1. Introduction

Microgrids (MGs) are well-known for “taking advantage” of local renewable energy sources (RES) in order to provide energy to communities and, thus, ensuring sustainable development [

1,

2]. Therefore, the microgrid industry is expected to grow in future years [

3].

Alternatively, productive use of energy (PUE), primarily in rural settlements, has received much attention in recent years due to its potential to contribute to the economic growth and social progress of communities [

4]. Consequently, the benefits of MGs combined with the PUE have stimulated the deployment of several small productive processes (SPPs), which can be embedded in MGs (see

Figure 1) and offer different economic benefits to communities.

According to the Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ), the PUE is defined as “agricultural, commercial, and industrial activities involving electricity services as a direct input to the production of goods or provision of services” [

5]. In this context, SPPs consist of integrating technological solutions in traditional and small-scale productive activities to add value to their goods and services. These SPPs may include small-scale industrial and household loads, distributed energy resources (DERs), e.g., photovoltaic panels (PV), and in some cases, a storage unit (see

Figure 1).

Generally speaking, SPPs may include an array or a mix of different electric devices (e.g., cooling and heating devices, motors, drills, conveyor belts, chainsaws, dryers, etc.) [

6]. These as a whole transform the inputs into goods or services providing economic benefits to communities by adding value to their traditional productive activities.

Due to the benefits of the SPPs mentioned above, several successful initiatives have been implemented worldwide, especially in rural communities. Some small processes are, for example, milling processes of maize (corn) to produce flour to sell in the local community and water treatment systems for bottled water [

4]. Moreover, more general productive processes have been implemented, such as heating and cooling systems, grain mills, crop farming, food processing, milking systems, and incubators for poultry farming, among others [

7]. More examples regarding the implementation of SPPs in several countries can be found in [

8].

In Chile, through the Ayllu Solar initiative, some SPPs have been implemented to foster the sustainable development of the rural communities in the Arica and Parinacota region located in northern Chile [

9]. The Ayllu Solar project consists of four main representative projects that make intensive use of solar energy, such as an alpaca fiber processing center [

10], farming of river shrimp, a center for processing agricultural products, and the upgrading of tourism in pre-Hispanic routes through PV technology [

9].

On the other hand, MGs are small distribution systems, which consist of local generation systems (e.g., PV, wind turbines, fuel cells, etc.), energy storage systems (e.g., batteries, flywheels, etc.), loads, either conventional or flexible [

11], and more recently, the SPPs [

9].

For adequate and efficient operation of MGs, different approaches of energy management systems (EMSs) are used [

12]. Roughly speaking, an EMS is in charge of matching the generation and demand by determining:

The amount of energy provided by programmable local generators (such as diesel generators).

The amount of energy provided to/taken from the grid by the energy storage systems (ESSs).

The amount of flexible demand that must be fed.

These decisions are made based on both the expected electric energy demand (flexible plus conventional/non-flexible) and the available power from local DERs based on variable generation technologies, such as solar [

12]. On the other hand, due to the small size of MGs, the load variability rises, and the aggregation or smoothing effect is considerably reduced in contrast to that of large power systems [

11]. Moreover, considerable voltage variations in MGs may occur more frequently in isolated ones. These variations will influence the EMS operation strategies.

SPPs have a particular “behavior” involving the interaction between several types of loads (not only conventional ones, but also complex ones). Thus, the uncertainty increases, which can directly impact the reliable, secure, and economic operation of such MGs.

As stated above, load modeling and, consequently, expected load consumption play a key role in the operation of MGs. Since, based on its characterization, the expected electric energy demand is estimated and, therefore, the decisions of the EMS are made [

13,

14,

15].

However, the pattern of use of the SPP loads and the timing at which they are employed change from one process to another based on complex dynamics and weather conditions. Moreover, SPPs generally include loads that are sensitive to voltage variations [

16]. These voltage variations under normal MG operating conditions (i.e., 1 p.u. ± 5%) [

17,

18] may increase/decrease the load consumption of the SPPs. For example, a 5% reduction in operating voltage will decrease the power demand in residential loads by around 7.6% [

19]. Thus, this can influence the proper operation and energy management in the MG.

To summarize, the diverse nature of the SPP loads combined with weather-sensible features, make the modeling of such loads a difficult task and a big challenge. Therefore, representing such SPP complex load interactions through a load model, estimating the parameters of such load model, and considering the voltage influence, is still an open research question [

16].

One way to represent arrays of loads, with an aggregated approach, is by using the information available at the measurement points. For this purpose, the specialized literature presents different modeling approaches, such as those based on artificial intelligence (AI), e.g., fuzzy models [

20] and artificial neural networks (ANN) [

21], those based on statistical models, e.g., auto-regressive moving average models (ARMA) [

22], and those based on gray box models and black box models [

23]. However, such approaches do not directly consider changes in load consumption due to voltage variations, which may affect the MG operation.

Two of the most used models that address this drawback are the ZIP load model [

24] and the exponential model [

25]. The former has the advantage of representing the entire load behavior through all three load characteristics. In fact, the abbreviation “ZIP” refers to the representation of a load by its constant impedance “Z”, constant current “I”, and constant power “P” characteristics. However, complex loads have a wide nature and complicated behavior. Thus, to represent such complex behavior, some studies have proposed multi-stage or multi-step load models [

26,

27,

28,

29]. These models may combine several models at the same time, such as dynamic models, exponential models, ZIP models, etc.

The authors’ first attempt at looking for modeling the SPPs, in the context of MGs, was in the work presented in [

30], where the time-variant ZIP load model was used. Nonetheless, the works described above either assume certain known parameters or have only focused on load modeling in specific contexts, and have not considered an integrated approach contemplating MG operation and voltage influence.

To the best of our knowledge, no previous studies have provided a comprehensive methodology to represent the behavior of SPPs in the context of EMS for MG operation. Therefore, to fill this research gap, this paper proposes a methodology for modeling the SPPs for MG operation through an extended multi-zone ZIP model, which is able to:

Consider the influence and behavior of voltage on load consumption for a new type of complex load called SPPs, which will play a key role in the development of MGs.

Both represent unnoticeable devices and can manage transitions between zones. This is because the extended multi-zone ZIP model considers a flexible component.

Identify the contributions of each load category against total load consumption considering the different time zones of the analysis window. This has to do with the structure of the extended multi-zone ZIP model.

More concretely, the proposed methodology ensures that SPP models have general validity and can efficiently integrate into a range of EMS approaches. Nevertheless, thorough detail of EMS operation is not part of the scope of this study. Finally, to assess the proposed methodology and its contribution, an application using actual data gathered from productive processes installed in Chile was developed.

The remainder of the paper is organized as follows:

Section 2 presents the proposed methodology for modeling of the SPSs for the operation of MG;

Section 3 describes the case study;

Section 4 presents the results and the discussion; and

Section 5 presents the conclusions and future work.

2. Proposed Methodology

As previously mentioned, the SPPs may include complex loads that are sensitive to voltage variations. Hence, the proposed methodology considers such voltage influence to develop the SPP load model.

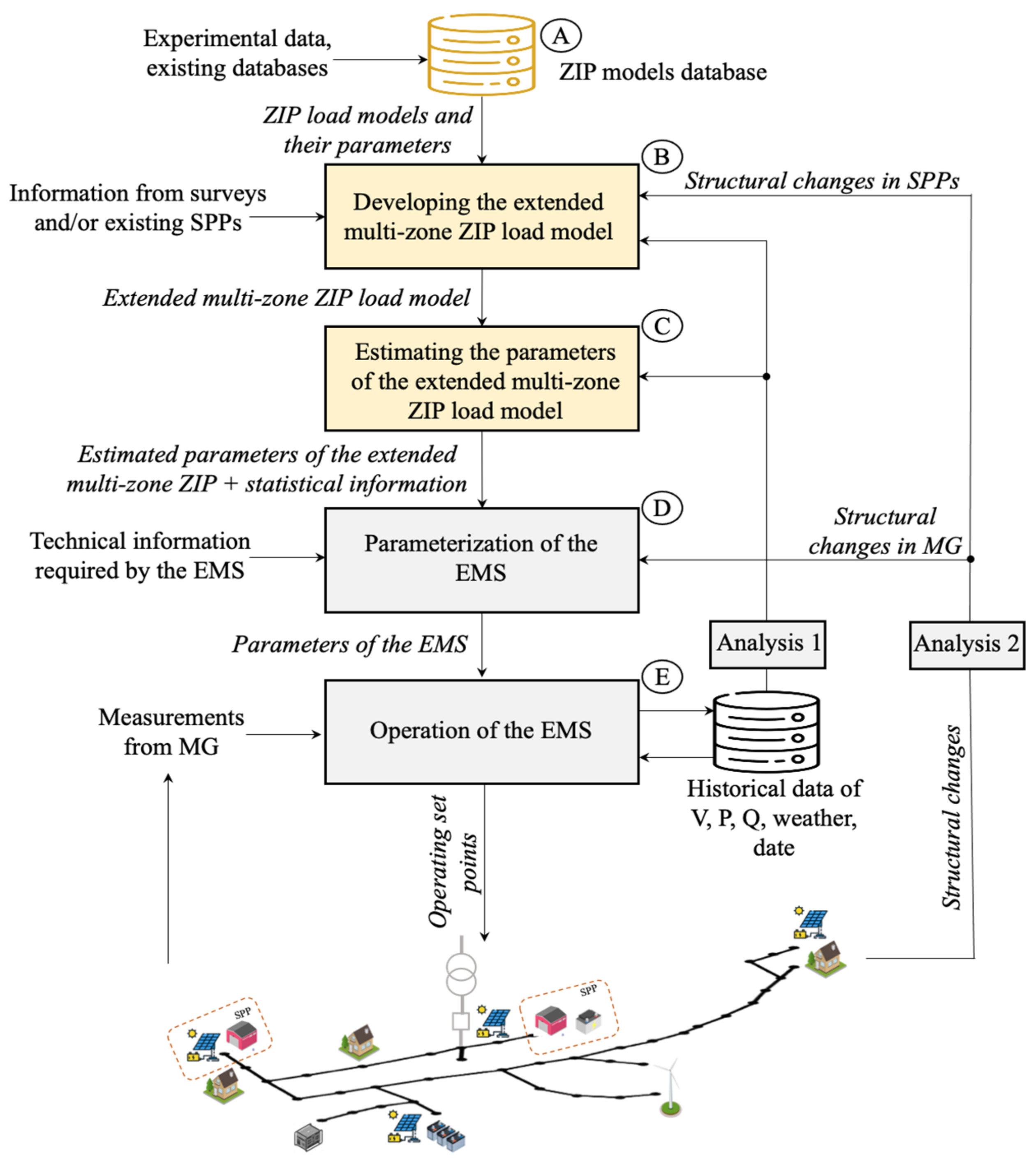

The proposed methodology for modeling the SPPs consists of five main stages with their respective inputs and outputs, as can be seen in

Figure 2. In stage A, a database is developed. This database contains the ZIP load models and their parameters for specific devices that an SPP may include. Such ZIP parameters can be obtained from either experimental data or existing databases.

In stage B, an extended ZIP load model is developed. For this purpose, the information gathered through surveys and/or from existing SPPs is considered. This is feasible and convenient, considering the engagement of customers promoted by an MG owner. Then, through the collected information, it is feasible to know the structure of the SPPs and the specific time in which the devices are used (i.e., patterns of energy consumption). Then, the extended ZIP load model combines a generic flexible ZIP, and ZIP load models for specific devices stored in the database created previously. Furthermore, using the patterns of energy consumption, a zone division procedure is performed. Then, an extended ZIP load model is developed for each zone. Consequently, the extended multi-zone ZIP load model can be established.

In stage C, the parameters of the extended multi-zone ZIP load model are estimated. This procedure is performed through an optimization problem and the use of the historical data of power and voltage. In this stage, the estimated parameters of the extended multi-zone ZIP load model and statistical information of residuals are provided. For SPPs in the design phase, it is feasible to use measurements from similar existing SPPs or results from system simulations.

Stage D refers to the parameterization of the EMS. For this purpose, the estimated parameters of the extended multi-zone ZIP load model with the parameters of other loads and DERs are integrated into the system operation modeling of the EMS. Therefore, both, time and spatial correlations are integrated in the overall load forecasting. Moreover, due to the voltage sensitivity of the developed models, an AC approach is recommended. For example, an AC multi-period optimal power flow (OPF) will be able to define the operating conditions for the scheduling horizon of the EMS.

Furthermore, the statistical information (i.e., residuals distribution) produced in stage C, can be used to define the input parameters for stochastic or robust EMS approaches. More concretely, if an abnormal operation occurs, this phenomenon should be captured as part of the stochastic description of the loads (time correlations). Thus, this information should be used by the EMS to assign the necessary reserves to the system. For example, a load surge scenario resulting from simultaneous powering on of a large number of SPPs can be captured through the calculation of a dynamic system reserve margin considered in the MG operation procedure of the EMS.

Additional technical information about MG elements is also integrated at this stage. For example, cost information for generation/storage units, supplementary technical constraints (e.g., maximum and minimum limits, ramps, efficiencies, etc.), and parameters of other individual loads in the MG.

Finally, once the EMS is parameterized, it is capable of performing MG operation (stage E). To achieve this, the EMS gathers measurements of power, voltage, among others, from MG, in addition to historical data regarding power, voltage, weather, and time. After that, the EMS runs its optimizing routines and sends the operating set points to generation/storage units and other devices. This procedure is carried out in a predefined period (e.g., 5 min, 15 min) until a predetermined condition, such as those described below, is detected.

At the

all stages (A–E) are performed following the sequence in

Figure 2. However, if considerable changes are detected in analysis blocks 1 or 2 at the time

, certain stages are conducted again. For example, analysis block 1 evaluates statistical information from historical data. Therefore, if a significant variation in the errors in either the zone transitions or in the zone length is detected, it is necessary to execute stage B and, consequently, the other stages are executed too. For example, if the analysis window is in hours, it is evaluated whether it is improved by extending or reducing the current zone duration. Besides, if new historical power and voltage data exist, then it is necessary to re-estimate the parameters of the extended multi-zone ZIP model by running stage C. Alternatively, analysis block 2 analyzes the structural changes in either the MG or SPPs or both. For example, if new devices are installed in the SPPs, it will be necessary to run from stage A again. Thus, the extended multi-zone ZIP model will include the ZIP models of the newly added devices. Moreover, if analysis block 2 detects structural changes in the MG (e.g., changes in the topology, adding or removing generation units or loads different from those of the SPPs), then it is necessary to execute stage D to re-parameterize the EMS, and include such structural changes.

Finally, the proposed methodology for modeling the SPPs involves the aforementioned five stages. This strategy is compatible with different EMS architectures and approaches. Nevertheless, stages D and E are highly dependent on the specific EMS architecture. Based on the scope defined for this work, stages A, B, and C are thoroughly described in the next sections. Consequently, a comprehensive description of the potential integration of this proposal for different EMS solutions is offered.

2.1. Development of a Database with ZIP Load Models of Specific Devices

As mentioned in the previous section, the ZIP load model is one of the various appealing alternatives for load modeling. The mathematical expressions of the ZIP load models for the active and reactive power at any discrete time step

(

are expressed as follows:

where

and

are the total active and reactive power consumed by the load at any time step

, respectively;

is the current voltage at time step

;

and

are the active and reactive power at nominal voltage

;

,

,

, and

,

,

are the ZIP coefficients for the active and reactive power, respectively, and they define the contribution of each feature of the load and must satisfy (3) and (4).

As mentioned earlier, based on information gathered through surveys or information about existing SPPs, it is feasible to know the structure of such SPPs in terms of the type and number of specific devices that they comprise, such as a “fingerprint” of each SPP. Thus, it is possible to acquire the ZIP parameters (i.e.,

,

,

,

,

,

,

) for each potential device used by the SPPs from either experimental data or existing load model databases, for example, from [

25,

31]. This database will be the main source of information for the next stages.

To illustrate the use of the database, let us assume that an SPP consists of the following devices: (i) a conveyor belt; (ii) an electrical heater; and (iii) two water pumps. Then, the ZIP parameters for each device are acquired and stored in the database. Hence, the parameters

,

,

,

,

,

(

i ∈ {heater, belt, two pumps}) are available for the next stages. Note that, to define the parameters

and

it is necessary to know the number

(

of devices of each type. Consequently, the parameters

and

for each type of device are defined as (5) and (6).

Moreover, this example considers two pumps, thus,

Besides, for the heater and the belt

, hence,

2.2. Development of the Multi-Zone ZIP Load Model

2.2.1. Extending the ZIP Load Model

Although the ZIP model captures the variations of load based on voltage profile, uncertainties of load behavior in the SPPs could remain. In fact, some devices from the survey/cadaster could be missed or the assigned device from the database could mismatch the load behavior for specific devices. Thus, the first extension of the ZIP model based on the incorporation of a generic extra ZIP component is proposed. More concretely, a time-variant ZIP load model is used to account for these changes [

32]. The time-variant ZIP component for the active power is thus mathematically expressed as (12). Moreover, for notation simplicity, (11) is established in the remainder of this paper, hence,

where

represents the active power at time step

,

stands for the nominal active power at nominal voltage

,

is the current voltage at time step

,

,

,

are the time-dependent parameters, which represent the load features of constant impedance, constant current, and constant power, respectively. Moreover, as in the conventional ZIP load model case, the coefficients must fulfill (13) for every time step

. As for reactive power, the mathematical expression is similar to (12), with the difference that it has to consider the ZIP coefficients for reactive power.

On the other hand, electric consumption may change depending on customer behavior, weather, and time of the year. Consequently, by using the information obtained via the surveys, it is also feasible to establish various periods (zones) in which a set of devices is active. Thus, an extra extension to the model that considers the active devices for different time zones is proposed. The zoning procedure is further described in the next section.

Accordingly, the complete extended ZIP load model combines both the time-variant ZIP load model and the ZIP parameters of the set of active devices for each time zone. Let

denote the contribution of each load category, to the total load consumption. Then, the extended ZIP load model is expressed in (14)–(17).

where,

represents the value of nominal active power at nominal voltage

,

represents the flexible component of the extended ZIP load model for which it is necessary to identify all its parameters (i.e.,

) and its contribution

to total load. On the other hand,

represents each device of the SPP, of which their ZIP coefficients (

,

,

) are already known (see

Section 2.1). Thus, solely the identification of its contribution

is needed. Equation (15) reflects the contribution of each device of the SPP through the values of

. Finally, the term

(

represents the number of devices that belong to an SPP.

Conversely, without any measurement or additional information from the SPP, the initial estimation of the parameters is as described in (18)–(20).

As measurements are acquired, the set of parameters, including is estimated for each time interval k. For example, if the time step k corresponds to 10 min, and the measurements are acquired every 10 s, 60 data sets are available for each time step.

2.2.2. Zoning the Extended ZIP Load Model

Based on the information gathered from surveys, the time in which the different devices considered in (14) are active can be known in advance (see

Section 2). Thus, a zone division of the analysis window (e.g., 24 h) can be done so that at every zone of the analysis window, just a set of devices is considered. This is useful for both significantly decreasing the complexity of the parameter identification process (because solely a set of parameters are identified instead of estimating all of them), and for properly representing the sensitivity of SPP loads to voltage.

For illustrative purposes, let us consider the active power shown in

Figure 3, which was measured at each time step

(every hour). These active power data were collected from a specific location where it is known that (i) lights are active from 5:00 p.m. until 7:00 a.m. of the following day; (ii) industrial activities work from 8:00 a.m. to 5:00 p.m.; and (iii) a water pump and non-identified loads can be active at any time of the day. Hence, based on these patterns of energy use, three zones can be established: zone I (12:00 a.m.–7:59 a.m.), zone II (8:00 a.m.–5:00 p.m.), and zone III (5:01 p.m.–11:59 p.m.).

Table 1 puts forward the established zones based on the electric demand profile (see

Figure 3) and the knowledge regarding the use of energy in the SPP as described above.

It is worth noting that the flexible component of the EMZ-ZIP (i.e., ) plays a key role during transitions between time zones. This is because the flexible component is able to represent a combination of devices unnoticeable in the transition. Moreover, the flexible component can be updated at each time step k using the measurements.

Consequently, as the EMZ-ZIP is considerably flexible for both handling the zone transitions and representing unnoticeable devices, the zoning procedure is based on a practical zoning definition, primarily using the information regarding the patterns of energy use collected through surveys. Moreover, the length of the zones can be adjusted according to the procedure described in the analysis block 1 of the proposed methodology (see

Section 2).

Finally, based on (14)–(17), and once the zones

(

) have been established, the general mathematical expression for the extended multi-zone ZIP load model (EMZ-ZIP) is expressed as follows:

where the terms are similar to those of expression (14), with the difference of the term

that stands for the number of active devices in each time zone

j.

Similarly, the same procedures described for both extending the ZIP model and developing the EMZ-ZIP can be applied for representing the reactive power of the SPPs.

On the other hand, as previously explained, the initial zoning procedure is primarily based on the knowledge regarding the patterns of energy consumption of the SPP (surveys and secondary information). However, the zoning procedure could be improved by considering the measurements of the system after the commissioning period of the SPPs. For this purpose, suitable signals can be the total active power, voltage profile [

26], and reactive power. Moreover, for the automated definition of time zones, cluster analysis [

33], Markov Chain [

34], or artificial neural network techniques [

35] can be applied. Nevertheless, the automated definition of the zones is beyond the scope of this manuscript.

2.3. Estimation of Parameters of the EMZ-ZIP Load Model

The parameter identification procedure is performed by using actual measurements and an optimization problem. Let

be the estimated active power at time step

for zone

, and

denote the data set of measurements for each time step

k. Then, the set of parameters to be identified is determined by solving the minimization problem in (22).

Subject to:

where,

and

.

However, the parameter

in (22) is non-identifiable [

36]. Hence, the splitting of the minimization problem (22) into three stages is proposed.

Then, the ZIP model to estimate the active power becomes:

Replacing the expression (24) in (22), the minimization problem becomes:

The minimization problem (25) corresponds to the first stage of the splitting procedure. Since

is unknown, the big-M is used to limit the value of

. It is worth mentioning that the big-M must be selected, large enough, but not too high to prevent the

M value influencing the results of the optimization problem [

37]. For instance, in this case, the values of all variables are in p.u., thus, an

M value of 10 is adequate.

Once the variables

and

are found, the original parameters

and

are determined, considering

as fixed values. Thus, such parameters are obtained in the second stage by solving the minimization problem in (22) adding the constraints (28).

Because

is an unbounded (non-identifiable) variable, a correction on its estimation is needed. For this purpose, the values already obtained for

and

are taken as constants (i.e., resulting solutions of (22) for

and of (25) for

. Thus,

is obtained in the third stage by solving the minimization problem in (29).

Note that the minimization problems (22), (25), (29) and the resulting problem from adding the constraint

are all convex and, thus, they have a global optimum, which can be numerically found in a finite number of steps [

38]. In this work, the strictly convex programming tool CVX [

38] was used to compute their solutions. However, any other convex programming tool can be used instead.

Finally, it is worth mentioning that each measurement can be assigned to a specific time step

k in zone

j for a typical day. Thus, all measurements are stored in an updated database (see

Section 2). Consequently, the set of parameters in (21) can be updated from time-to-time using the parameter estimation procedure described in this section for both active and reactive power.

5. Conclusions

This paper proposed a methodology for modeling SPPs for the operation of a MG. For this purpose, a novel extended multi-zone ZIP approach was used to model the SPP loads and consider their sensitivity to voltage changes. The results showed the usefulness of the proposed methodology—it can represent the load behavior complexities of the SPPs while considering their sensitivity to voltage changes. Moreover, the EMZ-ZIP considers a flexible component that can both represent unnoticeable devices and handle the transitions between zones.

Further, the proposed approach was able to identify the contributions of each load category to total load consumption, considering the different time zones of the analysis window. The case study and performance analysis exhibited the benefits gained from extending and zoning the ZIP load model to represent the load behavior of the SPPs for the operation of a MG. Moreover, the proposed scheme can be efficiently integrated into several EMS approaches for MGs that may include SPPs, following the general framework described in this paper.

For a more general validation of the proposal, future work should consider additional types of SPP devices. Furthermore, SPPs will include DG to operate autonomously. Further research will consider DG injections to SPPs. Future work should also focus on the development of a load disaggregation strategy. Consequently, tariff incentives can be developed inside the MG structure. On the other hand, other potential research, for example, should consider more power outage scenarios, and develop a more robust approach to consider these sudden events.

Finally, we consider that, in the future, the requirements for modeling SPPs in MGs will grow considerably in the context of the pandemic scenario we are living in. This is due to the need for resilient decentralized systems that are also capable of being self-sufficient (i.e., water, food, and energy). Consequently, improved modeling of these types of loads will allow EMS to operate a MG in a cost-effective way.