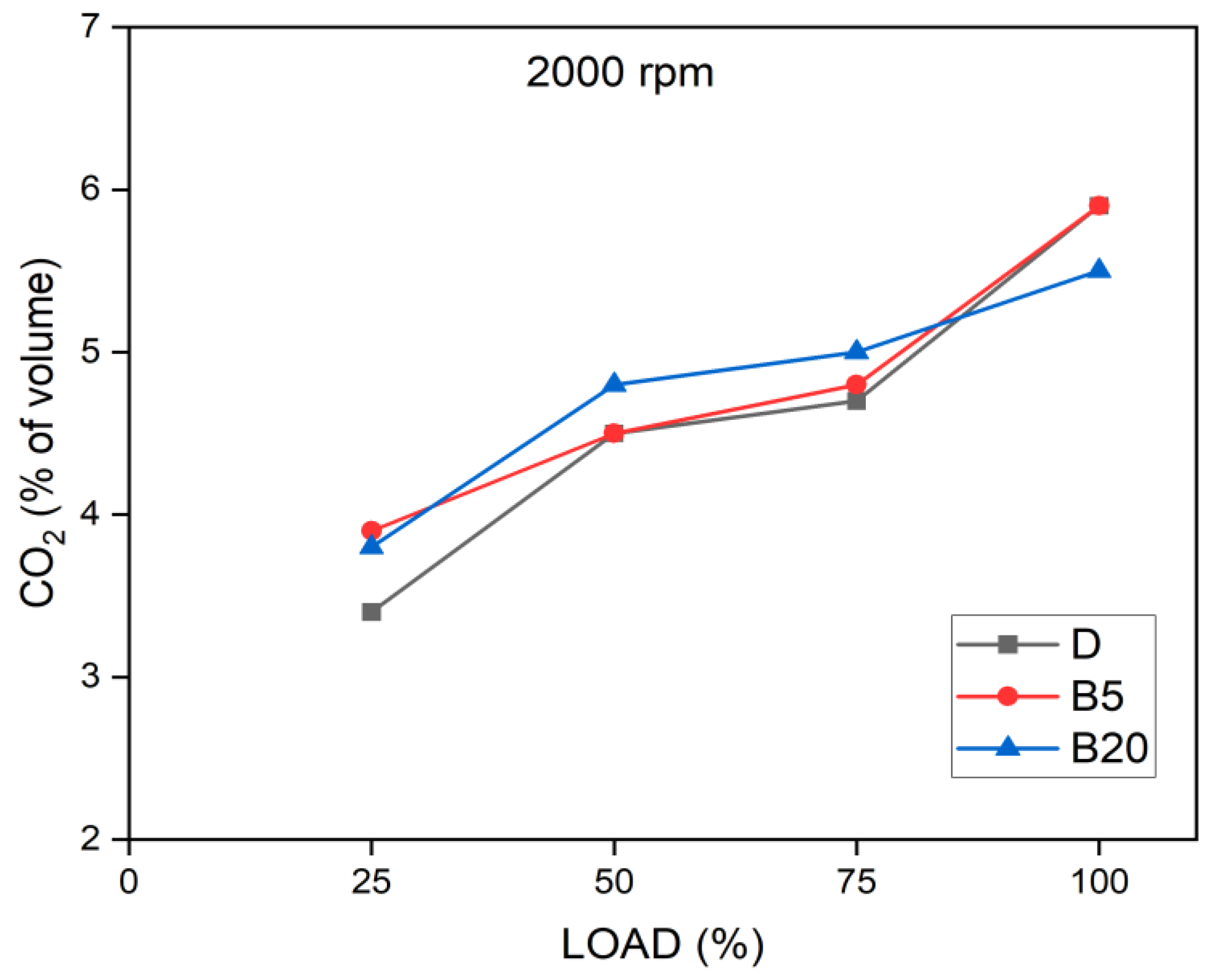

4.4. Carbon Dioxide (CO2) Outflow

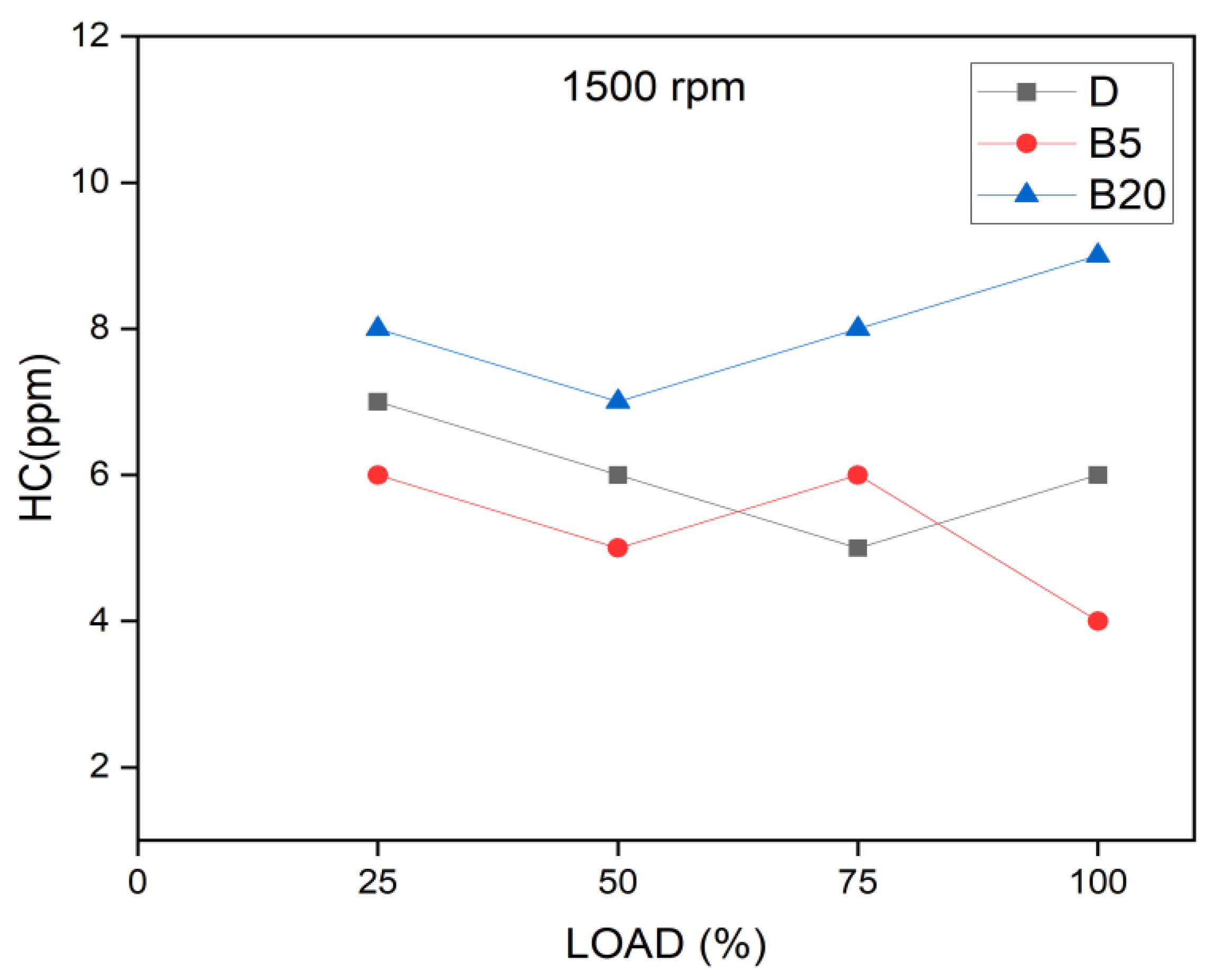

4.5. Emission of UHC (Unburned Hydrocarbon)

4.6. Emission of Nitrous Oxide (NOx)

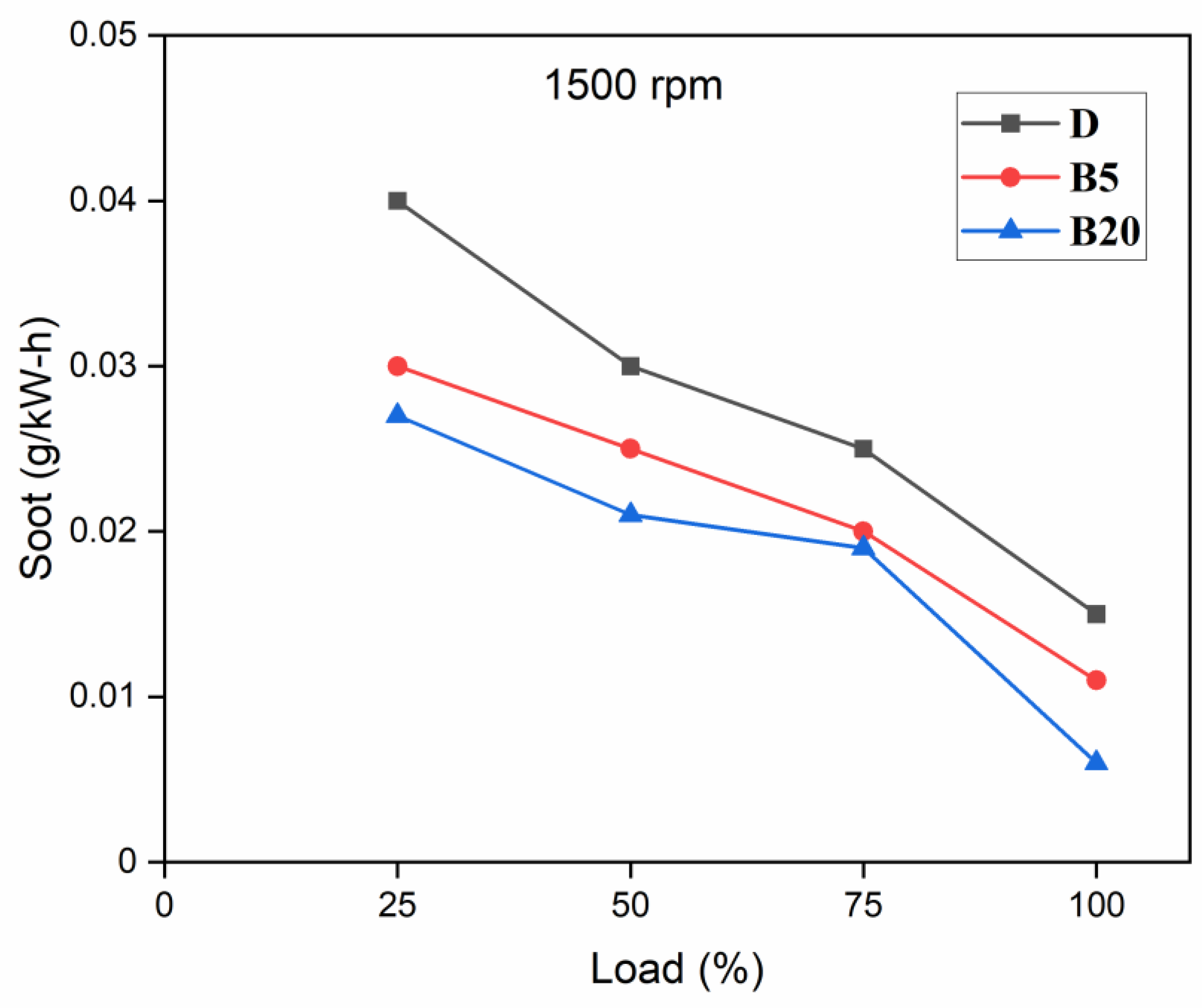

4.7. Soot Emission

5. Conclusions

- According to engine performance, brake power reduced while increasing the biodiesel percentage in the blend at two different speeds. This may due to changes in the calorific value of different blending of biodiesels.

- While running at 1500 rpm and 2000 rpm on partial and complete loads, the BSFC of B5 and B20 are comparatively higher than diesel. This may due to various mixing ratios of esters.

- The outcomes of outflow demonstrate that B5 emits very low carbon dioxide (CO2), HC and nitrogen oxides (NOx) in comparison with B20 and Diesel in the case of the soot emissions, diesel fuel had the higher amount in comparison with B5 and B20. This occurred because of biodiesel has less carbon content than regular diesel, and the proportion of hydrocarbon is even lower than the standard fuel.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ASTM | American Society for Testing and Materials |

| bTDC | before Top Dead Center |

| Bd | Biodiesel |

| BSFC | Brake Specific Fuel Consumption |

| CO2 | Carbon dioxide |

| CO | Carbon monoxide |

| cSt | Centistoke |

| CI | Compression Ignition |

| CR | Compression Ratio |

| cc | cubic centimeter |

| °C | Degree centigrade |

| HSU | Hatridge Smoke Unit |

| h | Hour |

| HC | Hydrocarbon |

| K | Kelvin |

| kJ | Kilo Joule |

| D | Diesel |

| kW | Kilo Watt |

| kg | Kilogram |

| mm | Millemeter |

| NOP | Nozzle Opening Pressure |

| NOx | Oxides of Nitrogen |

| ppm | Parts per Million |

| KOH | Potassium Hydroxide |

| P | Pressure (bar) |

| UHC | Unburned Hydro carbon |

| Rpm | Revolution per minute |

References

- Fadhil, A.B.; Al-Tikrity, E.T.B.; Albadree, M.A. Biodiesel production from mixed non-edible oils, castor seed oil and waste fish oil. Fuel 2017, 210, 721–728. [Google Scholar] [CrossRef]

- Swaminathan, C.; Sarangan, J. Performance and exhaust emission characteristics of a CI engine fueled with biodiesel (fish oil) with DEE as additive. Biomass Bioenergy 2012, 39, 168–174. [Google Scholar] [CrossRef]

- Gharehghani, A.; Mirsalim, M.; Hosseini, R. Effects of waste fish oil biodiesel on diesel engine combustion characteristics and emission. Renew. Energy 2017, 101, 930–936. [Google Scholar] [CrossRef]

- Behçet, R. Performance and emission study of waste anchovy fish biodiesel in a diesel engine. Fuel Process. Technol. 2011, 92, 1187–1194. [Google Scholar] [CrossRef]

- Roy, T.; Sahani, S.; Sharma, Y.C. Green synthesis of biodiesel from Ricinus Communis oil (castor seed oil) using potassium promoted lanthanum oxide catalyst: Kinetic, thermodynamic and environmental studies. Fuel 2020, 274, 117644. [Google Scholar] [CrossRef]

- Balan, K.N.; Yashvanth, U.; Booma Devi, P.; Arvind, T.; Nelson, H.; Devarajan, Y. Investigation on emission characteristics of alcohol biodiesel blended diesel engine. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 41, 1879–1889. [Google Scholar] [CrossRef]

- Fadhil, A.B.; Sedeeq, S.H.; AI-Layla, N.M.T. Transesterification of non-edible seed oil for biodiesel production: Characterization and analysis of biodiesel. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 41, 892–901. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, A.; Maurya, S.; Deswal, V. Experimental investigation of the influence of blending on engine emissions of the diesel engine fueled by mahua biodiesel oil. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 994–998. [Google Scholar] [CrossRef]

- Mohamed Musthafa, M.; Joshua, A.; Dhilip, A.H.; Ravi Kumar, B. Performance and emission characteristics of a diesel engine using diesel-raw Jatropha oil blends. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 1–8. [Google Scholar] [CrossRef]

- Ramalingam, S.; Ganesan, P.; Murugasan, E. Effect of antioxidant additives on performance and emission behavior of biodiesel fueled DI diesel engine. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 42, 1085–1096. [Google Scholar] [CrossRef]

- Rangabashiam, D.; Jayaprakash, V.; Ganesan, S.; Nagaraj, M.; Rameshbabu, A. Emission, performance, and combustion study on nanoparticle-biodiesel fueled diesel engine. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 1–12. [Google Scholar] [CrossRef]

- Şanli, B.G. Energetic and exergetic performance of a diesel engine fueled with diesel and microalgae biodiesel. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 41, 2519–2533. [Google Scholar] [CrossRef]

- Saini, P.; Gupta, C.; Shankar, R. Characterization of corn oil biodiesel and its application in diesel engine. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 1–15. [Google Scholar] [CrossRef]

- Singh, M.; Sandhu, S.S. Performance, emission and combustion characteristics of multi-cylinder CRDI engine fueled with argemone biodiesel/diesel blends. Fuel 2020, 265, 117024. [Google Scholar] [CrossRef]

- Rajak, U.; Nashine, P.; Verma, T.N. Effect of spirulina microalgae biodiesel enriched with diesel fuel on performance and emission characteristics of CI engine. Fuel 2020, 268, 117305. [Google Scholar] [CrossRef]

- Shrivastava, P.; Verma, T.N.; Pugazhendhi, A. An experimental evaluation of engine performance and emisssion characteristics of CI engine operated with Roselle and Karanja biodiesel. Fuel 2019, 254, 115652. [Google Scholar] [CrossRef]

- Arunkumar, M.; Kannan, M.; Murali, G. Experimental studies on engine performance and emission characteristics using castor biodiesel as fuel in CI engine. Renew. Energy 2019, 131, 737–744. [Google Scholar] [CrossRef]

- Rajak, U.; Verma, T.N. Effect of emission from ethylic biodiesel of edible and non-edible vegetable oil, animal fats, waste oil and alcohol in CI engine. Energy Convers. Manag. 2018, 166, 704–718. [Google Scholar] [CrossRef]

- Emiroğlu, A.O.; Şen, M. Combustion, performance and exhaust emission characterizations of a diesel engine operating with a ternary blend (alcohol-biodiesel-diesel fuel). Appl. Therm. Eng. 2018, 133, 371–380. [Google Scholar] [CrossRef]

- Yilmaz, N.; Atmanli, A. Experimental assessment of a diesel engine fueled with diesel-biodiesel-1-pentanol blends. Fuel 2017, 191, 190–197. [Google Scholar] [CrossRef]

- Li, L.; Wang, J.; Wang, Z.; Liu, H. Combustion and emissions of compression ignition in a direct injection diesel engine fueled with pentanol. Energy 2015, 80, 575–581. [Google Scholar] [CrossRef]

- Balamurugan, T.; Nalini, R. Experimental investigation on performance, combustion and emission characteristics of four stroke diesel engine using diesel blended with alcohol as fuel. Energy 2014, 78, 356–363. [Google Scholar] [CrossRef]

- Rajesh Kumar, B.; Saravanan, S.; Rana, D.; Nagendran, A. A comparative analysis on combustion and emissions of some next generation higher-alcohol/diesel blends in a direct-injection diesel engine. Energy Convers. Manag. 2016, 119, 246–256. [Google Scholar] [CrossRef]

- Datta, A.; Mandal, B.K. Impact of alcohol addition to diesel on the performance combustion and emissions of a compression ignition engine. Appl. Therm. Eng. 2016, 98, 670–682. [Google Scholar] [CrossRef]

- Wei, L.; Yao, C.; Han, G.; Pan, W. Effects of methanol to diesel ratio and diesel injection timing on combustion, performance and emissions of a methanol port premixed diesel engine. Energy 2016, 95, 223–232. [Google Scholar] [CrossRef]

- Wang, Q.; Wei, L.; Pan, W.; Yao, C. Investigation of operating range in a methanol fumigated diesel engine. Fuel 2015, 140, 164–170. [Google Scholar] [CrossRef]

- Nirmala, N.; Dawn, S.S.; Harindra, C. Analysis of performance and emission characteristics of Waste cooking oil and Chlorella variabilis MK039712.1 biodiesel blends in a single cylinder, four strokes diesel engine. Renew. Energy 2019, 147, 284–292. [Google Scholar] [CrossRef]

- Krishnamoorthi, M.; Malayalamurthi, R. Availability analysis, performance, combustion and emission behavior of bael oil-diesel-diethyl ether blends in a variable compression ratio diesel engine. Renew. Energy 2018, 119, 235–252. [Google Scholar] [CrossRef]

- Harari, P.A.; Banapurmath, N.R.; Yaliwal, V.S.; Khan, T.M.Y.; Soudagar, M.E.M. Experimental studies on performance and emission characteristics of reactivity controlled compression ignition (RCCI) engine operated with gasoline and Thevetia Peruviana biodiesel. Renew. Energy 2020, 160, 865–875. [Google Scholar] [CrossRef]

- Suiuay, C.; Laloon, K.; Katekaew, S.; Senawong, K.; Noisuwan, P.; Sudajan, S. Effect of Gasoline-Like-Fuel Obtained from hard-resin of Yang (Dipterocarpus alatus) on Single Cylinder Gasoline Engine Performance and Exhaust Emissions. Renew. Energy 2020, 153, 634–645. [Google Scholar] [CrossRef]

- Prakash, T.; Geo, V.E.; Martin, L.J.; Nagalingam, B. Effect of ternary blends of bio-ethanol, diesel and castor oil on performance, emission and combustion in a CI engine. Renew. Energy 2018, 122, 301–309. [Google Scholar] [CrossRef]

- Kaur, R.; Gera, P.; Jha, M.K.; Bhaskar, T. Reaction Parameters Effect on Hydrothermal Liquefaction of Castor (Ricinus Communis) Residue for Energy and Valuable Hydrocarbons Recovery. Renew. Energy 2019, 141, 1024–1041. [Google Scholar] [CrossRef]

- Karthickeyan, V. Experimental Investigation on Combined Effect of Ignition Promoters and Ceramic Coating Fuelled with Papaya Seed Oil Methyl Ester in DI Diesel Engine. Renew. Energy 2019, 148, 772–789. [Google Scholar] [CrossRef]

- Wei, M.; Li, S.; Xiao, H.; Guo, G. Combustion performance and pollutant emissions analysis using diesel/gasoline/iso-butanol blends in a diesel engine. Energy Convers. Manag. 2017, 149, 381–391. [Google Scholar] [CrossRef]

- Verma, S.; Das, L.M.; Kaushik, S.C. Effects of varying composition of biogas on performance and emission characteristics of compression ignition engine using exergy analysis. Energy Convers. Manag. 2017, 138, 346–359. [Google Scholar] [CrossRef]

- Ithnin, A.M.; Ahmad, M.A.; Bakar, M.A.A.; Rajoo, S.; Yahya, W.J. Combustion performance and emission analysis of diesel engine fuelled with water-in-diesel emulsion fuel made from low-grade diesel fuel. Energy Convers. Manag. 2015, 90, 375–382. [Google Scholar] [CrossRef]

- Kannan, D.; Pachamuthu, S.; Nurun Nabi, M.; Hustad, J.E.; Løvås, T. Theoretical and experimental investigation of diesel engine performance, combustion and emissions analysis fuelled with the blends of ethanol, diesel and jatropha methyl ester. Energy Convers. Manag. 2012, 53, 322–331. [Google Scholar] [CrossRef]

- Khatri, D.; Goyal, R. Effects of silicon dioxide nanoparticles on the performance and emission features at different injection timings using water diesel emulsified fuel. Energy Convers. Manag. 2020, 205, 112379. [Google Scholar] [CrossRef]

- Amid, S.; Aghbashlo, M.; Tabatabaei, M.; Hajiahmad, A.; Najafi, B.; Ghaziaskar, H.S.; Mohammadi, P. Effects of waste-derived ethylene glycol diacetate as a novel oxygenated additive on performance and emission characteristics of a diesel engine fueled with diesel/biodiesel blends. Energy Convers. Manag. 2020, 203, 112245. [Google Scholar] [CrossRef]

- Hosseinzadeh-Bandbafha, H.; Khalife, E.; Tabatabaei, M.; Aghbashlo, M.; Khanali, M.; Mohammadi, P.; Soltanian, S. Effects of aqueous carbon nanoparticles as a novel nanoadditive in water-emulsified diesel/biodiesel blends on performance and emissions parameters of a diesel engine. Energy Convers. Manag. 2019, 196, 1153–1166. [Google Scholar] [CrossRef]

- Nabi, M.N.; Rasul, M.G. Influence of second generation biodiesel on engine performance, emissions, energy and exergy parameters. Energy Convers. Manag. 2018, 169, 326–333. [Google Scholar] [CrossRef]

- Wei, X.; Hellier, P.; Baganz, F. Impact on performance and emissions of the aspiration of algal biomass suspensions in the intake air of a direct injection diesel engine. Energy Convers. Manag. 2020, 205, 112347. [Google Scholar] [CrossRef]

- Simsek, S.; Uslu, S. Comparative evaluation of the influence of waste vegetable oil and waste animal oil-based biodiesel on diesel engine performance and emissions. Fuel 2020, 280, 118613. [Google Scholar] [CrossRef]

- Jagtap, S.P.; Pawar, A.N.; Lahane, S. Improving the usability of biodiesel blend in low heat rejection diesel engine through combustion, performance and emission analysis. Renew. Energy 2020, 155, 628–644. [Google Scholar] [CrossRef]

- Gurbuz, H. Analysis of the effects of multiple injection strategies with hydrogen on engine performance and emissions in diesel engine. Int. J. Hydrog. Energy 2020, 45, 27969–27978. [Google Scholar] [CrossRef]

- Elumalai, P.; Sivakandhan, C.; Parthasarathy, M.; Iqbal, S.M.; Arunkumar, M. Investigation on the mitigation of environmental harmful emissions by incorporating nanoparticles to biofuel water nano emulsion in low heat rejection engine. Heat Mass Transf. 2021. [Google Scholar] [CrossRef]

- Jafari, M.; Verma, P.; Bodisco, T.A.; Zare, A.; Brown, R.J. Multivariate analysis of performance and emission parameters in a diesel engine using biodiesel and oxygenated additive. Energy Convers. Manag. 2019, 201, 112183. [Google Scholar] [CrossRef]

- Jiaqiang, E.; Zhang, Z.; Chen, J.; Pham, M.; Zhao, X.; Peng, Q.; Yin, Z. Performance and emission evaluation of a marine diesel engine fueled by water biodiesel-diesel emulsion blends with a fuel additive of a cerium oxide nanoparticle. Energy Convers. Manag. 2018, 169, 194–205. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Nik-Ghazali, N.-N.; Abul Kalam, M.; Badruddin, I.A.; Banapurmath, N.R.; Akram, N. The effect of nano-additives in diesel-biodiesel fuel blends: A comprehensive review on stability, engine performance and emission characteristics. Energy Convers. Manag. 2018, 178, 146–177. [Google Scholar] [CrossRef]

- Anand, G.; Kuchhal, P. Experimental and theoretical investigation of viscosity, density and sound velocity of jatropha diesel and pure diesel blends. Biofuels 2016, 24, 1–6. [Google Scholar] [CrossRef]

- Srikanth, H.V.; Venkatesh, J.; Godiganur, S.; Manne, B.; Bharath Kumar, S.; Spurthy, S. Combustion, performance, and emission characteristics of dairy-washed milk scum biodiesel in a dual cylinder compression ignition engine. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 42, 2873–2890. [Google Scholar] [CrossRef]

- Kavitha, M.S.; Murugavelh, S. Optimization and transesterification of sterculia oil: Assessment of engine performance, emission and combustion analysis. J. Clean. Prod. 2019, 234, 1192–1209. [Google Scholar] [CrossRef]

- Da Costa, R.B.R.; Hernández, J.J.; Teixeira, A.F.; Diniz Netto, N.A.; Valle, R.A.; Roso, V.R.; Coronado, C.J.R. Combustion, performance and emission analysis of a natural gas-hydrous ethanol dual-fuel spark ignition engine with internal exhaust gas recirculation. Energy Convers. Manag. 2019, 195, 1187–1198. [Google Scholar] [CrossRef]

- Dinesha, P.; Kumar, S.; Rosen, M.A. Performance and emission analysis of a domestic wick stove using biofuel feedstock derived from waste cooking oil and sesame oil. Renew. Energy 2019, 136, 342–351. [Google Scholar] [CrossRef]

- Thomas, J.J.; Sabu, V.R.; Nagarajan, G.; Kumar, S.; Basrin, G. Effects of waste vegetable oil biodiesel and hexanol on a reactivity controlled compression ignition engine combustion and emissions. Energy 2020, 206, 118199. [Google Scholar] [CrossRef]

- Milano, J.; Ong, H.C.; Masjuki, H.H.; Silitonga, A.S.; Kusumo, F.; Dharma, S.; Sebayang, A.H.; Cheah, M.Y.; Wang, C.-T. Physicochemical property enhancement of biodiesel synthesis from hybrid feedstocks of waste cooking vegetable oil and Beauty leaf oil through optimized alkaline-catalysed transesterification. Waste Manag. 2018, 80, 435–449. [Google Scholar] [CrossRef] [PubMed]

- Afzal, A.; Kareemullah, M.; Abdul Razak, R.K. Production of biodiesel from various sources and comparative engine performance studies by using different biodiesel blends. J. Eng. Res. 2018, 6, 1–21. [Google Scholar]

- Kannan, M.; Arunkumar, M.; Kumar, K.S. Experimental Studies of Diesel Engine Performance, Combustion and Emission Characteristics with Diesel and Pumpkin Seed Oil Blends. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 1294–1299. [Google Scholar] [CrossRef]

- Murali, G.; Anusha, M.; Arunkumar, M. Performance study of a single cylinder diesel engine using diesel with Pongamia pinnata and Camelina sativa seed oil blends. Mater. Today Proc. 2019, 21, 206–211. [Google Scholar] [CrossRef]

- Kareemullah, M.; Afzal, A.; Rehman, K.F. Performance and emission analysis of compression ignition engine using biodiesels from Acid oil, Mahua oil, and Castor oil. Heat Transf. 2019, 49, 858–871. [Google Scholar] [CrossRef]

- David, O.; Okwu, M.O.; Oyejide, O.J.; Taghinezhad, E.; Asif, A.; Kaveh, M. Optimizing biodiesel production from abundant waste oils through empirical method and grey wolf optimizer. Fuel 2020, 281, 118701. [Google Scholar] [CrossRef]

- David, O.; Waheed, M.A.; Taheri-garavand, A.; Nath, T.; Dairo, O.U.; Bolaji, B.O.; Afzal, A. Prandtl number of optimum biodiesel from food industrial waste oil and diesel fuel blend for diesel engine. Fuel 2021, 285, 119049. [Google Scholar] [CrossRef]

| Source of Biodiesel | Kinetic Viscosity at 40 °C | Density (g/cm3) | Flash Point (°C) | References |

|---|---|---|---|---|

| Castor | 3.5–5.6 | 0.853–0.870 | 161–236 | [1,5] |

| Algal | 2.41–4.3 | 0.841–0.937 | 114–243.5 | [12,15,42] |

| Neem | 2.93–4.90 | 0.840–0.896 | 133–257 | [2,16] |

| Corn | 4–4.7 | 0.871–0.883 | 73–111 | [11,19,24] |

| Camalina sativa | 4.04–4.94 | 0.882–0.893 | 65–142 | [19,20,37,38] |

| Animal fat | 4.3–5.7 | 0.875–0.880 | 83–176 | [18,43] |

| Jatropha | 4.1–4.3 | 0.835–0.884 | 92–181 | [9,37,39,40] |

| Pure Diesel | 2.3–5.5 | 0.814–0.844 | 76(Min) | [17,44,45] |

| ASTM Standard | 1.7–5.8 | 0.830–0.890 | 122(Max) | [46,47] |

| (D-B100) Present Work | 13.15 | 0.932 | 162 | Present work |

| Type | Vertical Single Cylinder DI Diesel Engine |

|---|---|

| Engine Speed | 1500 rpm |

| Bore X Stroke | 97 mm × 128 mm |

| Brake Power | 5.2 kW |

| Compression Ratio | 17:01 |

| Standard Injection Timing | 15° bTDC at full load condition |

| Standard Injection Pressure | 200 bar |

| Parameters | Systematic Errors (±) | Measuring Range |

|---|---|---|

| Speed | ±10 rpm | 250–8000 rpm |

| Temperature | ±1 °C | 1–120 °C |

| Soot | ±0.1% | 0–100% |

| CO | ±0.01 Vol.% | 0–10 Vol.% |

| CO2 | ±0.1 Vol.% | 0–20 Vol.% |

| HC | ±1 ppm | 0–20,000 ppm |

| NO | ±1 ppm | 1–4000 ppm |

| PROPERTY | Diesel | B5 | B20 | B100 | Unit |

|---|---|---|---|---|---|

| Flash point | 42.6 | 42.8 | 48 | 166 | deg cel. |

| Cloud point | −4 | −5 | −8 | −24 | deg cel. |

| Heating value | 45.11 | 43.41 | 43.76 | 36.7 | MJ/kg |

| Kinematic viscosity @ 40 °C | 3.1 | 3.41 | 4.87 | 5.18 | cSt |

| Calorific value | 43,200 | 39,575 | 39,572 | 39,499 | kJ/kg |

| Density at 15 °C | 830 | 880.2 | 878 | 876 | kg/m3 |

| Cetane no. | 51 | 51.4 | 51.7 | 52 | - |

| Hydrogen content | 13.34 | 11.73 | 11.79 | 11.80 | (wt.%) |

| Oxygen content | 16 | 11.37 | 11.61 | 11.28 | (wt.%) |

| Sulfur content | 26 | 6.3 | 6.5 | 6.9 | (ppm) |

| Carbon content | 85.92 | 76.36 | 75.9 | 75.1 | (wt.%) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arunkumar, M.; Mohanavel, V.; Afzal, A.; Sathish, T.; Ravichandran, M.; Khan, S.A.; Abdullah, N.A.; Bin Azami, M.H.; Asif, M. A Study on Performance and Emission Characteristics of Diesel Engine Using Ricinus Communis (Castor Oil) Ethyl Esters. Energies 2021, 14, 4320. https://doi.org/10.3390/en14144320

Arunkumar M, Mohanavel V, Afzal A, Sathish T, Ravichandran M, Khan SA, Abdullah NA, Bin Azami MH, Asif M. A Study on Performance and Emission Characteristics of Diesel Engine Using Ricinus Communis (Castor Oil) Ethyl Esters. Energies. 2021; 14(14):4320. https://doi.org/10.3390/en14144320

Chicago/Turabian StyleArunkumar, Munimathan, Vinayagam Mohanavel, Asif Afzal, Thanikodi Sathish, Manickam Ravichandran, Sher Afghan Khan, Nur Azam Abdullah, Muhammad Hanafi Bin Azami, and Mohammad Asif. 2021. "A Study on Performance and Emission Characteristics of Diesel Engine Using Ricinus Communis (Castor Oil) Ethyl Esters" Energies 14, no. 14: 4320. https://doi.org/10.3390/en14144320

APA StyleArunkumar, M., Mohanavel, V., Afzal, A., Sathish, T., Ravichandran, M., Khan, S. A., Abdullah, N. A., Bin Azami, M. H., & Asif, M. (2021). A Study on Performance and Emission Characteristics of Diesel Engine Using Ricinus Communis (Castor Oil) Ethyl Esters. Energies, 14(14), 4320. https://doi.org/10.3390/en14144320