Improved Immune Algorithm Combined with Steepest Descent Method for Optimal Design of IPMSM for FCEV Traction Motor

Abstract

:1. Introduction

2. Proposed Algorithm

- To ensure the convergence to the optimal solution, optimization is performed with a memory cell. The memory cell group is composed of the superior entities among the population for each iteration.

- The IA has an affinity calculation process for realizing the diversity of the immune system. There are two kinds of affinity in the IA. One is the antigen-antibody affinity and the other is the antibody-antibody affinity. The antigen-antibody affinity indicates the objective function value. The antibody-antibody affinity is a criterion for evaluating mutual similarity. It can be calculated as:where affab is the antibody-antibody affinity between entity a and b, and dista,b is the distance between two entities. Among the memory cell that converges to the same solution, only the best one survives, and the rest are removed. With antibody-antibody affinity, the global solution and local solutions can be simultaneously searched.affab = 1/(1 + dista,b)

- With the expectation concept, the generation of the new antibody can be automatically adjusted. The expectation of the antibody i is defined as:where affi is the antigen-antibody affinity and ci is the concentration. ci can be calculated by dividing the number of similar entities by the total number of entities. The expectation prevents the excessive generation of new antibodies around the solutions, which are regarded as global or local solutions.ei = affi/ci

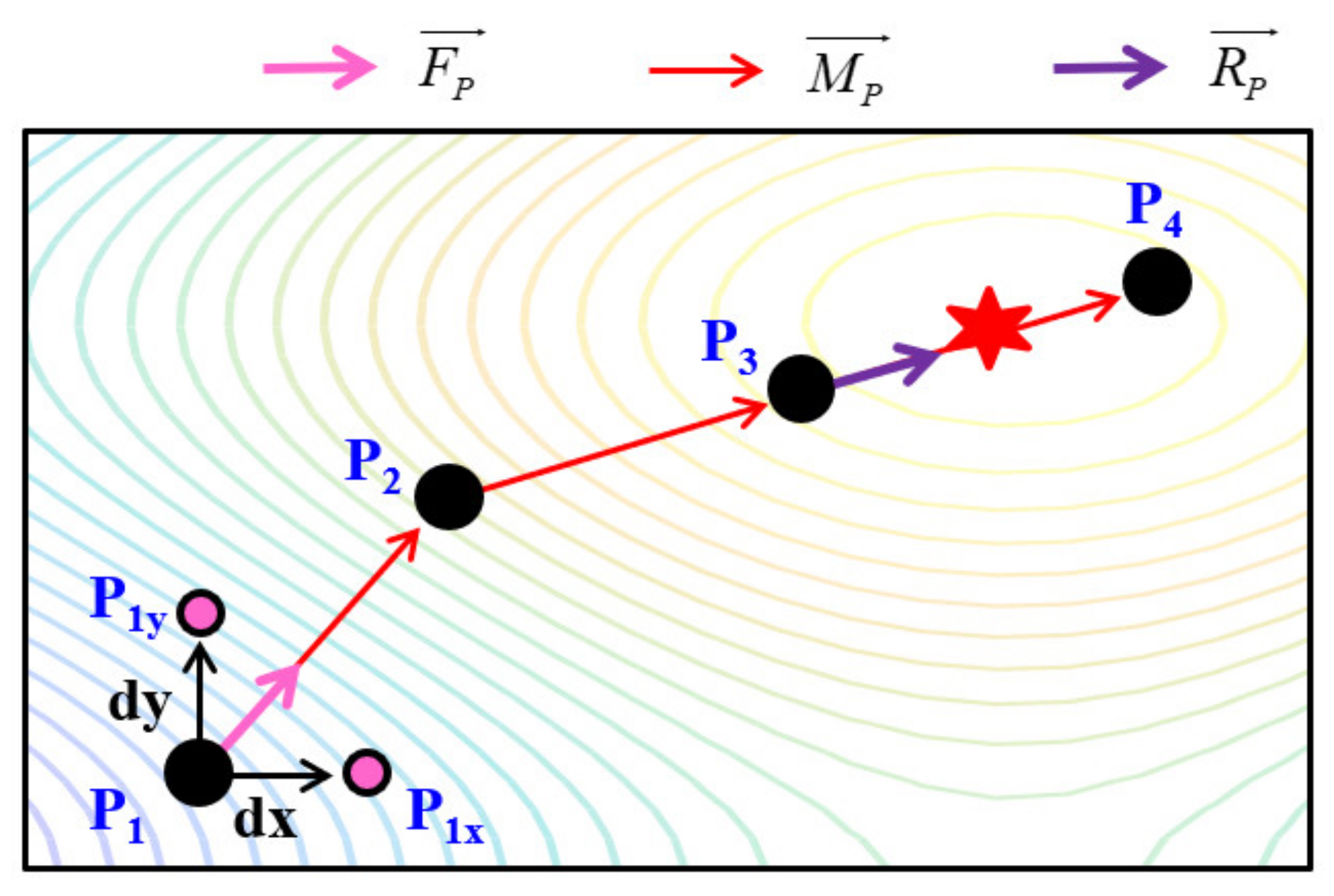

2.1. Memory Cell Sampling

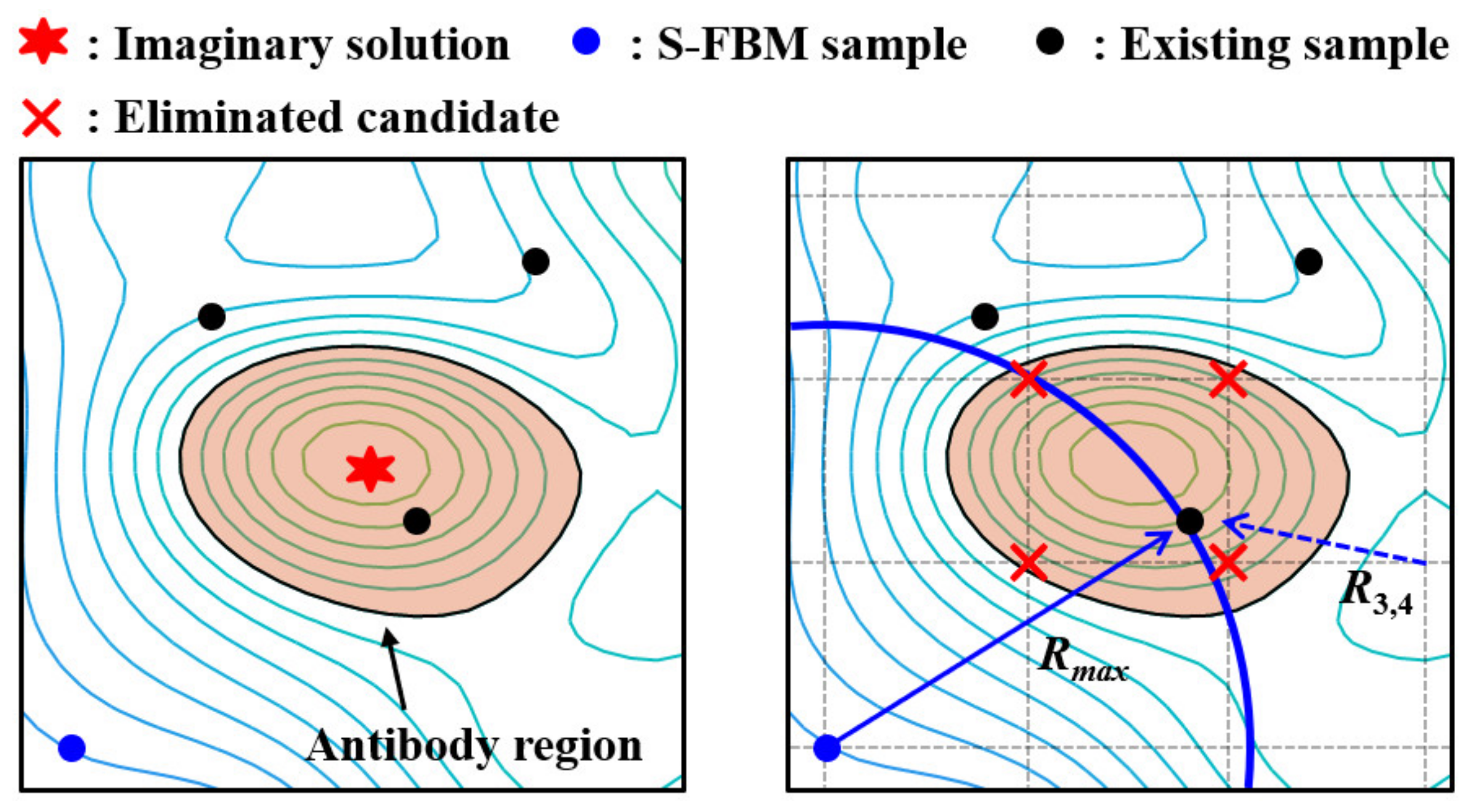

2.2. Antibody Region and Selective-Filling Blank Method

2.3. Steepest Descent Method

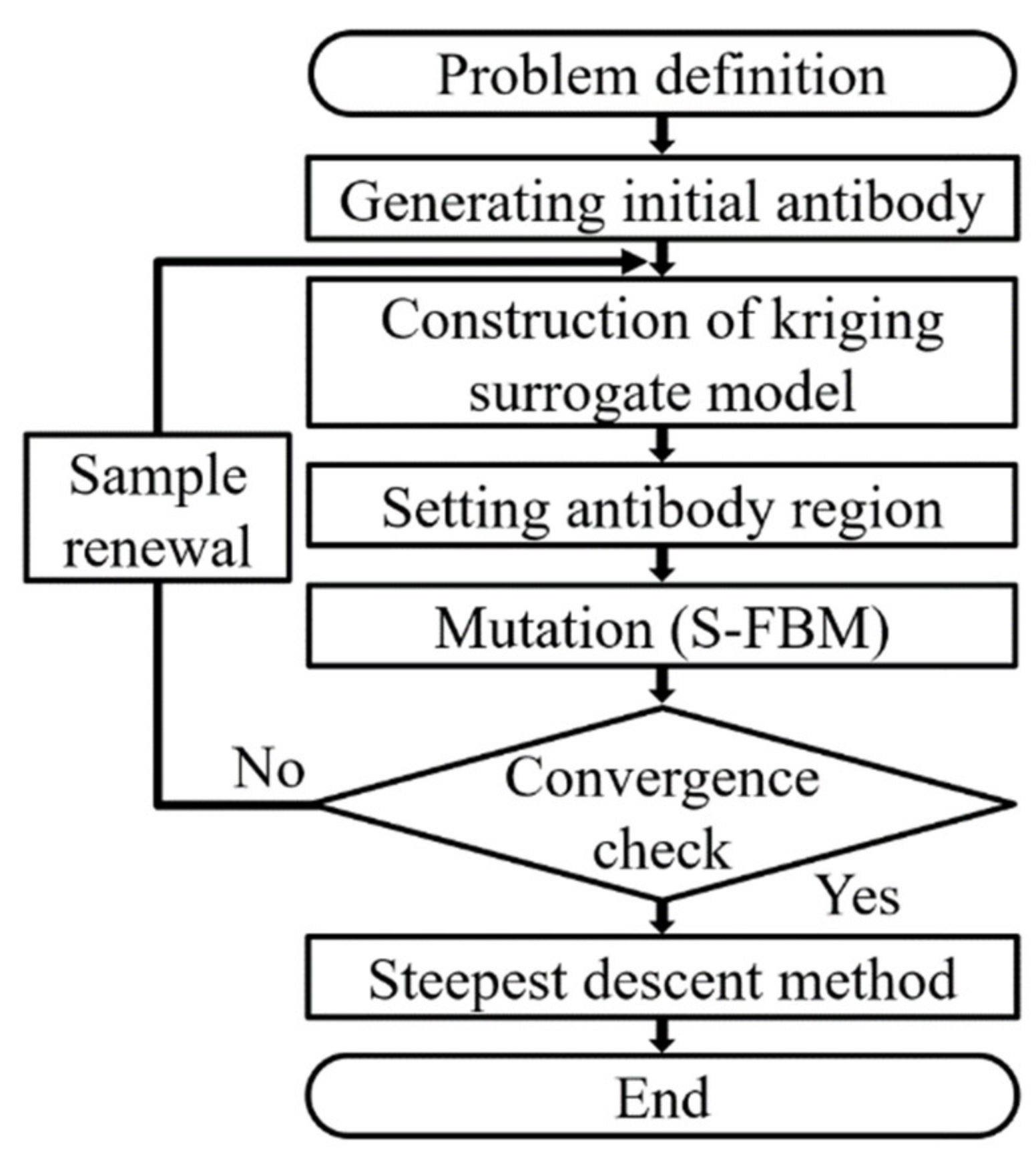

2.4. Flow Chart of the IIA

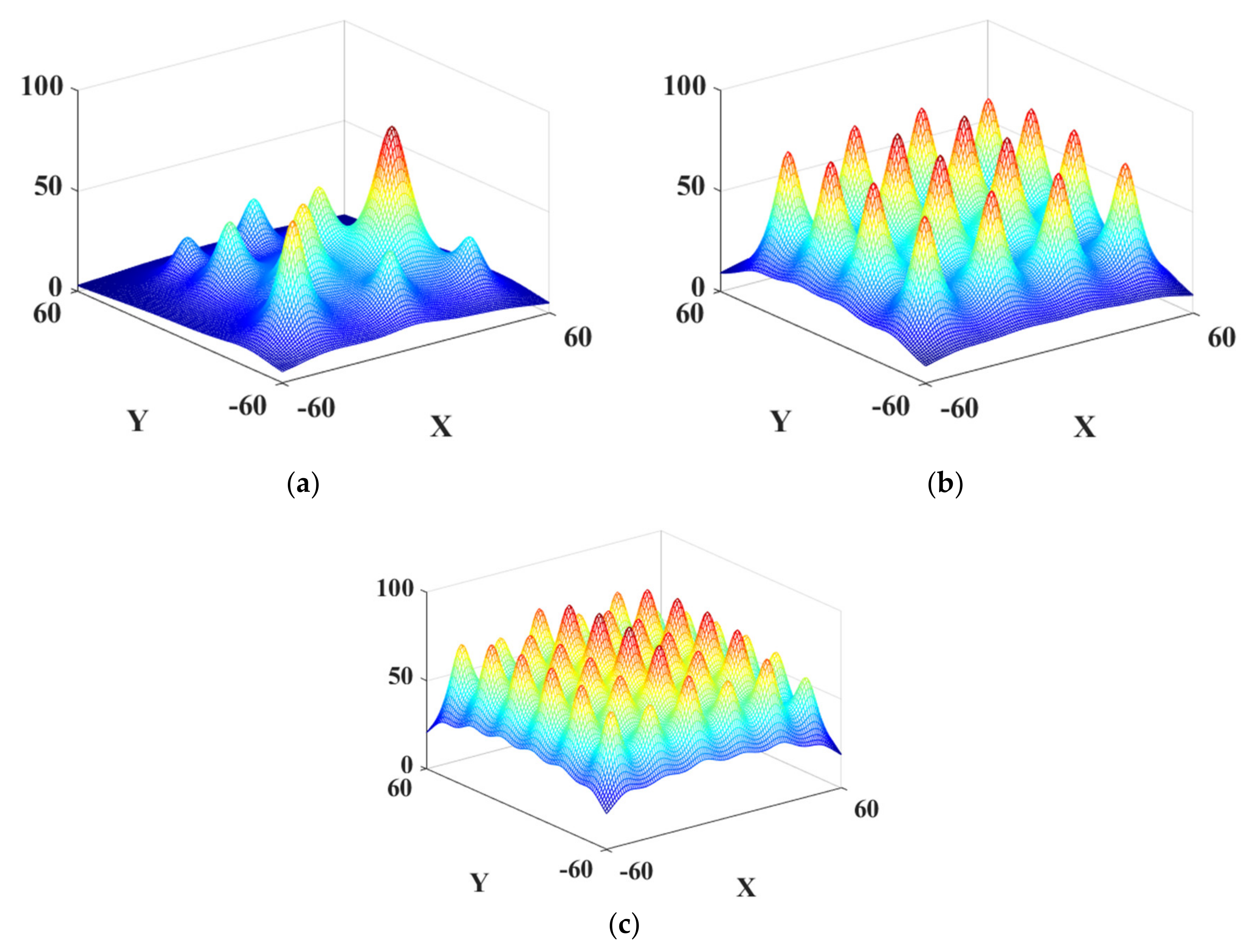

3. Performance Verification

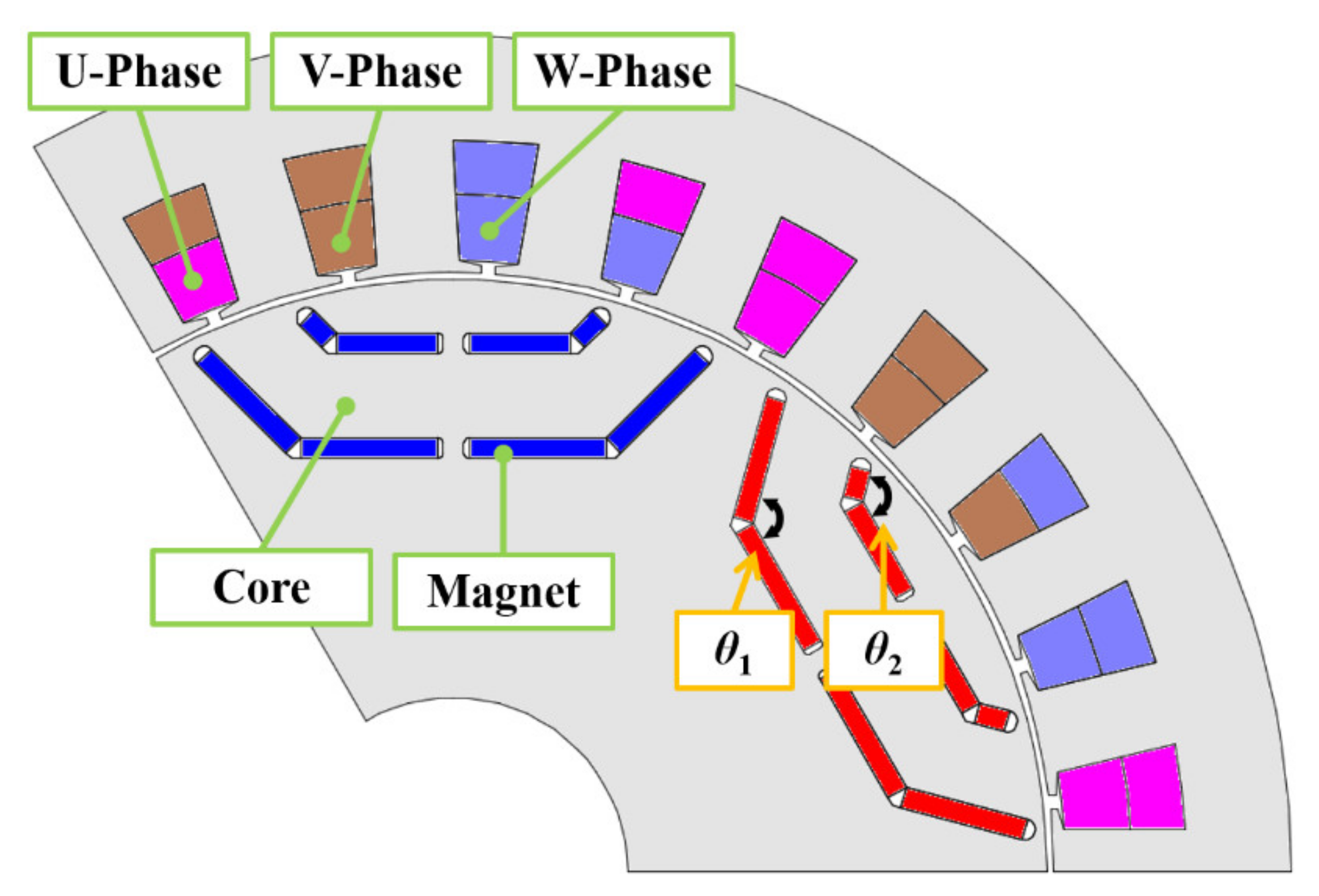

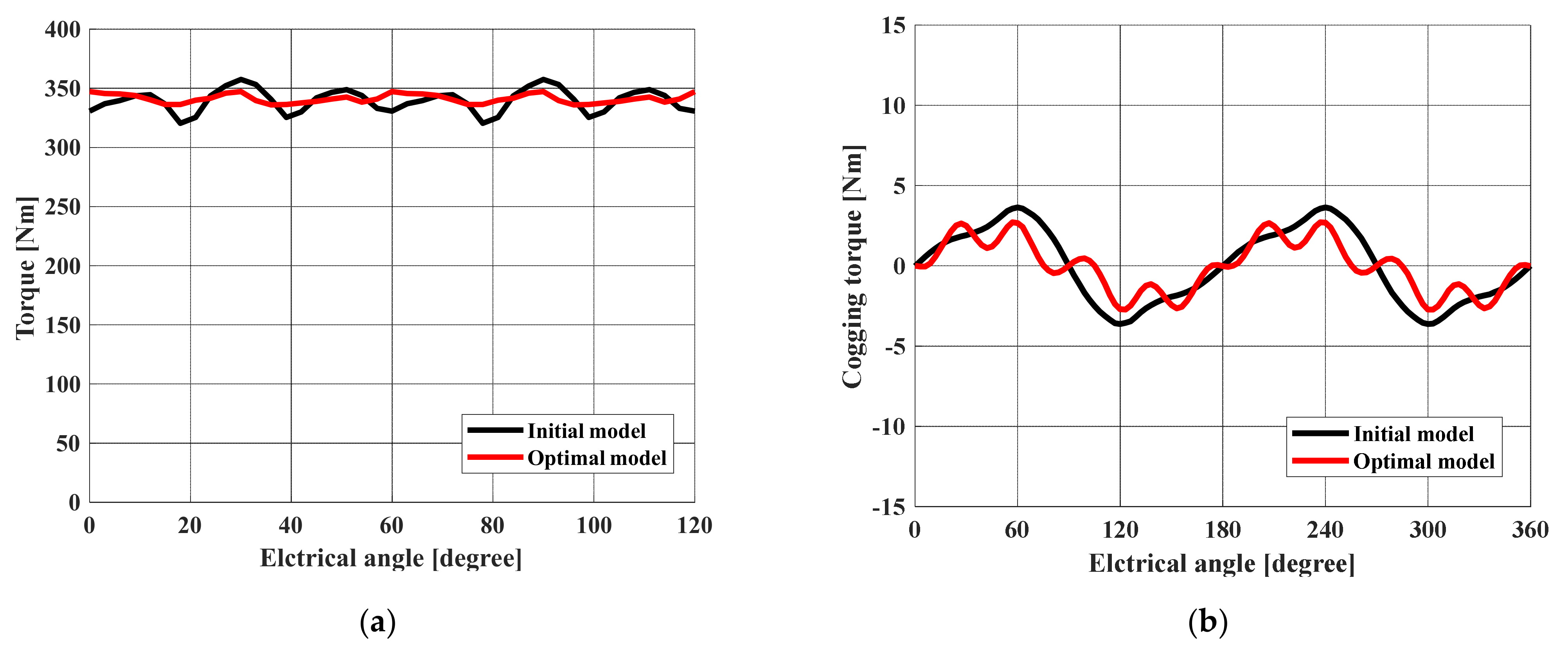

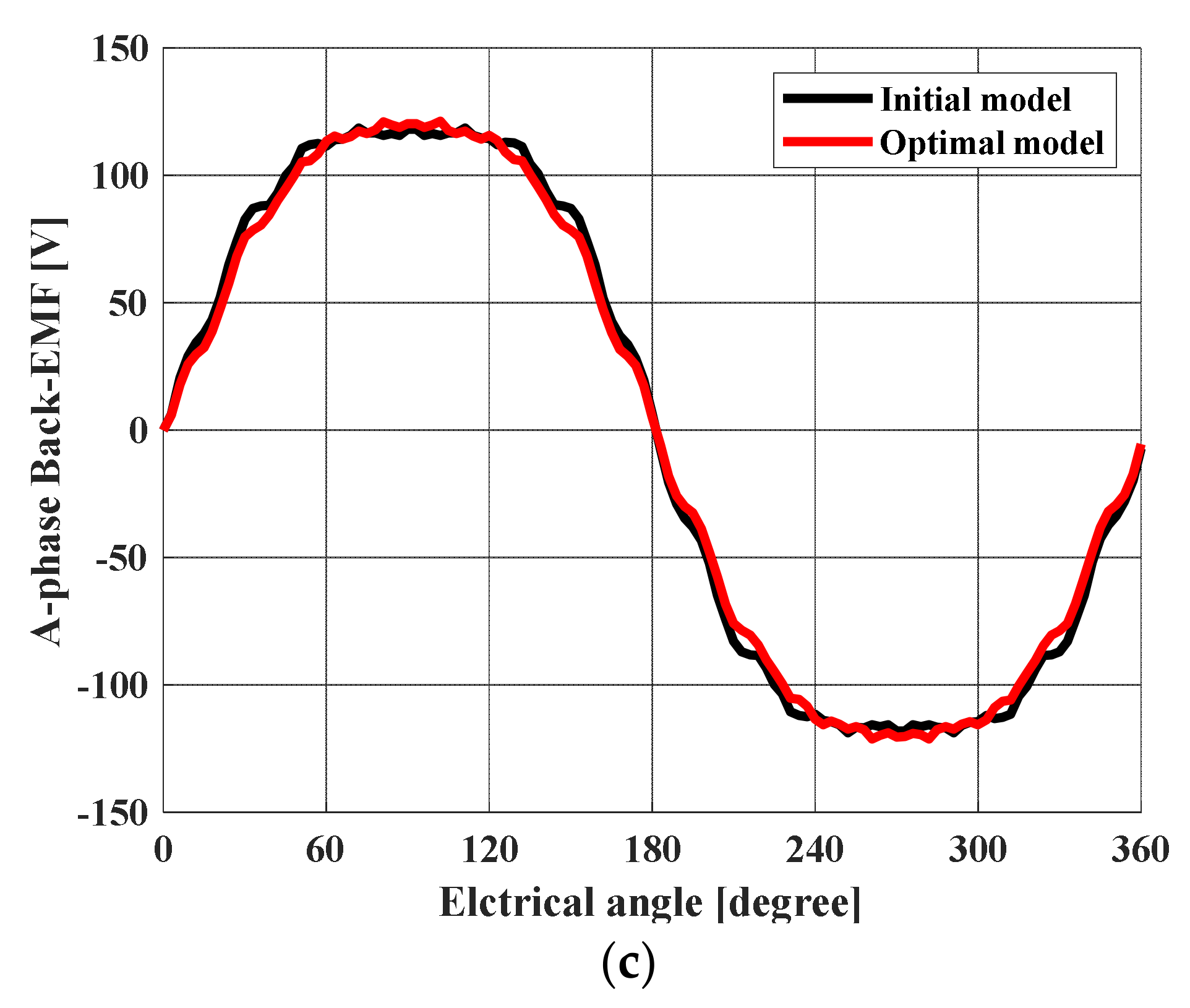

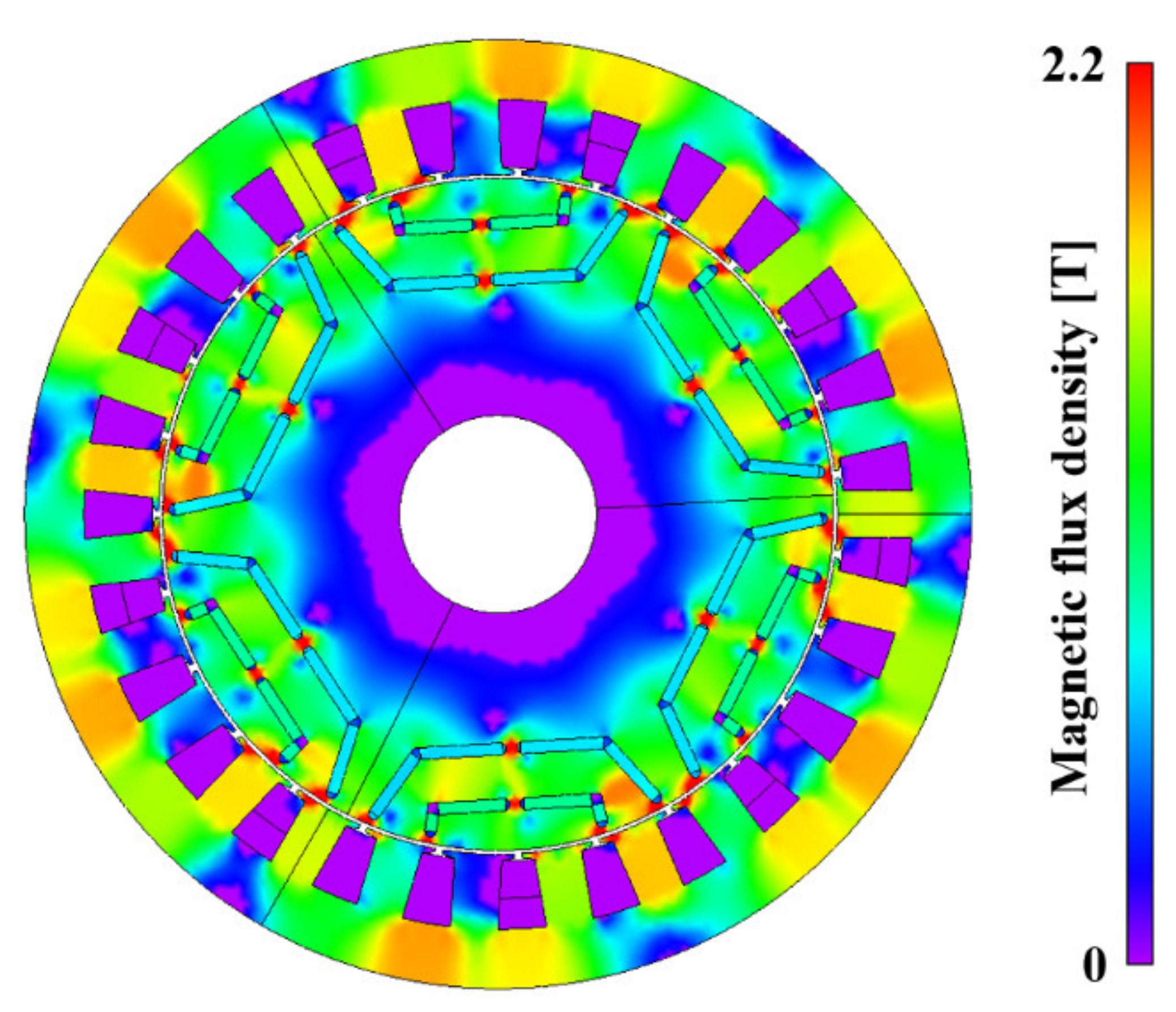

4. Optimal Design of an IPMSM for a FCEV Traction Motor

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lim, D.-K.; Yi, K.-P.; Jung, S.-Y.; Jung, H.-K.; Ro, J.-S. Optimal Design of an Interior Permanent Magnet Synchronous Motor by Using a New Surrogate-Assisted Multi-Objective Optimization. IEEE Trans. Magn. 2015, 51, 8207504. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, D.; Liu, J.; Gao, S.; Xu, W. Performance Improvement of Model-Predictive Current Control of Permanent Magnet Synchronous Motor Drives. IEEE Trans. Ind. Appl. 2017, 53, 3683–3695. [Google Scholar] [CrossRef]

- Seo, J.-H.; Woo, D.-K.; Chung, T.-K.; Jung, H.-K. A Study on Loss Characteristics of IPMSM for FCEV Considering the Rotating Field. IEEE Trans. Magn. 2010, 46, 3213–3216. [Google Scholar] [CrossRef]

- Wu, C.; Yang, J.; Li, Q. GPIO-Based Nonlinear Predictive Control for Flux-Weakening Current Control of the IPMSM Servo System. Energies 2020, 13, 1716. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; Wang, J.; Gan, C.; Sun, Q.; Kong, W. Efficiency Optimization of PMSM Drives Using Field-Circuit Coupled FEM for EV/HEV Applications. IEEE Access 2018, 6, 15192–15201. [Google Scholar] [CrossRef]

- Ren, W.; Xu, Q.; Li, Q.; Zhou, L. Reduction of Cogging Torque and Torque Ripple in Interior PM Machines with Asymmetrical V-Type Rotor Design. IEEE Trans. Magn. 2016, 52, 8104105. [Google Scholar] [CrossRef]

- Kim, H.-S.; Kwon, B.-I. Optimal design of motor shape and magnetization direction to obtain vibration reduction and average torque improvement in IPM BLDC motor. IET Electr. Power Appl. 2017, 11, 378–385. [Google Scholar] [CrossRef]

- Kim, W.-H.; Kim, K.-S.; Kim, S.-J.; Kang, D.-W.; Go, S.-C.; Chun, Y.-D.; Lee, J. Optimal PM Design of PMA-SynRM for Wide Constant-Power Operation and Torque Ripple Reduction. IEEE Trans. Magn. 2009, 45, 4660–4663. [Google Scholar] [CrossRef]

- Hao, J.; Suo, S.; Yang, Y.; Wang, Y.; Wang, W.; Chen, X. Optimization of Torque Ripples in an Interior Permanent Magnet Synchronous Motor Based on the Orthogonal Experimental Method and MIGA and RBF Neural Networks. IEEE Access 2020, 8, 27202–27209. [Google Scholar] [CrossRef]

- Fang, L.; Kim, S.-I.; Kwon, S.-O.; Hong, J.-P. Novel Double-Barrier Rotor Designs in Interior-PM Motor for Reducing Torque Pulsation. IEEE Trans. Magn. 2010, 46, 2183–2186. [Google Scholar] [CrossRef]

- Son, J.-C.; Kang, Y.-R.; Lim, D.-K. Optimal Design of IPMSM for FCEV Using Novel Immune Algorithm Combined with Steepest Descent Method. Energies 2020, 13, 3395. [Google Scholar] [CrossRef]

- Lim, D.-K.; Woo, D.-K.; Yeo, H.-K.; Jung, S.-Y.; Ro, J.-S.; Jung, H.-K. A Novel Surrogate-Assisted Multi-Objective Optimization Algorithm for an Electromagnetic Machine Design. IEEE Trans. Magn. 2015, 51, 8200804. [Google Scholar] [CrossRef]

- The Mathworks Inc. Contour. Available online: http://www.mathworks.com/help/techdoc/ref/contour.html (accessed on 29 June 2021).

- Yu, H.; Chung, C.Y.; Wong, K.P.; Lee, H.W.J.; Zhang, J.H. Probabilistic Load Flow Evaluation with Hybrid Latin Hypercube Sampling and Cholesky Decomposition. IEEE Trans. Power Syst. 2009, 24, 661–667. [Google Scholar] [CrossRef]

- Kang, Y.-R.; Son, J.-C.; Lim, D.-K. Optimal Design of IPMSM for Fuel Cell Electric Vehicles Using Autotuning Elliptical Niching Genetic Algorithm. IEEE Access 2020, 8, 117405–117412. [Google Scholar] [CrossRef]

| Test function 1 (11 peaks) | Number of function calls (EA) | Convergence rate (%) |

|---|---|---|

| IA | 2750 | 96.99 |

| IIA | 276 | 99.04 |

| Test function 2 (16 peaks) | Number of function calls (EA) | Convergence rate (%) |

| IA | 7660 | 97.64 |

| IIA | 368 | 99.71 |

| Test function 3 (36 peaks] | Number of function calls (EA) | Convergence rate (%) |

| IA | 10,950 | 98.97 |

| IIA | 738 | 99.89 |

| Requirement | Value |

|---|---|

| Rated torque | 330 (Nm) |

| Rated output | 103.7 (kW) |

| Rated/maximum speed | 3000/10,000 (rpm) |

| Torque ripple | Less than 10 (%) |

| Parameter | Value |

|---|---|

| Pole/slot number | 6/27 |

| Stator inner/outer diameter (mm) | 172/240 |

| Rotor inner/outer diameter (mm) | 50/170 |

| Air gap (mm) | 1 |

| Bridge, Center-post (mm) | 1.5 |

| Stacking length (mm) | 230 |

| Stator and rotor core material | POSCO 35PN230 |

| Permanent magnet material | NEOMAX-42 (Br = 1.30 [T]) |

| Permanent magnet thickness (mm) | 3 |

| Current density (Arms/mm2) | 13.5 |

| Model | Initial Model | Candidate 1 | Candidate 2 | Candidate 3 |

|---|---|---|---|---|

| θ1 (degree) | 110.0 | 118.9 | 137.0 | 129.0 |

| θ2 (degree) | 158.8 | 138.7 | 115.6 | 110.8 |

| AC phase (degree) | 40 | 42 | 42 | 42 |

| Model | Initial Model | Candidate 1 | Candidate 2 | Candidate 3 |

|---|---|---|---|---|

| Torque ripple (%) | 10.92 | 6.57 | 4.03 | 3.38 |

| Average torque (Nm) | 339.52 | 340.65 | 336.93 | 341.22 |

| Cogging torque (Nm) | 7.15 | 4.45 | 4.47 | 5.32 |

| THD (BEMF) (%) | 11.67 | 11.53 | 8.79 | 7.69 |

| BEMF (Vpk) | 118.76 | 115.97 | 116.20 | 121.20 |

| Model | Initial Model | Optimal Model |

|---|---|---|

| Copper loss | 2212.16 (W) | 2212.16 (W) |

| Iron loss | 686.11 (W) | 679.83 (W) |

| Total loss | 2898.27 (W) | 2891.99 (W) |

| Input power | 109.61 (kW) | 110.06 (kW) |

| Output power | 106.71 (kW) | 107.16 (kW) |

| Efficiency | 97.36 (%) | 97.37 (%) |

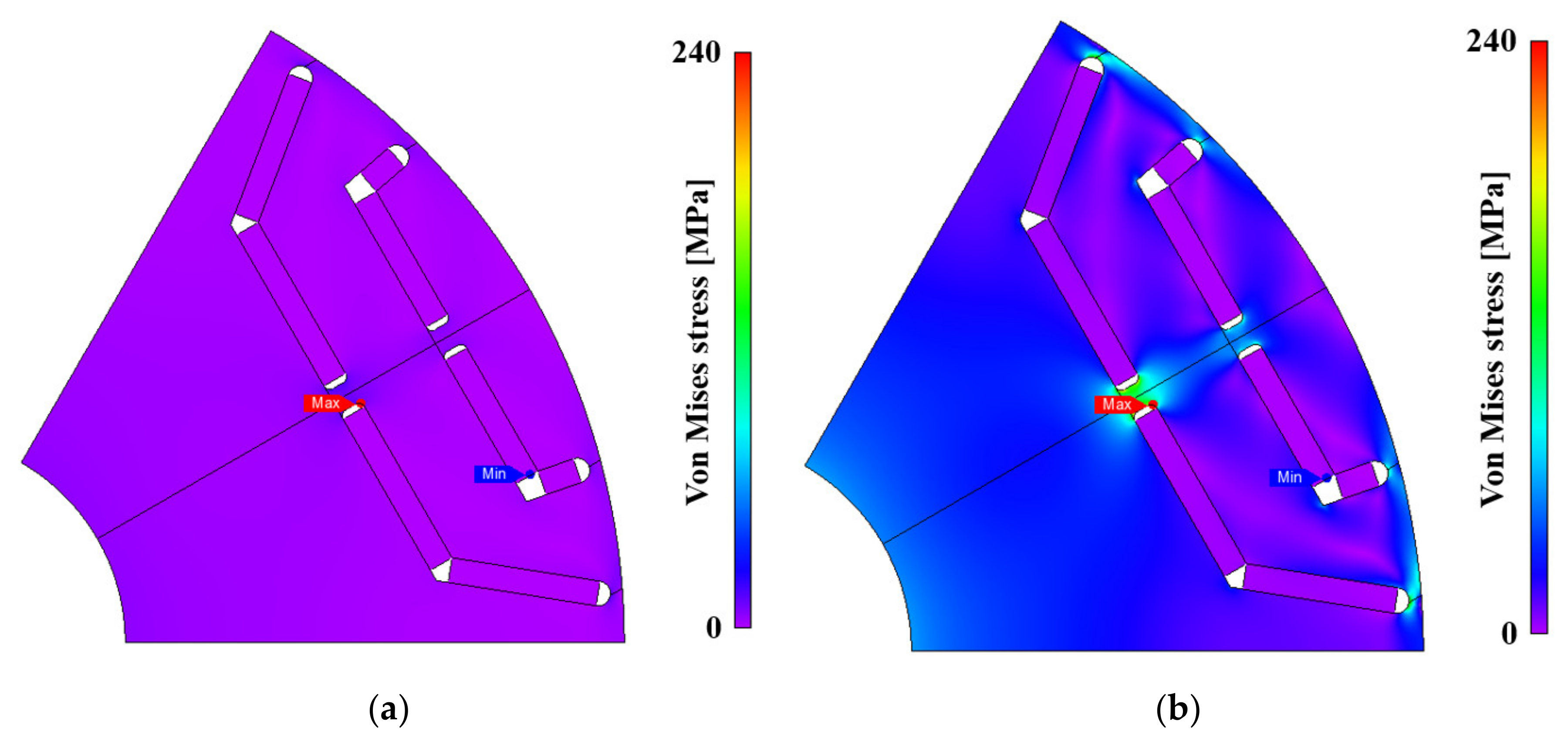

| Requirement | Value |

|---|---|

| Young’s modulus (Core/Magnet) | 210/160 (GPa) |

| Poisson’s ratio (Core/Magnet) | 0.3/0.24 |

| Density (Core/Magnet) | 7850/7500 (kg/m3) |

| Rotation speed | 3000/10,000 (r/m) |

| Yield stress | 250 (MPa) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Son, J.-C.; Baek, M.-K.; Park, S.-H.; Lim, D.-K. Improved Immune Algorithm Combined with Steepest Descent Method for Optimal Design of IPMSM for FCEV Traction Motor. Energies 2021, 14, 3904. https://doi.org/10.3390/en14133904

Son J-C, Baek M-K, Park S-H, Lim D-K. Improved Immune Algorithm Combined with Steepest Descent Method for Optimal Design of IPMSM for FCEV Traction Motor. Energies. 2021; 14(13):3904. https://doi.org/10.3390/en14133904

Chicago/Turabian StyleSon, Ji-Chang, Myung-Ki Baek, Sang-Hun Park, and Dong-Kuk Lim. 2021. "Improved Immune Algorithm Combined with Steepest Descent Method for Optimal Design of IPMSM for FCEV Traction Motor" Energies 14, no. 13: 3904. https://doi.org/10.3390/en14133904

APA StyleSon, J.-C., Baek, M.-K., Park, S.-H., & Lim, D.-K. (2021). Improved Immune Algorithm Combined with Steepest Descent Method for Optimal Design of IPMSM for FCEV Traction Motor. Energies, 14(13), 3904. https://doi.org/10.3390/en14133904