Assessing the Cost of Biomass and Bioenergy Production in Agroindustrial Processes

Abstract

:1. Introduction

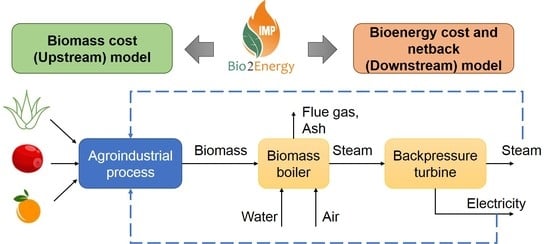

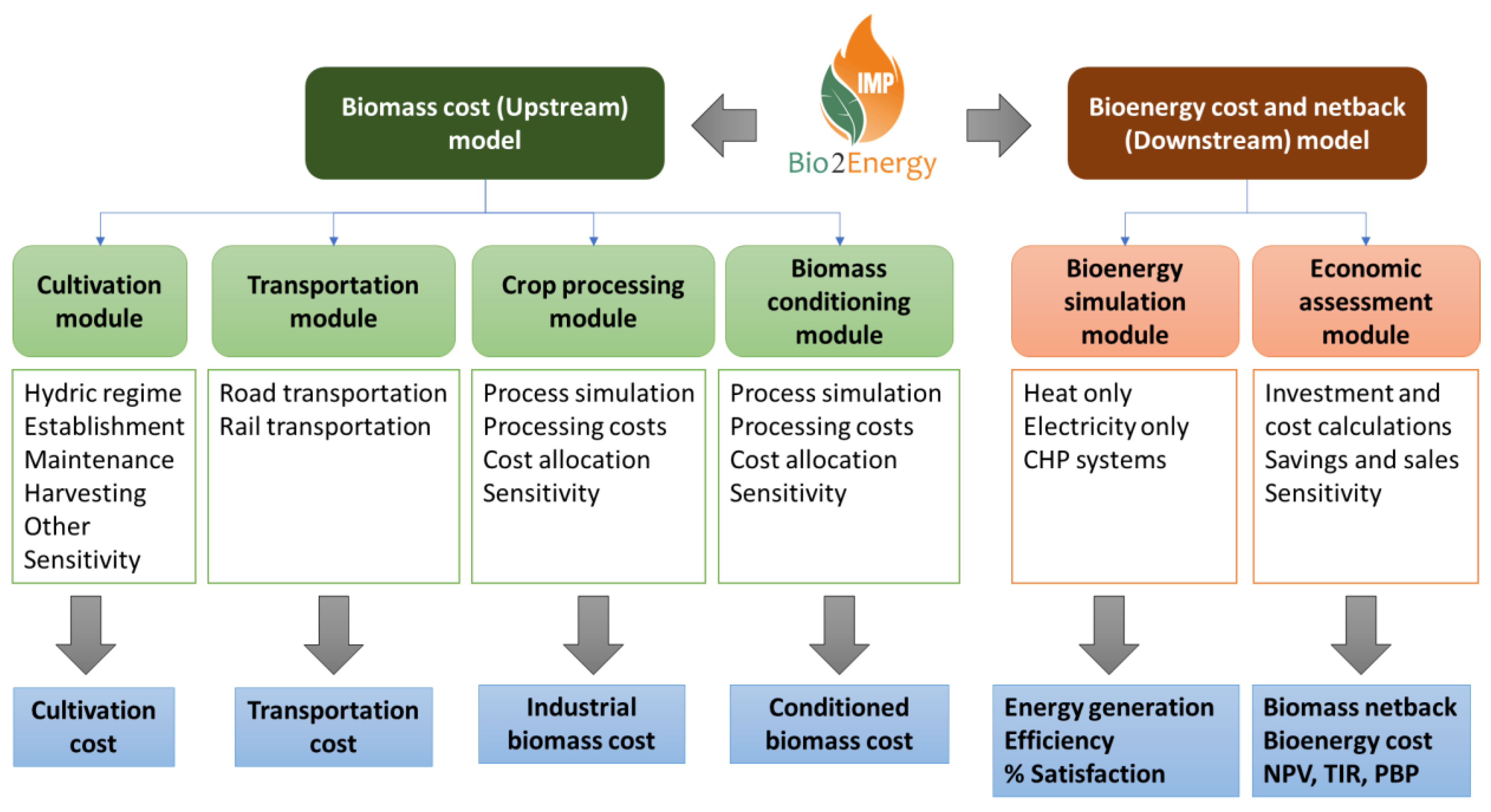

2. Materials and Methods

2.1. Biomass Production Cost (Upstream) Model

2.1.1. Cultivation

2.1.2. Transportation

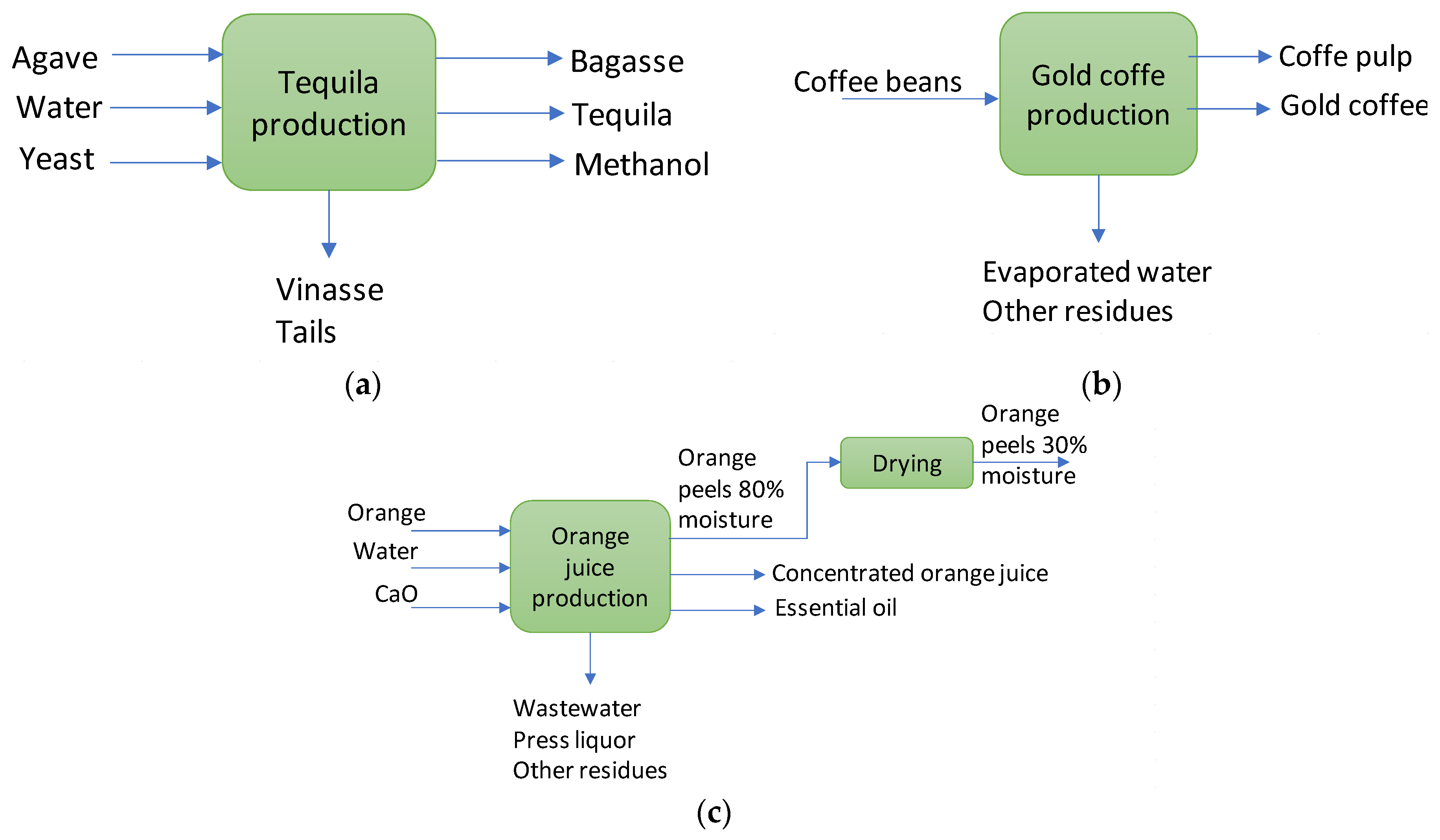

2.1.3. Crop Processing

2.1.4. Biomass Conditioning

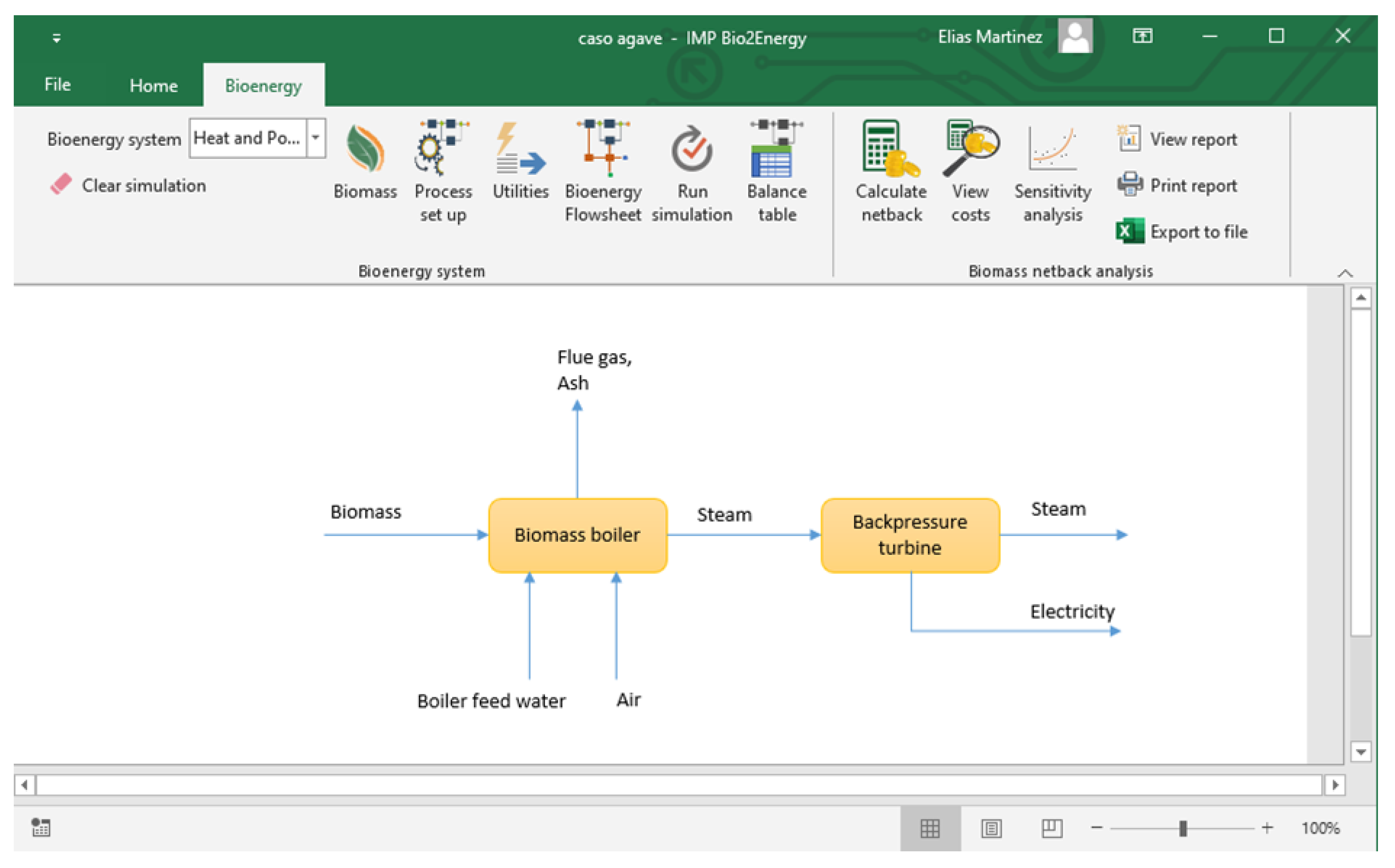

2.2. Biomass Netback and Energy Production Cost (Downstream) Model

2.2.1. Bioenergy Simulation Module

2.2.2. Economic Assessment Module

3. Case Studies

4. Results and Discussion

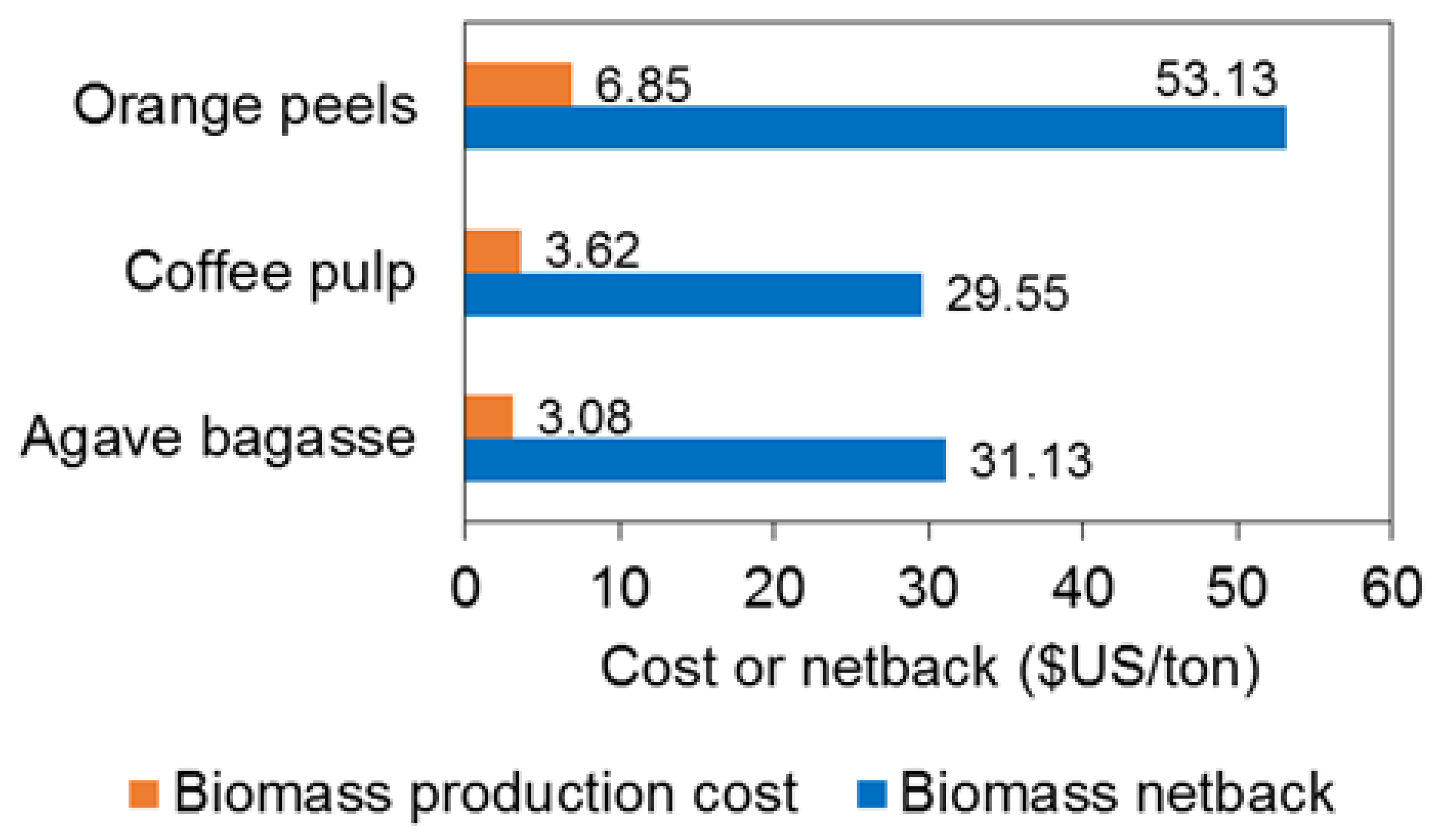

4.1. Biomass Production Cost vs. Biomass Netback

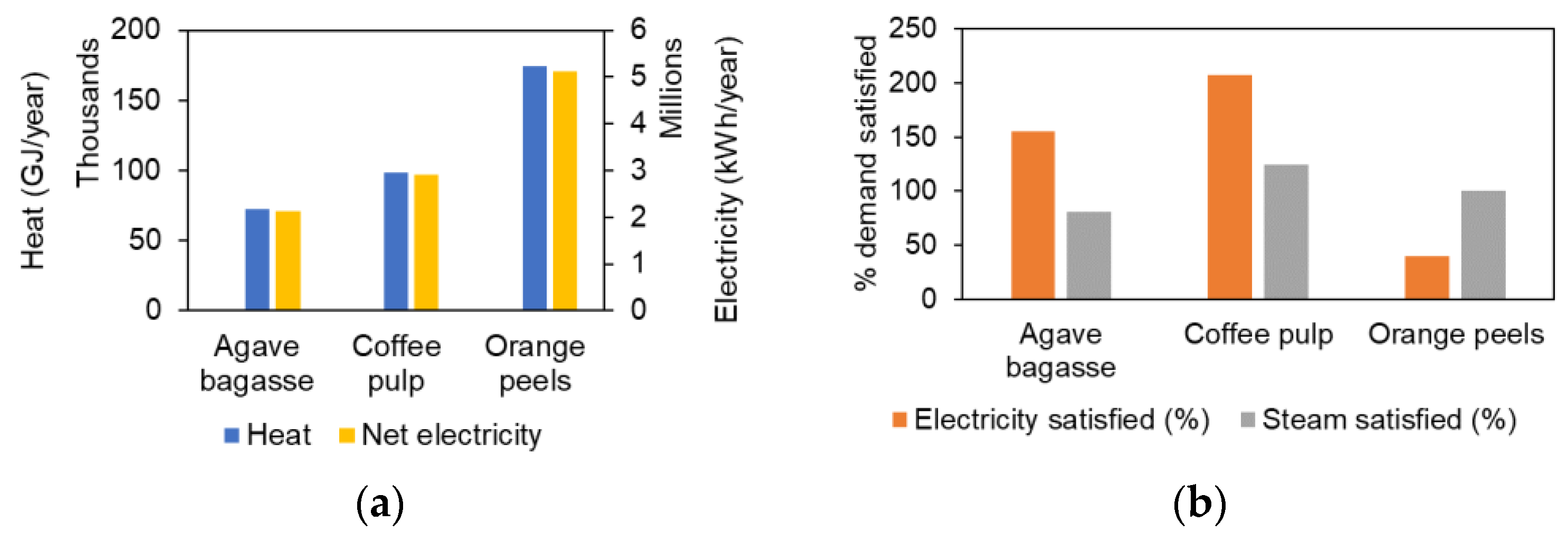

4.2. Bioenergy Production and Demand Satisfaction

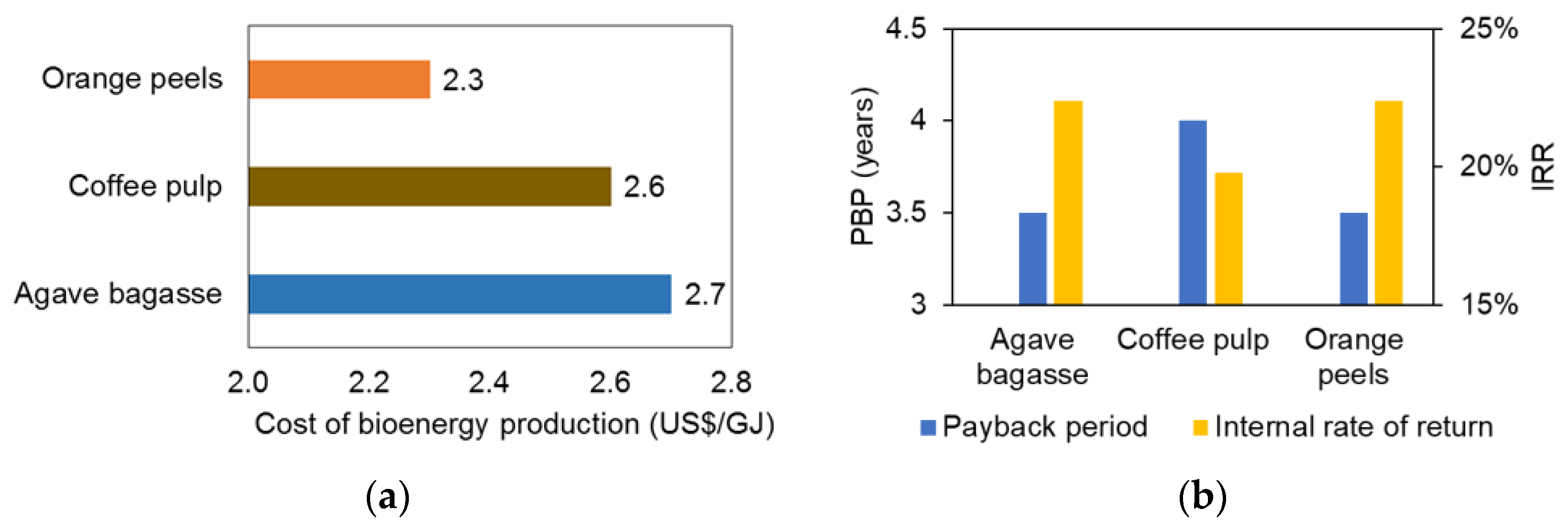

4.3. Bioenergy Cost of Production and Other Economic Indicators

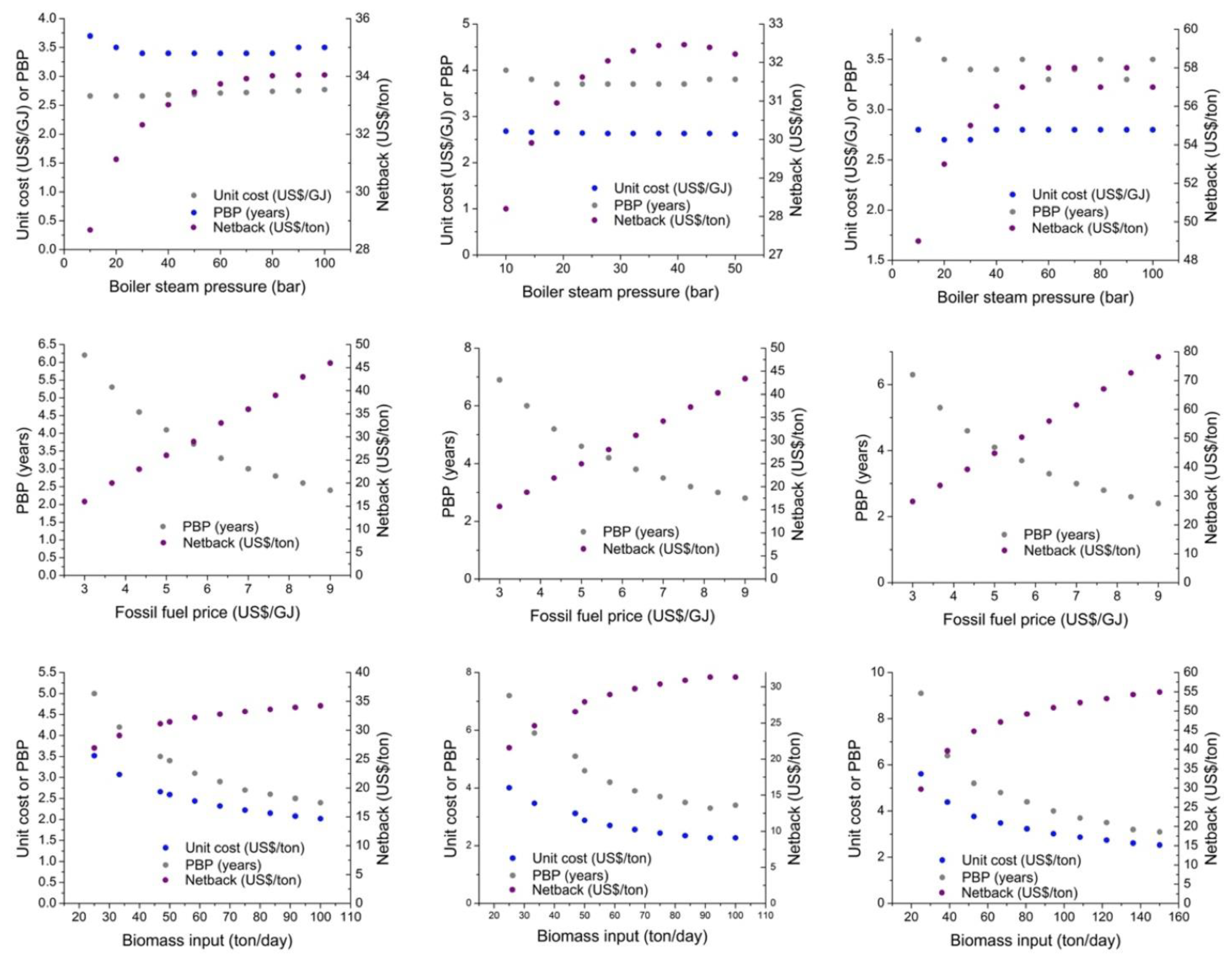

4.4. Sensitivity

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- International Energy Agency (IEA). Renewable Power Generation Costs in 2017; International Energy Agency (IEA): Paris, France, 2018. [CrossRef]

- Dornburg, V.; Faaij, A.P. Efficiency and economy of wood-fired biomass energy systems in relation to scale regarding heat and power generation using combustion and gasification technologies. Biomass Bioenergy 2001, 21, 91–108. [Google Scholar] [CrossRef]

- Kempegowda, R.S.; Skreiberg, Ø.; Tran, K.-Q. Techno-economic Evaluations of Various Biomass CHP Technologies and Policy Measures Under Norwegian Conditions. Energy Procedia 2012, 20, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Gregg, J.S.; Jürgens, J.; Happel, M.K.; Strøm-Andersen, N.; Tanner, A.N.; Bolwig, S.; Klitkou, A. Valorization of bio-residuals in the food and forestry sectors in support of a circular bioeconomy: A review. J. Clean. Prod. 2020, 267, 122093. [Google Scholar] [CrossRef]

- Ajila, C.M.; Brar, S.K.; Verma, M.; Rao, U.J.S.P. Sustainable Solutions for Agro Processing Waste Management: An Overview. In Environmental Protection Strategies for Sustainable Development; Springer: Dordrecht, The Netherlands, 2012; pp. 65–109. [Google Scholar]

- Di Fraia, S.; Fabozzi, S.; Macaluso, A.; Vanoli, L. Energy potential of residual biomass from agro-industry in a Mediterranean region of southern Italy (Campania). J. Clean. Prod. 2020, 277, 124085. [Google Scholar] [CrossRef]

- Anwar, Z.; Gulfraz, M.; Irshad, M. Agro-industrial lignocellulosic biomass a key to unlock the future bio-energy: A brief review. J. Radiat. Res. Appl. Sci. 2014, 7, 163–173. [Google Scholar] [CrossRef]

- Wright, D.G.; Dey, P.; Brammer, J. A barrier and techno-economic analysis of small-scale bCHP (biomass combined heat and power) schemes in the UK. Energy 2014, 71, 332–345. [Google Scholar] [CrossRef] [Green Version]

- Lo, S.L.Y.; How, B.S.; Leong, W.D.; Teng, S.Y.; Rhamdhani, M.A.; Sunarso, J. Techno-economic analysis for biomass supply chain: A state-of-the-art review. Renew. Sustain. Energy Rev. 2021, 135, 110164. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Ng, K.S.; Hernandez, E.M. Biorefineries and Chemical Processes: Design, Integration and Sustainability Analysis. Green Process. Synth. 2014, 4, 65–66. [Google Scholar] [CrossRef]

- Bang, C.; Vitina, A.; Gregg, J.S.; Lindboe, H.H. Analysis of Biomass Prices; Ea Energy Analyses: Copenhagen, Dermark, 2013. [Google Scholar]

- Latourrette, T.; Ortiz, D.S.; Hlavka, E.; Burger, N.; Cecchine, G. Supplying Biomass to Power Plants; RAND Corporation: Santa Monica, CA, USA, 2010. [Google Scholar]

- Tauro, R.; García, C.A.; Skutsch, M.; Masera, O. The potential for sustainable biomass pellets in Mexico: An analysis of energy potential, logistic costs and market demand. Renew. Sustain. Energy Rev. 2018, 82, 380–389. [Google Scholar] [CrossRef]

- Havlíčková, K.; Weger, J.; Knápek, J. Modelling of biomass prices for bio-energy market in the Czech Republic. Simul. Model. Pr. Theory 2011, 19, 1946–1956. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, J.; Zhang, X.; Grushecky, S. Environmental and Economic Assessments and Uncertainties of Multiple Lignocellulosic Biomass Utilization for Bioenergy Products: Case Studies. Energies 2020, 13, 6277. [Google Scholar] [CrossRef]

- Restrepo-Valencia, S.; Walter, A. Techno-Economic Assessment of Bio-Energy with Carbon Capture and Storage Systems in a Typical Sugarcane Mill in Brazil. Energies 2019, 12, 1129. [Google Scholar] [CrossRef] [Green Version]

- Ahmadi, L.; Kannangara, M.; Bensebaa, F. Cost-effectiveness of small scale biomass supply chain and bioenergy production systems in carbon credit markets: A life cycle perspective. Sustain. Energy Technol. Assess. 2020, 37. [Google Scholar] [CrossRef]

- Purkus, A.; Gawel, E.; Szarka, N.; Lauer, M.; Lenz, V.; Ortwein, A.; Tafarte, P.; Eichhorn, M.; Thrän, D. Contributions of flexible power generation from biomass to a secure and cost-effective electricity supply—a review of potentials, incentives and obstacles in Germany. Energy, Sustain. Soc. 2018, 8, 18. [Google Scholar] [CrossRef]

- Meng, L.; Alengebawy, A.; Ai, P.; Jin, K.; Chen, M.; Pan, Y. Techno-Economic Assessment of Three Modes of Large-Scale Crop Residue Utilization Projects in China. Energies 2020, 13, 3729. [Google Scholar] [CrossRef]

- Eksi, G.; Karaosmanoglu, F. Combined bioheat and biopower: A technology review and an assessment for Turkey. Renew. Sustain. Energy Rev. 2017, 73, 1313–1332. [Google Scholar] [CrossRef]

- Czekała, W.; Bartnikowska, S.; Dach, J.; Janczak, D.; Smurzyńska, A.; Kozłowski, K.; Bugała, D.; Lewicki, A.; Cieślik, M.; Typańska, D.; et al. The energy value and economic efficiency of solid biofuels produced from digestate and sawdust. Energy 2018, 159, 1118–1122. [Google Scholar] [CrossRef]

- Campbell, R.M.; Anderson, N.M.; Daugaard, D.E.; Naughton, H.T. Technoeconomic and Policy Drivers of Project Performance for Bioenergy Alternatives Using Biomass from Beetle-Killed Trees. Energies 2018, 11, 293. [Google Scholar] [CrossRef] [Green Version]

- Taner, T.; Sivrioglu, M. A techno-economic & cost analysis of a turbine power plant: A case study for sugar plant. Renew. Sustain. Energy Rev. 2017, 78, 722–730. [Google Scholar] [CrossRef]

- Wan, Y.K.; Sadhukhan, J.; Ng, K.S.; Ng, D.K. Techno-economic evaluations for feasibility of sago-based biorefinery, Part 1: Alternative energy systems. Chem. Eng. Res. Des. 2016, 107, 263–279. [Google Scholar] [CrossRef]

- Gan, S.H.; Wan, Y.K.; Leong, Y.T. Synthesize an optimum combined heat and power (CHP) system for sago industry via mathematical approach. AIP Conf. Proc. 2019, 2137, 020003. [Google Scholar] [CrossRef]

- Martinez-Hernandez, E.; Ibrahim, M.H.; Leach, M.; Sinclair, P.; Campbell, G.M.; Sadhukhan, J. Environmental sustainability analysis of UK whole-wheat bioethanol and CHP systems. Biomass Bioenergy 2013, 50, 52–64. [Google Scholar] [CrossRef]

- Havrysh, V.; Kalinichenko, A.; Mentel, G.; Mentel, U.; Vasbieva, D.G. Husk Energy Supply Systems for Sunflower Oil Mills. Energies 2020, 13, 361. [Google Scholar] [CrossRef] [Green Version]

- Hernandez, E.M.; Martinez-Herrera, J.; Campbell, G.; Sadhukhan, J. Process integration, energy and GHG emission analyses of Jatropha-based biorefinery systems. Biomass Convers. Biorefinery 2013, 4, 105–124. [Google Scholar] [CrossRef]

- Sims, R.; Flammini, A.; Puri, M.; Bracco, S. Opportunities for Agri-Food Chains to Become Energy-Smart; FAO: Washington, DC, USA; USAID: Washington, DC, USA, 2015.

- Ebadian, M.; Sowlati, T.; Sokhansanj, S.; Stumborg, M.; Townley-Smith, L. A new simulation model for multi-agricultural biomass logistics system in bioenergy production. Biosyst. Eng. 2011, 110, 280–290. [Google Scholar] [CrossRef]

- Keppo, I.; Savola, T. Economic appraisal of small biofuel fired CHP plants. Energy Convers. Manag. 2007, 48, 1212–1221. [Google Scholar] [CrossRef]

- Wood, S.; Rowley, P. A techno-economic analysis of small-scale, biomass-fuelled combined heat and power for community housing. Biomass Bioenergy 2011, 35, 3849–3858. [Google Scholar] [CrossRef] [Green Version]

- Centro Mario Molina. Bioenergía: Análisis Regional del Aprovechamiento Integral de los Residuos de la Industria Agropecuaria; Mario Molina Center: Mexico City, Mexico, 2016. [Google Scholar]

- Valdez-Vazquez, I.; Acevedo-Benítez, J.A.; Hernández-Santiago, C. Distribution and potential of bioenergy resources from agricultural activities in Mexico. Renew. Sustain. Energy Rev. 2010, 14, 2147–2153. [Google Scholar] [CrossRef]

- Parascanu, M.; Sandoval-Salas, F.; Soreanu, G.; Valverde, J.; Sanchez-Silva, L. Valorization of Mexican biomasses through pyrolysis, combustion and gasification processes. Renew. Sustain. Energy Rev. 2017, 71, 509–522. [Google Scholar] [CrossRef]

- SADER. Biomasa, Creación Ecológica de Energía|Secretaría de Agricultura y Desarrollo Rural|Gobierno|gob.mx n.d. Available online: https://www.gob.mx/agricultura/articulos/biomasa-creacion-ecologica-de-energia (accessed on 4 April 2021).

- Martinez-Hernandez, E.; Amezcua-Allieri, M.A.; Sadhukhan, J.; Anell, J.A. Sugarcane Bagasse Valorization Strategies for Bioethanol and Energy Production. Sugarcane Technol. Res. 2018. [Google Scholar] [CrossRef] [Green Version]

- Amezcua-Allieri, M.A.; Martínez-Hernández, E.; Anaya-Reza, O.; Magdaleno-Molina, M.; Melgarejo-Flores, L.A.; Palmerín-Ruiz, M.E.; Eguía-Lis, J.A.Z.; Rosas-Molina, A.; Enríquez-Poy, M.; Aburto, J. Techno-economic analysis and life cycle assessment for energy generation from sugarcane bagasse: Case study for a sugar mill in Mexico. Food Bioprod. Process. 2019, 118, 281–292. [Google Scholar] [CrossRef]

- Martinez-Hernandez, E.; Molina, M.M.; Flores, L.A.M.; Ruiz, M.E.P.; EguiaLis, J.A.Z.; Molina, A.R.; Aburto, J.; Amezcua-Allieri, M.A. Energy-water nexus strategies for the energetic valorization of orange peels based on techno-economic and environmental impact assessment. Food Bioprod. Process. 2019, 117, 380–387. [Google Scholar] [CrossRef]

- Pantaleo, A.; Candelise, C.; Bauen, A.; Shah, N. ESCO business models for biomass heating and CHP: Profitability of ESCO operations in Italy and key factors assessment. Renew. Sustain. Energy Rev. 2014, 30, 237–253. [Google Scholar] [CrossRef]

- Konieczna, A.; Roman, K.; Roman, M.; Śliwiński, D.; Roman, M. Energy Efficiency of Maize Production Technology: Evidence from Polish Farms. Energies 2020, 14, 170. [Google Scholar] [CrossRef]

- Wagner, W.; Pruss, A. Release of the IAPWS Formulation 1995 for the Thermodynamic Properties of Ordinary Water Substance for General and Scientific Use. J. Phys. Chem. Ref. Data 2002, 31, 387–535. [Google Scholar] [CrossRef] [Green Version]

- Puga Andrade, J.; Vazquez Frias, A. Ingeniería Básica Para la Producción de Tequila; Universidad Nacional Autonoma de Mexico: Mexico City, Mexico, 1998. [Google Scholar]

- Centro Mario Molina. Estrategia de sustentabilidad para la Cadena Productiva Agave Tequila; Mario Molina Center: Mexico City, Mexico, 2016. [Google Scholar]

- Gomez-Mora, J.M. Modelación del Procesamiento Agroindustrial del Café Desde la Fruta Hasta el Café Oro; Universidad de Costa Rica: San José, Costa Rica, 2019. [Google Scholar]

- Hernandez-Diaz, W.N.; Hernandez-Campos, F.J.; Vargas-Galarza, Z.; Rodriguez-Jimenes, G.C.; Garcia-Alvarado, M.A. Coffee Grain Rotary Drying Optimization. Rev. Mex. Ing. Quím. 2013, 12, 315–325. [Google Scholar]

- Pérez Ayala, M. Línea de Elaboración de Zumo de Naranja y Refrigerado de 6.000 L/h en Lorquí (Murcia); Universidad Politecnica de Cartagena: Cartagena, Spain, 2005. [Google Scholar]

- Barrera Naranjo, V. Proceso Industrial de Elaboración de zumo de Naranja; Universidad de Sevilla: Sevilla, Spain, 2015. [Google Scholar]

- Franco, A.; Velázquez, M. Una aproximación sociodemográfica al consumo de energía en los hogares mexicanos, 2014. In La Situación Demográfica México 2016, 1st ed.; Márquez Villeda, M., Ed.; CONAPO: Mexico City, Mexico, 2017; p. 24. [Google Scholar]

| Agroindustry Value Chain | Tequila | Coffee | Orange |

|---|---|---|---|

| Main crop | Agave | Coffee | Orange |

| Crop processing input (ton/year) | 19,500 | 47,175 | 366,000 |

| Operating time (h/year) | 8400 | 7200 | 4652 |

| Steam demand (ton/ton input) | 2.087 | 0.68 | 0.125 |

| Electricity demand (kWh/ton input) | 70.51 | 29.68 | 20.12 |

| Main crop price ($US/ton) | 1100 | 2753 | 125 |

| Biomass generated | Agave bagasse | Coffee pulp | Orange peels |

| Biomass to CHP (ton/year) | 16,409 | 19,333 | 23,493 |

| Component | Agave Bagasse | Coffee Pulp | Orange Peels |

|---|---|---|---|

| C | 17.57 | 20.21 | 28.89 |

| H | 2.24 | 2.65 | 4.05 |

| N | 0.79 | 1.17 | 0.38 |

| S | 0.13 | 0.16 | 0.03 |

| O | 23.40 | 22.44 | 23.13 |

| Ash | 5.86 | 3.37 | 13.51 |

| Moisture | 50.00 | 50.00 | 30.00 |

| Reference | [35] | [35] | [39] |

| Parameter | Value | Unit |

|---|---|---|

| Boiler steam pressure | 20 | bar |

| Boiler steam temperature | 212.4 | °C |

| Boiler air excess ratio | 50 | % |

| Flue gas exit temperature | 150 | °C |

| Air inlet temperature | 25 | °C |

| Water inlet temperature | 25 | °C |

| Turbine isentropic efficiency | 75 | % |

| Turbine mechanical efficiency | 90 | % |

| Turbine outlet pressure | 2 | bar |

| Outlet steam temperature | 120.2 | °C |

| Economic Parameter | Agroindustrial Processing | Bioenergy | Unit |

|---|---|---|---|

| Labour costs | Tequila: 72,186 Coffee: 100,000O range: 325,000 | Agave bagasse: 35,414 Coffee pulp: 48,341 Orange peels: 85,575 | US$/year |

| Working capital | 10 | - | % of operating costs |

| Plant cost | - | Estimated | US$ |

| Project lifetime | 20 | 20 | years |

| Maintenance | 0 | 0.5 | % of annual capital cost |

| Annual inflation rate | 3 | 3 | % |

| Biomass value as animal feed | 5 | - | US$/ton |

| Grid electricity cost | 0.0858 | US$/kWh | |

| Current steam cost | 14.87945 | US$/ton | |

| Current fuel used | Fuel oil | - | |

| Fuel price | 6 | US$/GJ | |

| Independent Variable (x) | Dependent Variable (y) | Equation | R2 |

|---|---|---|---|

| Orange peels | |||

| Fuel price | Netback | y = 8.3486x + 3.0406 | 1 |

| Fuel price | PBP | y = 16.596x−0.875 | 0.9993 |

| Biomass input | Netback | y = 13.259ln(x) − 9.959 | 0.9612 |

| Biomass input | PBP | y = 54.416x−0.575 | 0.9895 |

| Biomass input | Unit cost | y = 21.672x−0.432 | 0.9935 |

| Agave bagasse | |||

| Fuel price | Netback | y = 4.9725x + 1.2961 | 1 |

| Fuel price | PBP | y = 16.326x−0.866 | 0.9988 |

| Biomass input | Netback | y = 5.1375ln(x) + 10.995 | 0.9785 |

| Biomass input | PBP | y = 27.052x−0.53 | 0.9974 |

| Biomass input | Unit cost | y = 12.369x−0.397 | 0.9959 |

| Coffee pulp | |||

| Fuel price | Netback | y = 4.6086x + 1.9011 | 1 |

| Fuel price | PBP | y = 17.459x−0.829 | 0.999 |

| Biomass input | Netback | y = 7.0032ln(x) − 0.0185 | 0.9716 |

| Biomass input | PBP | y = 42.304x−0.562 | 0.9863 |

| Biomass input | Unit cost | y = 15.11x−0.42 | 0.9912 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martinez-Hernandez, E.; Amezcua-Allieri, M.A.; Aburto, J. Assessing the Cost of Biomass and Bioenergy Production in Agroindustrial Processes. Energies 2021, 14, 4181. https://doi.org/10.3390/en14144181

Martinez-Hernandez E, Amezcua-Allieri MA, Aburto J. Assessing the Cost of Biomass and Bioenergy Production in Agroindustrial Processes. Energies. 2021; 14(14):4181. https://doi.org/10.3390/en14144181

Chicago/Turabian StyleMartinez-Hernandez, Elias, Myriam A. Amezcua-Allieri, and Jorge Aburto. 2021. "Assessing the Cost of Biomass and Bioenergy Production in Agroindustrial Processes" Energies 14, no. 14: 4181. https://doi.org/10.3390/en14144181

APA StyleMartinez-Hernandez, E., Amezcua-Allieri, M. A., & Aburto, J. (2021). Assessing the Cost of Biomass and Bioenergy Production in Agroindustrial Processes. Energies, 14(14), 4181. https://doi.org/10.3390/en14144181