Application of Dynamic Fault Tree Analysis to Prioritize Electric Power Systems in Nuclear Power Plants

Abstract

:1. Introduction

2. Methodology Development

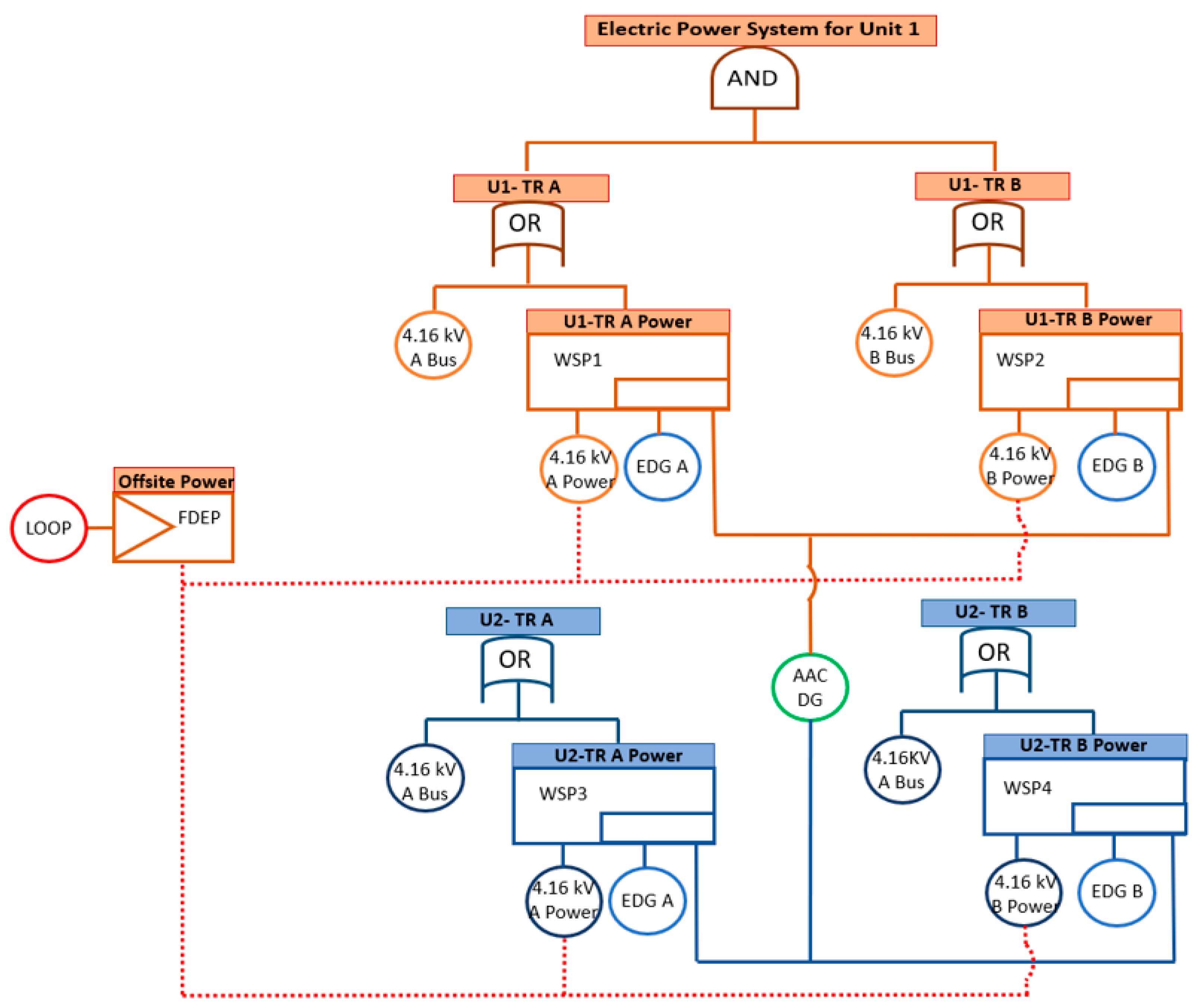

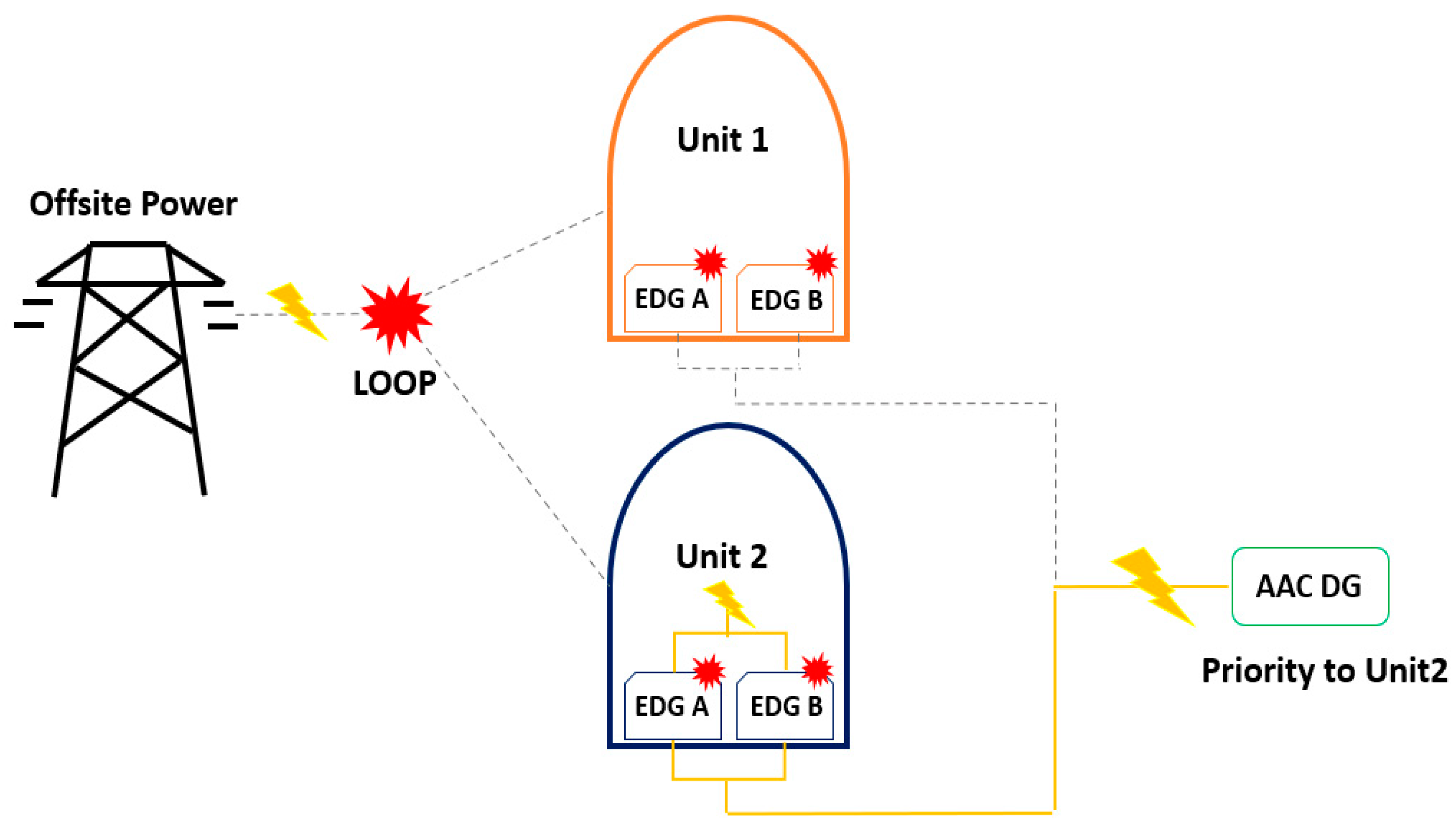

2.1. EPS Structure

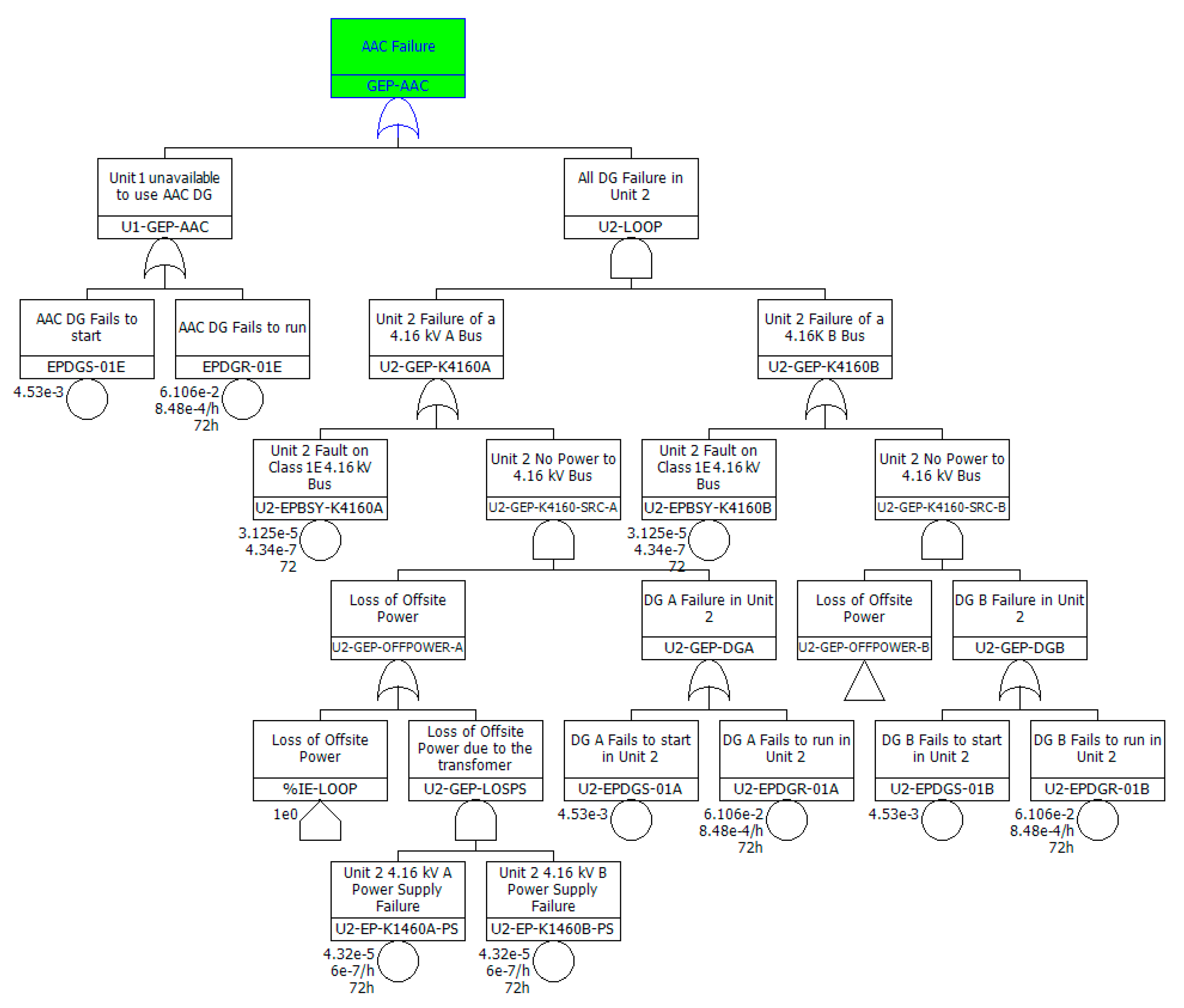

2.2. Static Fault Tree Analysis

- It is assumed that 4.16 kV is the offsite power.

- Failure to run to the supply power, and failure of the bus are considered for each 4.16 kV A/B bus.

- Batteries and lower voltage buses are not considered.

- A LOOP accident is taken as the initiating event with the probability one.

- Standby failure, failure to start, and failure to run are considered for EDG A/B and the AAC DG.

- Only part of the EPS in Unit 2 is considered.

- Unavailable to use AAC DG in Unit 1 is considered to accommodate a failure of EDG A/B in Unit 2 (only for SFT).

2.3. Dynamic Fault Tree Analysis

2.3.1. Characteristics of a Dynamic Fault Tree

2.3.2. Dynamic Gates

2.3.3. Development of Dynamic Gate for a Specific Shared Facility

2.3.4. Construction of the Dynamic Fault Tree

3. Results and Discussion

3.1. Static Fault Tree Evaluation

3.2. Dynamic Fault Tree Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AAC DG | Alternate AC Diesel Generator |

| DFT | Dynamic Fault Tree |

| EPS | Electric Power System |

| EDG | Emergency Diesel Generator |

| FDEP gate | Functional dependency gate |

| LOOP | Loss Of Offsite Power |

| NPP | Nuclear Power Plant |

| PSA | Probabilistic Safety Assessment |

| PAND gate | Priority AND gate |

| SFT | Static Fault Tree |

| SBO | Station Blackout |

| SLD | Single Line Diagram |

| SPARE gate | Standby or Spare gate |

| SEQ gate | Sequence Enforcing gate |

| WSP gate | Warm Standby or Spare gate |

References

- Zhou, T.; Modarres, M.; Droguett, E.L. Multi-unit nuclear power plant probabilistic risk assessment: A comprehensive survey. Reliab. Eng. Syst. Saf. 2021, 213, 107782. [Google Scholar] [CrossRef]

- Dugan, J.; Bavuso, S.; Boyd, M. Dynamic fault-tree models for fault-tolerant computer systems. IEEE Trans. Reliab. 1992, 41, 363–377. [Google Scholar] [CrossRef] [Green Version]

- Čepin, M.; Mavko, B. A dynamic fault tree. Reliab. Eng. Syst. Saf. 2002, 75, 83–91. [Google Scholar] [CrossRef]

- Lei, X. Static and Dynamic Fault Tree Analysis with Application to Hybrid Vehicle Systems and Supply Chains. Master’s Thesis, Iowa State University, Ames, IA, USA, 2017. [Google Scholar]

- Xing, L.; Fleming, K.N.; Loh, W.T. Comparison of markov model and fault tree approach in determining initiating event frequency for systems with two train configurations. Reliab. Eng. Syst. Saf. 1996, 53, 17–29. [Google Scholar] [CrossRef]

- Neuman, C.; Bonhomme, N. Evaluation of maintenance policies using markov chains and fault tree analysis. IEEE Trans. Reliab. 1975, 24, 37–44. [Google Scholar] [CrossRef]

- Gulati, R.; Dugan, J.B. A modular approach for analyzing static and dynamic fault trees. In Proceedings of the Annual Reliability and Maintainability Symposium, Philadelphia, PA, USA, 13–16 January 1997; pp. 57–63. [Google Scholar]

- Sullivan, K.; Dugan, J.; Coppit, D. The Galileo fault tree analysis tool. In Proceedings of the Twenty-Ninth Annual International Symposium on Fault-Tolerant Computing (Cat. No. 99CB36352), Madison, WI, USA, 15–18 June 1999; pp. 232–235. [Google Scholar]

- Rao, K.D.; Gopika, V.; Rao, V.S.; Kushwaha, H.; Verma, A.; Srividya, A. Dynamic fault tree analysis using Monte Carlo simulation in probabilistic safety assessment. Reliab. Eng. Syst. Saf. 2009, 94, 872–883. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Chang, Y.-R. An improved decomposition scheme for assessing the reliability of embedded systems by using dynamic fault trees. Reliab. Eng. Syst. Saf. 2007, 92, 1403–1412. [Google Scholar] [CrossRef]

- Amari, S.; Dill, G.; Howald, E. A new approach to solve dynamic fault trees. In Proceedings of the Annual Reliability and Maintainability Symposium 2003, Tampa, FL, USA, 27–30 January 2003; pp. 374–379. [Google Scholar]

- Dugan, J.; Venkataraman, B.; Gulati, R. DIFtree: A software package for the analysis of dynamic fault tree models. In Proceedings of the Annual Reliability and Maintainability Symposium, Philadelphia, PA, USA, 13–16 January 1997; pp. 64–70. [Google Scholar]

- Dugan, J.B.; Sullivan, K.J.; Coppit, D. Developing a low-cost high-quality software tool for dynamic fault-tree analysis. IEEE Trans. Reliab. 2000, 49, 49–59. [Google Scholar] [CrossRef]

- Manno, G.; Chiacchio, F.; Compagno, L.; D’Urso, D.; Trapani, N. MatCarloRe: An integrated FT and Monte Carlo simulink tool for the reliability assessment of dynamic fault tree. Expert Syst. Appl. 2012, 39, 10334–10342. [Google Scholar] [CrossRef]

- Bobbio, A.; Portinale, L.; Minichino, M.; Ciancamerla, E. Improving the analysis of dependable systems by mapping fault trees into Bayesian networks. Reliab. Eng. Syst. Saf. 2001, 71, 249–260. [Google Scholar] [CrossRef]

- Siuta, D.; Markowski, A.S.; Mannan, M.S. Uncertainty techniques in liquefied natural gas (LNG) dispersion calculations. J. Loss Prev. Process. Ind. 2013, 26, 418–426. [Google Scholar] [CrossRef]

- Jiang, G.; Yuan, H.; Li, P.; Li, P. A new approach to fuzzy dynamic fault tree analysis using the weakest n-dimensional t-norm arithmetic. Chin. J. Aeronaut. 2018, 31, 1506–1514. [Google Scholar] [CrossRef]

- Jung, W.S.; Yang, J.-E.; Ha, J. A new method to evaluate alternate AC power source effects in multi-unit nuclear power plants. Reliab. Eng. Syst. Saf. 2003, 82, 165–172. [Google Scholar] [CrossRef]

- Kim, D.S.; Park, J.H.; Lim, H.G. Considering dual-unit loss of offsite power initiating event in a single-unit Level 1 PSA. In Proceedings of the 13th International Conference on Probabilistic Safety Assessment and Management (PSAM 13), Seoul, Korea, 2–7 October 2016. [Google Scholar]

- Kim, D.-S.; Han, S.H.; Park, J.H.; Lim, H.-G.; Kim, J.H. Multi-unit Level 1 probabilistic safety assessment: Approaches and their application to a six-unit nuclear power plant site. Nucl. Eng. Technol. 2018, 50, 1217–1233. [Google Scholar] [CrossRef]

- Kim, M.C. Feasibility of shared use of alternative AC diesel generator under dual-unit station blackout. J. Nucl. Sci. Technol. 2017, 54, 1029–1035. [Google Scholar] [CrossRef]

- Han, S.H.; Lim, H.G. Fault tree modeling of AAC power source in multi-unit nuclear power plants PSA. In Proceedings of the Transactions of Korea Nuclear Society Autumn Meeting, Gyeongju, Korea, 29–30 October 2015. [Google Scholar]

- Han, S.H.; Oh, K.; Lim, H.-G.; Yang, J.-E. Aims-Mupsa software package for multi-unit PSA. Nucl. Eng. Technol. 2018, 50, 1255–1265. [Google Scholar] [CrossRef]

- Kim, D.S.; Park, J.H.; Lim, H.G. The contribution to site core damage frequency from independent occurrences of initiators in two or more units: How low is it? In Proceedings of the Transactions of the Korean Nuclear Society Autumn Meeting, Gyeongju, Korea, 27–28 October 2016. [Google Scholar]

- USNRC. Industry-Average Performance for Components and Initiating Events at U.S. Commercial Nuclear Power Plants, NUREG/CR-6928. Available online: https://www.nrc.gov/docs/ML0706/ML070650650.pdf (accessed on 3 June 2021).

- Chiacchio, F.; Compagno, L.; D’Urso, D.; Manno, G.; Trapani, N. Dynamic fault trees resolution: A conscious trade-off between analytical and simulative approaches. Reliab. Eng. Syst. Saf. 2011, 96, 1515–1526. [Google Scholar] [CrossRef]

- Colaboratory. Available online: https://colab.research.google.com/notebooks/intro.ipynb?utm_source=scs-index (accessed on 3 June 2021).

| Event Name | Description | Failure Mode | Failure Rate (h−1) | Mission Time (h) |

|---|---|---|---|---|

| %IE-LOOP | Loss of Offsite Power | Demand | 1 | |

| EPBSY-K4160B | Fault on Class 1E 4.16 kV Bus in Unit 1 | Running | 72 | |

| EPBSY-K4160A | Fault on Class 1E 4.16 kV Bus in Unit 1 | Running | 72 | |

| EP-K1460A-PS | 4.16 kV A Power Supply Failure in Unit 1 | Running | 72 | |

| EP-K1460B-PS | 4.16 kV B Power Supply Failure in Unit 1 | Running | 72 | |

| EPDGS-01A | EDG A Fails To Start in Unit 1 | Demand | ||

| EPDGS-01B | EDG B Fails To Start in Unit 1 | Demand | ||

| EPDGS-01E | AAC DG Fails To Start | Demand | ||

| EPDGR-01A | EDG A Fails To Run in Unit 1 | Running | 72 | |

| EPDGR-01B | EDG B Fails To Run in Unit 1 | Running | 72 | |

| EPDGR-01E | AAC DG Fails To Run | Running | 72 | |

| U2-EPBSY-K4160A | Fault on Class 1E 4.16 kV Bus in Unit 2 | Running | 72 | |

| U2-EPBSY-K4160B | Fault on Class 1E 4.16 kV Bus in Unit 2 | Running | 72 | |

| U2-EP-K1460A-PS | 4.16 kV A Power Supply Failure in Unit 2 | Running | 72 | |

| U2-EP-K1460B-PS | 4.16 kV B Power Supply Failure in Unit 2 | Running | 72 | |

| U2-EPDGS-01A | EDG A Fails To Start in Unit 2 | Demand | ||

| U2-EPDGS-01B | EDG B Fails To Start in Unit 2 | Demand | ||

| U2-EPDGR-01A | EDG A Fails To Run in Unit 2 | Running | 72 | |

| U2-EPDGR-01B | EDG B Fails To Run in Unit 2 | Running | 72 |

| Gate | ||

|---|---|---|

| PAND | , |

| Component | ||

|---|---|---|

| SP1-SB (Stand By) | ||

| SP1-AC (Active) | )* | |

| Gate | Time of Failure () | State () |

| SPARE |

| Gate | ||

|---|---|---|

| SEQ |

| Component | ||

|---|---|---|

| A | ||

| B |

| Component | Additional Condition 1 (AC1) | Additional Condition 2 (AC2) |

| SP1-SB for SPARE Gate 1 (Standby) | ||

| SP1-SB for SPARE Gate 2 (Standby) | ||

| Gate | Time of Failure (Ti) | State (Si) |

| SPARE 1 (Spare-Active) | ||

| SPARE 2 (Spare-Active) |

| Component | Time to Failure (Ti) | State (Si) |

| EDG A-SB (Standby) | ||

| EDG A-AC (Active) | )* | |

| Component | Additional Condition for EDG | |

| EDG A for Train A | = | |

| Gate | Time to Failure (Ti) | State (Si) |

| SPARE Train A with EDG (AC) | ||

| Component | Time to Failure (Ti) | State (Si) |

| AAC DG-SB (Standby) | ||

| AAC DG-AC (Active) | )* | |

| Component | Additional Conditions for AAC DG | |

| AAC DG for Train A (AC1) | ||

| AAC DG for Train A (AC2) | ||

| AAC DG for Train A (AC3) | = | |

| AAC DG for Train A (AC4) | ||

| Gate | Time to Failure (Ti) | State (Si) |

| SPARE Train A with EDG and AAC DG | ( | |

| Group | No. | Basic Event 1 | Basic Event 2 | Basic Event 3 | Basic Event 4 | Basic Event 5 |

|---|---|---|---|---|---|---|

| Ⅰ | 1 | %IE-LOOP | EPDGR-01A | EPDGR-01B | EPDGR-01E | |

| 2 | %IE-LOOP | EPDGR-01A | EPDGR-01B | EPDGS-01E | ||

| 3 | %IE-LOOP | EPDGR-01A | EPDGR-01E | EPDGS-01B | ||

| 4 | %IE-LOOP | EPDGR-01B | EPDGR-01E | EPDGS-01A | ||

| 5 | %IE-LOOP | EPDGR-01E | EPDGS-01A | EPDGS-01B | ||

| 6 | %IE-LOOP | EPDGR-01A | EPDGS-01B | EPDGS-01E | ||

| 7 | %IE-LOOP | EPDGR-01B | EPDGS-01A | EPDGS-01E | ||

| 8 | %IE-LOOP | EPBSY-K4160B | EPDGR-01A | EPDGR-01E | ||

| 9 | %IE-LOOP | EPBSY-K4160A | EPDGR-01B | EPDGR-01E | ||

| 10 | %IE-LOOP | EPDGS-01A | EPDGS-01B | EPDGS-01E | ||

| 11 | %IE-LOOP | EPBSY-K4160B | EPDGR-01A | EPDGS-01E | ||

| 12 | %IE-LOOP | EPBSY-K4160A | EPDGR-01B | EPDGS-01E | ||

| 13 | %IE-LOOP | EPBSY-K4160A | EPDGR-01E | EPDGS-01B | ||

| 14 | %IE-LOOP | EPBSY-K4160B | EPDGR-01E | EPDGS-01A | ||

| Ⅱ | 15 | %IE-LOOP | EPDGR-01A | EPDGR-01B | U2-EPDGR-01A | U2-EPDGR-01B |

| 16 | %IE-LOOP | EPDGR-01B | EPDGS-01A | U2-EPDGR-01A | U2-EPDGR-01B | |

| 17 | %IE-LOOP | EPDGR-01A | EPDGS-01B | U2-EPDGR-01A | U2-EPDGR-01B | |

| 18 | %IE-LOOP | EPDGR-01A | EPDGR-01B | U2-EPDGR-01B | U2-EPDGS-01A | |

| 19 | %IE-LOOP | EPDGR-01A | EPDGR-01B | U2-EPDGR-01A | U2-EPDGS-01B | |

| 20 | %IE-LOOP | EPDGS-01A | EPDGS-01B | U2-EPDGR-01A | U2-EPDGR-01B | |

| 21 | %IE-LOOP | EPDGR-01A | EPDGS-01B | U2-EPDGR-01A | U2-EPDGS-01B | |

| 22 | %IE-LOOP | EPDGR-01B | EPDGS-01A | U2-EPDGR-01B | U2-EPDGS-01A | |

| 23 | %IE-LOOP | EPDGR-01B | EPDGS-01A | U2-EPDGR-01A | U2-EPDGS-01B | |

| 24 | %IE-LOOP | EPDGR-01A | EPDGS-01B | U2-EPDGR-01B | U2-EPDGS-01A | |

| 25 | %IE-LOOP | EPDGR-01A | EPDGR-01B | U2-EPDGS-01A | U2-EPDGS-01B | |

| 26 | %IE-LOOP | EPDGR-01A | EPDGR-01B | U2-EPBSY-K4160A | U2-EPDGR-01B | |

| 27 | %IE-LOOP | EPBSY-K4160B | EPDGR-01A | U2-EPDGR-01A | U2-EPDGR-01B | |

| 28 | %IE-LOOP | EPBSY-K4160A | EPDGR-01B | U2-EPDGR-01A | U2-EPDGR-01B | |

| 29 | %IE-LOOP | EPDGR-01A | EPDGR-01B | U2-EPBSY-K4160B | U2-EPDGR-01A | |

| 30 | %IE-LOOP | EPDGS-01A | EPDGS-01B | U2-EPDGR-01B | U2-EPDGS-01A |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baek, S.; Heo, G. Application of Dynamic Fault Tree Analysis to Prioritize Electric Power Systems in Nuclear Power Plants. Energies 2021, 14, 4119. https://doi.org/10.3390/en14144119

Baek S, Heo G. Application of Dynamic Fault Tree Analysis to Prioritize Electric Power Systems in Nuclear Power Plants. Energies. 2021; 14(14):4119. https://doi.org/10.3390/en14144119

Chicago/Turabian StyleBaek, Sejin, and Gyunyoung Heo. 2021. "Application of Dynamic Fault Tree Analysis to Prioritize Electric Power Systems in Nuclear Power Plants" Energies 14, no. 14: 4119. https://doi.org/10.3390/en14144119

APA StyleBaek, S., & Heo, G. (2021). Application of Dynamic Fault Tree Analysis to Prioritize Electric Power Systems in Nuclear Power Plants. Energies, 14(14), 4119. https://doi.org/10.3390/en14144119