Energy Parameters of Miscanthus Biomass Pellets Supplemented with Copra Meal in Terms of Energy Consumption during the Pressure Agglomeration Process

Abstract

:1. Introduction

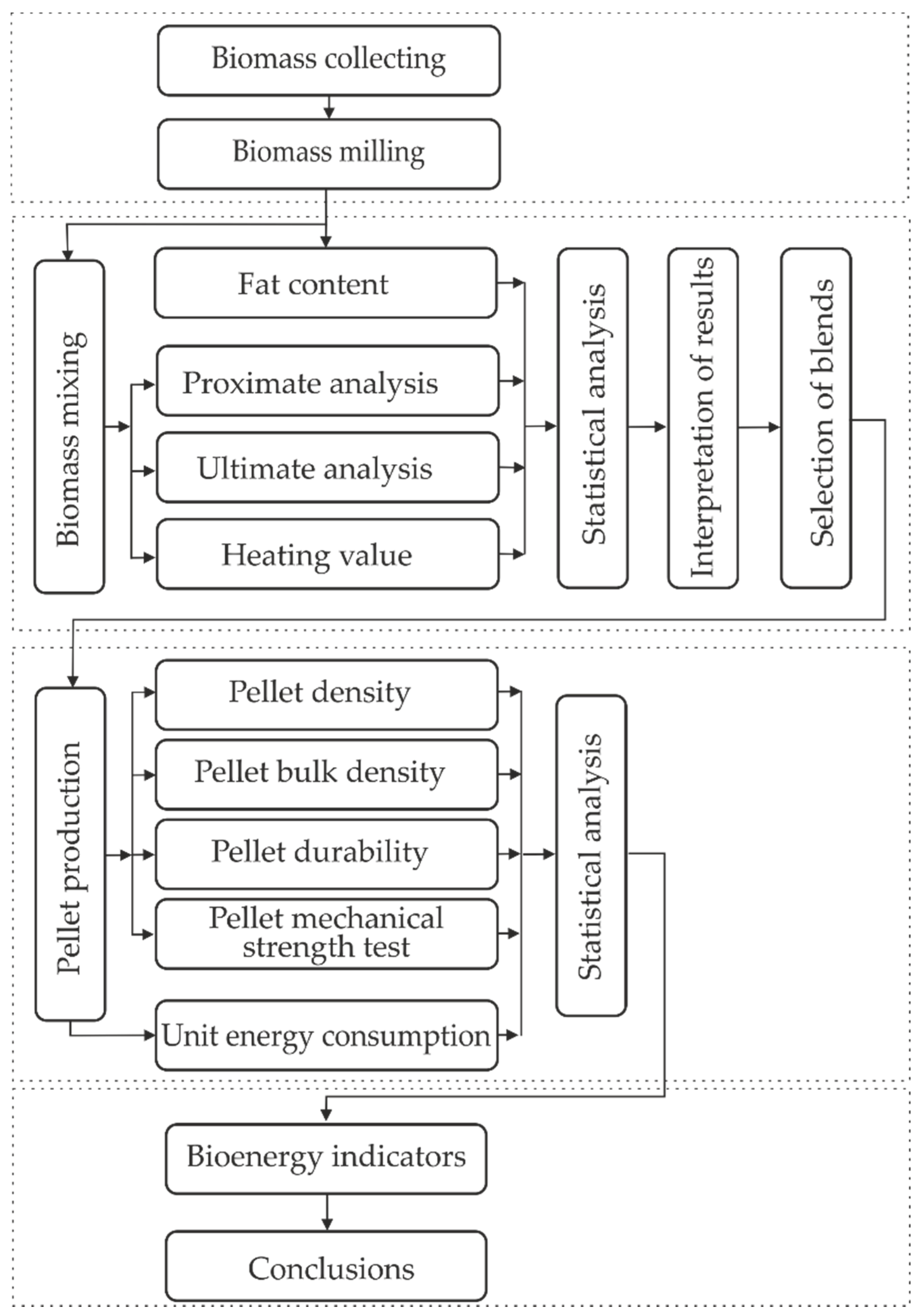

2. Materials and Methods

2.1. Research Material

2.2. Preparation of Samples

- 90% miscanthus and 10% copra—M90C10,

- 80% miscanthus and 20% copra—M80C20,

- 70% miscanthus and 30% copra—M70C30,

- 60% miscanthus and 40% copra—M60C40,

- 50% miscanthus and 50% copra—M50C50,

- 40% miscanthus and 60% copra—M60C40.

2.3. Heating Value Estimation and Ultimate and Proximate Analysis

2.4. Determination of Fat Content

2.5. Pellet Production

2.6. Properties of Pellets

2.6.1. Pellet Density

2.6.2. Pellet Bulk Density

2.6.3. Mechanical Durability of Pellets

- mA—final mass (g),

- mE—initial mass (g).

2.6.4. Pellet Mechanical Strength Test

2.7. Statistical Analysis

3. Results and Discussion

3.1. Properties of Raw Materials and Mixtures

3.2. Properties of Pellets

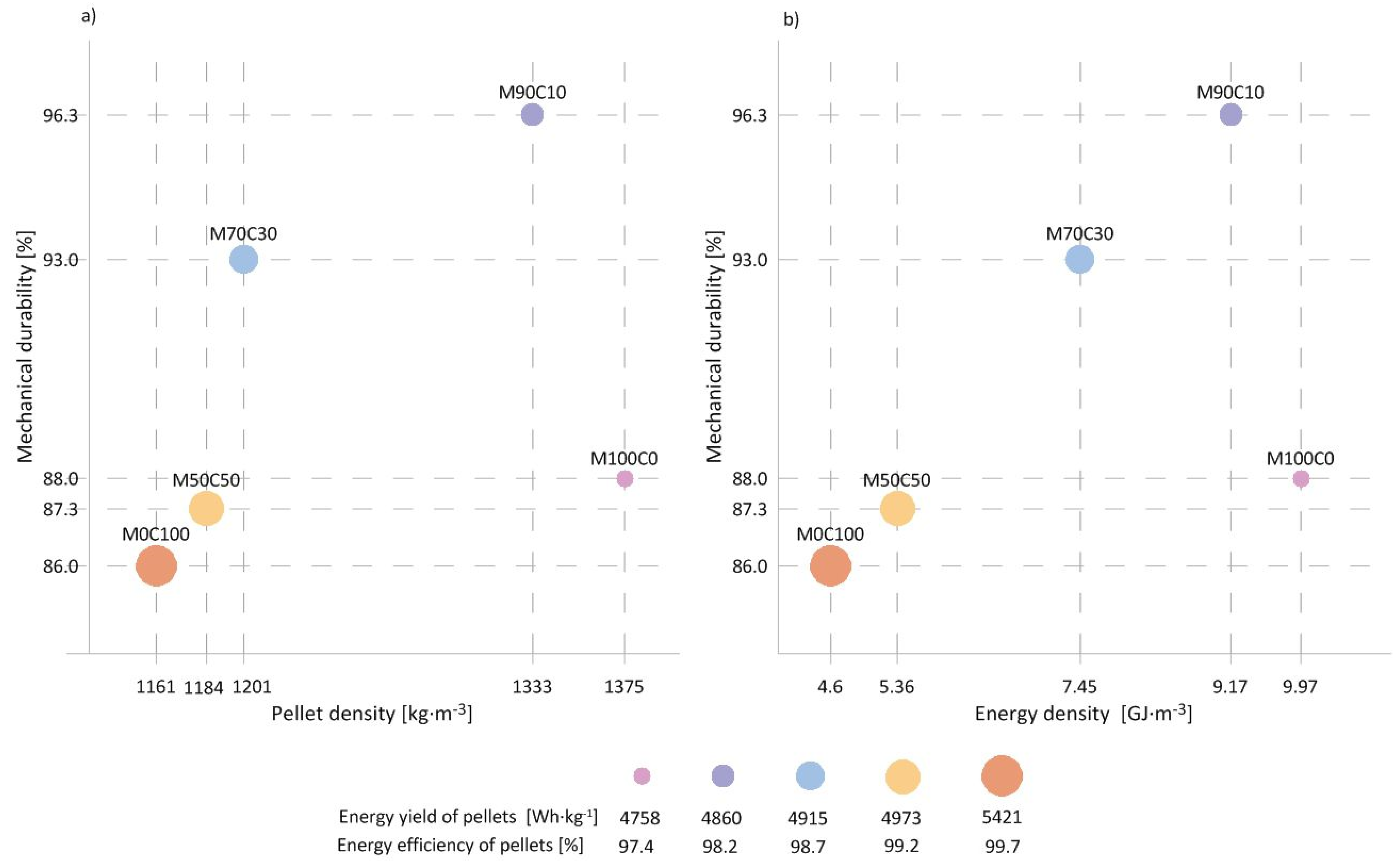

3.3. Bioenergy Indicators

- EY—Energy yield of pellets [Wh·kg−1],

- LHV—Lower heating value [Wh·kg−1],

- ECU—Energy consumption unit [Wh·kg−1].

- EE—Energy efficiency [%],

- IE—Initial energy content of biomass [Wh·kg−1],

- ECU—Energy consumption unit [Wh·kg−1].

- ED—Energy density [GJ·m−3],

- LHV—Lower heating value [GJ·kg−1],

- DB—Bulk density [kg·m−3].

4. Conclusions

Research Limitations and Suggestions for Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jasinskas, A.; Streikus, D.; Šarauskis, E.; Palšauskas, M.; Venslauskas, K. Energy Evaluation and Greenhouse Gas Emissions of Reed Plant Pelletizing and Utilization as Solid Biofuel. Energies 2020, 13, 1516. [Google Scholar] [CrossRef] [Green Version]

- Kang, S.B.; Oh, H.Y.; Kim, J.J.; Choi, K.S. Characteristics of Spent Coffee Ground as a Fuel and Combustion Test in a Small Boiler (6.5 KW). Renew. Energy 2017, 113, 1208–1214. [Google Scholar] [CrossRef]

- Jasinskas, A.; Minajeva, A.; Šarauskis, E.; Romaneckas, K.; Kimbirauskienė, R.; Pedišius, N. Recycling and Utilisation of Faba Bean Harvesting and Threshing Waste for Bioenergy. Renew. Energy 2020, 162, 257–266. [Google Scholar] [CrossRef]

- Szyszlak-Bargłowicz, J.; Zając, G.; Kuranc, A.; Słowik, T.; Dudziak, A.; Stoma, M.; Wasilewski, J. Chemical Properties of Selected Agri-Food Industry Waste Products in the Aspect of Their Use for Energetics Purposes. Przem. Chem. 2018, 97, 779–783. [Google Scholar] [CrossRef]

- Szyszlak-Bargłowicz, J.; Zając, G.; Stoma, M.; Kuranc, A.; Wasilewski, J. Renewable Energy Sources Used for Agricultural Purposes as Exemplified by a Rural Municipality. In Proceedings of the IX International Scientific Symposium Farm Machinery and Processes Management Sustainable Agriculture Symp. Proc. Ed. Edmund Lorencowicz Jacek Uziak Bruno Huyghebaert, Lublin, Poland, 22–24 November 2017; pp. 375–378. [Google Scholar]

- Ben Fradj, N.; Rozakis, S.; Borzęcka, M.; Matyka, M. Miscanthus in the European Bio-Economy: A Network Analysis. Ind. Crop. Prod. 2020, 148, 112281. [Google Scholar] [CrossRef]

- Lewandowski, I.; Clifton-Brown, J.C.; Scurlock, J.M.O.; Huisman, W. Miscanthus: European Experience with a Novel Energy Crop. Biomass Bioenergy 2000, 19, 209–227. [Google Scholar] [CrossRef]

- Lewandowski, I.; Clifton-Brown, J.; Kiesel, A.; Hastings, A.; Iqbal, Y. 2—Miscanthus. In Perennial Grasses for Bioenergy and Bioproducts; Alexopoulou, E., Ed.; Academic Press: Cambridge, MA, USA, 2018; pp. 35–59. ISBN 978-0-12-812900-5. [Google Scholar]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An Overview of the Chemical Composition of Biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Izquierdo, M.; Querol, X. Leaching Behaviour of Elements from Coal Combustion Fly Ash: An Overview. Int. J. Coal Geol. 2012, 94, 54–66. [Google Scholar] [CrossRef] [Green Version]

- Kowalczyk-Juśko, A. Chemical composition and energetic characteristics of Miscanthus sacchariflorus biomass as used for generation of energy. Przem. Chem. 2016, 95, 2326–2329. [Google Scholar] [CrossRef]

- Lanzerstorfer, C. Combustion of Miscanthus: Composition of the Ash by Particle Size. Energies 2019, 12, 178. [Google Scholar] [CrossRef] [Green Version]

- Ahn, B.J.; Chang, H.; Lee, S.M.; Choi, D.H.; Cho, S.T.; Han, G.; Yang, I. Effect of Binders on the Durability of Wood Pellets Fabricated from Larix Kaemferi C. and Liriodendron Tulipifera L. Sawdust. Renew. Energy 2014, 62, 18–23. [Google Scholar] [CrossRef]

- Moon, Y.-H.; Yang, J.; Koo, B.-C.; An, J.-W.; Cha, Y.-L.; Youn, Y.-M.; Yu, G.-D.; An, G.H.; Park, K.-G.; Choi, I.-H. Analysis of Factors Affecting Miscanthus Pellet Production and Pellet Quality Using Response Surface Methodology. BioResources 2014, 9, 3334–3346. [Google Scholar] [CrossRef] [Green Version]

- Mani, S.; Sokhansanj, S.; Bi, X.; Turhollow, A. Economics of Producing Fuel Pellets from Biomass. Appl. Eng. Agric. 2006, 22, 421–426. [Google Scholar] [CrossRef]

- Jamradloedluk, J.; Lertsatitthanakorn, C. Influences of Mixing Ratios and Binder Types on Properties of Biomass Pellets. Energy Procedia 2017, 138, 1147–1152. [Google Scholar] [CrossRef]

- Rajput, S.P.; Jadhav, S.V.; Thorat, B.N. Methods to Improve Properties of Fuel Pellets Obtained from Different Biomass Sources: Effect of Biomass Blends and Binders. Fuel Process. Technol. 2020, 199, 106255. [Google Scholar] [CrossRef]

- González, W.A.; López, D.; Pérez, J.F. Biofuel Quality Analysis of Fallen Leaf Pellets: Effect of Moisture and Glycerol Contents as Binders. Renew. Energy 2020, 147, 1139–1150. [Google Scholar] [CrossRef]

- Santana, D.A.R.; Scatolino, M.V.; Lima, M.D.R.; de Oliveira Barros Junior, U.; Garcia, D.P.; Andrade, C.R.; de Cássia Oliveira Carneiro, A.; Trugilho, P.F.; de Paula Protásio, T. Pelletizing of Lignocellulosic Wastes as an Environmentally Friendly Solution for the Energy Supply: Insights on the Properties of Pellets from Brazilian Biomasses. Environ. Sci. Pollut. Res. 2021, 28, 11598–11617. [Google Scholar] [CrossRef] [PubMed]

- Index Mundi. Index Mundi Country Reports. 2021. Available online: http://www.indexmundi.com (accessed on 30 June 2021).

- Sundu, B.; Kumar, A.; Dingle, J. Feeding Value of Copra Meal for Broilers. Worlds Poult. Sci. J. 2009, 65, 481–492. [Google Scholar] [CrossRef]

- Kraikaew, J.; Morakul, S.; Keawsompong, S. Nutritional Improvement of Copra Meal Using Mannanase and Saccharomyces Cerevisiae. 3 Biotech 2020, 10, 274. [Google Scholar] [CrossRef] [PubMed]

- Pampuro, N.; Bagagiolo, G.; Priarone, P.C.; Cavallo, E. Effects of Pelletizing Pressure and the Addition of Woody Bulking Agents on the Physical and Mechanical Properties of Pellets Made from Composted Pig Solid Fraction. Powder Technol. 2017, 311, 112–119. [Google Scholar] [CrossRef]

- Missagia, B.; Guerrero, C.; Narra, S.; Sun, Y.; Ay, P.; Krautz, H.J. Physicomechanical Properties of Rice Husk Pellets for Energy Generation. Energy Fuels 2011, 25, 5786–5790. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, S.; Wang, C.; Mu, C.; Huang, X. High-Strength Charcoal Briquette Preparation from Hydrothermal Pretreated Biomass Wastes. Fuel Process. Technol. 2018, 171, 293–300. [Google Scholar] [CrossRef]

- Parsons, A.S.; Buchanan, N.P.; Blemings, K.P.; Wilson, M.E.; Moritz, J.S. Effect of Corn Particle Size and Pellet Texture on Broiler Performance in the Growing Phase. J. Appl. Poult. Res. 2006, 15, 245–255. [Google Scholar] [CrossRef]

- Celma, A.R.; Cuadros, F.; López-Rodríguez, F. Characterization of Pellets from Industrial Tomato Residues. Food Bioprod. Process. 2012, 90, 700–706. [Google Scholar] [CrossRef]

- Obernberger, I.; Thek, G. Physical Characterisation and Chemical Composition of Densified Biomass Fuels with Regard to Their Combustion Behaviour. Biomass Bioenergy 2004, 27, 653–669. [Google Scholar] [CrossRef]

- Fasina, O.O. Physical Properties of Peanut Hull Pellets. Bioresour. Technol. 2008, 99, 1259–1266. [Google Scholar] [CrossRef] [PubMed]

- Karaosmanoglu, F. Biobriquetting of Rapeseed Cake. Energy Sources 2000, 22, 257–267. [Google Scholar] [CrossRef]

- Oktay, Z. Olive Cake as a Biomass Fuel for Energy Production. Energy Sources Part A 2006, 28, 329–339. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Kato, H.; Kanai, G.; Togashi, T. Producing Bio-Pellets from Sunflower Oil Cake for Use as an Energy Source; International Commission of Agricultural Engineering (CIGR), Institut fur: Landtechnik, Bonn, 2008. [Google Scholar]

- Ciunel, K.; Klugmann-Radziemska, E. Utilization of Rapeseed Pellet from Fatty Acid Methyl Esters Production as an Energy Source. Environ. Technol. 2014, 35, 195–202. [Google Scholar] [CrossRef]

- Behnke, K.C. Factors Influencing Pellet Quality. Feed Tech 2001, 5, 19–22. [Google Scholar]

- Temmerman, M.; Mignon, C.; Pieret, N. Influence of increasing shares of miscanthus on physical and mechanical properties of pellets produced in an industrial softwood pellets plant. In Proceedings of the V International Scientific Symposium Farm Machinery and Process Management in Sustainable Agriculture, Lublin, Poland, 23–24 November 2011; pp. 151–166. [Google Scholar]

- Carroll, J.P.; Finnan, J. Physical and Chemical Properties of Pellets from Energy Crops and Cereal Straws. Biosyst. Eng. 2012, 112, 151–159. [Google Scholar] [CrossRef]

- Fusi, A.; Bacenetti, J.; Proto, A.R.; Tedesco, D.E.; Pessina, D.; Facchinetti, D. Pellet Production from Miscanthus: Energy and Environmental Assessment. Energies 2021, 14, 73. [Google Scholar] [CrossRef]

- Zawiślak, K.; Sobczak, P.; Kraszkiewicz, A.; Niedziółka, I.; Parafiniuk, S.; Kuna-Broniowska, I.; Tanaś, W.; Żukiewicz-Sobczak, W.; Obidziński, S. The Use of Lignocellulosic Waste in the Production of Pellets for Energy Purposes. Renew. Energy 2020, 145, 997–1003. [Google Scholar] [CrossRef]

- Narra, S.; Tao, Y.; Glaser, C.; Gusovius, H.-J.; Ay, P. Increasing the Calorific Value of Rye Straw Pellets with Biogenous and Fossil Fuel Additives. Energy Fuels 2010, 24, 5228–5234. [Google Scholar] [CrossRef]

- Rhén, C.; Gref, R.; Sjöström, M.; Wästerlund, I. Effects of Raw Material Moisture Content, Densification Pressure and Temperature on Some Properties of Norway Spruce Pellets. Fuel Process. Technol. 2005, 87, 11–16. [Google Scholar] [CrossRef]

- Abdoli, M.A.; Golzary, A.; Hosseini, A.; Sadeghi, P. Wood Pellet Characteristics (Definition, Determination and Internal Relation). In Wood Pellet as a Renewable Source of Energy: From Production to Consumption; Abdoli, M.A., Golzary, A., Hosseini, A., Sadeghi, P., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 111–138. ISBN 978-3-319-74482-7. [Google Scholar]

- Garcia, D.P.; Caraschi, J.C.; Ventorim, G.; Vieira, F.H.A.; de Paula Protásio, T. Assessment of Plant Biomass for Pellet Production Using Multivariate Statistics (PCA and HCA). Renew. Energy 2019, 139, 796–805. [Google Scholar] [CrossRef]

- Miranda, M.; Sepúlveda, F.; Arranz, J.; Montero, I.; Rojas, C. Analysis of Pelletizing from Corn Cob Waste. J. Environ. Manag. 2018, 228, 303–311. [Google Scholar] [CrossRef] [PubMed]

| Parameter | M100C0 | M0C100 | M90C10 | M80C20 | M70C30 | M60C40 | M50C50 | M40C60 |

|---|---|---|---|---|---|---|---|---|

| Moisture [%] | 7.20 | 5.43 | 6.76 | 6.56 | 6.41 | 6.24 | 6.06 | 5.87 |

| ±0.05 h | ±0.02 a | ±0.03 g | ±0.03 f | ±0.02 e | ±0.03 d | ±0.06 c | ±0.02 b | |

| Volatile substances [%] | 73.61 | 75.62 | 74.93 | 74.92 | 74.56 | 75.07 | 74.18 | 75.23 |

| ±0.29 d | ±0.15 b | ±0.43 abc | ±0.27 abc | ±0.43 ac | ±0.18 ab | ±0.10 cd | ±0.42 ab | |

| Ash [%] | 2.36 | 5.46 | 2.70 | 2.78 | 3.09 | 3.11 | 3.72 | 3.80 |

| ±0.14 a | ±0.04 e | ±0.04 d | ±0.07 a | ±0.15 b | ±0.02 b | ±0.06 c | ±0.11 c | |

| Fixed carbon [%] | 16.40 | 13.49 | 15.94 | 15.82 | 15.94 | 15.58 | 16.03 | 15.10 |

| ±0.23 b | ±0.18 d | ±0.37 ab | ±0.17 abc | ±0.31 ab | ±0.18 ac | ±0.11 ab | ±0.49 c | |

| C [%] | 48.45 | 46.60 | 47.90 | 47.83 | 47.36 | 47.26 | 46.87 | 46.43 |

| ±0.11 e | ±0.07 a | ±0.07 d | ±0.02 cd | ±0.04 bc | ±0.01 b | ±0.04 ab | ±0.53 a | |

| H [%] | 6.09 | 7.02 | 6.33 | 6.42 | 6.54 | 6.64 | 6.68 | 6.78 |

| ±0.04 e | ±0.03 f | ±0.04 a | ±0.01 a | ±0.06 b | ±0.01 bc | ±0.05 cd | ±0.02 d | |

| N [%] | 0.240 | 3.155 | 0.371 | 0.492 | 0.554 | 0.718 | 0.949 | 1.325 |

| ±0.003 a | ±0.021 h | ±0.008 b | ±0.003 c | ±0.021 d | ±0.017 e | ±0.029 f | ±0.029 g | |

| S [%] | 0.004 | 0.1250 | 0.008 | 0.011 | 0.017 | 0.019 | 0.027 | 0.0450 |

| ±0.0001 b | ±0.002 g | ±0.001 c | ±0.0005 d | ±0.001 a | ±0.0005 a | ±0.0005 e | ±0.001 f | |

| HHV [kJ∙kg−1] | 17578 | 19606 | 17801 | 17853 | 17924 | 18023 | 18046 | 18221 |

| ±20.0 c | ±50.6 d | ±50.5 a | ±78.8 a | ±28.6 ab | ±9.5 b | ±49.9 b | ±40.0 c | |

| LHV [kJ∙kg−1] | 16307 | 18384 | 16542 | 16588 | 16661 | 16762 | 16789 | 16967 |

| ±20.0 c | ±50.6 d | ±50.0 a | ±78.8 a | ±28.6 ab | ±9.8 b | ±49.9 b | ±40.0 c |

| Parameter | M100C0 | M0C100 | M90C10 | M70C30 | M50C50 |

|---|---|---|---|---|---|

| Durability [%] | 91.4 | 87.2 | 97.2 | 95.1 | 89.1 |

| ±1.0 b | ±0.0 a | ±0.6 d | ±0.0 c | ±0.6 ab | |

| Bulk density [kg∙m−3] | 567.3 | 255.1 | 514.9 | 417.4 | 298.9 |

| ±6.7 e | ±0.5 a | ±3.4 d | ±3.2 c | ±0.5 b | |

| Pellet density [kg∙m−3] | 1375 | 1161 | 1334 | 1201 | 1184 |

| ±10.7 e | ±4.4 a | ±2.5 d | ±4.0 c | ±3.8 b | |

| Energy consumption [Wh∙kg−1] | 114.33 | 24.11 | 84.45 | 63.42 | 39.09 |

| ±1.53 e | ±0.42 a | ±1.20 d | ±0.81 c | ±1.01 b |

| Parameter | M100C0 | M0C100 | M90C10 | M70C30 | M50C50 |

|---|---|---|---|---|---|

| Axial compression, AC [MPa] | 3.025 | 0.330 | 1.976 | 1.602 | 0.985 |

| ±0.260 a | ±0.047 e | ±0.182 b | ±0.025 c | ±0.170 d | |

| Three-point compression, 3PC [MPa] | 0.094 | 0.009 | 0.056 | 0.049 | 0.021 |

| ±0.004 a | ±0.003 c | ±0.009 b | ±0.013 b | ±0.006 c | |

| Point compression, PC [MPa] | 0.704 | 0.152 | 0.412 | 0.449 | 0.477 |

| ±0.136 a | ±0.020 c | ±0.006 b | ±0.077 b | ±0.026 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szyszlak-Bargłowicz, J.; Słowik, T.; Zając, G.; Blicharz-Kania, A.; Zdybel, B.; Andrejko, D.; Obidziński, S. Energy Parameters of Miscanthus Biomass Pellets Supplemented with Copra Meal in Terms of Energy Consumption during the Pressure Agglomeration Process. Energies 2021, 14, 4167. https://doi.org/10.3390/en14144167

Szyszlak-Bargłowicz J, Słowik T, Zając G, Blicharz-Kania A, Zdybel B, Andrejko D, Obidziński S. Energy Parameters of Miscanthus Biomass Pellets Supplemented with Copra Meal in Terms of Energy Consumption during the Pressure Agglomeration Process. Energies. 2021; 14(14):4167. https://doi.org/10.3390/en14144167

Chicago/Turabian StyleSzyszlak-Bargłowicz, Joanna, Tomasz Słowik, Grzegorz Zając, Agata Blicharz-Kania, Beata Zdybel, Dariusz Andrejko, and Sławomir Obidziński. 2021. "Energy Parameters of Miscanthus Biomass Pellets Supplemented with Copra Meal in Terms of Energy Consumption during the Pressure Agglomeration Process" Energies 14, no. 14: 4167. https://doi.org/10.3390/en14144167

APA StyleSzyszlak-Bargłowicz, J., Słowik, T., Zając, G., Blicharz-Kania, A., Zdybel, B., Andrejko, D., & Obidziński, S. (2021). Energy Parameters of Miscanthus Biomass Pellets Supplemented with Copra Meal in Terms of Energy Consumption during the Pressure Agglomeration Process. Energies, 14(14), 4167. https://doi.org/10.3390/en14144167