Measurement Method of Thermal Diffusivity of the Building Wall for Summer and Winter Seasons in Poland

Abstract

:1. Introduction

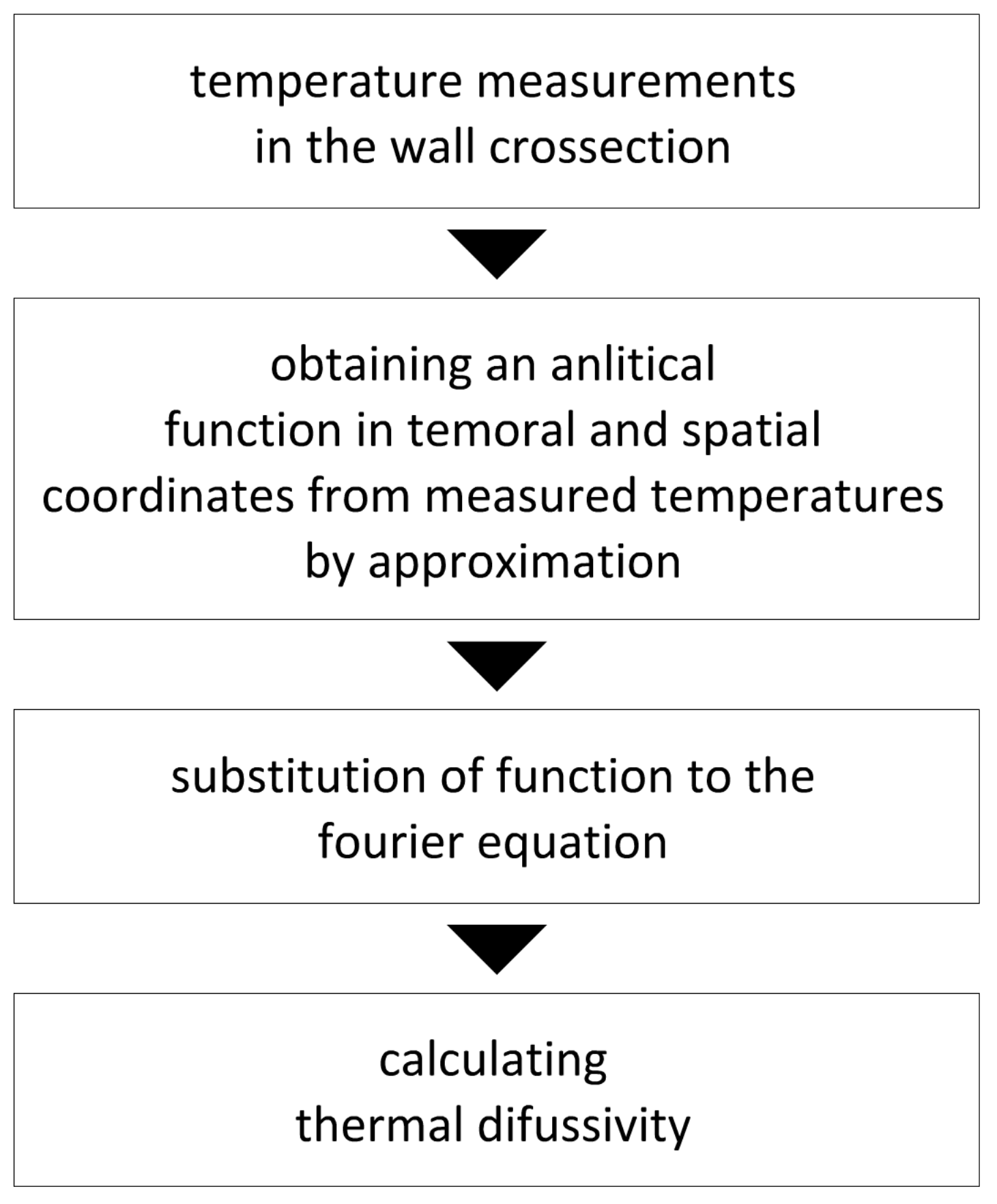

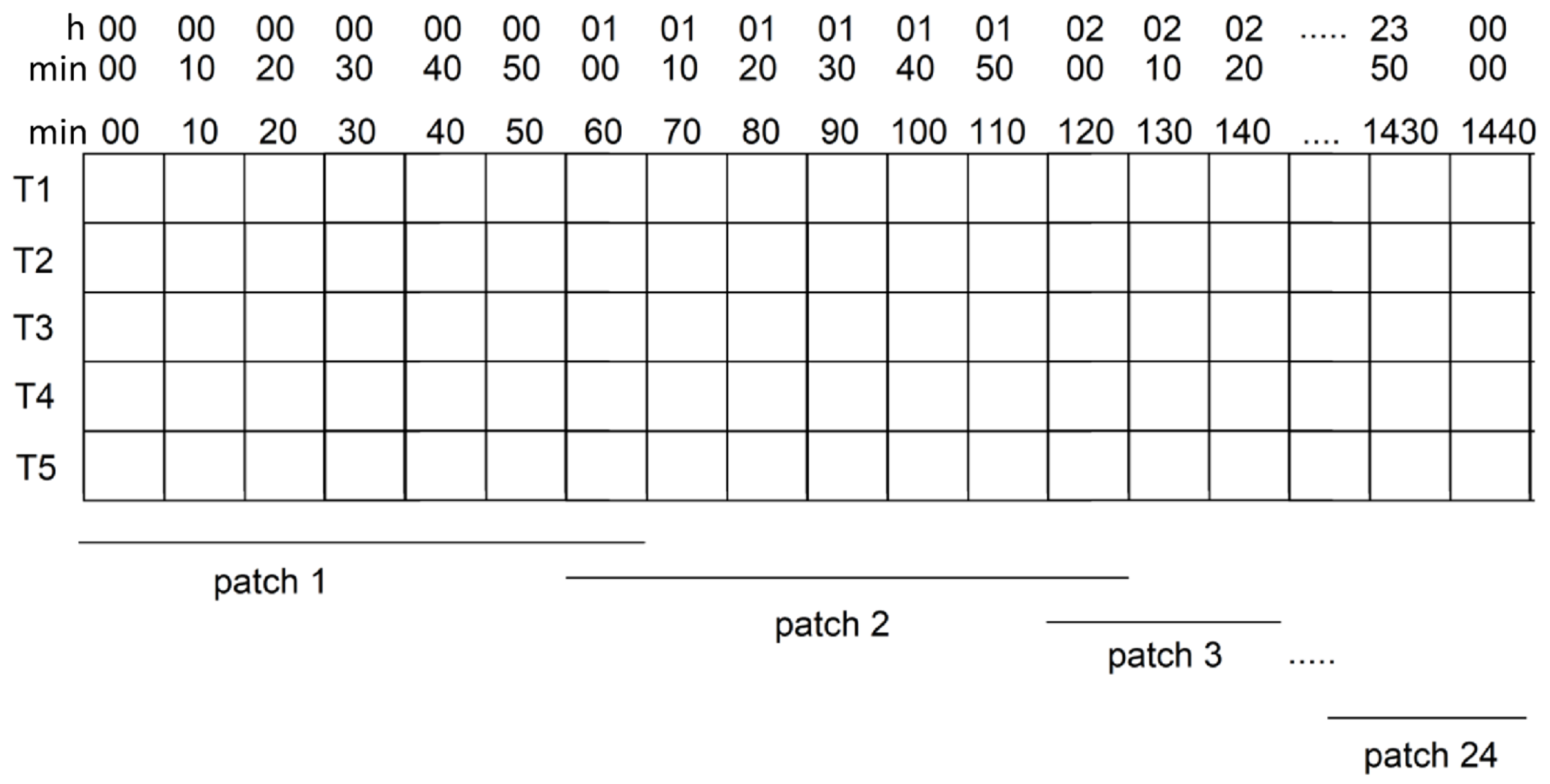

2. Method Description

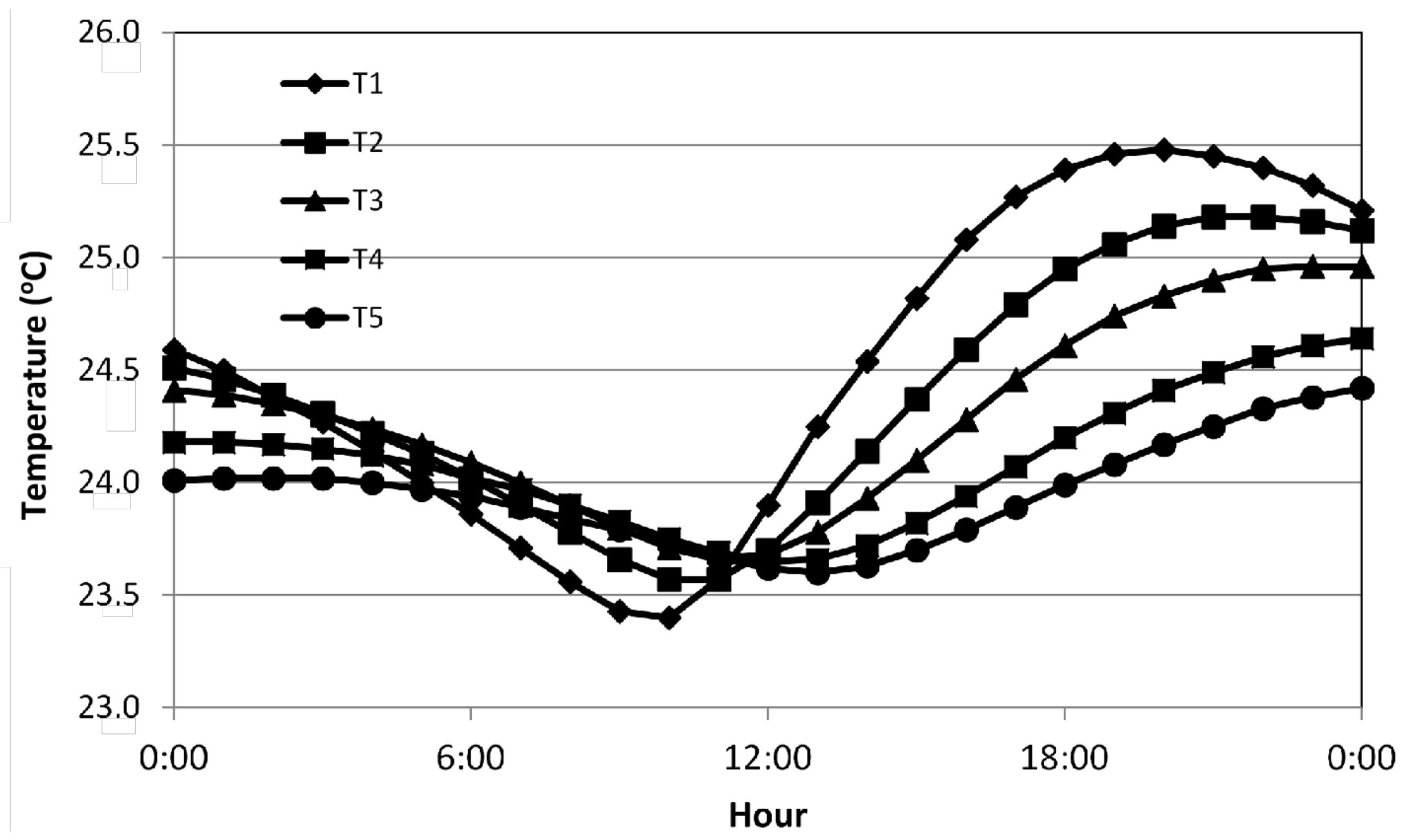

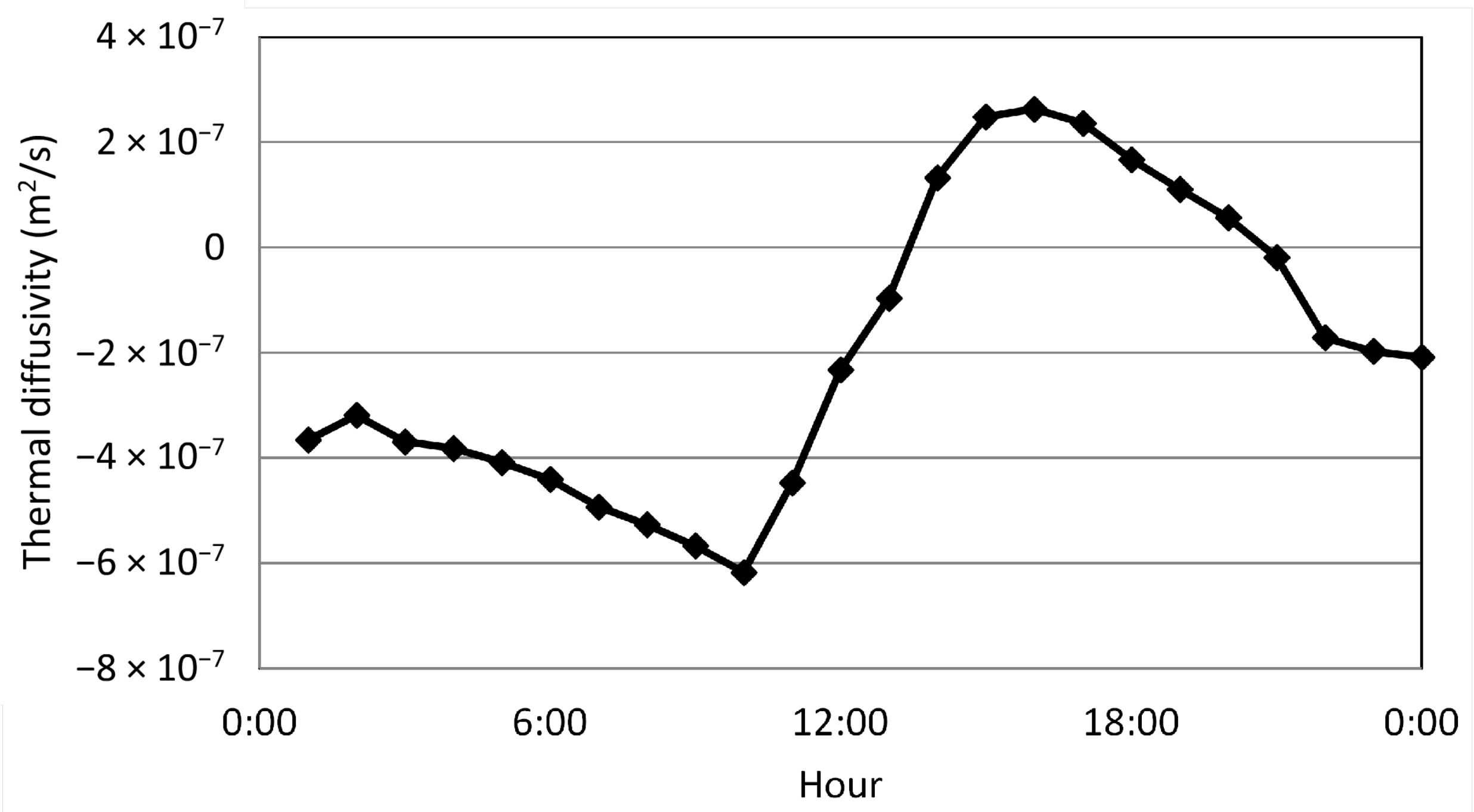

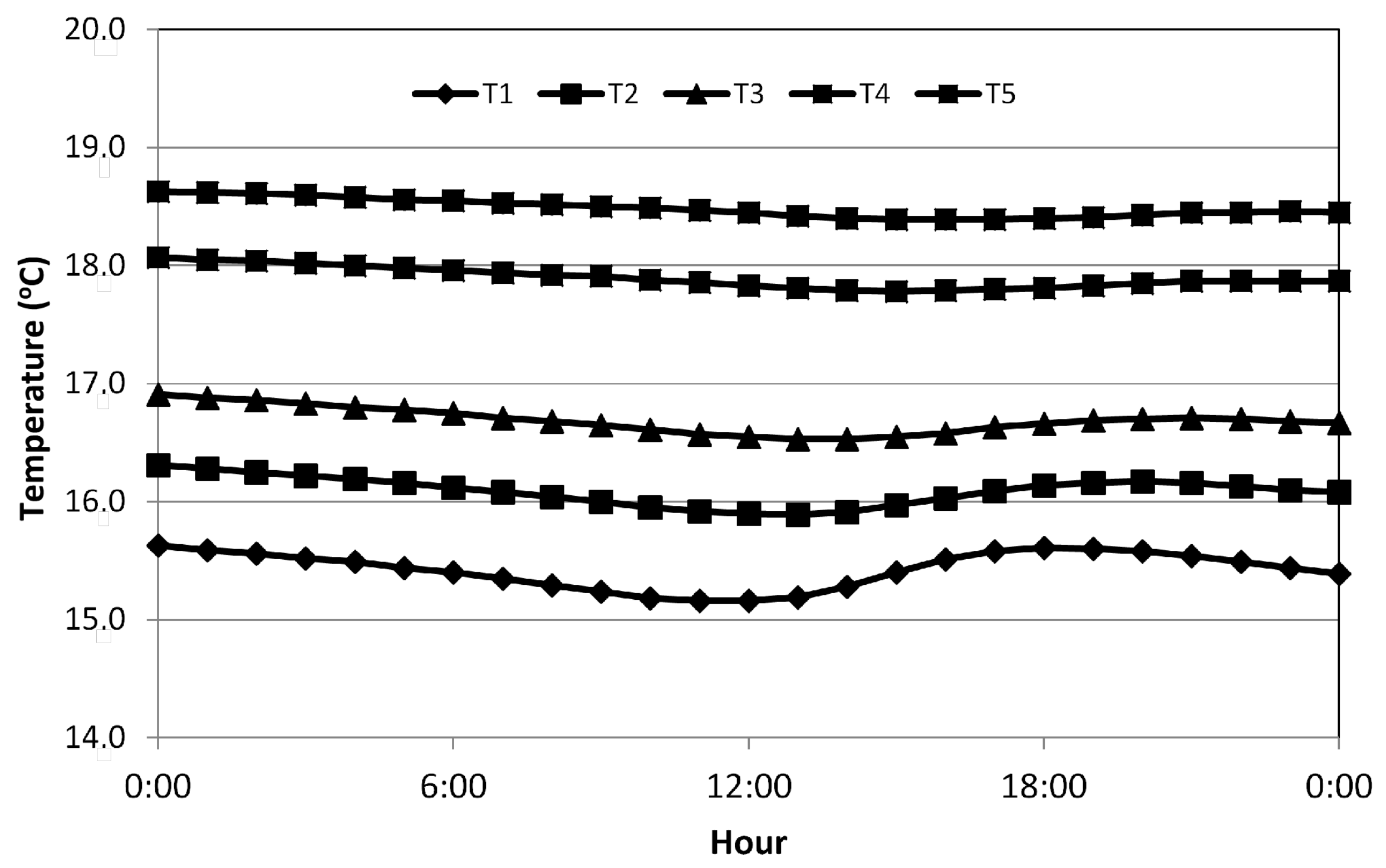

3. Results

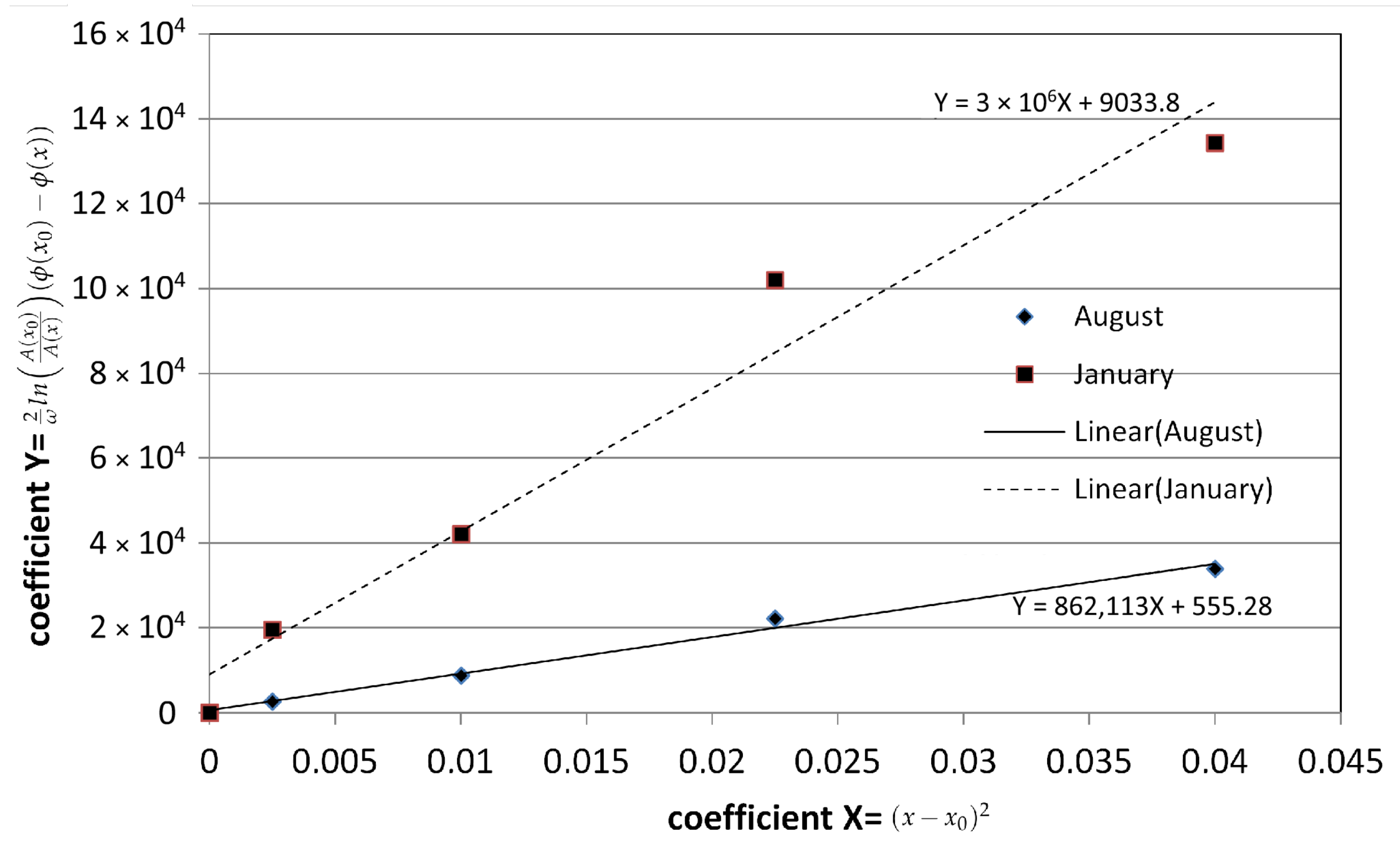

Comparison to the Modified Ångström’s Method

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Salazar, A. On thermal diffusivity. Eur. J. Phys. 2003. [Google Scholar] [CrossRef]

- Baryłka, A.; Tomaszewicz, D. Influence of measuring deviations of the components of layered walls on their durability. Inż. Bezpieczeństwa Obiektów Antropog. 2020. [Google Scholar] [CrossRef]

- Carslaw, H.S.; Jeager, J.C. Conduction of Heat in Solids, 2nd ed.; Clarendon Press: Oxford, UK, 1986. [Google Scholar]

- Lakatos, Á. Comprehensive thermal transmittance investigations carried out on opaque aerogel insulation blanket. Mater. Struct. 2017. [Google Scholar] [CrossRef]

- Boubaker, K.M.; Bouhafs, M.; Yacoubi, N. A quantitative alternative to the Vickers hardness test based on a correlation between thermal diffusivity and hardness—Applications to laser-hardened carburized steel. NDT&E Int. 2003, 36. [Google Scholar] [CrossRef]

- Noh, H.G.; Lee, J.H.; Kang, H.C.; Park, H.S. Effective Thermal Conductivity and Diffusivity of Containment Wall for Nuclear Power Plant OPR1000. Nucl. Eng. Technol. 2017, 49, 459–465. [Google Scholar] [CrossRef]

- Asadi, I.; Shafigh, P.; Bin Abu Hassan, Z.F.; Mahyuddin, N.B. Thermal conductivity of concrete—A review. J. Build. Eng. 2016. [Google Scholar] [CrossRef]

- Pomianowski, M.; Heiselberg, P.; Jensen, R.L.; Cheng, R.; Zhang, Y. A new experimental method to determine specific heat capacity of inhomogeneous concrete material with incorporated microencapsulated-PCM. Cem. Concr. Res. 2014, 55. [Google Scholar] [CrossRef]

- Łasica, W.; Małek, M.; Szcześniak, Z.; Owczarek, M. Characterization of recycled glass-cement composite: Mechanical strength. Mater. Tehnol. 2020. [Google Scholar] [CrossRef]

- Małek, M.; Jackowski, M.; Życiński, W.; Łasica, W.; Owczarek, M. Influence of silicone carbide additions on the mechanical properties of concrete. Mater. Technol. 2019. [Google Scholar] [CrossRef]

- Azhary, E.; Raefat, S.; Laaroussi, N.; Garoum, M. Energy performance and thermal proprieties of three types of unfired clay bricks. Energy Procedia 2018, 147. [Google Scholar] [CrossRef]

- Sassine, E.; Younsi, Z.; Cherif, Y.; Chauchois, A.; Antczak, E. Experimental determination of thermal properties of brick wall for existing construction in the north of France. J. Build. Eng. 2017. [Google Scholar] [CrossRef]

- El Fgaier, F.; Lafhaj, Z.; Brachelet, F.; Antczak, E.; Chapiseau, C. Thermal performance of unfired clay bricks used in construction in the north of France: Case study. Case Stud. Constr. Mater 2015. [Google Scholar] [CrossRef]

- Fujisawa, H.; Ryu, M.; Lundgaard, S.; Linklater, D.P.; Ivanova, E.P.; Nishijima, Y.; Juodkazis, S.; Morikawa, J. Direct Measurement of Temperature Diffusivity of Nanocellulose-Doped Biodegradable Composite Films. Micromachines 2020, 11, 738. [Google Scholar] [CrossRef]

- Stolarska, A.; Strzałkowski, J. The Thermal Parameters of Mortars Based on Different Cement Type and W/C Ratios. Materials 2020, 13, 458. [Google Scholar] [CrossRef] [PubMed]

- Khan, M. Factors affecting the thermal properties of concrete and applicability of its prediction models. Build. Environ. 2002. [Google Scholar] [CrossRef]

- Szczesniak, A.; Siwinski, J.; Stolarski, A. Experimental Study on the Use of Granite as Fine Aggregatein Very-High-Strength Concrete. IOP Conf. Ser. Mater. Sci. Eng. 2019. [Google Scholar] [CrossRef]

- Vitiello, V.; Castelluccio, R.; Del Rio Merino, M. Experimental research to evaluate the percentage change of thermal and mechanical performances of bricks in historical buildings due to moisture. Constr. Build. Mater. 2020, 244, 118107. [Google Scholar] [CrossRef]

- Corasaniti, S.; Potenza, M.; Coppa, P.; Bovesecchi, G. Comparison of different approaches to evaluate the equivalent thermal diffusivity of building walls under dynamic conditions International. J. Therm. Sci. 2020. [Google Scholar] [CrossRef]

- Ångstrom, A.J. Neue Methode, das Wärmeleitungsvermögen der Körper zu bestimmen. Ann. Phys. Leipzig 1861. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y. Heat-loss modified Angstrom method for simultaneous measurements of thermal diffusivity and conductivity of graphite sheets: The origins of heat loss in Angstrom method. Int. J. Heat Mass Transf. 2016. [Google Scholar] [CrossRef]

- Prasad, A.; Ambirajan, A. Thermal diffusivity, Ångström method, Measurement technique, Thermal wave. Int. J. Therm. Sci. 2018, 134, 216–223. [Google Scholar] [CrossRef]

- Ulgen, K. Experimental and theoretical investigation of effects of wall’s thermophysical properties on time lag and decrement factor. Energy Build. 2002. [Google Scholar] [CrossRef]

- Lakatos, A. Investigation of heat transfer decrement of wall structures comparison of measurements and calculations. WSEAS Trans. Heat Mass Transf. 2016, 11, 1–7. [Google Scholar]

- Ryu, M.; Batsale, J.-C.; Morikawa, J. Quadrupole modelling of dual lock-in method for the simultaneous measurements of thermal diffusivity and thermal effusivity. Int. J. Heat Mass Transf. 2020. [Google Scholar] [CrossRef]

- El Rassy, E.; Billaud, Y.; Saury, D. Unconventional flash technique for the identification of multilayer thermal diffusivity tensors. Int. J. Therm. Sci. 2020. [Google Scholar] [CrossRef]

- Baryłka, A.; Obolewicz, J. Technical diagnosis as an important engineering tool of electrical power facilities. Rynek Energii 2020, nr 6, 151. [Google Scholar]

- Kleszcz, J.; Kmiecik, P.; Świerzawski, J. Vegetable and Gardening Tower of Othmar Ruthner in the Voivodeship Park of Culture and Recreation in Chorzów—The First Example of Vertical Farming in Poland. Sustainability 2020, 12, 5378. [Google Scholar] [CrossRef]

- Parker, W.J.; Jenkins, R.J.; Butler, C.P.; Abbot, G.L. Flash method of determining thermal diffusivity, heat capacity and thermal conductivity. J. Appl. Phys. 1961. [Google Scholar] [CrossRef]

- Owczarek, M. Parametric study of the method for determining the thermal diffusivity of building walls by measuring the temperature profile. Energy Build. 2019. [Google Scholar] [CrossRef]

- Owczarek, M.; Baryłka, A. Estimation of thermal diffusivity of building elements based on temperature measurement for periodically changing boundary conditions. Rynek Energii 2019, 5, 76–79. [Google Scholar]

- Baryłka, A.; Bąk, G. Metodyka szacowania wartości współczynnika wyrównania temperatury obsypki gruntowej schronu w warunkach pożaru Bulletin of the Mil. Univ. Technol. 2015. (In Polish) [Google Scholar] [CrossRef]

- Curve Fitting Toolbox for Use with Matlab—User Guide the MathWorks. 2005. Available online: http://128.174.199.77/matlab_pdf/curvefit.pdf (accessed on 5 January 2021).

- Hall, M.R. Assessing the environmental performance of stabilised rammed earth walls using a climatic simulation chamber. Build. Environ. 2007, 42, 139–145. [Google Scholar] [CrossRef]

- Hall, M.R.; Allinson, D. Transient numerical and physical modelling of temperature profile evolution in stabilised rammed earth walls. Appl. Therm. Eng. 2010. [Google Scholar] [CrossRef] [Green Version]

- Baryłka, A.; Obolewicz, J. Safety and health protection (s&hp) in managing construction projects. Inż. Bezpieczeństwa Obiektów Antropog. 2020, 1. [Google Scholar] [CrossRef]

- Taller, J.; Duda, P. Solving Direct and Inverse Heat Conduction Problems, 2006th ed.; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Bouchard, A.M. Angstrom’s Method of Determining Thermal Conductivity; The College of Wooster: Wooster, OH, USA, 2000; Available online: https://physics.wooster.edu/JrIS/Files/Drew.pdf (accessed on 6 January 2021).

- Lytle, A.L. Ångström’s Method of Measuring Thermal Conductivity; The College of Wooster: Wooster, OH, USA, 2000; Available online: http://216.92.172.113/courses/phys39/ThermalMeasurement/AngstromMethodBrassRod.pdf (accessed on 6 January 2021).

- Hahn, J.; Felts, T.; Vatter, M.; Reid, T.; Marconnet, A. Measurement of hair thermal diffusivity with infrared microscopy enhanced Ångström’s method. Materialia 2020. [Google Scholar] [CrossRef]

- Habib, E.; Cianfrini, M.; de Lieto Vollaro, R. Definition of parameters useful to describe dynamic thermal behavior of hollow bricks. Energy Procedia 2017, 126, 50–57. [Google Scholar] [CrossRef]

| Patch no. | 1 | 2 | 3 | 4 | 5 | 6 |

| a (m/s) | 4.50 × 10 | 5.71 × 10 | 5.36 × 10 | 6.10 × 10 | 6.39 × 10 | 6.76 × 10 |

| Patch no. | 7 | 8 | 9 | 10 | 11 | 12 |

| a (m/s) | 6.81 × 10 | 6.94 × 10 | 6.77 × 10 | 5.77 × 10 | 6.91 × 10 | 3.01 × 10 |

| Patch no. | 13 | 14 | 15 | 16 | 17 | 18 |

| a (m/s) | 1.36 × 10 | 1.22 × 10 | 1.30 × 10 | 1.31 × 10 | 1.29 × 10 | 1.36 × 10 |

| Patch no. | 19 | 20 | 21 | 22 | 23 | 24 |

| a (m/s) | 1.60 × 10 | 2.48 × 10 | 2.75 × 10 | −1.10 × 10 | −4.53 × 10 | 2.07 × 10 |

| Patch no. | 1 | 2 | 3 | 4 | 5 | 6 |

| a (m/s) | −3.66 × 10 | −3.19 × 10 | −3.69 × 10 | −3.82 × 10 | −4.09 × 10 | −4.41 × 10 |

| Patch no. | 7 | 8 | 9 | 10 | 11 | 12 |

| a (m/s) | −4.93 × 10 | −5.27 × 10 | −5.67 × 10 | −6.18 × 10 | −4.48 × 10 | −2.33 × 10 |

| Patch no. | 13 | 14 | 15 | 16 | 17 | 18 |

| a (m/s) | −9.63 × 10 | 1.33 × 10 | 2.48 × 10 | 2.63 × 10 | 2.37 × 10 | 1.67 × 10 |

| Patch no. | 19 | 20 | 21 | 22 | 23 | 24 |

| a (m/s) | 1.11 × 10 | 5.65 × 10 | −1.87 × 10 | −1.71 × 10 | −1.97 × 10 | −2.09 × 10 |

| Measurement Point | Amplitude A | Phase |

|---|---|---|

| T1 | 1298.1 | 0.578 |

| T2 | 981.0 | 0.246 |

| T3 | 760.3 | −0.020 |

| T4 | 541.3 | −0.343 |

| T5 | 419.5 | −0.512 |

| Measurement Point | Amplitude A | Phase |

|---|---|---|

| T1 | 233.3 | 0.602 |

| T2 | 161.8 | 0.236 |

| T3 | 119.4 | −0.064 |

| T4 | 72.5 | −0.708 |

| T5 | 66.3 | −1.064 |

| Temperature Profile Method | 9 August 2019 | 3 February 2020 |

|---|---|---|

| Avg | 9.15 × 10 | 2.95 × 10 |

| Max | 1.60 × 10 | 6.18 × 10 |

| Min | 4.50 × 10 | 1.87 × 10 |

| 1.15 × 10 | 5.99 × 10 | |

| Ångström method | 1.16 × 10 (whole August) | 3.33 × 10 (whole January) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Owczarek, M.; Owczarek, S.; Baryłka, A.; Grzebielec, A. Measurement Method of Thermal Diffusivity of the Building Wall for Summer and Winter Seasons in Poland. Energies 2021, 14, 3836. https://doi.org/10.3390/en14133836

Owczarek M, Owczarek S, Baryłka A, Grzebielec A. Measurement Method of Thermal Diffusivity of the Building Wall for Summer and Winter Seasons in Poland. Energies. 2021; 14(13):3836. https://doi.org/10.3390/en14133836

Chicago/Turabian StyleOwczarek, Mariusz, Stefan Owczarek, Adam Baryłka, and Andrzej Grzebielec. 2021. "Measurement Method of Thermal Diffusivity of the Building Wall for Summer and Winter Seasons in Poland" Energies 14, no. 13: 3836. https://doi.org/10.3390/en14133836

APA StyleOwczarek, M., Owczarek, S., Baryłka, A., & Grzebielec, A. (2021). Measurement Method of Thermal Diffusivity of the Building Wall for Summer and Winter Seasons in Poland. Energies, 14(13), 3836. https://doi.org/10.3390/en14133836